Dynamic cross-linked SBS hot-melt pressure-sensitive adhesive and preparation method thereof

A hot-melt pressure-sensitive adhesive and dynamic cross-linking technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of low softening point, poor heat resistance, low cohesive strength, etc. Improved softening temperature, high mechanical properties, simple and easy-to-operate synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation operation steps of a kind of dynamically cross-linked SBS hot-melt pressure-sensitive adhesive are as follows:

[0039] (1) Preparation of phenylboronate dynamic crosslinking agent

[0040] The phenylboronic ester dynamic crosslinking agent used is the reaction product of 1,4-benzenediboronic acid and 1-thioglycerol, and the preparation method is as follows: 2 g (12 mmol) of 1,4-benzenediboronic acid and 2.59 g ( 24 mmol) of 1-thioglycerol, dissolved in 68.9 g of tetrahydrofuran, and added 17.2 g of anhydrous magnesium sulfate, reacted for 24 hours under nitrogen protection at 30 ° C, filtered to obtain a liquid mixture, and 80% of the tetrahydrofuran to obtain a concentrated solution of the phenylboronate dynamic crosslinker. Finally, the precipitate was washed three times with 700 g of n-hexane to obtain a phenylboronate dynamic crosslinking agent, which was a white solid.

[0041] (2) Prepare the mixture

[0042] Weigh each raw material according t...

Embodiment 2

[0072] The preparation operation steps of a kind of dynamically cross-linked SBS hot-melt pressure-sensitive adhesive are as follows:

[0073] (1) Preparation of phenylboronate dynamic crosslinking agent

[0074] The phenylboronic ester dynamic crosslinking agent used is the reaction product of 1,4-benzenediboronic acid and 1-thioglycerol, and the preparation method is the same as that in Example 1.

[0075] (2) Prepare the mixture

[0076] The antioxidant used is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester and tris[2,4-di-tert-butylphenyl]phosphite The compound (mass ratio is 3:1), and the ultraviolet photoinitiator is 2,2-dimethoxy-2-phenylacetophenone.

[0077] Weigh each raw material according to the formula, first roll 100 g of SBS thermoplastic elastomer, then add 0.3 g of antioxidant, 0.5 g of ultraviolet photoinitiator and 5 g of phenyl boronate dynamic crosslinking agent in turn for mixing, and start The temperature of the fro...

Embodiment 3

[0083] The preparation operation steps of a kind of dynamically cross-linked SBS hot-melt pressure-sensitive adhesive are as follows:

[0084] (1) Preparation of phenylboronate dynamic crosslinking agent

[0085] The phenylboronic ester dynamic crosslinking agent used is the reaction product of 1,4-benzenediboronic acid and 1-thioglycerol, and the preparation method is the same as that in Example 1.

[0086] (2) Prepare the mixture

[0087] The antioxidant used is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester and tris[2,4-di-tert-butylphenyl]phosphite The compound (mass ratio is 3:1), and the ultraviolet photoinitiator is 2,2-dimethoxy-2-phenylacetophenone.

[0088] Weigh each raw material according to the formula, first roll 100 g of SBS thermoplastic elastomer, then add 0.3 g of antioxidant, 0.5 g of ultraviolet photoinitiator and 7 g of phenyl borate dynamic crosslinking agent in turn for mixing, and start The temperature of the front...

PUM

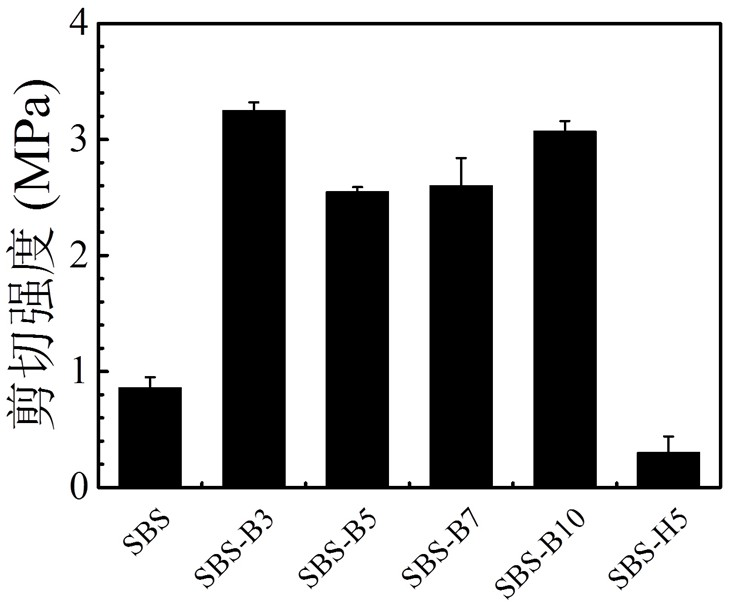

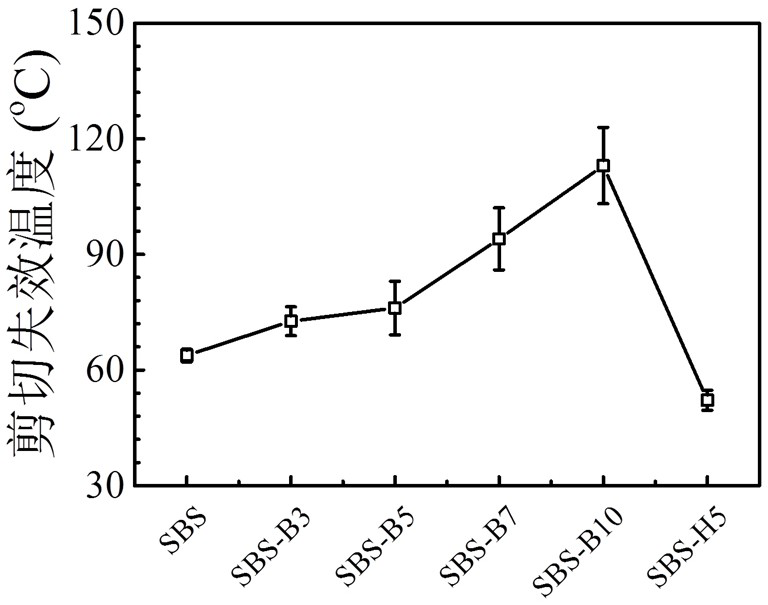

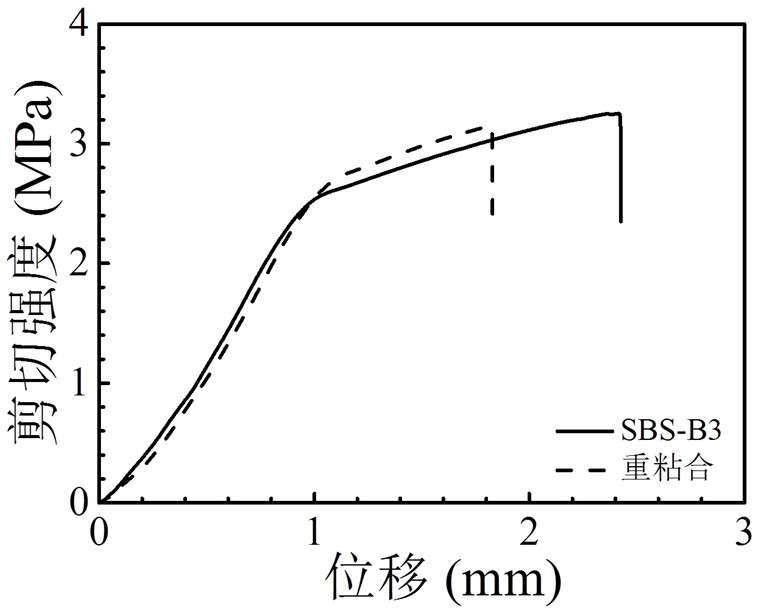

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com