High-stability fire extinguishing microcapsule and preparation method thereof

A high-stability, microcapsule technology, applied in microcapsule preparation, microsphere preparation, fire prevention equipment and other directions, can solve the problems of short service life, storage leakage of fire-extinguishing microcapsule shell, poor stability of fire-extinguishing microcapsule, etc. Effects of thermal stability, increased strength, enhanced air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

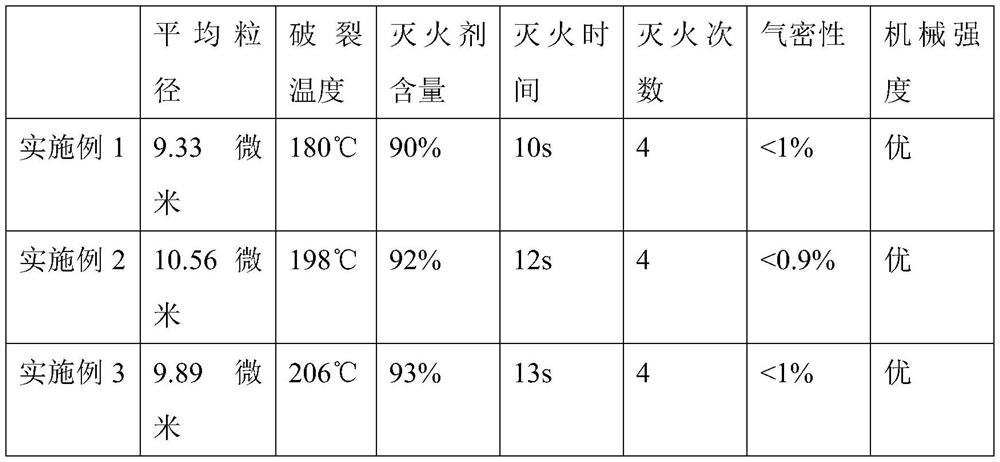

Examples

Embodiment 1

[0039] A high-stability fire extinguishing microcapsule includes a shell and a core material, the core material includes a fire extinguishing agent and a thermochromic material that changes color at 100-150°C, and the shell includes an inner layer, an outer layer and an airtight enhancer.

[0040]Among them, 5 parts of perfluorohexanone are used as fire extinguishing agent; 1 part of BiV03 is used as thermochromic material; Formaldehyde resin as the inner layer; modified by the reaction of 5 parts of trimethylol dodecane with 10 parts of hexamethylene diisocyanate and 1 part of gelatin. Polyurethane resin is used as the outer layer; a compound of 3 parts of diisopropyl oxide and lamellar carbon is used as an airtight enhancer.

[0041] The preparation steps of above-mentioned fire extinguishing microcapsules are as follows:

[0042] a) Add 3 parts of airtightness enhancer in the stirring tank, the airtightness enhancer is a composite of diisopropyl oxide and lamellar carbon, ...

Embodiment 2

[0051] A high-stability fire extinguishing microcapsule includes a shell and a core material, the core material includes a fire extinguishing agent and a thermochromic material that changes color at 100-150°C, and the shell includes an inner layer, an outer layer and an airtight enhancer.

[0052] Among them, 4 parts of red phosphorus and 3 parts of Al(OH)3 are used as fire extinguishing agents; 2 parts of leuco dyes are used as thermochromic materials; 3 parts of melamine, 4 parts of 4% formaldehyde solution, 0.4 parts of urea and 3 parts of The melamine-formaldehyde resin produced by the reaction of resorcinol is used as the inner layer; the trimethylol dodecane-diisocyanate adduct produced by the reaction of 4 parts of trimethylol dodecane and 11 parts of isophorone diisocyanate is used The modified polyurethane resin produced by reacting with 2 parts of gelatin is used as the outer layer; the compound of 4 parts of diisopropyl oxide and lamellar carbon is used as the airtig...

Embodiment 3

[0063] A high-stability fire extinguishing microcapsule includes a shell and a core material, the core material includes a fire extinguishing agent and a thermochromic material that changes color at 100-150°C, and the shell includes an inner layer, an outer layer and an airtight enhancer.

[0064] Among them, 4 parts of ammonium polyphosphate are used as fire extinguishing agent; 1 part of BiV03 is used as thermochromic material; The resin is used as the inner layer; the modified polyurethane resin generated by the reaction of 7 parts of trimethylol dodecane and 12 parts of toluene diisocyanate and the modified polyurethane resin generated by the reaction of 3 parts of gelatin are used as the outer layer. layer; use 2 parts of diisopropyl oxide and laminated carbon composite as an airtight enhancer.

[0065] The preparation steps of above-mentioned fire extinguishing microcapsules are as follows:

[0066] a) Add 2 parts of airtightness enhancer in the mixing tank. The airtigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com