Gradient composite impacting energy absorption pipe fitting

A collision energy absorption and gradient technology, applied in the direction of bumpers, etc., can solve the problems that ordinary thin-walled pipe fittings are difficult to adapt to the multi-angle oblique collision conditions of automobiles, the energy absorption structure is insufficient, and the energy absorption efficiency is reduced. The effect of protecting life and property safety, diversifying energy-absorbing methods, and high energy-absorbing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

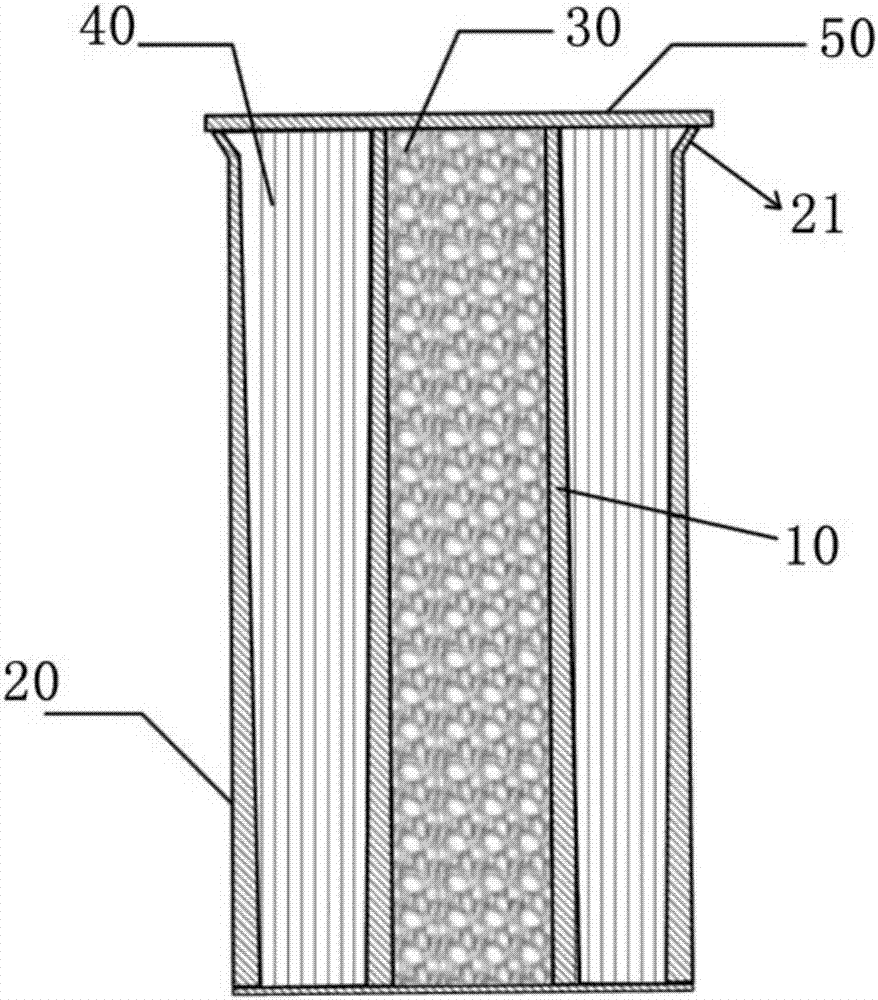

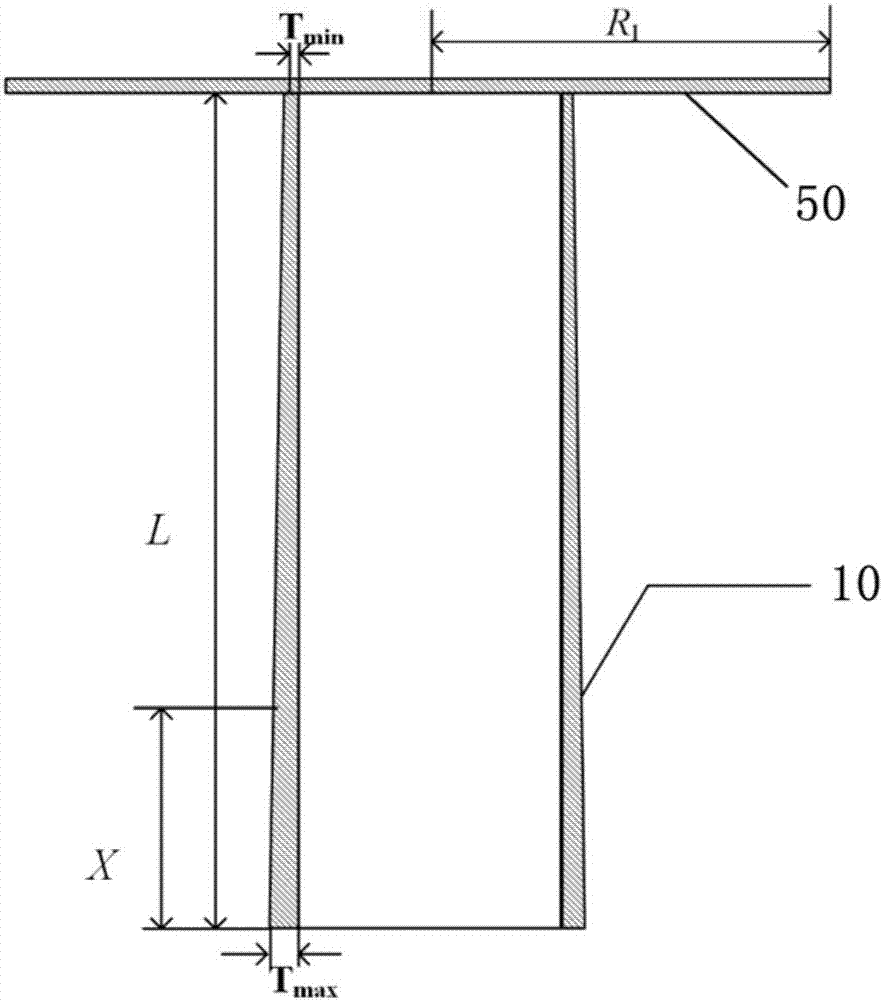

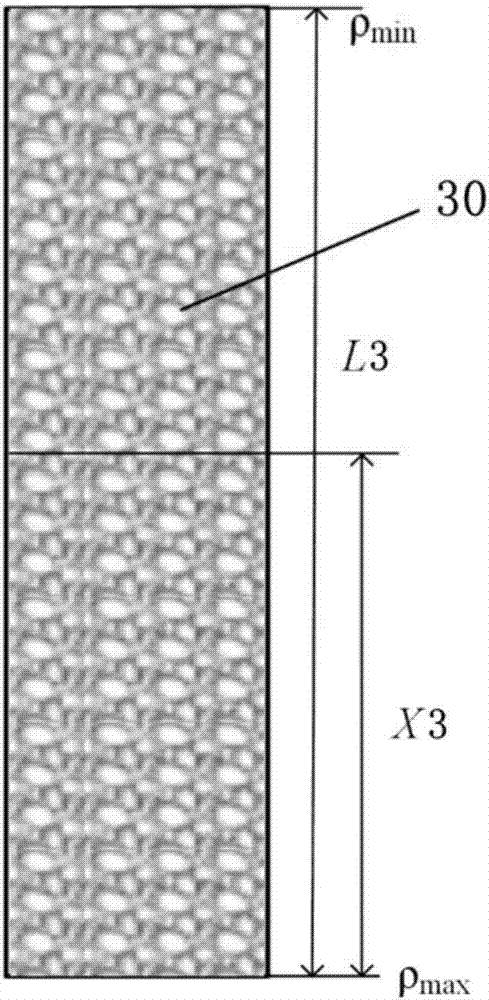

[0024] Please check Figure 1 to Figure 5 , gradient composite crash energy-absorbing pipe fittings, including a gradient inner tube 10, a gradient outer tube 20, an aluminum foam filling layer 30, a fiber-reinforced cloth filling layer 40 and a closed end plate 50, and the gradient outer tube 20 is sleeved on the gradient inner tube 10 In addition, the aluminum foam filling layer 30 is filled in the gradient inner tube 10, the fiber reinforced cloth 40 is filled between the gradient inner tube 10 and the gradient outer tube 20, and the first port of the gradient inner tube 10 is fixed on the closed On the end plate 50 , the first port of the gradient outer tube 20 is in contact with the closed end plate 50 . The gradient inner tube 10 and the gradient outer tube 20 are coaxially arranged; the end surface of the closed end plate 50 can form the impact place of the collision source. Both the gradient inner tube 10 and the gradient outer tube 20 are hollow circular tubes made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com