Two-dimensional nanocomposite, preparation method therefor and application of two-dimensional nanocomposite

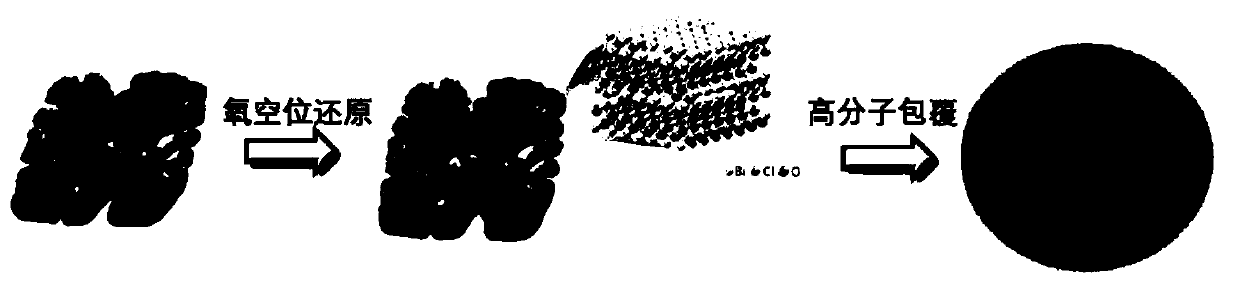

A nano-composite material and nano-material technology are applied in the field of two-dimensional black bismuth oxyhalide nano-materials, which can solve the problems of many restrictions and shallow penetration depth, and achieve the effects of simple process, low cost and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0131] (1) Weigh 486mg Bi(NO 3 ) 3 ·5H 2 0. After mixing 400mgPVP and 455mg mannitol, dissolve it into 25mL of ultrapure water. After stirring the mixed solution for 10min, carry out ultrasonic treatment to make it evenly mixed, and then put it into an ultrasonic machine for ultrasonication for 10min to obtain solution a;

[0132] (2) Subsequently, in the process of continuous stirring, 5 mL of saturated NaCl solution was slowly added dropwise into the mixed solution through a syringe, and stirred while dropping. After the dropwise addition, a uniform white suspension b was obtained;

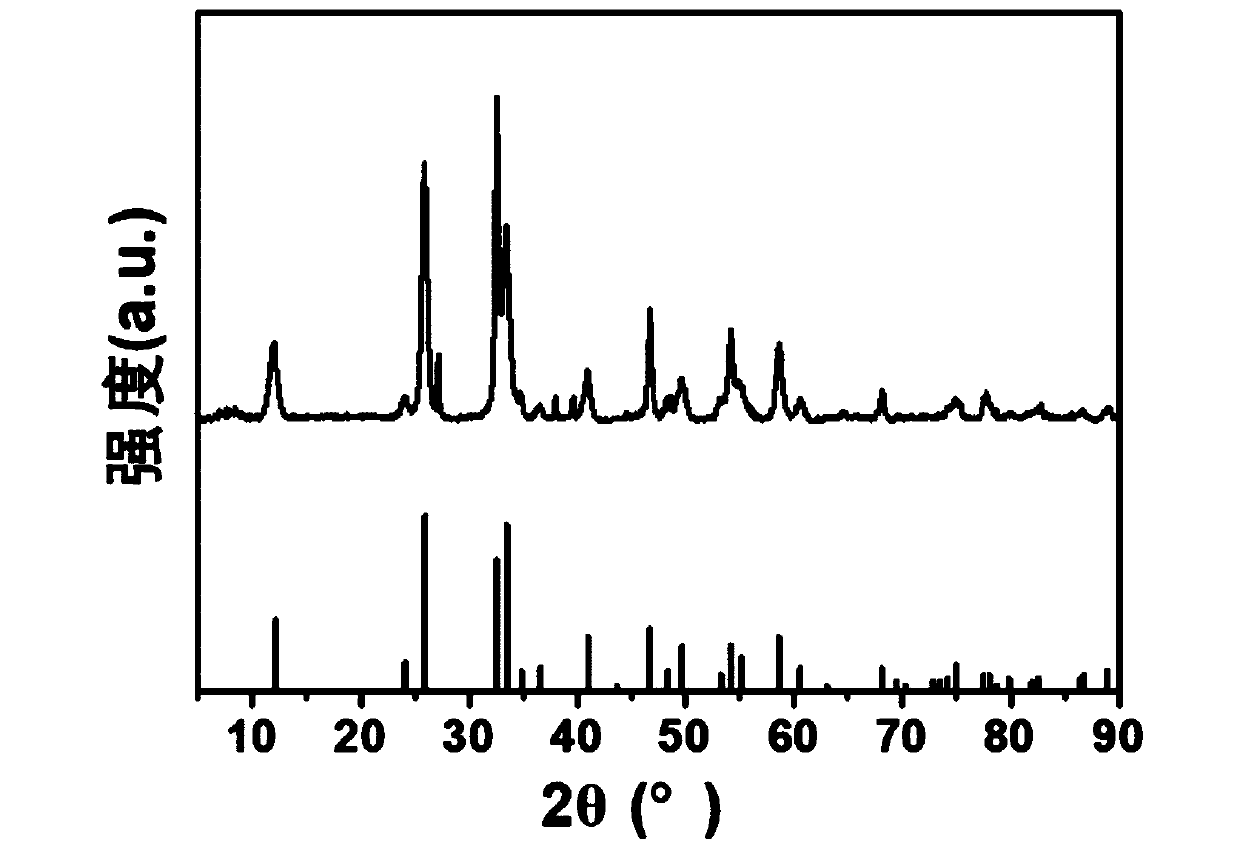

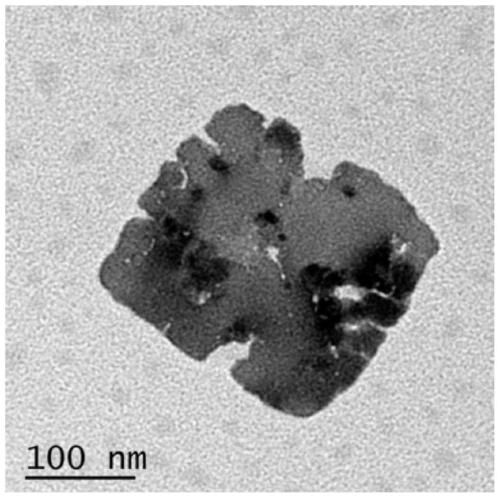

[0133] (3) The white suspension b was ultrasonically diffused again for 10 minutes, and then the mixed solution was transferred to a 50ml polytetrafluoroethylene hydrothermal reaction kettle, and then hydrothermally reacted at 160°C for 3 hours, and naturally cooled to leave a precipitate Use water and ethanol to clean 8 times in turn and dry to obtain white bismuth oxyhalide material c for l...

Embodiment 2

[0165] (1) Weigh 486mg Bi(NO 3 ) 3 ·5H 2 0. After mixing 400mgPVP and 455mg mannitol, dissolve it into 25mL of ultrapure water. After stirring the mixed solution for 10min, carry out ultrasonic treatment to make it evenly mixed, and then put it into an ultrasonic machine for ultrasonication for 10min to obtain solution a;

[0166] (2) Subsequently, in the process of continuous stirring, 5 mL of saturated NaCl solution was slowly added dropwise into the mixed solution through a syringe, and stirred while dropping, and a uniform white suspension b was obtained after the dropwise addition;

[0167] (3) The white suspension b was ultrasonically diffused again for 10 minutes, and then the mixed solution was transferred to a 50ml polytetrafluoroethylene hydrothermal reaction kettle, and then hydrothermally reacted at 180°C for 6 hours, and naturally cooled to leave a precipitate Use water and ethanol to clean 8 times in turn and dry to obtain white bismuth oxyhalide material c for...

Embodiment 3

[0174] (1) Weigh 972mg Bi(NO 3 ) 3 ·5H 2 O, 800mgPVP and 910mg mannitol are mixed and dissolved in 50mL of ultrapure water, and the mixed solution is stirred for 10min, then subjected to ultrasonic treatment to make it evenly mixed, and then placed in an ultrasonic machine for 10min to obtain solution a;

[0175] (2) Subsequently, in the process of continuous stirring, 10 mL of saturated NaCl solution was slowly added dropwise into the mixed solution through a syringe, and stirred while dropping. After the dropwise addition, it can be found that a uniform white suspension b has been formed;

[0176] (3) The white suspension b was ultrasonically diffused again for 10 minutes, and then the mixed solution was transferred to a 50ml polytetrafluoroethylene hydrothermal reaction kettle, and then hydrothermally reacted at 160°C for 9 hours, and naturally cooled to leave a precipitate Use water and ethanol to clean 8 times in turn and dry to obtain white bismuth oxyhalide material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com