Wear-resistant hammer head for crusher and production method thereof

A crusher and hammer technology, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of insufficient work hardening performance, reducing surface hardness, strength, and short service life of castings, and achieve high hardness and low price. , the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] In the wear-resistant hammer head for crushers in this embodiment, the wear-resistant hammer head includes the following raw materials in mass percentages, C: 0.9-1.2%, Mn: 11.0-14.0%, Si: 0.3-0.7%, Cr : 0.1~0.5%, Mo≤0.3%, V≤0.1%, Ti≤0.1%, P and S≤0.04%, Re: 0.1~0.4%, Tieshen No. 1: 0.3~0.6%, and the rest is Fe.

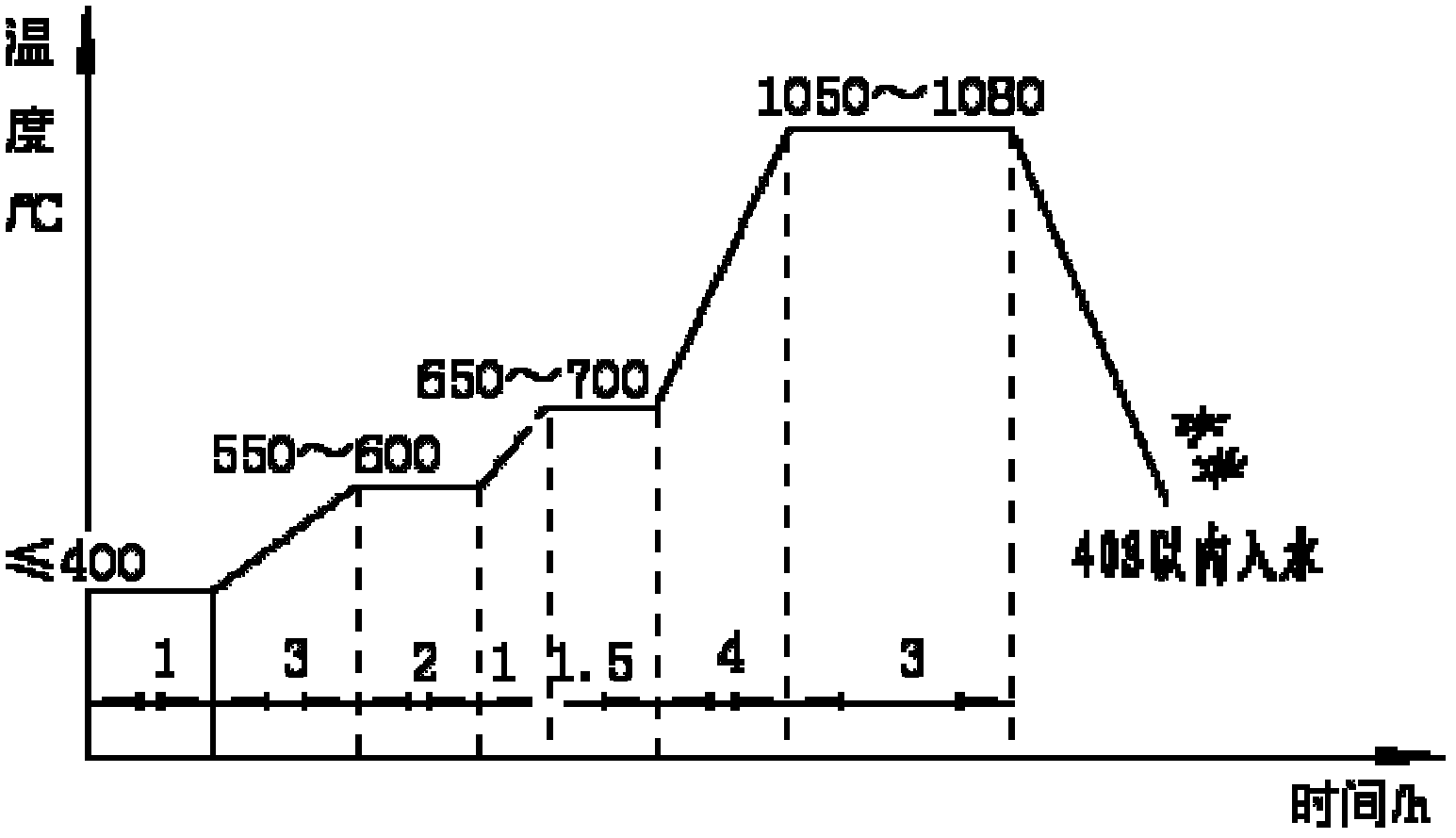

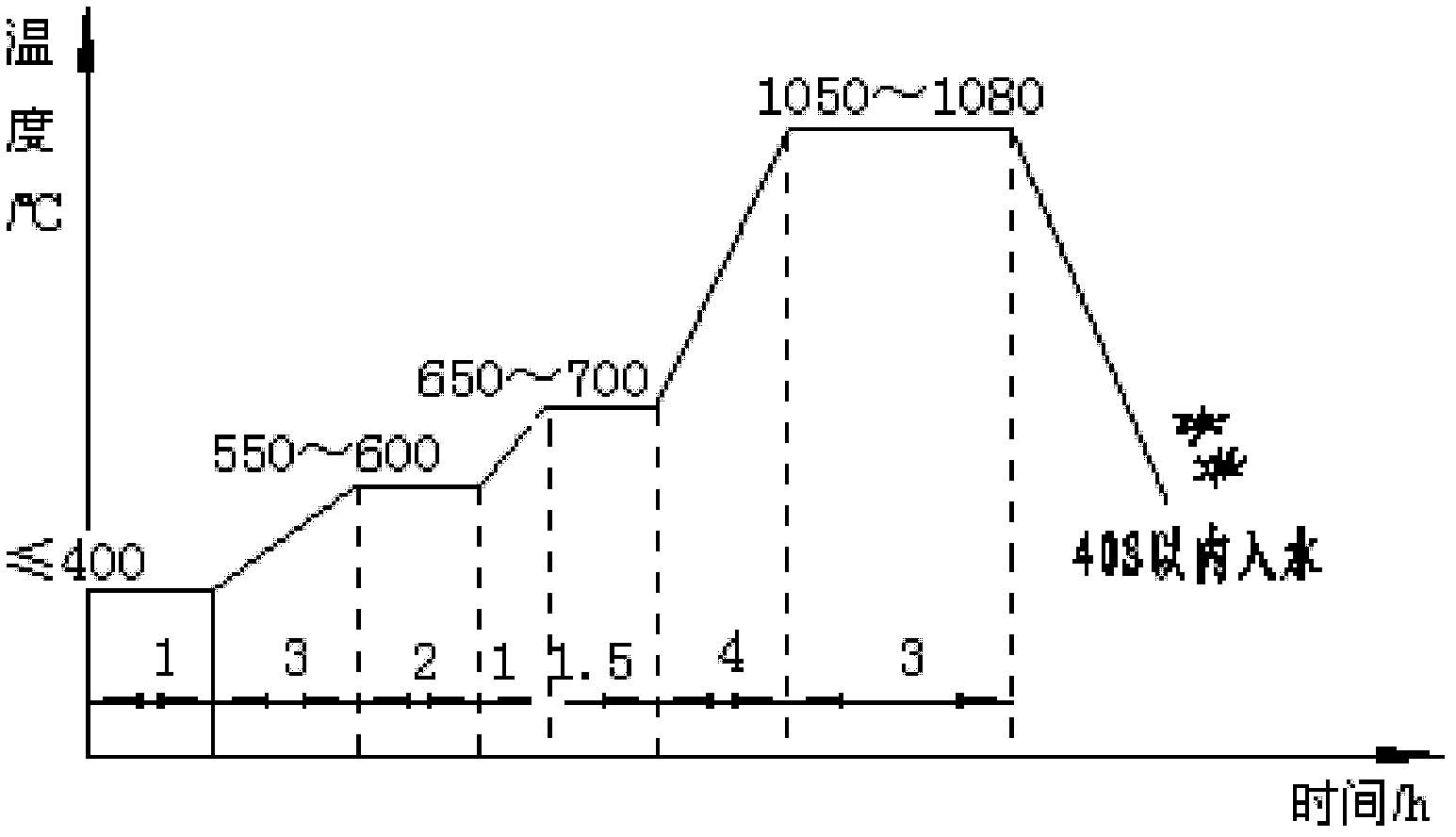

[0013] The method for producing the above-mentioned wear-resistant hammer head for the crusher includes the following steps: manufacturing lost foam—making sand mold—smelting alloy—modifying treatment—casting—cleaning—heat treatment; the manufacturing of lost foam is made of foam Polystyrene (EPS) is used as a raw material to make a model according to the shape of the part, and the multilayer coating (magnesia powder) is applied to the surface of the model, and dried to make a lost foam; Sand molds are made under negative pressure; the above-mentioned raw materials are smelted in an intermediate frequency or power frequency induction furnace, and the furnace t...

Embodiment 2

[0015] In the wear-resistant hammer head for crushers in this embodiment, the wear-resistant hammer head includes the following raw materials in mass percentages, C: 0.9-1.2%, Mn: 11.0-14.0%, Si: 0.3-0.7%, Cr : 0.1~0.5%, Mo≤0.3%, V≤0.1%, Ti≤0.1%, P and S≤0.04%, Re: 0.1~0.4%, Tieshen No. 1: 0.3~0.6%, and the rest is Fe.

[0016] The method for producing the above-mentioned wear-resistant hammer head for the crusher includes the following steps: manufacturing lost foam—making sand mold—smelting alloy—modifying treatment—casting—cleaning—heat treatment; the manufacturing of lost foam is made of foam Polystyrene (EPS) is used as a raw material to make a model according to the shape of the part, and the multilayer coating (magnesia powder) is applied to the surface of the model, and dried to make a lost foam; Sand molds are made under negative pressure; the above-mentioned raw materials are smelted in an intermediate frequency or power frequency induction furnace, and the furnace t...

Embodiment 3

[0018] In the wear-resistant hammer head for crushers in this embodiment, the wear-resistant hammer head includes the following raw materials in mass percentages, C: 0.9-1.2%, Mn: 11.0-14.0%, Si: 0.3-0.7%, Cr : 0.1~0.5%, Mo≤0.3%, V≤0.1%, Ti≤0.1%, P and S≤0.04%, Re: 0.1~0.4%, Tieshen No. 1: 0.3~0.6%, and the rest is Fe. The method for producing the above-mentioned wear-resistant hammer head for the crusher includes the following steps: manufacturing lost foam—making sand mold—smelting alloy—modifying treatment—casting—cleaning—heat treatment; the manufacturing of lost foam is made of foam Polystyrene (EPS) is used as a raw material to make a model according to the shape of the part, and the multilayer coating (magnesia powder) is applied to the surface of the model, and dried to make a lost foam; Sand molds are made under negative pressure; the above-mentioned raw materials are smelted in an intermediate frequency or power frequency induction furnace, and the furnace temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com