Novel block copolymer mixture elastic fiber and manufacturing method thereof

A technology of block copolymer and elastic fiber, which is applied in the field of manufacturing elastic fiber of new block copolymer mixture, can solve the problems of limitation degree, elongation at break and elastic recovery rate that are not as good as those of spandex.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

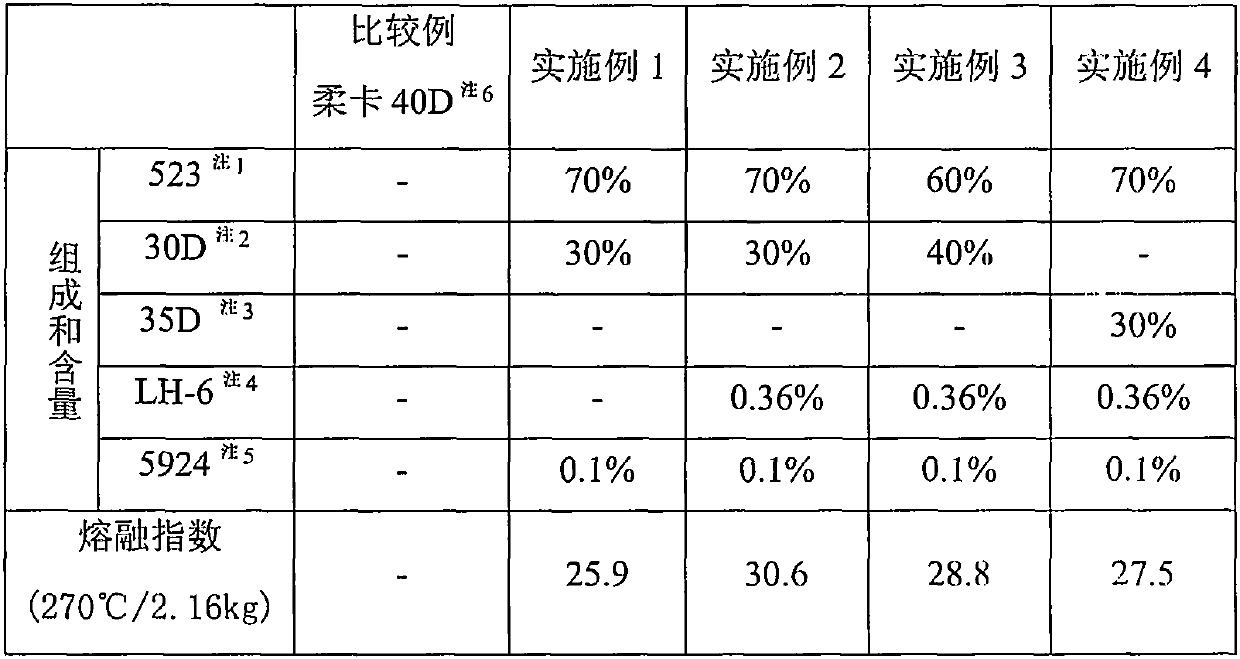

Embodiment 1

[0105] In Example 1, no ultra-high molecular weight silicone powder was added. During the process of melting and mixing raw materials for granulation, die mouth adhesion and granulation interruption occurred twice in a row. Endless cutting will lead to material sticking, and production cannot proceed smoothly, so the next step of spinning experiment will not be carried out.

Embodiment 2

[0106] Example 2 After adding ultra-high molecular weight silicone powder, the mixed raw materials were melted and granulated smoothly, and the temperature range of the screw extruder in the subsequent spinning experiment was set as: 170°C~235°C~255°C~265°C~270°C , while the temperature of the spinning head (including the spinneret) was set at 270°C.

Embodiment 3

[0107]In Example 3, the mixed raw materials were melted and granulated smoothly after adding ultra-high-quality silicone powder, and the temperature range of the screw extruder in the subsequent spinning experiment was set as: 170°C~235°C~255°C~265°C~271°C °C, while the temperature of the spinning head (including the spinneret) was set at 271 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com