Novel styrene block copolymer mixture elastic fiber and manufacturing method thereof

A styrene block, elastic fiber technology, applied in the direction of conjugated synthetic polymer rayon, rayon manufacturing, fiber chemical characteristics, etc., can solve problems such as inability to use directly, cannot withstand dyeing, drying and heat setting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

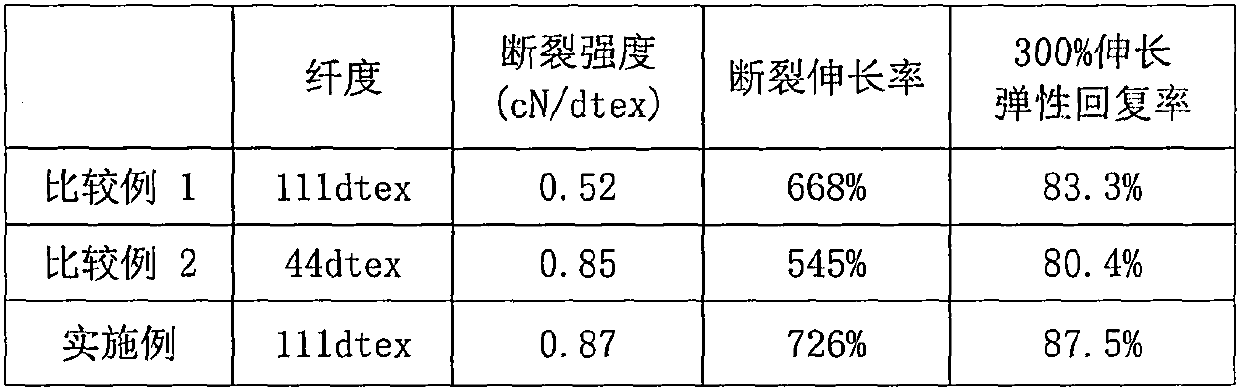

[0091] The present invention will be further described in detail through the following examples.

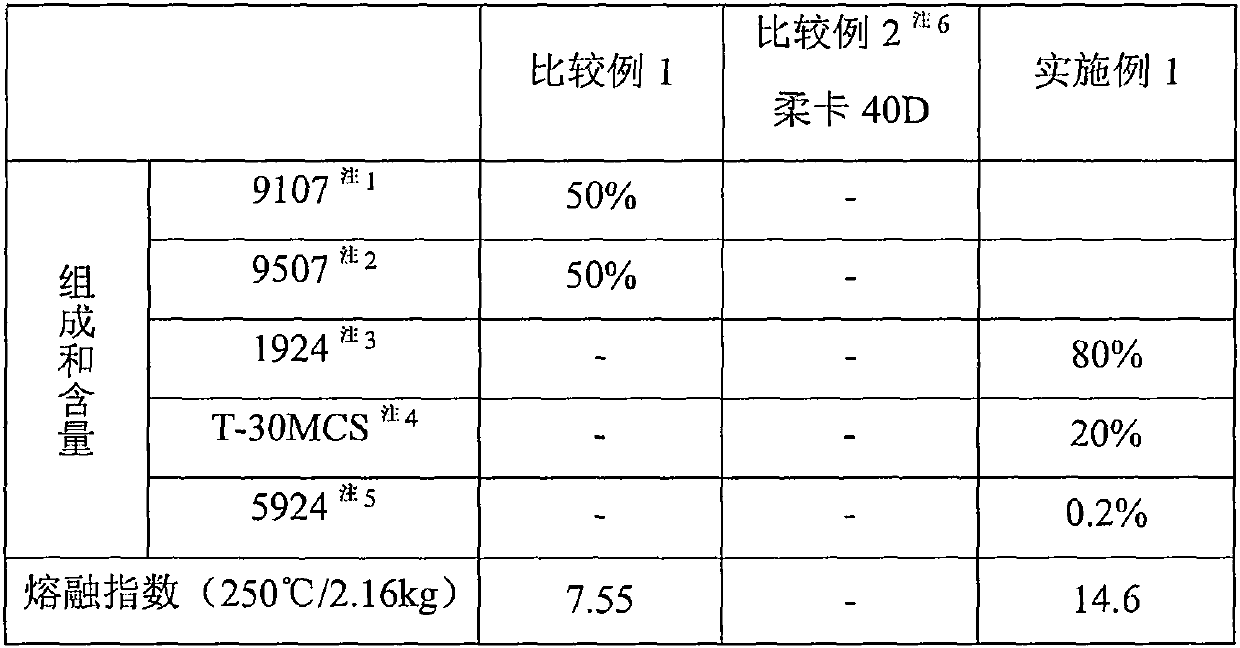

[0092] The components shown in Table 1 were fully dried in advance, added to a small high-speed mixer for mixing, and then transported to a twin-screw extruder for mixing and granulation to produce 5-10 kg of granular experimental samples.

[0093] The melt flow rate:

[0094] According to GB / T3682-2000 "Determination of Melt Flow Rate and Melt Volume Flow Rate of Thermoplastics", the melt flow rate of the obtained styrene block copolymer mixture particles was measured at 250°C and a load of 2.16kg. The results are shown in Table 1.

[0095] Composition and content (% by weight) of the styrene block copolymer mixture of table 1

[0096]

[0097] Note:

[0098] 1) Ethylene-octene block copolymer, INFUSE-9107, supplier Dow Chemical, melt index (190°C / 2.16kg): 1.0, density: 0.866g / cm 3 ;

[0099] 2) Ethylene-octene block copolymer, INFUSE-9507, supplier Dow Chemical, melt in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com