Patents

Literature

150results about How to "Sufficient support strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

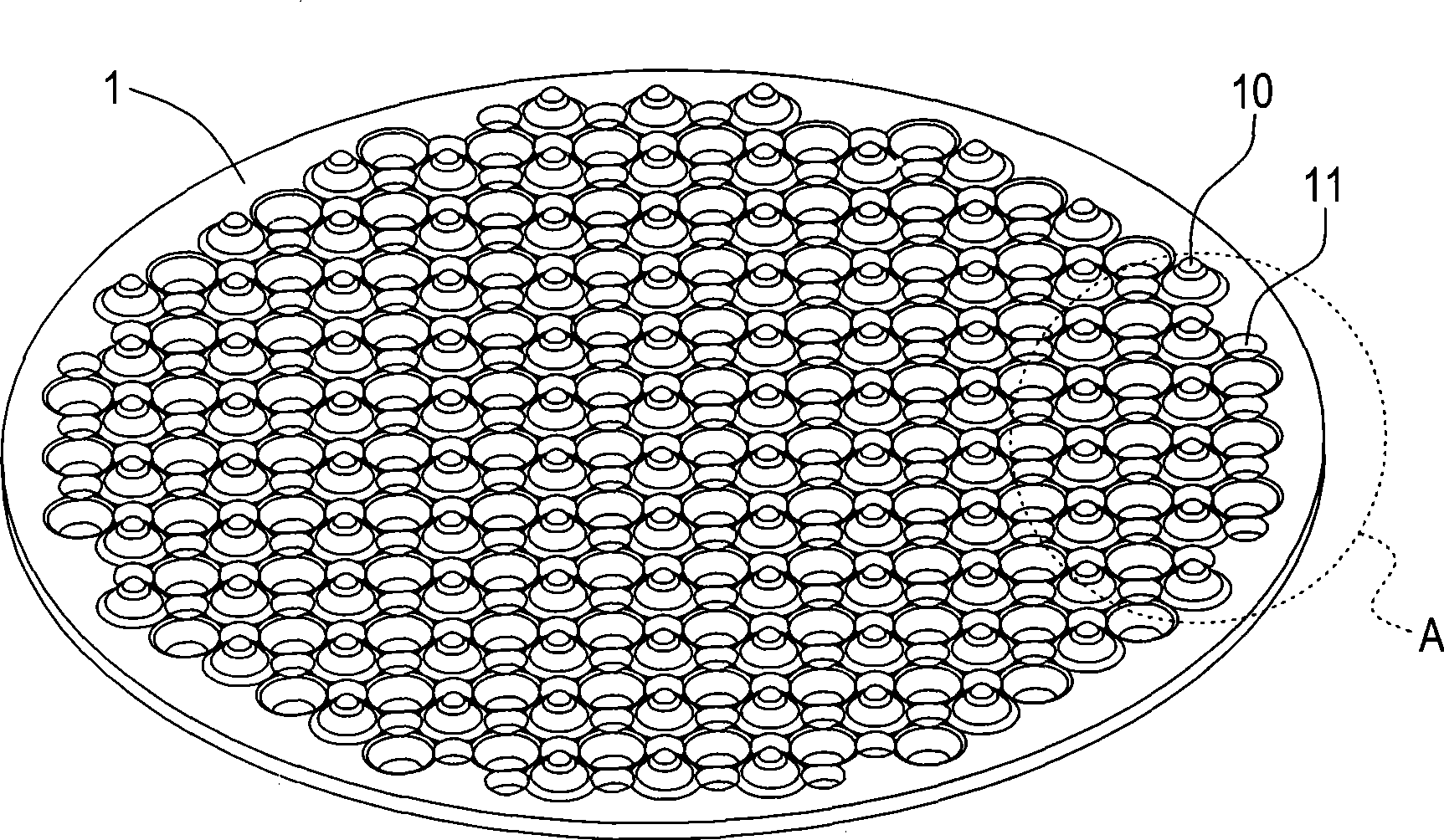

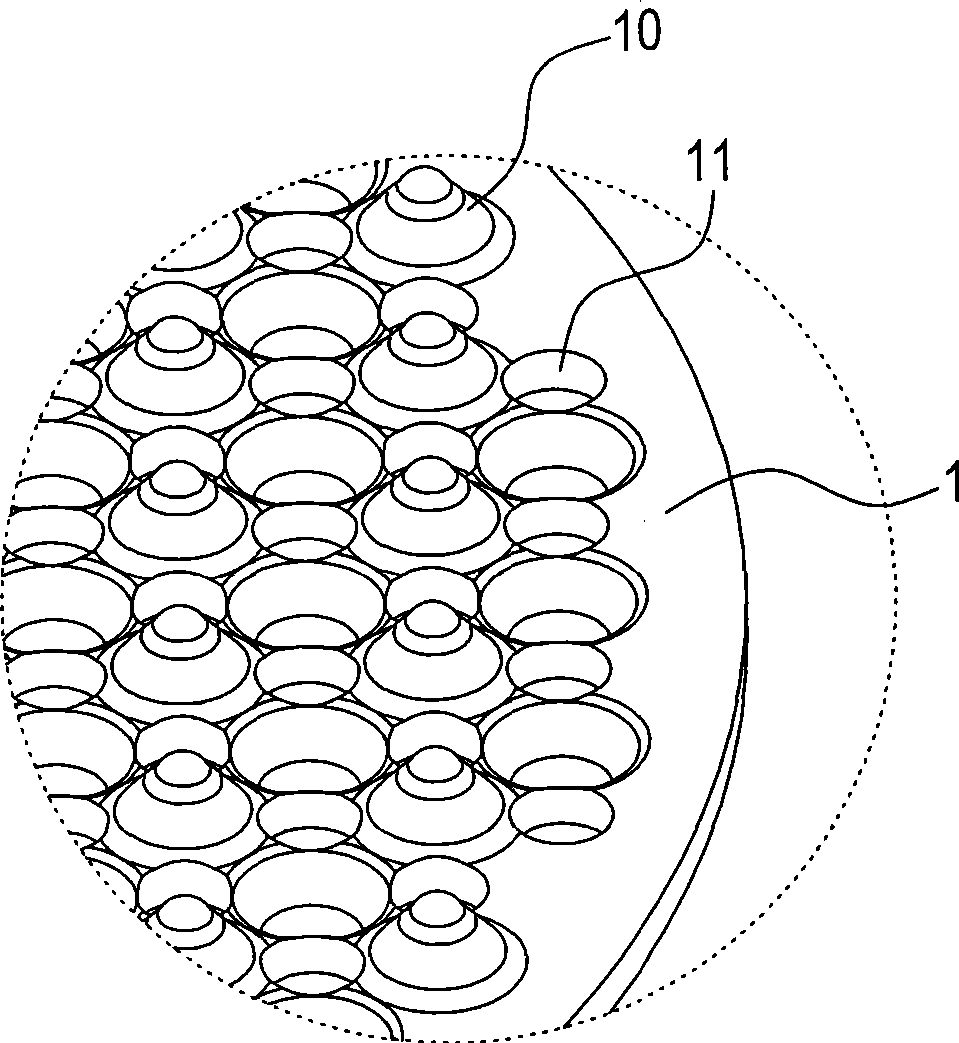

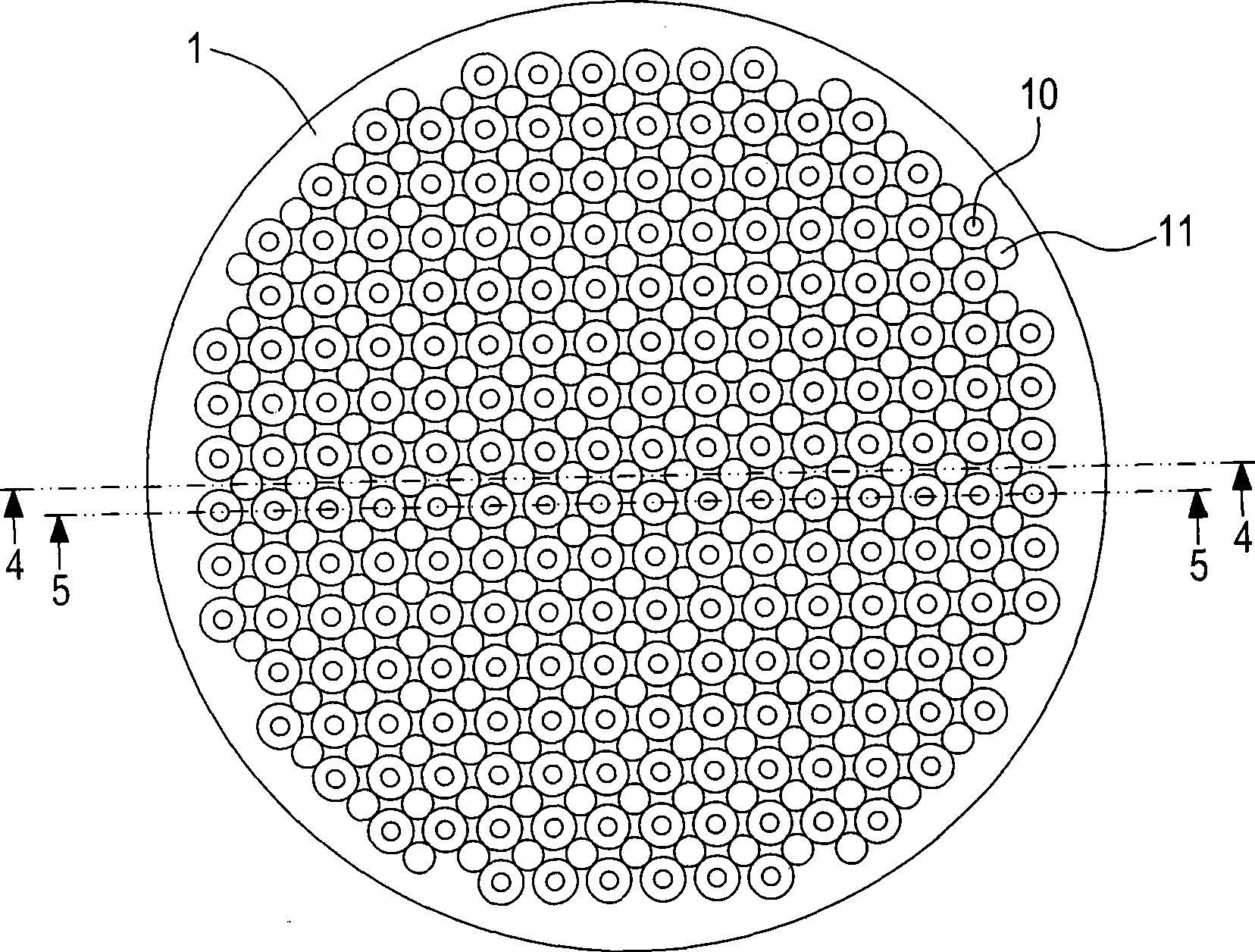

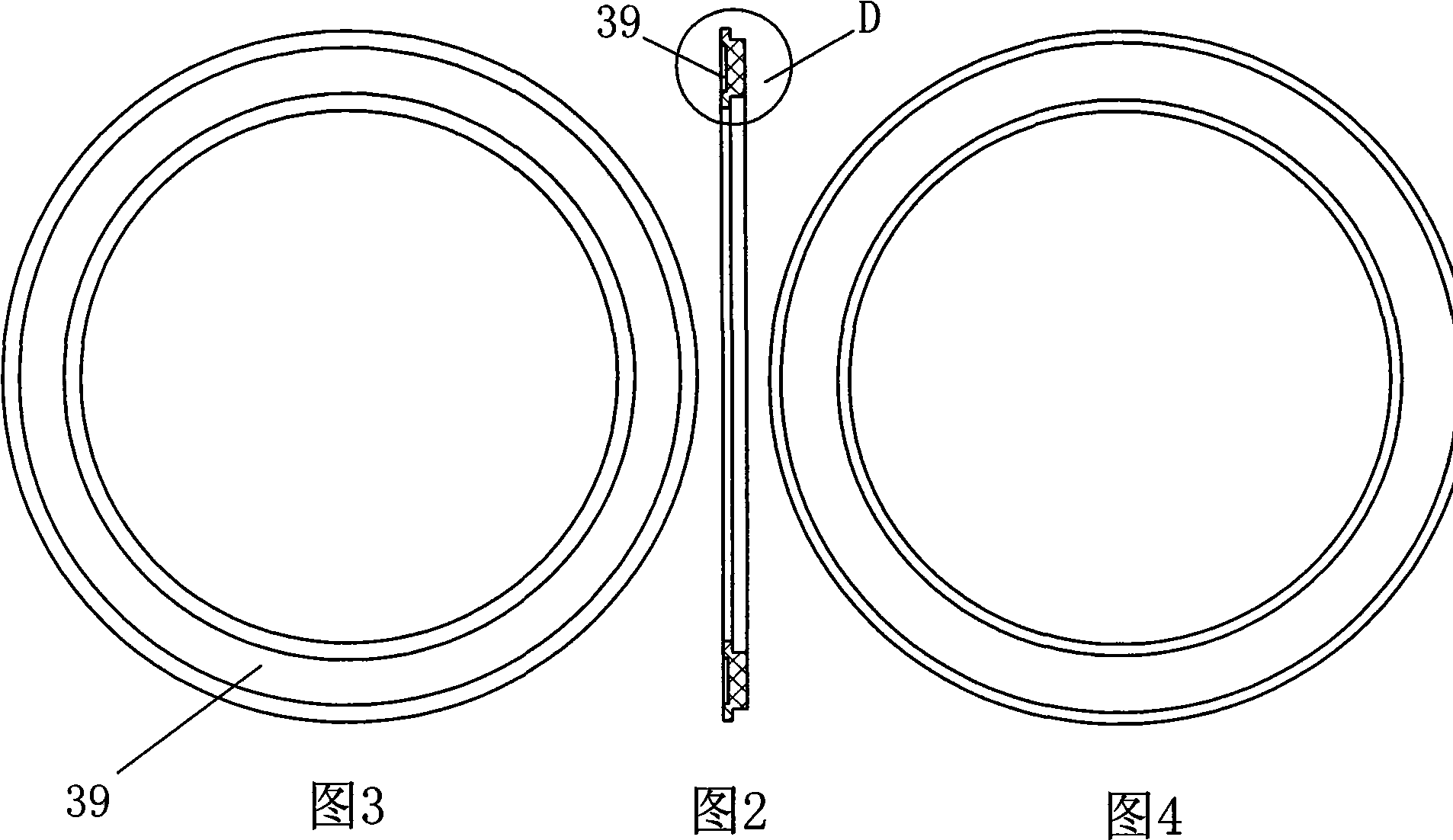

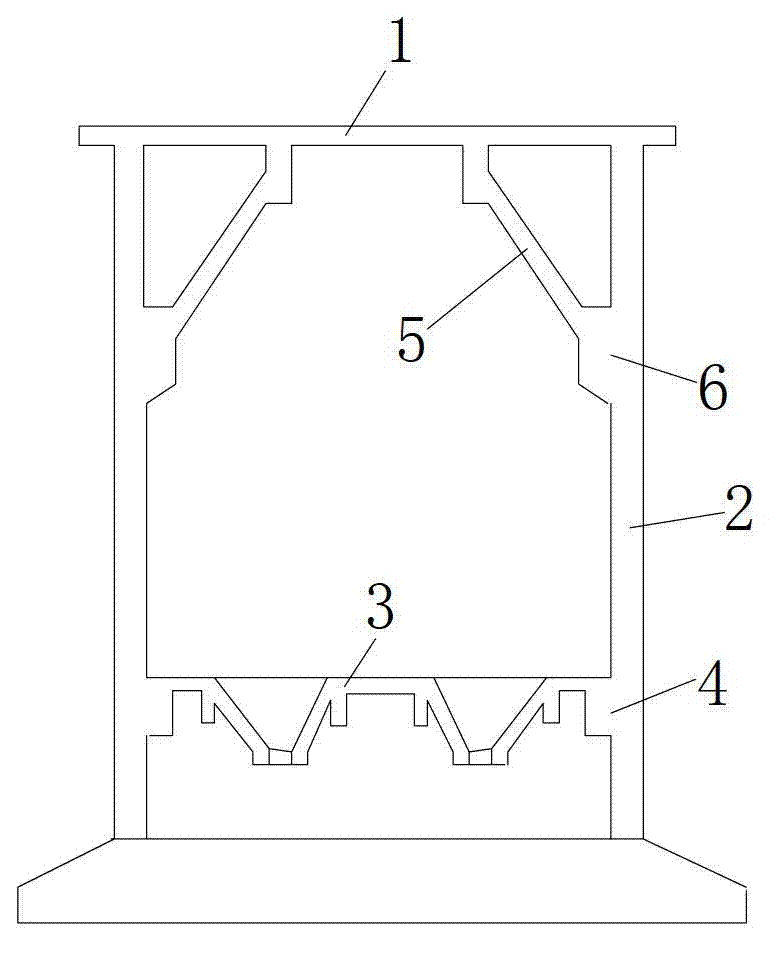

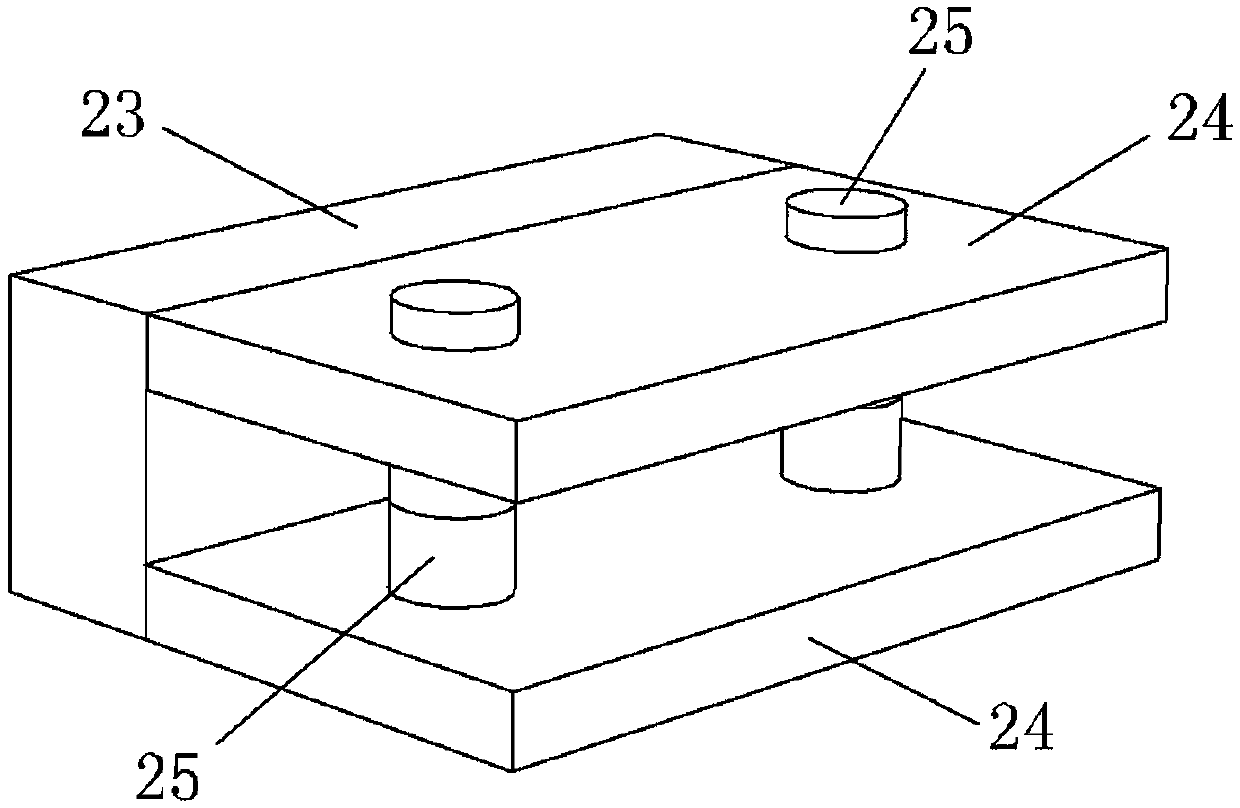

Inside supporter of uniform temperature plate and production method thereof, and uniform temperature plate

InactiveCN101520286ADoes not affect heat conductionEasy processing and assemblyIndirect heat exchangersHeat exchanger casingsPunchingEngineering

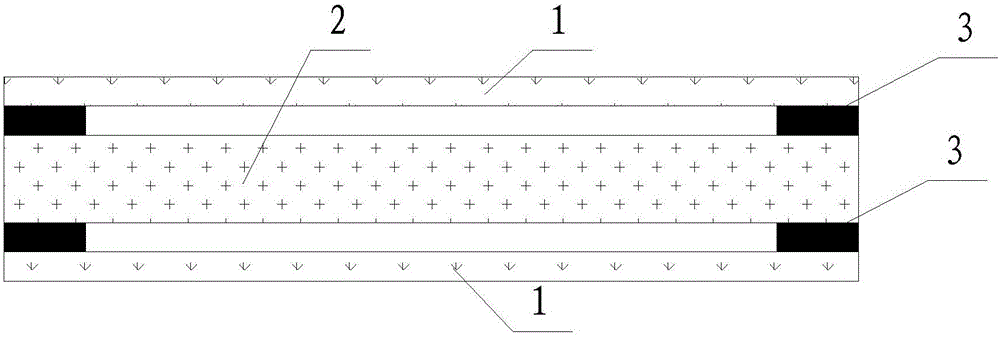

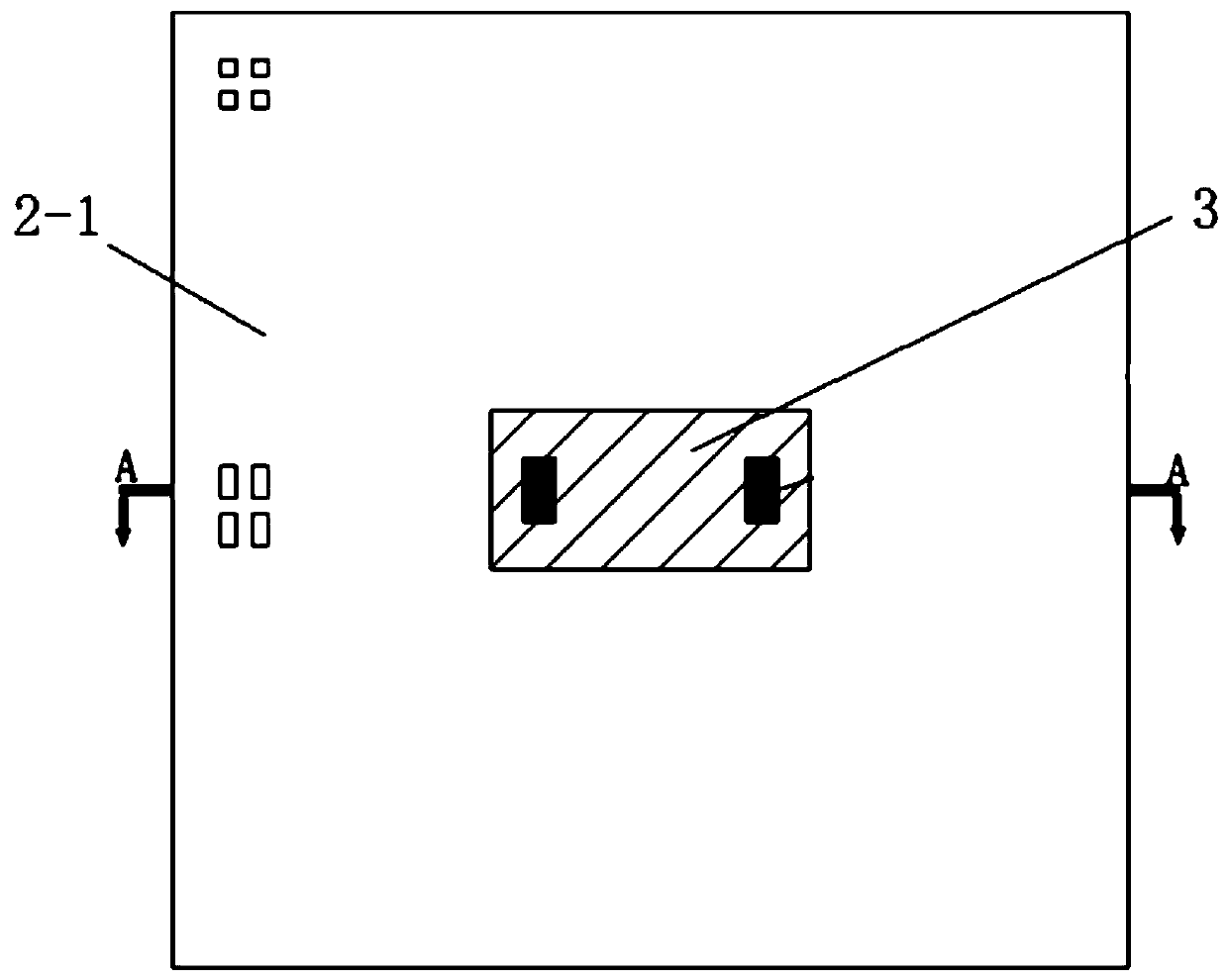

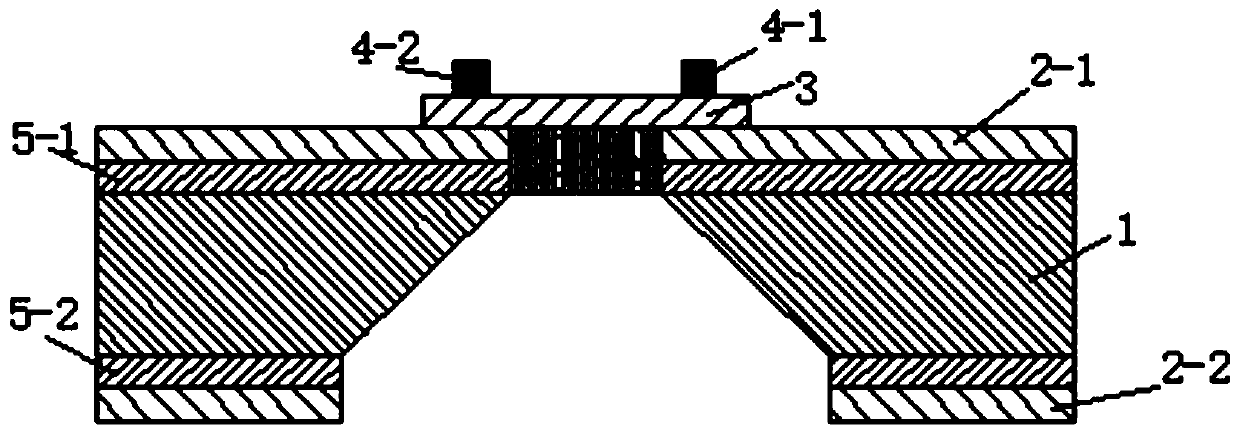

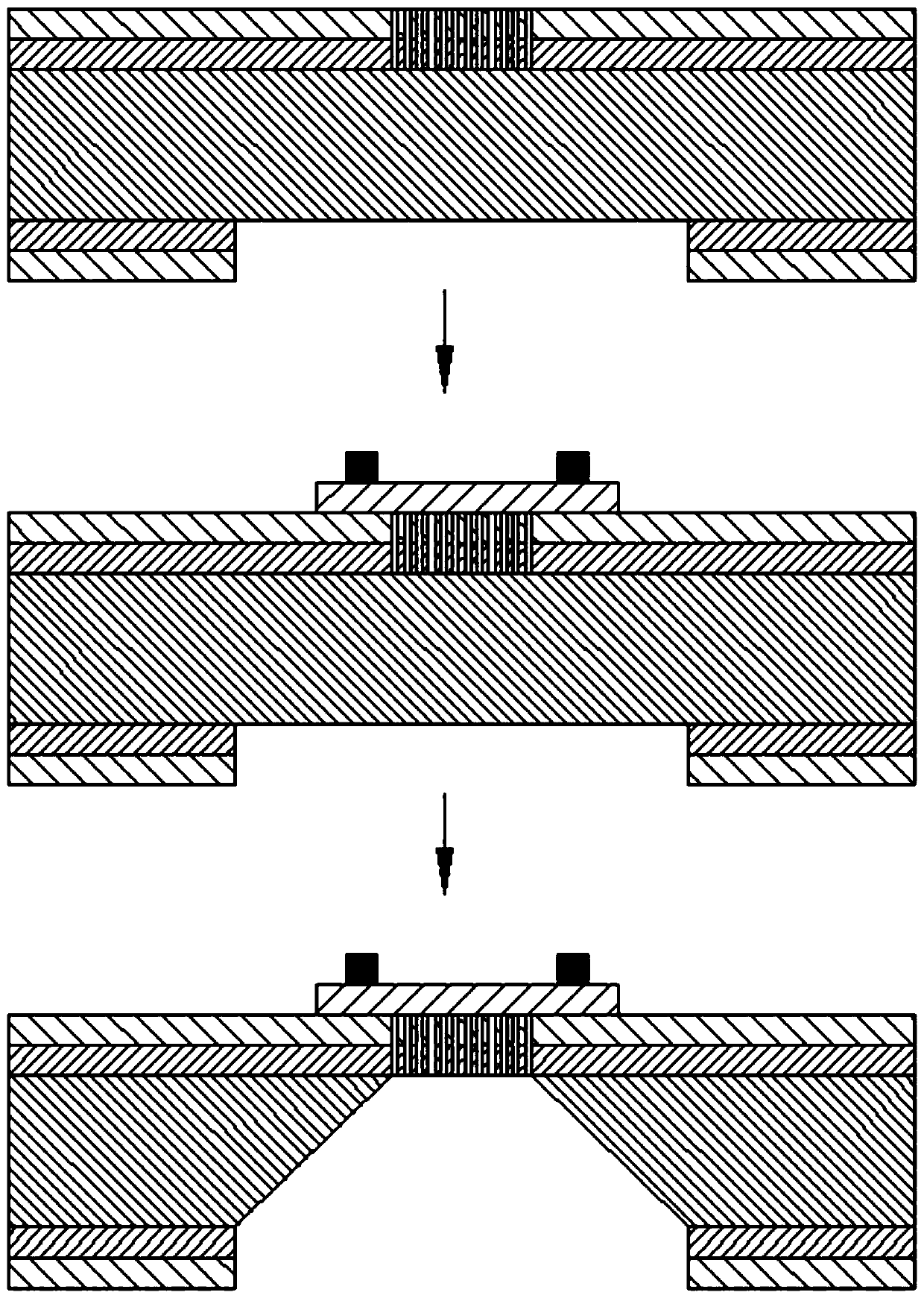

The invention discloses an inside supporter of a uniform temperature plate, a production method and the uniform temperature plate. The uniform temperature plate comprises the following components: a shell, which consists of two shell covers that are mutually closed, and delicate tissues are arranged on an inner wall surface of the two shell covers; a plate, which is tabular, has two plate surfaces and is flatly arranged between the two shell covers; and two or more concavo-convex parts, which are arranged on the plate and distribute in the positions of the two plate surfaces; wherein the plate is also provided with two or more through holes respectively among the concavo-convex parts, and one part of the concavo-convex parts protrude to one plate surface position of the plate, and the other part protrude to the other plate surface position of the plate. The supporter is formed by punching the two or more concavo-convex parts and the two or more through holes on plank stuffs, thus having convenient assembly and processing as well as sufficient bearing strength by the punching molding.

Owner:贸晖科技股份有限公司 +1

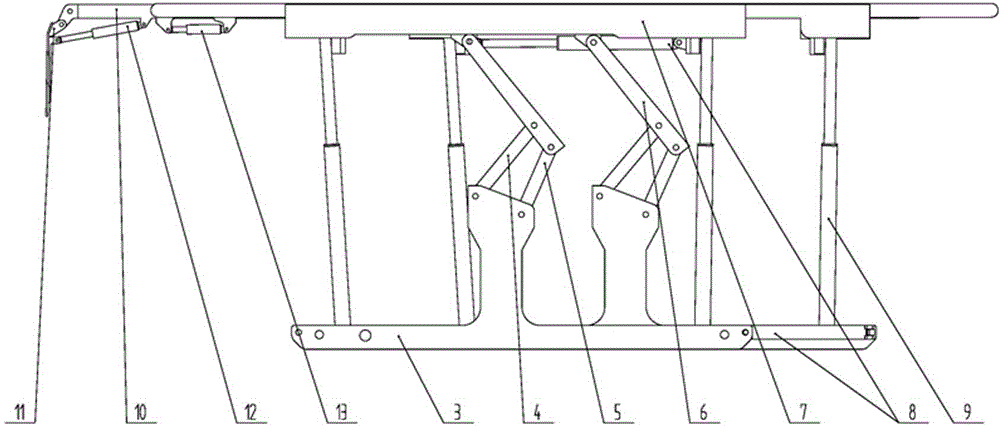

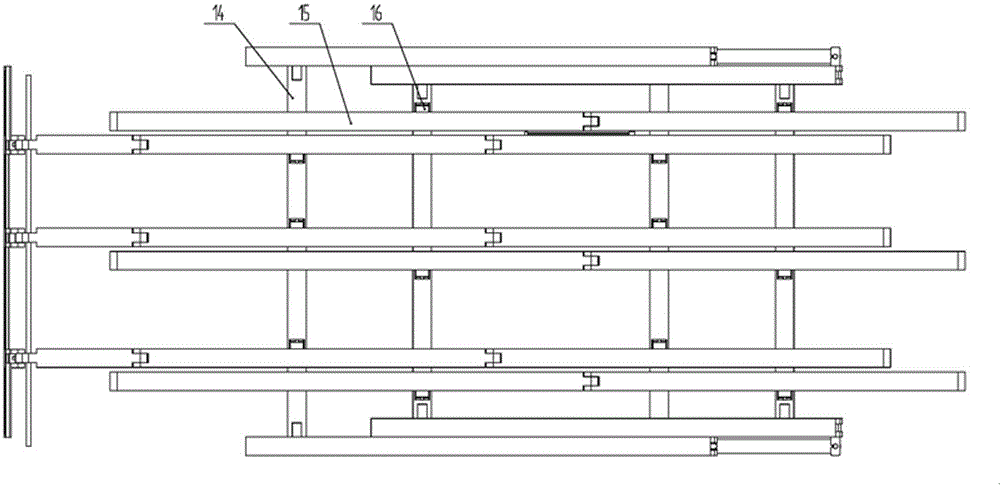

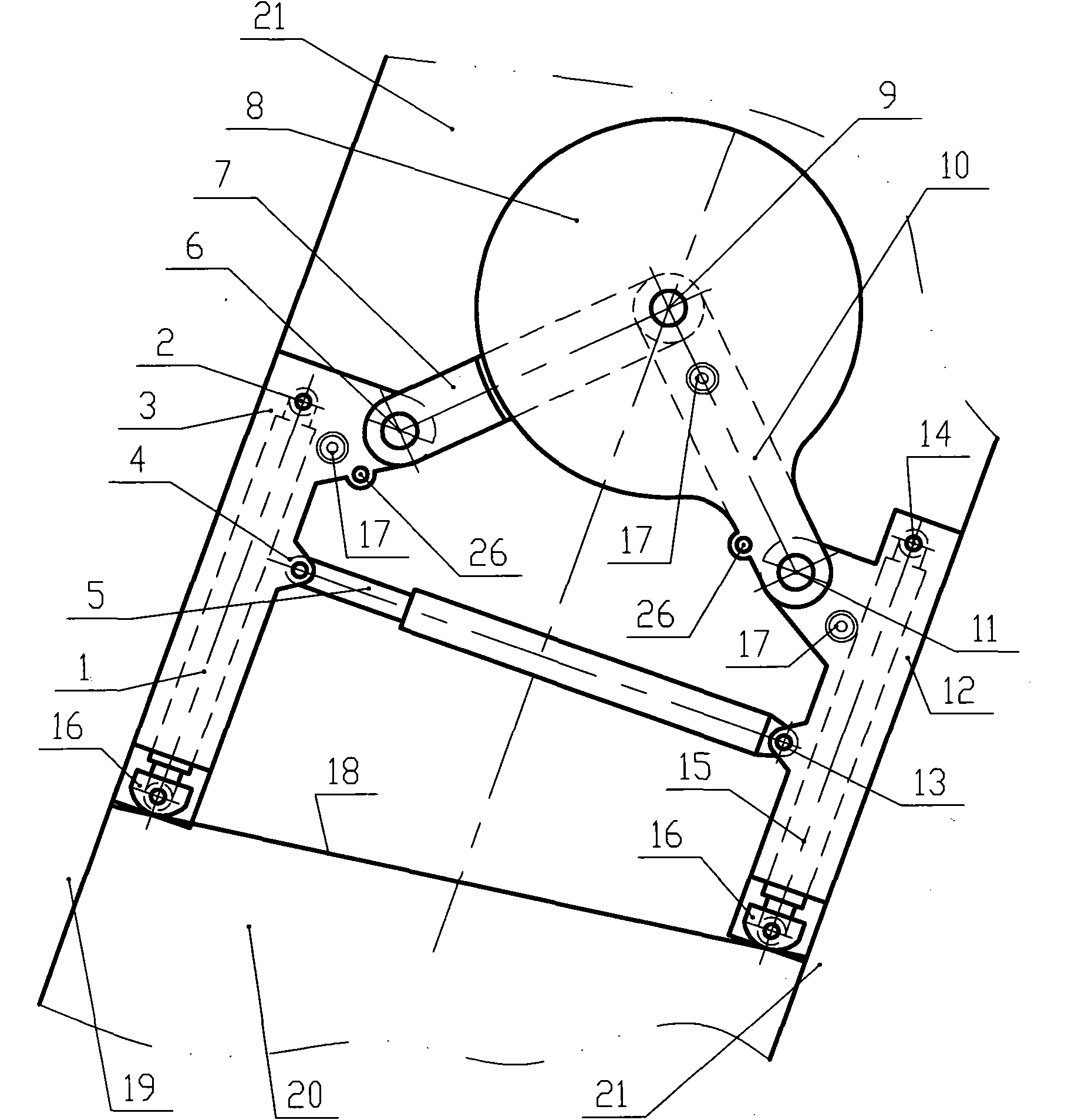

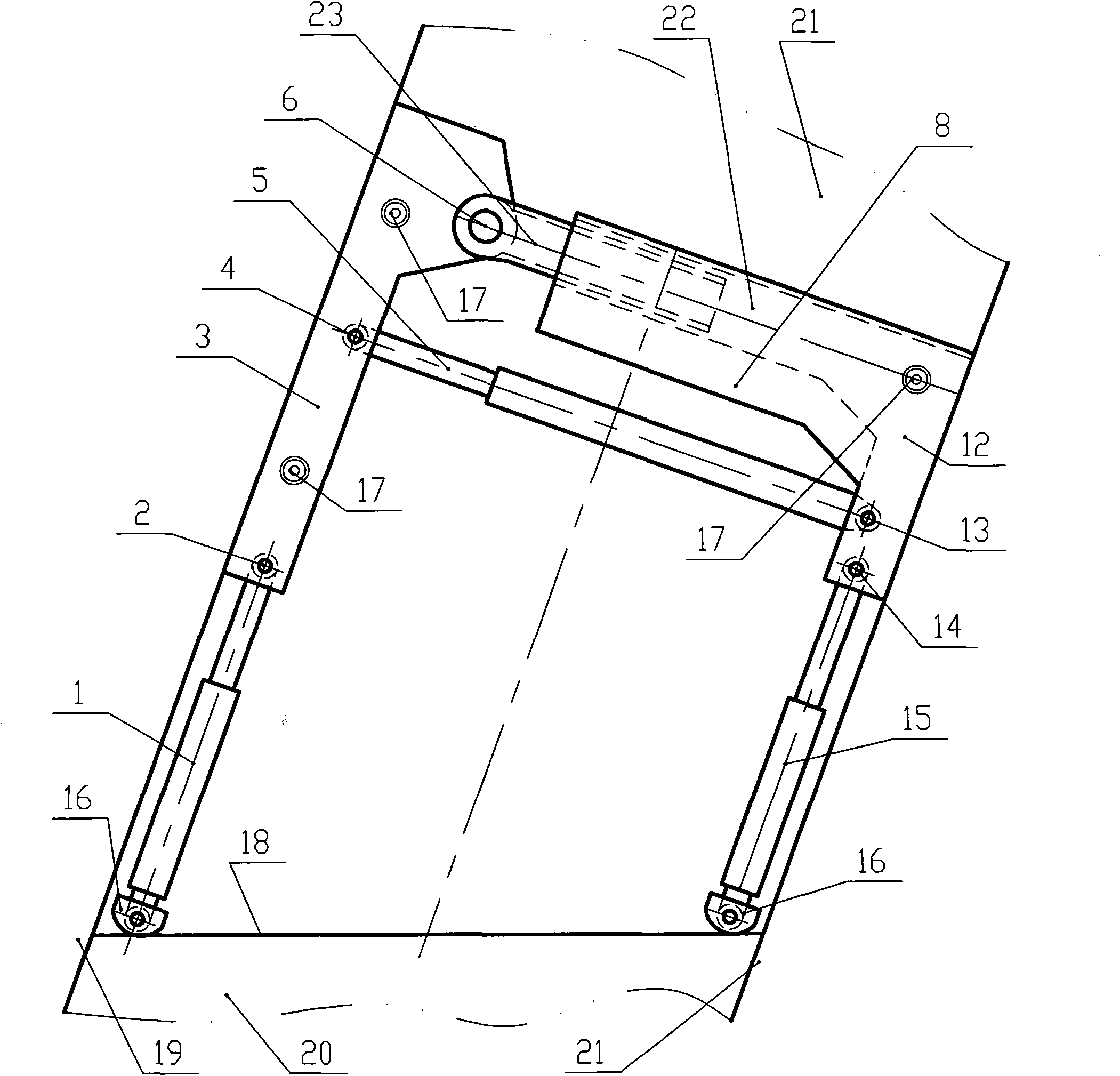

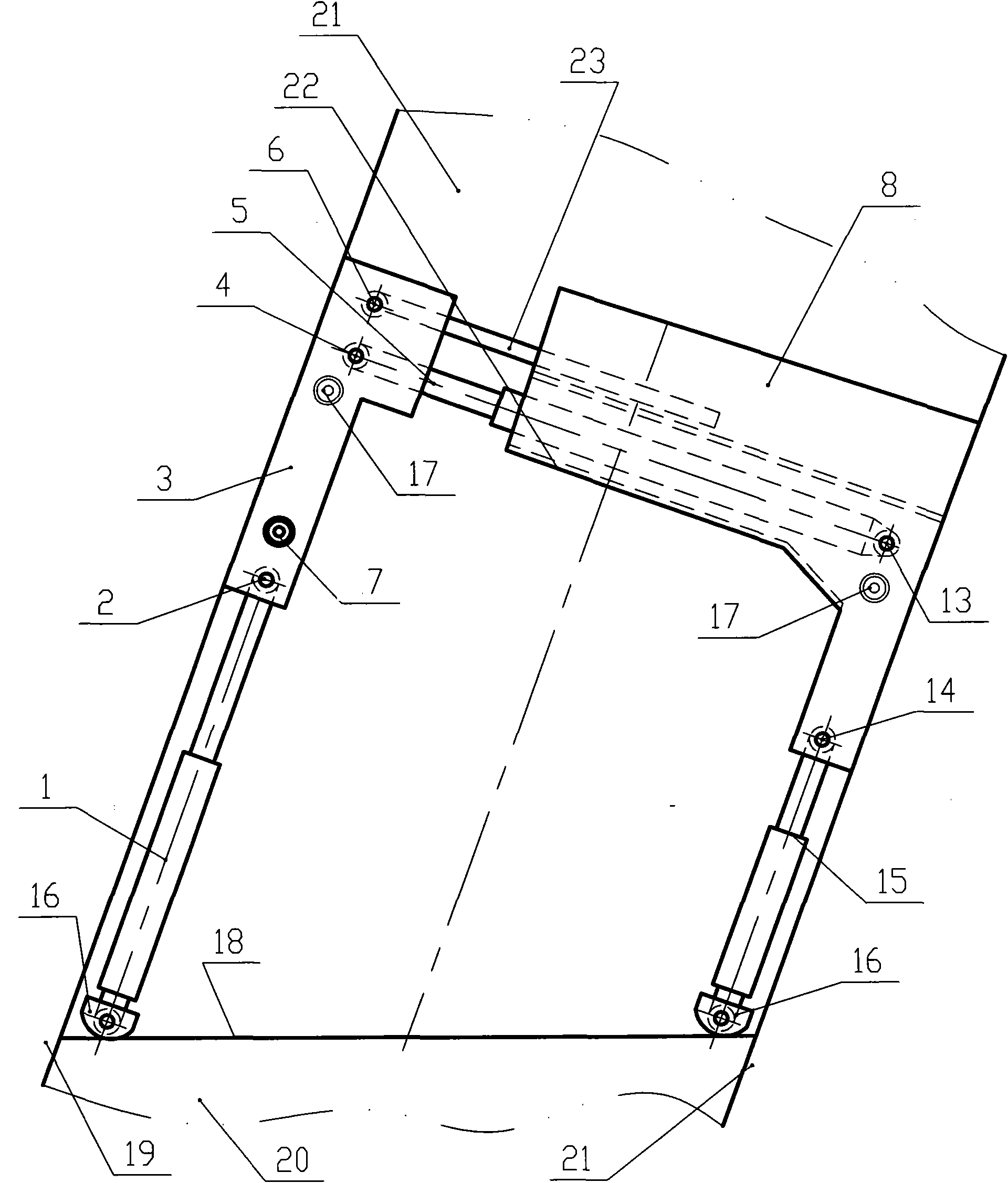

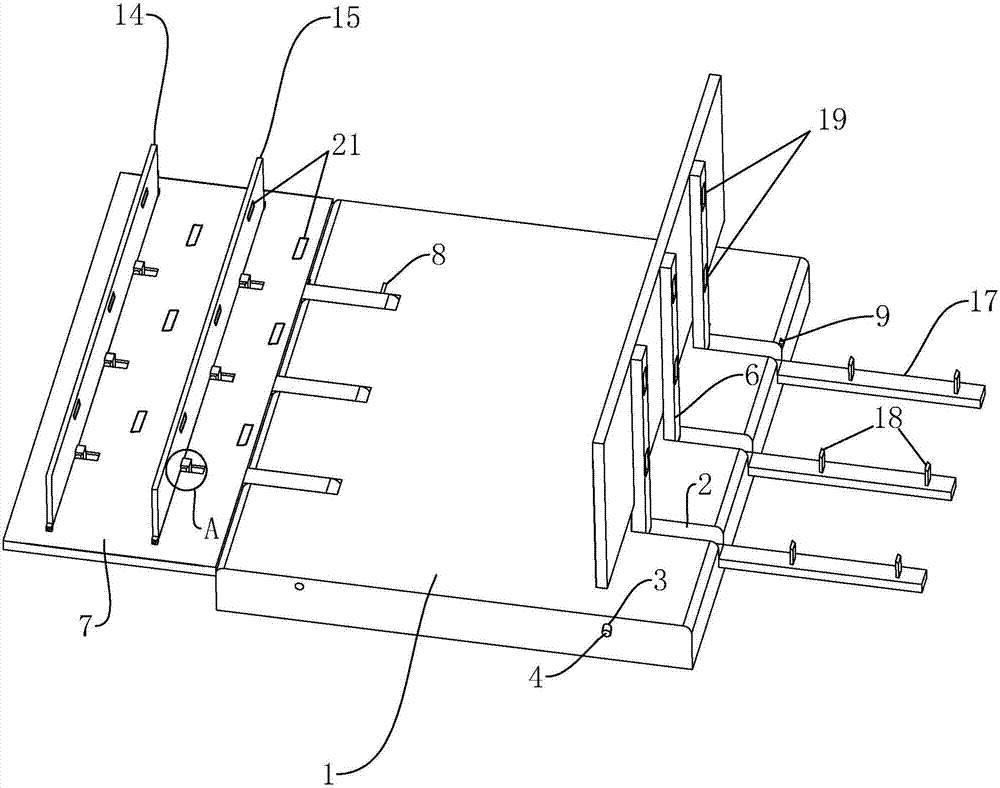

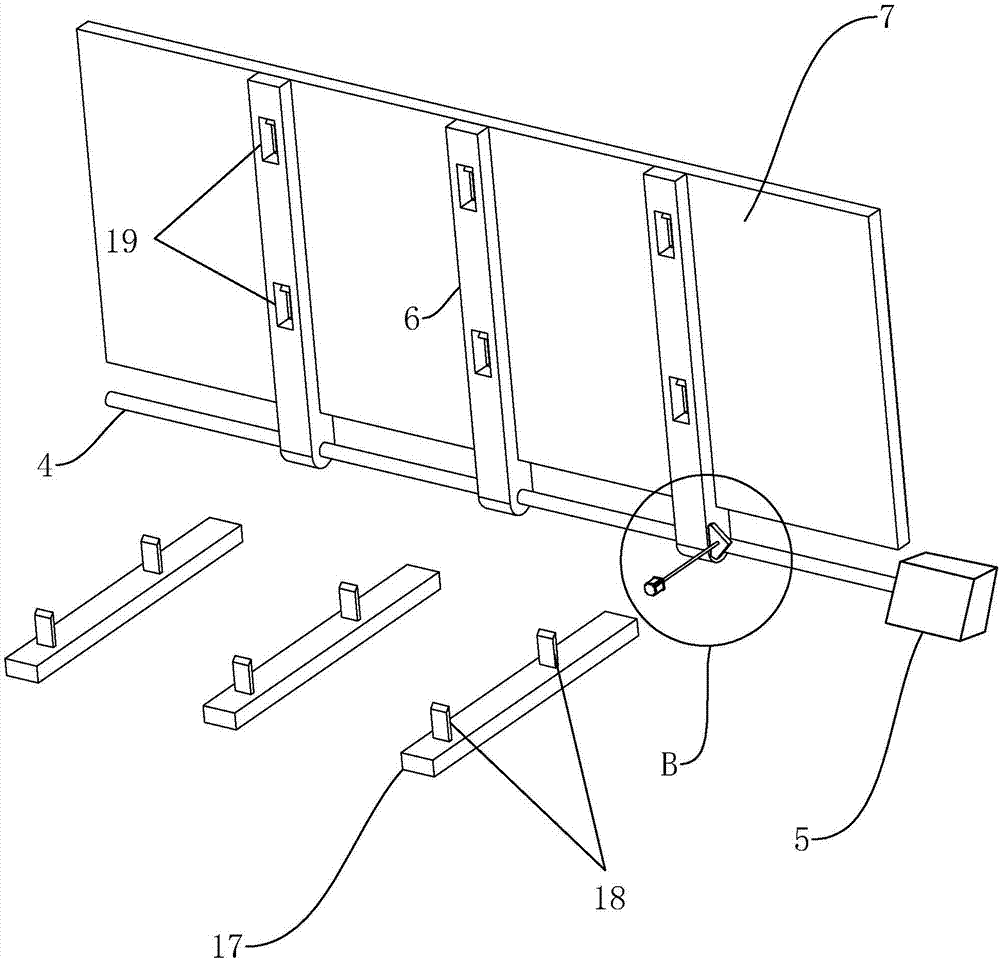

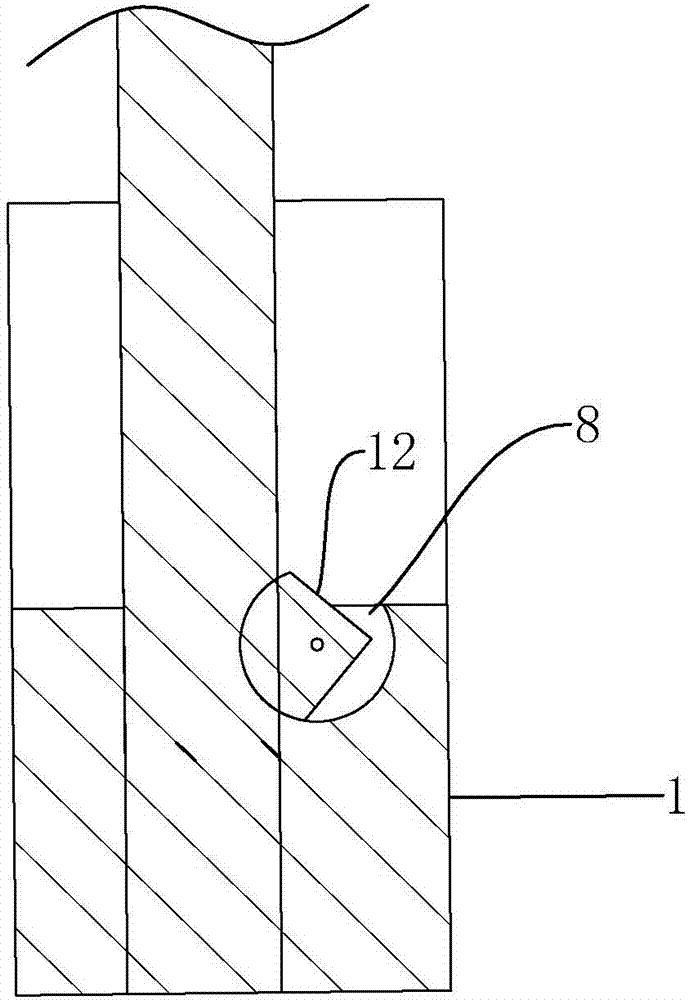

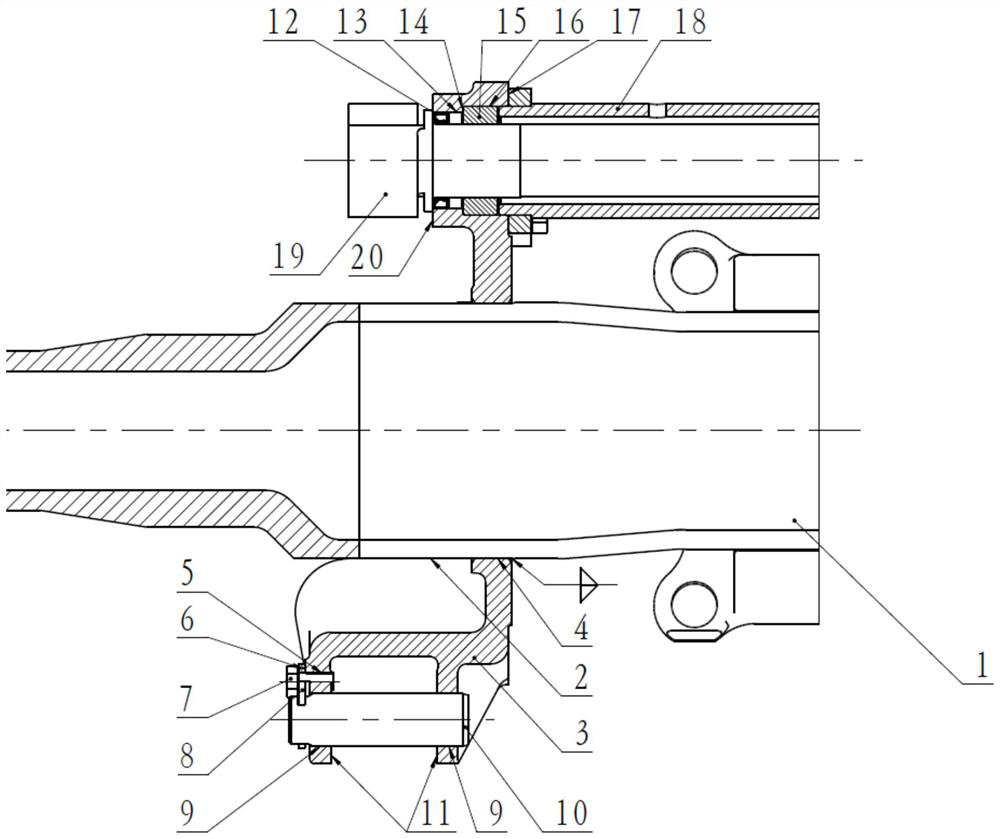

Speedy drivage forepoling

The invention belongs to the technical field of temporary support of a fully mechanized drivaging face of an underground coal mine, particularly relates to a speedy drivage forepoling and solves the safety problem of the forepoling of the existing heading face. The speedy drivage forepoling comprises an inner side bracket group and an outer side bracket group, wherein each of the inner side bracket group and the inner side bracket group comprises a left bracket and a right bracket; the left bracket and the right bracket of the inner side bracket group are arranged on the inner sides of the left bracket and the right bracket of the outer side bracket group; crossbeams and longitudinal beams of the inner side and outer side bracket groups are arranged alternately; a cantilever beam is arranged at the front ends of the longitudinal beams of the inner side bracket group; push-pull oil cylinders are respectively arranged on left and right bases and the crossbeams of the inner and outer side bracket groups; a height difference exists between the tops of the crossbeams and the bottoms of the longitudinal beams of each bracket group; carrier rollers are arranged in positions, corresponding to the bottoms of the longitudinal beams of the other bracket group, of the tops of the crossbeams of one bracket group. According to the invention, top plates for full faces can be supported easily, timely and actively, and safety management for the top plates of a mine is facilitated.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

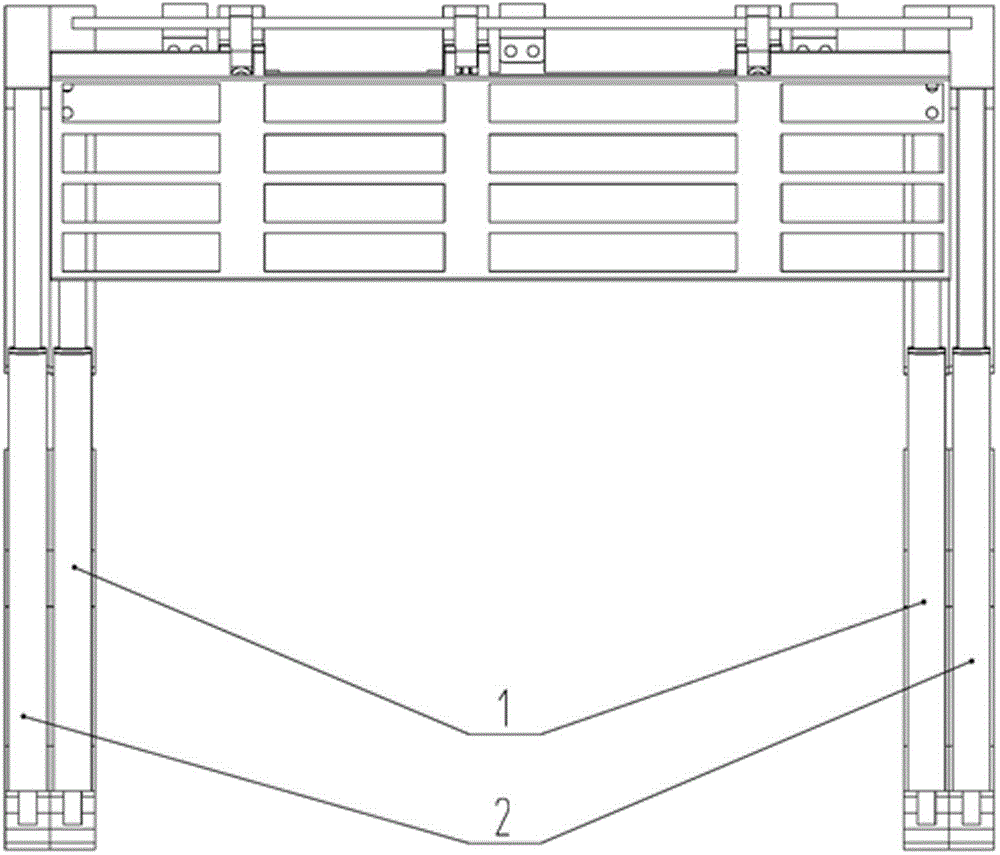

Plate-type sludge dewatering machine and dewatering method therefor

InactiveCN101544459AReasonable structureImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningElastomerHigh pressure

The invention discloses a plate-type sludge dewatering machine and a dewatering method therefore. The plate-type sludge dewatering machine adopts elastomers positioned among pressing filter plates, adjacent anti-thrust filter plates, air-inlet filter plates, feeding filter plates and thrust filter plates to form at least three hermetic pressing filter chambers variable in volume, utilizes the compression deformation and resilience of the elastomers to deep squeeze and dewater a filter cake, and adopts sealing plugs which are arranged in front of air-inlet holes of the air-inlet filter plates and the thrust filter plates and are on positions opposite to feeding holes on the feeding filter plates and the anti-thrust filter plates, wherein the feeding filter plates are adjacent and involutory to the air-inlet filter plates. After low-pressure filter dewatering is over and feeding is stopped, the sealing plugs block and seal the feeding holes so as to prevent sludge from flowing back and entering pipelines during pressing filtration. The dewatering method adopts the variable hermetic pressing filter chambers formed by the elastomers to perform pressing filtration and dewatering, and adds the operation of adopting the sealing plugs to block the feeding holes before high-pressure squeezing-dewatering operation. The invention has the advantages of high dewatering efficiency, strong adaptability, low energy consumption, low use cost and the like.

Owner:ZHEJIANG HUAZHANG TECH

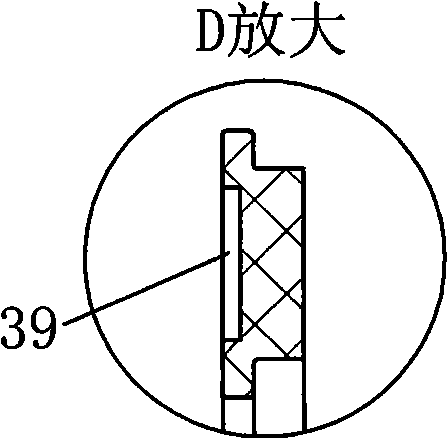

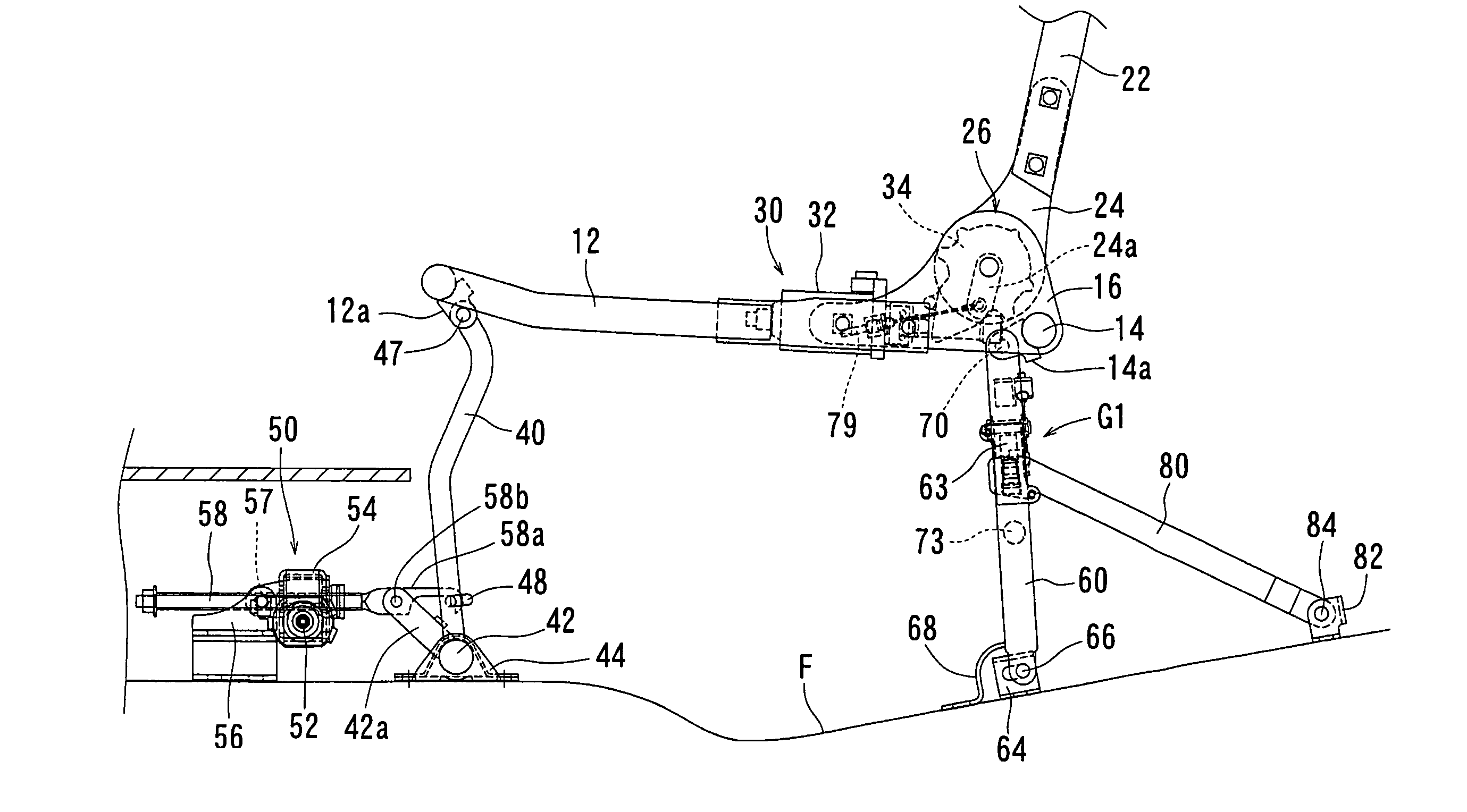

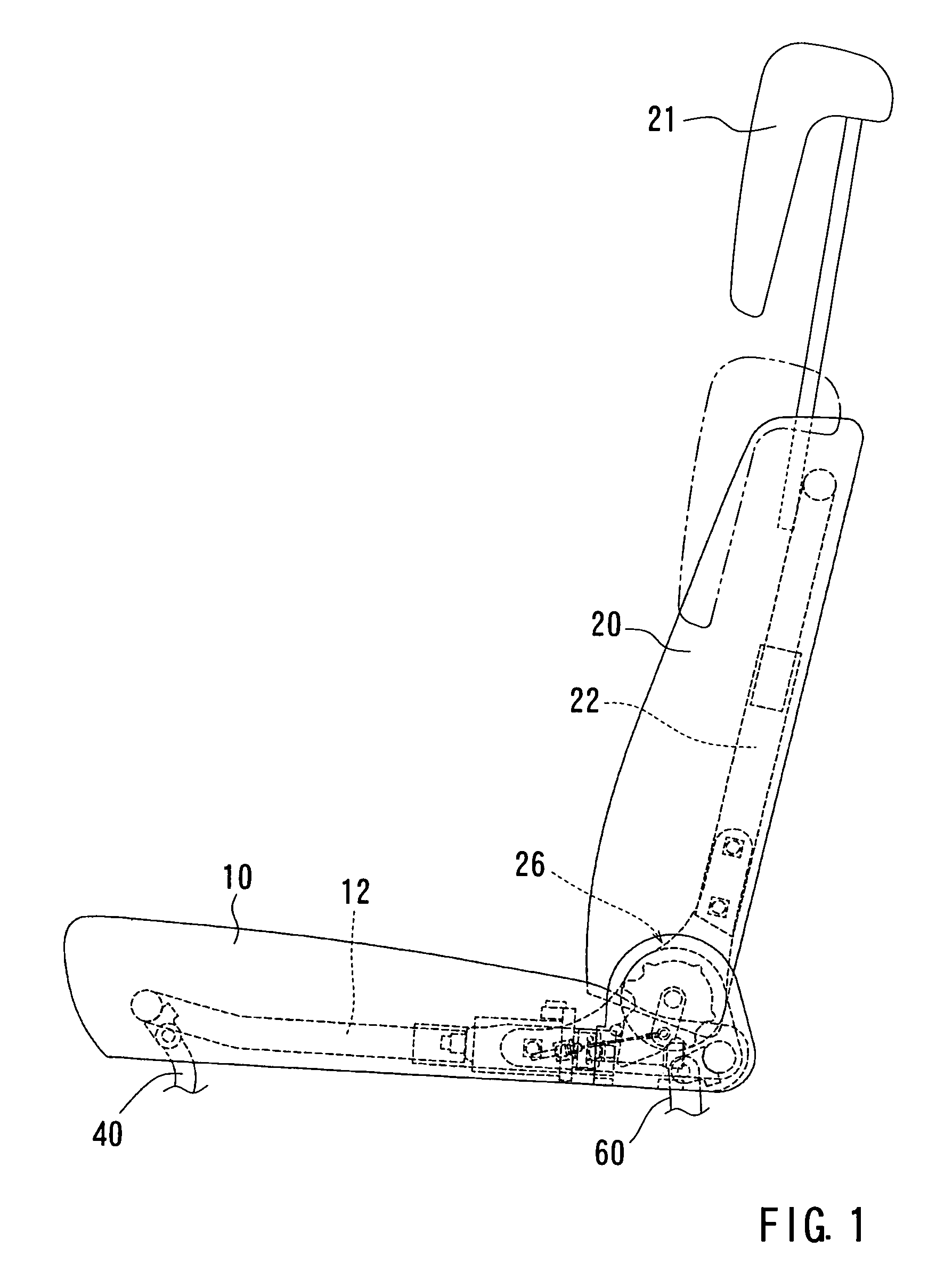

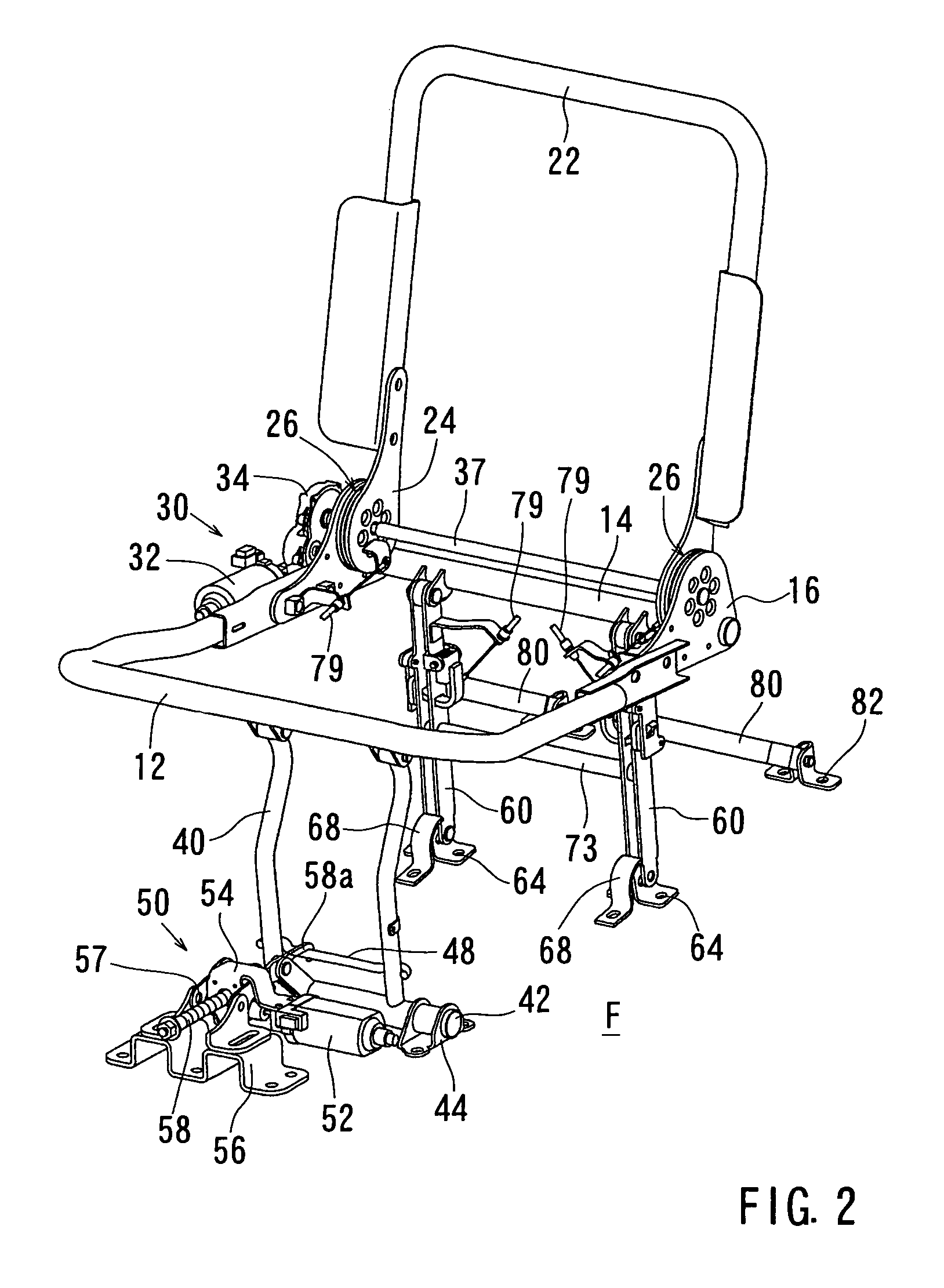

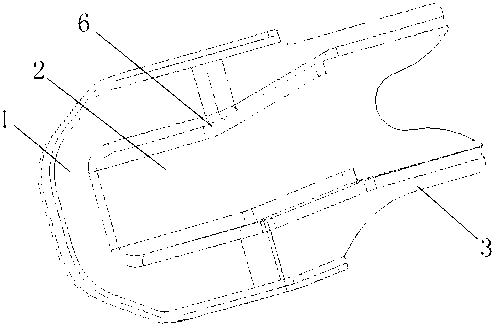

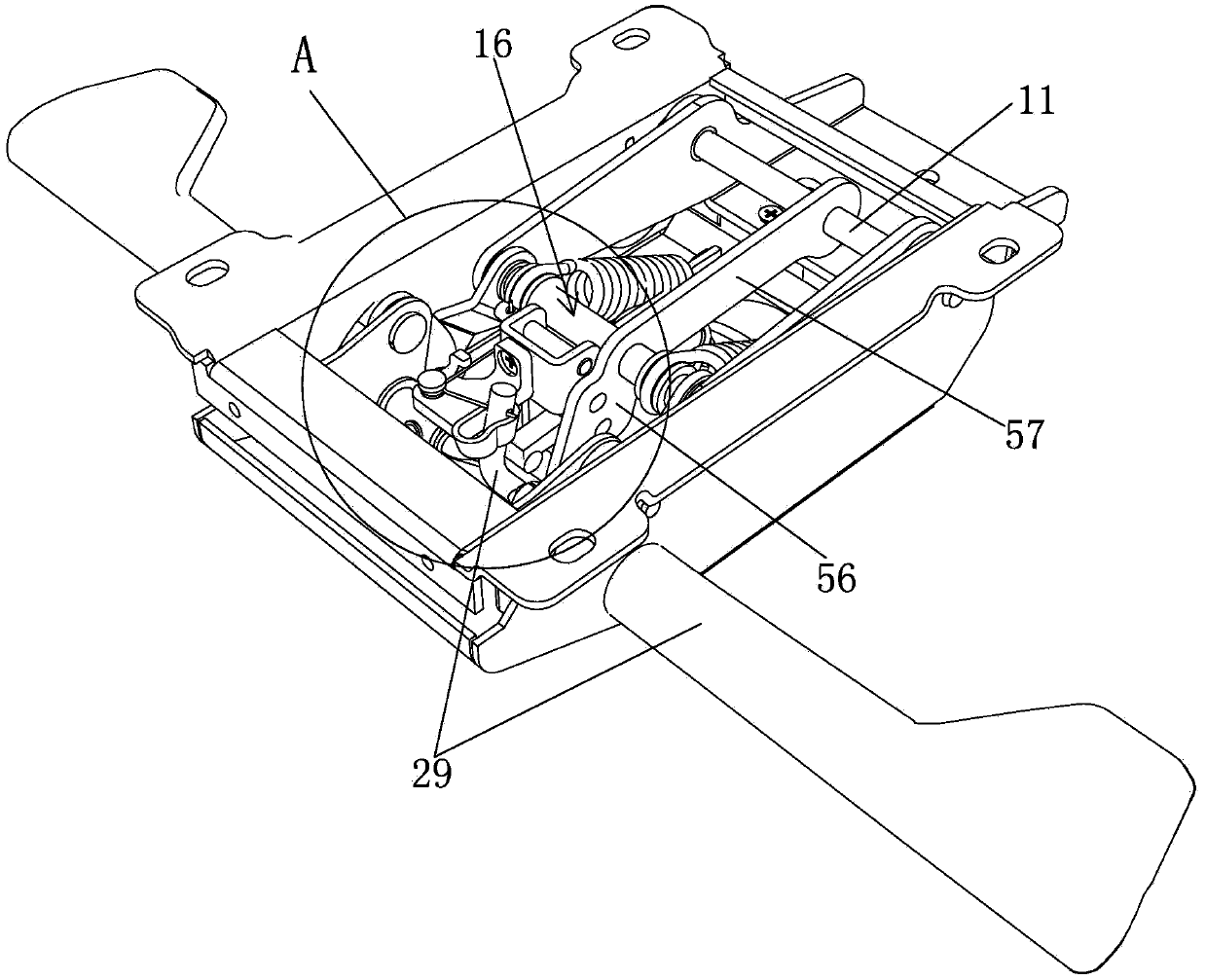

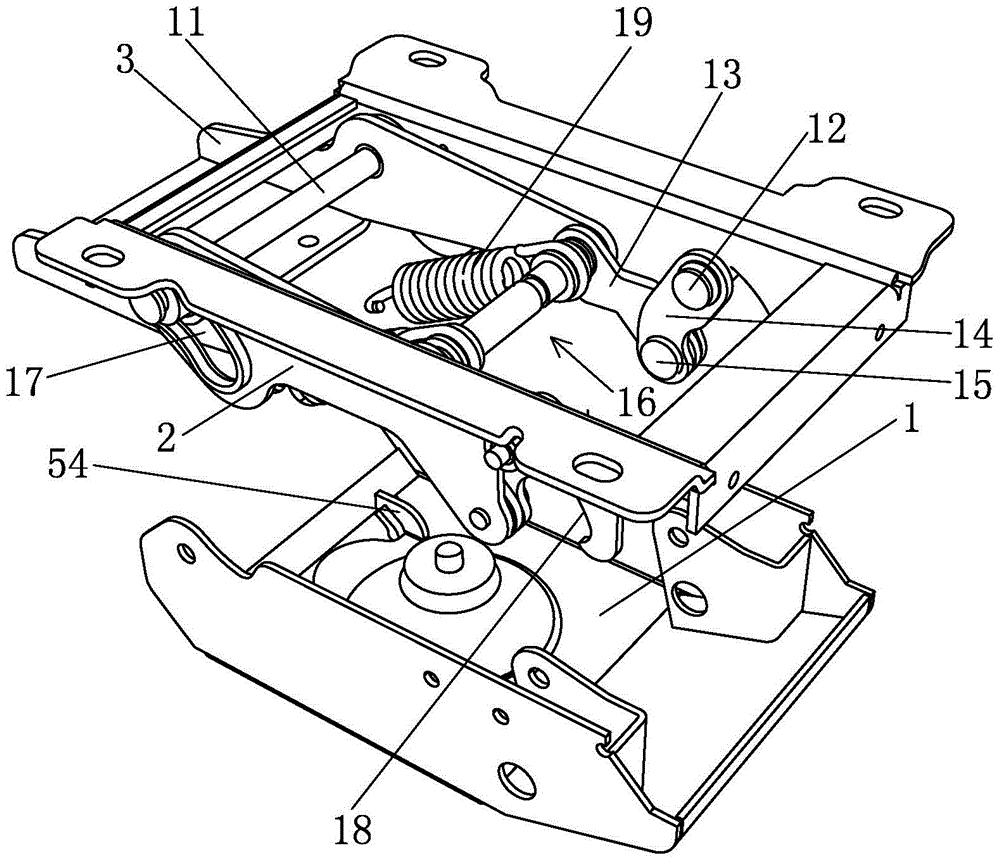

Retractable seats

InactiveUS6974174B2Sufficiently and reliably supportSufficient support strengthOperating chairsDental chairsCushionEngineering

A retractable seat may include a seat cushion, a seat back rotatably supported on the seat cushion, and a link mechanism for supporting the seat cushion on a floor. The link mechanism includes a front leg and a rear leg that are pivotally connected to the seat cushion and the floor so that the seat cushion and the seat back can be switched between a use condition and a retracted condition. The seat may further include a restraint mechanism provided on the floor for preventing the link mechanism from moving when the seat is in a use condition.

Owner:ARACO CORP

Automobile engine mounting bracket and manufacture method thereof

ActiveCN103009985ASuspension assembly is stableLarge operating spaceJet propulsion mountingInternal combustion mountingAutomobile designThinning

The invention aims at providing an automobile engine mounting bracket and a manufacture method thereof. The automobile engine mounting bracket comprises a base, a support plate, a bracket, an installing hole and a suspending hole, wherein a bending part is arranged on the support plate. According to the automobile engine mounting bracket, the special bending part is adopted, and thus parts structures in an automobile can be avoided, larger operation space is provided for automobile design, especially for a compact automobile, a better design flexibility is achieved; and meanwhile, the shape and the structure ensure enough support strength, and thus the stability of an automobile engine mounting assembly is ensured. The invention also provides a manufacture method of the mounting bracket. By using a specially designed discharging block, the stability in a machining process is ensured; and due to the arrangement of a locating hole and a locating edge, a corresponding locating module is arranged on a matched forming mould, the machining precision can be well ensured, and excessive thinning and cracking on the thickness of parts materials during machining are avoided, and better practicability is achieved.

Owner:LIUZHOU JINYUAN MACHINERY MFG

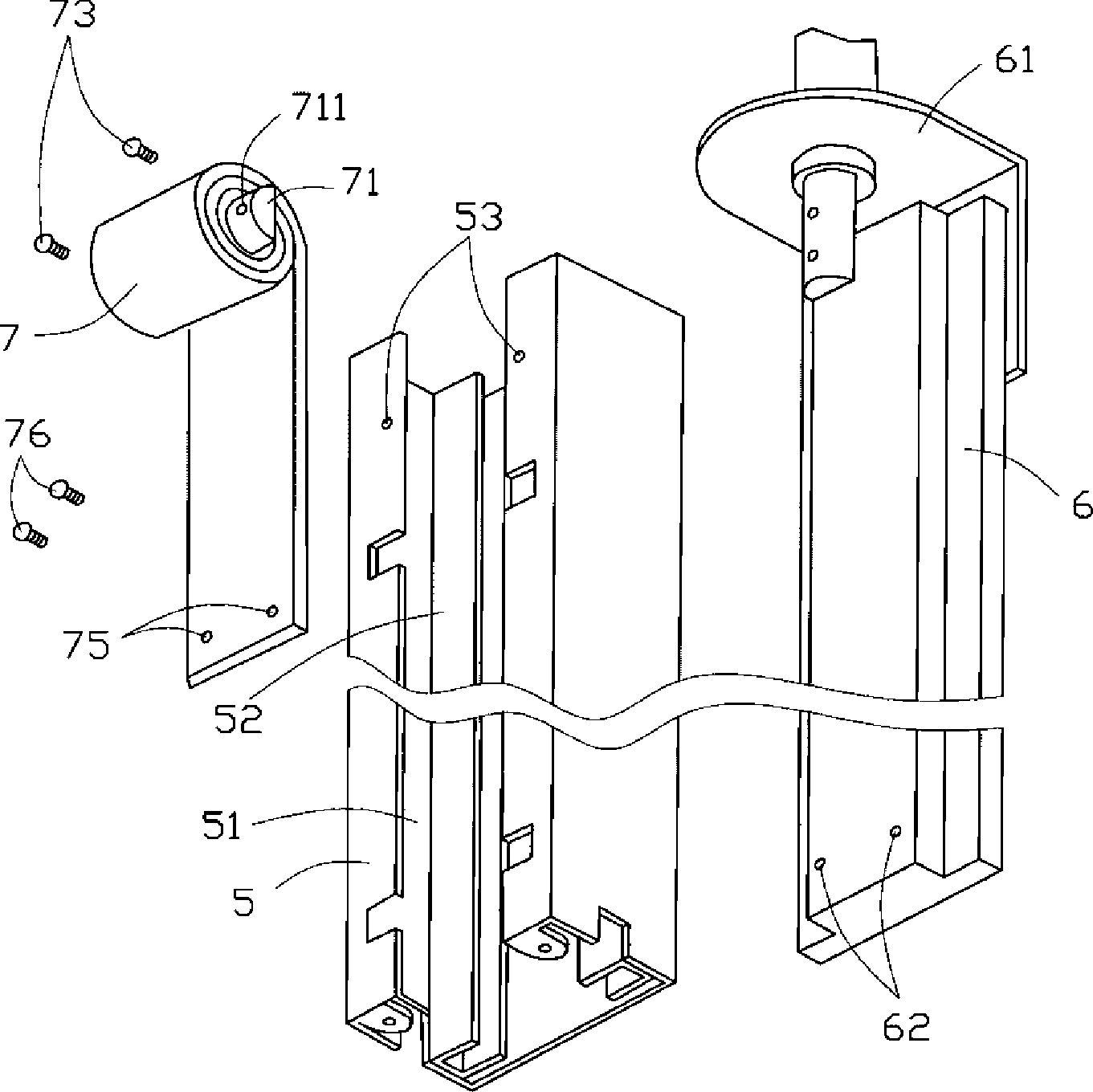

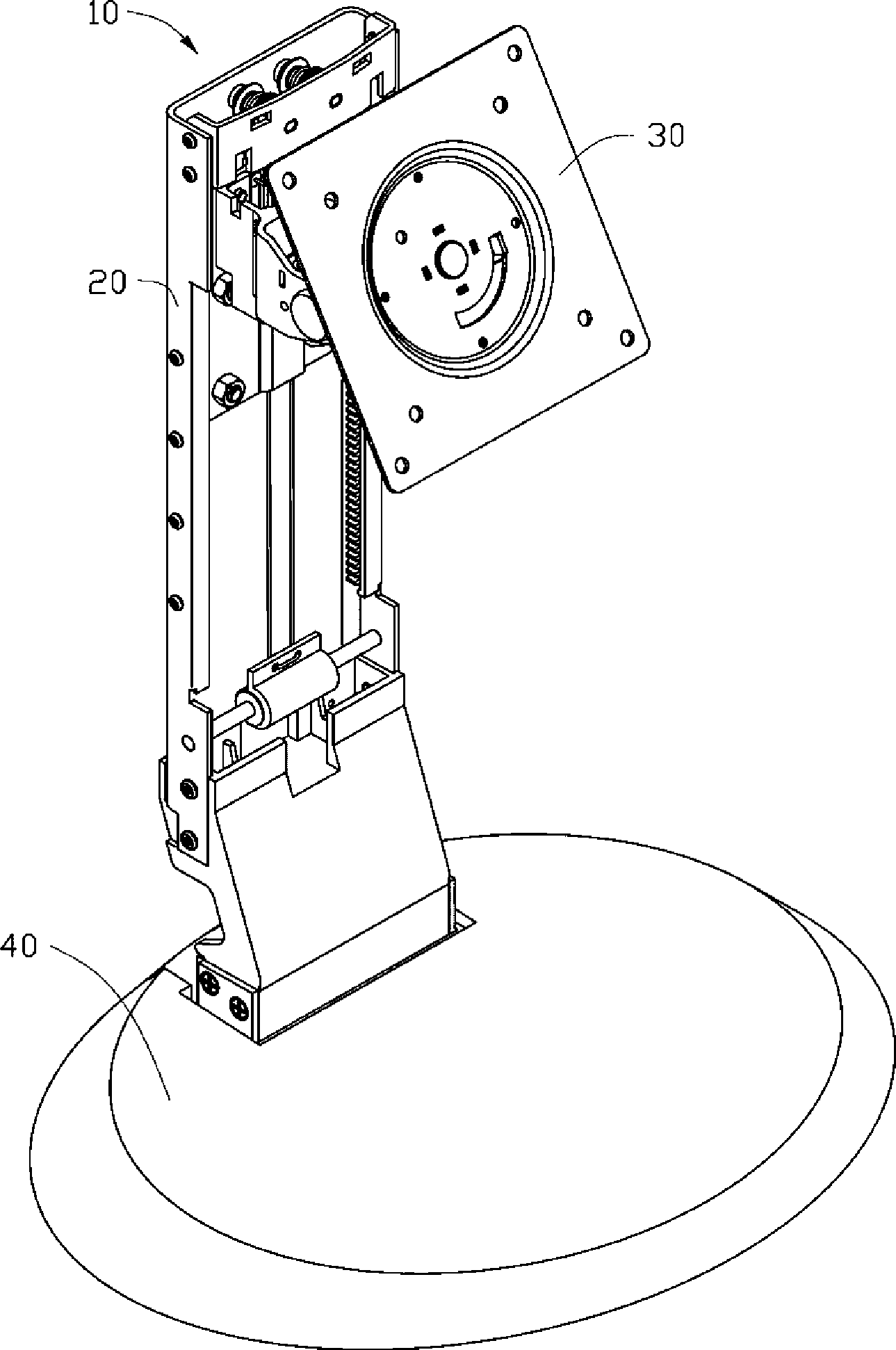

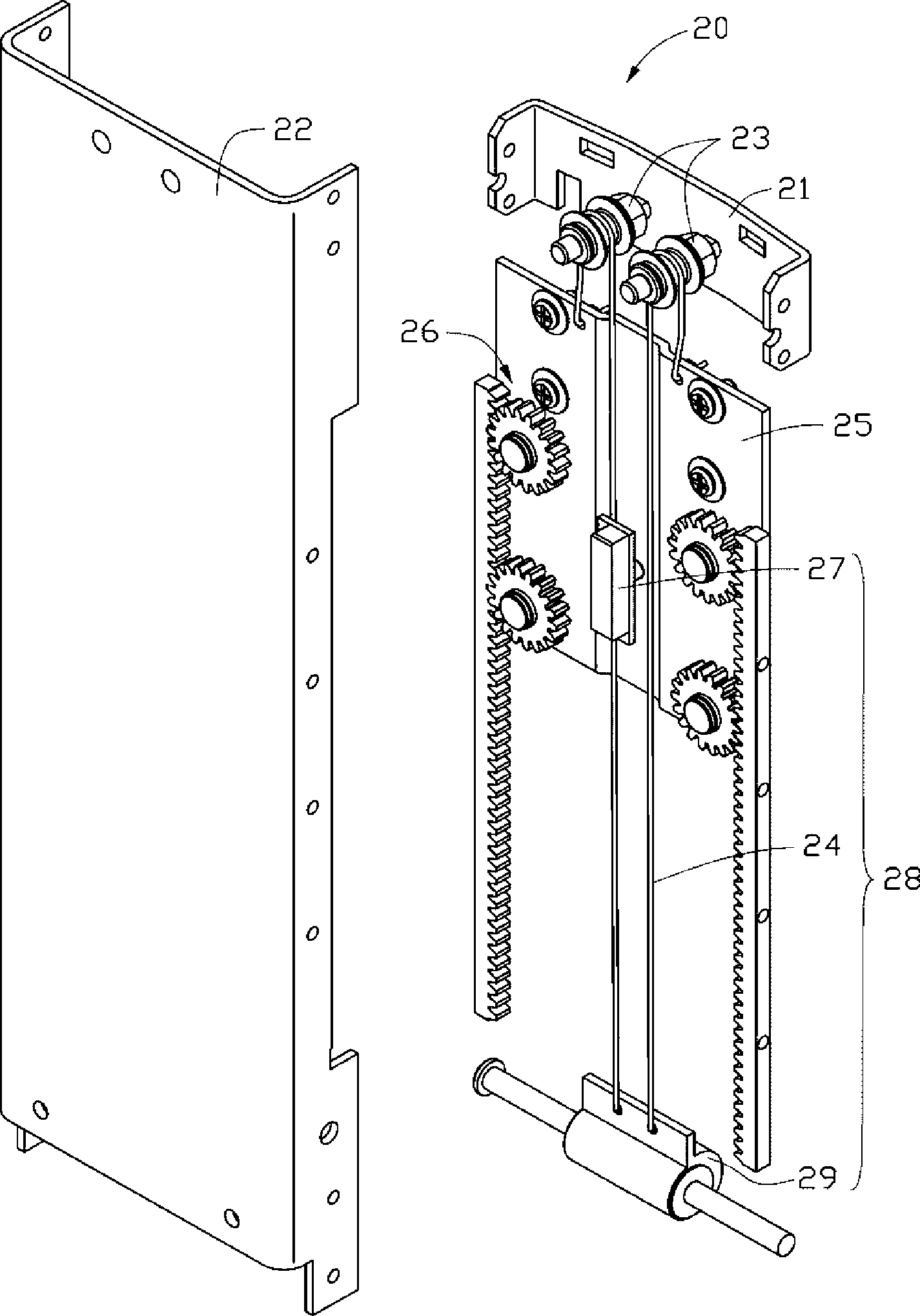

Lifting mechanism

InactiveCN101487558AReduce manufacturing costPrecise positioningDigital data processing detailsStands/trestlesGear wheelCoil spring

The invention provides an elevator mechanism, which comprises a bracket, a sliding panel, two roller components, a transmission component and a gravity balance device. The roller components comprise two rollers which are rotatably arranged on the roller components. The transmission component comprises two racks and at least two gears. The two racks are symmetrically arranged on the bracket. The at least two racks are arranged on the sliding panel and meshed with the rack in a rolling way. The gravity balance device comprises a guy rope and a coil spring. The guy rope is connected with the coil spring, bypasses the roller and is connected with the sliding panel. The coil spring is rotatably connected with the bracket. The invention provides the elevator mechanism with compact structure, low cost and better stability.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

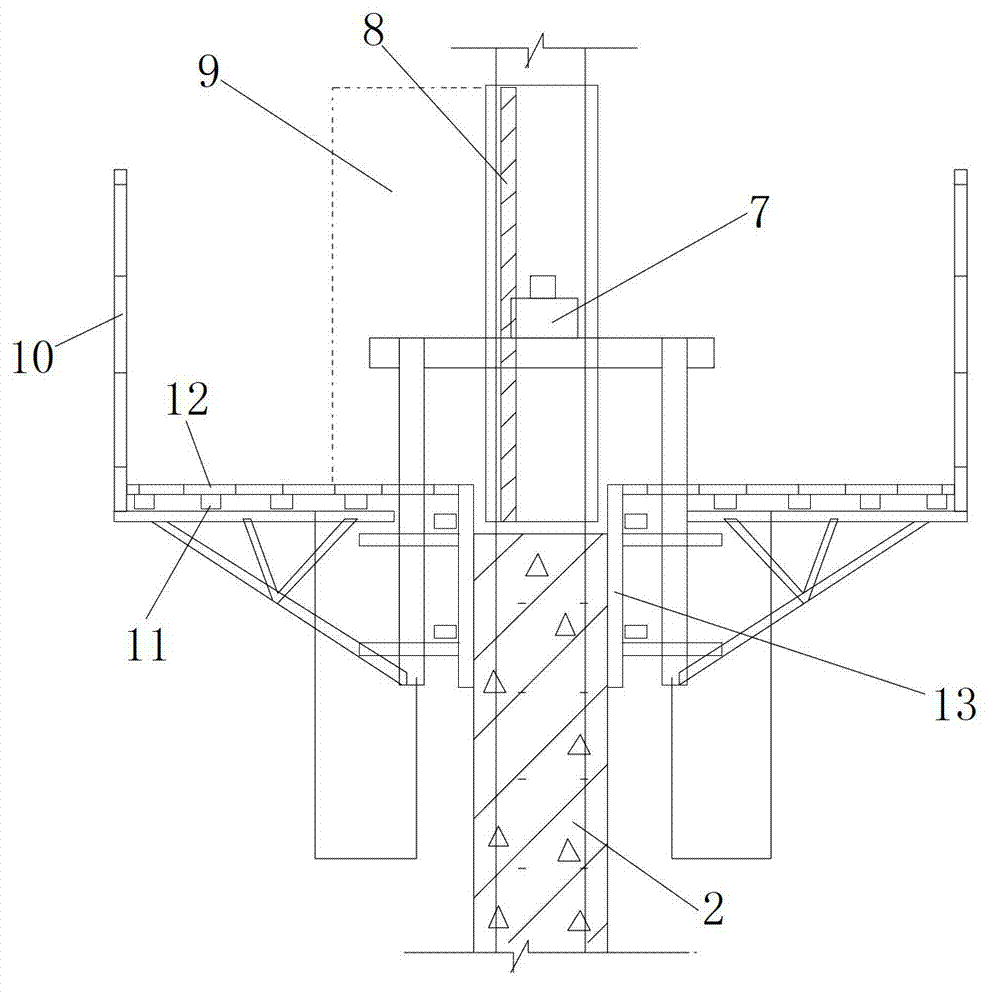

Large coal bunker wall construction method and ring beam portion construction method

The invention discloses a large coal bunker wall construction method and a ring beam portion construction method which are beneficial for shortening the construction period of a large coal bunker. The large coal bunker wall construction method mainly includes that temporary supports are arranged in mounting seams of two ring beam portions; and then inner side ends of corresponding stirrups are bent to avoid a rising path of a slip form operation system, so that the slip form operation system is not required to be detached or remounted at the ring beam portions. Accordingly, the construction period can be shortened remarkably. Besides, the ring beam portion construction method includes that after the corresponding temporary supports are taken out, concrete is poured in the mounting seams, and the inner side ends of the corresponding stirrups are bent again and are connected with an internal structure of the coal bunker.

Owner:CHINA 19TH METALLURGICAL CORP

Intelligent video monitoring device and mounting method

InactiveCN107917324AThe image is clear and completeImprove image processing capabilitiesStands/trestlesEngineeringIntelligent sensor

The invention discloses an intelligent video monitoring device and a mounting method. A longitudinal-axis adjusting device of the intelligent video monitoring device comprises an upper end plate, a lower end plate and fixing rods, a guiding rod is arranged between the fixing rods, and an adjusting rod is arranged in the guiding rod. A transverse adjusting device comprises a first fixing seat, a second fixing seat and a length adjusting block, a rotating adjusting device comprises a rotating seat, a mechanical arm and a base plate, and a camera is arranged on the base plate. The mounting methodcomprises the steps that (1) the mounting position is arranged; (b) according to the mounting place and the type of the camera, auxiliary equipment is mounted; (c) a relevant line is arranged according to a drawing; (d) a transverse positioning plate is mounted; (e) the longitudinal-axis adjusting device is mounted; (f) the camera is mounted in a mounting plate; (g) the monitoring position of thecamera is adjusted in the X-axis direction; (h) the monitoring position of the camera is adjusted in the Y-axis direction; (i) the monitoring position of the camera is adjusted in the Z-axis direction; and (j) the mounting angle of the camera is adjusted. According to the intelligent video monitoring device and the mounting method, integral clear images can be caught, and monitoring warning is conducted in real time.

Owner:SHANGQIU INST OF TECH

Telescopic arm type lorry-mounted crane

InactiveCN101927966AGuaranteed waterproof sealingAvoid the problems of too large section, large amount of steel, and increased weight of the whole machineCranesEngineeringSlewing bearing

The invention relates to a telescopic arm type lorry-mounted crane which belongs to the technical field of telescopic arm type lorry-mounted crane. Compared with the existing telescopic arm type lorry-mounted crane, the weight and size of the entire machine are reduced and the height and manufacturing cost of the entire machine are lowered. In the crane of the invention, an integral slewing device is fixed on the front end of the base assembly of a slewing bearing; the slewing bearing is fixed on the back end of the base assembly of the slewing bearing; an upright is fixed on the slewing bearing; the top of the upright is connected with a suspension arm; the front end of the upright is hinged with the cylinder barrel of a derricking cylinder; the piston rod of the derricking cylinder is hinged with the middle part of the suspension arm; an integral winch is arranged below the suspension arm; a telescopic arm is arranged in the suspension arm; the lower part of the front end of the telescopic arm is provided with a hook; and the upright has a groove-shaped box structure, and the inclination of the slope of the box on the upright is matched with the inclination of a lower slope at the tail end of the suspension arm. The crane of the invention can be widely used to lift weights in various projects.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY

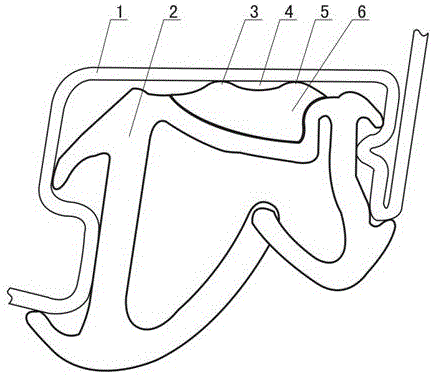

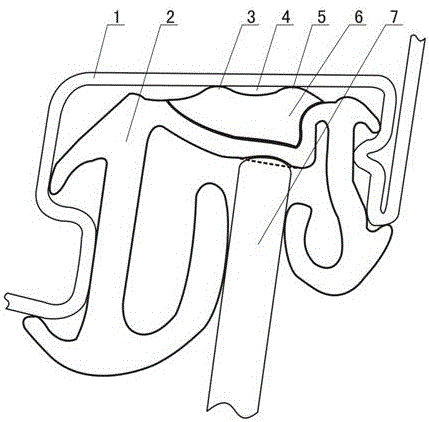

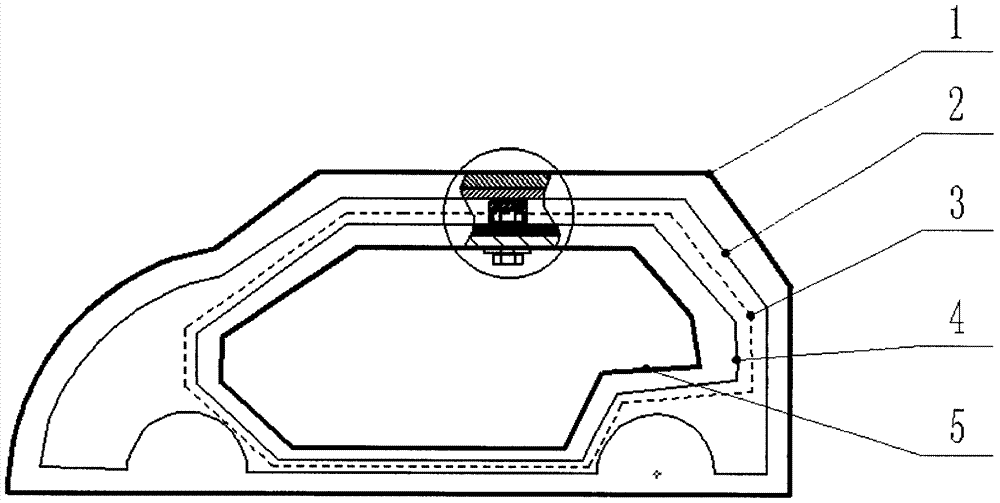

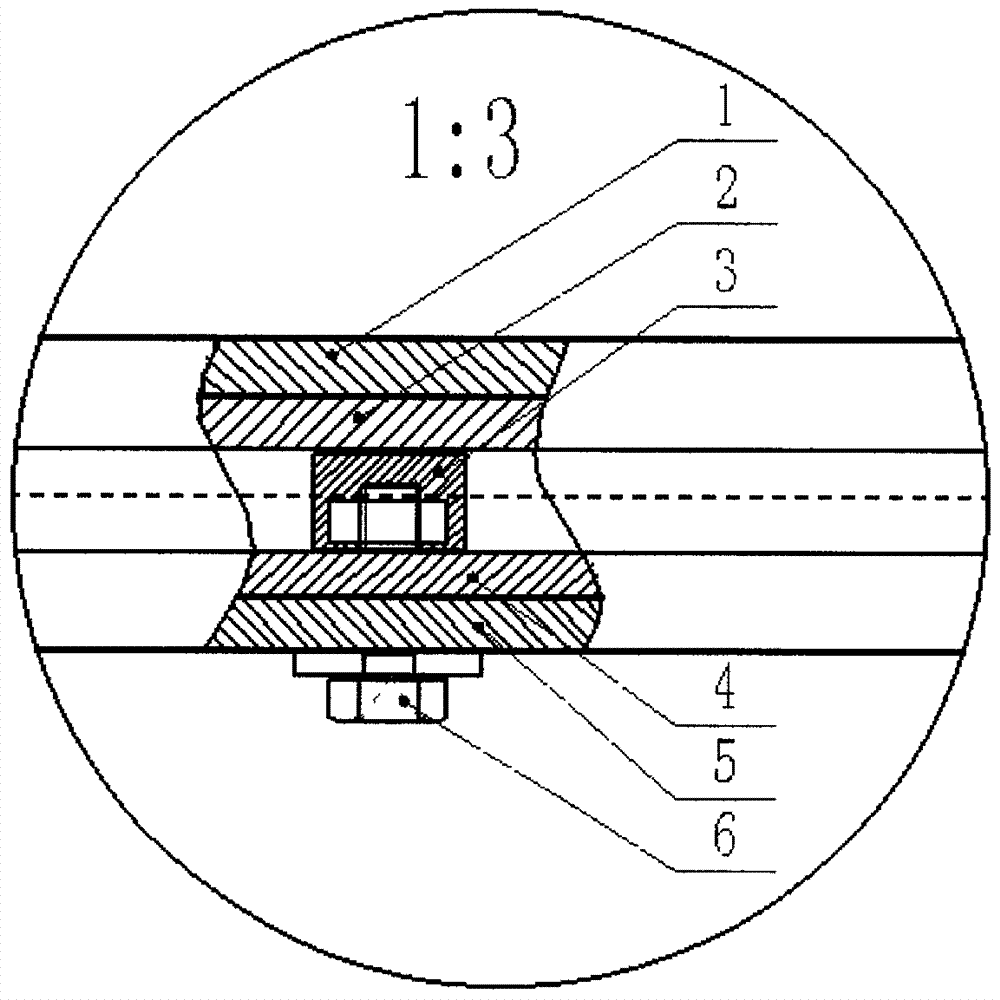

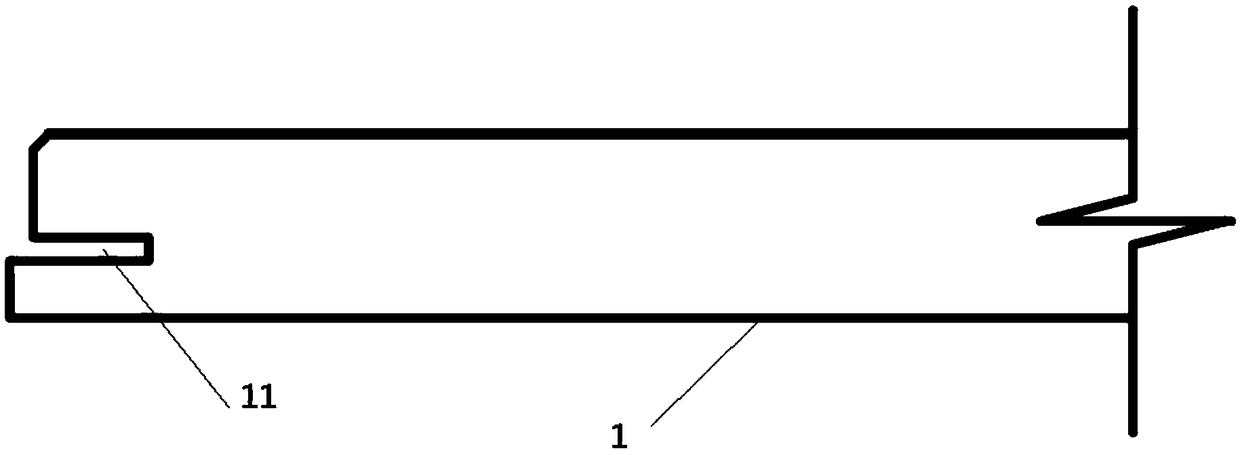

Novel automobile groove-shaped sealing strip

InactiveCN105667277AGood cushioning effectIncreased durabilityEngine sealsVehicle sealing arrangementsComposite structureEngineering

The invention discloses a new type of automobile felting groove sealing strip, which is placed on the inner side of the door frame of a car door. The novel automobile woolening groove sealing strip is formed by composite co-extrusion of EPDM compact glue and EPDM sponge rubber. The new type of automobile woolening groove sealing strip is The part close to the door frame is the EPDM sponge glue, and the other parts are the EPDM compact glue. The new type of automobile woolen groove sealing strip of the present invention adopts a composite structure combining EPDM dense glue and EPDM sponge glue. The thicker EPDM sponge glue can quickly absorb the impact energy of glass rising and play a good buffering role. The original position can be quickly restored, the durability is enhanced, and only the extrusion process can be completed. The process implementation is relatively simple and reliable, and the cost is low.

Owner:SAARGUMMI CHINA INVESTMENT CO LTD

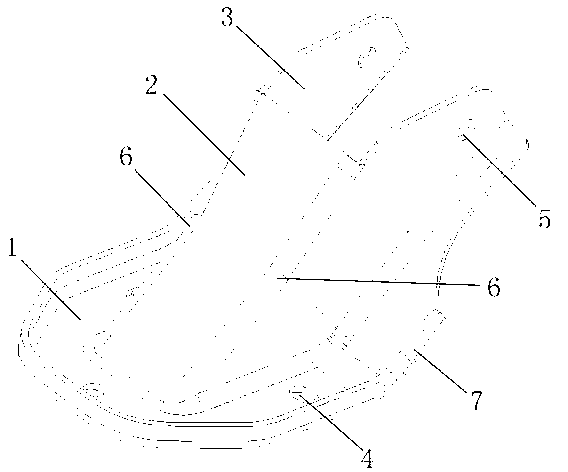

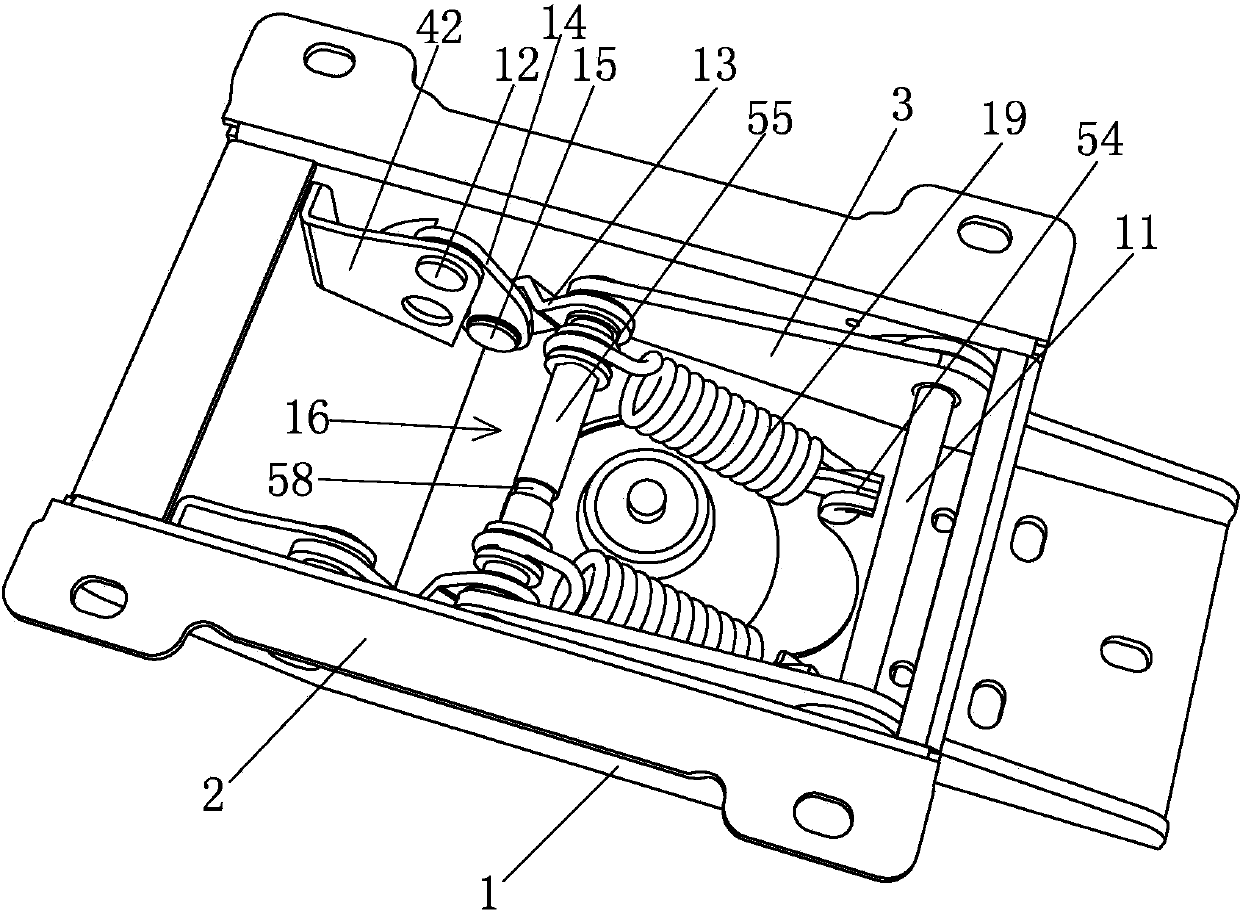

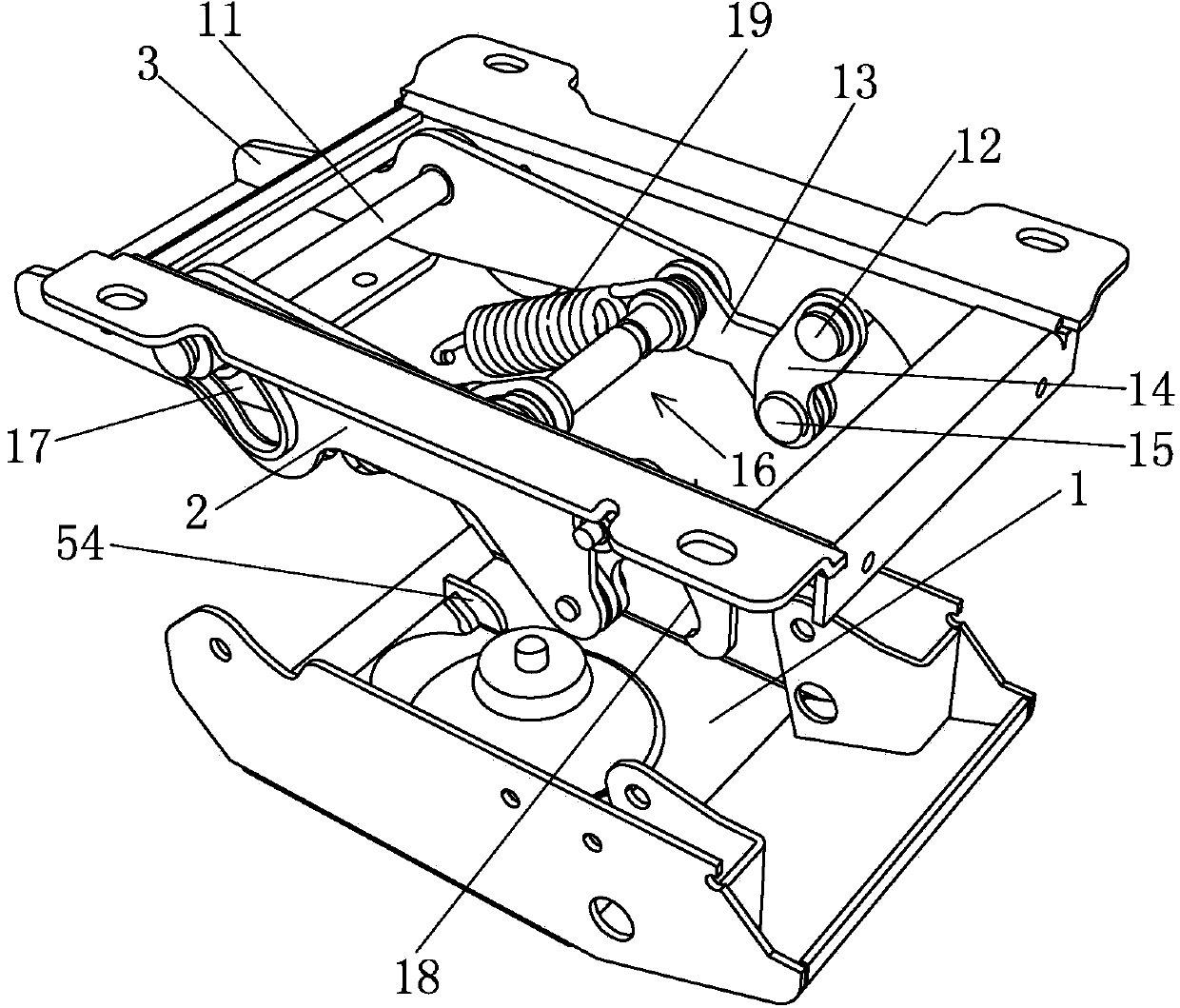

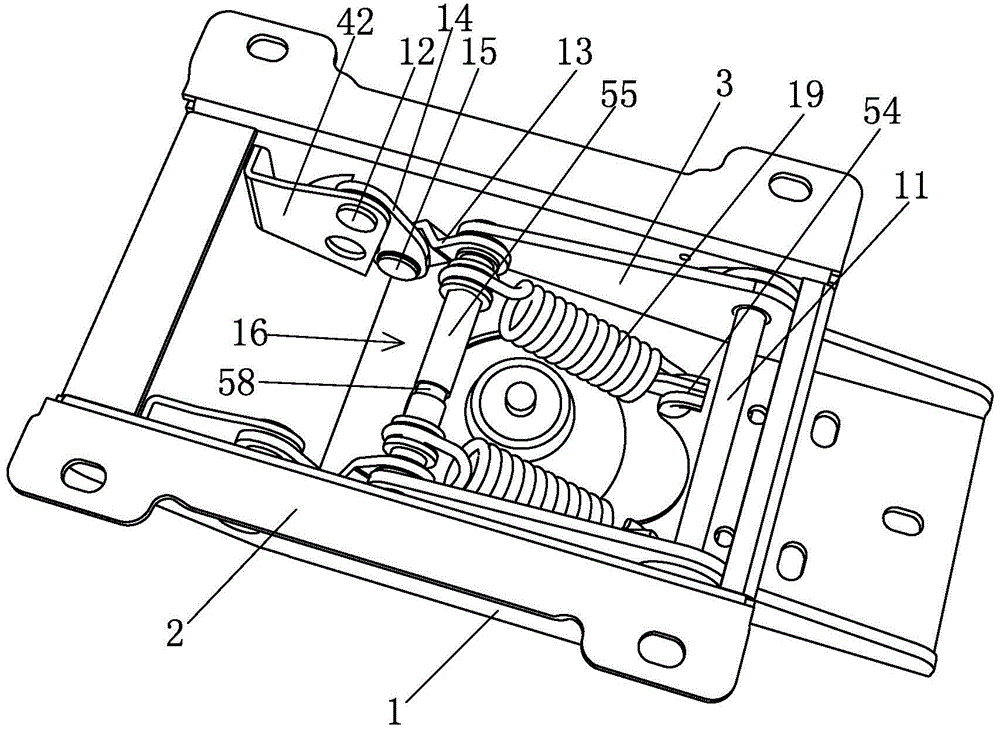

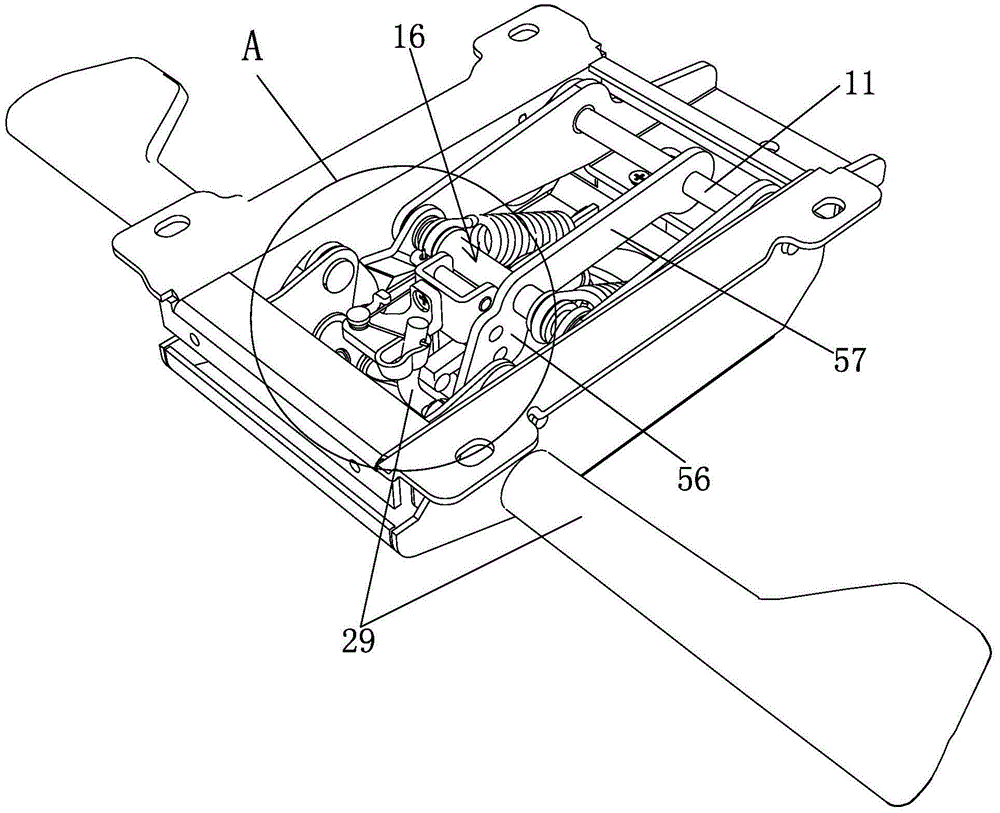

Chair back and rocker locking mechanism for chassis of swivel chair

ActiveCN104207520ASimple and ingenious structureEasy to useStoolsAdjustable chairsTorsion springEngineering

The invention discloses a chair back and rocker locking mechanism for a chassis of a swivel chair. The chair back and rocker locking mechanism comprises a locking plate, a torsion spring a, a bolt and a bolt seat, wherein a row of locking holes are formed in the locking plate, the locking plate is fixedly connected with a fourth pin shaft and performs synchronous motion along with the fourth pin shaft under the action of a rocker, the fourth pin shaft is a whole long shaft, the bolt seat is arranged beside the locking plate, the bolt seat is fixedly connected with a base of a chassis, the bolt is penetrated and inserted into the bolt seat in a sliding manner and matched with the locking holes, a first spring arm of the torsion spring a is connected with the bolt, and a second spring arm of the torsion spring a is connected to a driving device for driving the torsion spring a to rotate back and forth. The chair back and rocker locking mechanism disclosed by the invention is provided with the locking plate and the bolt, and the bolt can realize dialing according to the rotation of the torsion spring, thereby achieving the purpose that the bolt is inserted into or withdrawn from the locking holes; the locking of the rocker is realized by matching the bolt with the locking plate, thereby facilitating the control.

Owner:UE FURNITURE CO LTD

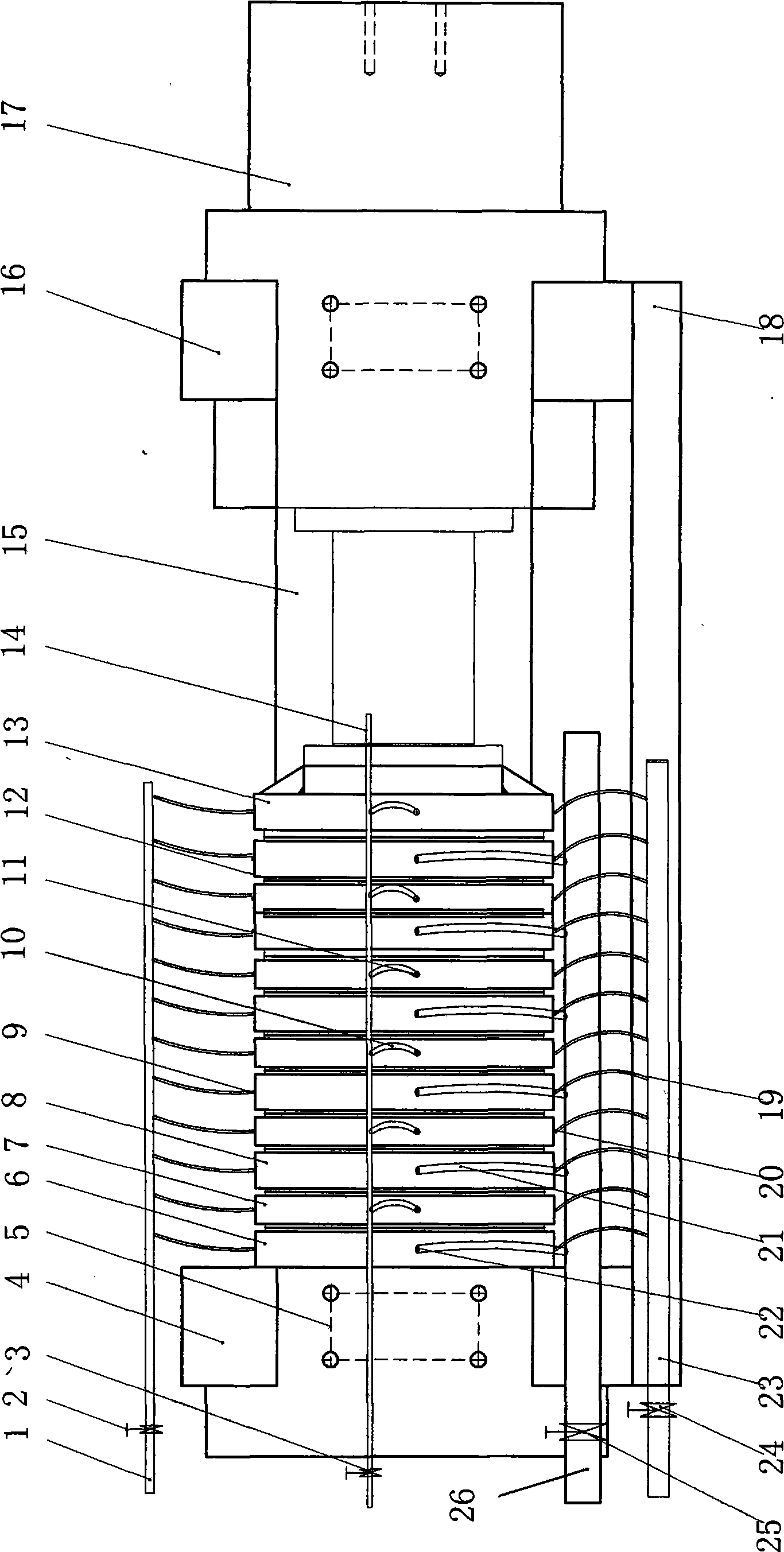

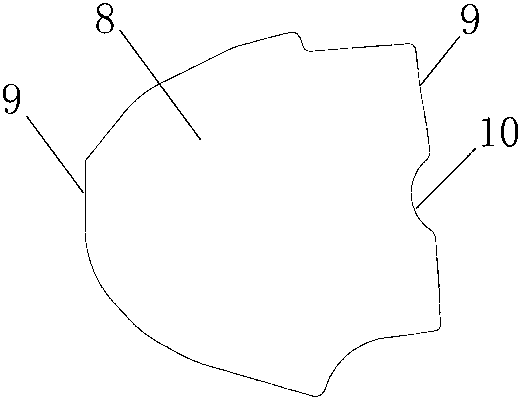

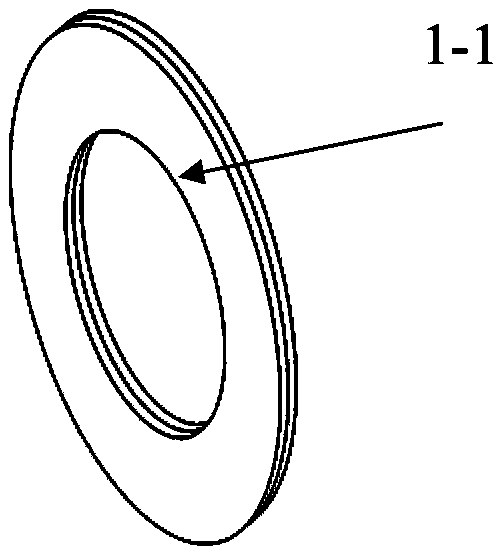

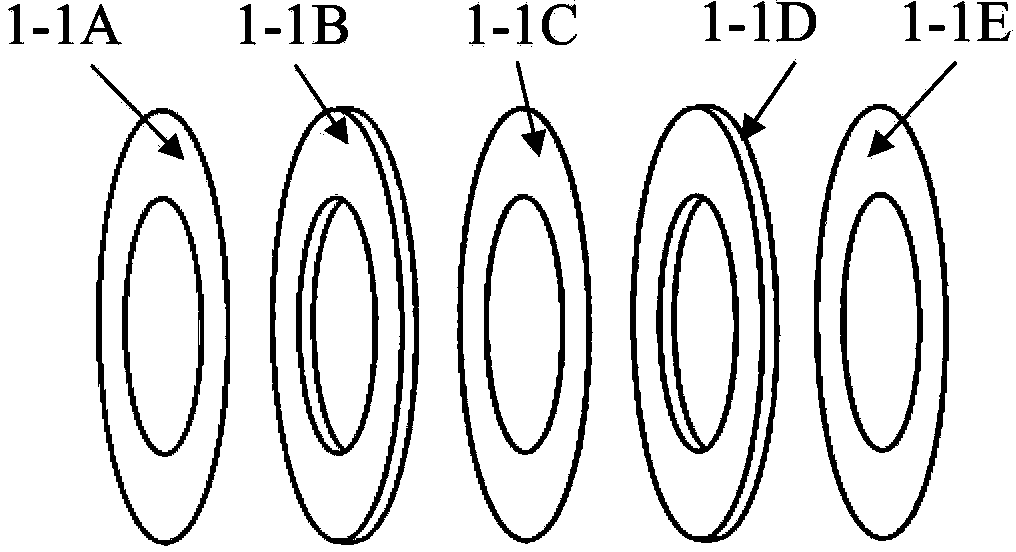

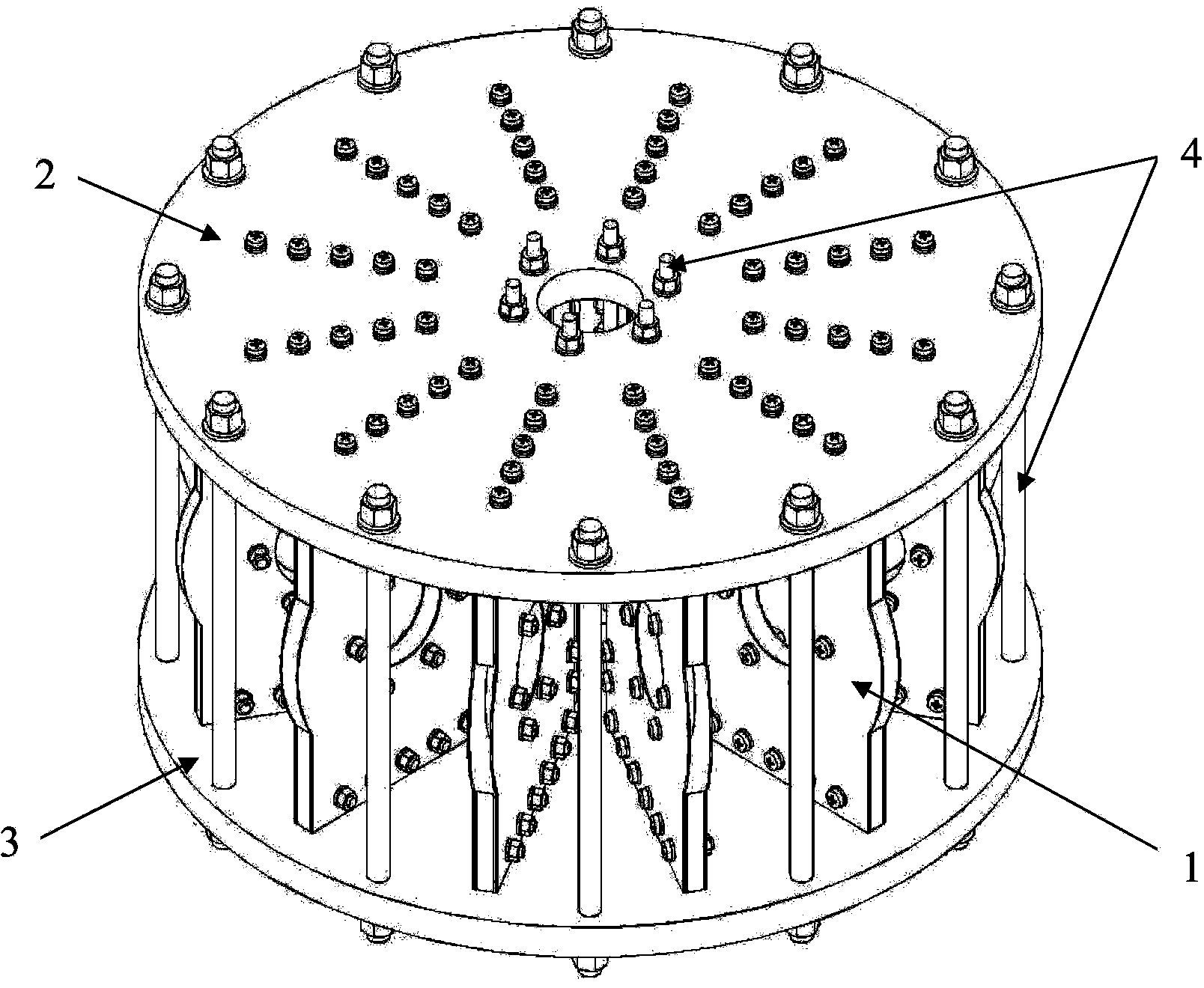

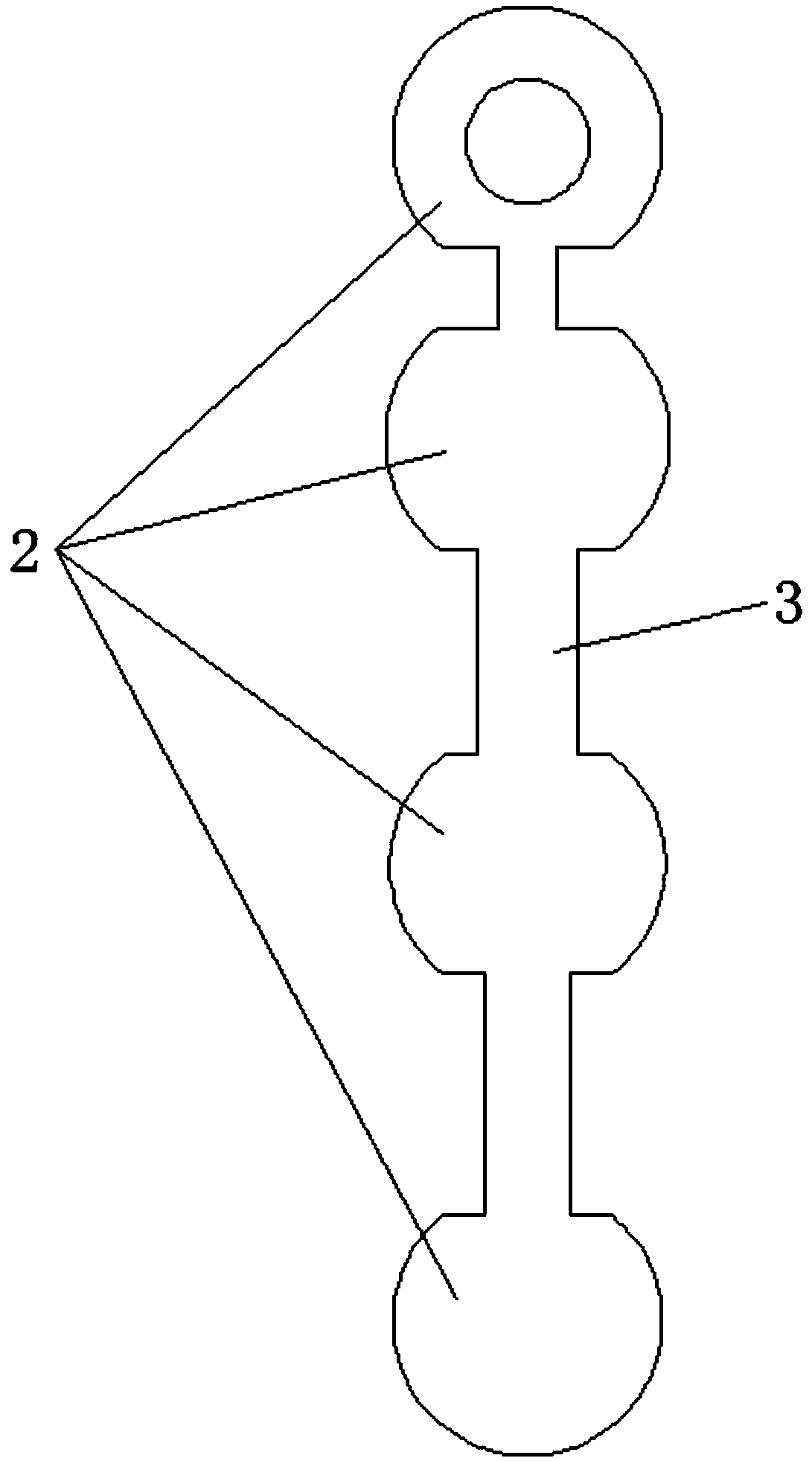

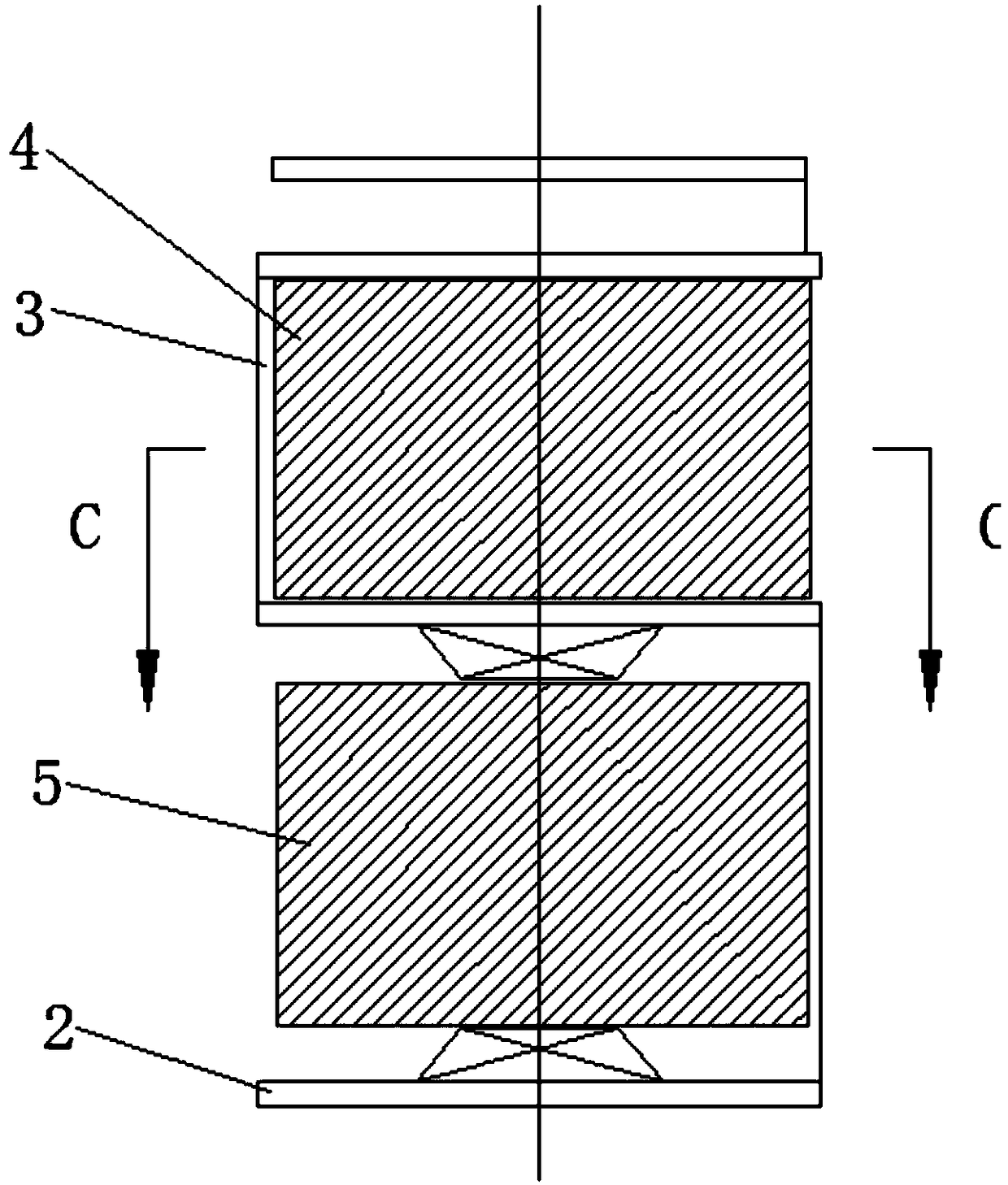

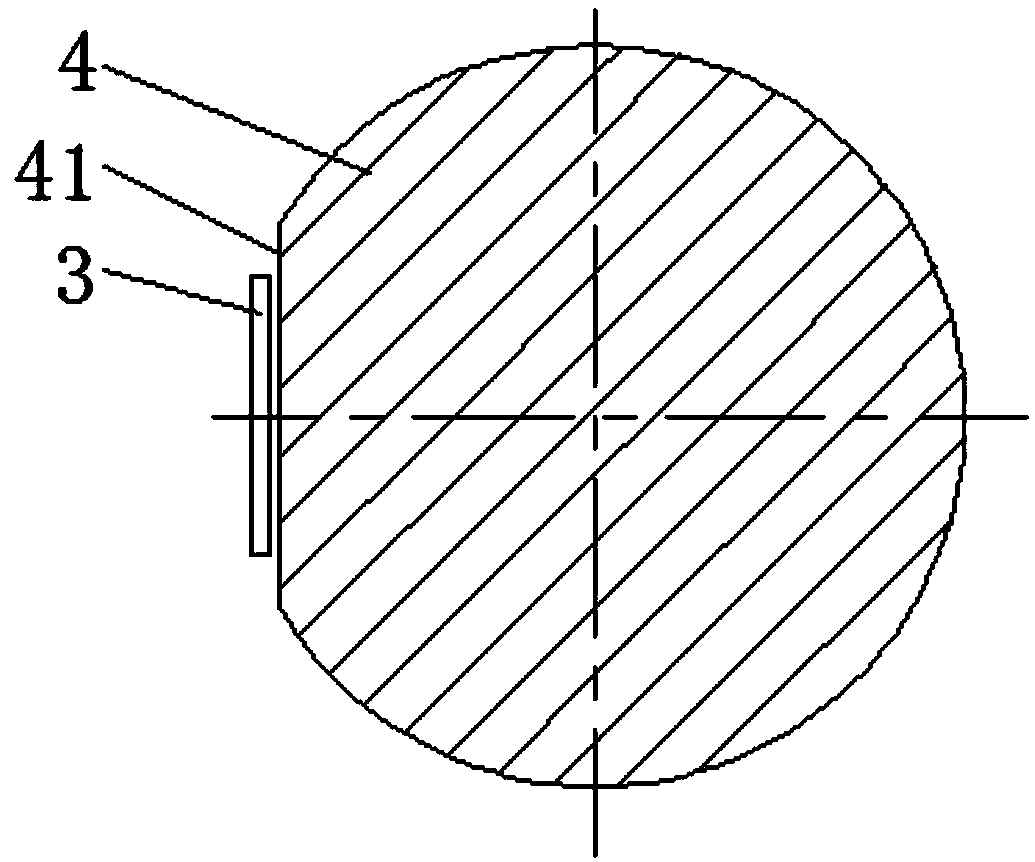

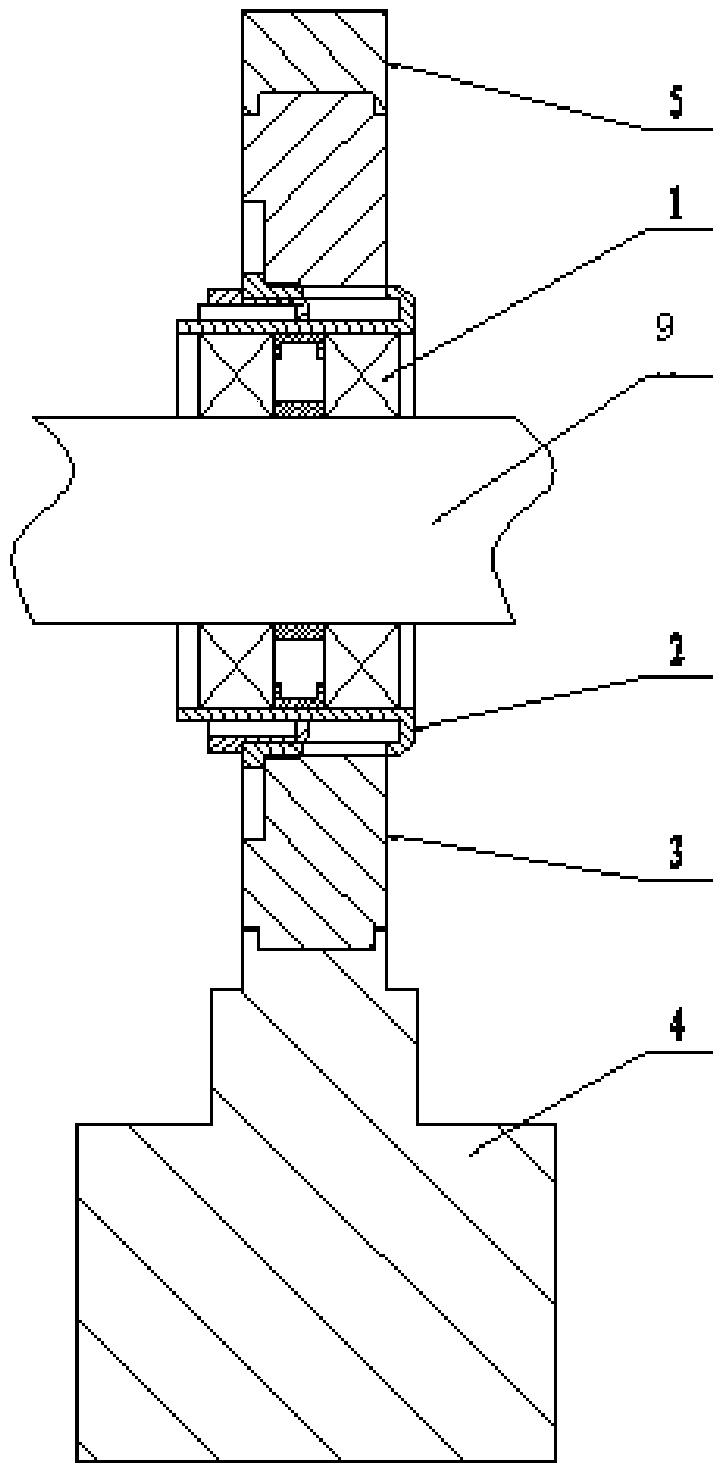

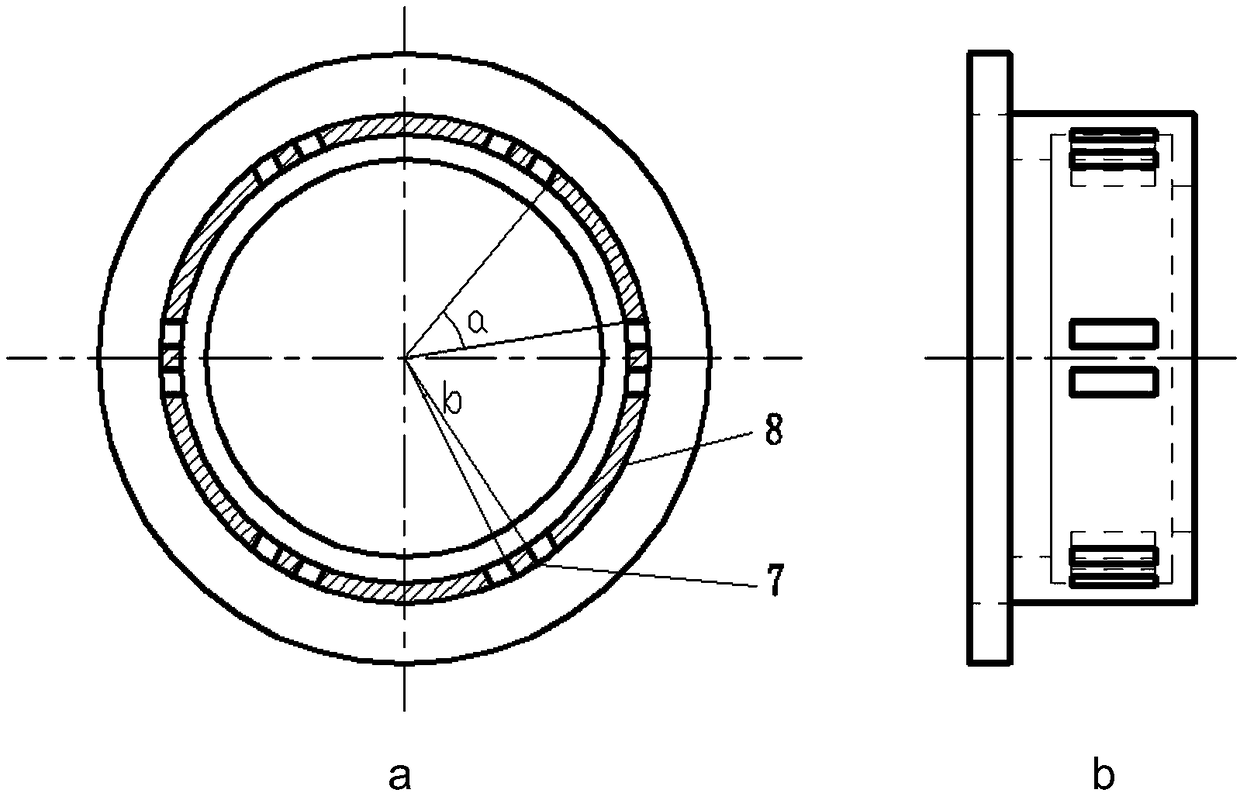

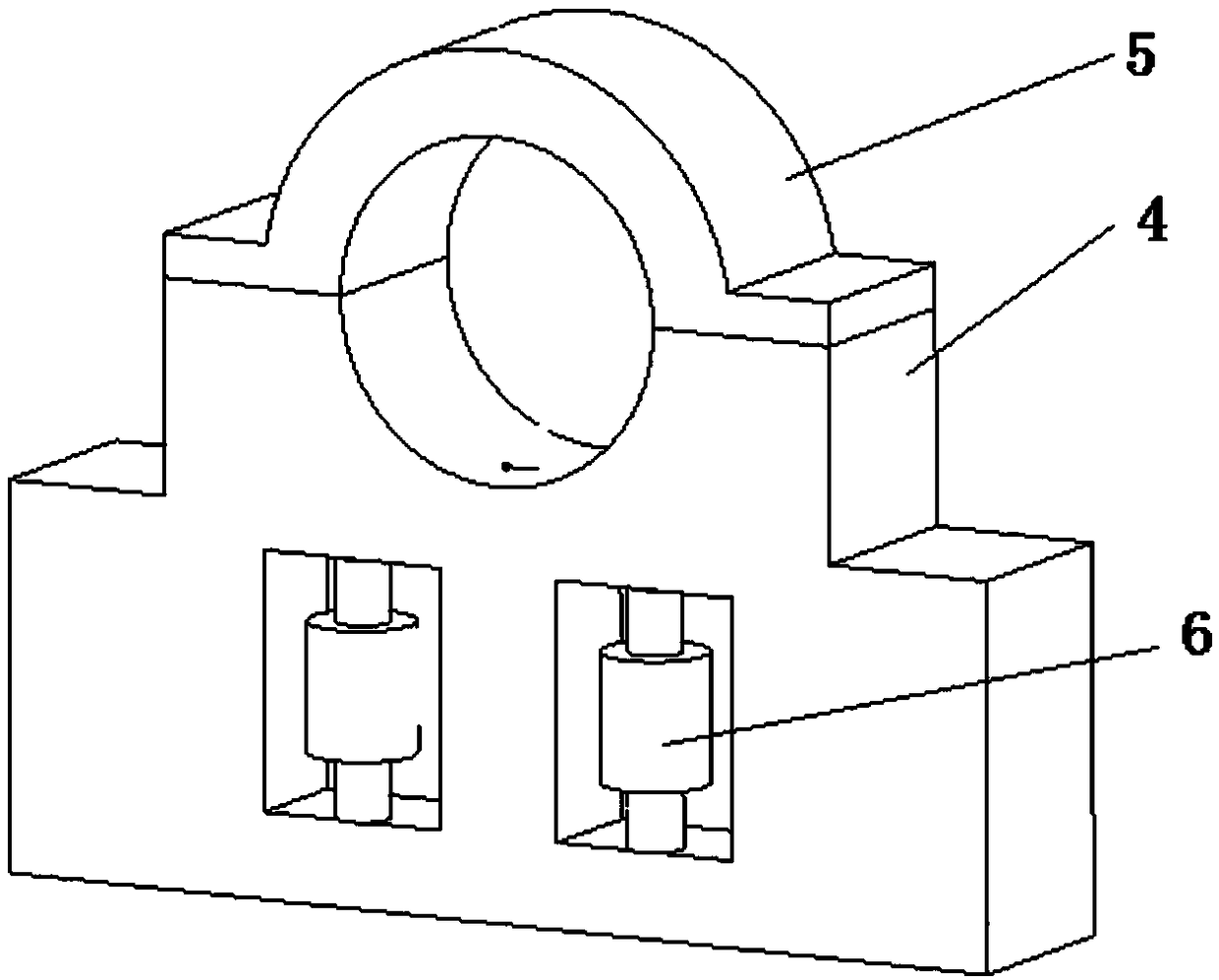

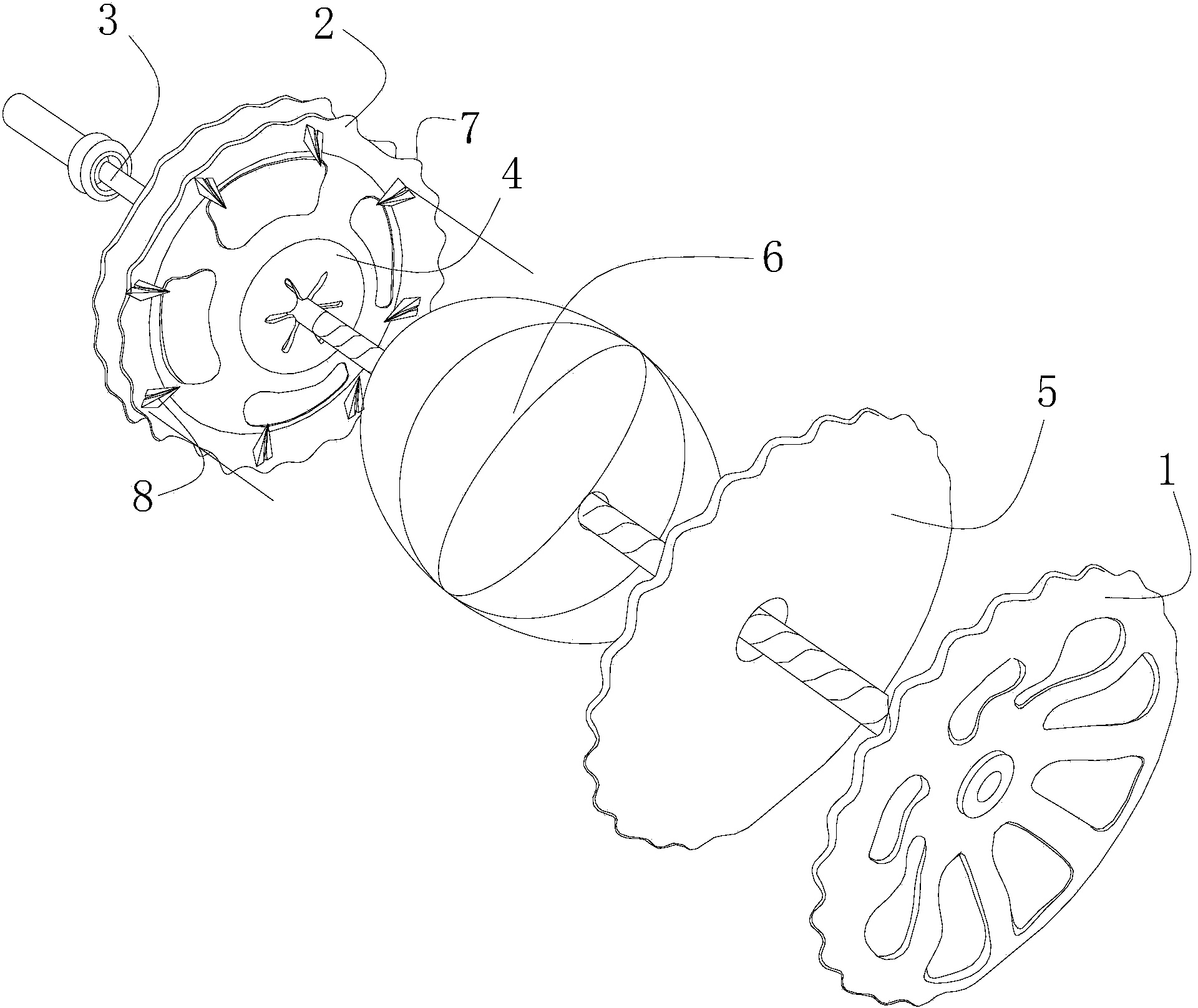

Supporting device of annular superconducting magnet

InactiveCN103511811AIncrease profitSufficient support strengthAc network load balancingStands/trestlesSuperconducting CoilsMechanical stability

The invention provides a supporting device of an annular superconducting magnet and belongs to superconducting double-cake supporting devices of superconducting magnetic energy storing devices. The supporting device of the annular superconducting magnet solves the problem that huge electromagnetic force exerted on superconducting magnets has the negative effect on a magnet system in an existing superconducting magnetic energy storing device. The annular device of the annular superconducting magnet comprises N superconducting magnet clamping assemblies. Each superconducting magnet clamping assembly is composed of an inner supporting ring, an outer fixing plate, a left cover plate and a right cover plate. The superconducting magnet clamping assemblies are evenly and vertically placed between an upper end cover and a lower end cover along the circumference in a radial mode. The upper end cover and the lower end cover are connected and fixed with each other through long screws. In the work state, each superconducting double-cake inner ring side is supported by an inner supporting ring, and the two sides of each superconducting double-cake are fastened through one left cover plate and one right cover plate. The upper end and the lower end of each superconducting double-cake are fixed through one outer fixing plate, and therefore a modular magnet work assembly is formed. A plurality of magnet work assemblies are evenly and vertically placed between the upper end cover and the lower end cover along the circumference in the radial mode, annular supporting and fixing are conducted, and the mechanical stability and the operational stability of the annular superconducting magnet are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Capsule endoscope

ActiveCN108742480AImprove performanceGuaranteed service lifeSurgeryEndoscopesEngineeringCapsule Endoscopes

The invention discloses a capsule endoscope. PCB stratified structures are located in a closed inner cavity defined by a shell and an optical front cover, magnets and batteries are arranged in internal spaces formed by the PCB stratified structures, avoiding planes are arranged on the circumferential surfaces of the magnets, containing spaces are formed between the avoiding planes and the inner wall of the shell, and the sections, corresponding to the side edges of the magnets, of FPC flexible flat cables are located in the containing spaces. Multiple convex ribs are arranged at the same height of the inner wall of the shell in the circumferential direction, a layer of PCBs on the lowest portion are supported by the convex ribs jointly, and one layer of PCBs on the upper portion are pressed by a step surface on the inner wall of the optical front cover. The avoiding planes are arranged on the surfaces of the magnets, the FPC flexible flat cables are prevented from being extruded by theinner wall of the shell, the FPC flexible flat cables are effectively prevented from cracking or being fractured, and the use performance and the service life of the capsule endoscope are guaranteed.The PCB stratified structure achieves positioning through the cooperation of the convex ribs and the step surface, the structure is simpler, and the reliability is high.

Owner:重庆金山医疗技术研究院有限公司

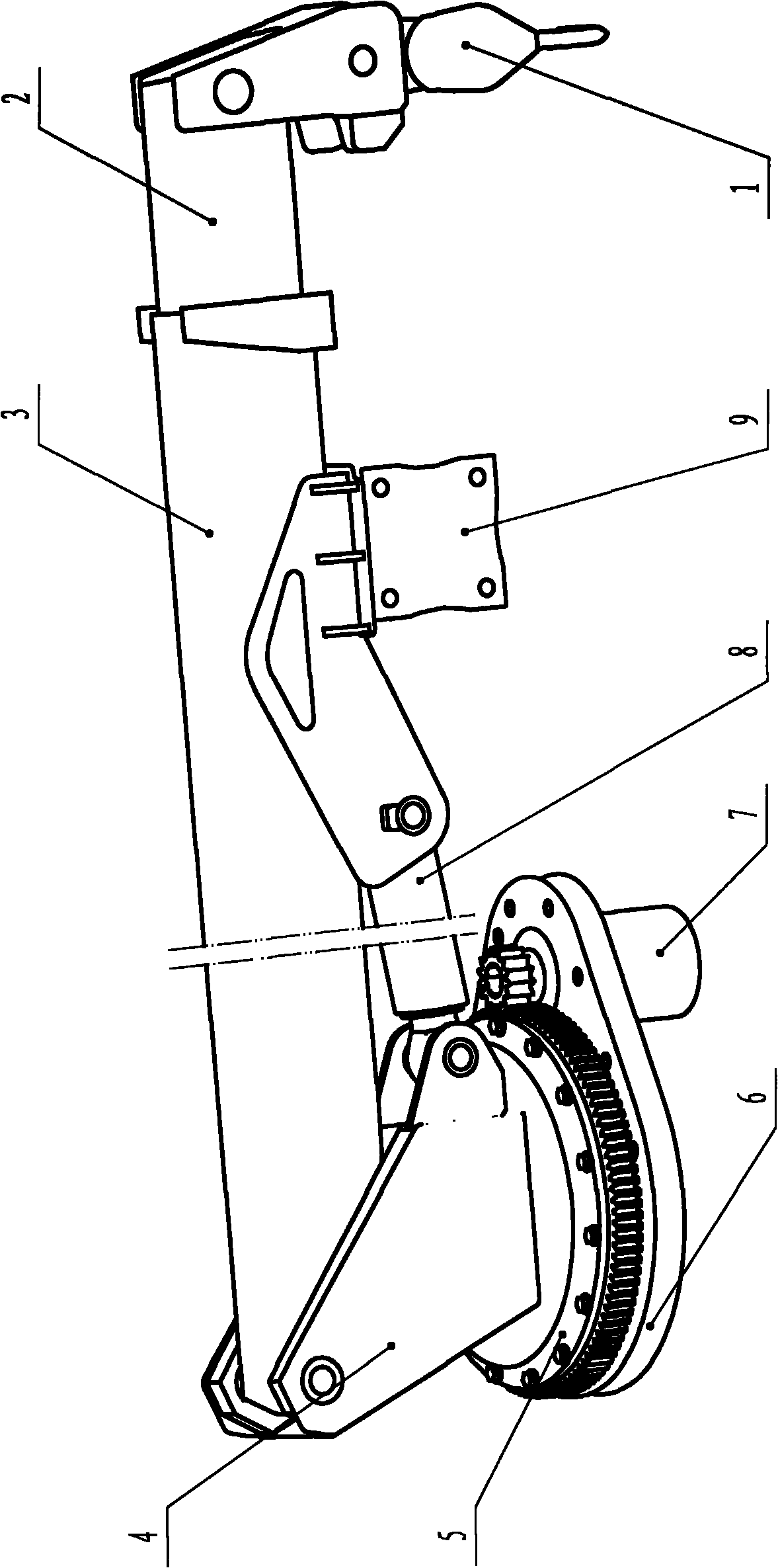

Vertical hydraulic bracket

InactiveCN102116163ASolve the problem of flying straight down and hurting peopleEliminate the feeling of being in the abyssMine roof supportsHydraulic pumpStops device

The invention discloses a vertical hydraulic bracket used for an underground heavy pitch coal mining working surface of a coal mine, which comprises a supporting device, a bracket moving device, a recrement stopping device, and a bracket adjusting device. The vertical hydraulic bracket is characterized in that at least one of hydraulic props forming the supporting device is a wall support prop; the upper end of the wall support prop is hinged with the vertical hydraulic bracket; the lower end of the wall support prop is supported on a coal wall; in the process of moving the bracket, the wall support prop bears the dead weight of the vertical hydraulic bracket and the loads of the recrement on the bracket; meanwhile, the wall support prop can also serve as a bracket moving cylinder; the bracket moving direction of the hydraulic bracket is downwards along the inclined direction of a coal seam; a person stands on the approximately horizontal coal walls to operate; therefore, the dangers that operating personnel in the heavy pitch working surface roll down along large-obliquity slopes and large lump coals roll along sharp slopes hurt people are avoided. The vertical hydraulic bracket is suitable for being used in 45-90 degree working surfaces.

Owner:李泽宇

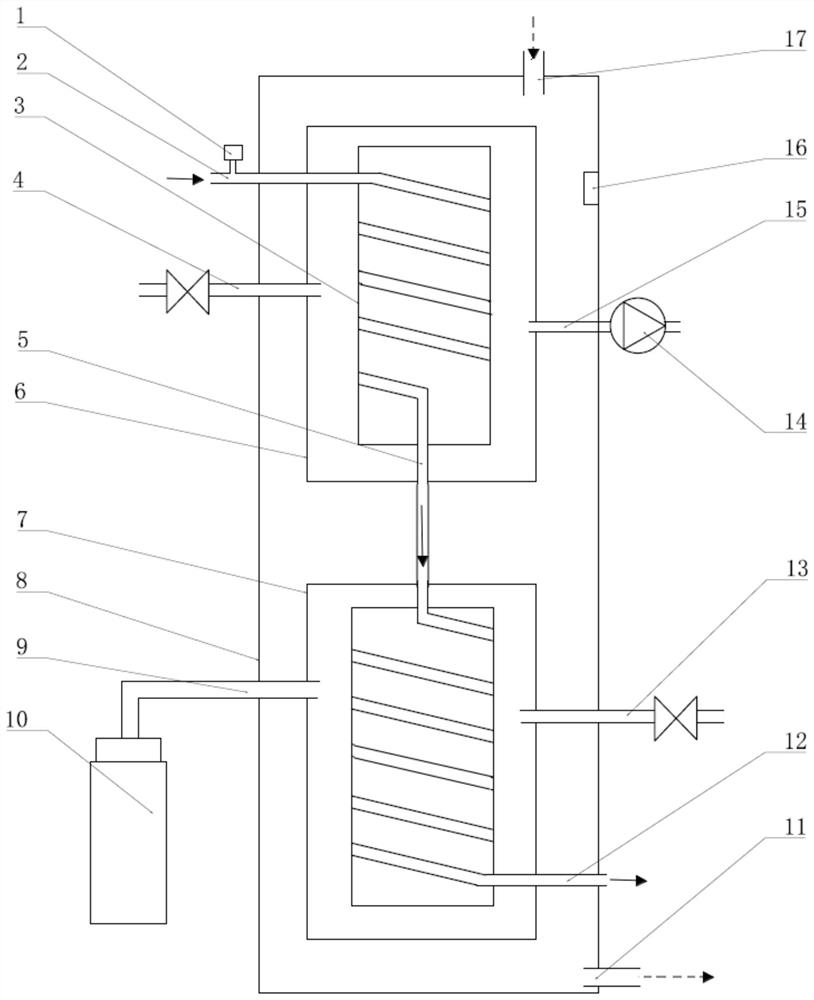

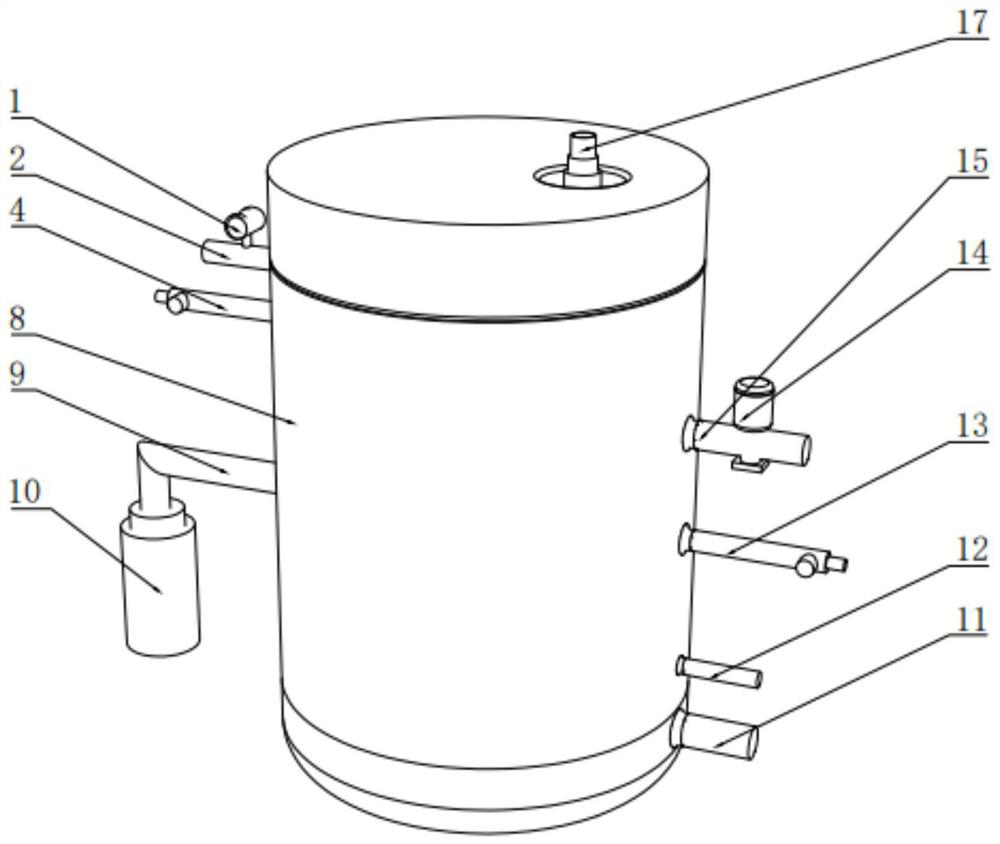

Membrane oxygenator with high-efficiency gas-fluid exchange

PendingCN111760107AImprove replacement efficiencyImprove hydrophilicityOther blood circulation devicesMembrane oxygenatorsMembrane oxygenator

The invention provides a membrane oxygenator with high-efficiency gas-fluid exchange. The membrane oxygenator mainly comprises parts including a carbon discharge chamber, an oxygenation chamber, a temperature control chamber, a vacuum pump, a pure oxygen cylinder, a flow meter and the like. When flowing through a hollow silicone hydrogel tube placed in the carbon discharge chamber, venous blood drained from a human body permeates a tube wall to release carbon dioxide into a chamber body; a vacuum pump is utilized to apply micro-negative pressure to the carbon discharge chamber, so that the carbon dioxide is efficiently discharged; then the blood flows into a hollow silicone hydrogel spiral tube placed in the oxygenation chamber, and the pump is utilized to apply micro-positive pressure tothe oxygenation chamber, so that oxygen enters the blood efficiently and is combined with red blood cells; and the carbon discharge chamber and the oxygenation chamber are both placed in the temperature control chamber. The membrane oxygenator of the invention performs discharge of the carbon dioxide and absorption of oxygen in the blood step by step, and supplemented by a moderate negative pressure environment and positive pressure environment, the gas-fluid exchange efficiency can be effectively improved, the situation that acral necrosis of a patient is caused by using an existing oxygenator for long term to threaten life is avoided, the treatment rate is increased and sequelae are reduced.

Owner:BEIJING UNIV OF CHEM TECH

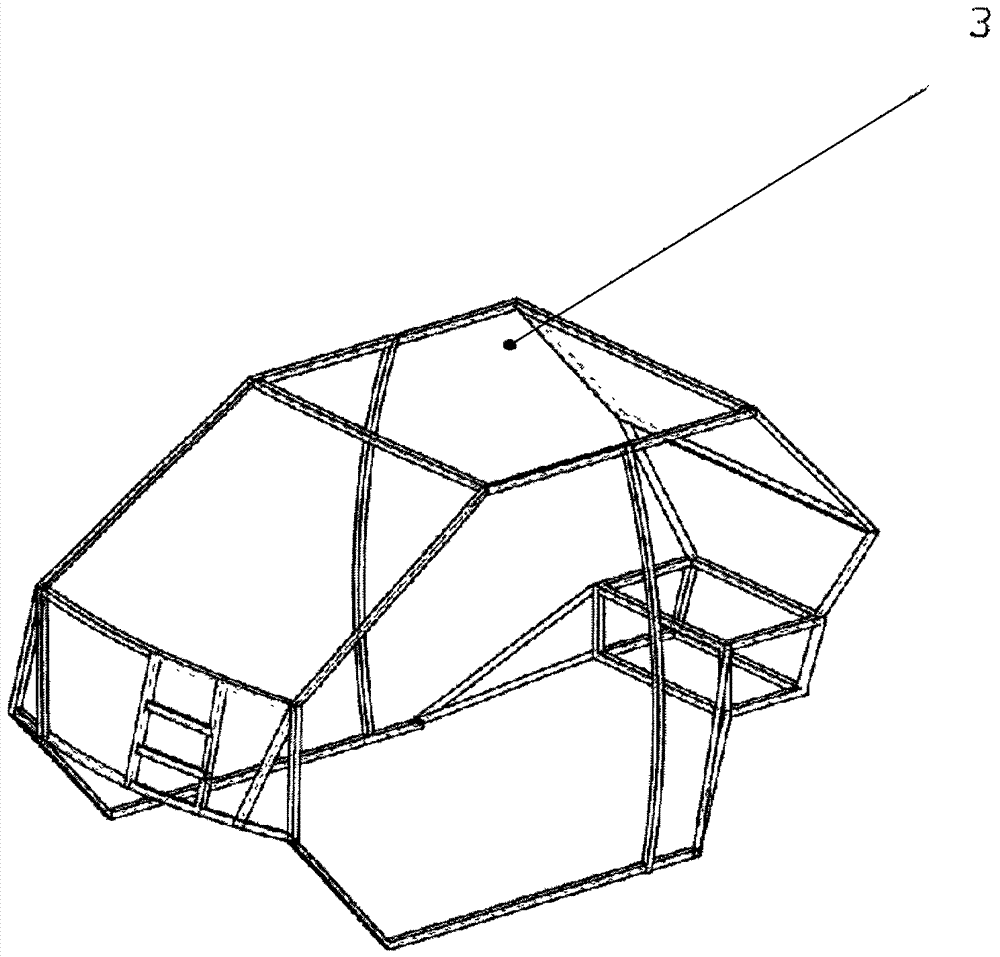

Plasticized car body overall-molding method

InactiveCN103707937AOvercoming problems in the manufacturing processAchieve lightweightSuperstructure subunitsCoatingsSheet steelKeel

The invention discloses a plasticized car body overall-molding method and belongs to the field of automobile production. The main trend of future car development is weight reduction, while weight reduction of the car body is the main way to reduce overall weight. In order to reduce weight, conventional production processes of stamping, welding, coating and the like for the car body are abandoned, instead, one-step molding of a novel plasticized car body is adopted. In order to guarantee safety of the plasticized car body, a mould for molding a spiral plastic car body is of customized structure, that is, structures like keels, reinforcing ribs and so on are placed in the mould, and by these structures, the strength of the car body can be improved, and safety of the same is ensured. Besides, materials for the spiral plastic car body can be subjected to fiber reinforcement treatment. By the plasticized car body overall-molding method, weight reduction of the car body is realized, the molding period is shortened, production cost is reduced and safety of the car body is guaranteed.

Owner:BEIJING UNIV OF CHEM TECH +1

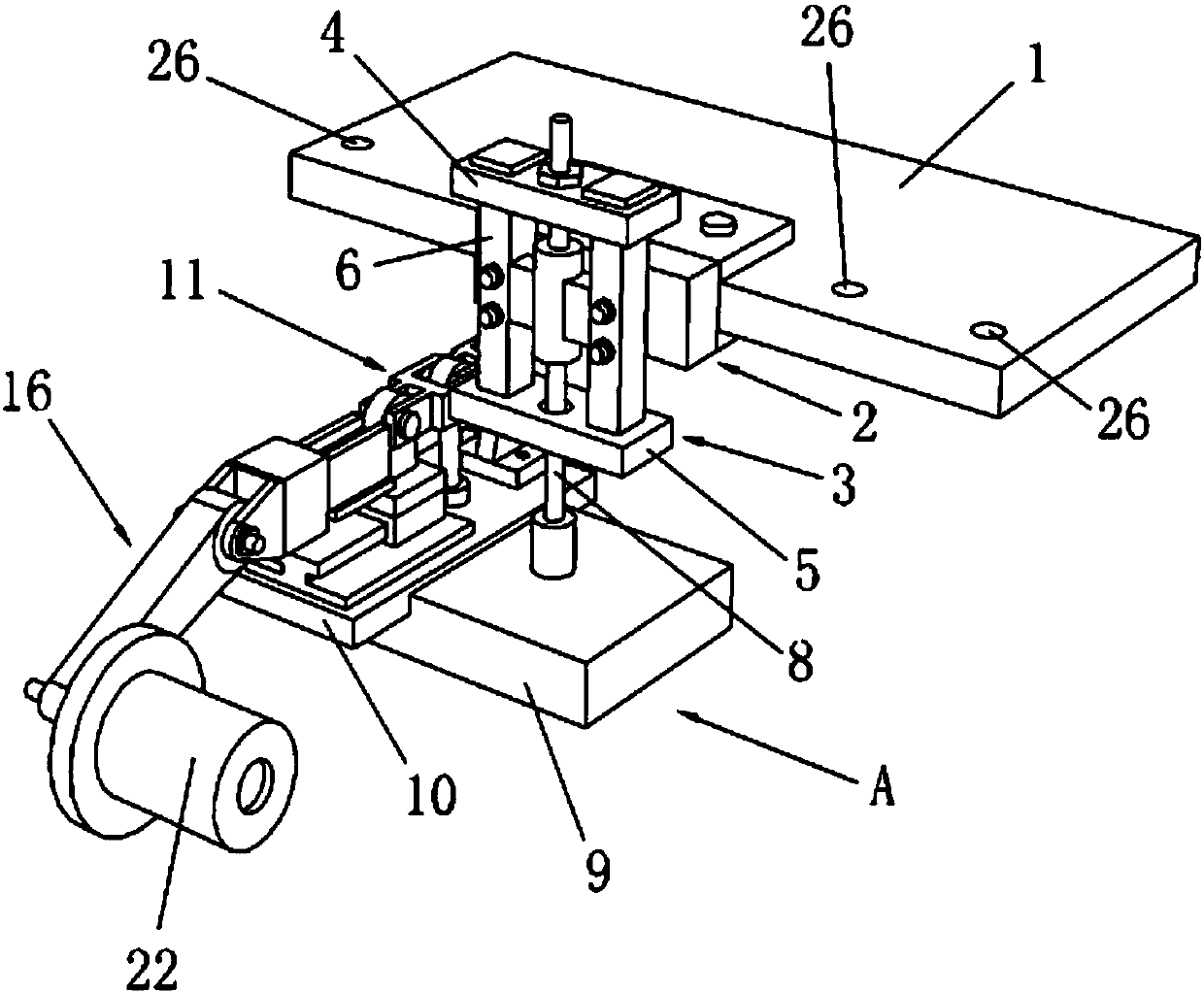

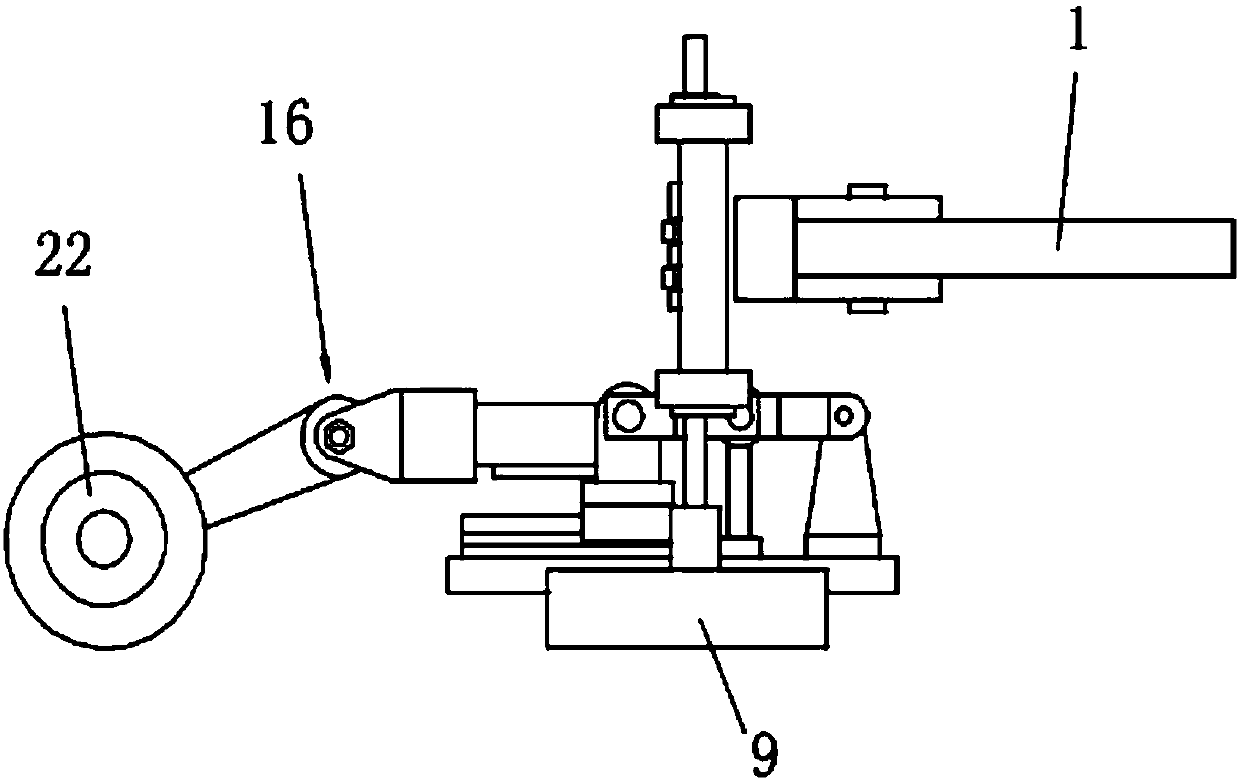

Supporting component used for similar simulation test of high-speed rotor and testing method

ActiveCN108663214AStrong support stiffness adjustment abilityWeaken adjustment errorEngine testingSoftware engineeringRotor cage

The invention provides a supporting component used for a similar simulation test of a high-speed rotor and a testing method, and belongs to the field of similar design of the high-speed rotor. The supporting component comprises a bearing, multiple rotor cages and a testing platform support. The bearing is used for supporting the simulation rotor to rotate, inner diameters of the rotor cages are identical and are matched with the outer diameter of the bearing, the rigidities of the rotor cages are different, in the test, different rotor cages are selected to sleeve the exterior of the bearing respectively, and the selected rotor cages and bearing are fixed through the testing platform support to simulate different supporting rigidities. The supporting rigidity of the provided supporting component can be two times or above that of a rotor original part, and the supporting component has high adjustment capacity for the supporting rigidity of a rotor system.

Owner:BEIJING AEROSPACE PROPULSION INST

Back rocker locking mechanism for swivel chair chassis

ActiveCN104207520BAchieve lockingEasy to controlStoolsAdjustable chairsLocking mechanismTorsion spring

Owner:UE FURNITURE CO LTD

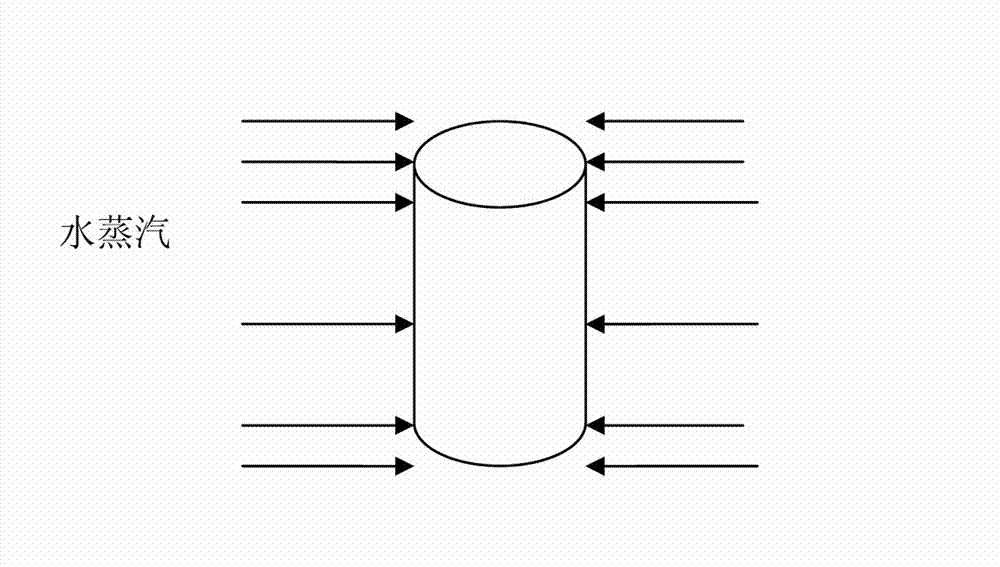

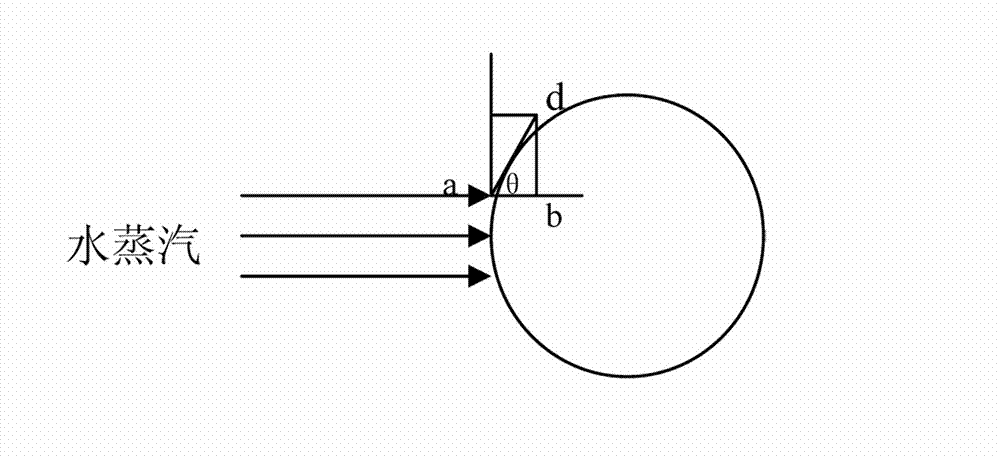

Steam treatment method for piston products

InactiveCN102828142AImprove air tightnessShorten the timeSolid state diffusion coatingThermodynamicsProcess engineering

The invention provides a steam treatment method for piston products. The steam treatment method includes pretreatment, first-stage treatment and second-stage treatment. The pretreatment includes filling steam after heating a furnace and filling nitrogen for a period of time. The method is characterized in that the piston products are subjected to react with the steam at the temperature ranging from 520 DEG C to 530 DEG C for 3.5 to 4.5 hours during the first-stage treatment; and the piston products are subjected to react with the steam at the temperature ranging from 580 DEG C to 590 DEG C for 1.5 to 2.5 hours during the second-stage treatment. By the method, the problem of gas leakage during steam treatment for the piston products can be solved. The invention further provides a method for improving the quality of the piston products.

Owner:GUANGDONG DONGMU NEW MATERIALS

Bridge

The invention discloses a bridge. The bridge comprises a bridge body. A certain number of storing grooves perpendicular to the two side edge lines of the bridge body are formed in the two sides of the bridge body. Guardrails which are matched with the storing grooves are rotationally connected with the interior of the storing grooves. A vehicle blocking baffle is arranged at the end, away from the hinged position of the guardrails, of the guardrails. The guardrails enter the storing grooves after the guardrails rotate around the hinged position of the guardrails. The vehicle blocking baffle is located outside the bridge body. The bridge body and the guardrails are provided with locking mechanisms which are matched with one another. According to the bridge, the guardrails can be overturned, the guardrails are rotated to a state that the guardrails are perpendicular to a bridge deck, the guardrails can be made to keep a state that the guardrails are perpendicular to the bridge deck through the locking mechanisms, meanwhile, the width of the bridge deck between the guardrails on the two sides is narrowed, so that vehicles cannot pass through the bridge, thus the effect on vehicle blocking is played, meanwhile, pedestrians can walk through the bridge on the bridge deck between the guardrails, the guardrails are overturned to the grooves, meanwhile, the guardrails and the bridge deck are paralleled, obstruction to vehicle traffic cannot be caused so as to widen the width of the bridge deck which allow the vehicles to pass through, so that the effect that the vehicles can pass through the bridge deck is achieved.

Owner:ZHEJIANG DACHENG PROJECT MANAGEMENT

Method for thinning liquid crystal display panel with thickness less than 200 micrometers

The invention discloses a method for thinning a liquid crystal display panel with thickness less than 200 micrometers. The method comprises the following steps: a. a piece of substrate glass is prepared; b. the substrate glass is used as an interlayer, two pieces of liquid crystal display panels to be processed and the substrate glass are aligned, UV glue is used for sealing edges of the liquid crystal display panels to be processed and the substrate glass for hermetical fixing; c. the fixed liquid crystal display panel glass and the substrate glass are cleaned; d. a mixed acid etching solution is used for spray, and the liquid crystal display panel glass is thinned to the required thickness; e. the thinned liquid crystal display panel glass and the substrate glass are cleaned; f. periphery of the cleaned liquid crystal display panel glass and the substrate glass is solidified by the UV glue again; g. the liquid crystal display panel glass and the substrate glass are immersed together in alkali liquor at 50-80 DEG C for 5-30 minutes in order to carry out separation; h. the thinned liquid crystal display panel glass is cleaned. The liquid crystal display panel processed by the method has high yield, and the finished product has stable properties.

Owner:惠晶显示科技(苏州)有限公司

Combined stirring mechanism capable of automatically lifting and controlling industrial liquid

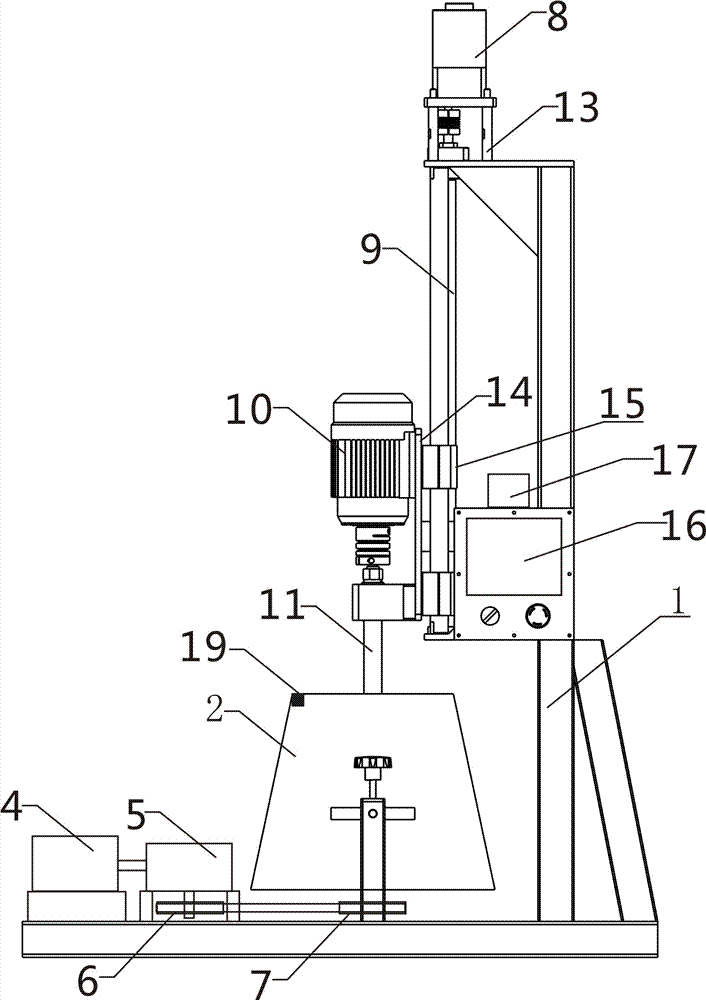

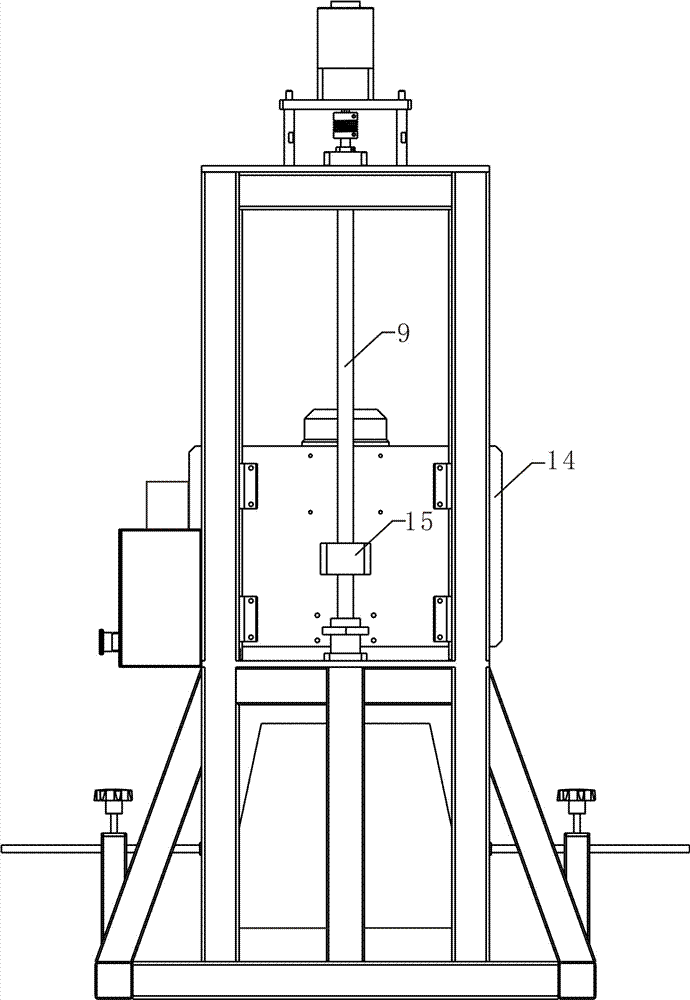

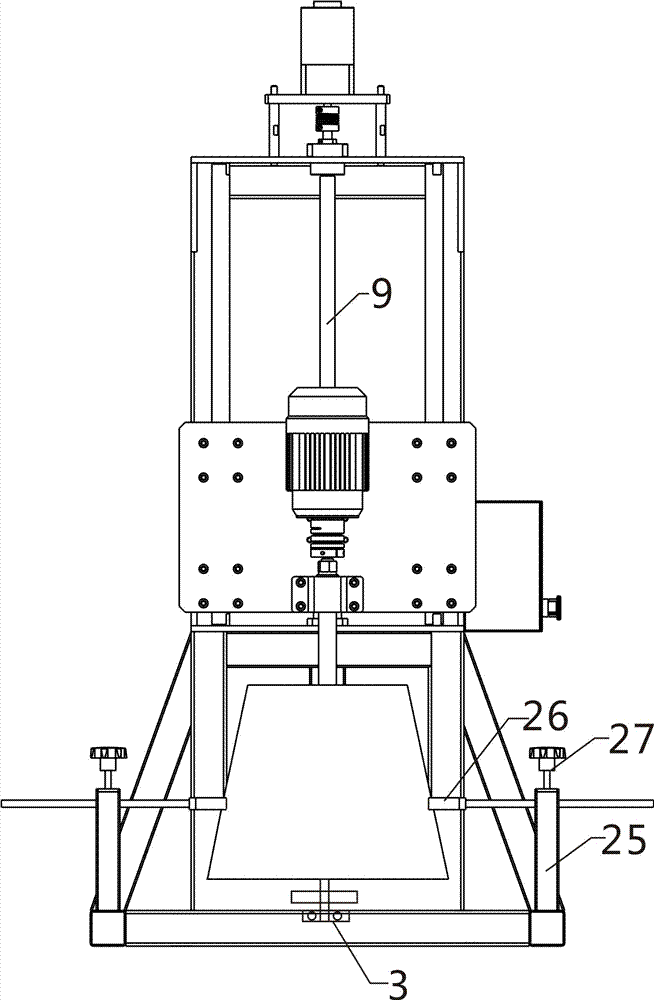

InactiveCN107126888ACoordinationImprove the mixing effectRotating receptacle mixersTransportation and packagingAutomatic controlProcess engineering

The invention discloses a combined stirring mechanism capable of automatically lifting and controlling industrial liquid. The stirring mechanism comprises a supporting frame, a combined stirring barrel, a combined stirring barrel rotation control system, a combined stirring barrel stirring mechanism, a combined stirring barrel lifting control mechanism and a combined stirring mechanism industrial control system. The improved combined stirring mechanism is suitable for stirring liquid in the industry and has automatic lifting, automatic control and automatic rotating functions in the stirring process; the stirring time can be set, the position of a stirring vane can be adjusted according to a height of a liquid surface, the stirring effect can be improved, the stirring is labor-saving, the energy is saved, the stirring efficiency is greatly increased, and the stirring mixing effect is more significant; and the application of thecombined stirring mechanism capable of automatically lifting and controlling industrial liquid is more stable by virtue of the automatic control, and the mechanical actions are harmonic in cooperation.

Owner:段建英

Suspension array hole graphene MEMS micropressure sensor and fabrication method thereof

InactiveCN110793682AHigh sensitivityLarge strainForce measurement using piezo-resistive materialsFull bridgeHemt circuits

The invention discloses a suspension array hole graphene MEMS micropressure sensor and a fabrication method thereof. The suspension array hole graphene MEMS micropressure sensor comprises a silicon substrate, wherein a back cavity is formed in the silicon substrate, an upper SiO2 thin film layer and an upper silicon nitride thin film layer are sequentially arranged on an upper surface of the silicon substrate, a lower SiO2 thin film layer and a lower silicon nitride thin film layer are sequentially arranged on a lower surface of the silicon substrate, a graphene thin film is arranged on the upper silicon nitride thin film layer, a first electrode and a second electrode are arranged on the graphene thin film and are connected to a Wheatstone full-bridge circuit by wires, and a plurality ofthrough holes are formed in the upper SiO2 thin film layer and the lower silicon nitride thin film layer which are suspended between the graphene thin film and an upper opening of the back cavity. Inthe suspension array hole graphene MEMS micropressure sensor, the plurality of through holes are formed in a support thin film, increased film strain is partially generated in the graphene thin film above the through holes, the strain force can be increased, and the sensitivity and the linearity of a chip can be improved.

Owner:XI AN JIAOTONG UNIV

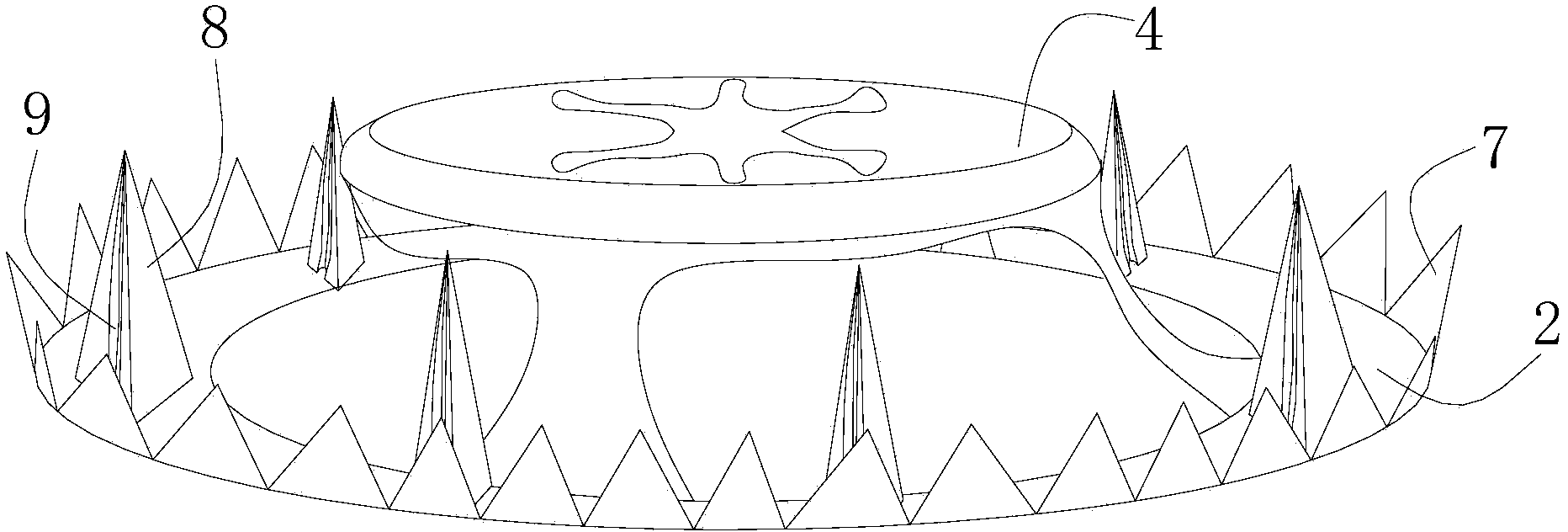

Composite skull base repair fixer

ActiveCN103976781AFixed and reliableAvoid displacementSurgerySkullBiomedical engineeringIntracranial infection

The invention discloses a composite skull base repair fixer. The top end of a connecting rod is provided with a fixed disc, the lower end of the connecting rod is provided with a movable disc capable of moving on the connecting rod, the fixed disc and the movable disc are coaxial on the connecting rod and use one side, opposite to the movable disc, of the fixed disc as the inner side, a biological dura mater matched with the shape of the fixed disc is pasted on the inner side surface of the fixed disc, a silica gel bag filled with water absorption resin is additionally arranged on the connecting rod arranged between the fixed disc and the movable disc, a plurality of through holes are uniformly formed in the movable disc, the inner side surface of the movable disc comprises an inner ring and an outer ring, the through holes are formed between the inner ring and the outer ring, the inner ring is butted against and in contact with the silica gel bag, a plurality of needle-shaped sawteeth are arranged at the outer ring, the needle-shaped sawteeth face the silica gel bag, in addition, a flow guide groove is formed in the needle-shaped sawteeth, when the silica gel bag is pierced by the needle-shaped sawteeth, one end of the flow guide groove is communicated with the silica gel bag, and the other end of the flow guide groove is communicated with a bone window gap of the skull of a patient. The composite skull base repair fixer has the advantages that the biological dura mater capable of being trimmed and the water absorption resin of the silica gel bag with good conformity can be applicable to the complete repair on various defective bone windows, the leakage of cerebrospinal fluid can be repaired, and the death rate and the occurrence rate of postoperative intracranial infection are reduced.

Owner:NANFANG HOSPITAL OF SOUTHERN MEDICAL UNIV

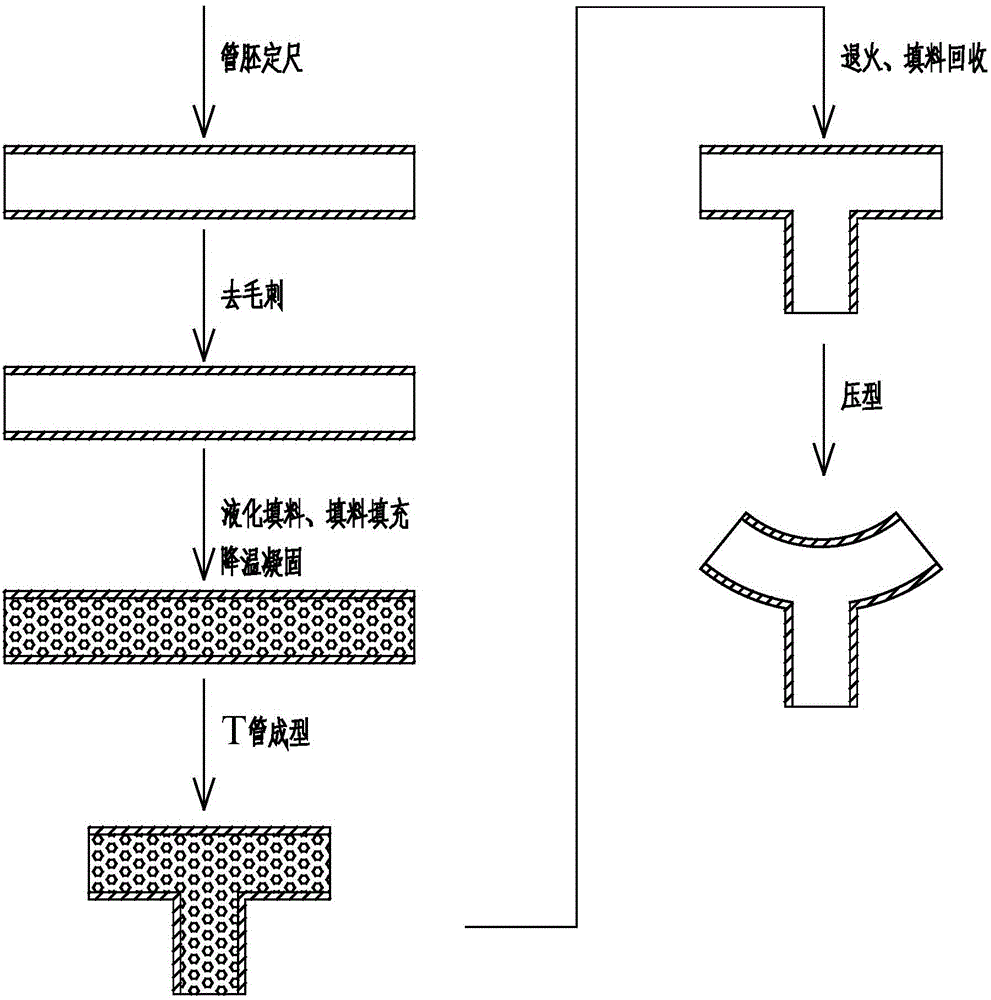

Extrusion processing process for special-shaped T-pipe

An extrusion processing process for a special-shaped T-pipe comprises the following steps: pipe blank sizing, deburring, filler liquefying, filler packing, cooling for solidification, T-pipe forming, annealing, filler recovering, and profiling. The special-shaped T-pipe uses a liquid-state molten inorganic nonmetal material as fillers, the liquid-state fillers flow into a pipe blank fully and the pipe blank is filled up with the liquid-state fillers, the amount of the fillers in the pipe blank is guaranteed to be sufficient, and enough fillers are guaranteed to be used for supporting and sizing in extrusion forming. After cooling for solidification, the fillers become liquid state fillers to be fixed in the pipe blank, the pipe blank needs not to be sealed, the process step is simplified, and the working efficiency is improved.

Owner:左铁军 +1

Fully degradable high molecular material cardiovascular stent

ActiveCN103480045AEasy to installSufficient support strengthStentsSurgeryCardiovascular stentBiocompatibility Testing

All coronary stents used on the current market are made of a metallic material, cannot be degraded and are remained in the coronaries of human bodies permanently once implanted. The new stent technology is developed towards the degradable high molecular material. The stent is made by melt-mixing PLLA (Poly L-Lactic Acid) and PLGA (Poly(Lactic-co-Glycolic Acid)) high molecules, so that sufficient mechanical support can be provided and the in-vivo degradation time is also much less than that of the pure PLLA stent. According to the stent, an original tube is injection molded, is annularly plasticized into a precursor tube and is laser-engraved into the stent; the stent has specific internal diameter and external diameter and is annularly coupled and clamped on a balloon when being implanted into the human body. The stent has sufficient strength and plasticity and good degradability and biocompatibility. The optimal ratio for melt mixing of PLLA and PLGA high molecules is discovered. According to the brand new technology, the annular distribution of a polymer molecular chain is effectively controlled and induced, and the damage to the polymer molecular chain is reduced as much as possible. The integral performance of the stent is affected through preferable structural design of the tube.

Owner:黄晚兰

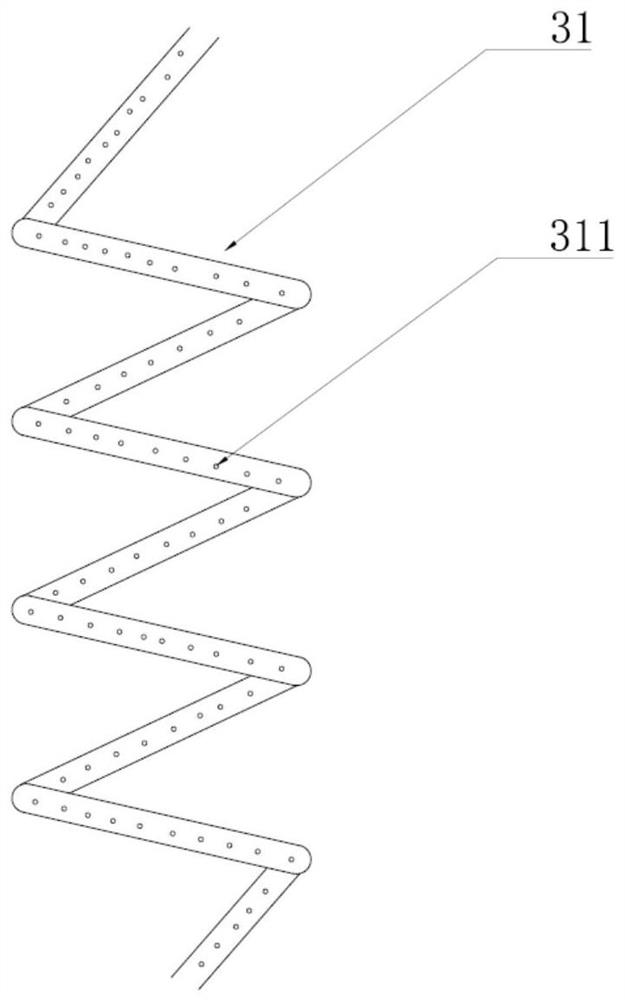

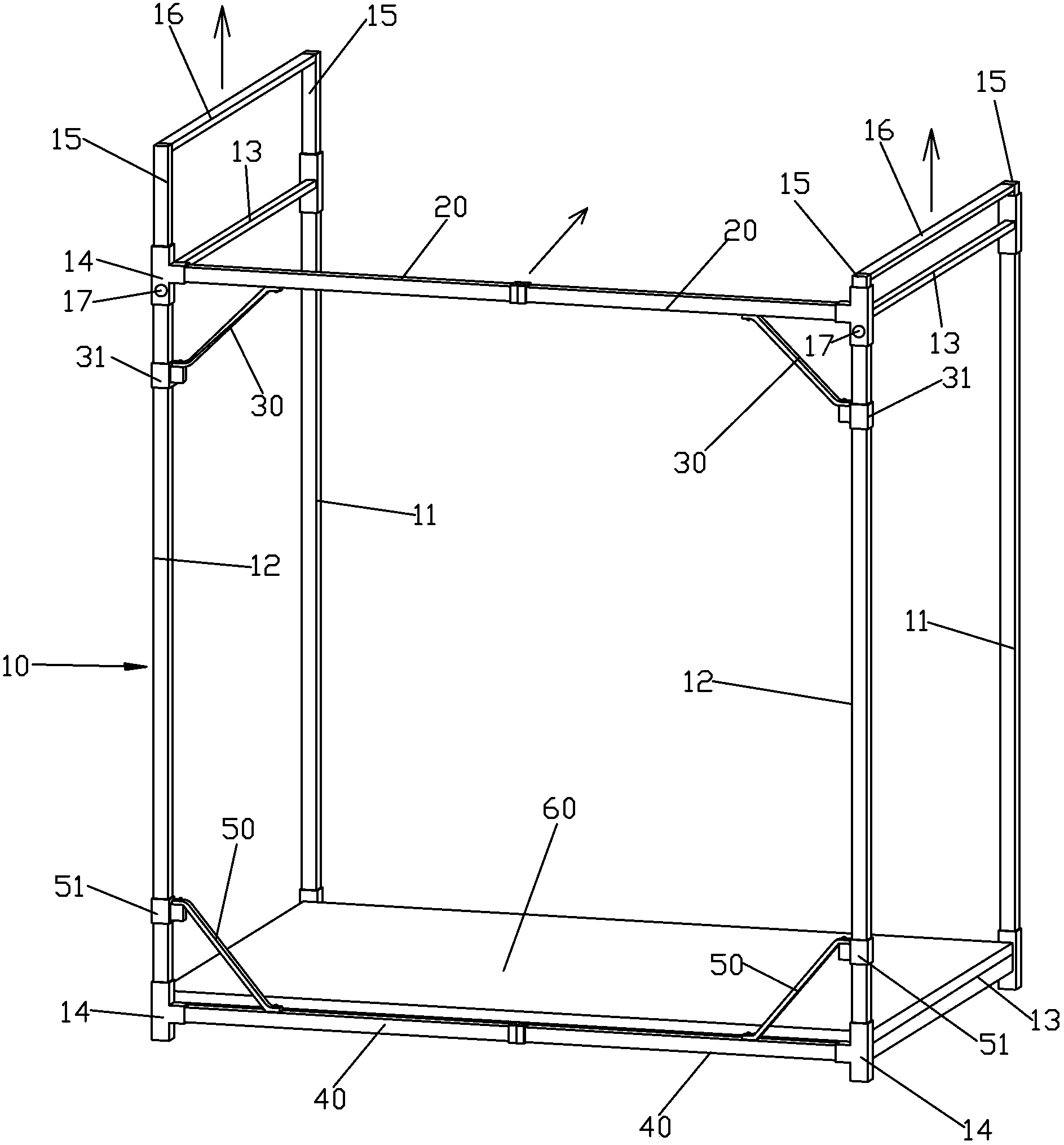

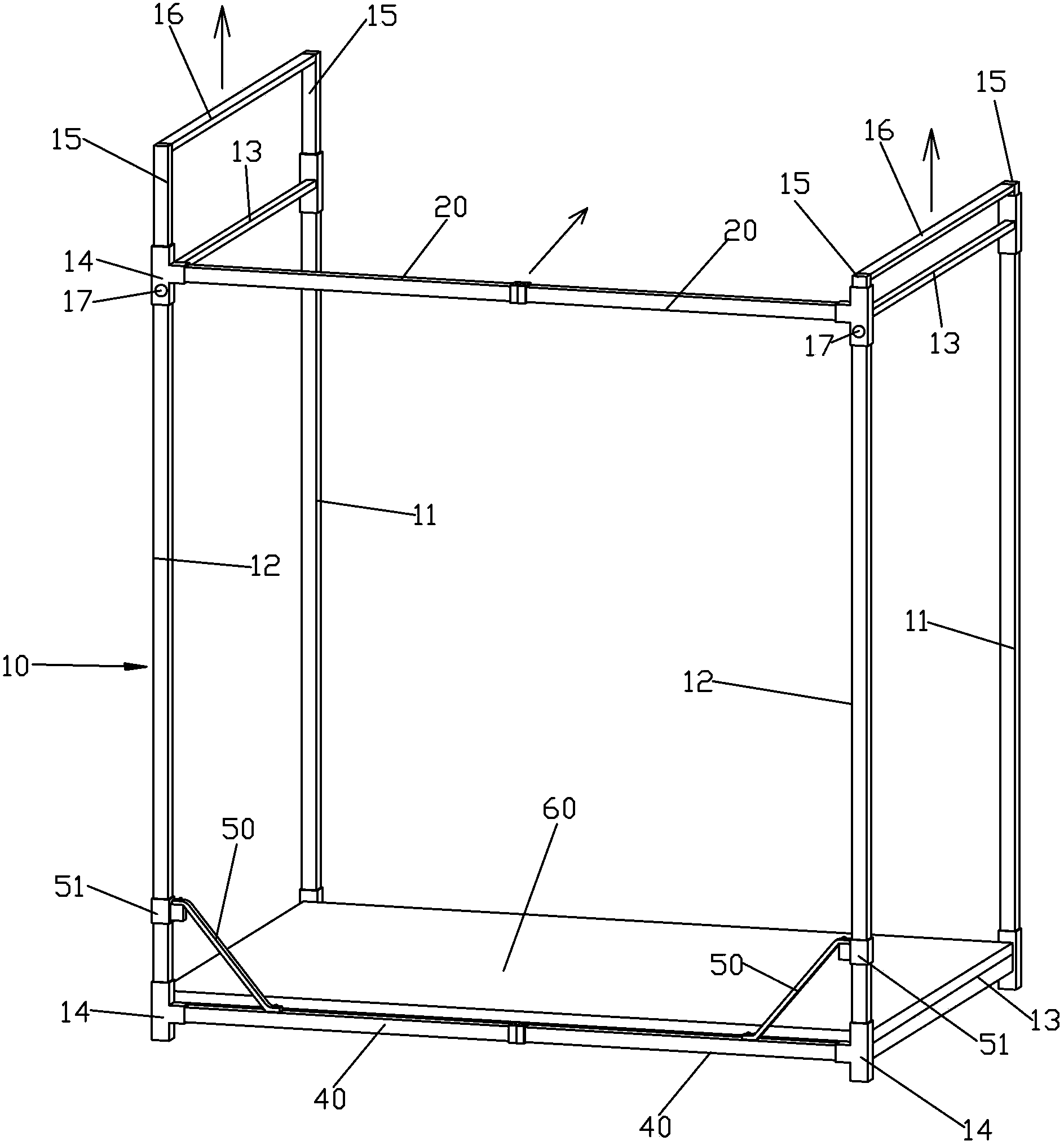

Folding frame of canvas wardrobe

InactiveCN103445504ALess materialSufficient support strengthWardrobesFolding cabinetsMaterial consumptionEngineering

The invention discloses a folding frame of a canvas wardrobe. The folding frame comprises two side frames. An upper pivot bar pair and a lower pivot bar lower arranged pivoted between the two side frames. The inner ends of the two first pivot bars are pivoted together. The outer ends of the first pivot bars are pivoted to two rear bars of the two side frames respectively. A first support bar is arranged between each first pivot bar and the corresponding rear bar. One first pivot bar is pivoted to the upper end of each first support bar. A first sleeve is arranged at the lower end of each first support bar, is fitly sleeved outside one rear bar and locates below the first pivot bar. The inner ends of the two second pivot bars are pivoted together. The outer ends of the second pivot bars are pivoted rear bars of the two side frames. A second support bar is arranged between each second pivot bar and the corresponding rear bar. One second pivot bar is pivoted to the lower end of each second support bar. A second sleeve is arranged at the upper end of each second support bar, is fitly sleeved outside the corresponding rear bar, and locates above the second pivot bar. The left, right, upper and lower support bars coordinate to support the four pivot bars, so that the folding frame, even having no interior frames, is provided with sufficient support strength; material consumption is low, and the cost is low.

Owner:XIAMEN BAWANGLONG HARDWARE PROD

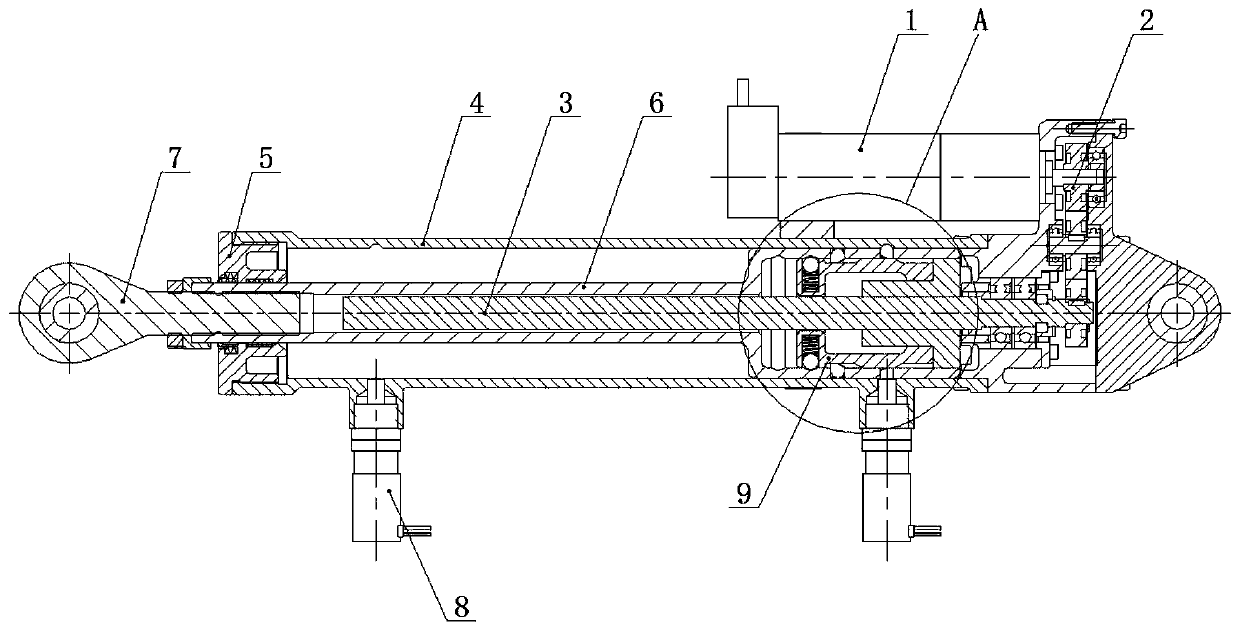

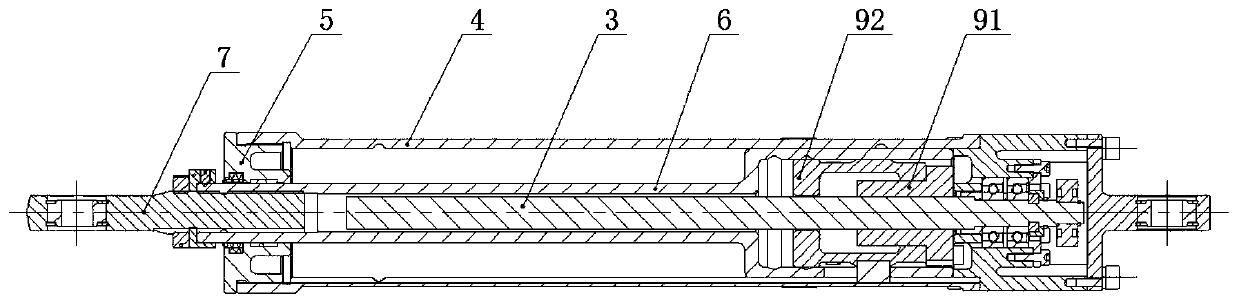

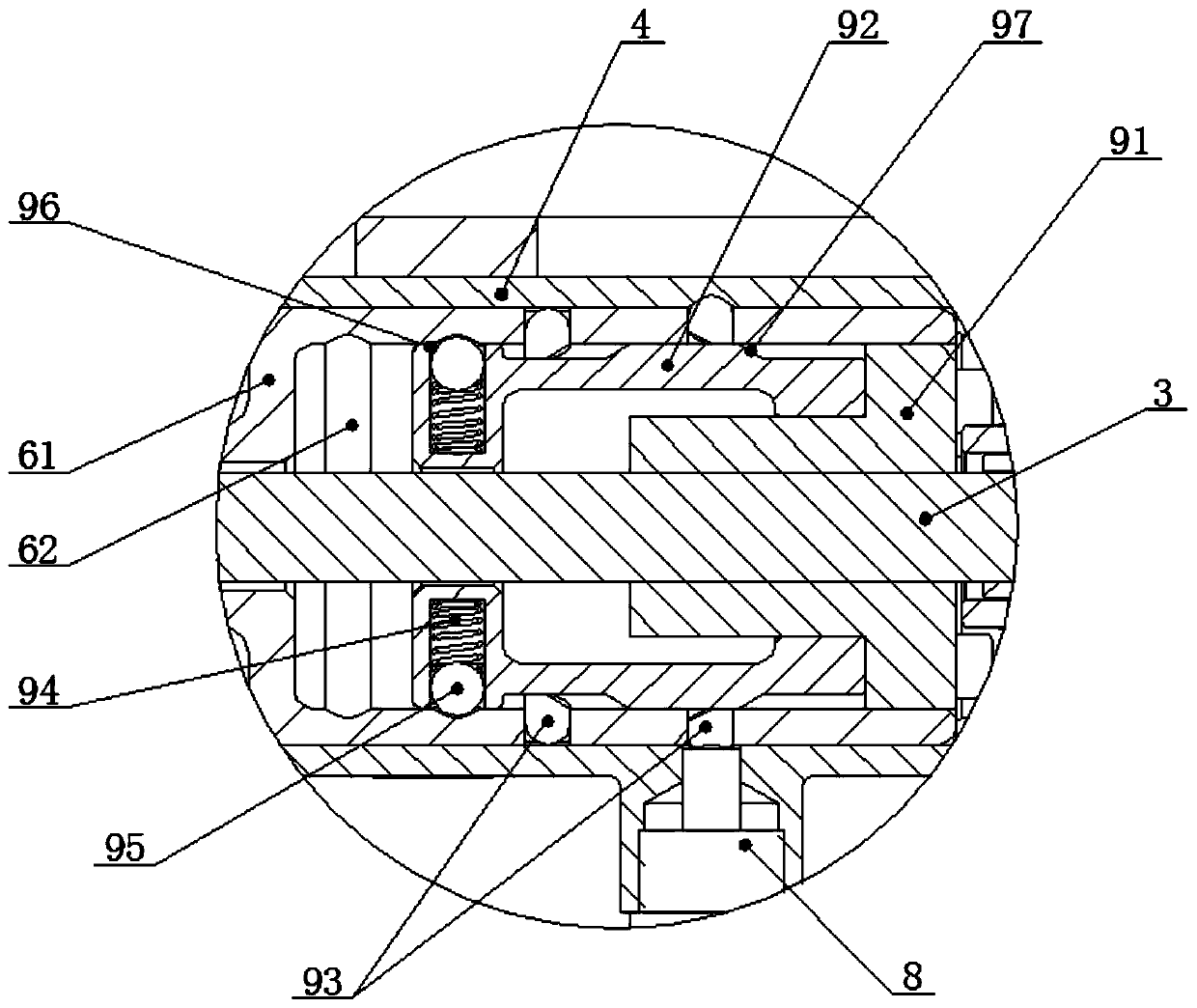

Locking mechanism for unfolding and folding of undercarriage of unmanned aerial vehicle

PendingCN110356545AReduce manufacturing costSmooth retractableUndercarriagesLocking mechanismEngineering

The invention discloses a locking mechanism for unfolding and folding of an undercarriage of an unmanned aerial vehicle. The locking mechanism comprises a cylinder barrel, a piston rod and a power assembly, wherein the piston rod is slidably arranged in the cylinder barrel, the power assembly drives the piston rod to move, a through hole is formed in the piston rod along the axis of the piston rod, one end of the piston rod penetrates out of the cylinder barrel and a guide sleeve is arranged between the piston rod and the cylinder barrel, a rod head is connected to the penetrating end of the piston rod, and a sliding sleeve which is in sliding fit with the inner wall of the cylinder barrel is formed at the other end of the piston rod; and the power assembly comprises a motor and a transmission locking mechanism, wherein the motor provides power, and the transmission locking mechanism ensures that the piston rod is stably telescopic. The whole folding and unfolding process of the structure is smooth, the mechanical connection relation is simple, the connection is reliable, the design is very ingenious, the unlocking of the piston rod can be performed only through the rotation of a nut, the locking mechanism has enough support strength or rigidity, and can bear impact generated when the undercarriage is touched.

Owner:成都弗格森液压机电有限公司

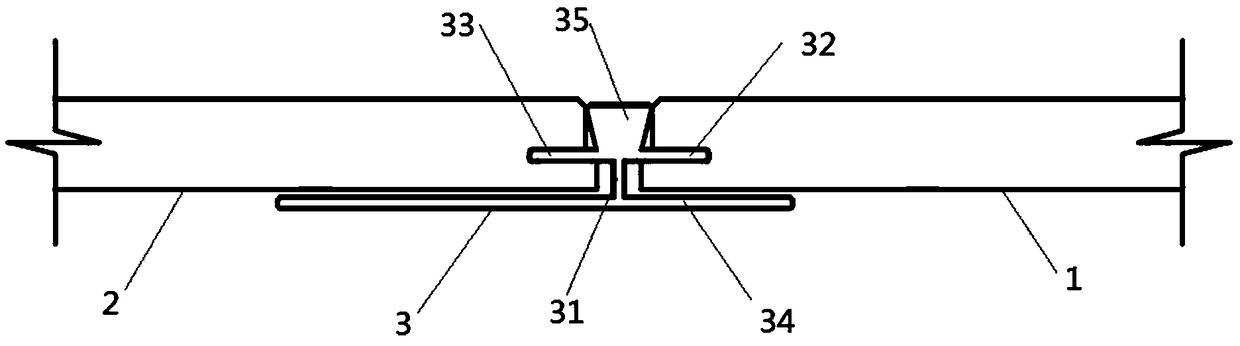

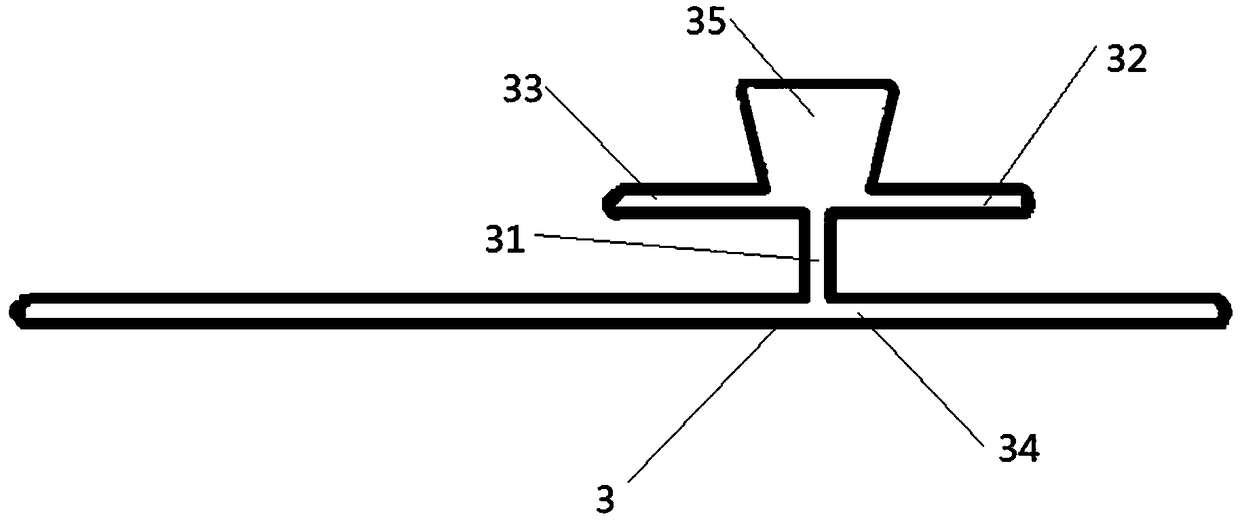

Wallboard assembly and wall

PendingCN108756111AEasy to installImprove waterproof performanceCovering/liningsEngineeringWall plate

The embodiment of the invention provides a wallboard assembly and a wall. The wallboard assembly comprises a first wallboard, a second wallboard and a connecting piece; the first wallboard is providedwith a first side edge for splicing, and a first groove is formed in the first side edge; the second wallboard is provided with a second side edge for splicing, and a second groove is formed in the second side edge; the connecting piece is provided with a connecting part, and the connecting piece is provided with a first extending part extending into the first groove, and a second extending partextending into the second groove; and the connecting piece further comprises a fixing board arranged at the bottom of the connecting part and simultaneously attached to the back face of the first wallboard and the back face of the second wallboard. The wallboard assembly can be mounted conveniently and quickly, mounting precision can be ensured through the connecting piece in the wallboard assembly during mounting, and after mounting, the wallboard assembly can further have the good waterproof property and meanwhile have the sufficient supporting strength.

Owner:TIANJIN DAYIN BUILDING MATERIAL CO LTD

Brake bottom plate integrated axle housing assembly

PendingCN111890844ASufficient support strengthGood for weight lossBraking element arrangementsAxle unitsClassical mechanicsCam

The invention relates to a brake bottom plate integrated axle housing assembly which comprises an axle housing and a brake bottom plate, a machining outer circle is arranged on the axle housing. The machining outer circle is annular limiting protrusions located at the two ends of the axle housing, a machining inner hole is formed in the brake bottom plate, the machining inner hole is located in the center of the brake bottom plate and can be matched with the machining outer circle, the machining outer circle sleeves the machining inner hole, and the two sides of the brake bottom plate and theaxle housing are connected into a whole through a welding process. A bearing limiting boss and a bearing inner hole are arranged on the brake bottom plate, a bearing is arranged close to the bearing limiting boss, a cam shaft support is inserted into the bearing inner hole, a cam shaft is arranged on the cam shaft support, and the cam shaft is inserted into a hole in the middle of the bearing. A supporting pin hole is further formed in the brake bottom plate, and a supporting pin is inserted into the supporting pin hole; the brake bottom plate and the axle housing are directly welded, parts such as fixing flange plates and connecting bolts are omitted, the structure is optimized, weight reduction of the axle is facilitated, and cost is saved.

Owner:SINO TRUK JINAN POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com