Inside supporter of uniform temperature plate and production method thereof, and uniform temperature plate

A technology of a uniform temperature plate and a support body is applied in the field of heat conduction, which can solve the problems of difficult placement, insufficient support strength, inconvenience, etc., and achieve the effect of convenient assembly and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order for those skilled in the art to further understand the features and technical contents of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. However, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

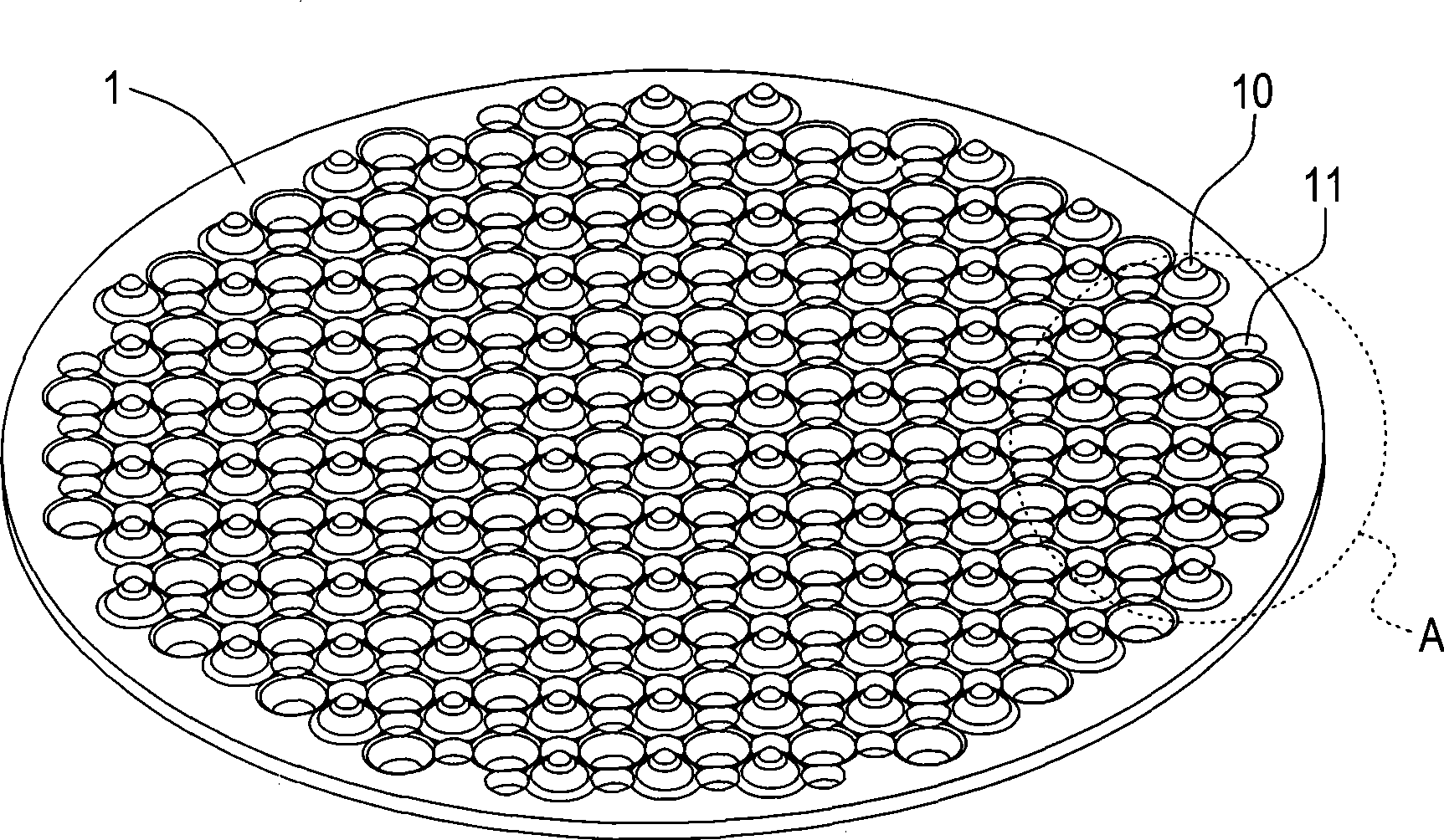

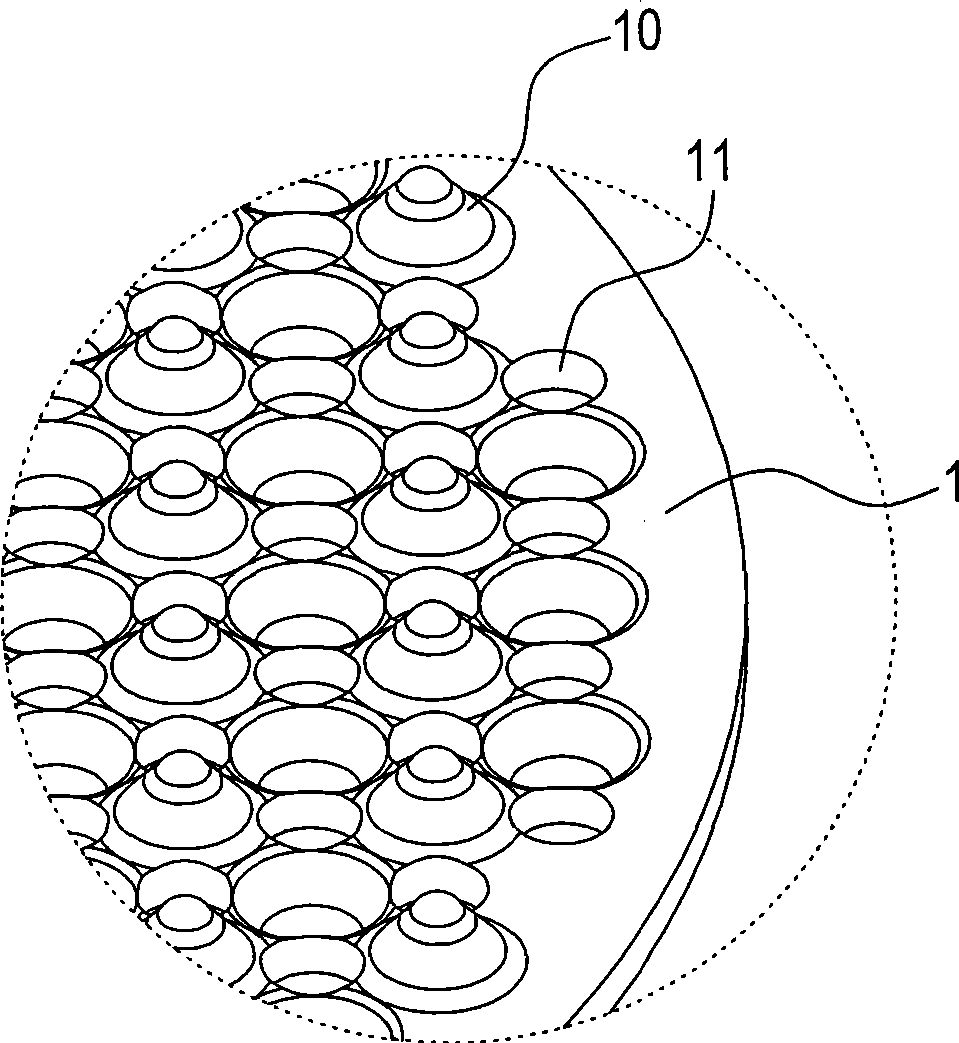

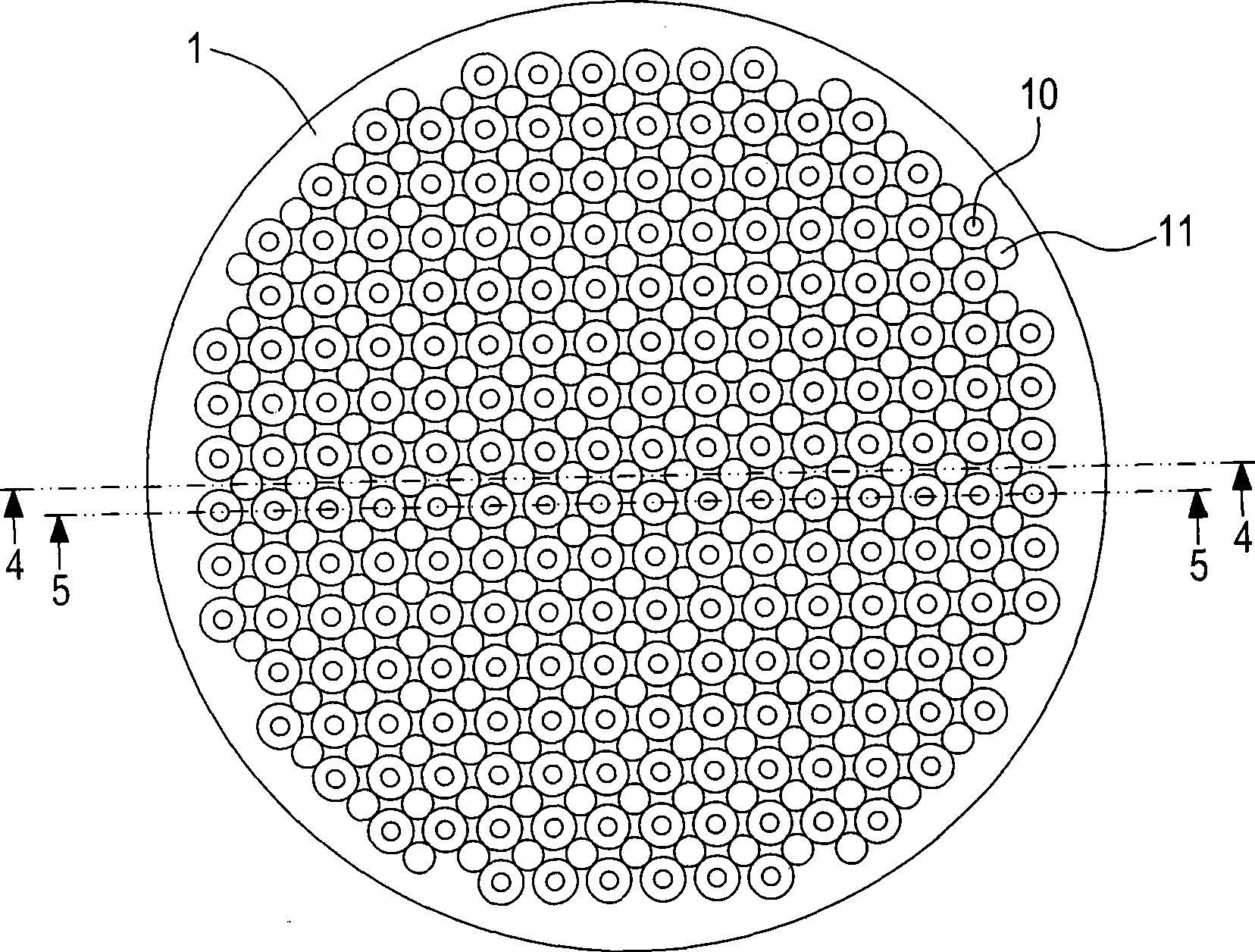

[0033] see Figure 1 to Figure 3 , are respectively the three-dimensional schematic view of the support body of the present invention, figure 1 A partially enlarged view of part A of the middle support body and a plan view of the support body of the present invention. The present invention provides a support body inside the chamber. The support body has a flat board body 1 with two board surfaces. In the embodiment of the present invention, it is a circular plate body. And its main structural feature is that the board body 1 is provided with two or more concave-convex parts 10 distributed on its two board surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com