Circular heat exchange system

A technology of heat exchange system and heating tube, which is applied in heat exchangers, water heaters, indirect heat exchangers, etc., can solve the problem that the waste heat of the furnace fire at the bottom of the pot cannot be effectively used, the thermal efficiency is low, the conversion rate of heat transfer is low, and the furnace fire is hot The problem of low utilization rate of volume can be solved, so as to achieve the effect of convenient space utilization, reducing heat loss and enhancing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

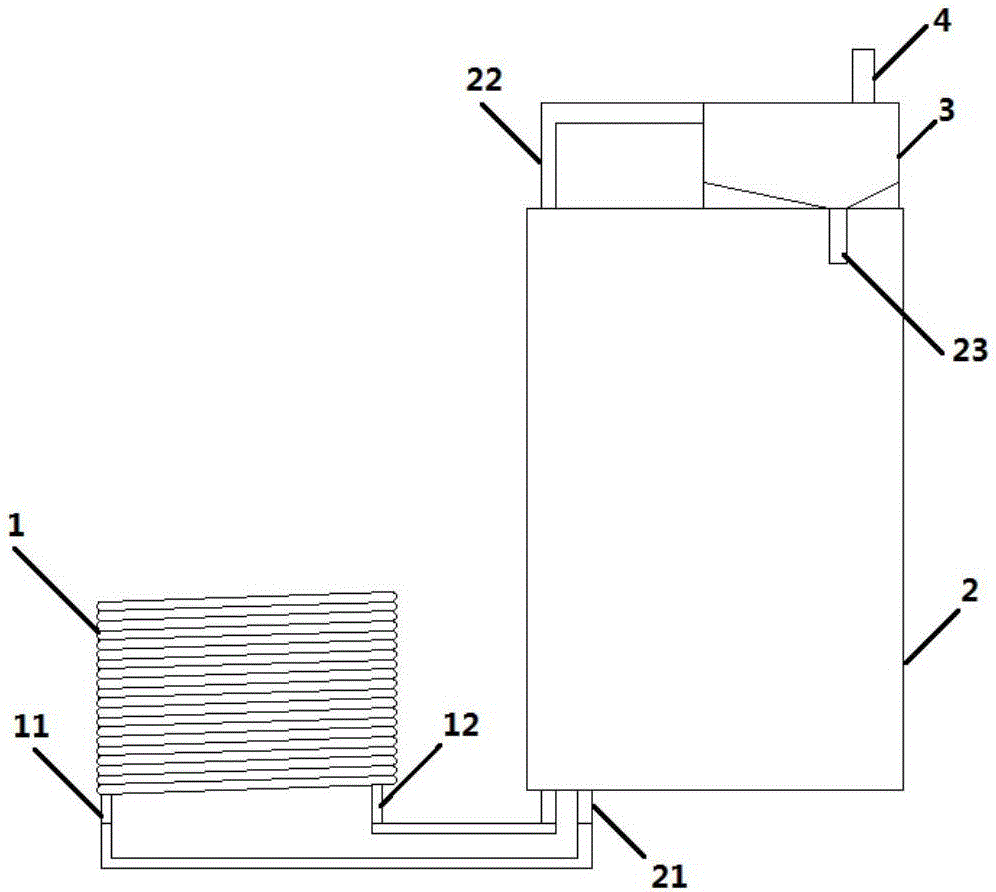

[0014] A circulating heat exchange system, comprising a heating pipe 1 and a water tank 2, the heating pipe 1 is arranged outside the water tank 2 and separated from the water tank 2, the heating pipe 1 is an ascending spiral annular pipe, and the heating pipe 1 is set In the fire of an open flame furnace, the nozzle at the bottom of the heating pipe 1 is the water inlet 11, and the nozzle at the top of the heating pipe 1 is the steam outlet 12, and the steam outlet 12 and the water inlet 11 are connected to the nozzle 21 at the bottom of the water tank 2 respectively. Connected to the inside of the water tank 2, the top of the water tank 2 is provided with an exhaust port 22 and a water injection port 23.

[0015] Further, the steam port 12 at the top of the heating tube 1 is bent toward the inner side of the ring and then bent downwards to be flush with the water inlet 11 at the bottom of the heating tube 1 .

[0016] Further, the top of the water tank 2 is provided with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com