Large coal bunker wall construction method and ring beam portion construction method

A construction method and silo wall technology, applied in the construction field of large coal bunker, can solve the problems of heavy workload, waste of construction period, lack of scientific rationalization, etc., and achieve the effect of shortening construction period and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

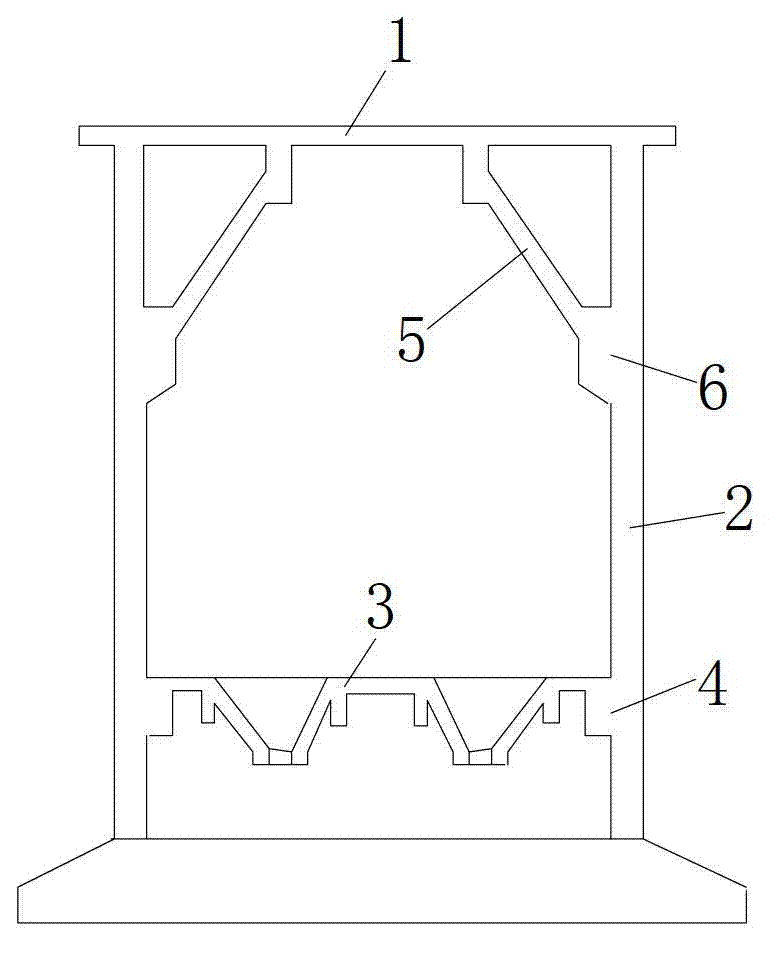

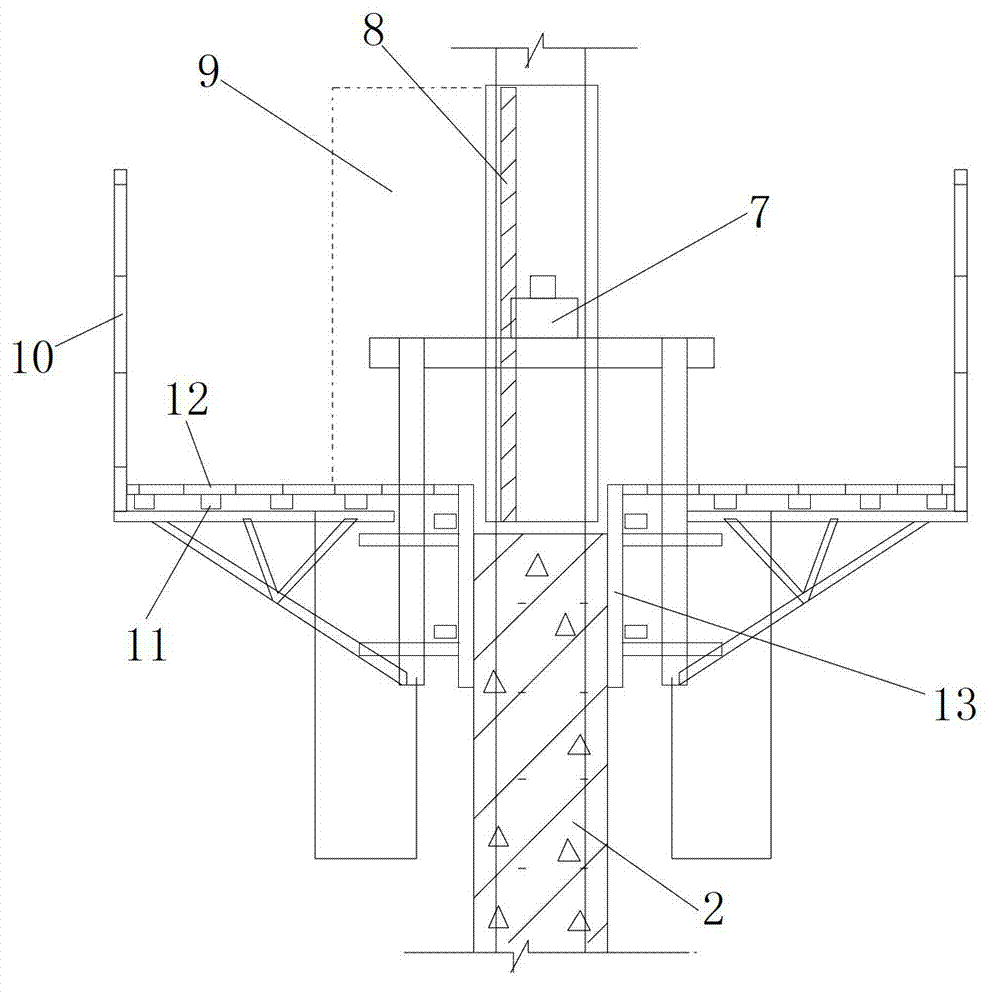

[0028] figure 1 The positional relationship of the bunker wall 2 of the coal bunker, the ring beam part 4 of the funnel platform and the ring beam part 6 of the conical top shell can be displayed. From figure 1 It can be seen from the figure that when the warehouse wall 2 is built by the sliding form construction method, the ring beam part 4 of the funnel platform and the ring beam part 6 of the conical top shell must be passed through. In the prior art, when the ring beam part 4 of the funnel platform and the ring beam part 6 of the conical top shell are built, the annular installation joints of the funnel platform and the annular installation joints of the conical top shell shall be formed respectively through steel bars, and corresponding stirrups, such as figure 2 The stirrups 9 in the middle, and then by pouring concrete into the corre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com