Steam treatment method for piston products

A technology of water vapor treatment and water vapor, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve problems such as redness, impact, and unfavorable piston quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

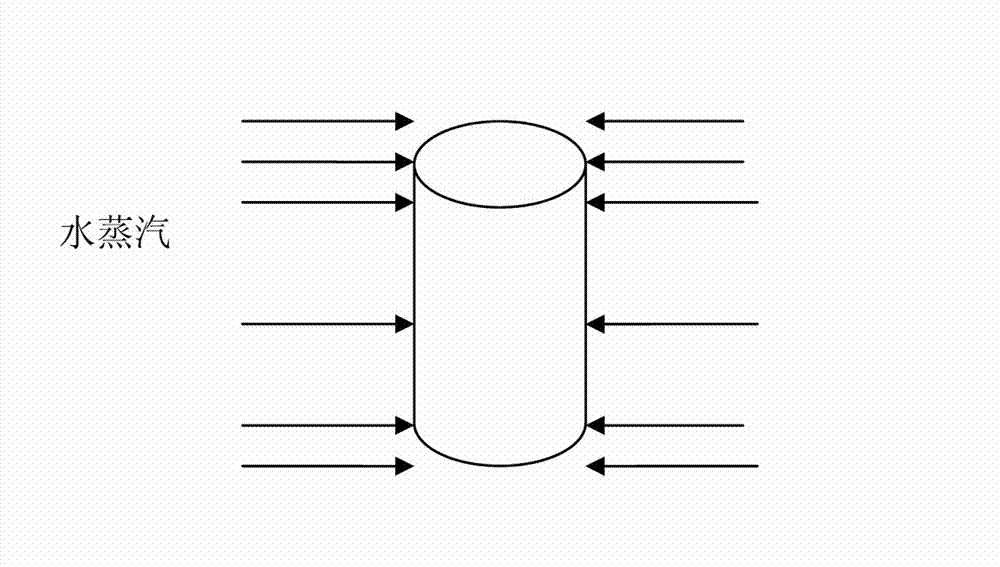

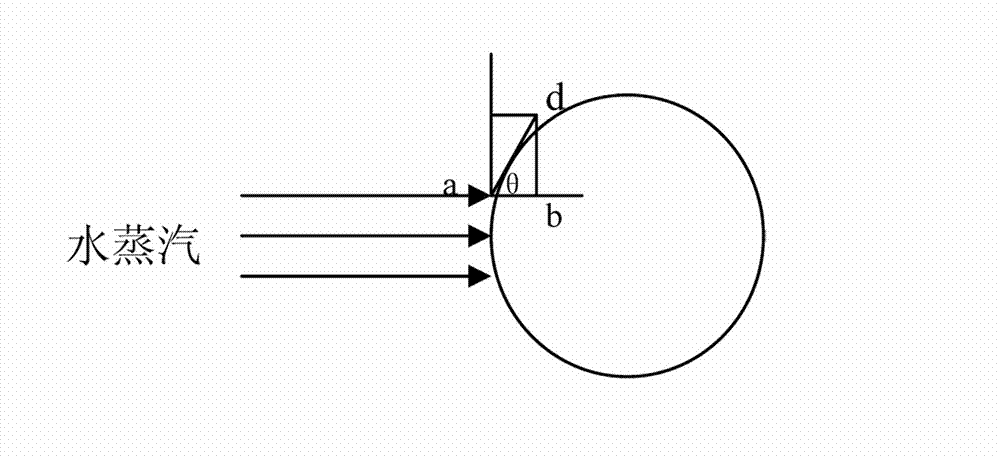

Method used

Image

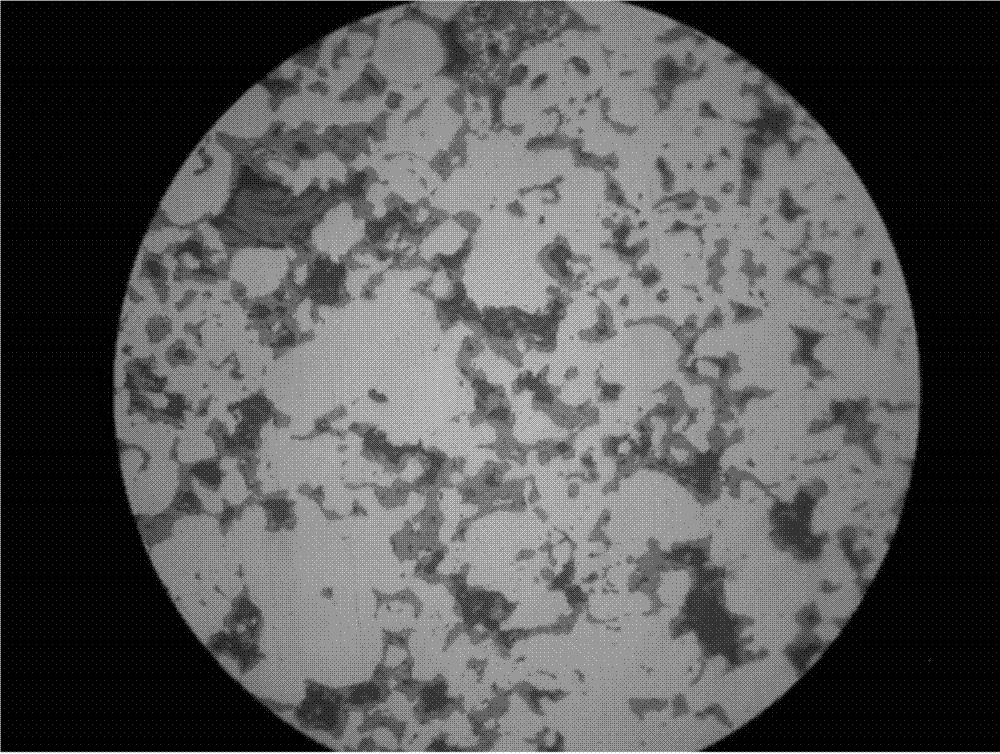

Examples

Embodiment 1

[0030] Embodiment 1 Traditional method and the method of the present invention carry out the comparison of water vapor treatment to piston product

[0031] Utilize traditional method and the inventive method to carry out steam treatment to piston product:

[0032] Traditional method: Raise the temperature in the furnace and pass nitrogen to remove the water vapor, some oxygen and waste gas left over from the previous furnace, pass nitrogen for 0.8h and then pass water vapor for 0.5h. Then the piston product was reacted with water vapor at 540°C for 3h in the first stage treatment, and the piston product was reacted with water vapor at 580°C for 3h in the second stage treatment.

[0033] The method of the present invention: pretreatment is carried out according to the traditional method, and then the piston product is reacted with water vapor at 530° C. for 4 hours in the first stage treatment, and the piston product is reacted with water vapor at 580° C. for 2 hours in the s...

Embodiment 2

[0037] Embodiment 2 The further improvement of piston quality

[0038] Pistons also often show redness during the steam treatment process. In view of this phenomenon of the piston, the following measures are taken on the basis of the above method to further improve the quality of the piston product:

[0039] (1) Extend the time of nitrogen protection products

[0040] Under the condition that the nitrogen protection and the total time of passing water vapor before the first stage remain unchanged, shorten the time of passing water vapor before the first stage, so that the overall temperature of the product tends to be relatively uniform before reacting with water vapor. The temperature rises from the original 450°C to the current 500°C, and the nitrogen protection time increases from 0.5h to 1h.

[0041] (2) In each layer of ST basket, the screen plate separates the piston

[0042] The volume of the piston product is relatively small. If you put densely packed pistons in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com