Method for thinning liquid crystal display panel with thickness less than 200 micrometers

A liquid crystal display panel and thinning technology, which is applied in the field of etching and thinning of ultra-thin liquid crystal display panel glass, can solve the problems of high breakage rate and inability to mass-produce, and achieve the effects of fast separation speed and reduction of breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The implementation of this case is used to illustrate that the thinning method of the present invention thins the white glass whose raw material is Asahi Glass AN100 single layer 0.7mm to 0.15mm.

[0023] Specific steps:

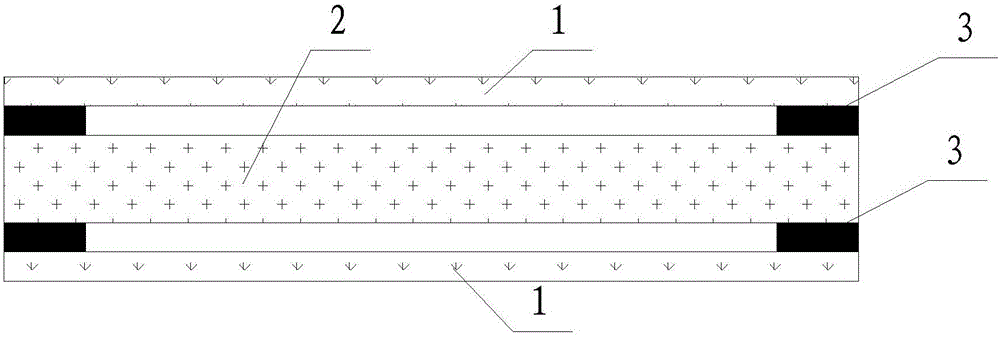

[0024] Take 2 pieces of Asahi Glass AN100 single-layer 0.7mm white glass with a size of 370×470mm, and then prepare a 0.7mm carrier glass with the same size as the glass to be thinned; use double-sided tape to neatly align and fit the carrier and the thinner glass that needs to be thinned. Chemicalized glass, carrier glass as interlayer; such as figure 1 As shown, use UV glue to seal the edges of the laminated three-layer glass; wash the glass surface with a cleaning solvent and use mixed acid to acid-thin it to 0.15mm in the top spray equipment; thin the glass surface to the target thickness. Cleaning; the thinned glass is subjected to strong UV curing again and then soaked in a strong alkaline solvent for 25 minutes, and the temperature of the alka...

Embodiment 2

[0026] The implementation of this case is used to illustrate that the thinning method of the present invention thins the white glass whose raw material is Asahi Glass AN100 single layer 0.7mm to 0.10mm.

[0027] Specific steps:

[0028] Take 2 pieces of Asahi Glass AN100 single-layer 0.7mm white glass with a size of 370×470mm, and then prepare a 1mm carrier glass with the same size as the glass that needs to be thinned; use double-sided adhesive to neatly align and fit the carrier and need to be thinned glass, carrier glass as interlayer; such as figure 1 As shown, use UV glue to seal the edges of the laminated three-layer glass; wash the glass surface with a cleaning solvent and use mixed acid to acid-thin it to 0.10mm in the top spray equipment; thin the glass surface to the target thickness. Cleaning; the thinned glass is subjected to strong UV curing again and then soaked in a strong alkaline solvent for 15 minutes, and the temperature of the alkaline solvent is kept at 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com