Plasticized car body overall-molding method

An integral molding, body technology, applied in vehicle components, superstructure sub-assemblies, coatings, etc., can solve the problems of heavy body weight, cumbersome and complex, welding defect process, etc., to improve production efficiency, ensure safety, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

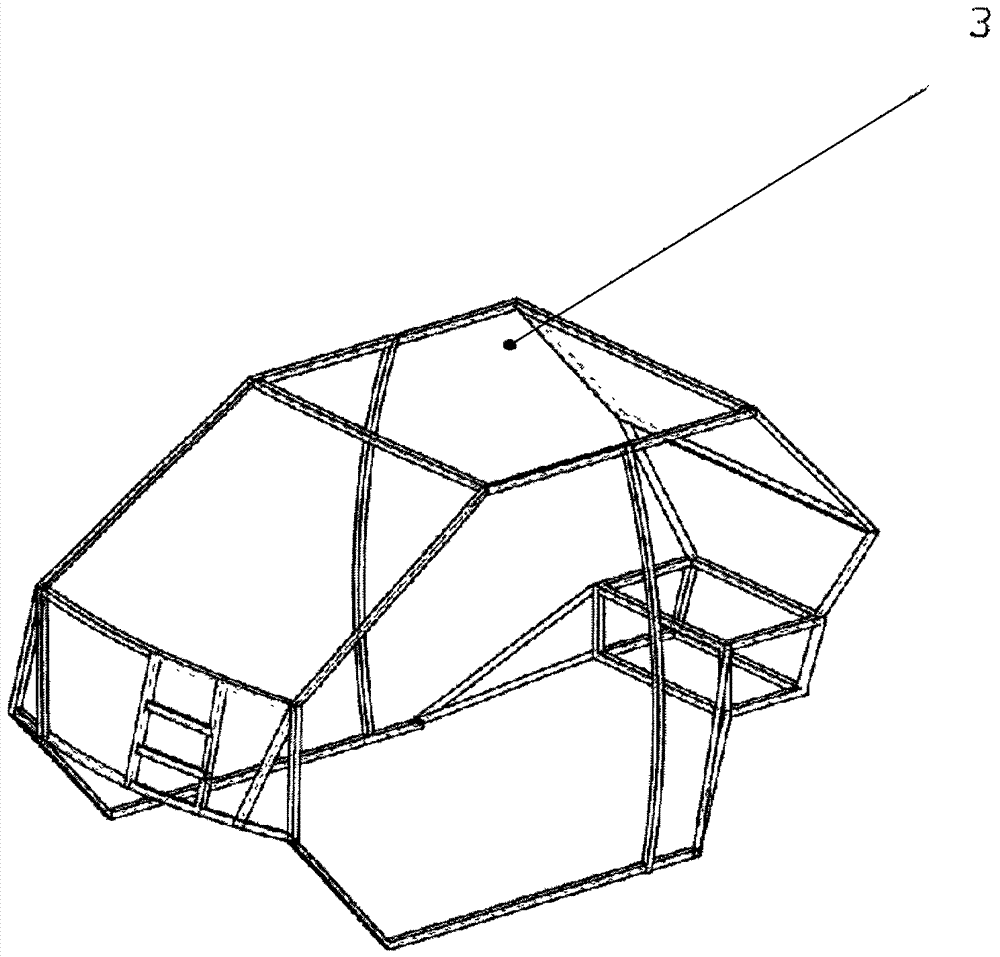

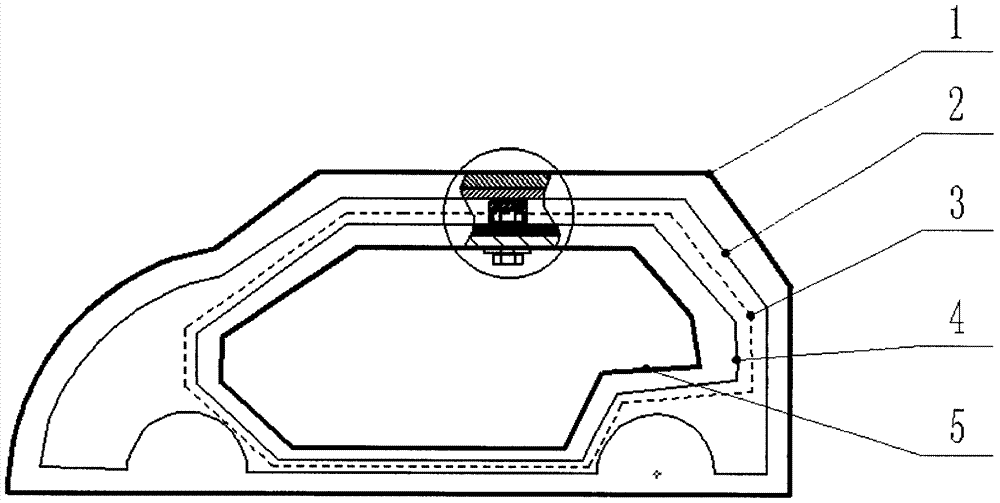

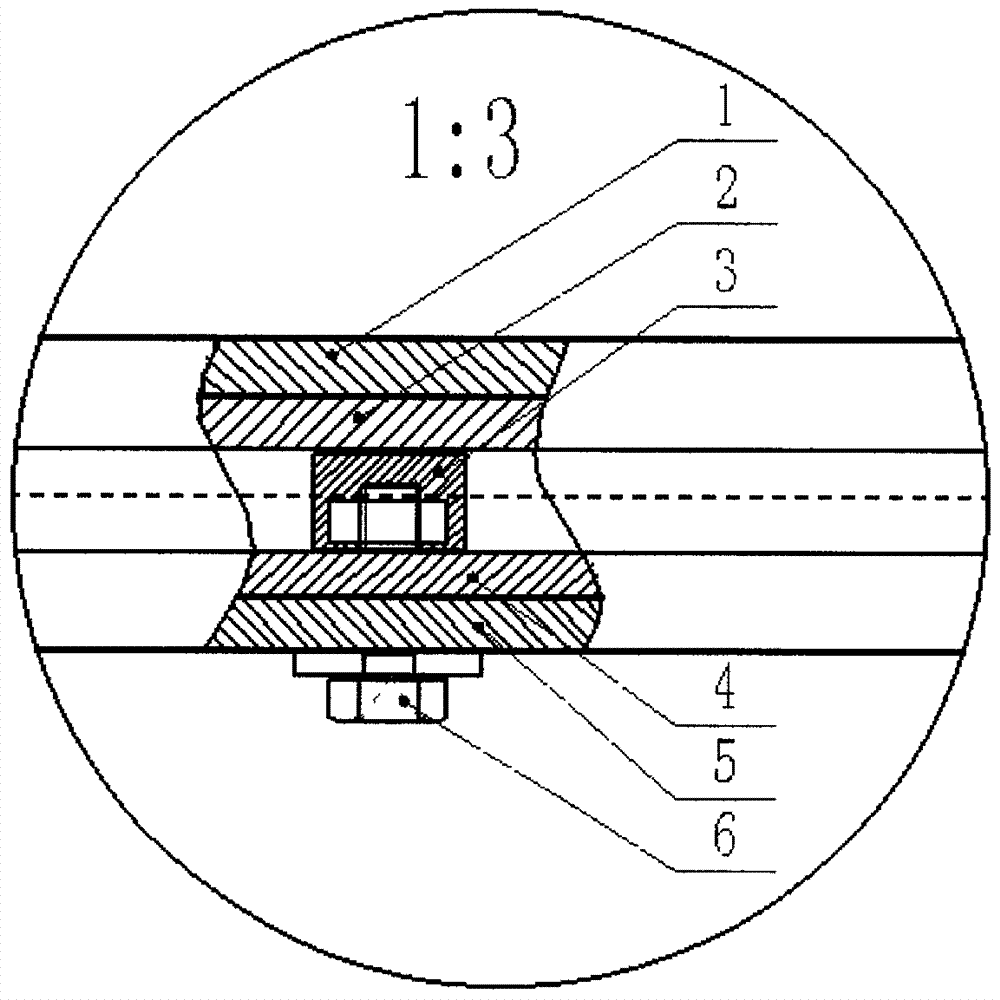

[0019] A kind of integral forming method of plasticized vehicle body of the present invention, as figure 1 As shown, after the vehicle body mold is assembled, the surface of the mold is cleaned, a release agent is applied, and the keel 3 is installed between the outer mold 1 and the inner mold 5 through bolts 6 . Put a certain amount of material into the body mold, close the mold, lock the mold with bolts or clamps, push the mold into the oven of the rotational molding equipment, heat the body mold to the specified temperature in the oven and make the mold along the two The axes perpendicular to each other rotate for a period of time, and the materials in the body mold are evenly coated and melted and adhered to the surface of the mold under the action of gravity and heat to form a car body product. After the heating is completed, the mold is cooled and kept for a period of time. Open the body mold bolts or clamps, and take out the body products.

[0020] A kind of integral f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com