Manufacturing method for flip chip gold bumps

A technology of flip-chip and bumps, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc. The need for mass production, the difficulty of obtaining nail-head bumps and other issues, to achieve the effect of improving production efficiency, avoiding damage, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A method for preparing flip-chip gold bumps, as shown in the figure, comprises the following steps:

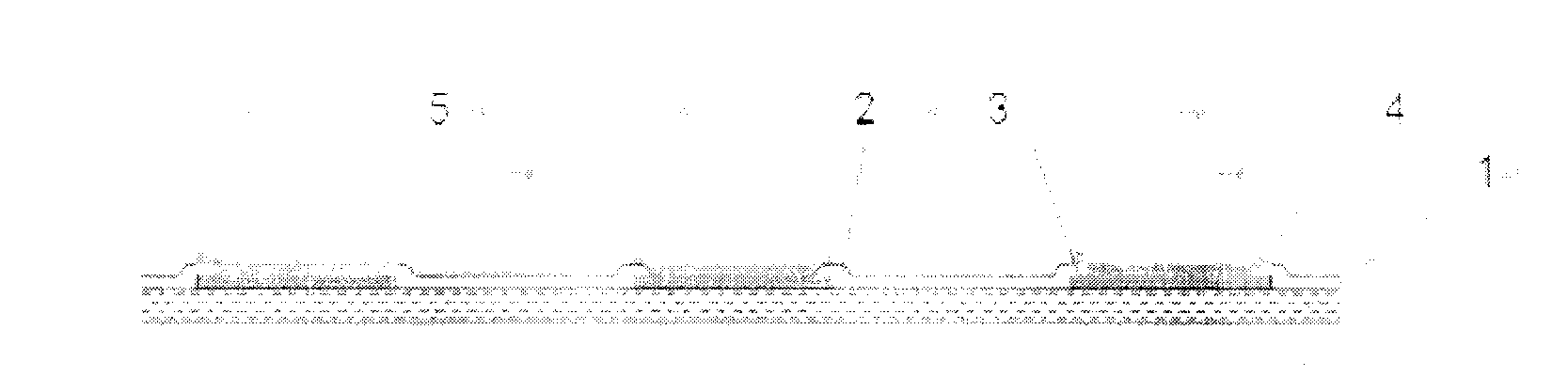

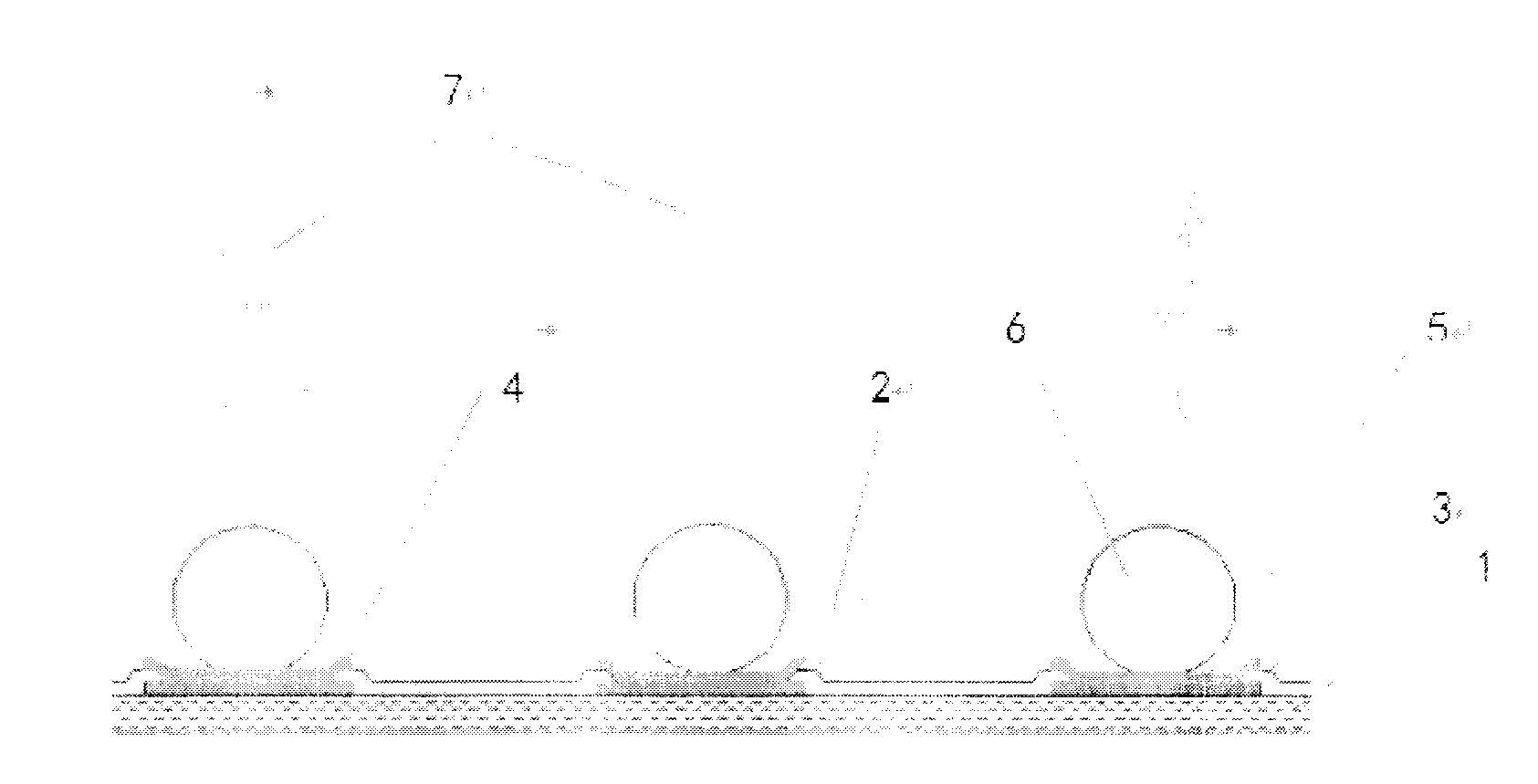

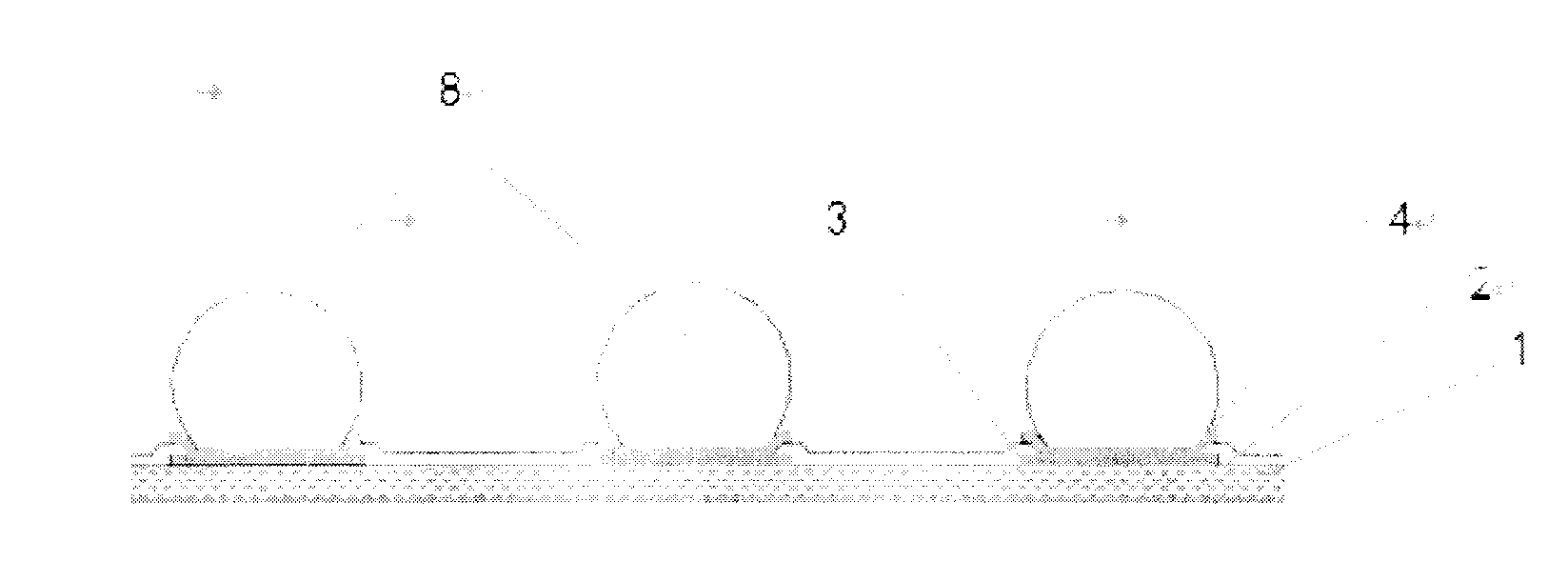

[0028] Such as figure 1 As shown, the invention evenly smears flux on the UBM coating 4 of the chip 1 pad. This technical solution uses high-viscosity flux to play the role of bonding and flux, and to ensure that the pattern of flux after printing is clear and does not flow . A special small template is used for printing. Usually, the thickness of the template and the size of the opening are determined according to the ball diameter and pitch. The thickness of the template is about one tenth of the ball diameter, and the opening size is slightly larger than the radius of the ball. According to the size requirements of the gold bumps, select gold nanospheres with a suitable diameter, and the size of the gold balls is on the order of tens of nanometers to microns. Using a ball planter, select a matching template. The opening size of the template should be 0.05-0.1mm lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com