Novel automobile groove-shaped sealing strip

A technology for sealing strips and automobiles, which is used in sealing devices, engine sealing, vehicle components, etc., can solve the problems of small compression set, increase post-process, buffer lip failure, etc., to increase elasticity and elastic recovery ability, technology Simple and reliable implementation, good cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

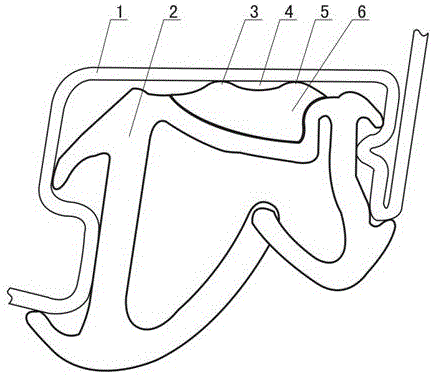

[0017] Such as figure 1 As shown, the novel automobile woolen sealing strip of the present invention is placed on the inner side of the door frame 1, and is formed by composite co-extrusion of EPDM compact glue 2 and EPDM sponge rubber 6. Part of it is EPDM sponge glue 6, and the other part is EPDM compact glue 2. On the EPDM sponge glue 6, the side surface near the door frame 1 is provided with a first bump 3 and a second bump 5. The first bump 3 and the second bump The apex of the bump 5 is in contact with the inner surface of the door frame 1 , and a groove 4 is formed between the first bump 3 and the second bump 5 . According to needs, there may be more bumps mentioned above.

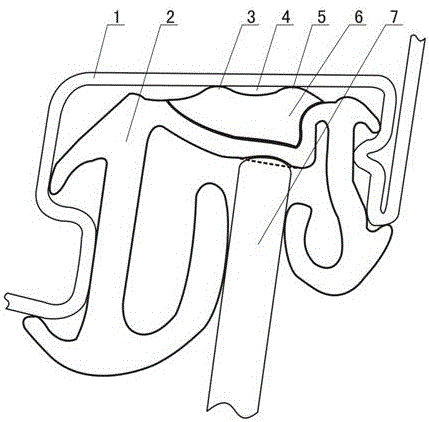

[0018] Such as figure 2 As shown, when applied, the door glass 7 rises, first passes through the two cross damping strips of the EPDM compact 2, and separates the two cross damping strips, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com