Patents

Literature

513results about How to "Safe working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

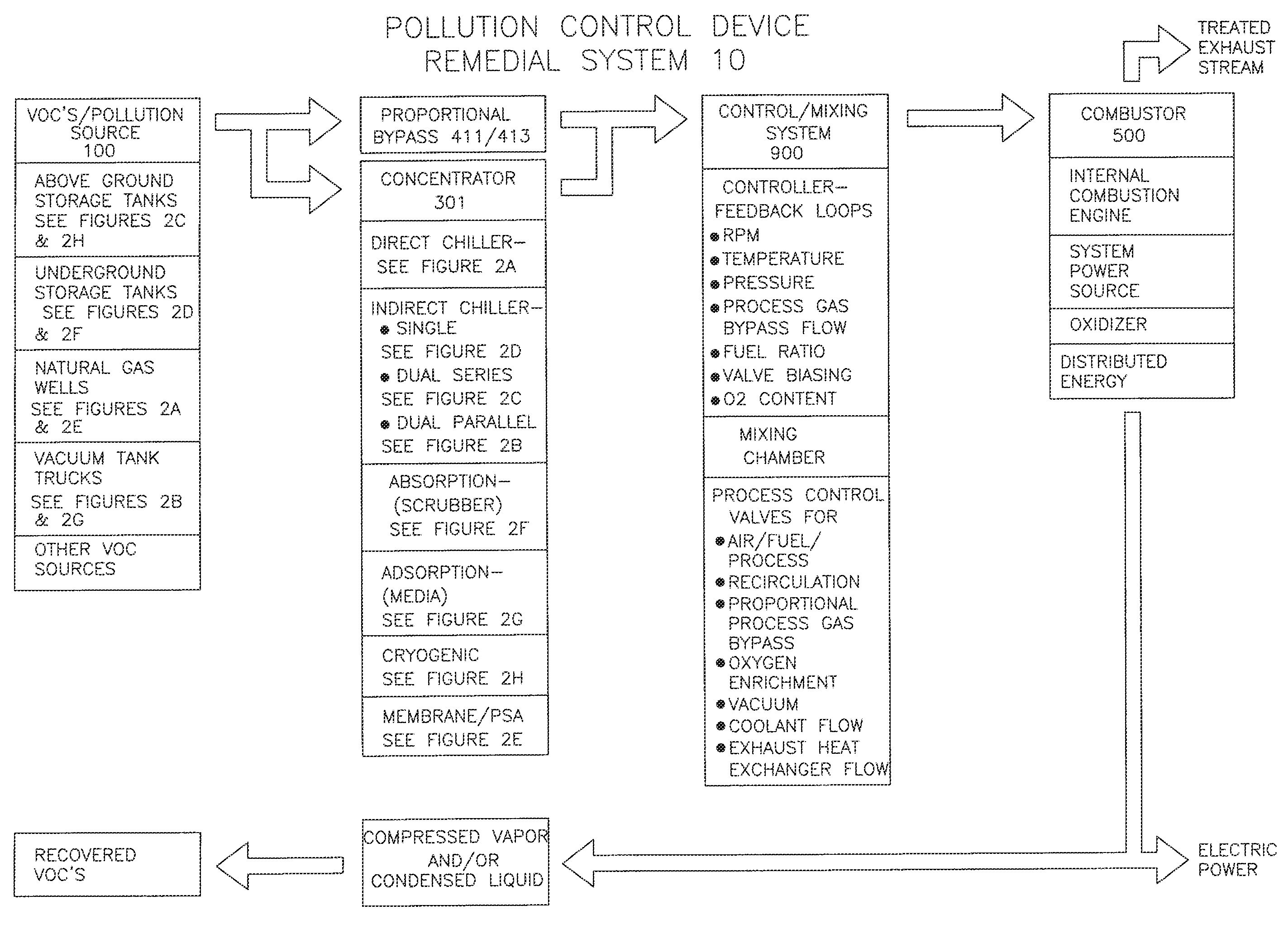

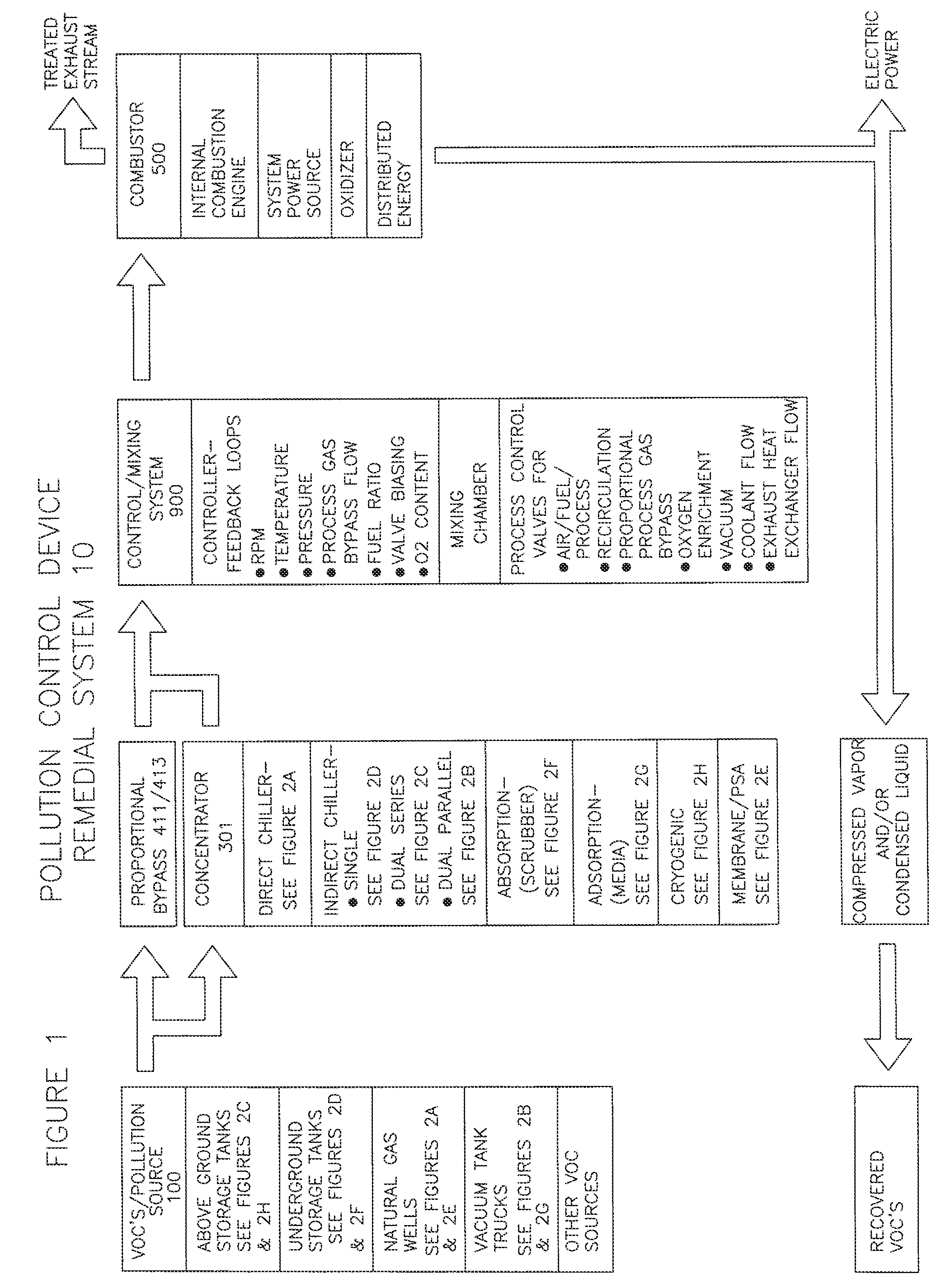

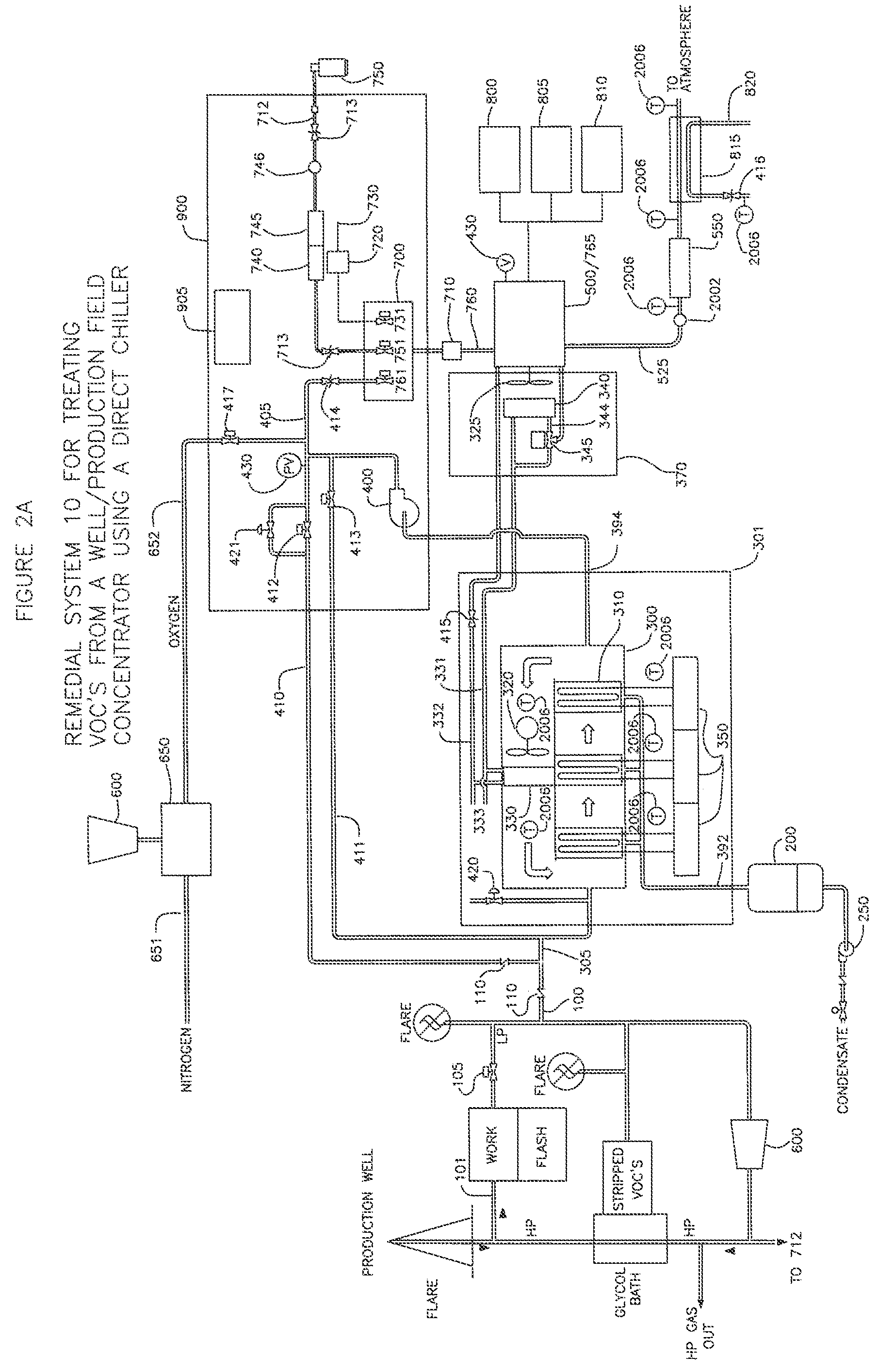

Remedial system: a pollution control device for utilizing and abating volatile organic compounds

ActiveUS8776734B1Easy to useTreatment safetyGas treatmentNon-fuel substance addition to fuelHybrid systemControl system

A remedial pollution control system for treating volatile organic compounds that may include a vapor concentrator connected to a line that is laden with volatile organic compounds, the concentrator has an organic condensate output line and a vapor output line; a mixing chamber adapted to receive air provided from an air supply line, combustible fuel from an alternate fuel supply line, and a vapor stream from the vapor output line to produce a mixed fuel supplied to an internal combustion engine, a control mixing system with a controller for producing a proper air to fuel ratio in the mixed fuel supply, and power generated to operate other devices used to more efficiently abate volatile organic compounds and reduce greenhouse gas emissions.

Owner:INNOVATIVE ENVIRONMENTAL SOLUTIONS LLC DBA REMEDIATION SERVICE INTL

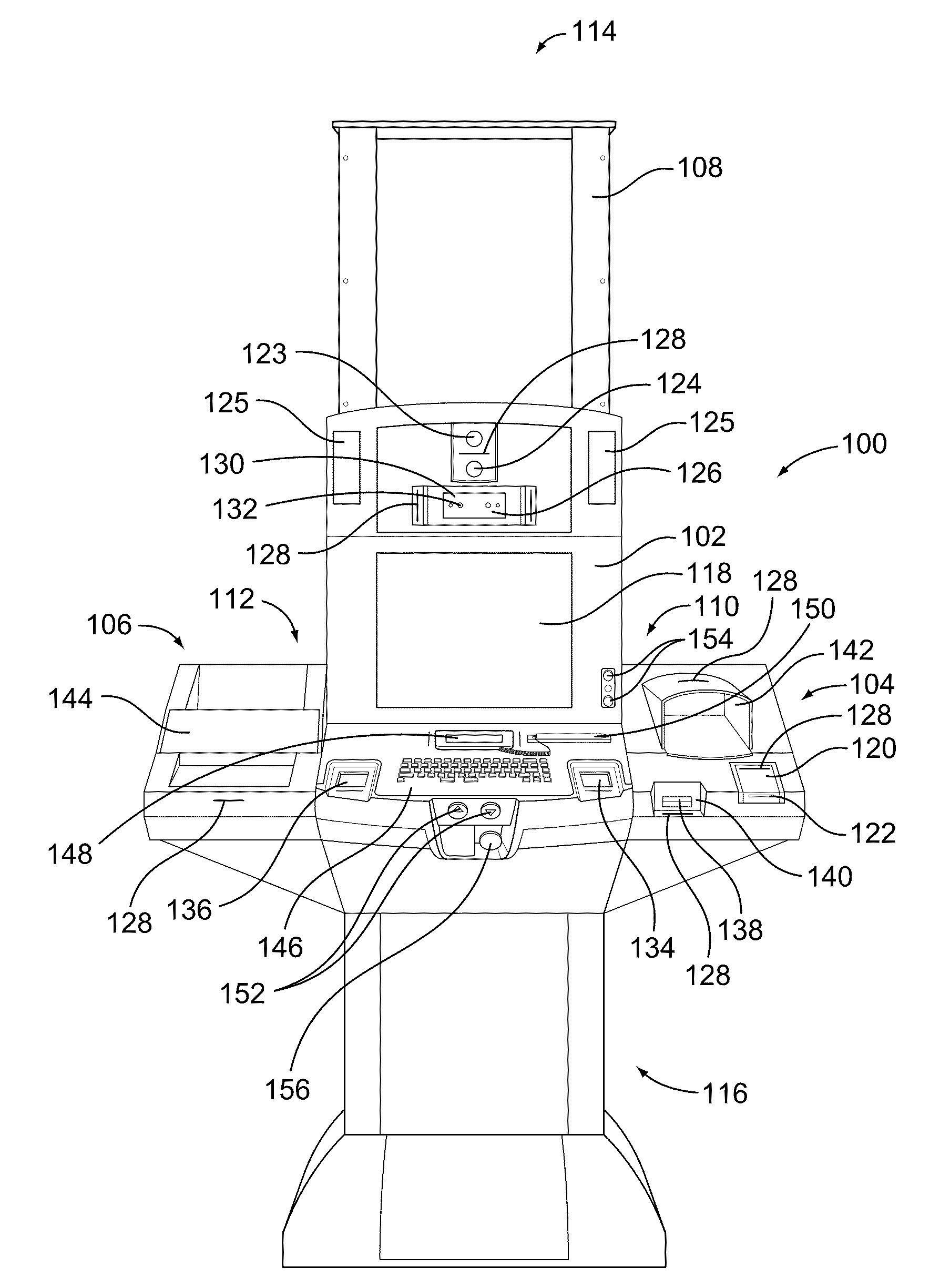

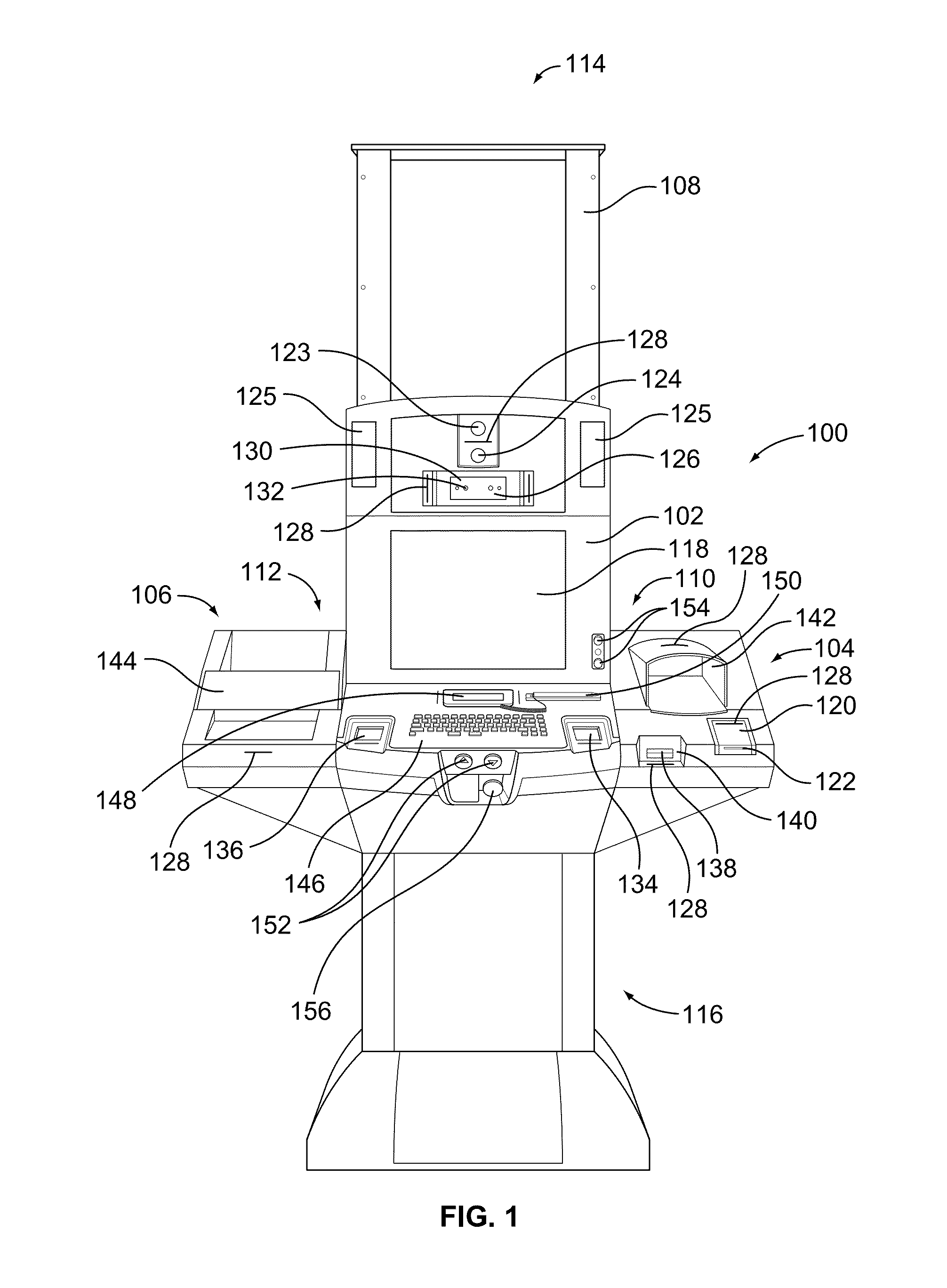

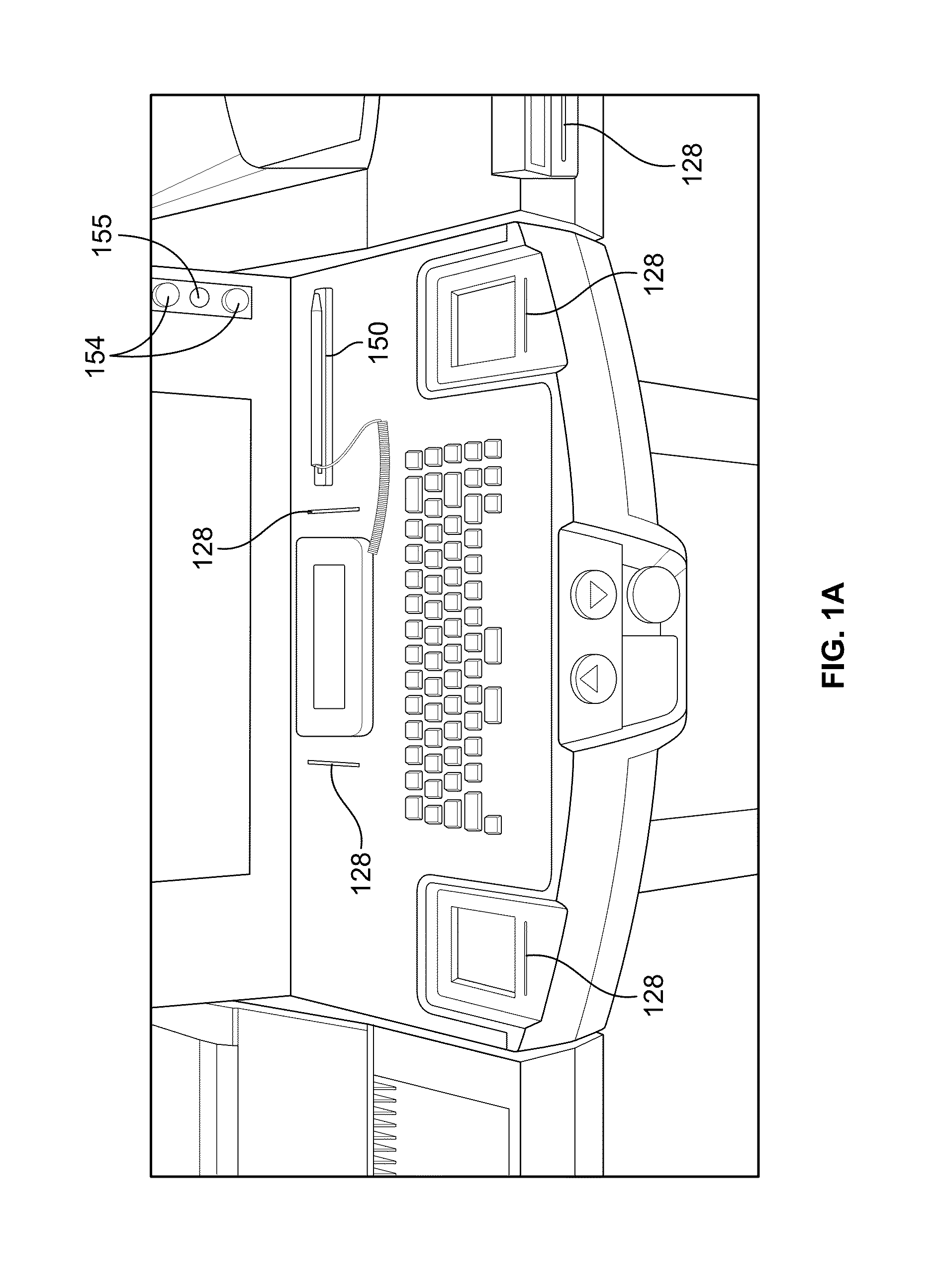

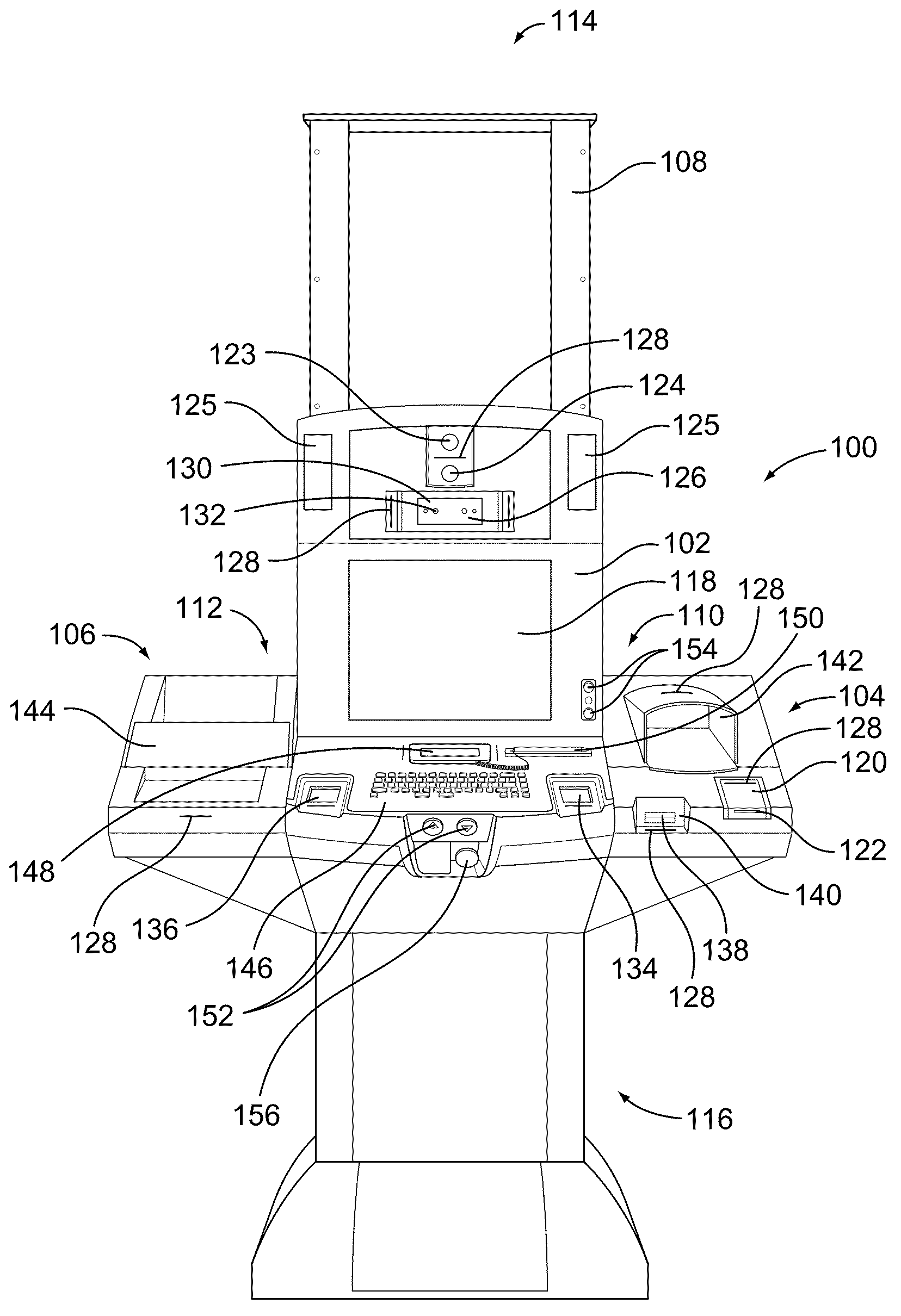

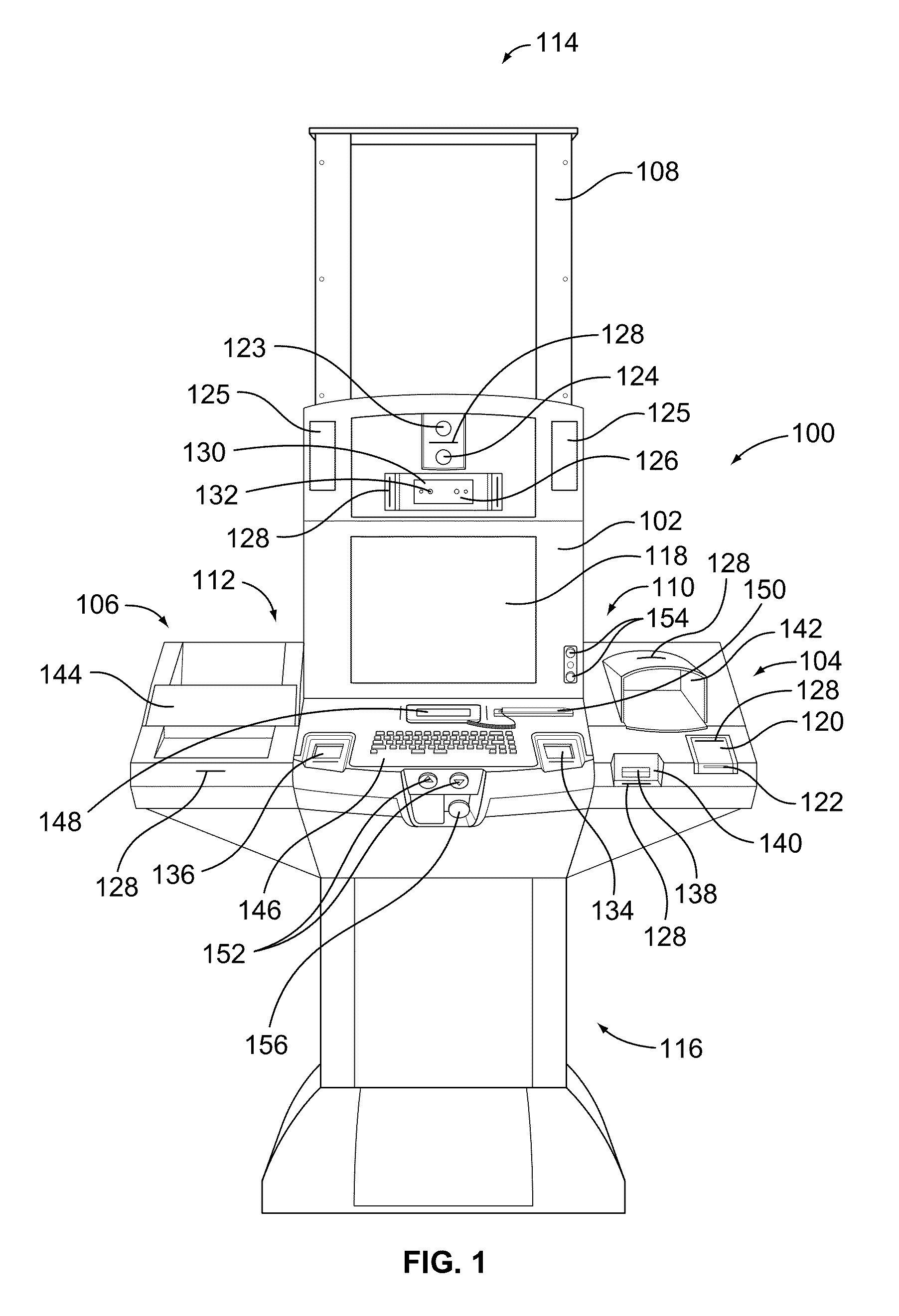

Enrollment kiosk including biometric enrollment and verification, face recognition and fingerprint matching systems

ActiveUS20130215275A1Easy to transportEasy to installAcquiring/recognising eyesColor television detailsVideo transmissionComputer module

An enrollment kiosk for collecting personal data includes a slidable main module and at least one modifiable section removably coupled to the main module. The main module includes a processor and one or more biometric sensing devices coupled to the processor. The one or more biometric sensing devices include a right fingerprint sensor coupled to the processor and a left fingerprint sensor coupled to the processor. The right fingerprint sensor is positioned a predetermined distance apart from the left fingerprint sensor. The at least one modifiable section includes at least one first input device coupled to the processor. The kiosk also includes a scene camera configured to record a video of an area surrounding the enrollment kiosk and to transmit the video to a remote operator being located remotely from the enrollment kiosk

Owner:NEXTGENID

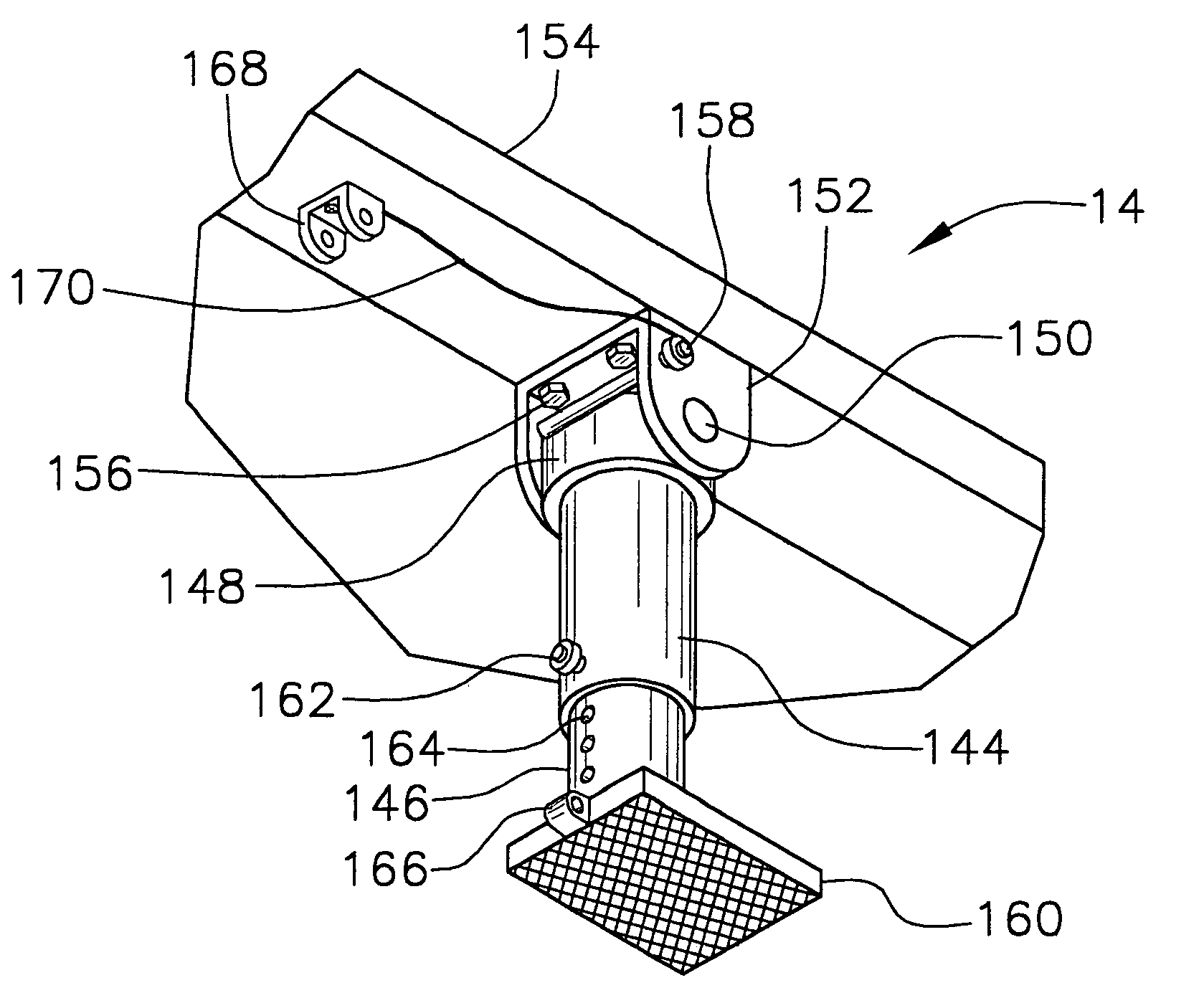

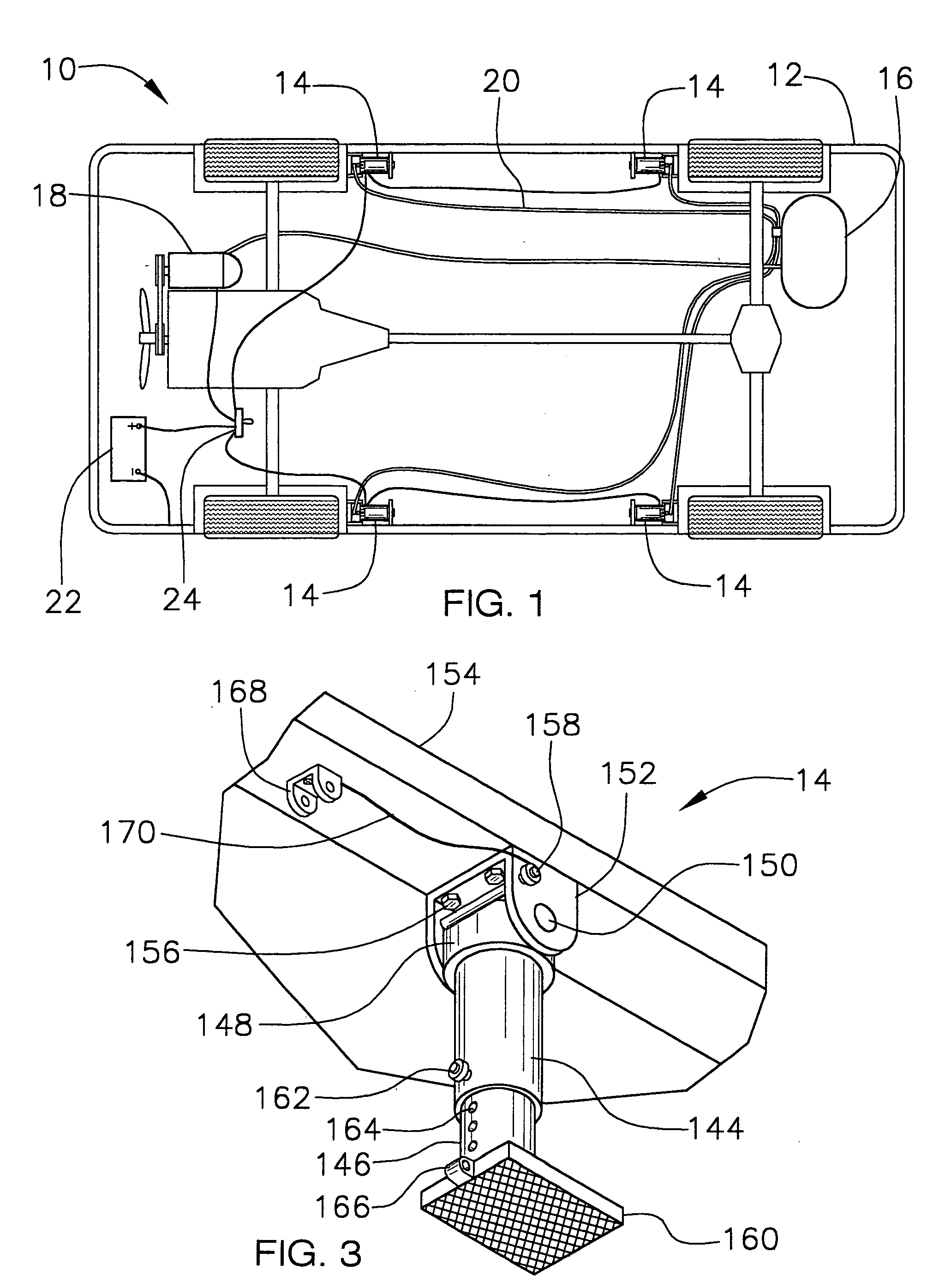

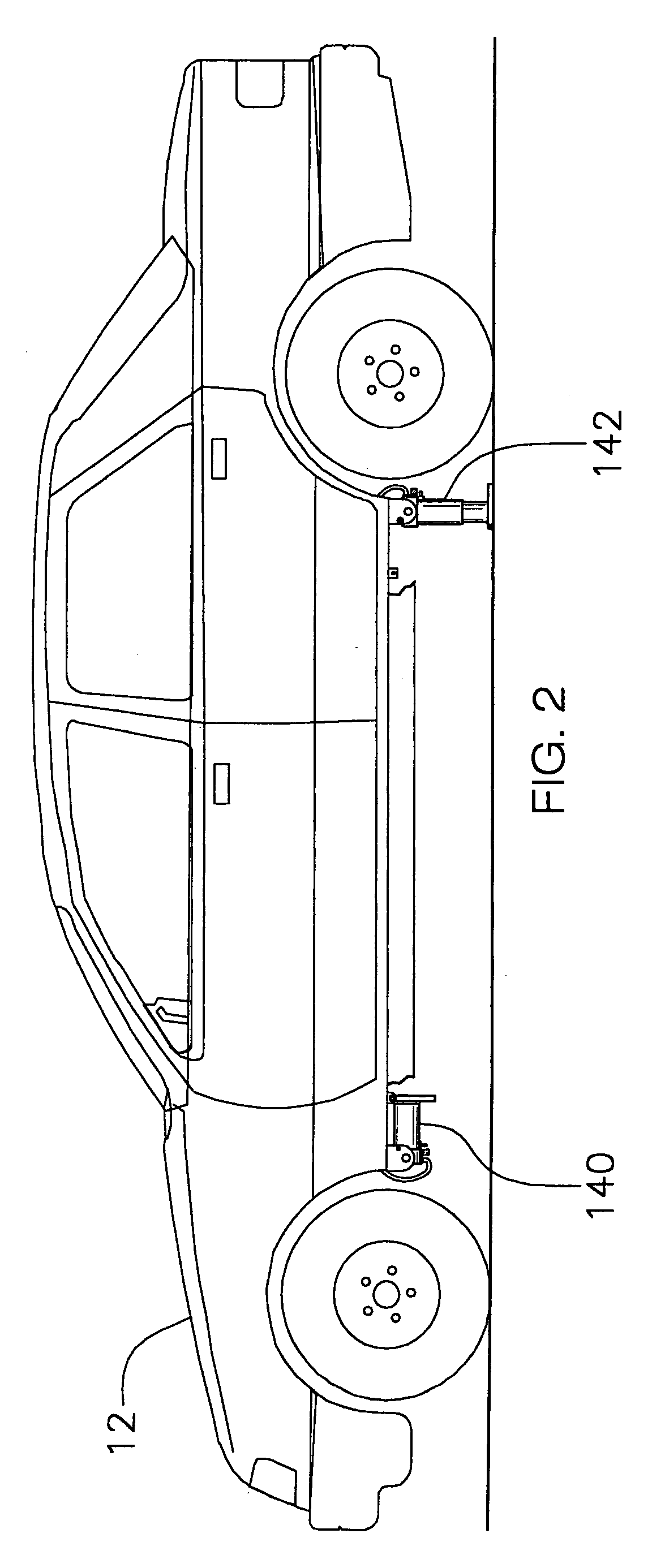

Motor vehicle pneumatic jacklift system

InactiveUS6895648B1Easy to modifyEasy and efficient to manufactureVehicle fittings for liftingVehicle cleaning apparatusSolenoid valveGas compressor

A permanently mounted pneumatic jack (jacklift) system for motor vehicles, as well as an impact wrench for removing and installing lug nuts. The system provides a quick and safe means of lifting one or more tires off the ground for replacement of a spare or rotating the tires on a motor vehicle. The present invention comprises two or more (typically four) pneumatic jacks, a system ON / OFF switch, an air compressor, a 120-psi air tank, air lines (hoses), individual jack extend / retract switches, jack position-locking pins, safety-locking pins, and impact wrench. Each jack can be locked in a horizontal stowaway or vertical operational position. The jack is cylindrical shaped with a telescopic body that can be extended or retracted as needed to raise and lower the vehicle. A solid cylindrical lift rod slides inside a cylindrical outer housing with a high-pressure seal means used to maintain pressure on the support rod. A ground support foot (plate) is mounted on the lower end of the solid cylindrical lift rod to provide sufficient traction with the ground to support the lifting process. A quick release air coupler is included on the pneumatic chamber to support the use of an air hose and impact wrench. An extend / retract toggle switch is included on each jack to control a solenoid valve to allow the air to flow into the jack. A quick release safety-locking pin is used to mechanically pin the solid cylindrical lift rod to the outer housing once the desired height is achieved to assure that the vehicle does not fall down in the event of a high-pressure air loss, thereby providing safety to the person(s) working around the vehicle. An air compressor located in the engine compartment of the vehicle is mechanically belt-driven off the engine. A high-pressure air line carries the air to a high-pressure (at least 120-psi) air tank located in the trunk or other suitable storage area on the vehicle. Separate air lines extend from the air tank to the individual jacks.

Owner:WILLETT MICHAEL J

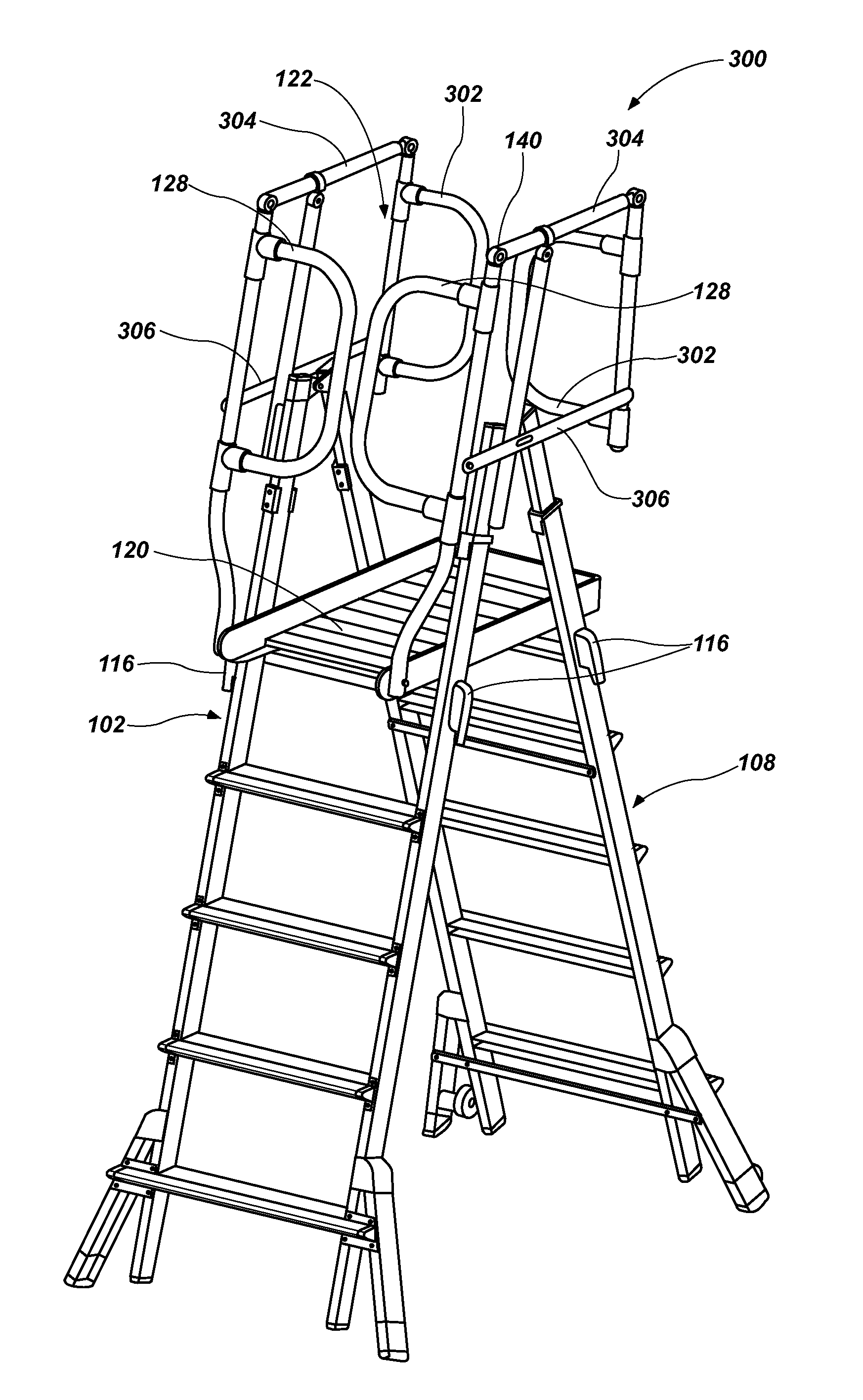

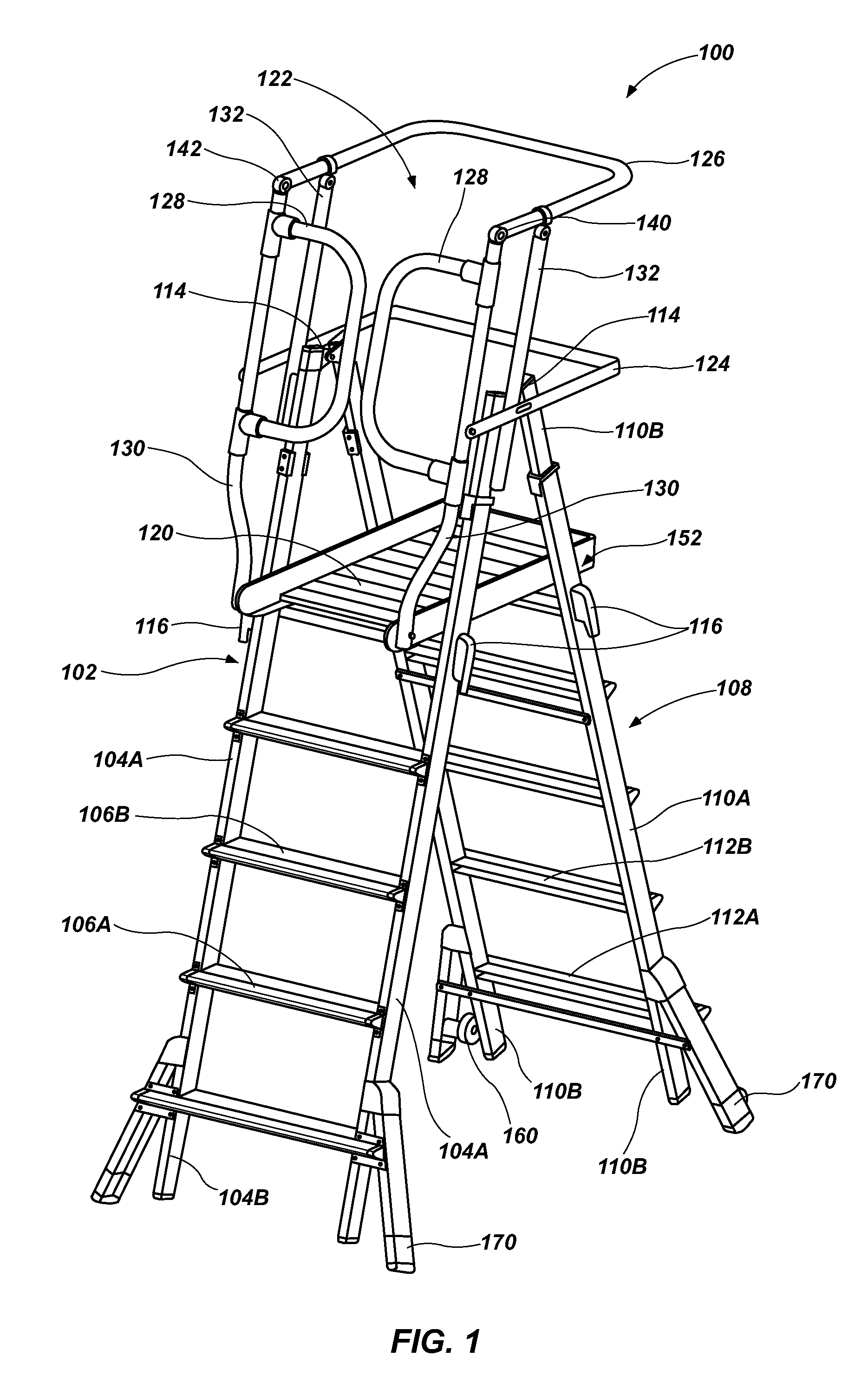

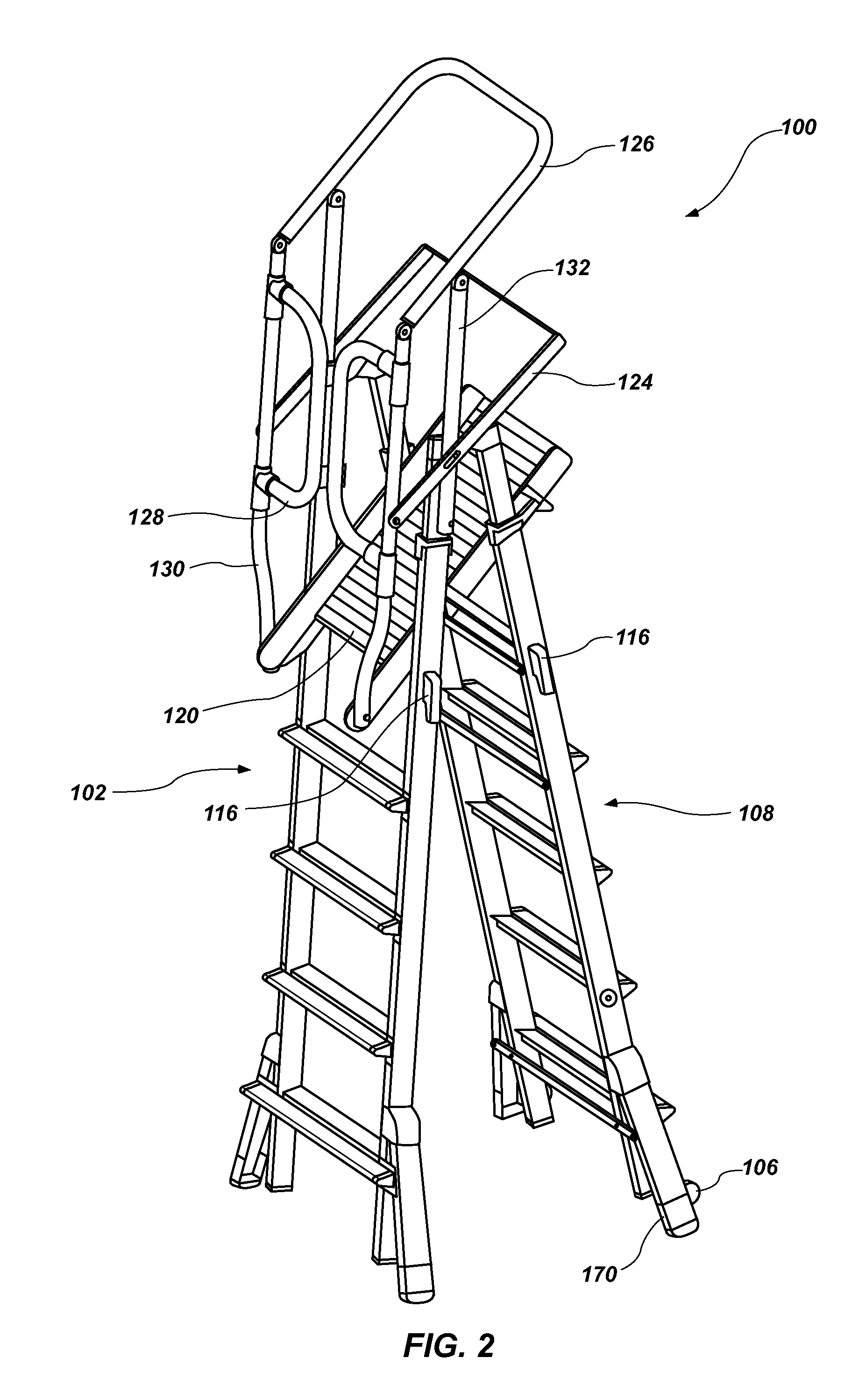

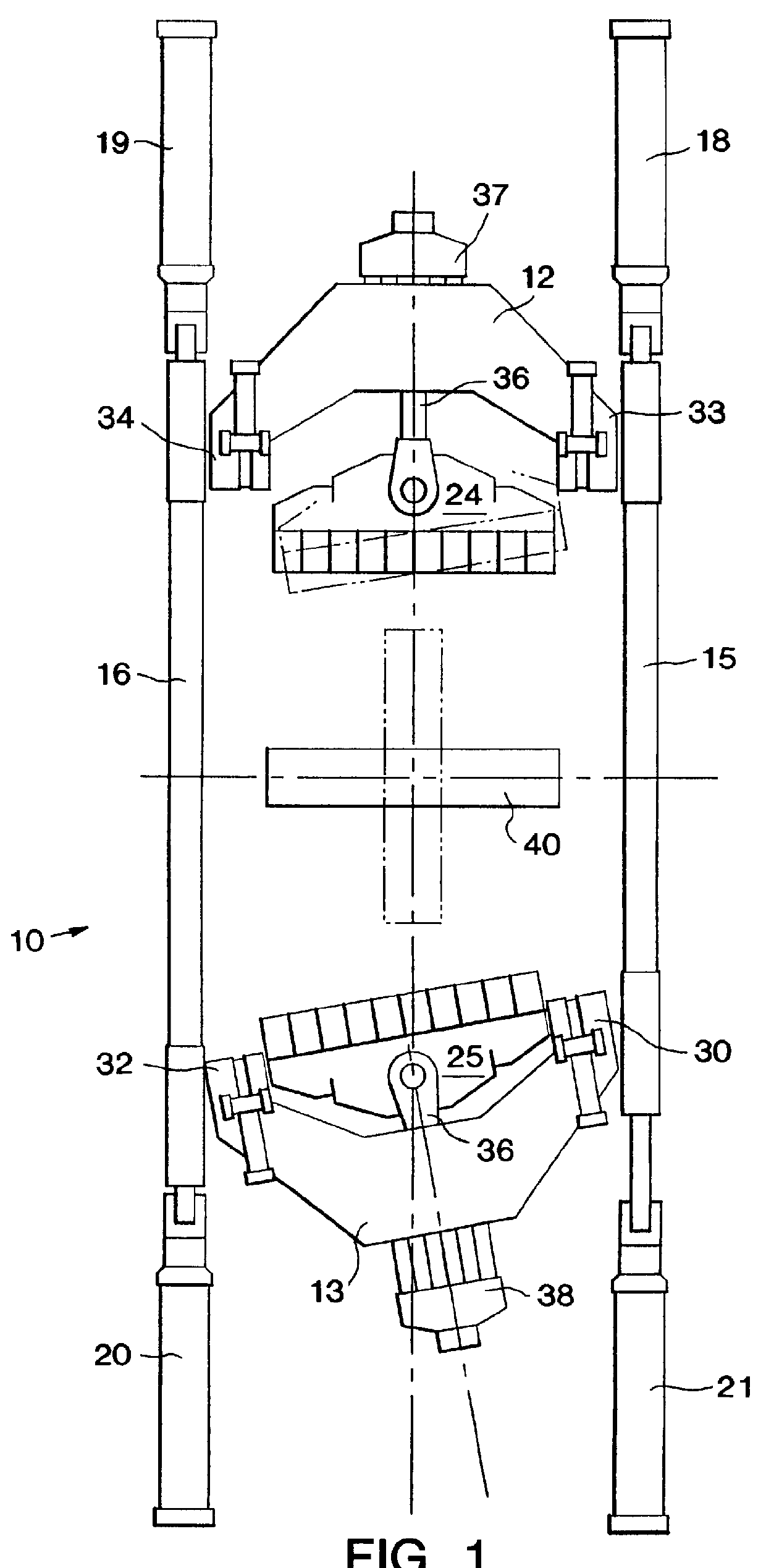

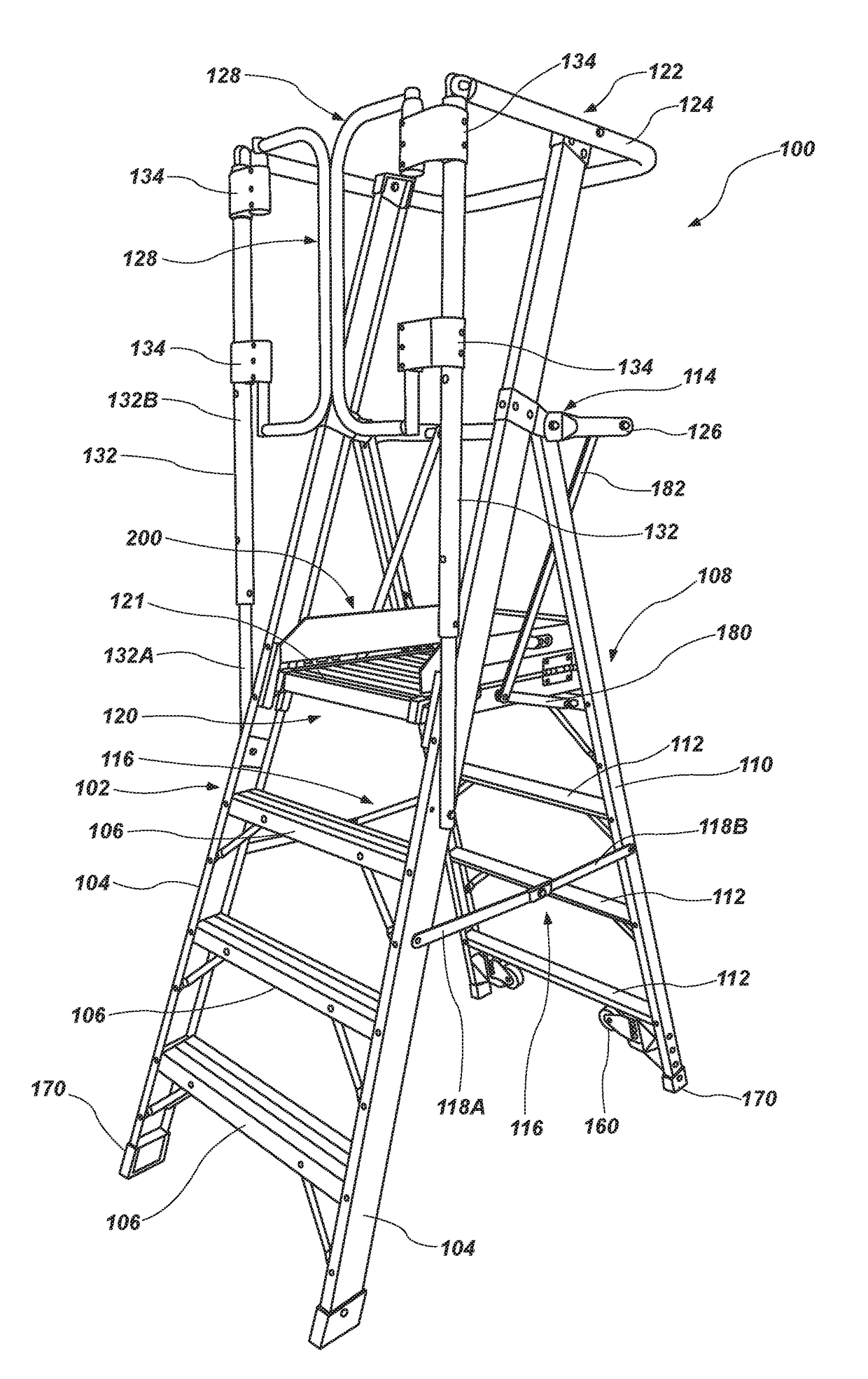

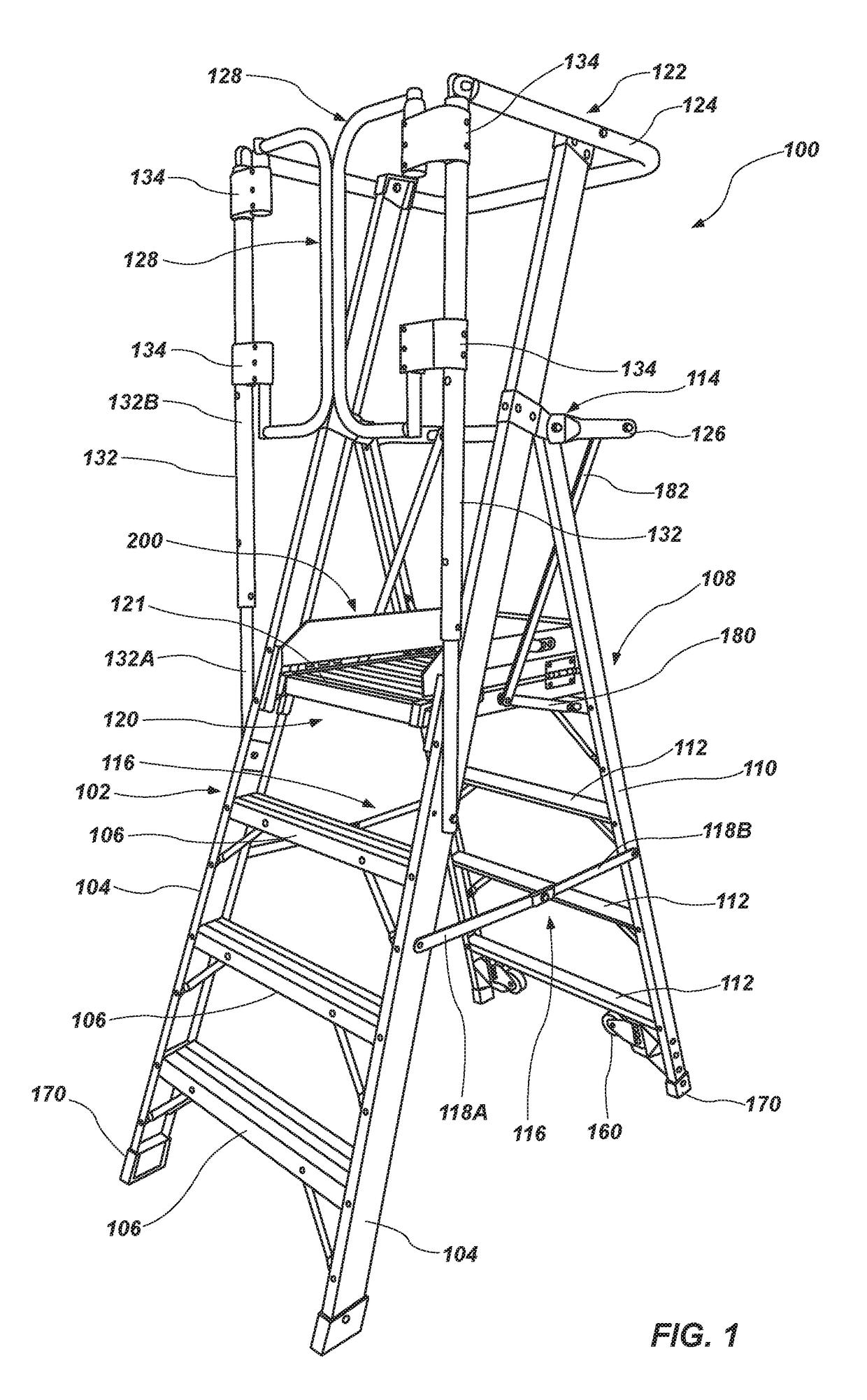

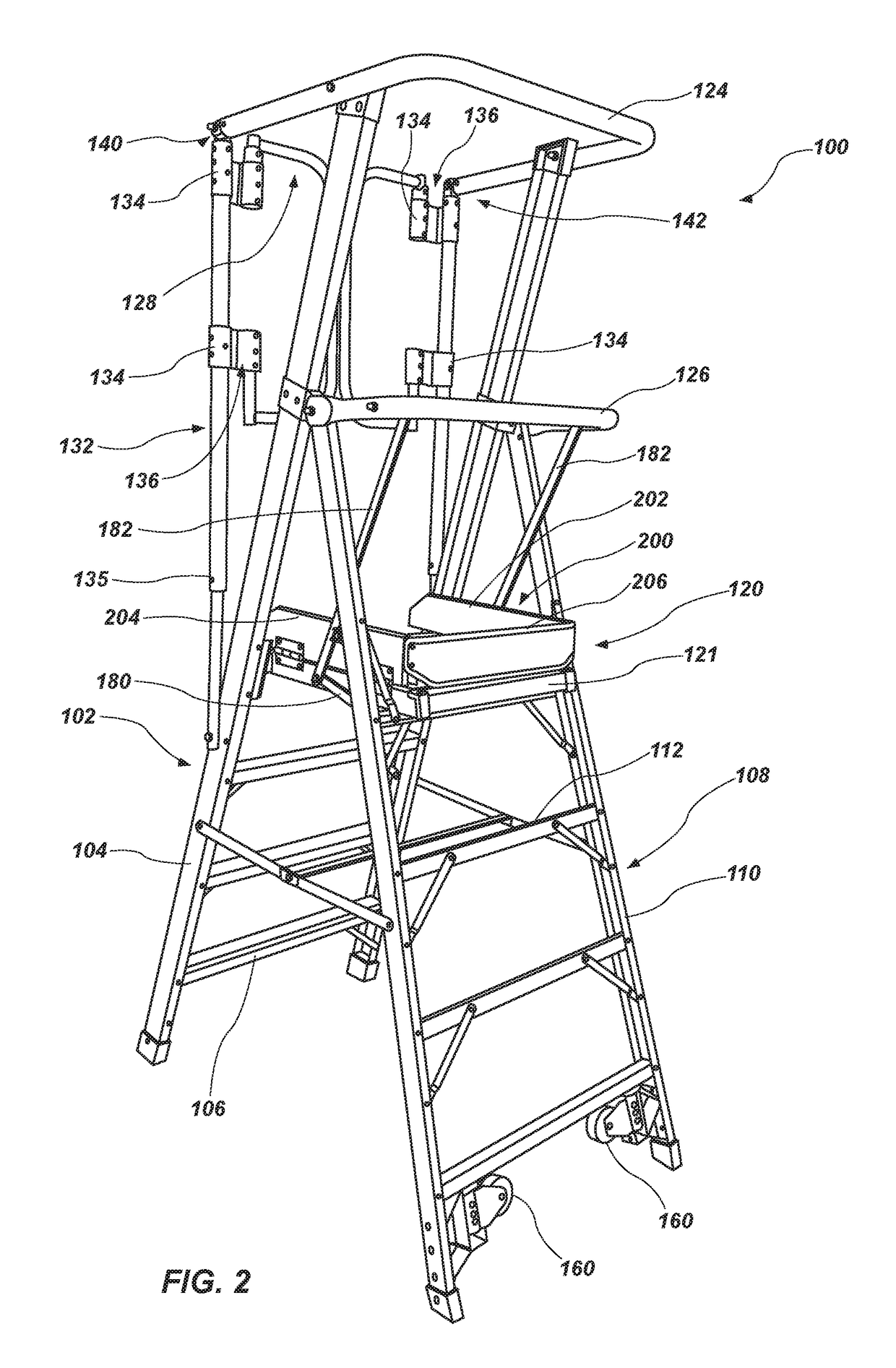

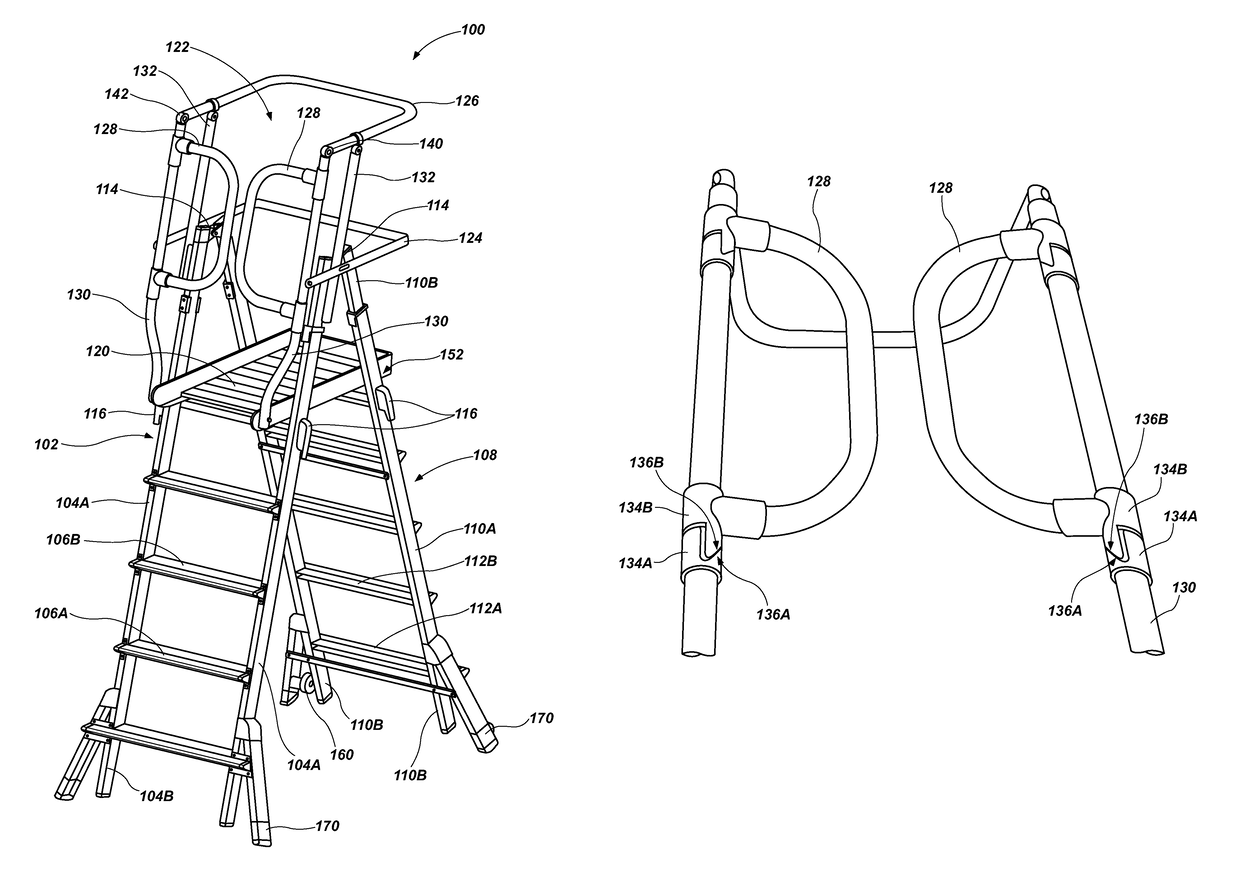

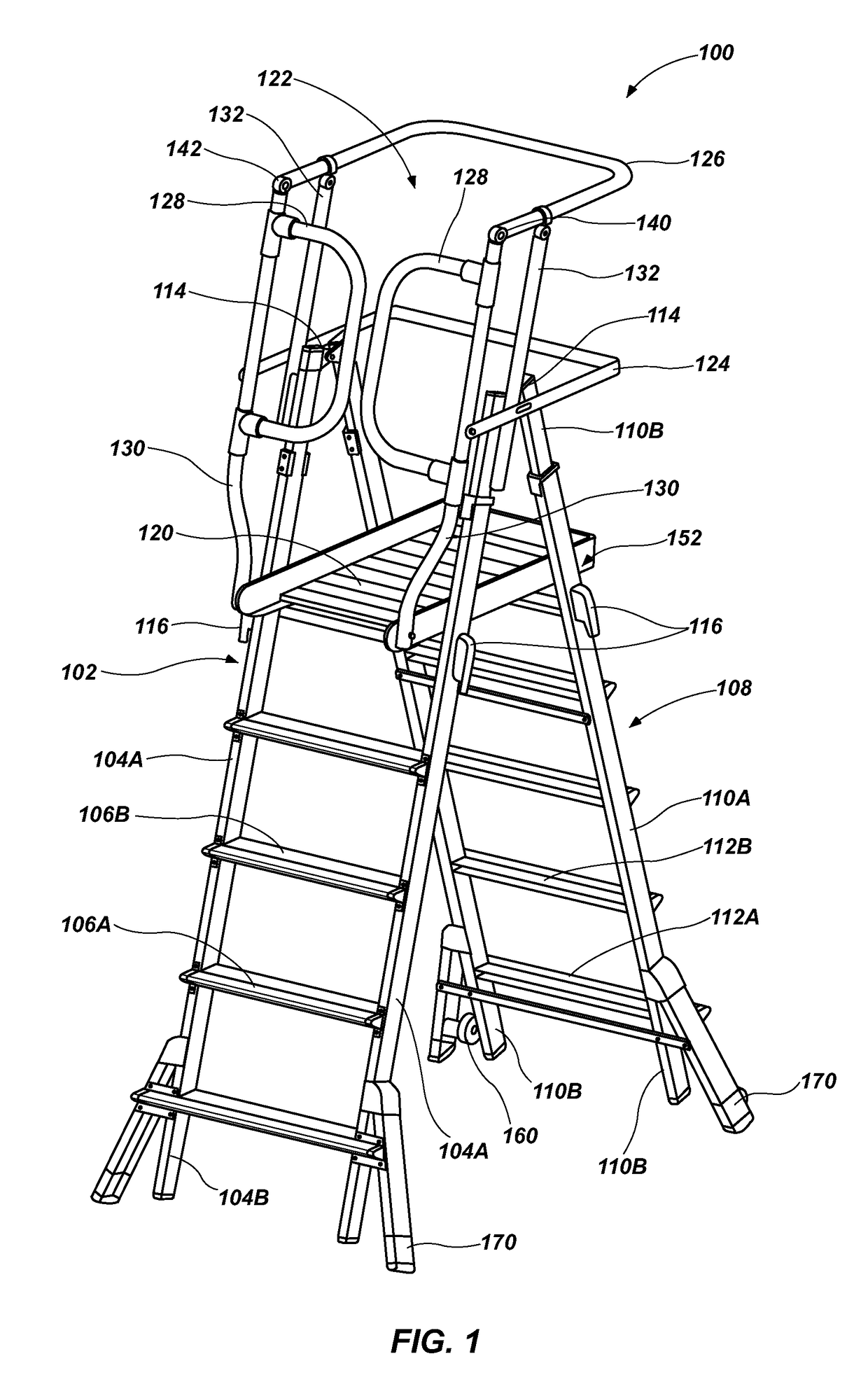

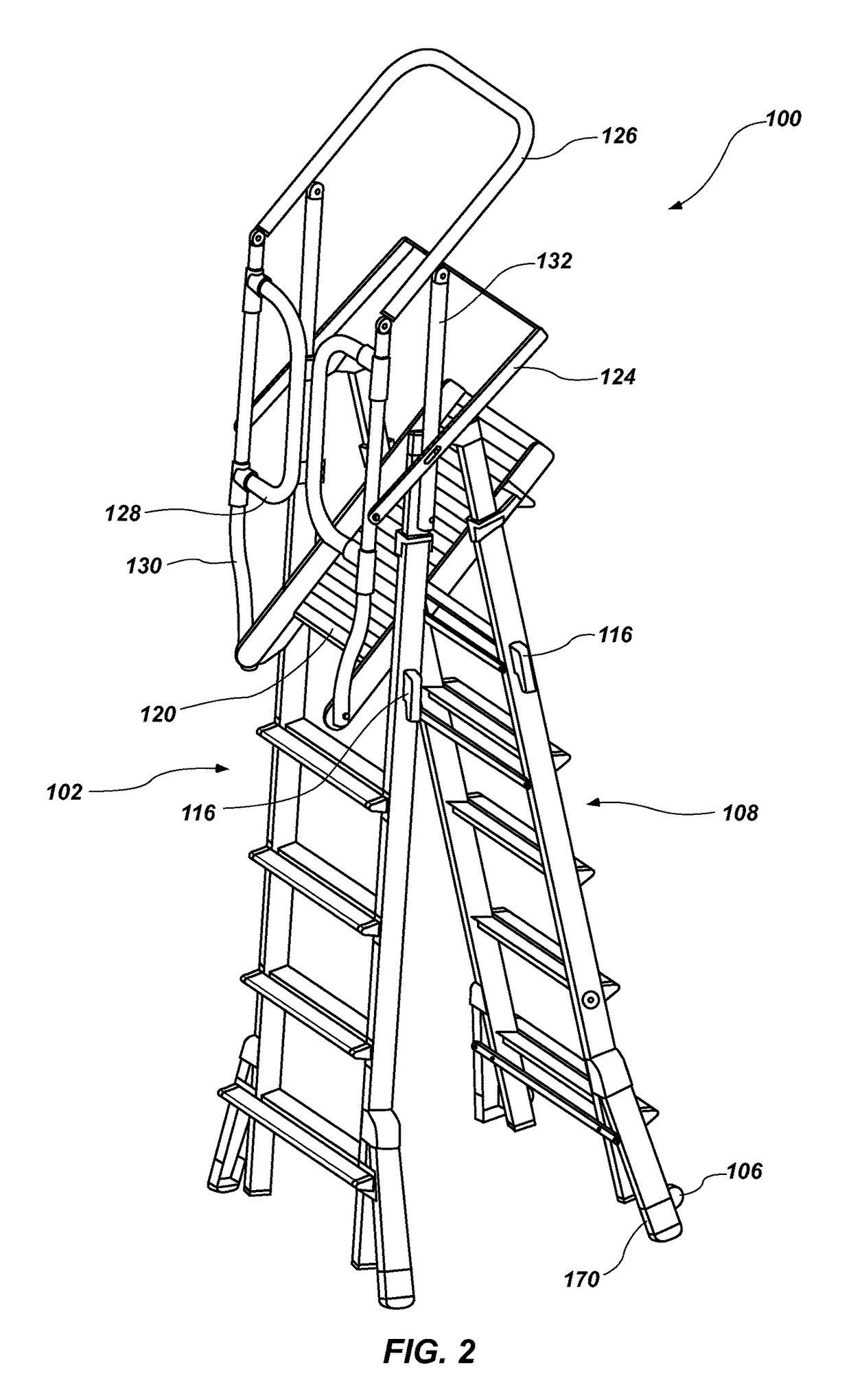

Elevated working platform and related methods

ActiveUS20130186710A1Safe working environmentIncrease surface areaLaddersEngineeringMechanical engineering

Elevated work platforms, as well as associated methods, are provided. In one particular embodiment, an elevated platform apparatus is provided comprising a first rail assembly having a pair of rails coupled with a plurality of rungs, a second rail assembly hingedly coupled with the first rail assembly, a platform configured to rest upon a portion of the first rail assembly and the second rails assembly and a cage associated with the platform. The cage may include at least one bar and at least one gate, the at least one gate being configured to swing in a first direction upon a user stepping on to the platform from the first rail assembly, and then swing back to a closed position after the user is standing on the platform. The at least one gate is also limited from being displaced in a second direction, opposite the first direction, beyond the closed position.

Owner:LITTLE GIANT LADDER SYST LLC

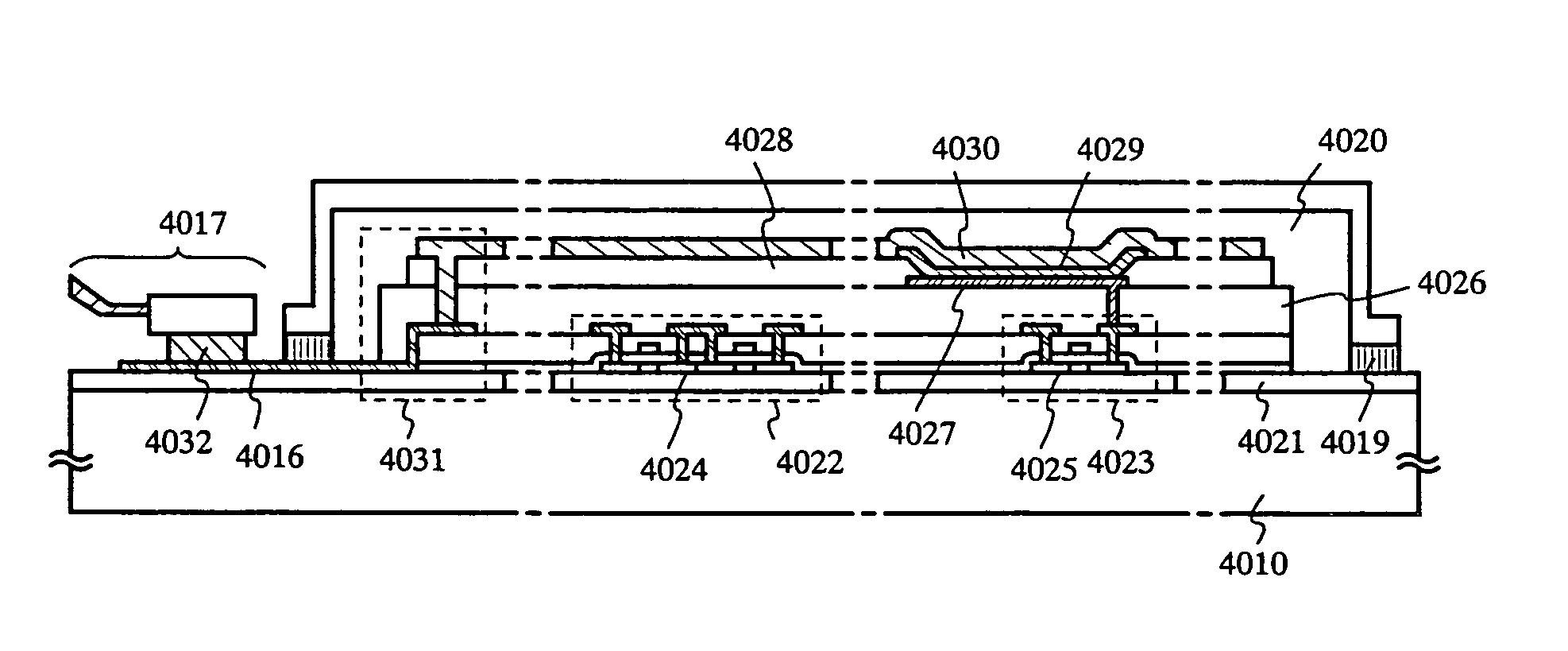

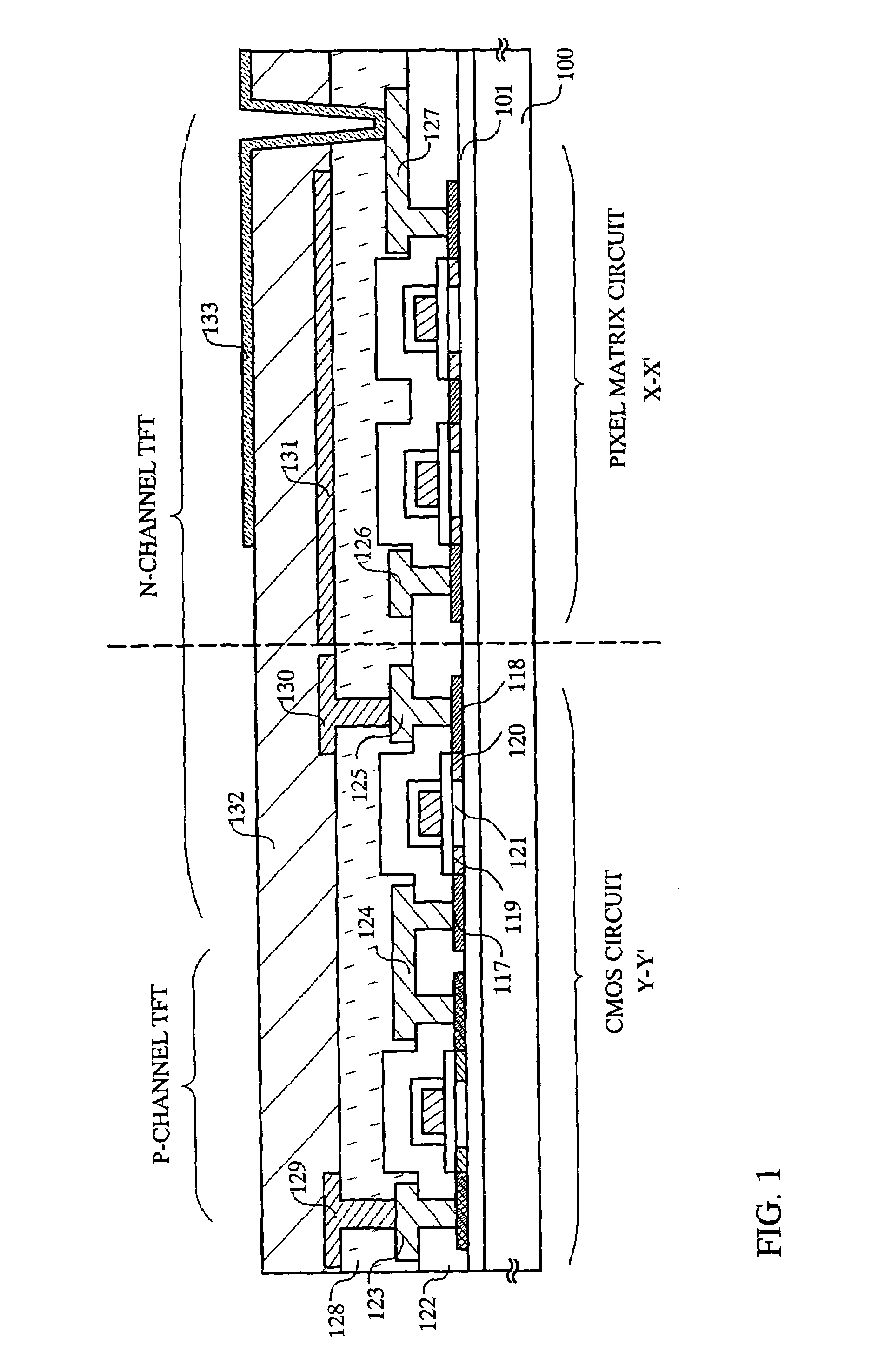

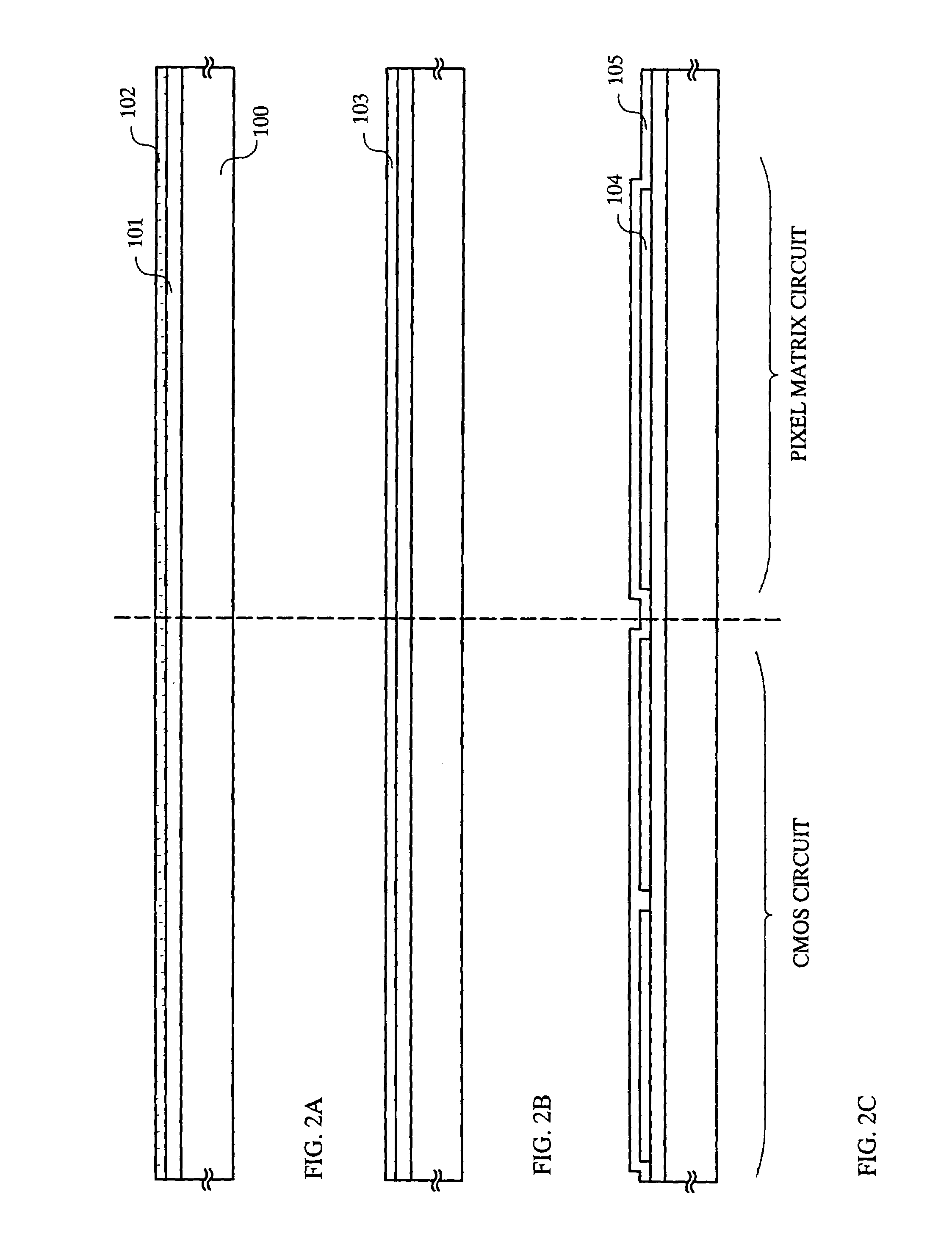

Semiconductor device having El layer and sealing material

InactiveUS7126161B2Increase production capacityImprove security levelDischarge tube luminescnet screensLamp detailsDevice materialEngineering

In the present invention, a semiconductor film is formed through a sputtering method, and then, the semiconductor film is crystallized. After the crystallization, a patterning step is carried out to form an active layer with a desired shape. The present invention is also characterized by forming a semiconductor film through a sputtering method, subsequently forming an insulating film. Next, the semiconductor film is crystallized through the insulating film, so that a crystalline semiconductor film is formed. According this structure, it is possible to obtain a thin film transistor with a good electronic property and a high reliability in a safe processing environment.

Owner:SEMICON ENERGY LAB CO LTD

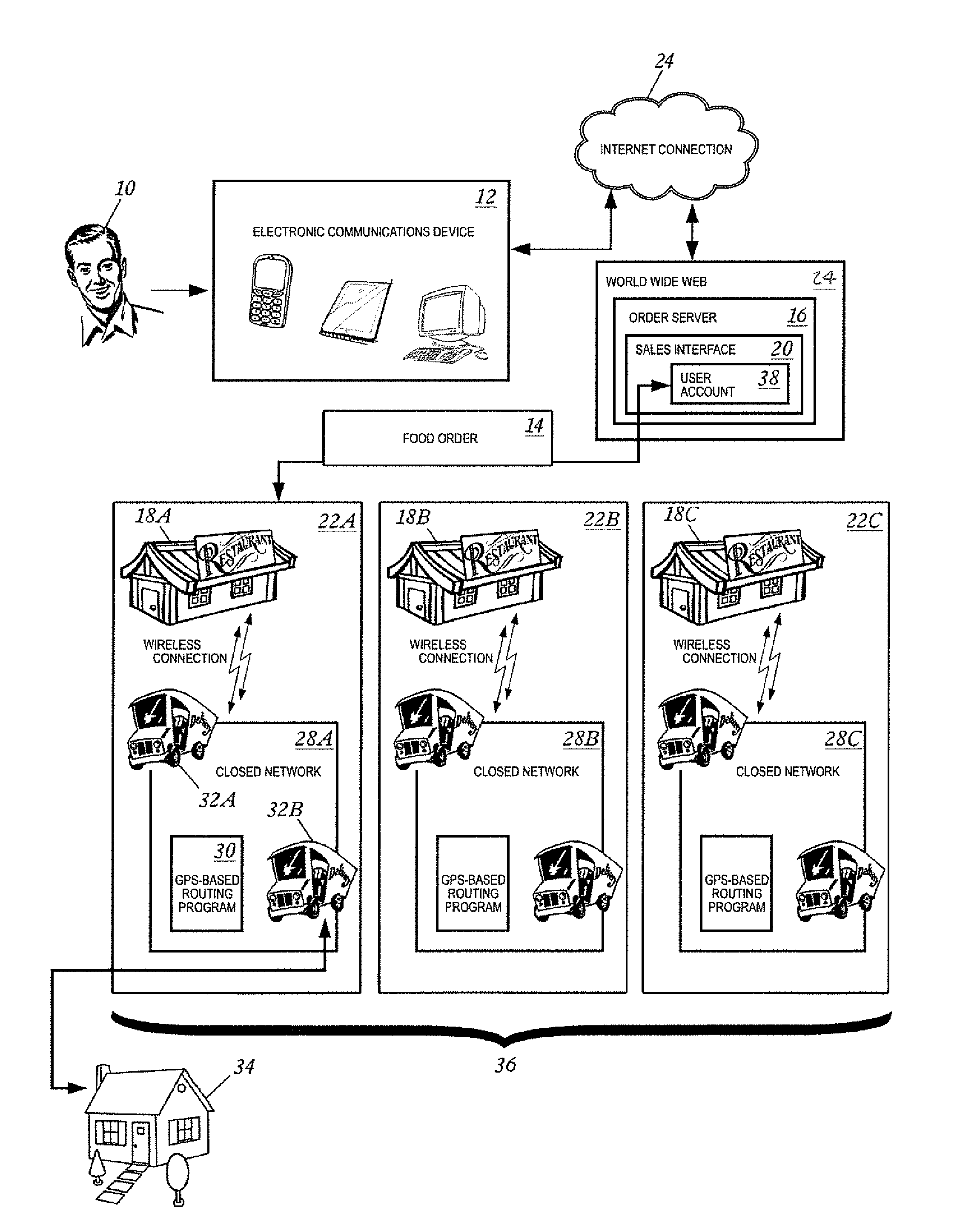

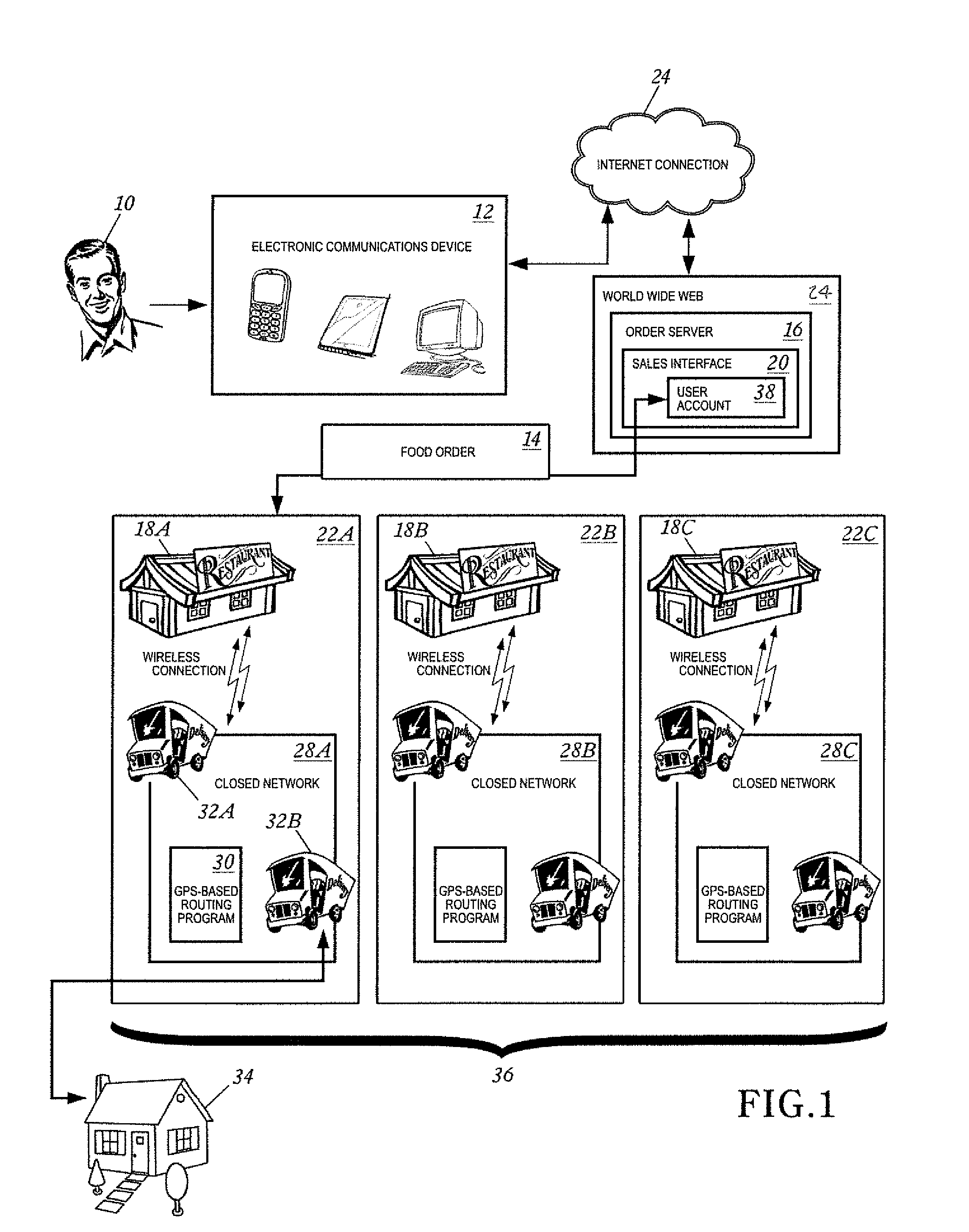

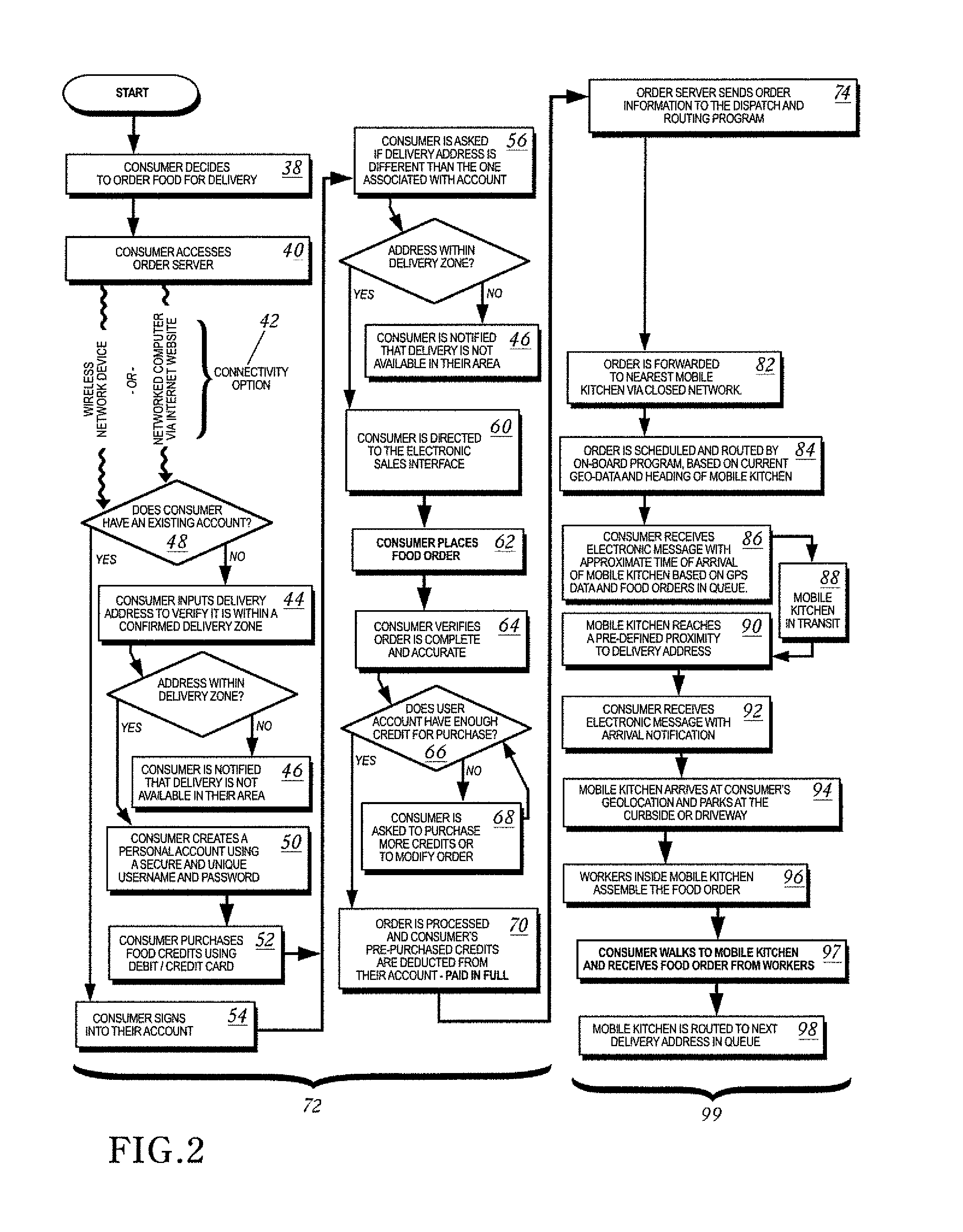

System and method for improving safety and efficiency of delivery services

ActiveUS20150170099A1Improve efficiencyImprove reliabilityInstruments for road network navigationSatellite radio beaconingOnboard computerDelivery system

An order and delivery system to be deployed over a regional delivery area includes a business within the regional delivery area, and a mobile storefront that includes stored inventory and operates within the regional delivery area. An order server receives orders from a consumer, then determines the consumer's location, verifies that the consumer's location is within the regional delivery area, and sends the order to the mobile storefront. The mobile storefront includes an onboard computer that receives the order from the order server, evaluates a current location and heading of the mobile storefront, prioritizes the order against other orders in queue, determines navigation and routing, estimates a time of arrival (ETA) to the consumer's location, and communicates the ETA to the consumer. The mobile storefront receives the order and facilitates preparation of the order with its stored inventory for delivery to the consumer at the consumer's location.

Owner:STREETLOGIC NETWORK INC

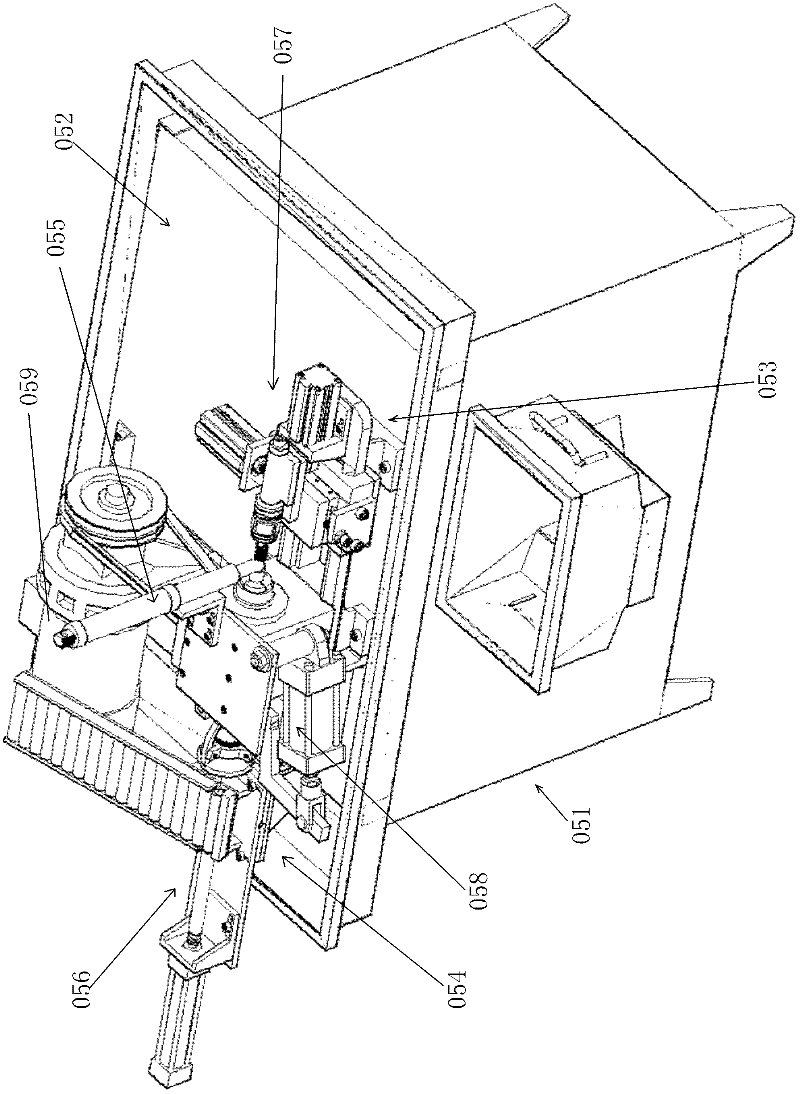

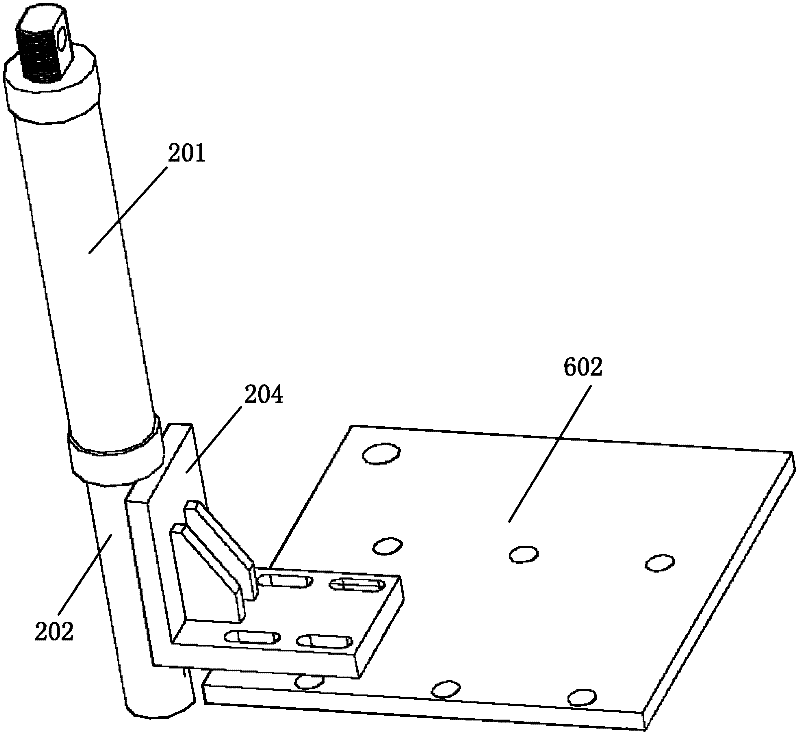

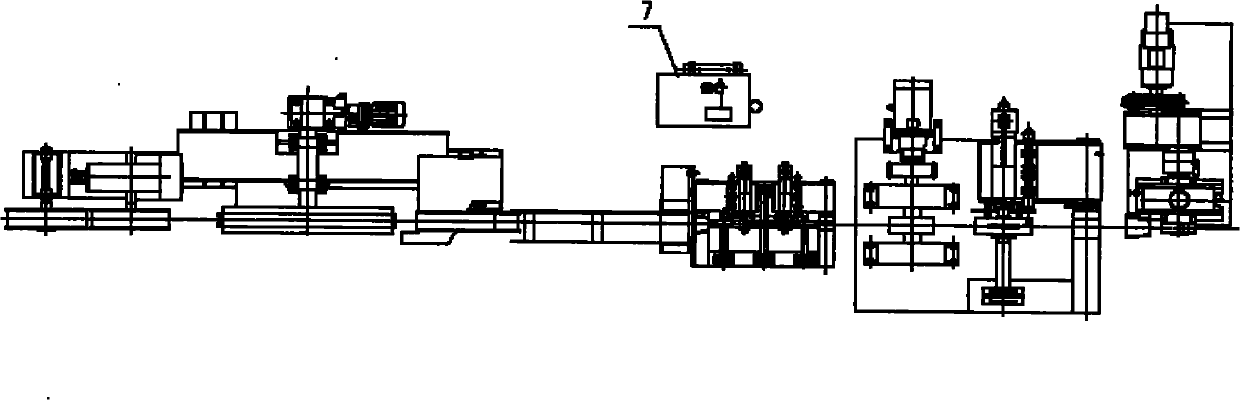

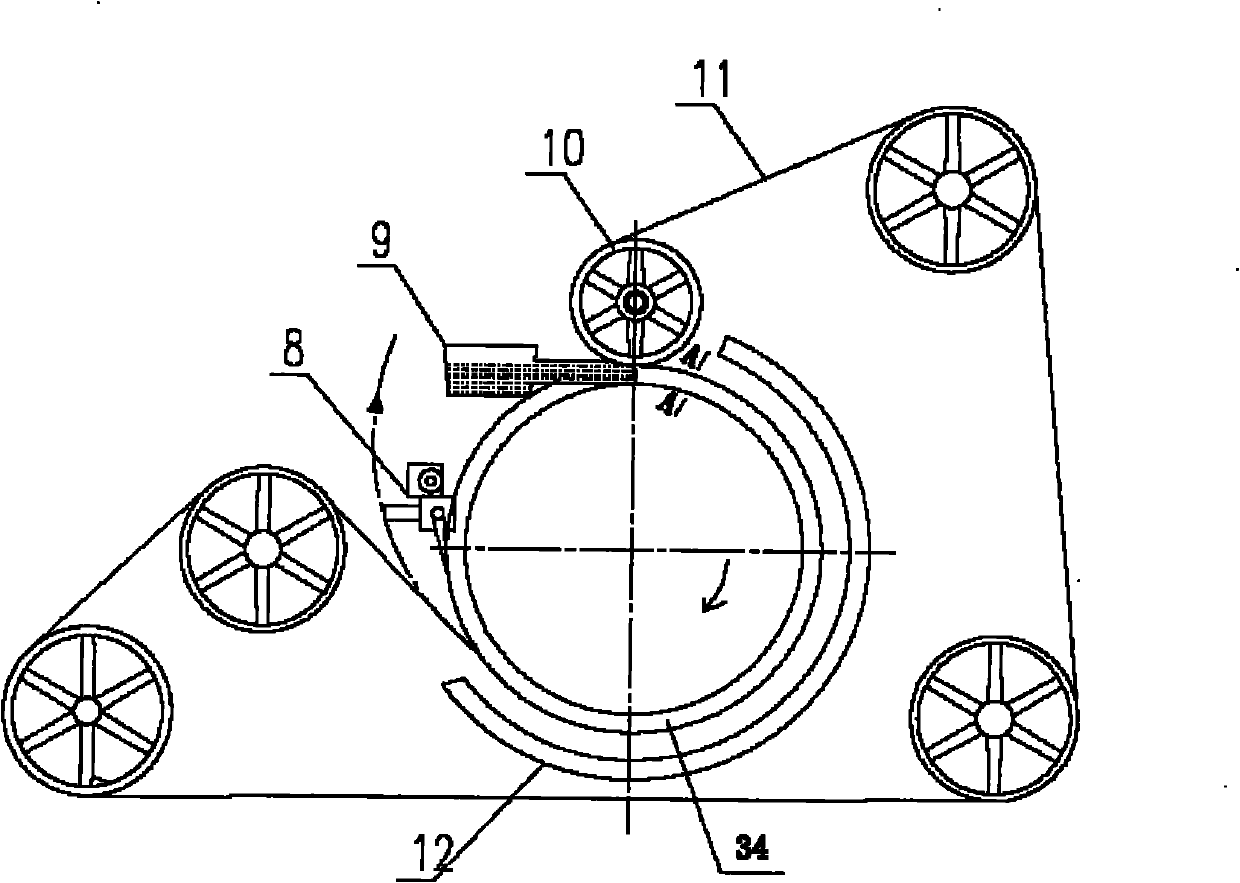

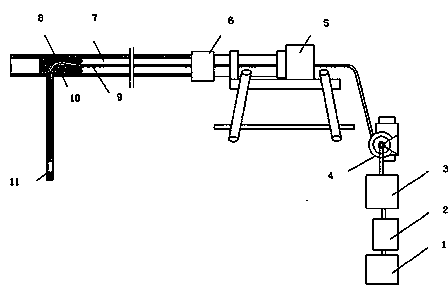

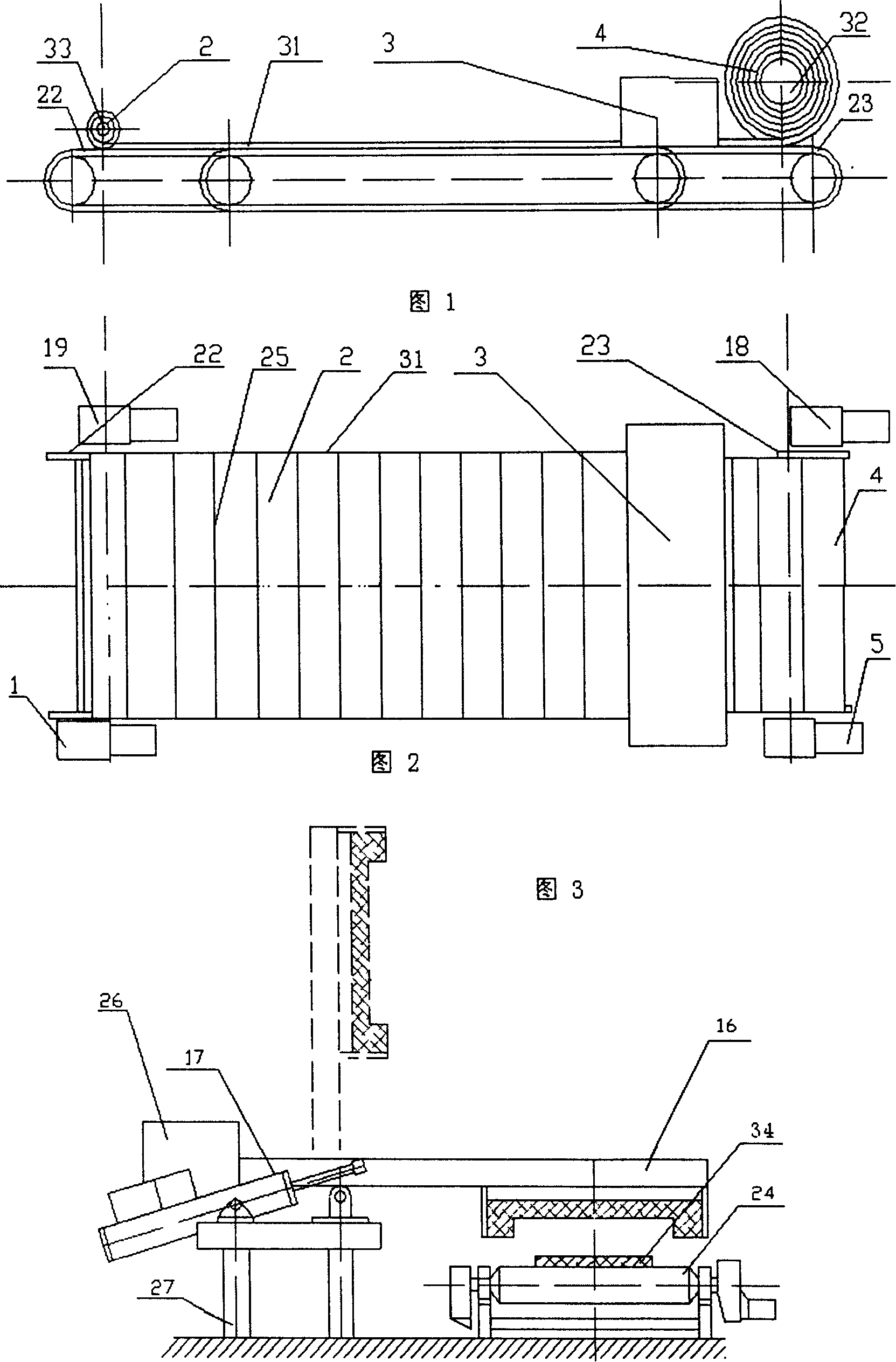

Automatic tapping machine

InactiveCN102310237AQuality improvementHigh precisionThread cutting feeding devicesThread cutting machinesProgrammable logic controllerEngineering

The invention discloses an automatic tapping machine and relates to a processing device used for processing internal screw threads. The automatic tapping machine disclosed by the invention comprises a PLC (Programmable Logic Controller) control circuit, a machine base 051, a marble slab 052, an instrument lathe 053, a positioning adjustment device 054, a limiting device 055, a feed device 056, a tapping device 057, a clamping device 058 and a deceleration motor 059, wherein the marble slab is arranged on the machine base, the positioning adjustment device and the instrument lathe are fixed onthe marble slab, and the deceleration motor is arranged at one side of the instrument lathe. Being controlled by the PLC control circuit, the feed device quickly conveys workpieces, the limiting device ensures the workpieces to be accurately clamped, and the tapping device completes the accurate positioning of screw taps and is matched with the clamping device to complete the tapping process. Theinvention aims to provide the automatic tapping machine to solve the technical problem that manual intervention is needed in the processes of feeding, positioning, clamping, tapping and loosening, and through the invention, the processing speed and the processing accuracy are improved.

Owner:莱州市山普管件制造有限公司

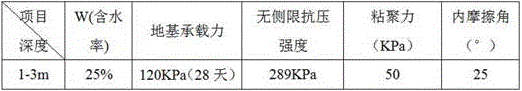

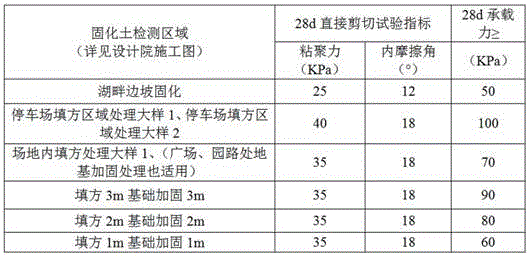

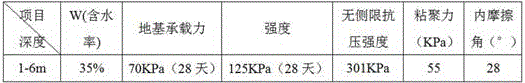

Silt solidification soil construction technology

The invention discloses a silt solidification soil construction technology which comprises the steps of surface cleaning drainage, silt sampling, detection analysis, excavation stacking, stirring and mixing, filling and grinding and stabilized soil maintenance. Through solidification soil in-situ solidification, silt and a curing agent are stirred and mixed to form silt solidification soil, and the curing agent is prepared through expanded graphite, activated carbon, cement, quick lime, gypsum, lignocelluloses, coal ash, granulated blast-furnace slag powder, coal gangue, caustic dross, hydroxypropyl methyl celluloses, furfural residues, medical stone and smectite clay. By means of the silt solidification soil construction technology, original flowing high-water-content low-strength high-compressibility silt is converted into high-compressive-strength excellent-entire-board-performance, good-durability and environment-friendly solidification soil, and the requirement of shallow ground earthwork materials for roads, storage yards, ports, reclamation projects, afforesting and the like can be met.

Owner:福建港湾岩土工程集团有限公司

Moving head dough press

A reciprocating press is configured to press articles while moving in synchronicity with a conveyor belt carrying the articles. The press is driven through a rack and pinion system. The press can be used for pressing any type of article, including, but without limitation, pieces of dough for forming tortillas.

Owner:MATTIAS SCOTT +1

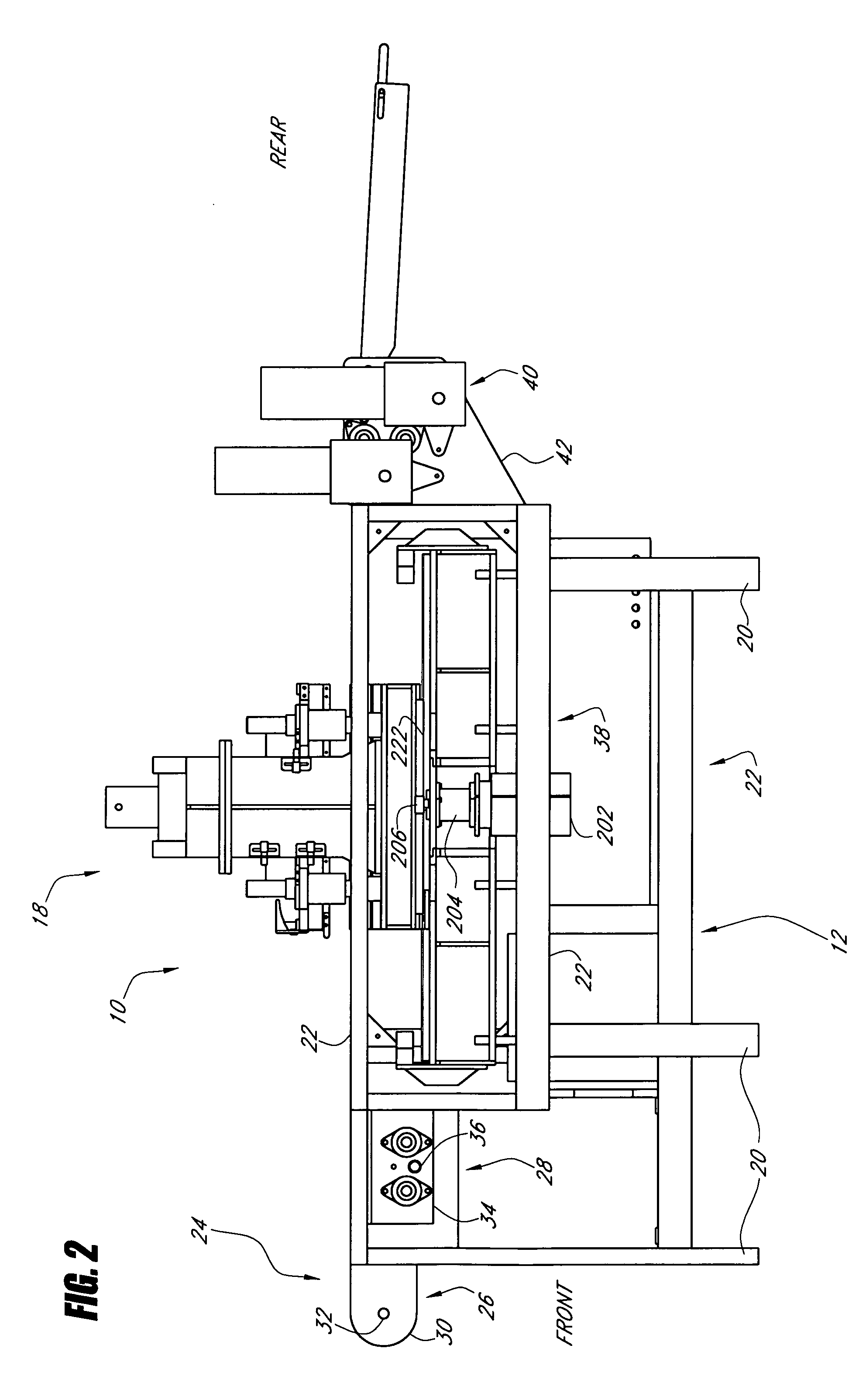

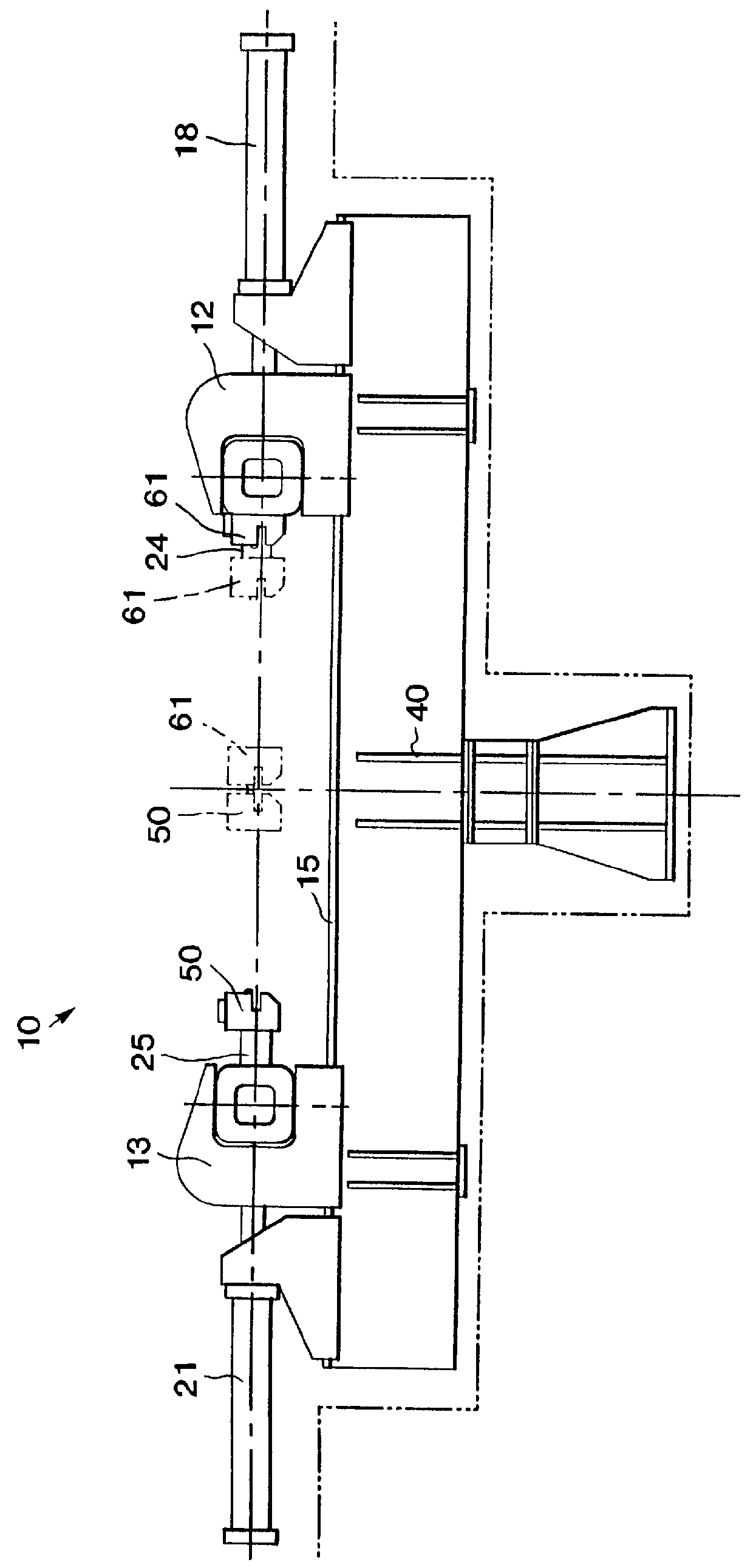

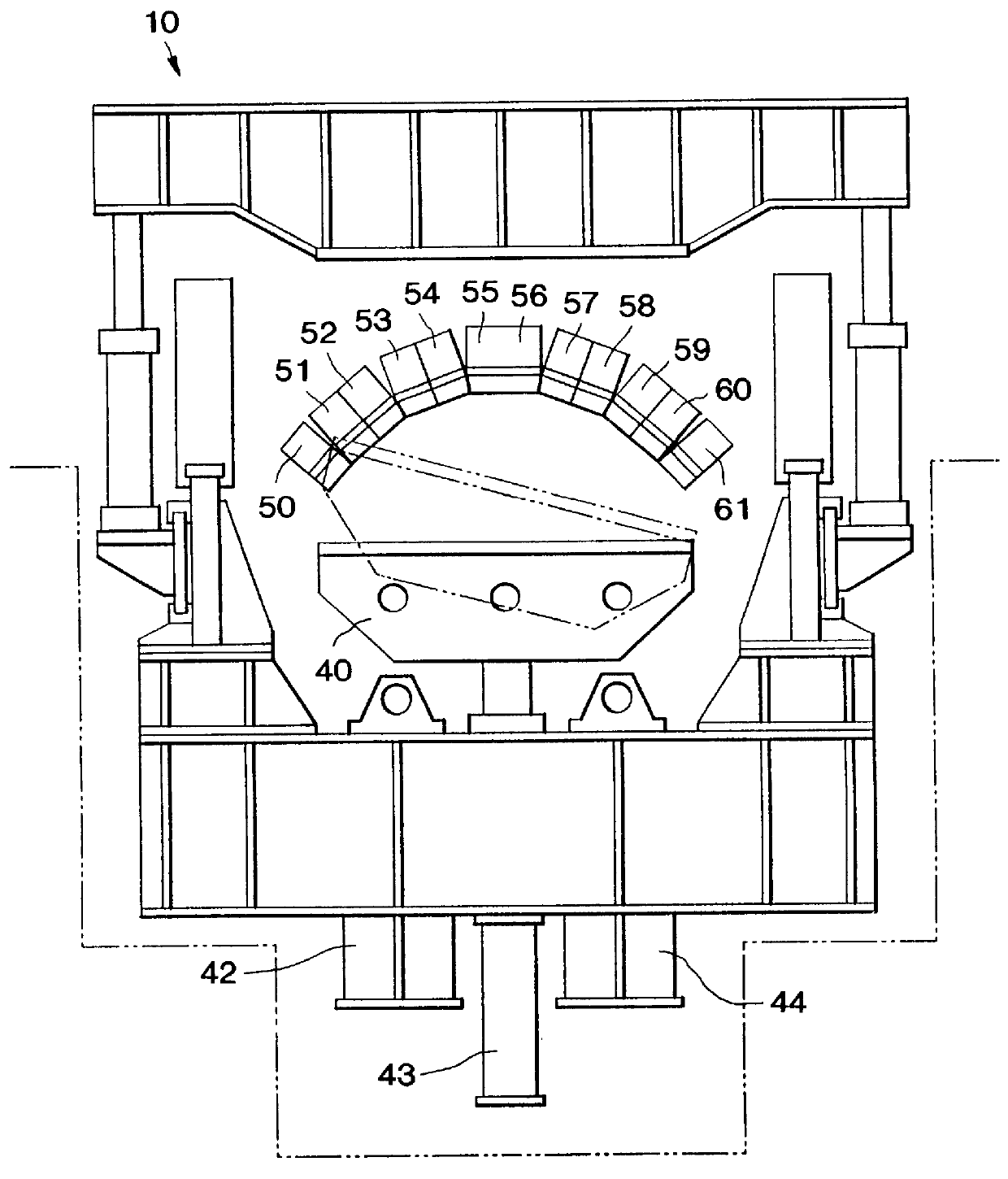

Stretch-forming machine with servo-controlled curving jaws

InactiveUS6018970AQuicker and precise machine set-upSafe working environmentMetal-working feeding devicesShaping safety devicesHydraulic cylinderClosed loop

A stretch-forming machine of the type wherein a pair of opposed curving jaws grips opposing ends of a metal sheet to be stretch-formed in a curved configuration. Each of the jaws are formed of an array of adjacent grippers movable relative to each other by respective hydraulic cylinders to define a part of the curve of the jaw. The improvement to the stretch-forming machine which is the subject of this application comprises a closed-loop servo-control means for moving each one of the grippers into a predetermined position relative to each other. Each of the servo-control means comprises a hydraulic cylinder position controller carried by the hydraulic cylinder of the one gripper for controlling hydraulic fluid flow to the hydraulic cylinder responsive to stored data representing the desired predetermined position of one of the grippers. A motor is provided for actuating the position controller in response to the data received by the position controller to move the hydraulic cylinder. Hydraulic cylinder position feedback means is positioned on the hydraulic cylinder for sensing the position of the hydraulic cylinder and communicating a signal representing the position of the hydraulic cylinder to the position controller.

Owner:CYRIL BATH

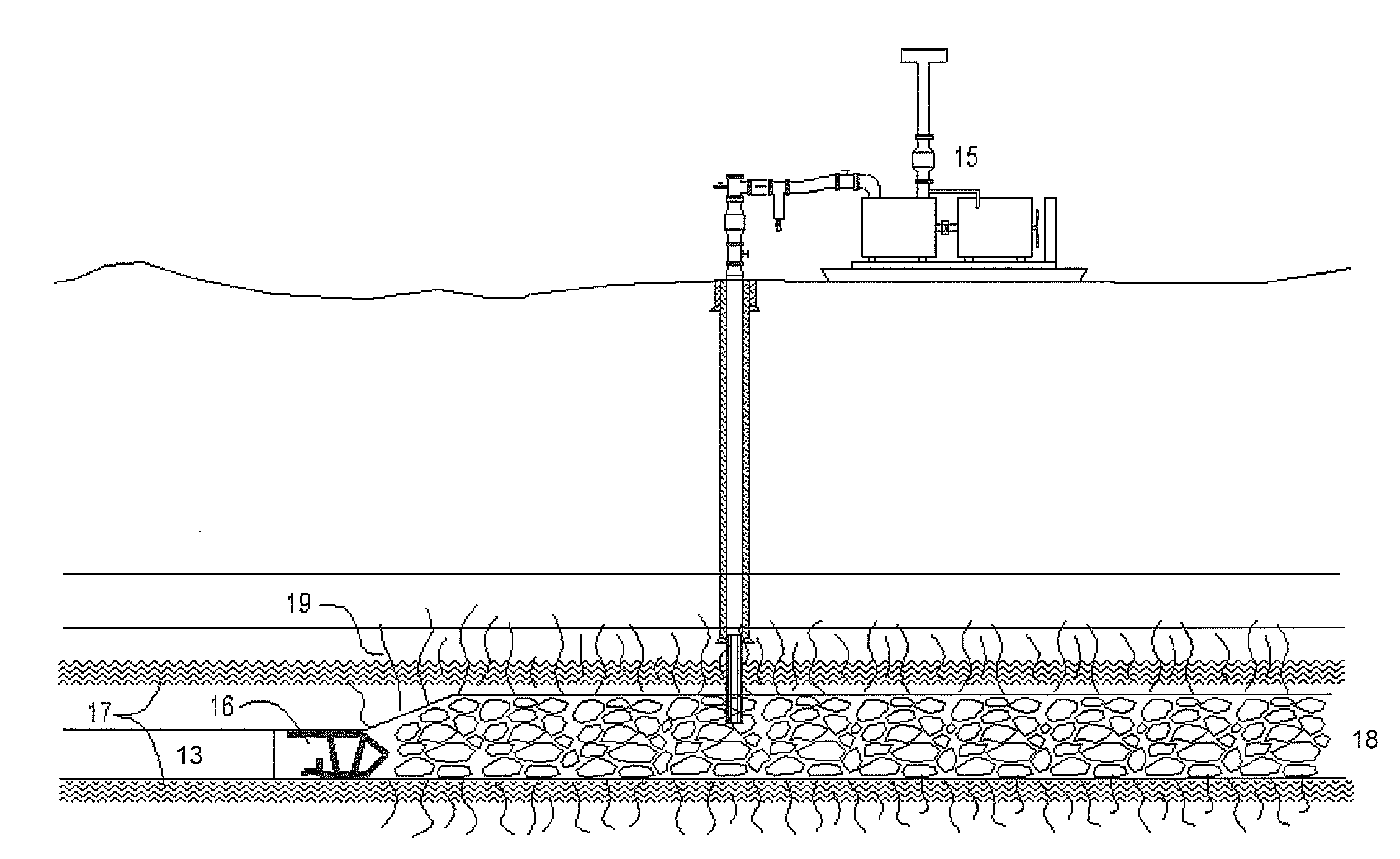

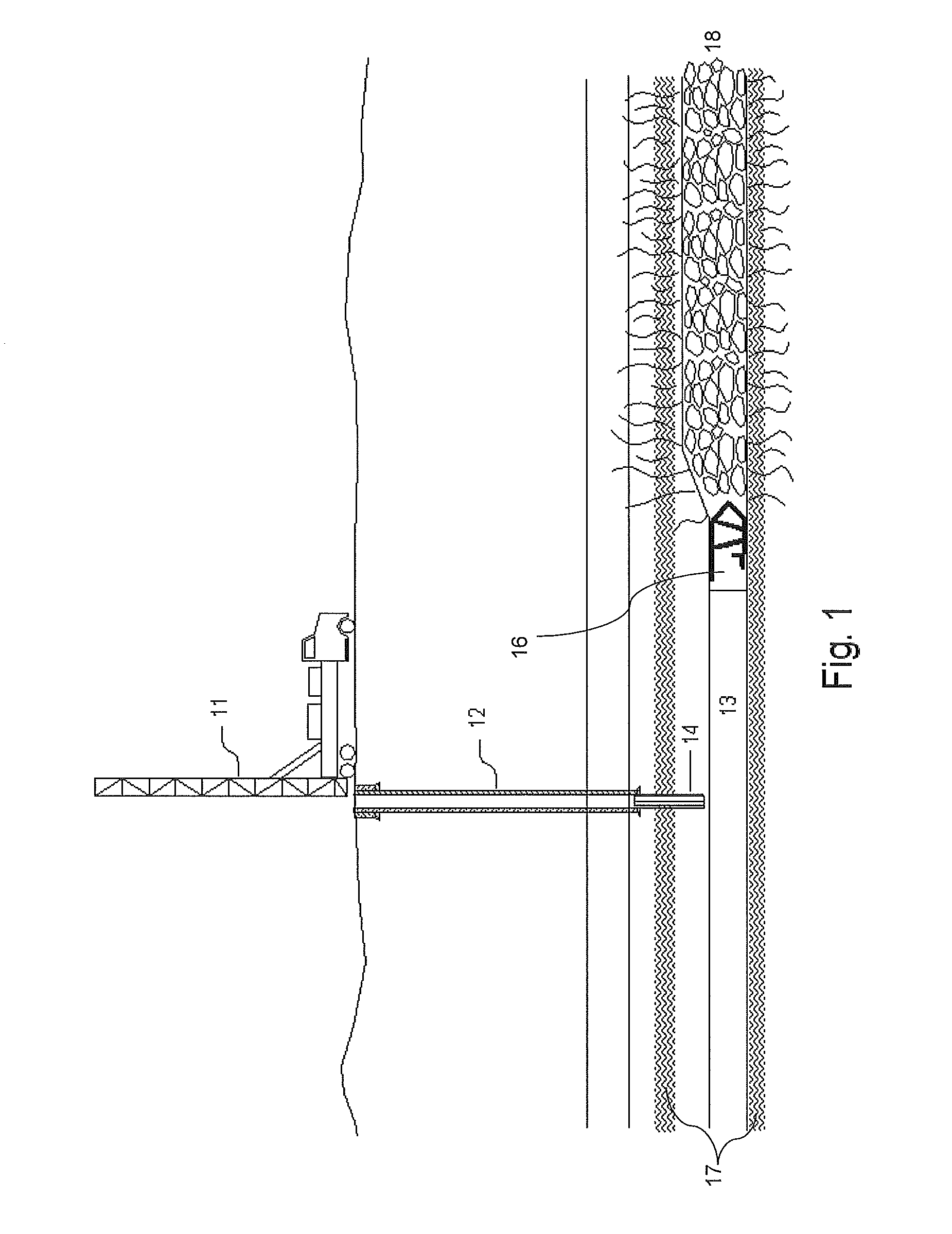

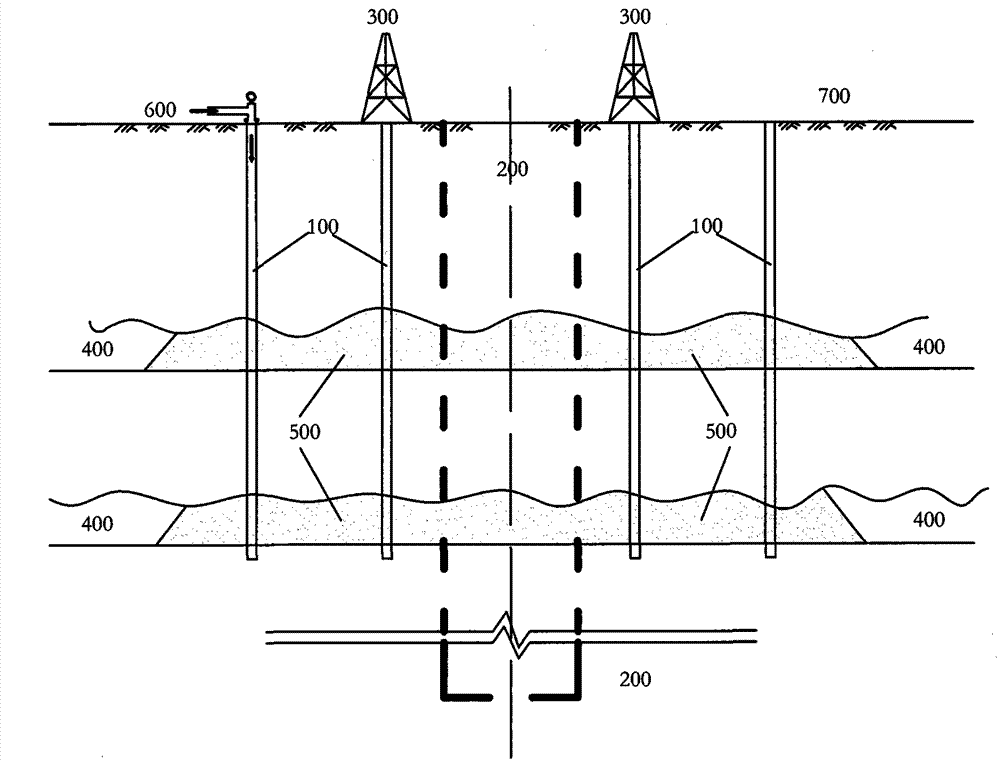

Mining method for co-extraction of non-combustible ore and mine methane

ActiveUS20090315388A1Safer working environment undergroundAvoid excessive dilutionDisloding machinesUnderground miningMineralogyMethane

Mining method for co-extraction of non-combustible ore and mine methane A method for co-extracting non-combustible ore (e.g., trona) and methane from an underground formation comprising at least one methane-bearing layer and a non-combustible ore bed having a rock roof, comprising:providing a well having a downhole end positioned above the ore bed roof;mining an ore region from an initial cavity and removing the mined ore, thereby creating a subsequent cavity;advancing the mining step to another ore region from the subsequent cavity;allowing the roof of the initial cavity to cave so as to create a gob;repeating the mining, advancing and caving steps, the caving being effective in generating fluid communication between the gob and the well downhole end and in fracturing the methane-bearing layer so as to release methane into the gob; andrecovering a gob gas comprising released methane through the well to the surface.

Owner:SOLVAY CHEM INC

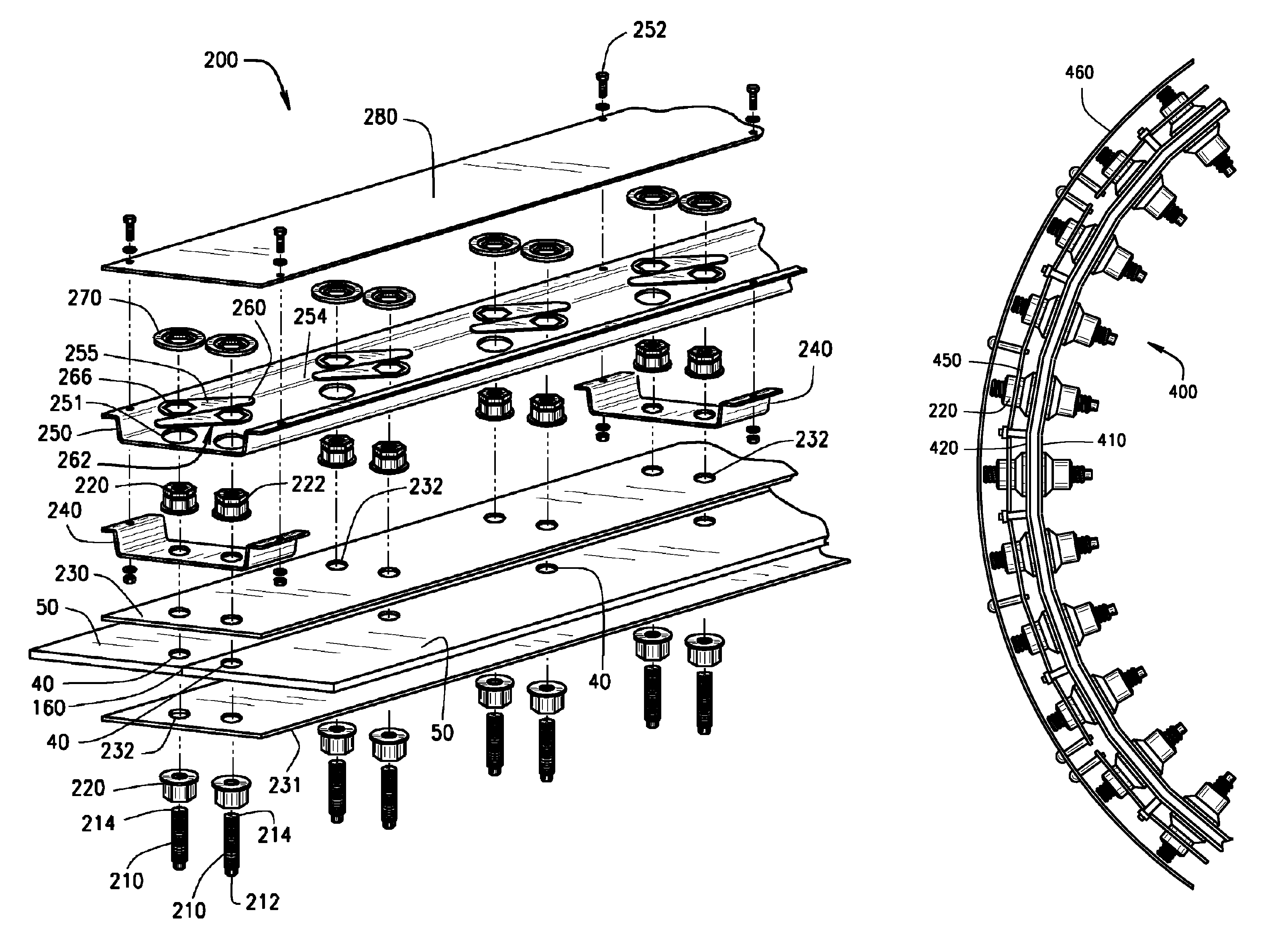

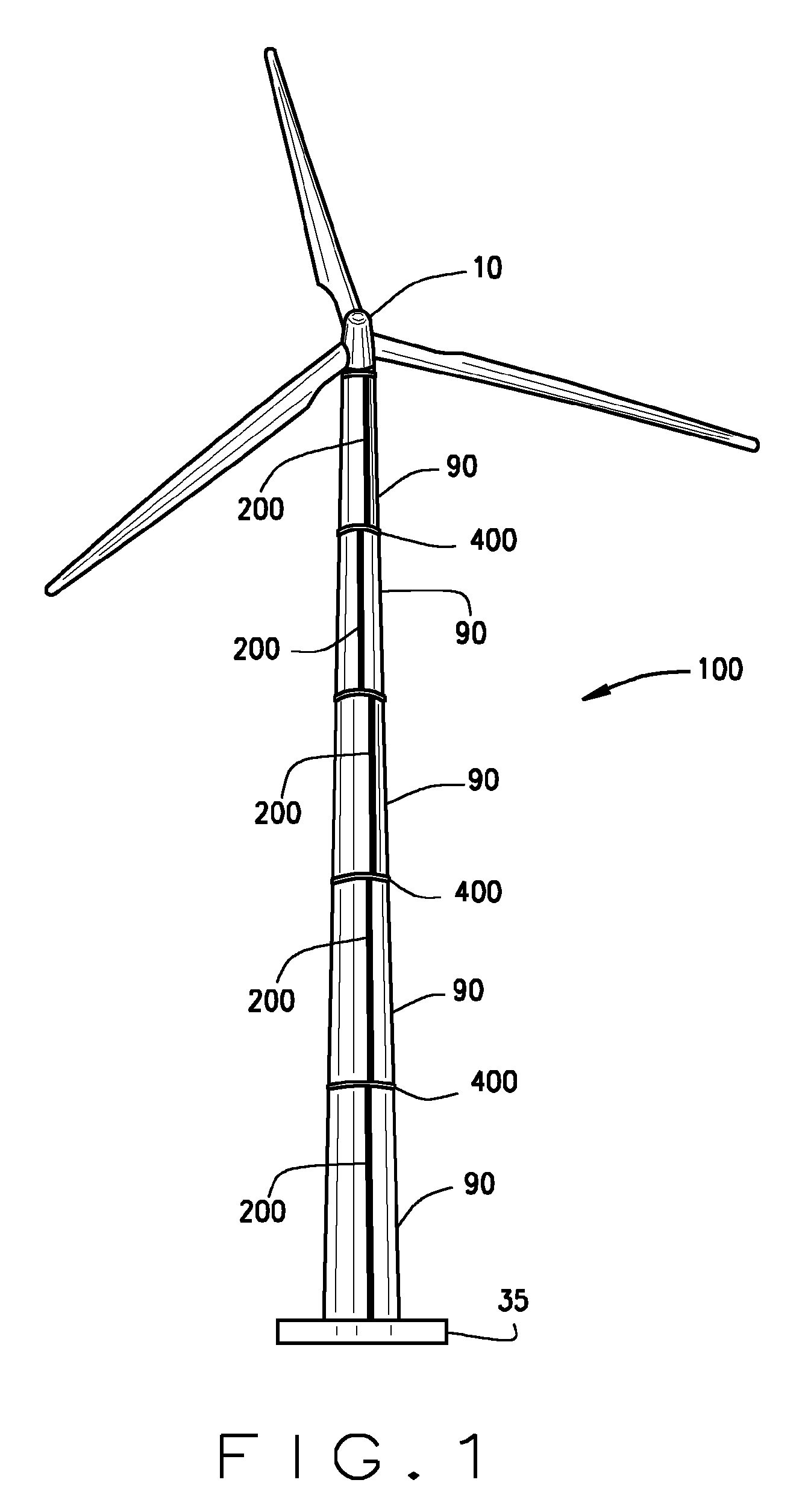

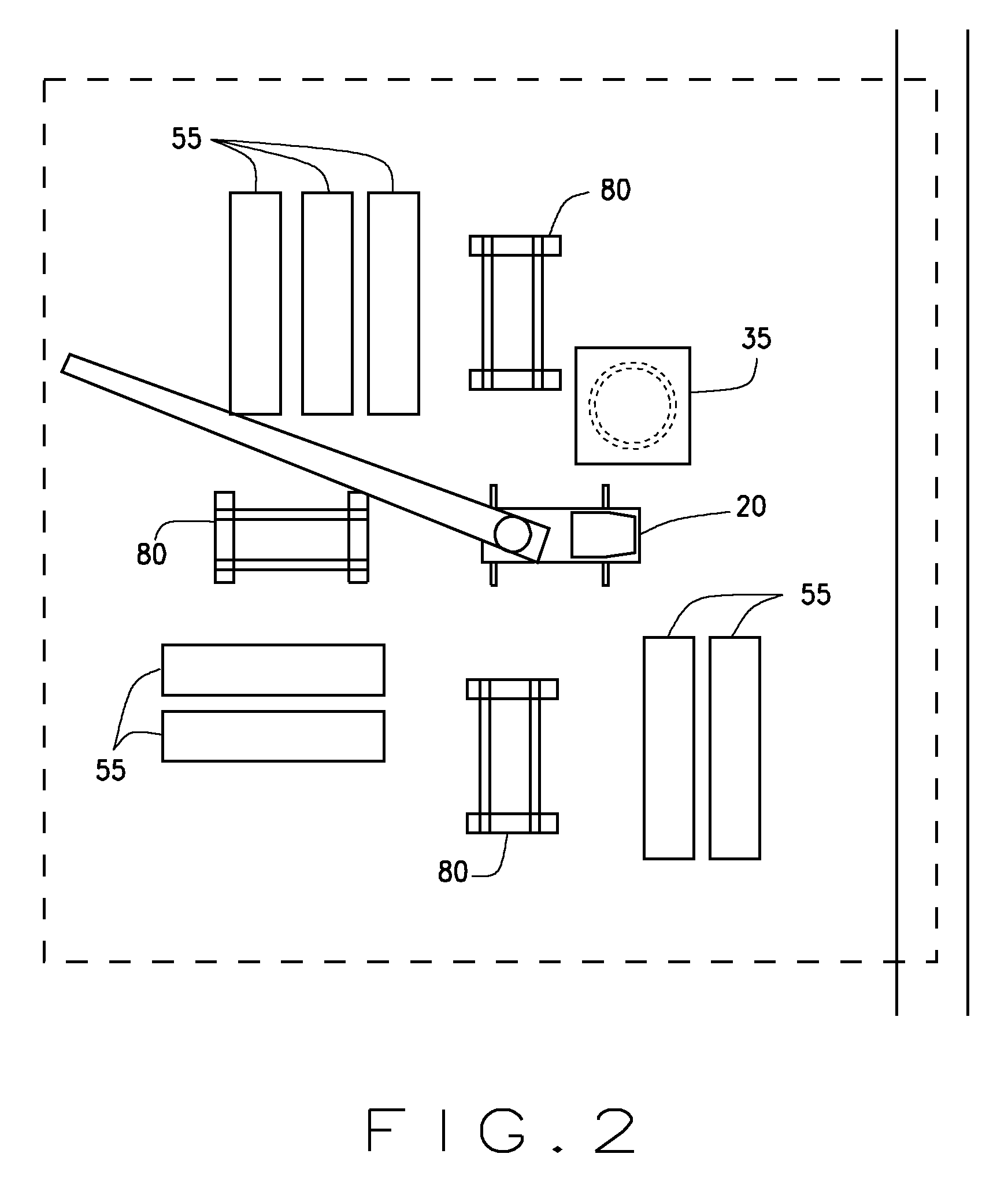

Tower structure and method of assembling

ActiveUS8136329B2Reduce the amount requiredCost-effectiveWind motor assemblyBuilding repairsVertical edgeArcuate shape

A modular tower structure is described herein. The modular tower uses a cost-effective, efficient design that reduces the amount of steel necessary for tower structures for wind turbines. The modular tower is constructed from sections. The sections are constructed from panels. The panels comprise a curved or arcuate shape. The panels include vertical edges and horizontal edges. A vertical connection connects or secures the panels at the vertical edges of the panels and forms the sections. The sections have a generally circular shape. The vertical connection includes an interior vertical friction plate positioned over a seam or gap between adjacent panels and an exterior vertical friction plate positioned over the seam or gap between adjacent panels. A horizontal connection connects or secures the sections at the horizontal edges of the panels. The horizontal connection comprises an interior friction plate that covers a seam or gap between the adjacent sections and an exterior friction plate that covers the seam or gap between the adjacent sections.

Owner:NORTHSTAR ENDEAVORS

Enrollment kiosk including biometric enrollment and verification, face recognition and fingerprint matching systems

ActiveUS9256720B2Easy to transportIncrease in costAcquiring/recognising eyesClosed circuit television systemsComputer moduleComputer terminal

An enrollment kiosk for collecting personal data includes a slidable main module and at least one modifiable section removably coupled to the main module. The main module includes a processor and one or more biometric sensing devices coupled to the processor. The one or more biometric sensing devices include a right fingerprint sensor coupled to the processor and a left fingerprint sensor coupled to the processor. The right fingerprint sensor is positioned a predetermined distance apart from the left fingerprint sensor. The at least one modifiable section includes at least one first input device coupled to the processor. The kiosk also includes a scene camera configured to record a video of an area surrounding the enrollment kiosk and to transmit the video to a remote operator being located remotely from the enrollment kiosk.

Owner:NEXTGENID

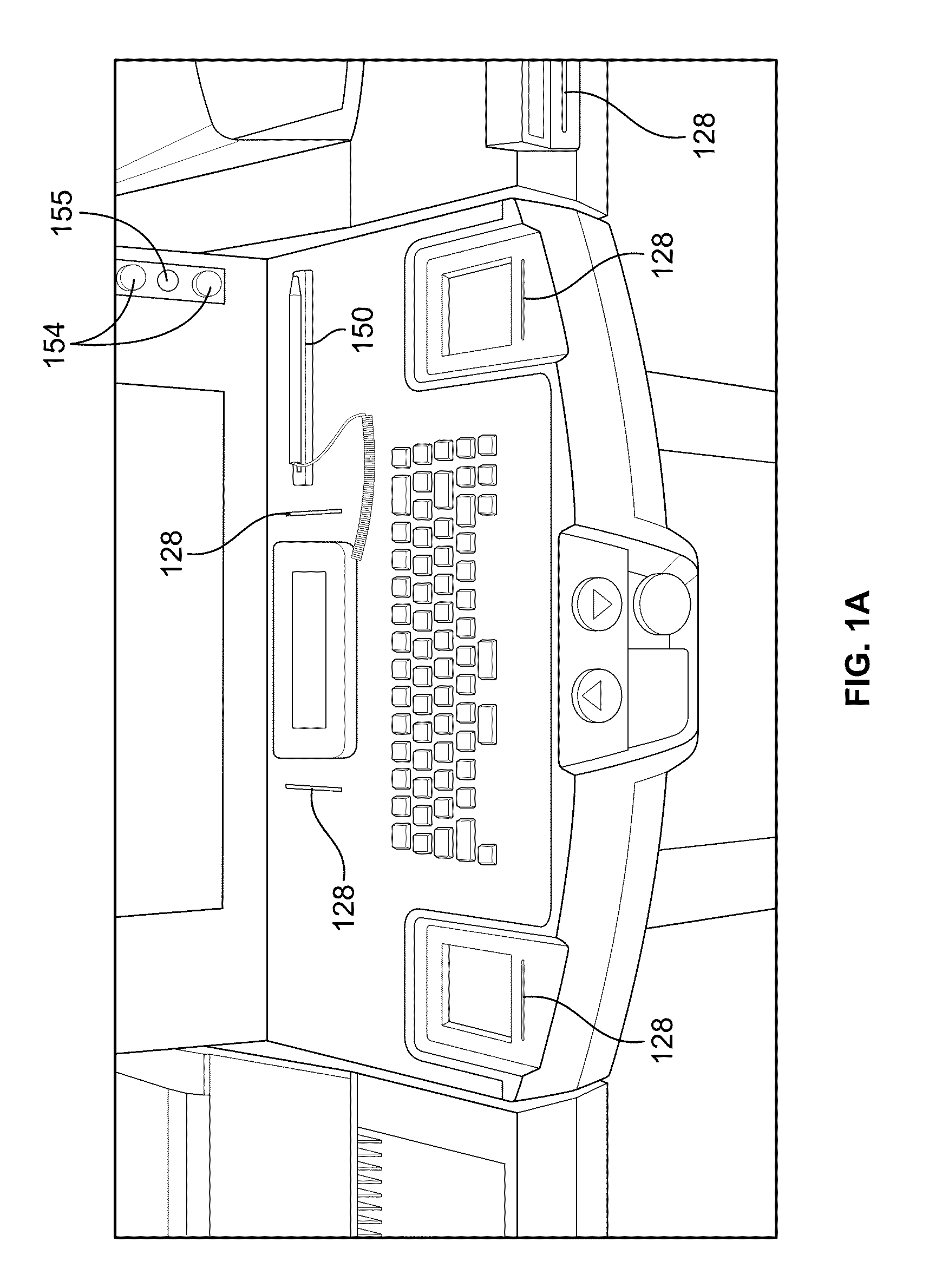

Self-cooled refrigerant recovery system

InactiveUS6158234ASafe working environmentVessel mounting detailsVessel geometry/arrangement/sizeRefrigerantEngineering

The refrigeration recovery system equips with a refrigerated container to cool the recovery tanks in order to have a desirable low pressure inside the recovery tank. This method is essential to accelerate the recovery speed and to achieve a complete recovery of refrigerants.

Owner:SZUTU HUI JEN

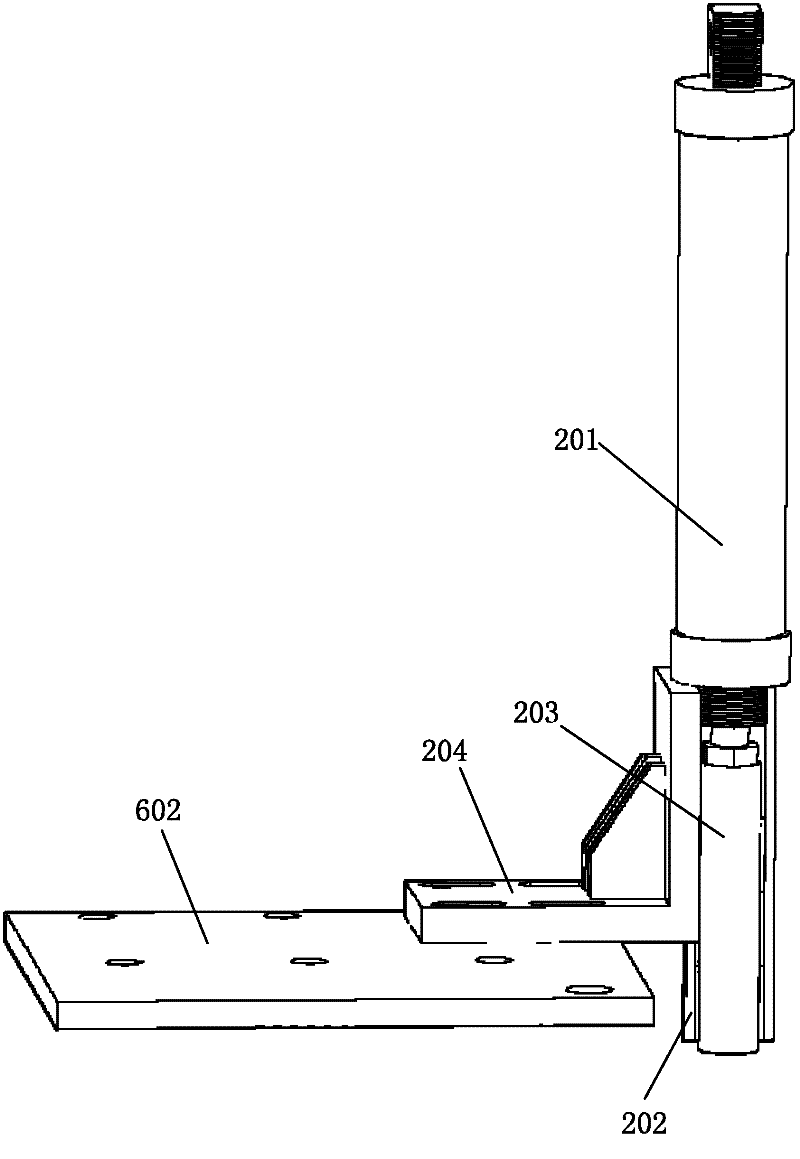

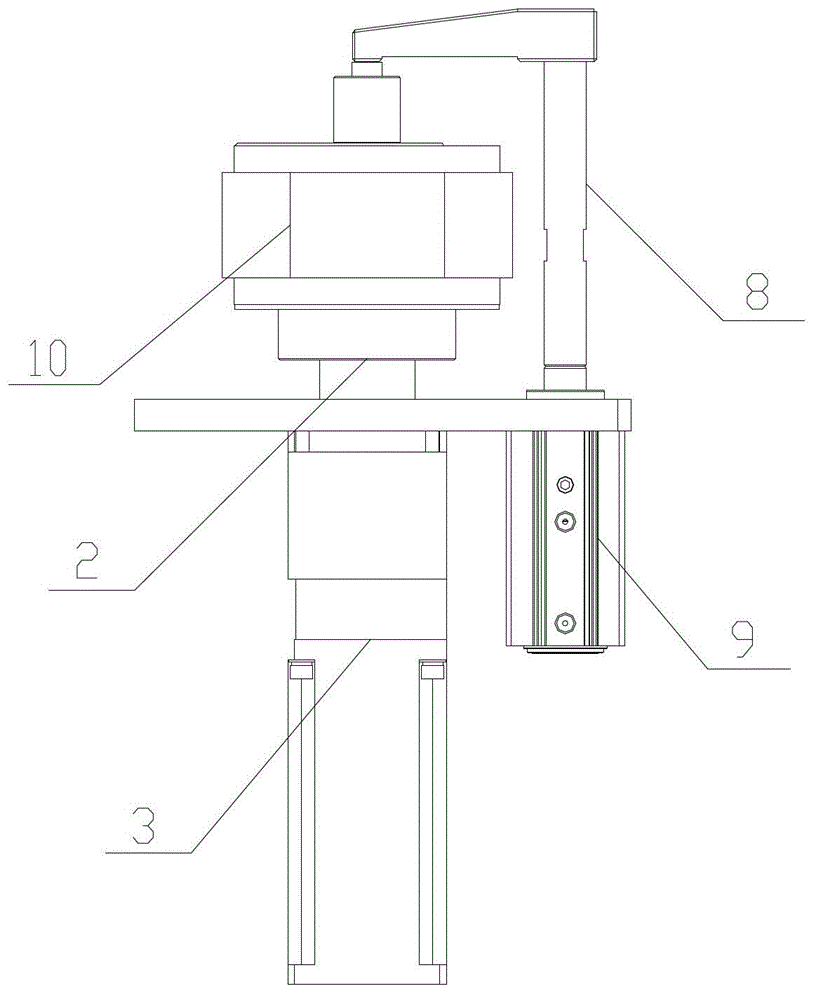

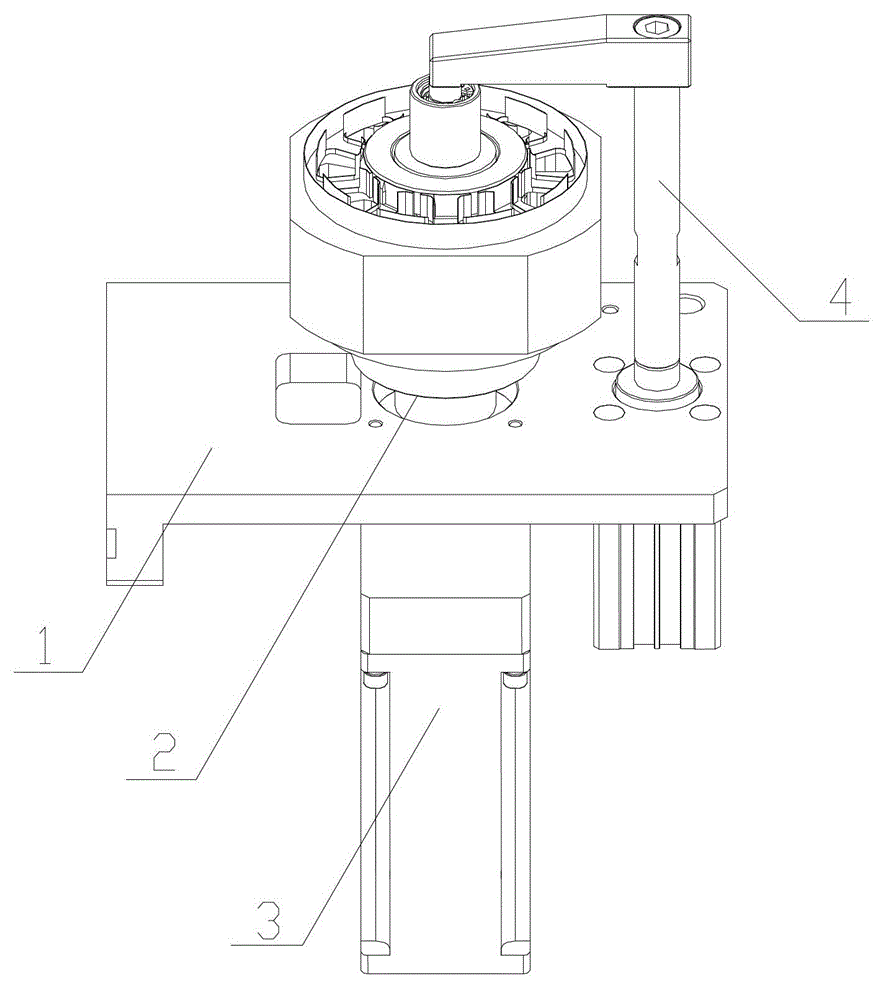

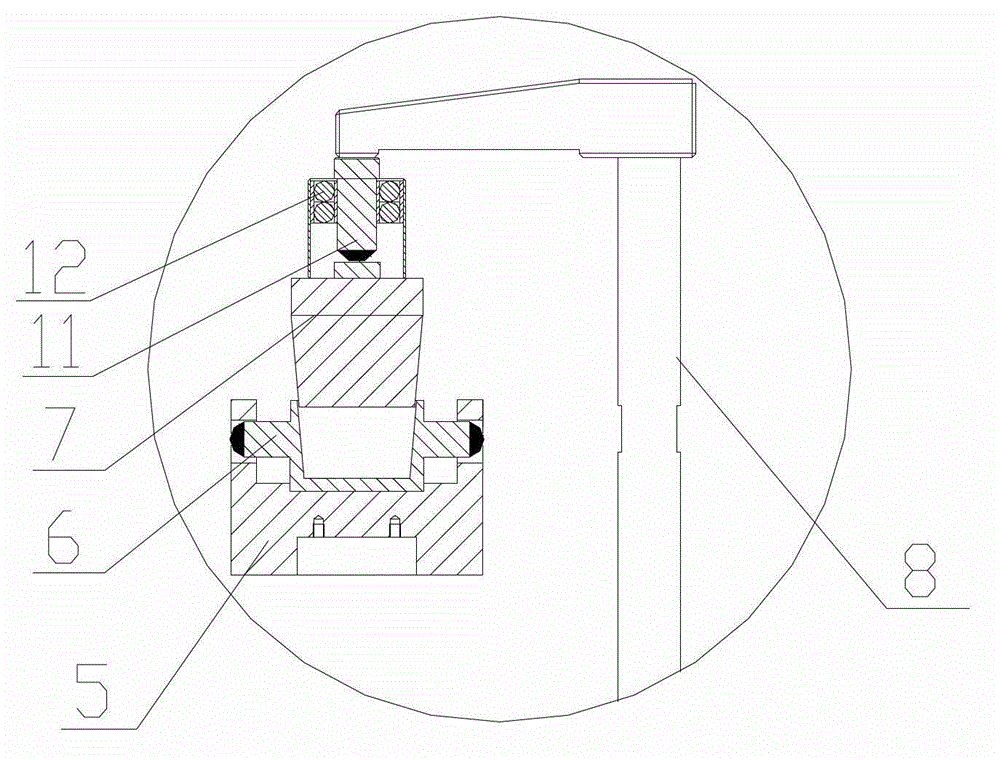

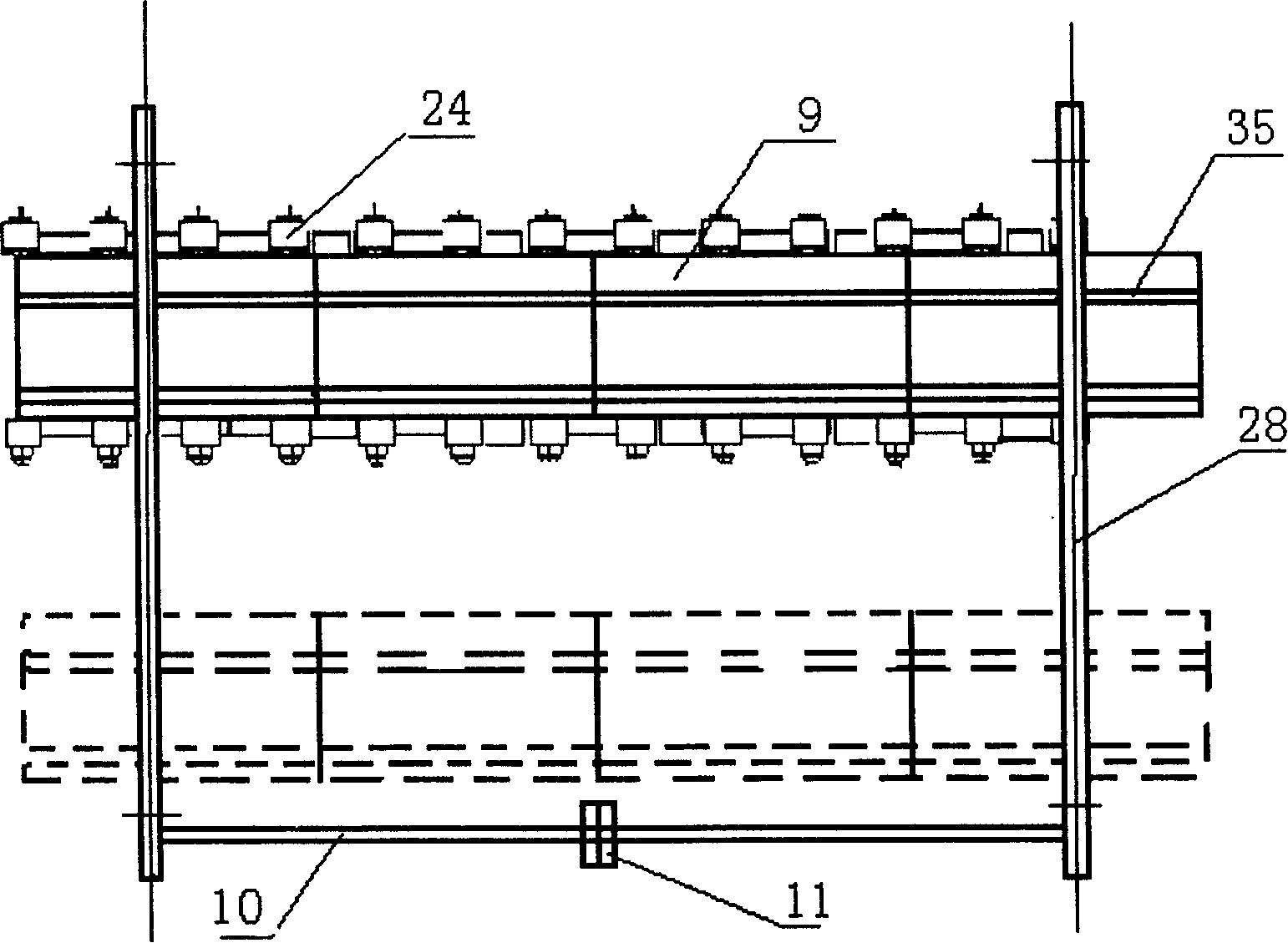

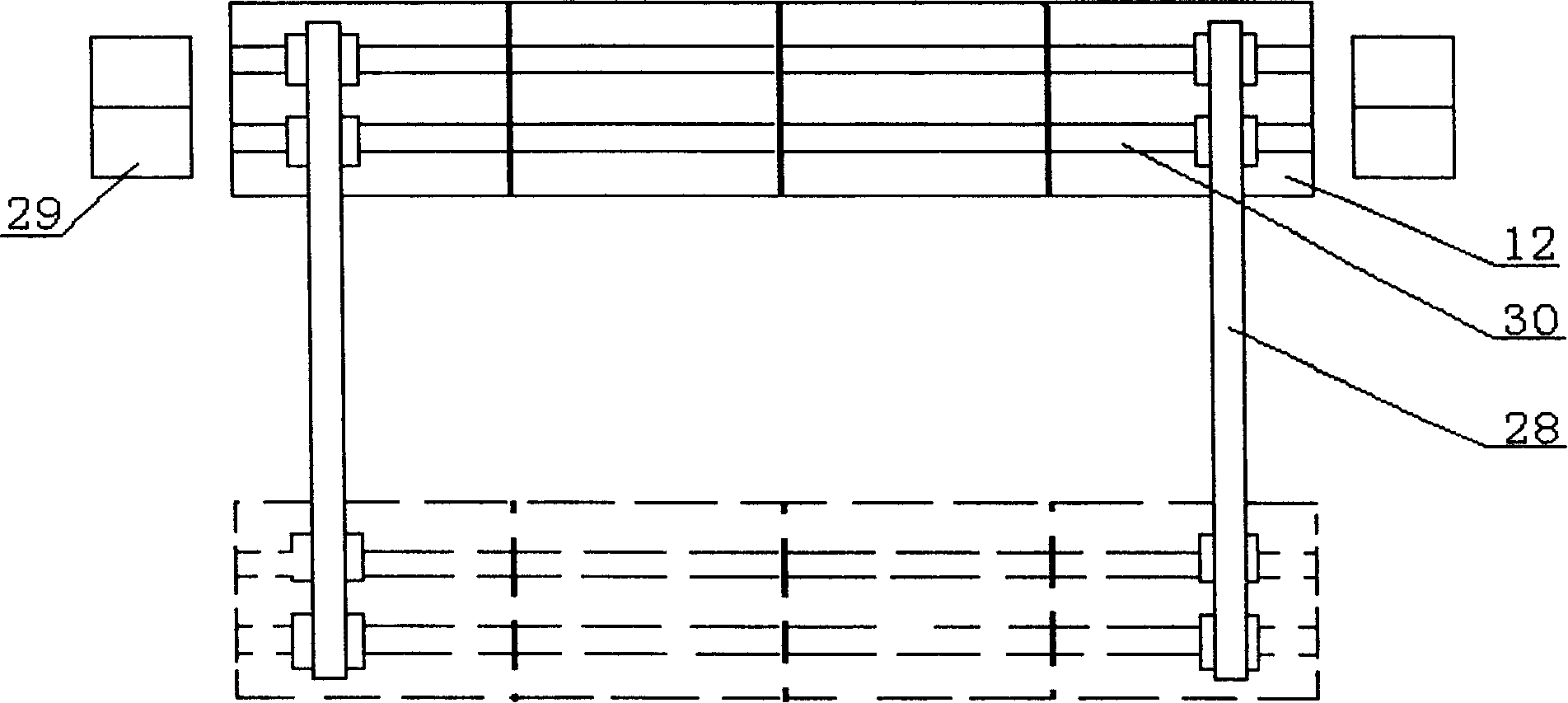

Stator clamping workbench used for pushing in insulation paper in stator

ActiveCN103337936ASafe working environmentSmooth switchingWindings insulation shape/form/constructionApplying solid insulationProcess engineeringWorkbench

The invention discloses a stator clamping workbench used for pushing in insulation paper in a stator, which mainly comprises a working platen, wherein a central hole is formed in the working platen; a rotary device is assembled in the central hole in the vertical direction; the rotary device is driven by a stator transposition motor; the stator transposition motor is fixed on the reverse side of the working platen; the working platen is further provided with a stator compressing device; the stator compressing device is vertical to the working platen and matched with the rotary device to compress a to-be-processed stator. Through the manner, the stator clamping workbench used for pushing in insulation paper in the stator is provided, and smooth switching of processing stations during the manufacturing process can be guaranteed through the power of the stator transposition motor; at the same time, an air cylinder is adopted for pushing a grasping rod to grasp a motor stator, convenience and high efficiency are ensured, and the work environment is guaranteed; a mechanical manner is utilized to position and hold out against the stator from the internal part of the stator, so external process is not affected.

Owner:圣玛特智能设备制造(浙江)有限公司

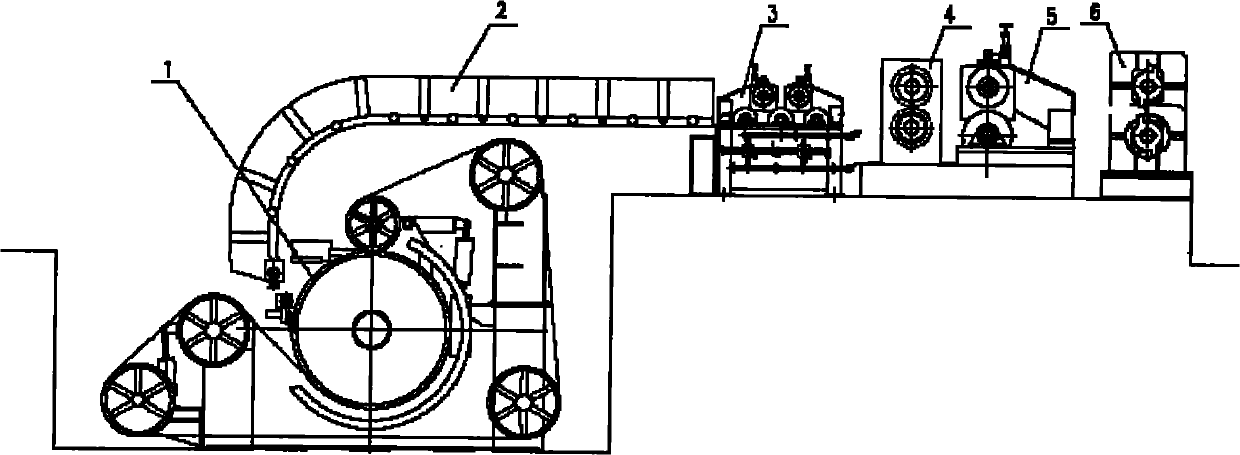

Method and device for producing A356 aluminum alloy by belt casting

The invention discloses a method and a device for producing A356 aluminum alloy by belt casting. The prepared A356 aluminum alloy liquid is subjected to furnace refining and on-line degassing filtration, and then is continuously poured into a crystallizer of a casting machine; and the periphery of the crystallizer is continuously filled with cooling water for crystallization. A crystalline region is divided into five sections from the higher temperature to the lower temperature, and a cooling region is divided into twelve regions according to different flow rates of the cooling water distributed at the periphery of the crystallizer. The belt casting machine comprises a casting machine, a straightening machine, a blank guiding machine, a rolling code machine, a roller shearing machine, and the like, which are arranged in turn; and an approach bridge is arranged between the casting machine and the straightening machine. Compared with the prior art, the method and the device have the advantages of simple production equipment, less investment, short production flow, low production cost, advanced technology, low gas-slag content in the products, low composition segregation, stable product quality, and excellent production flexibility, quickly adjustable product types, and safe working environment.

Owner:YUNNAN ALUMINUM

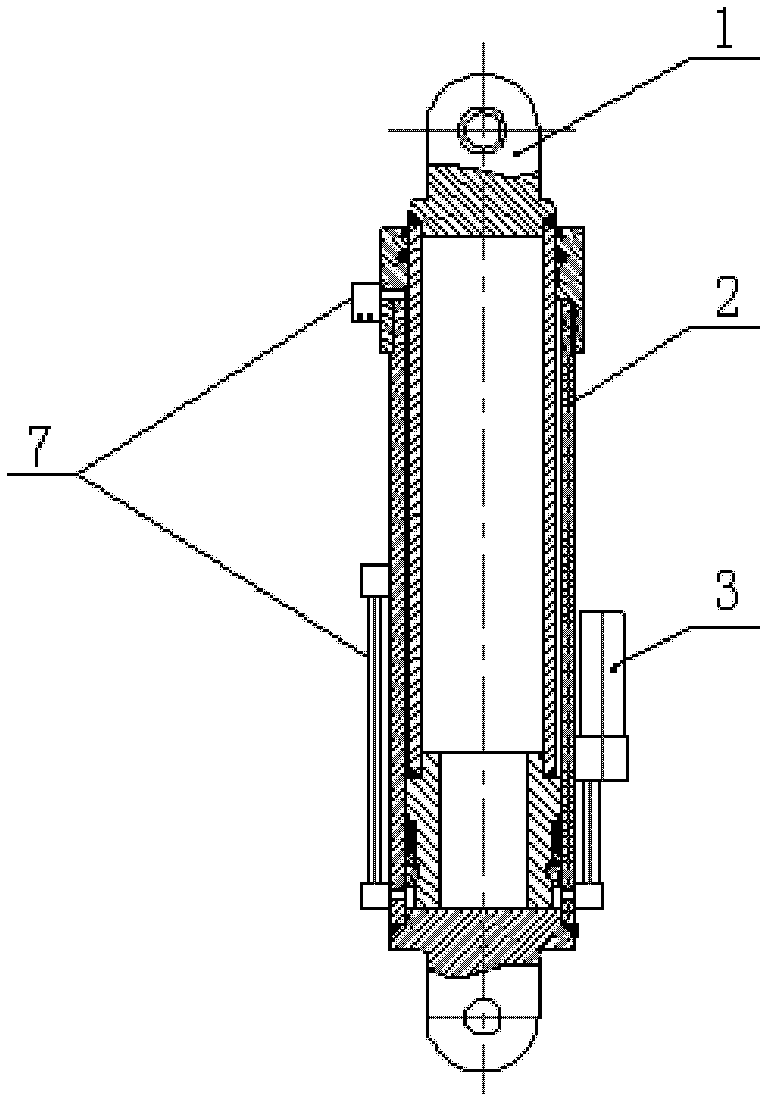

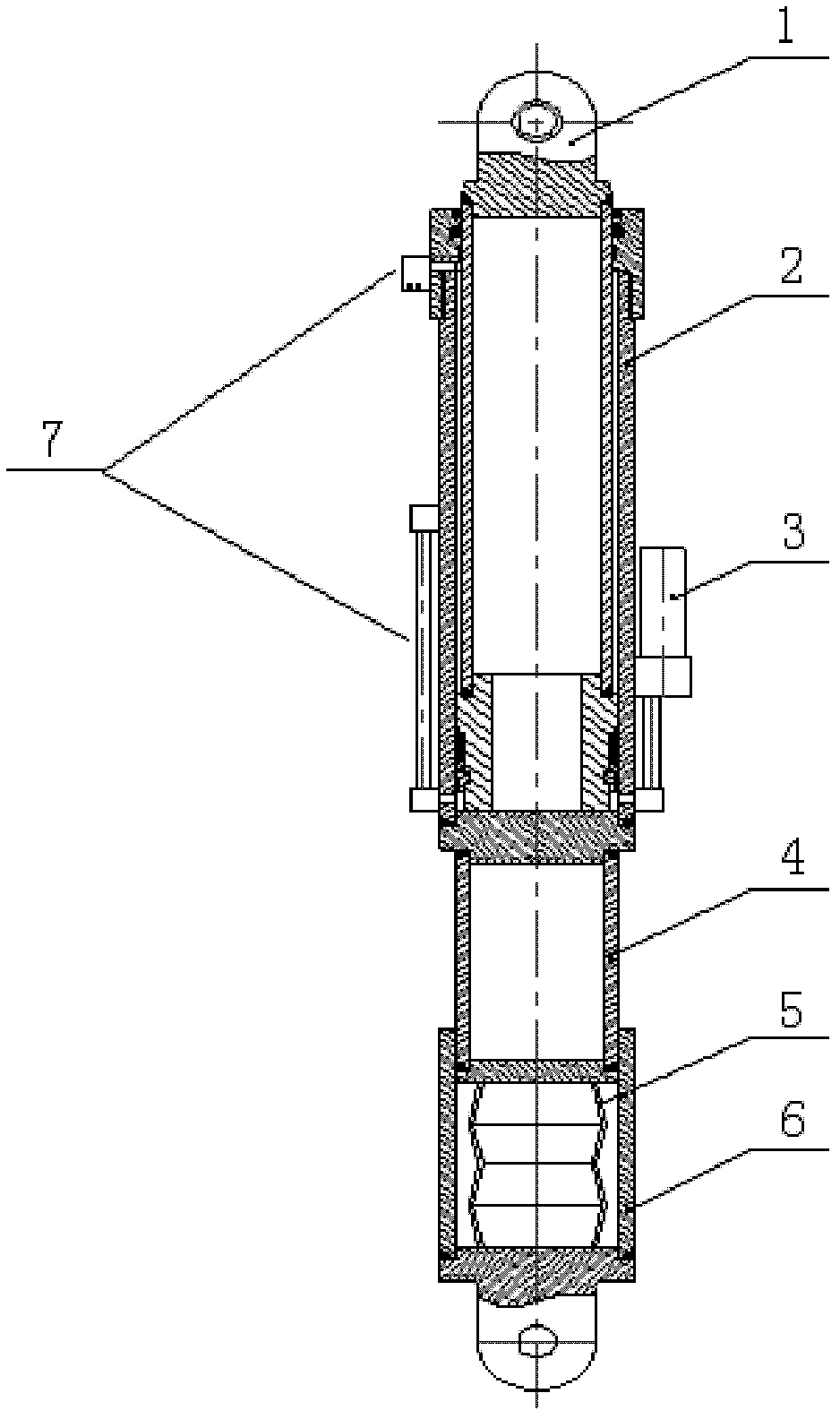

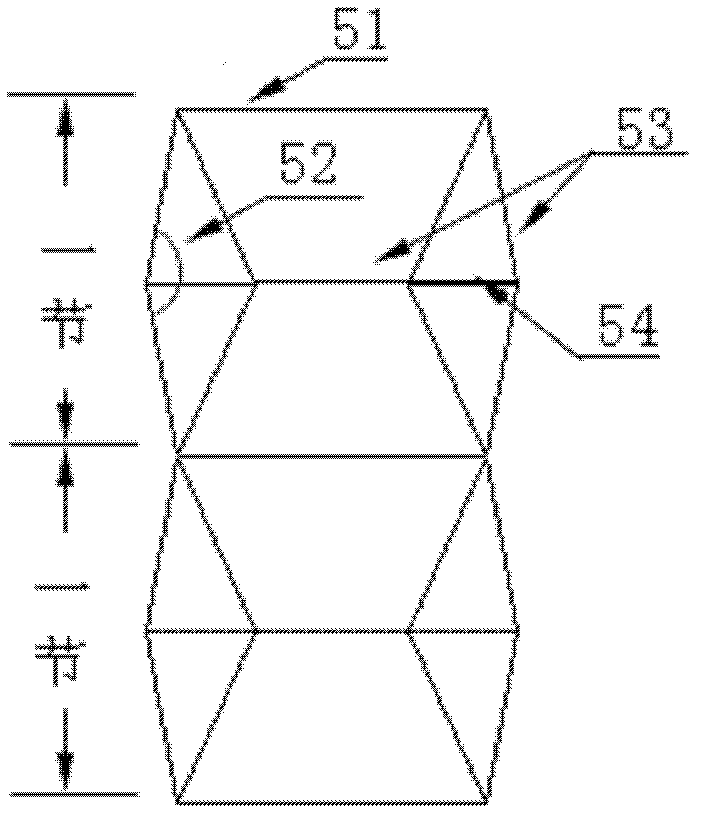

Hydraulic prop for hydraulic support system

ActiveCN102606177AIncrease working resistanceSufficient support strengthProps/chocksSupporting systemEnergy absorption

The invention discloses a hydraulic prop for a hydraulic support system, which comprises a hydraulic single prop (7). The hydraulic prop for the hydraulic support system is characterized by further comprising an energy absorption transitional section (4), an energy absorption scour prevention avoidance component (5) and a movable prop bottom (6). The energy absorption scour prevention avoidance component (5) is placed in the movable prop bottom (6), one end of the energy absorption transitional section (4) is sleeved in one end of the movable prop bottom (6), and the other end of the energy absorption transitional section (4) is embedded in the hydraulic single prop (7).

Owner:BEIJING CHENGTIAN HENGYE COAL MINE EQUIP CO LTD +1

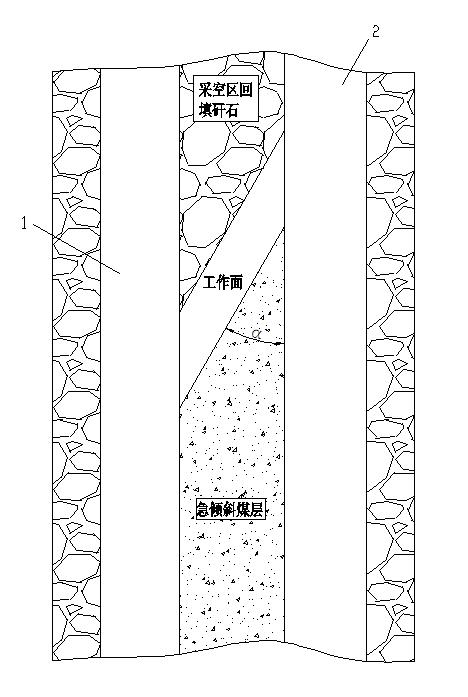

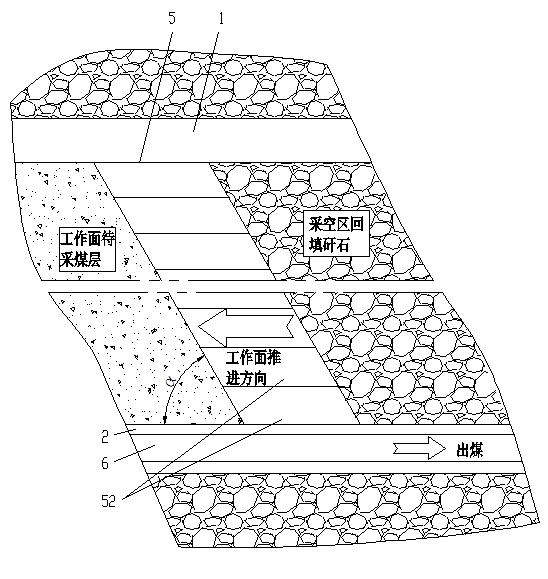

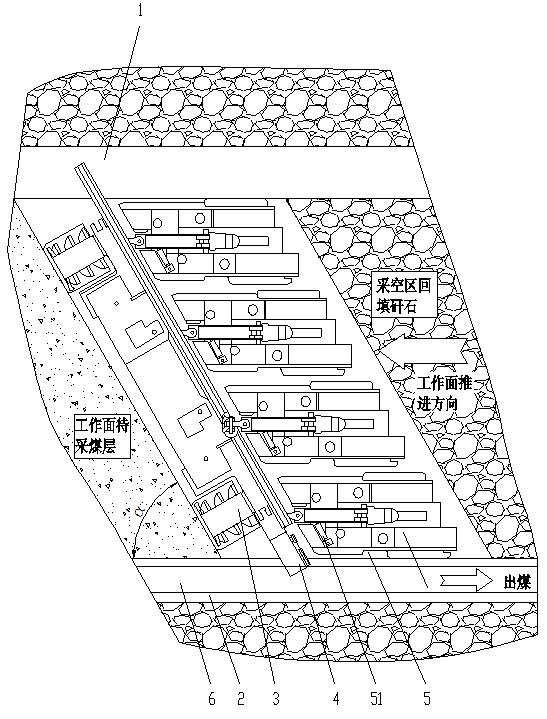

Steeply inclined seam dip oblique strike longwall comprehensive mechanical coal mining method

InactiveCN102587913ADecrease the inclinationReduce coal lossUnderground miningSurface miningSupporting systemResource utilization

The invention discloses a steeply inclined seam dip oblique strike longwall comprehensive mechanical coal mining method. The method comprises the following steps: preparation: digging a first laneway and a second laneway at the upper end and the lower end of the steeply inclined seam respectively; forming an initial mining working surface with the pitching oblique mining angle alpha of 25 to 35 degrees between the two laneways; arranging a coal mining machine, a scraper plate conveying machine, and a plurality of hydraulic brackets which are parallelogram-shaped in the overhead view and form a supporting system on the initial mining working surface; arranging the machine head of the scraper plate conveying machine behind relative to the machine tail while the hydraulic brackets in the propelling direction are sequentially behind a certain distance from the machine tail of the scraper plate conveying machine; arranging a reversed loader on the second laneway; coal mining: cutting coal up and low by using the coal-mining head of a coal-mining machine; moving the brackets: moving the hydraulic brackets sequentially from bottom to top; pushing and sliding: pushing and sliding by using a scraper trough conveyor of the scraper plate conveying machine in strokes to finish one time pushing and sliding quantity; and transporting coal: transporting coal to the outside by using the reversed loader. According to the method, the steeply inclined seam comprehensive mining operation is realized conveniently, and recovery ratio and resource utilization ratio are increased.

Owner:重庆市能源投资集团科技有限责任公司 +1

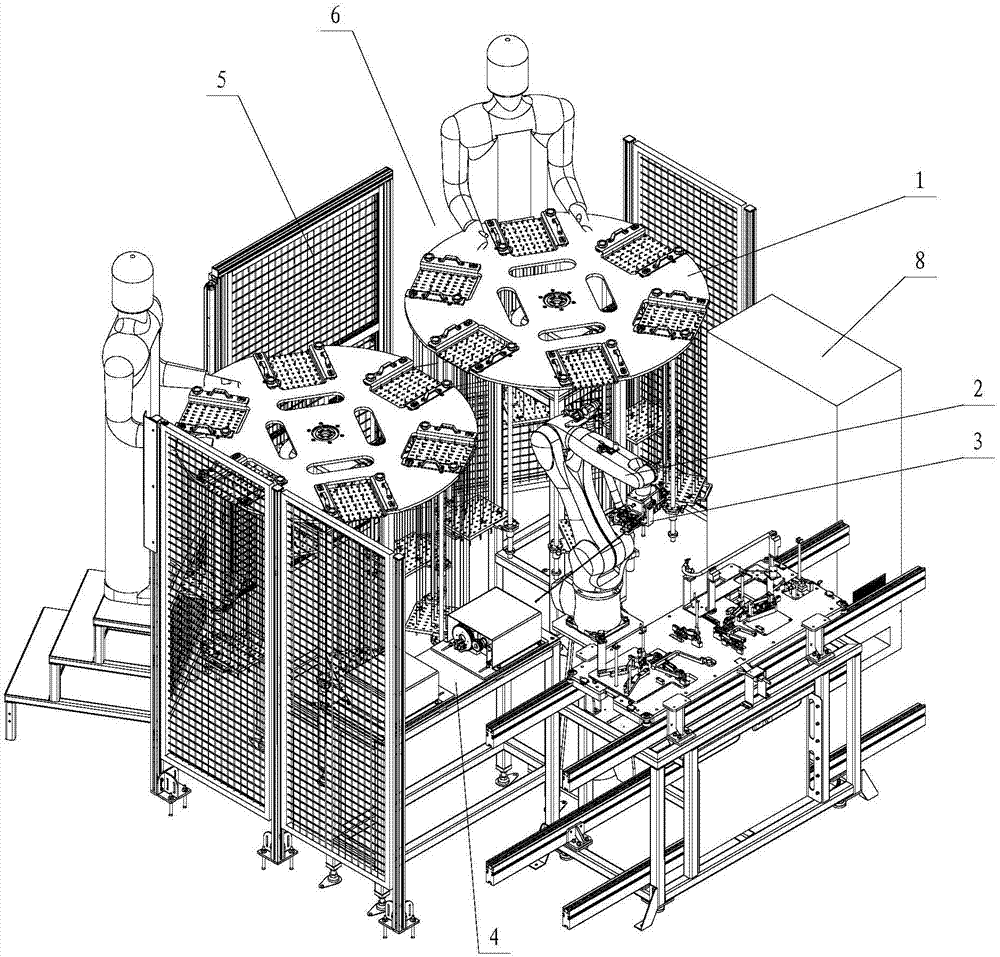

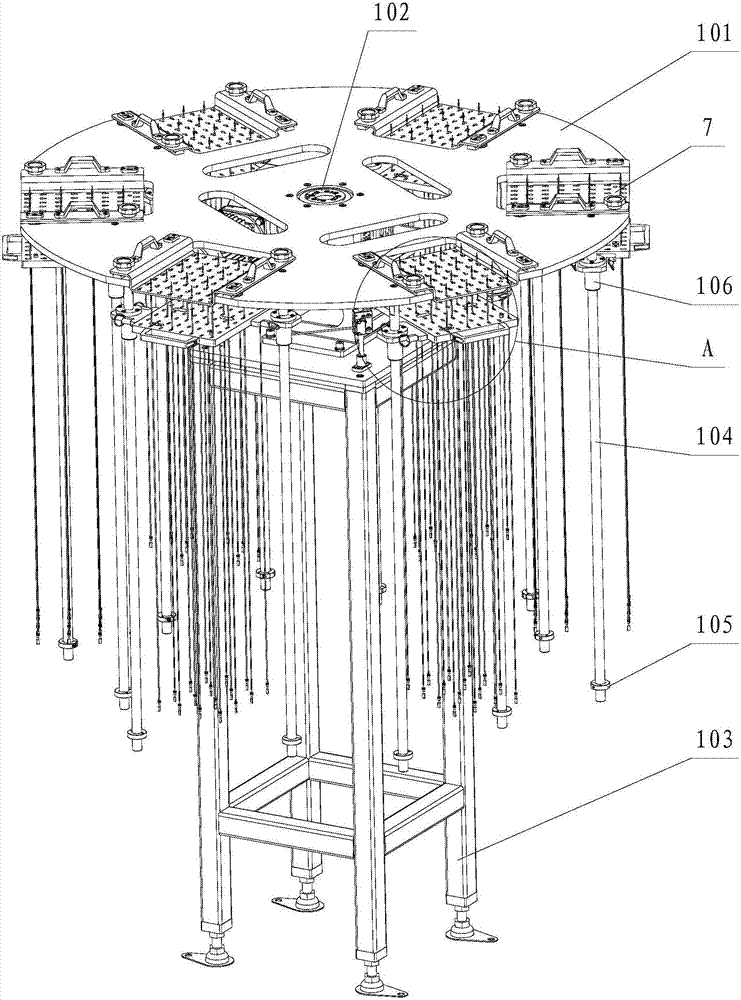

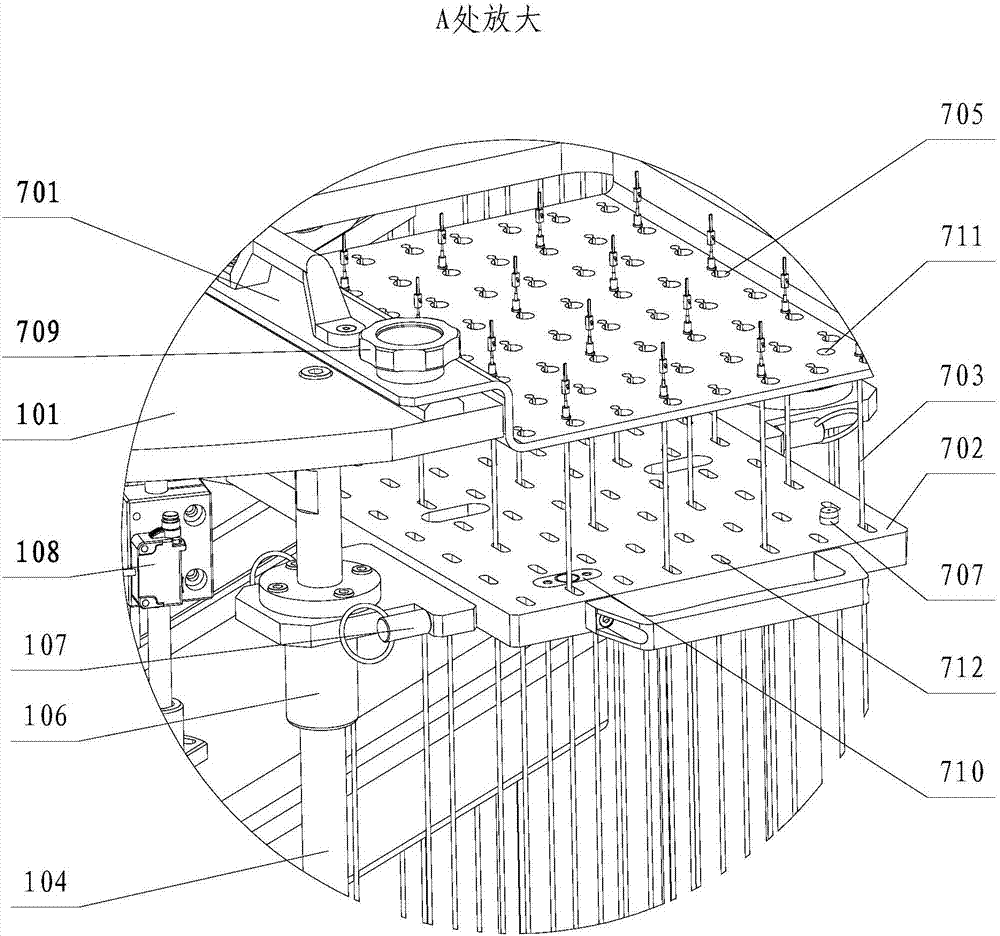

Robot-based wiring harness terminal automatic plugging device and wiring harness terminal plugging method thereof

ActiveCN107346857AImprove work efficiencyHigh precisionVehicle connectorsContact member assembly/disassemblyDiffuse reflectionEngineering

The invention belongs to the automotive wire harness assembling field and relates to a robot-based wiring harness terminal automatic plugging device and a wiring harness terminal plugging method thereof. The device comprises a material loading rotary mechanism, a multi-axis linkage robot, a wire plugging and collection clamping jaw and a visual verification work table; according to the material loading rotary mechanism, a splitter drives a rotary platform provided with tray assemblies; manual material loading is performed at a work station, the robot takes materials at a work station opposite the material loading work station; and material loading and unloading work and the wire plugging work of the robot can be performed simultaneously, and therefore, the work safety of a material loading worker can be ensured. With the robot-based wiring harness terminal automatic plugging device and the wiring harness terminal plugging method thereof of the invention adopted, fully-automatic material feeding, wiring harness terminal plugging and detection can be realized, work efficiency, precision and reliability are greatly improved, and human resource costs can be saved. According to the robot-based wiring harness terminal automatic plugging device and the wiring harness terminal plugging method thereof of the invention, a visual detection system, a tension and pressure sensor detection system and a laser diffuse reflection sensor detection system are integrated, so that the accuracy and reliability of terminal plugging can be ensured.

Owner:无锡新松机器人自动化有限公司

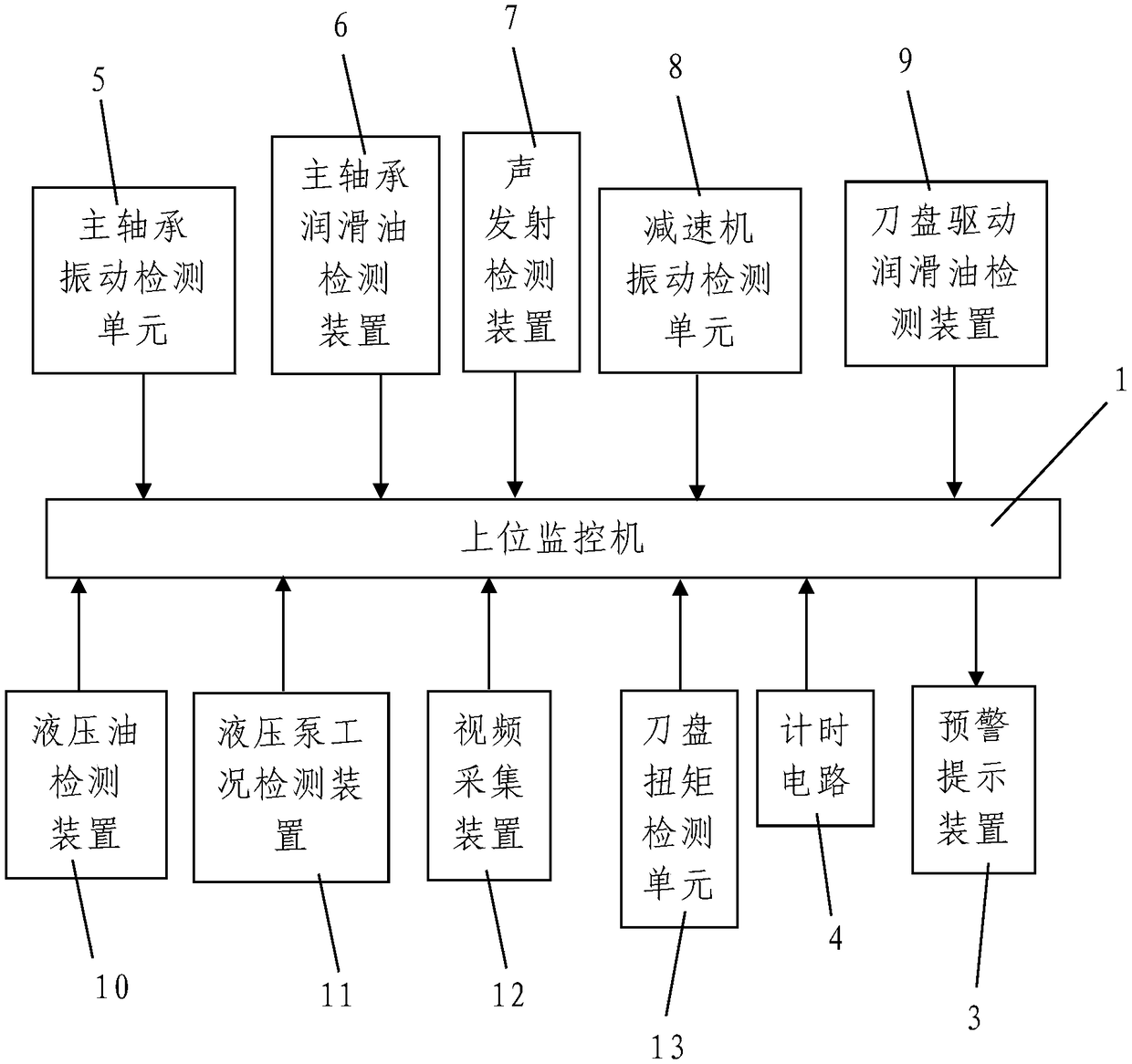

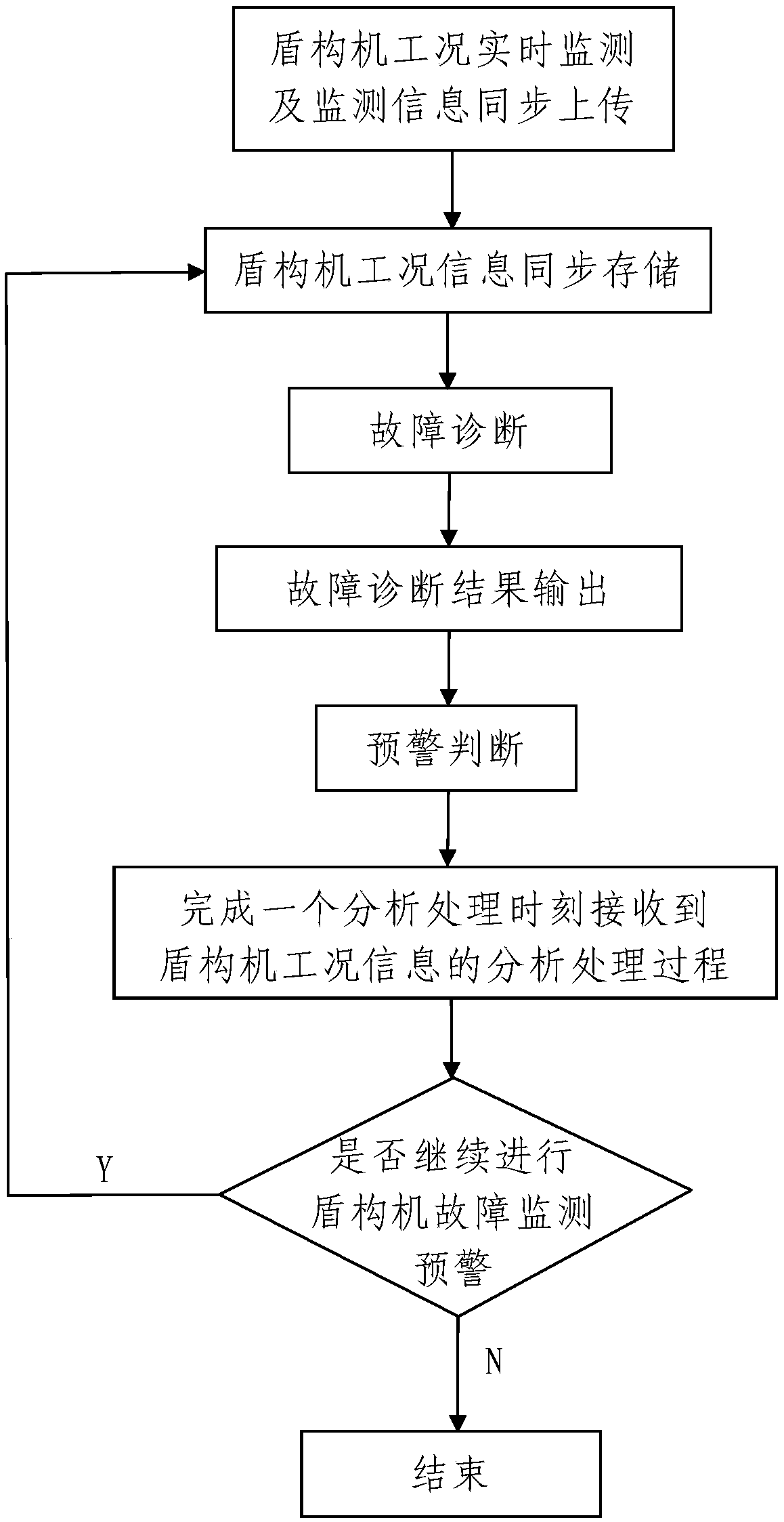

Fault monitoring early-warning system and method of shield machine

ActiveCN108760361ASimple structureReasonable designStructural/machines measurementEarly warning systemMain bearing

The invention discloses a fault monitoring early-warning system and method of a shield machine. The system comprises a host monitor, a shield machine condition detector for monitoring condition information of a monitored shield machine in real time, an early warning prompt device controlled by the host monitor, and a timing circuit connected with the host monitor; the early warning prompt device is connected with the host monitor; and the shield machine condition detector comprises a main bearing condition detection unit which monitors the condition of a main bearing of the shield machine in real time, a cutterhead detection unit which monitors the condition of a cutterhead of the shield machine in real time, and a cutterhead driving detection unit for monitoring the condition of a cutterhead driving system in real time. The method comprises the steps that 1) the condition of the shield machine is monitored, and monitoring information is uploaded synchronously; and 2) condition information of the shield machine is analyzed and processed. Thus, a fault in the shield machine can be monitored timely and accurately, and early warning prompt can be provided according to a monitoring result.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

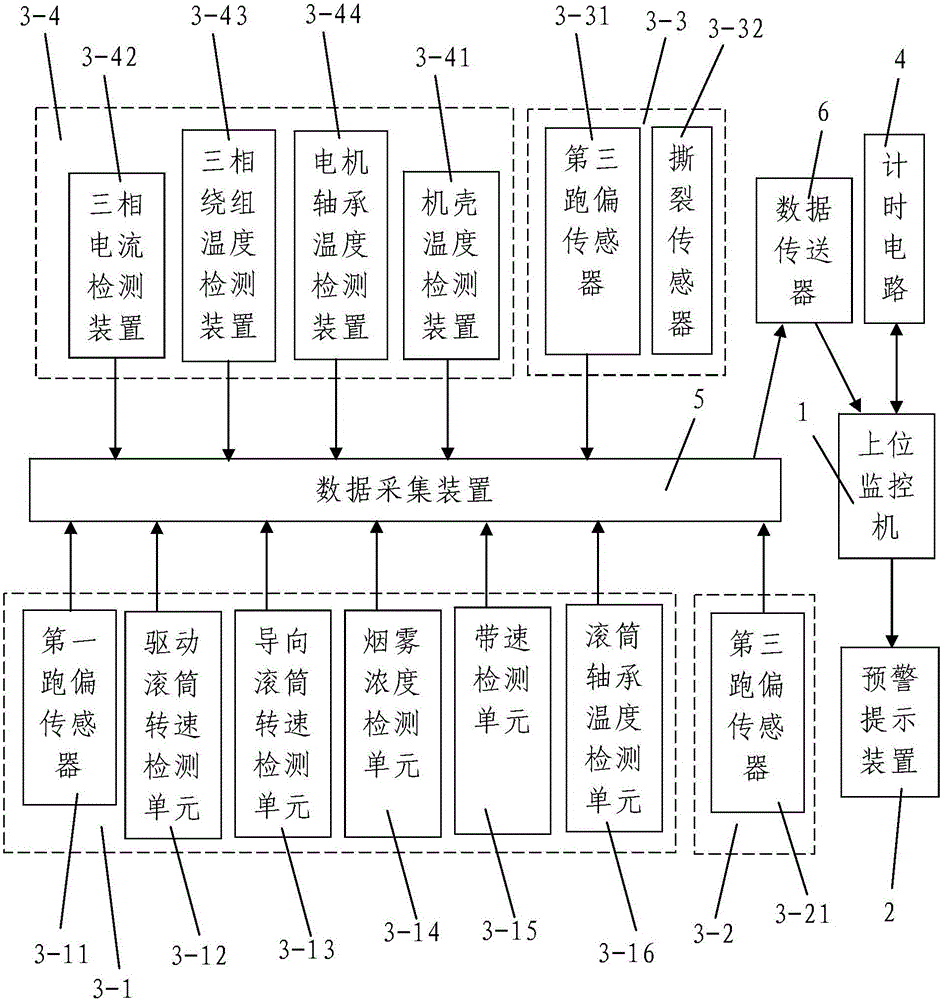

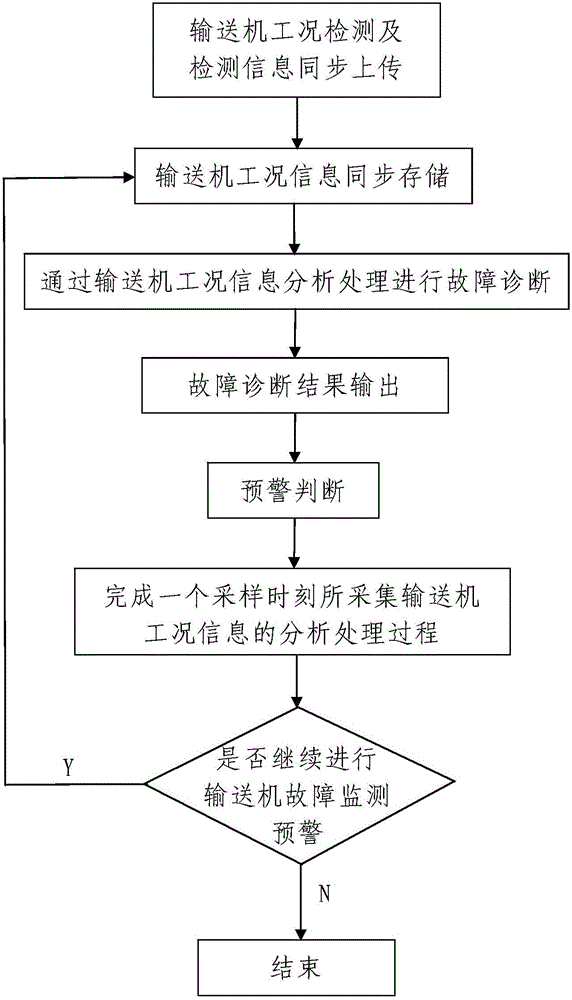

Fault monitoring and early warning system and method for belt conveyor of mine

ActiveCN105692118ASimple structureReasonable designConveyorsControl devices for conveyorsEarly warning systemData acquisition

The invention discloses a fault monitoring and early warning system and method for a belt conveyor of a mine. The fault monitoring and early warning system comprises an upper monitor, a conveyor working condition detecting device, a data acquiring device, an early warning prompting device and a timing circuit, wherein the conveyor working condition detecting device detects working conditions of a monitored belt conveyor in real time; the data acquiring device is connected with the conveyor working condition detecting device; the early warning prompting device is controlled by the upper monitor; and the timing circuit is connected with the upper monitor. The fault monitoring and early warning method comprises the following steps: 1, detecting the working conditions of the conveyor and synchronously uploading detection information; and 2, analyzing and processing of information of the working conditions of the conveyor: respectively analyzing and processing the information, which is acquired by the data acquiring device at various sampling times, of the working conditions of the conveyor by using the upper monitor in sequence according to the sampling times, and diagnosing faults of the monitored belt conveyor according to analyzed and processed results. The fault monitoring and early warning system is reasonable in design, easy and convenient to use and operate and good in using effect, can timely and accurately monitor faults of the belt conveyor, and can early warn in time.

Owner:XIAN UNIV OF SCI & TECH

Elevated working platform and related methods

Elevated work platform apparatuses, as well as associated methods, are provided. In one particular embodiment, an elevated platform apparatus is provided comprising a first assembly having a pair of rails coupled with a plurality of rungs, a second assembly hingedly coupled with the first assembly, a platform pivotally coupled with the first assembly and configured to extend to, and engage a portion of, the second assembly. The apparatus further includes a cage associated with the platform. The cage may include at least one bar and at least one gate, the at least one gate being configured to swing in a first direction upon a user stepping on to the platform from the first rail assembly, and then swing back to a closed position after the user is standing on the platform. Platform includes a toe-kick structure that is collapsible relative to the deck of the platform.

Owner:LITTLE GIANT LADDER SYST LLC

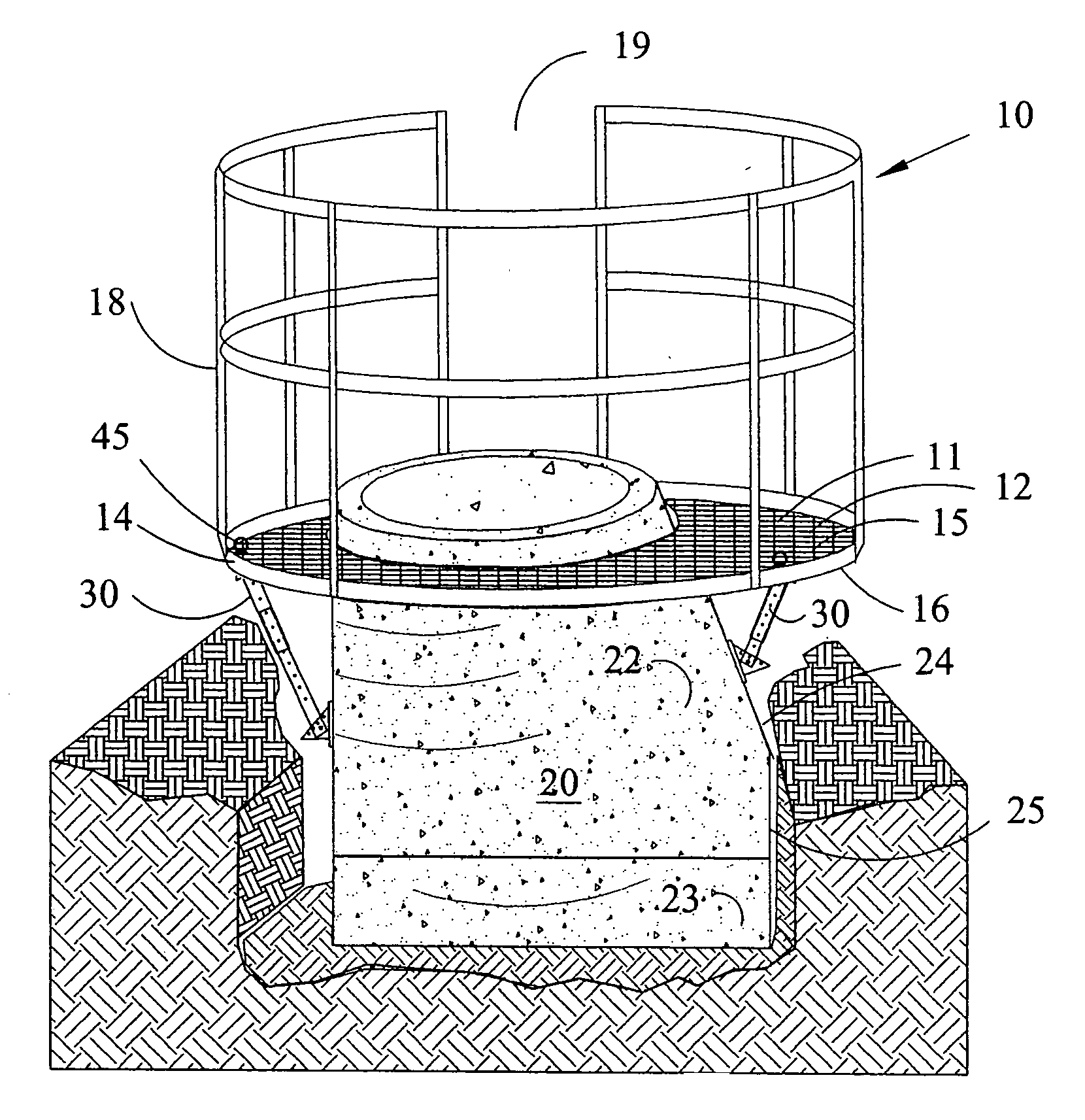

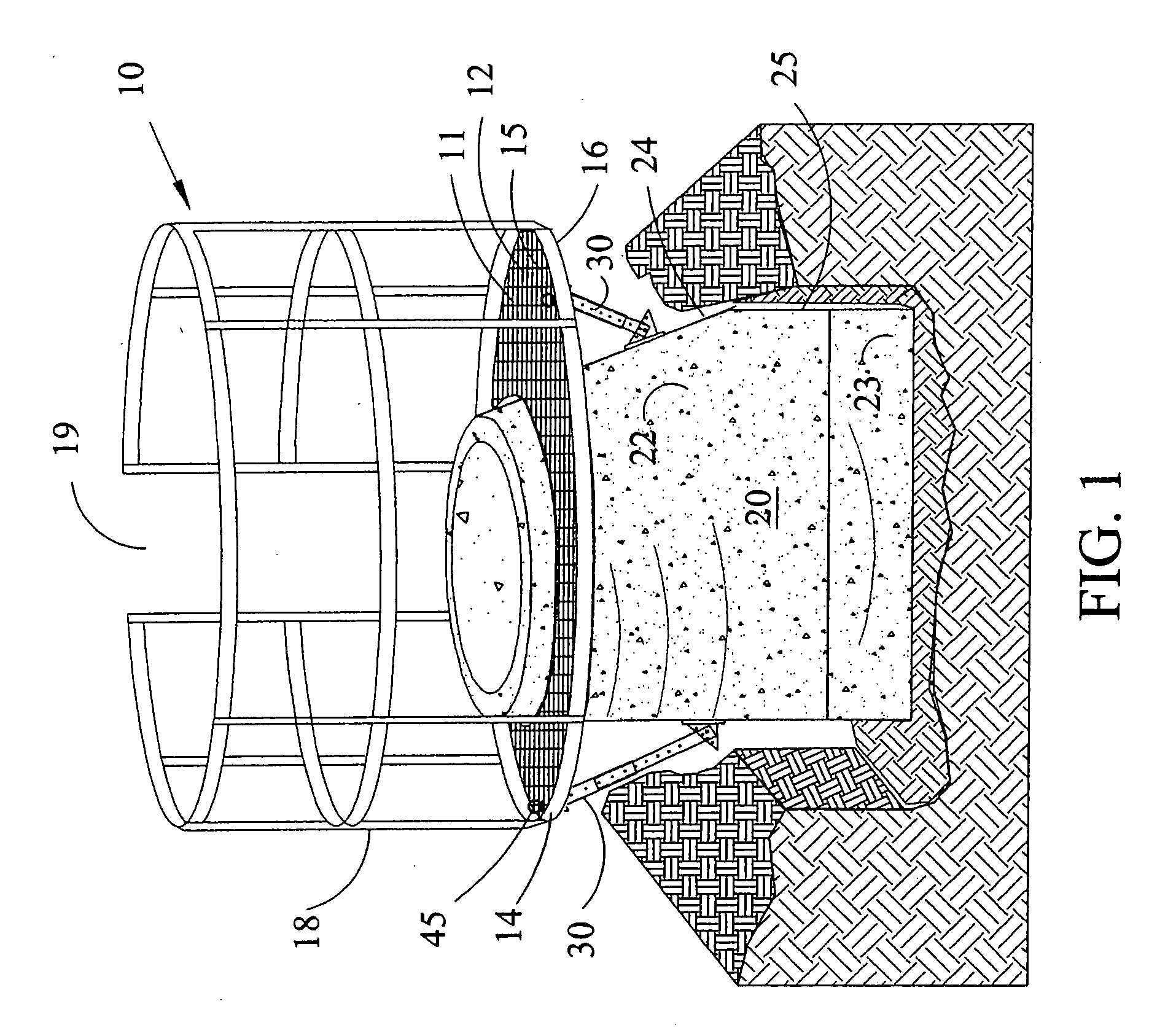

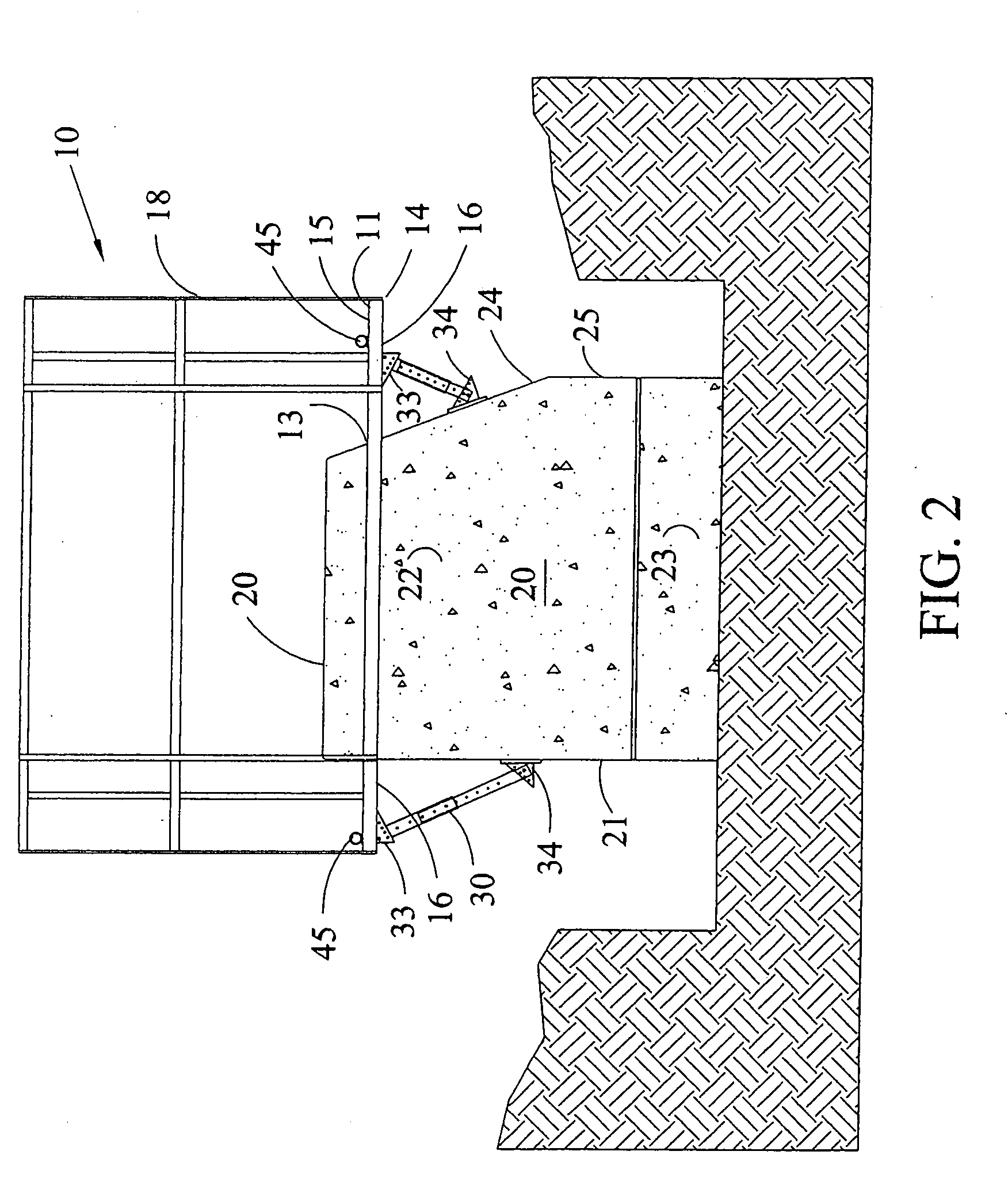

Manhole construction safety and work platform device

InactiveUS20090236180A1Safe working environmentUnderwater structuresBuilding scaffoldsWorking environmentEngineering

The invention is a manhole construction safety and work platform device having a scaffold catwalk for working on a manhole, providing the safety and work platform with adjustable braces engaging the side of a conical manhole casing. The inner perimeter of the device circumferentially defines a central access opening in order to slidably accept, receive, and fit around the conical section of the manhole casing, as typically used in the utility construction industry. The scaffold catwalk has a safety barrier means on the working surface to provide a safe working environment along the outer perimeter. As is common in the industry, the conical section of the manhole casing may be an asymmetrical conical section. One objective of the present invention is to provide a scaffolding platform supported with at least three adjustable brace members to securely support the said platform against the sidewall of any shape of manhole casing.

Owner:GRANDY MICHAEL ALLEN

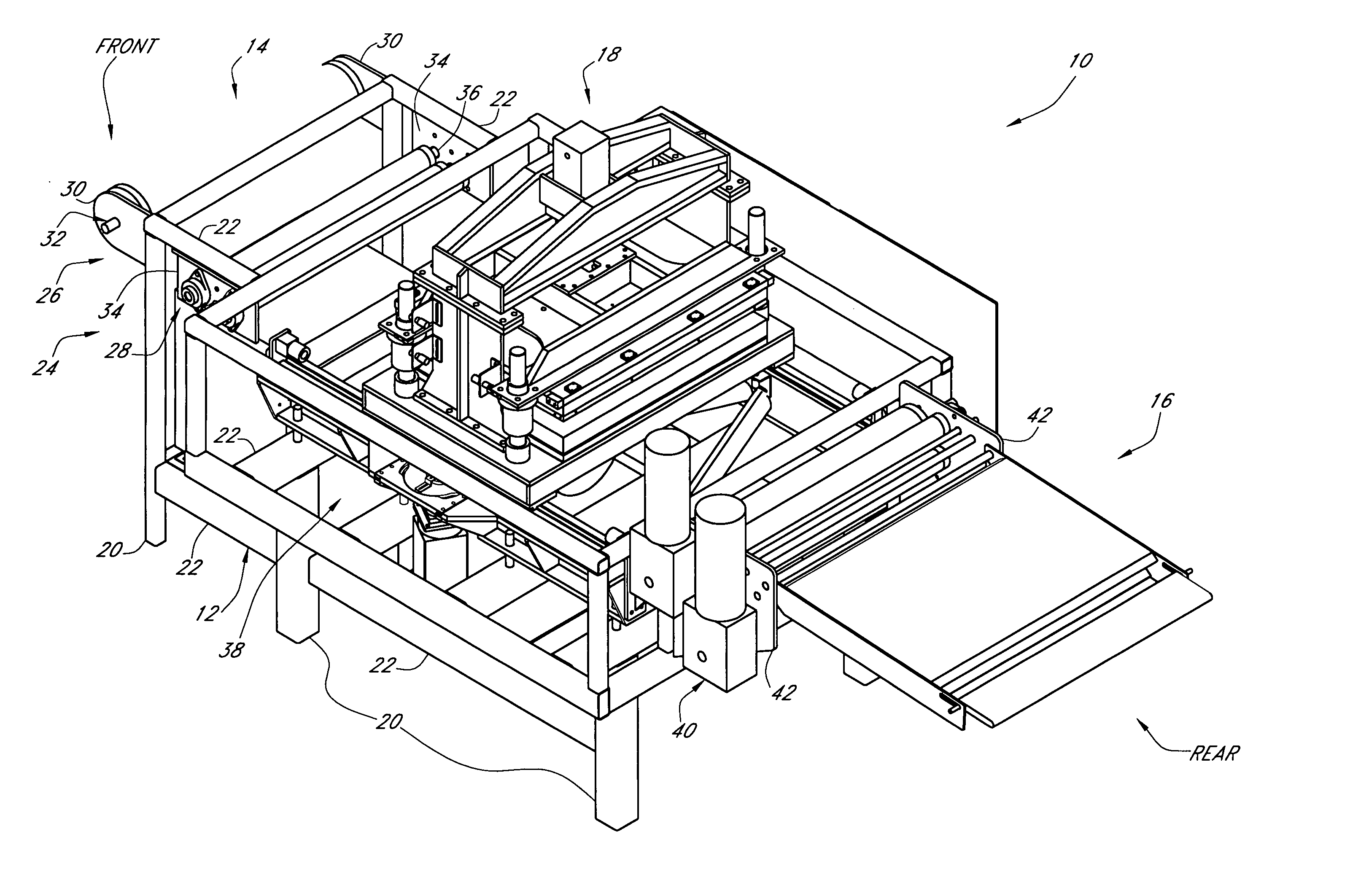

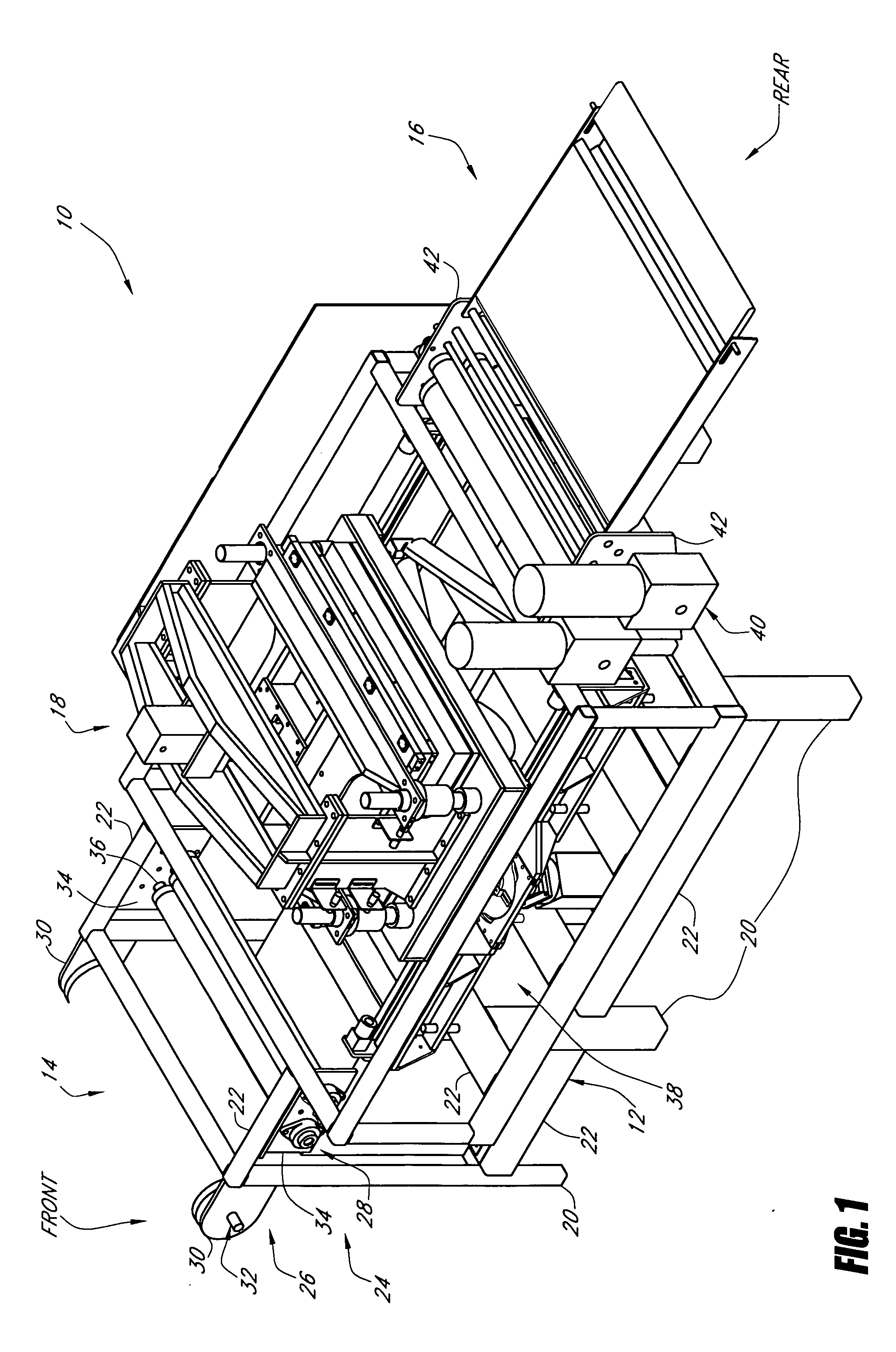

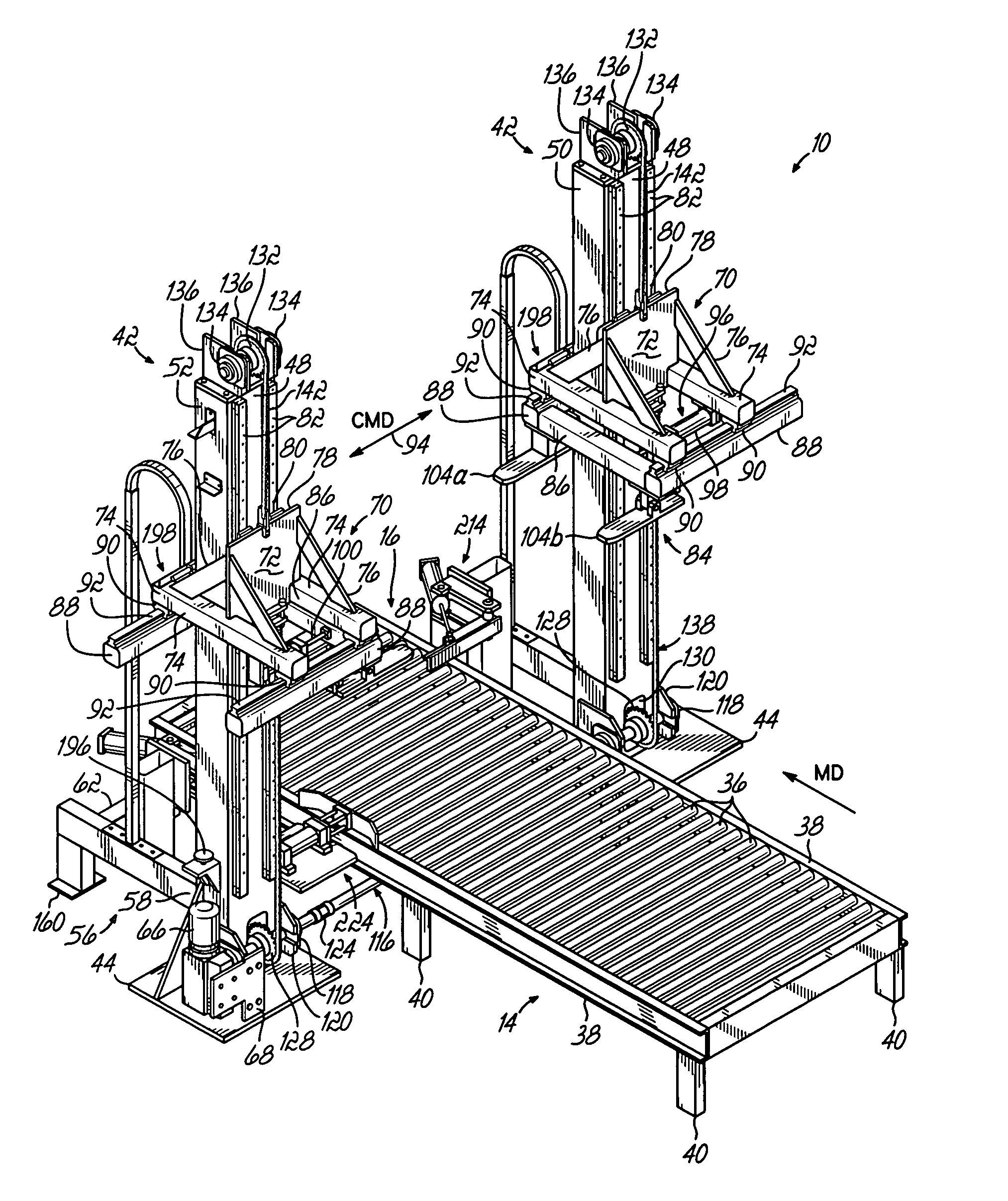

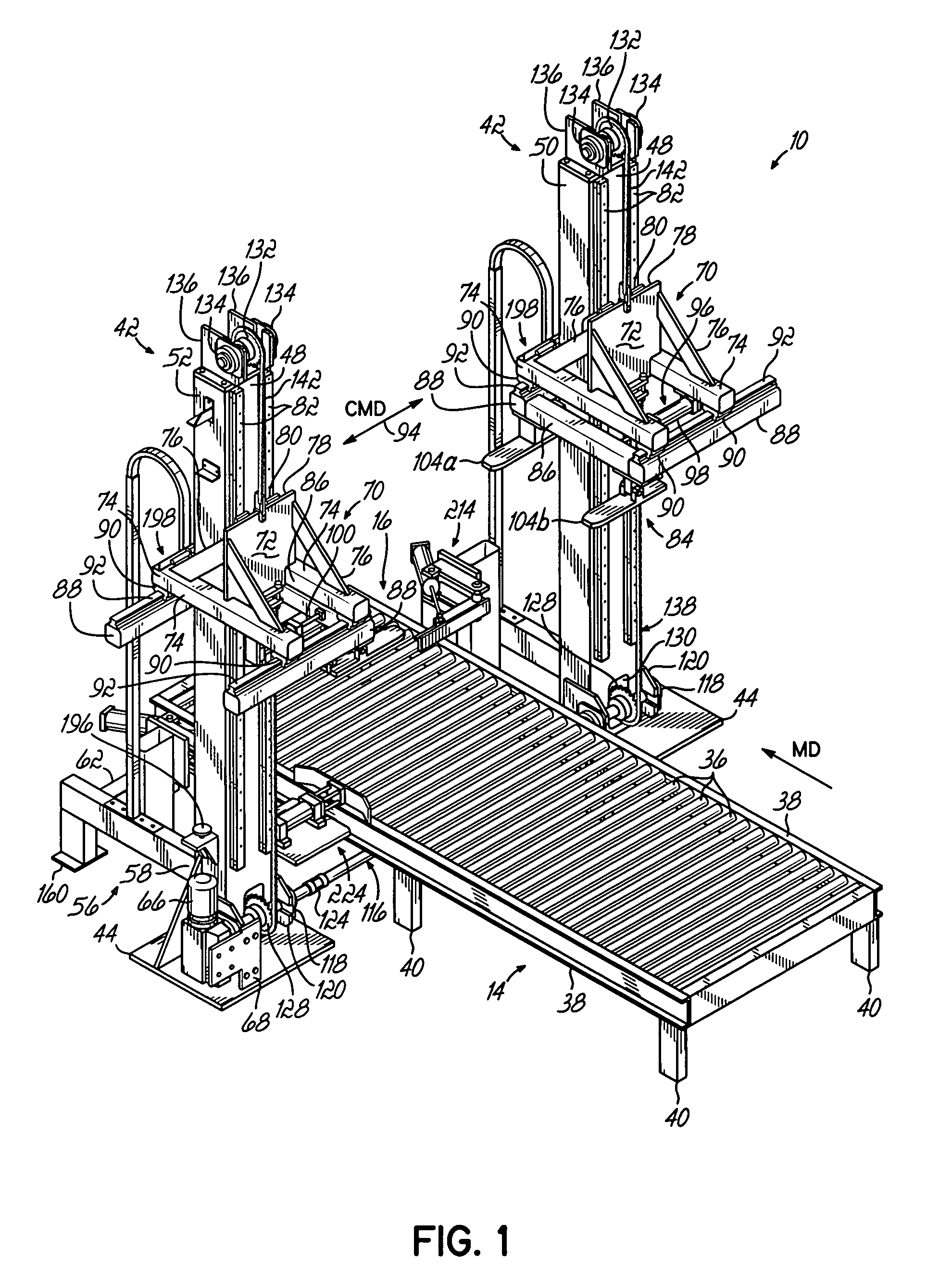

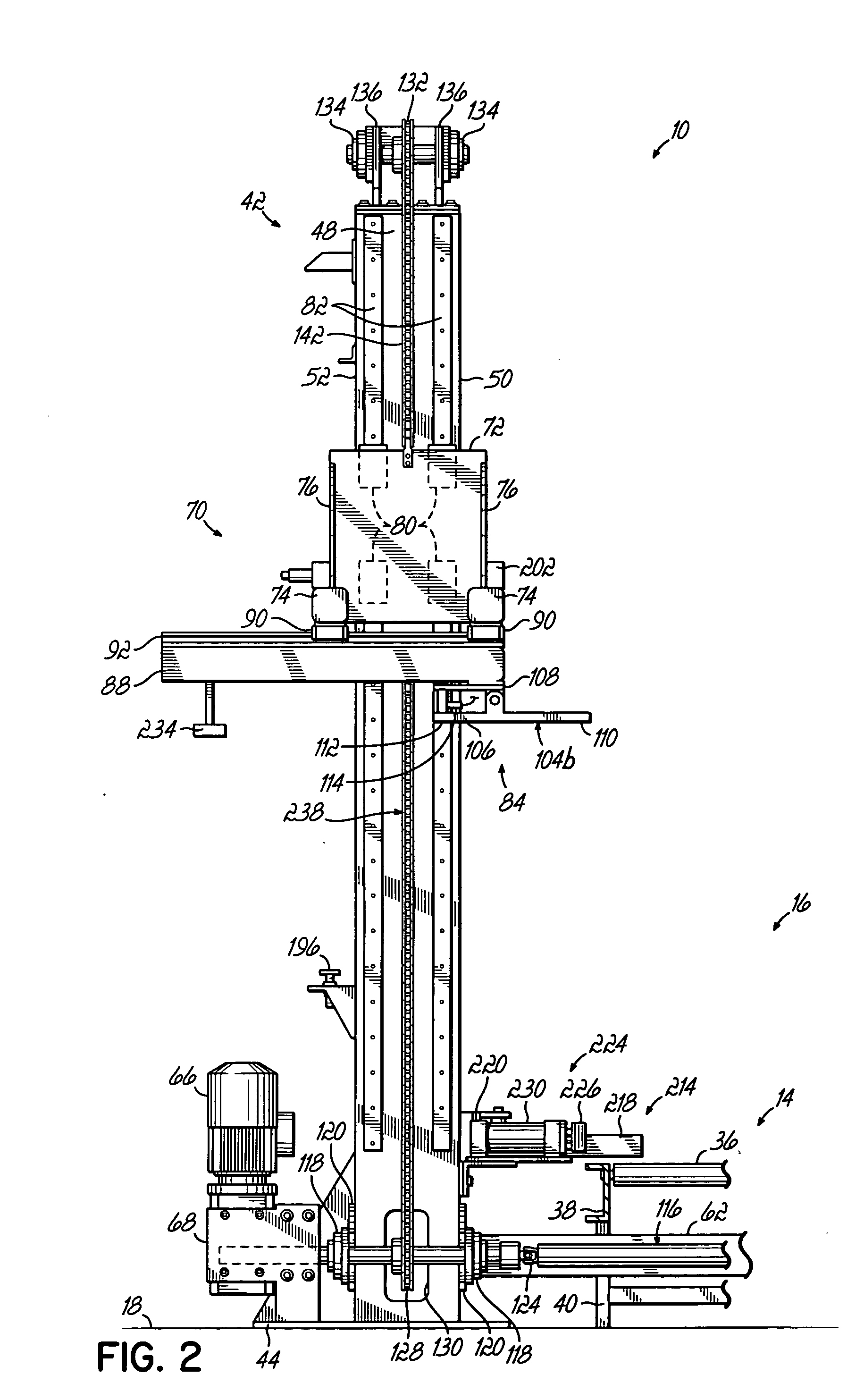

Pallet stacker system

ActiveUS20050095114A1Synchronization is simpleSafe working environmentPackagingStacking articlesEngineeringStacker

A method and apparatus for stacking first and second loaded pallets includes a pallet stacker that defines a stationary stacking location. A first loaded pallet is conveyed to the stationary stacking location. A pair of pallet lift carriages are vertically adjustable at the stationary stacking location to selectively engage the first loaded pallet and raise it to a temporary holding position. A second loaded pallet is conveyed into vertical registration with the first loaded pallet. The first loaded pallet is then vertically adjusted into stable stacked relation with the second loaded pallet, and the pallet lift carriages disengage the first loaded pallet. The first and second loaded pallets, in stable stacked relation to each other, thereafter are discharged from the stationary stacking location.

Owner:KOLINAHR SYST

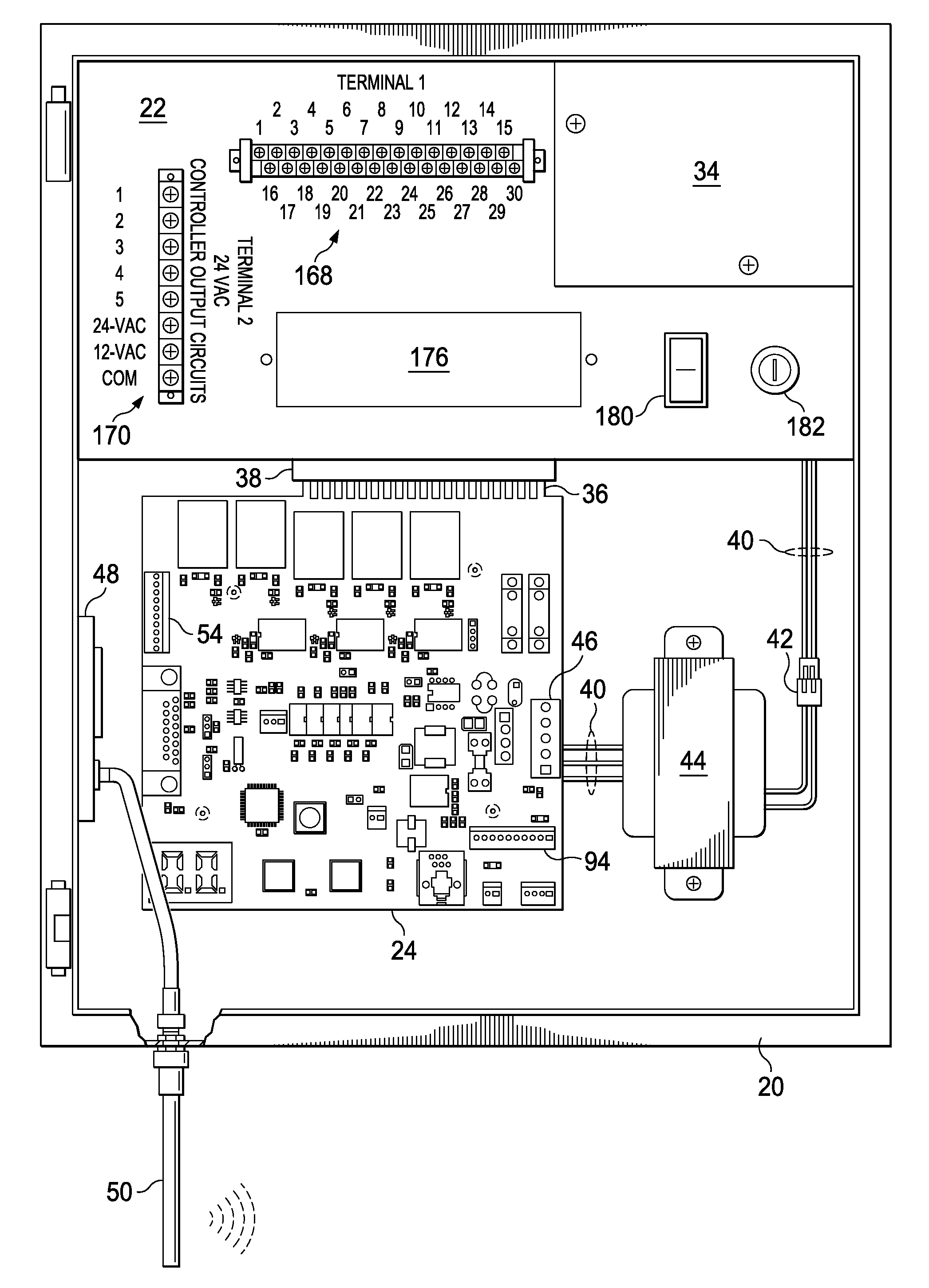

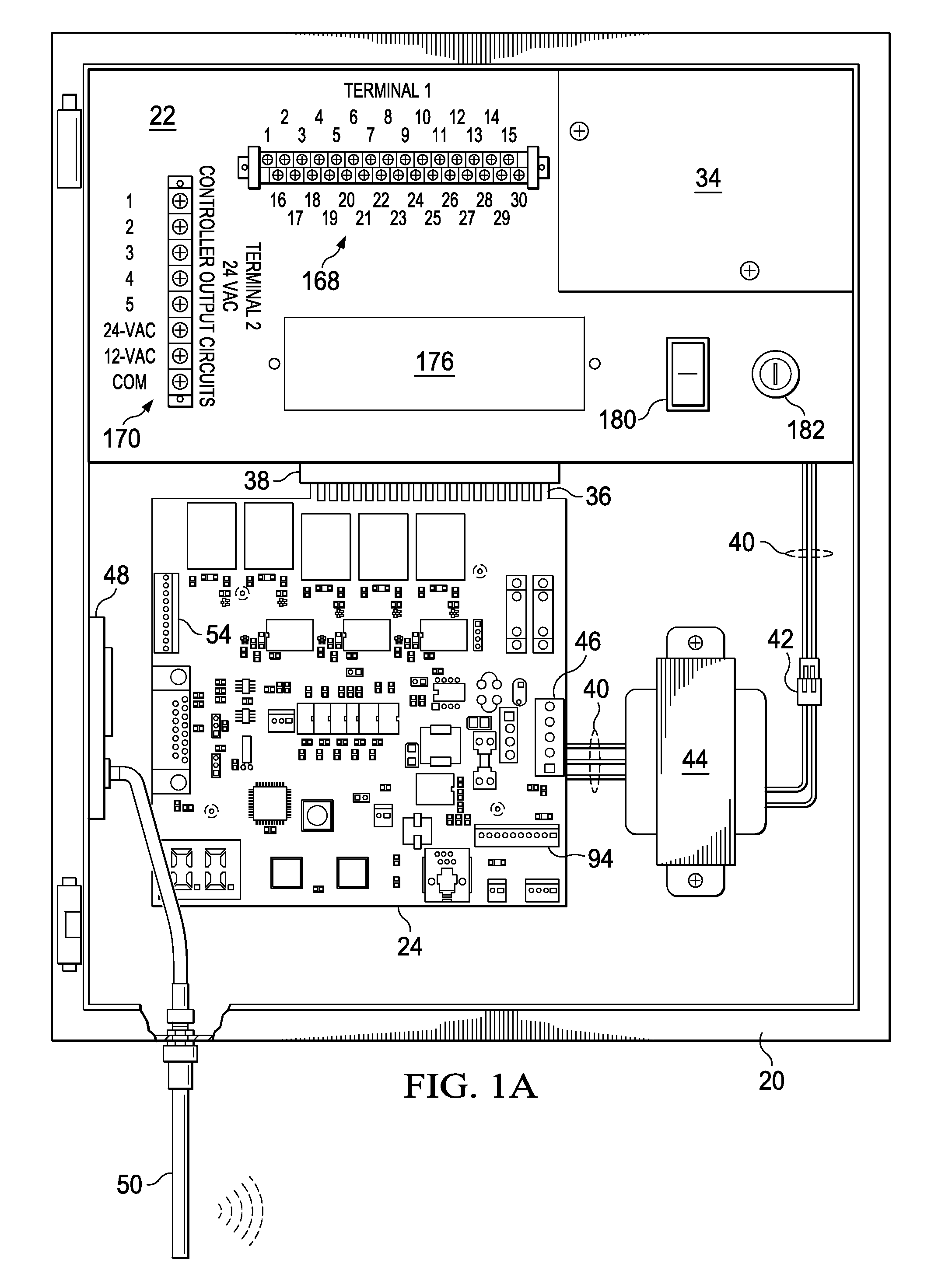

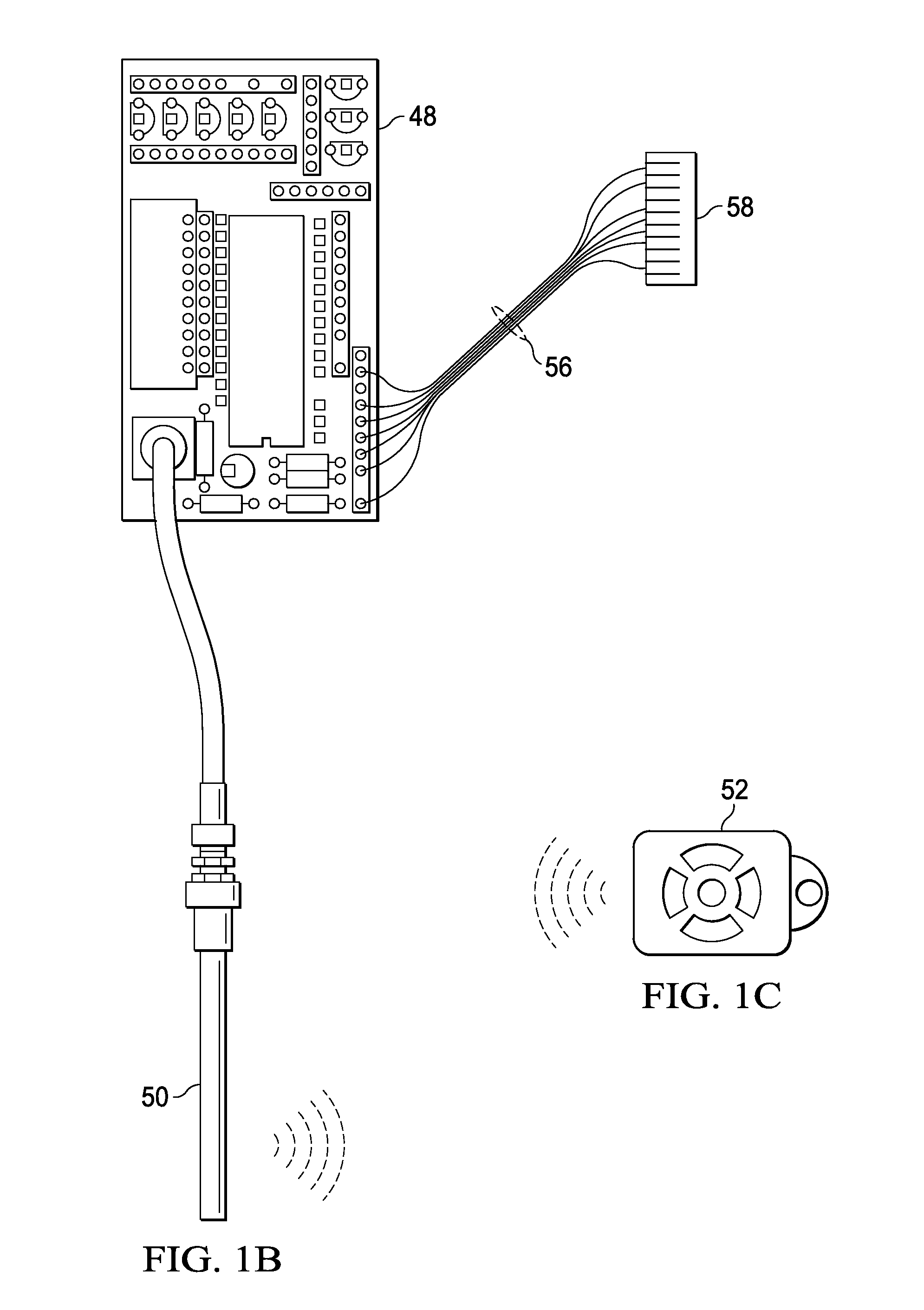

Service panel with microprocessor

ActiveUS20110178609A1Easy maintenanceSafe working environmentProgramme controlTransformersStructure of Management InformationTransmitter

A service panel for limiting access to authorized persons. A sub-region of the service panel controls at least one electrically-operated (e.g., solenoid-operated) valve that is connected to service utilities (e.g., water or gas) piping so as to control flow through the valve. According to one embodiment, another sub-region (i.e., a utility controller region) contains a PCB and other electrical controls for controlling the valve(s) and communicating with other services such as a remote transmitter, or an auxiliary monitoring system (e.g., a fire alarm system). The service panel facilitates the use of advantageous features including: emergency shutdown by anyone while permitting reset only by authorized personnel; modular construction so as to facilitate installation of the system. Various jumper terminals and connecting wires provide for programming of the system to accommodate a variety of applications.

Owner:ISIMET MAPA

Construction method for dismounting high-rise cast-in-place concrete building

InactiveCN102852344AAvoid enteringSolve puzzles that cannot be dismantledBuilding repairsFloor slabArchitectural engineering

The invention discloses a construction method for dismounting a high-rise cast-in-place concrete building. The construction method comprises the following steps of: (1) carrying out security checking calculation on bearing capability according to a load applied to a building structure when a building dismounting machine carries out dismounting operation among floors; arranging ejecting and supporting structures between the adjacent floors from a floor to be constructed to the bottom, wherein the ejecting and supporting structures are respectively ejected and fastened against an upper floor plate and a lower floor plate; and the quantity of floors in need of arranging the ejecting and supporting structures, and the quantity and the arrangement positions of the ejecting and supporting structures can be determined according to data obtained through the security checking calculation; (2) building a protection facility and erecting a passageway; (3) hoisting, assembling and debugging the building dismounting machine; and (4) crushing and dismounting the floors by using the floor dismounting machine. With the adoption of the construction method for dismounting the high-rise cast-in-place concrete building, provided by the invention, the bearing capabilities of a plurality of layers of floors are overlapped by using the ejecting and supporting structures, so as to provide the security for a large-size machine to do upstairs operation. The difficult problem that the large-size machine cannot be used for dismounting the high-rise building can be solved.

Owner:CHONGQING BLASTING CONSTR +1

Elevated working platform and related methods

ActiveUS9663989B2Increase surface areaSafe working environmentLaddersEngineeringMechanical engineering

Elevated work platforms, as well as associated methods, are provided. In one particular embodiment, an elevated platform apparatus is provided comprising a first rail assembly having a pair of rails coupled with a plurality of rungs, a second rail assembly hingedly coupled with the first rail assembly, a platform configured to rest upon a portion of the first rail assembly and the second rails assembly and a cage associated with the platform. The cage may include at least one bar and at least one gate, the at least one gate being configured to swing in a first direction upon a user stepping on to the platform from the first rail assembly, and then swing back to a closed position after the user is standing on the platform. The at least one gate is also limited from being displaced in a second direction, opposite the first direction, beyond the closed position.

Owner:LITTLE GIANT LADDER SYST LLC

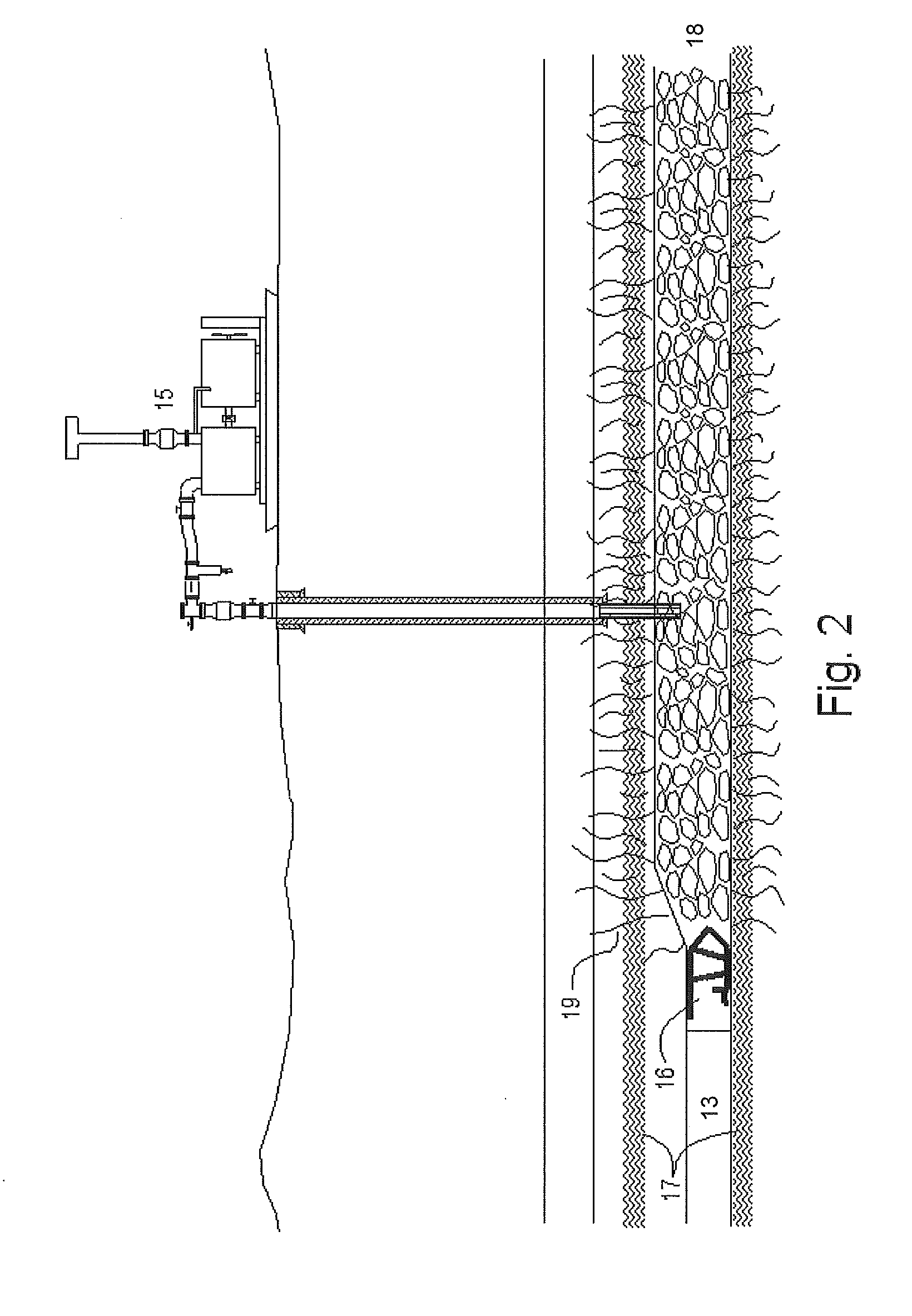

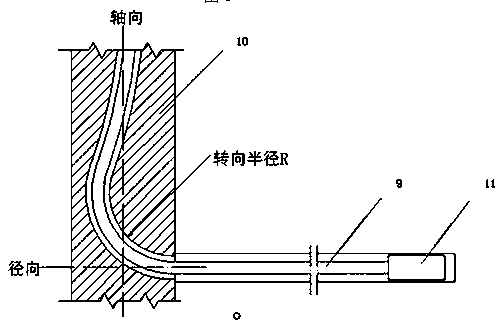

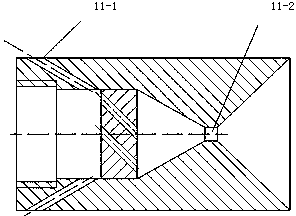

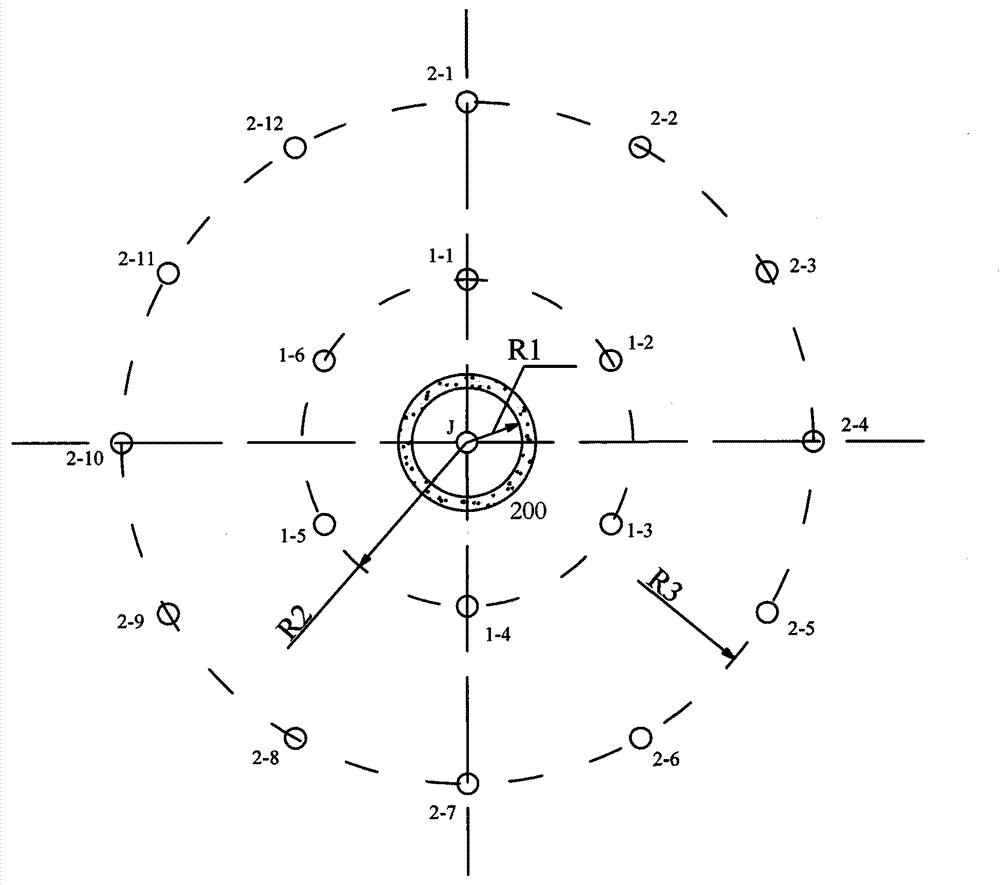

Method and device for conducting hydraulic jet self-propelled drilling to improve gas permeability of coal seam

ActiveCN103924925AReduce the number of drilled holesSimple constructionLiquid/gas jet drillingTree shapedDrilling system

The invention discloses a hydraulic jet self-propelled drilling method and device. The device comprises a water tank, a high-pressure pump, a high-pressure energy storage tank, a high-pressure hose supplying device, a drilling machine, an orientator, a high-pressure hose, a steering gear, a drill rod and a self-propelled drill bit. According to the method, a pilot hole is drilled firstly in a coal seam, the steering gear is installed in the pilot hole, the self-propelled drill bit enters the steering gear along the drill rod and is used for radial drilling along the pilot hole under the guidance of the steering gear, the self-propelled drill bit recedes to the position of the steering gear when radial drilling is conducted to a preset depth, the angle of the steering gear is adjusted by shifting the gear of the orientator so that radial drilling can be conducted in another direction, and a tree-shaped drilling system with the pilot hole as the trunk and radial holes formed in a radiating mode is formed through repeat drilling for gas extraction. The device is simple in structure, convenient to operate, and capable of reducing the number of gas extraction holes remarkably, widening the pressure relieving range of each drill hole, improving the gas permeability of the coal seam effectively, shortening gas extraction time and improving the gas extraction quantity of each hole effectively.

Owner:CHONGQING UNIV

Comprehensive pretreatment method for shaft penetration in mined-out area stratum

ActiveCN103835723AEnsure construction safetyImprove construction efficiencyShaft liningPretreatment methodFilling materials

The invention discloses a comprehensive pretreatment method for shaft penetration in a mined-out area stratum. The method comprises the steps that (1) treatment drilling holes are formed around the center of a proposed shaft and are formed on the periphery of the proposed shaft; (2) filling materials are conveyed to a mined-out area through the treatment drilling holes on the ground. According to the comprehensive pretreatment method for shaft penetration in the mined-out area stratum, mined-out area dangers during shaft construction can be effectively avoided, the milled-out area is pre-treated before the shaft is excavated, and shaft excavation construction safety and built shaft running safety are ensured.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Complete stroke thermal insulating cover for continuous casting conveying roller way

The present invention provides an omnirange heat-insulating cover for continuous casting roll gang. It is formed from several heat-insulating cover bodies. In the whole roll gang, including casting billet cutting zone roll gang, dummy bar roll gang and dressing machine roll gang, over every roll gang a heat-insulating cover body which can be opened is set respectively. The heat-insulating cover body positioned over the casting billet cutting zone roll gang is made into drawing-pulling type structure, the heat-insulating cover body positioned over the dummy bar roll gang is a tilting structure, formed from several heat-insulating cover bodies, at one side of every heat-insulating cover body its respective tilting mechanism is mounted; and the heat-insulating cover body positioned over the dressing machine is a translational structure, the transverse beam in the top portion of heat-insulating cover body can make the several cover bodies be connected into one body, and two ends of said transverse beam are respectively slide-connected with two transversely-moved guideways by means of pulleys.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com