Method and device for conducting hydraulic jet self-propelled drilling to improve gas permeability of coal seam

A hydraulic jet and self-propelled technology, which is applied in the direction of drilling with liquid/gas jet, can solve the problems of low efficiency, heavy workload, and low gas extraction volume in low-permeability coal seams, and achieve a safe working environment and convenient operation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

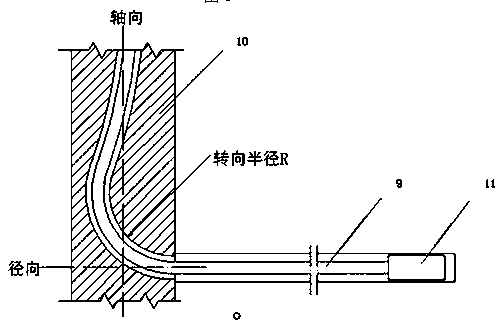

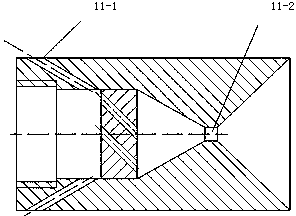

[0022] Below in conjunction with accompanying drawing, structure and using method of the present invention are described in detail:

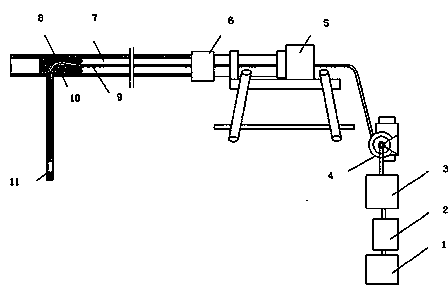

[0023] see figure 1 The main equipment specifically involved in the hydraulic jet self-propelled tree-shaped drilling device proposed by the present invention includes: water tank 1, high-pressure pump 2, high-pressure energy storage tank 3, high-pressure hose telescopic supply device 4, drilling rig 5, orienter 6, High-pressure hose 9, steering gear 10, drill pipe 8, self-advancing drill bit 11, etc., their connections are as follows:

[0024] Water tank 1, high-pressure pump 2, high-pressure energy storage tank 3 and high-pressure hose 9 are connected in sequence, and high-pressure hose 9 is contained on the high-pressure hose telescopic supply device 4.

[0025] The orienter 6 is a regular N-sided columnar body with a through hole in the center, and N sides are formed with N gears. The front end of the orienter is connected with the drill ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com