Mining overburden rock motion law in-situ observation drill hole layout method

A technology of drilling layout and movement rules, applied in the direction of optical exploration, etc., can solve the problems of high cost, scrapped drilling, waste of engineering time and project funds, etc., to reduce the initial engineering investment, reduce the number of drilling holes, and reduce the initial investment small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

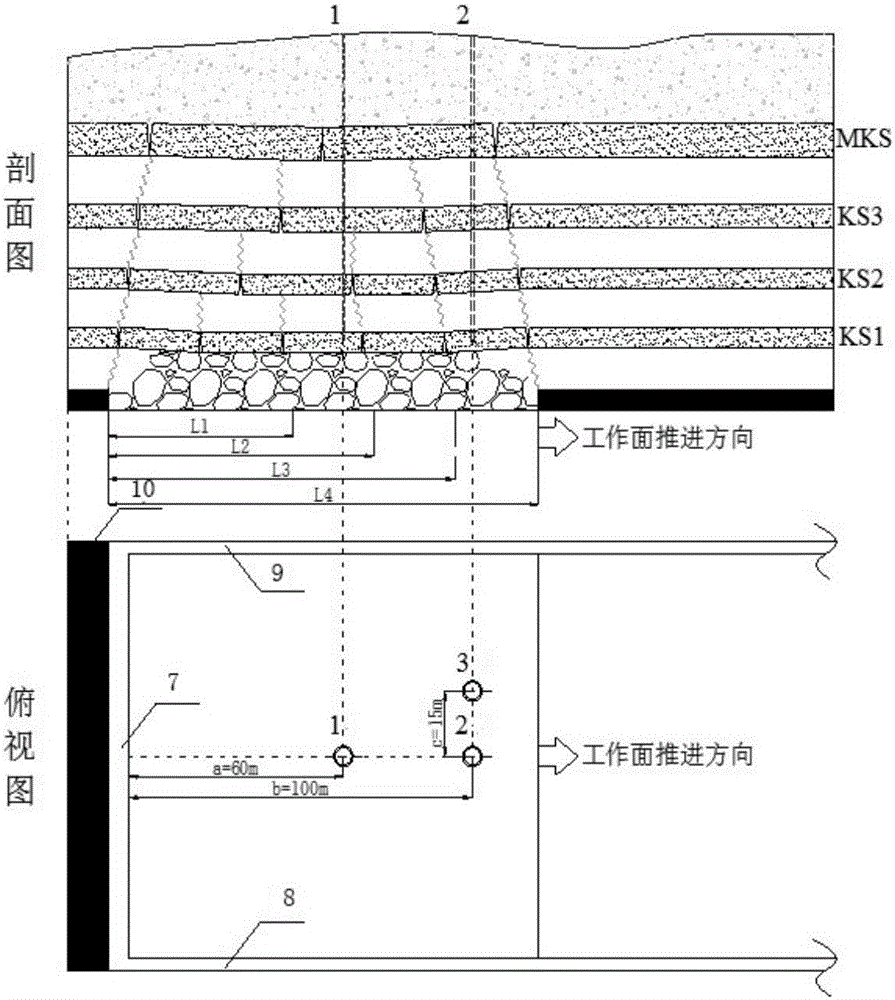

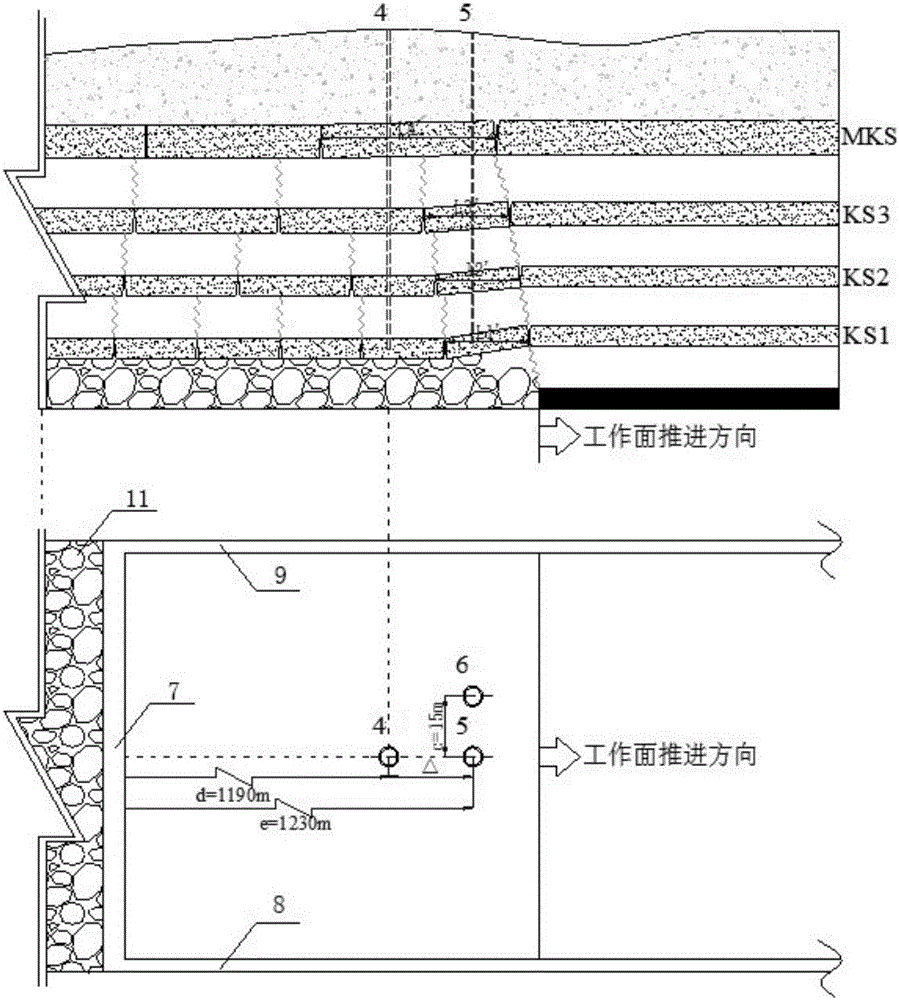

[0019] Below in conjunction with accompanying drawing, the implementation case of the present invention is described further:

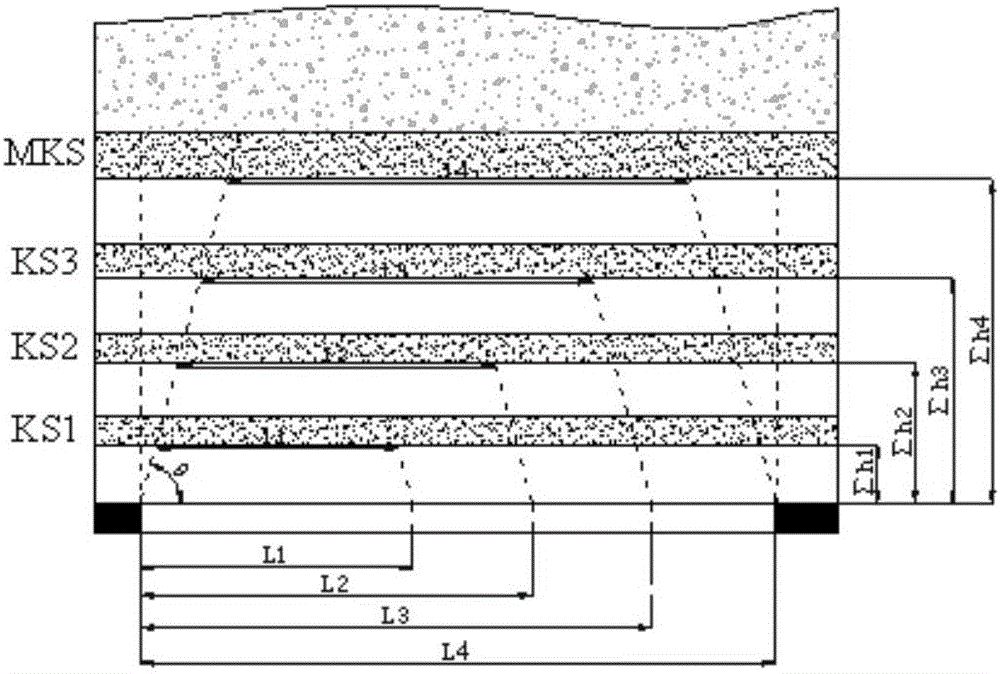

[0020] Such as figure 1 , figure 2 with image 3 As shown, the in-situ observation drilling arrangement method for mining overlying rock movement law of the present invention, its steps are as follows:

[0021] a. Collect the geological information of the mining area, obtain the full columnar strata in this area, use the key layer theory of rock strata movement, obtain the position and related parameters of the key layer of the overlying rock in the full columnar overlying rock, and use the formula: Calculate the limit span l of the key layer of overlying rock i ;using the formula: Calculate the primary breaking distance L of the key layer of overlying rock i ; using the formula Calculate the periodic breaking distance L of the key layer of overlying rock i '; in the formula: the value of i is i=1, 2, 3, 4, respectively representing the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com