Downward bedding Layer driLLing hydrauLic sLitting process method

A technology of bedding drilling and hydraulic slotting, which is applied in the direction of earth drilling, liquid/gas jet drilling, gas discharge, etc. It can solve the problem of low porosity rate and unsatisfactory drainage effect of downward bedding drilling To solve the problem, achieve the effect of reducing the number of drilling holes, increasing the effective range of influence and the success rate of slotting, and widely promoting the value of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

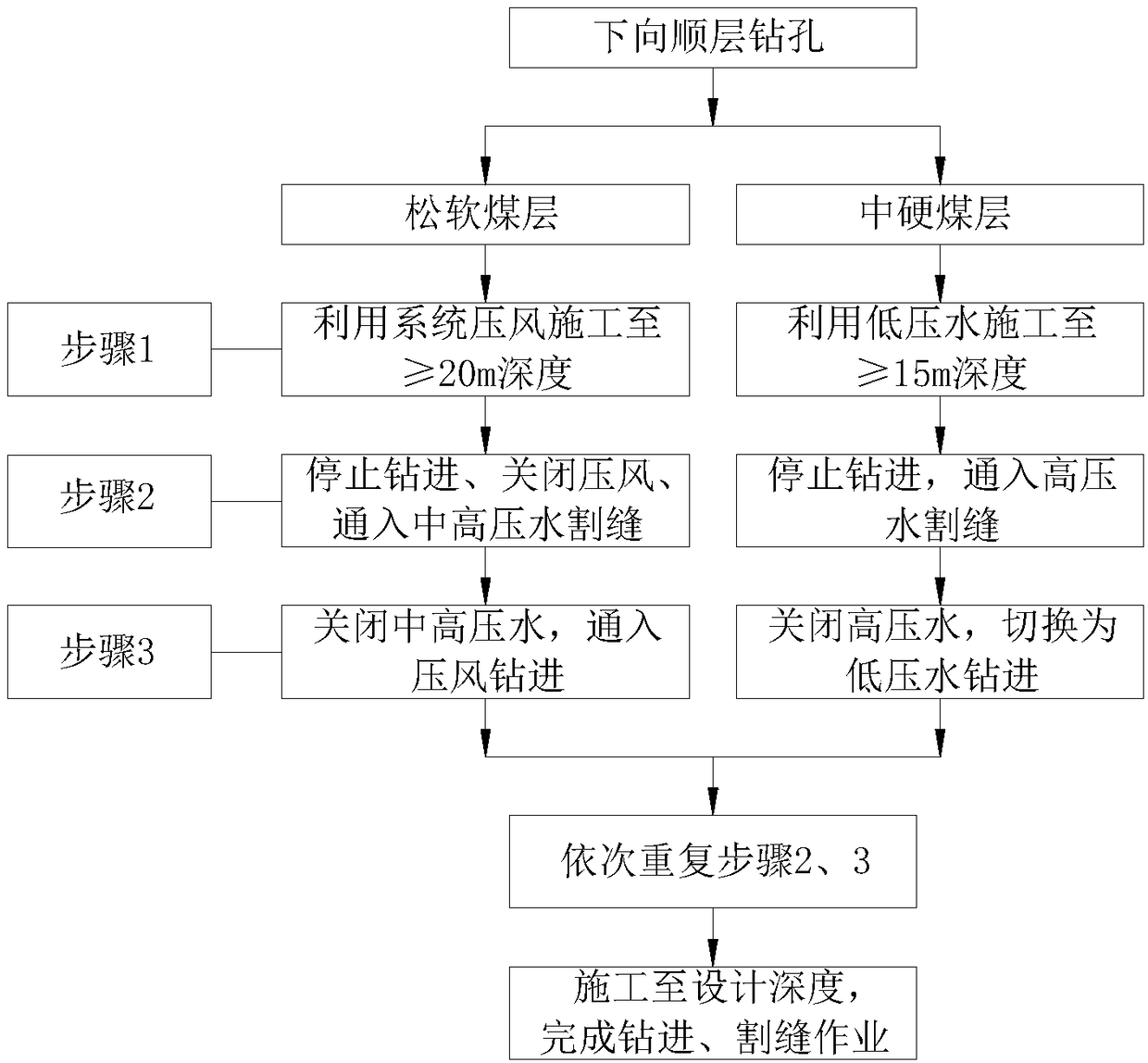

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0024] like figure 1 As shown, on the one hand, for a soft coal seam with a coal firmness coefficient f<0.5, the specific implementation steps of the downward drilling hydraulic slotting process are as follows:

[0025] 1. Utilize the drilling rig, 0.6-1MPa system pressure air and the auger drill pipe that is good for slag discharge to construct a layer-by-layer drilling (diameter Φ94-133mm) to a depth of ≥20m on the working face to be excavated or to be mined;

[0026] 2. Stop drilling, turn off the pressurized air, and pass in 40-60MPa medium-high pressure water to carry out the slotting work, and the slotting time is 3-5 minutes;

[0027] 3. After the slotting is completed, switch to 30-40MPa water pressure for 5-10 minutes of punching and slag discharge;

[0028] 4. Turn off the medium and high pressure water, connect 0.6~1MPa system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com