Hydraulic cutting device and hydraulic cutting method for drilling through bed

A technology of hydraulic slotting and layer-penetrating drilling, which is applied in safety devices, earthwork drilling, drilling with liquid/gas jets, etc. It can solve the problems of small coal body exposure and affect the gas drainage effect, and achieve improved gas Drainage effect, simple structure, and the effect of increasing the exposed area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

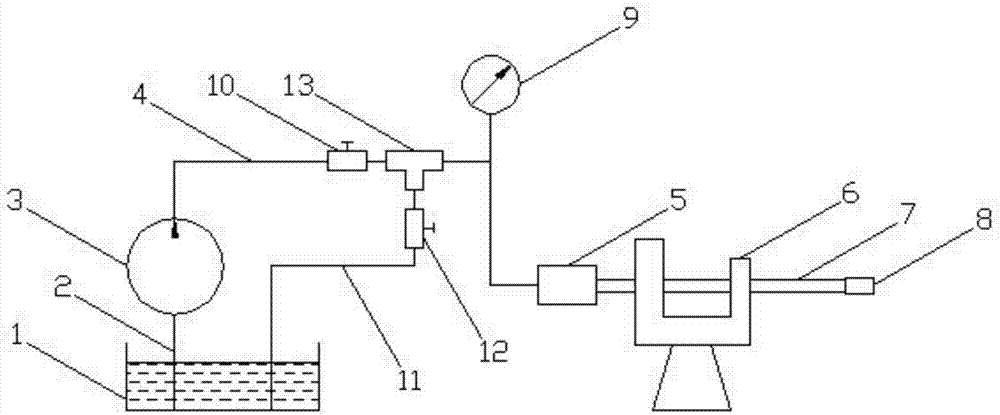

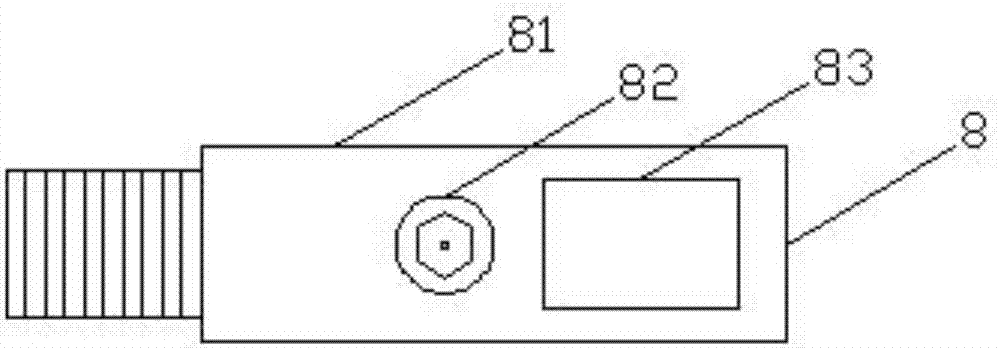

[0017] Such as Figure 1-2 As shown, the hydraulic cutting device for drilling through layers includes a water tank 1, a water inlet pipe 2, a water pump 3, an outlet pipe 4, a rotating water tail 5, a drilling rig 6, a drill pipe 7, a hydraulic cutting drill bit 8, a pressure gauge 9, and a pressure regulator Valve 10, pressure relief pipe 11, pressure relief valve 12, tee 13.

[0018] One end of the water inlet pipe 2 is connected to the water tank 1, and the other end is connected to the water inlet of the water pump 3; One end is connected to the hydraulic slotting drill bit 8; the drill pipe 7 is set on the drilling rig 6, which is driven to rotate by the drilling rig 6, and the rotating water tail 5 is used to connect the rotating drill pipe 7 and the stationary water outlet pipe 4 together; the water outlet pipe 4 is provided with The pressure gauge 9 is provided with a pressure regulating valve 10 on the water outlet pipe 4 between the pressure gauge 9 and the water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com