Coal mine downhole hydraulic jet tree-shaped drill hole guide device and method

A guiding device and hydraulic jetting technology, which is applied in liquid/gas jet drilling, directional drilling, earthwork drilling and production, etc. It can solve the complex operation of the guiding device's precise steering, lowering to a predetermined position, and small annular space of the guider, etc. Problems, to achieve the effect of convenient processing and use, convenient use and processing, and reduce its own volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

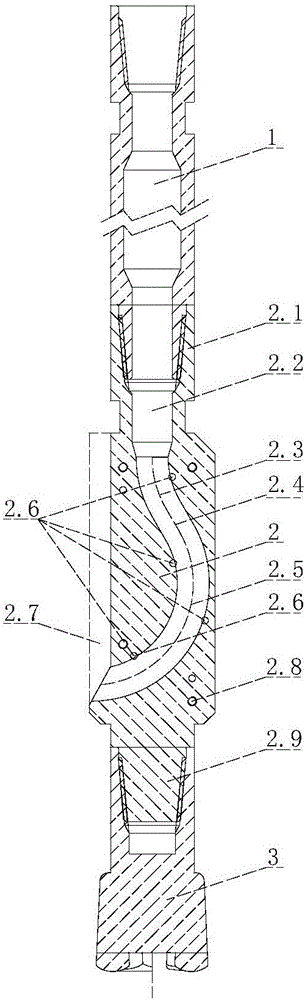

[0046] Such as figure 1 As shown, the guiding device includes a drill rod (1), a guide (2) and a drill bit (3) connected in sequence.

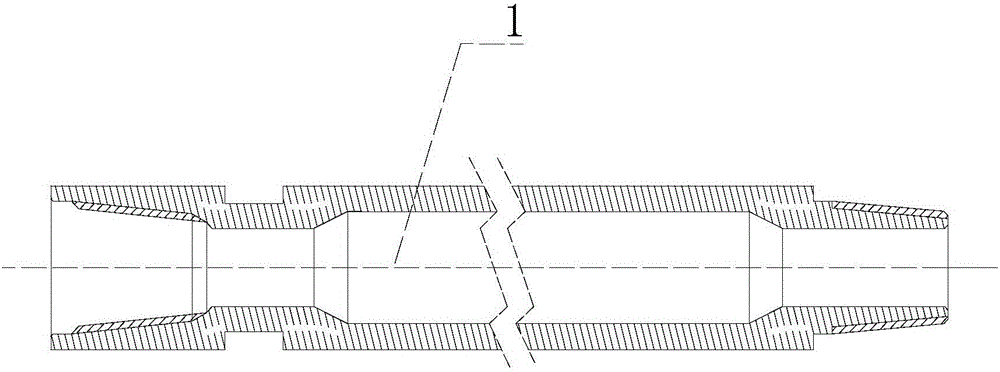

[0047] Such as figure 2As shown, the diameter of the drill pipe (1) is consistent with the diameter of the commonly used drill pipe for underground gas drainage in coal mines, with an outer diameter of 73mm and an inner diameter of 50mm. The front and rear threads of the drill pipe are designed in accordance with national standards for easy connection; the inside of the drill pipe is a smooth through hole, and the high-pressure hose can pass through smoothly. The drill rod is beneficial to accurately send the guide to the designated position and drive the guide to turn.

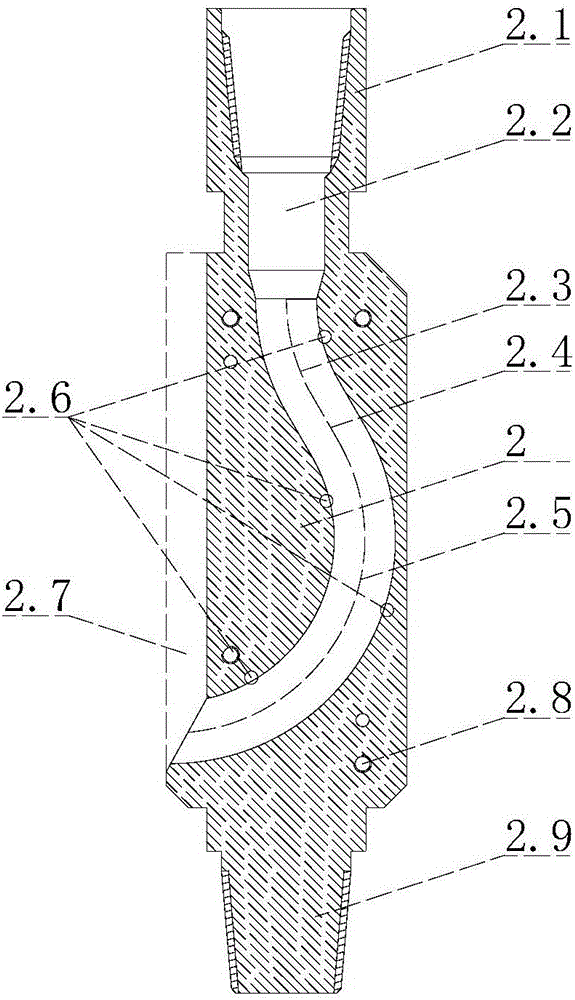

[0048] to combine figure 1 and image 3 , the upper end of the guide (2) is a drill pipe connecting portion (2.1), and the lower end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com