Manufacturing method of puffed corn dregs

A technology of puffed corn and its manufacturing method, which is applied in the direction of feed, animal feed, animal feed, etc., can solve the problems of high viscosity of modified starch, inability to run continuously, and inconvenient use, and achieve uniform shape, wide application range, and reduce meat consumption. than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

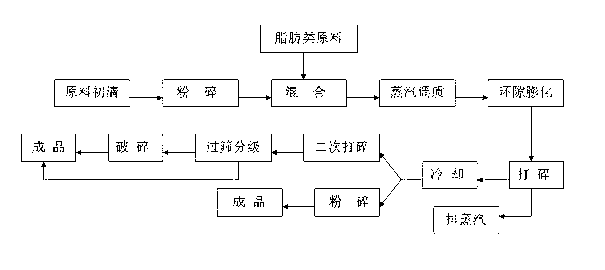

[0028] attached by figure 1 Shown: the method is to use corn as the main ingredient, add lubricating expansion aid in proportion, and use 360 0 C-ring gap discharge puffing or expander aging process to obtain puffed corn meal products, the specific steps are as follows:

[0029] ①Primary cleaning and crushing: Put 160 kg of corn raw materials into the feeding port, pass through the conveyor and hoist to the raw material bin, and rotate through the screen drum to remove large impurities in the raw materials, and the raw materials after primary cleaning are sent to the pulverizer Medium crushing, passing through a sieve with a pore size of 2mm, and the crushed material is ready for use;

[0030] ② Mixing treatment: Mix the crushed corn with 40 kg of rice bran containing about 15% oil for 3-5 minutes and add 4 kg of water at the same time.

[0031] ③. Conditioning treatment: Send the mixed material in ② into the conditioner of the extruder for steam conditioning treatment. The ...

Embodiment 2

[0039] ① The steps of primary clear pulverization are the same as in Example 1.

[0040] ② Mixing treatment: Mix 185 kg of crushed corn with 15 kg of oily feet, a by-product of soybean oil containing 40% oil, for 3-5 minutes, because the oily feet contain about 40-50% of water. No need to add water.

[0041] 3., 4., 5., 6., 7. steps are identical with embodiment 1.

Embodiment 3

[0043] ① The steps of primary clear pulverization are the same as in Example 1.

[0044] ② Mixing treatment: Mix 180 kg of crushed corn with 15 kg of corn germ and 5 kg of phospholipid for 3-5 minutes, and add 4 kg of water at the same time. 3., 4., 5., 6., 7. steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com