Guiding mechanism for rotary distributor capable of realizing multi-peak distribution

A technology of rotating distributor and cloth, which is used in furnaces, vertical furnaces, lighting and heating equipment, etc., can solve the problems of complex driving device structure of the overall structure, unadjustable distribution angle, and impact on production continuity, so as to ensure continuous production. The effect of running, easy adjustment of cloth method and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

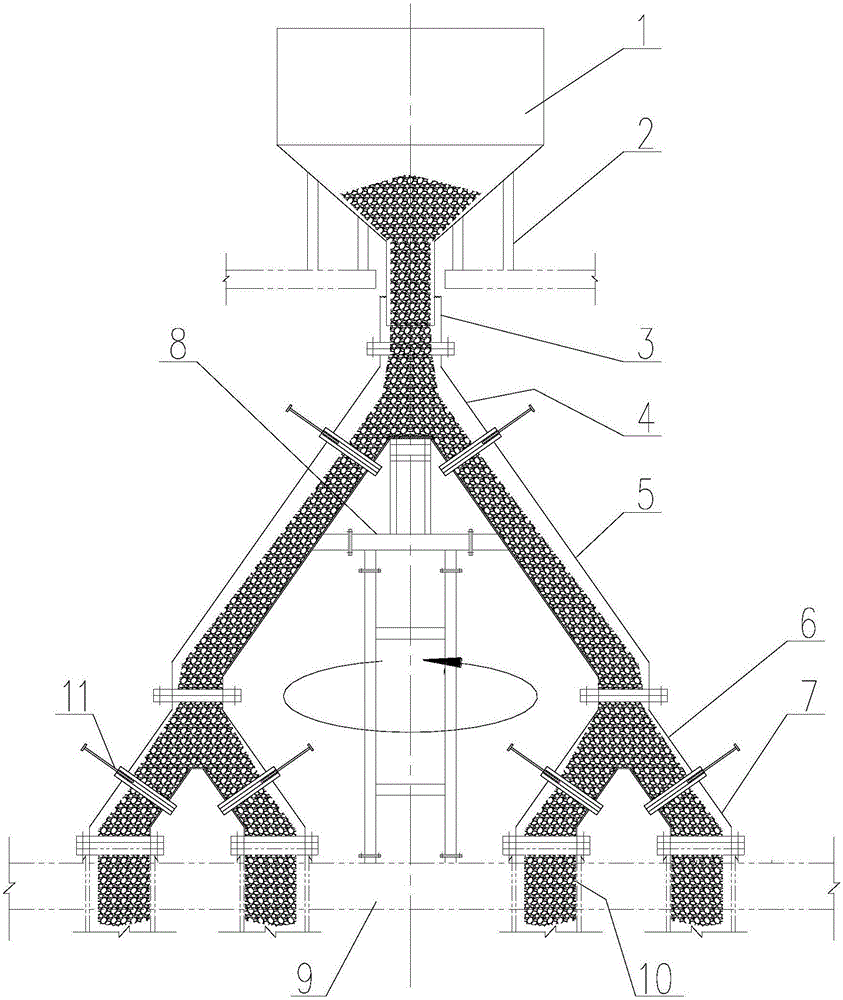

[0025] Such as figure 1 As shown, the material guide mechanism of the rotary distributor that can realize multi-peak distribution according to the present invention includes a receiving hopper 1, a sealed union pipe 3, a branch body 4, a material guide body 5, and a branch circuit sequentially connected from top to bottom. Branch body 6 and discharge body 7; the receiving hopper 1 is set at the center position above the furnace mouth through a fixed support frame 2, and its bottom is rotatably connected with the branch body 4 through a sealed joint 3; the branch body 4 There are at least 2 outlets in the lower part of the body, and the outlets are inclined outward and downward; the guide body 5 connected to the outlet of the branch body 4 is arranged along the direction of its inclination; the upper end of the branch branch body 6 It is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com