Device and method for coiled material centering and diameter measuring

A caliper and coil technology, applied in measuring devices, optical devices, instruments, etc., can solve the problems of unreachable caliper, occupying a large space, inconvenient installation, etc., achieving high precision, simple and reliable device, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

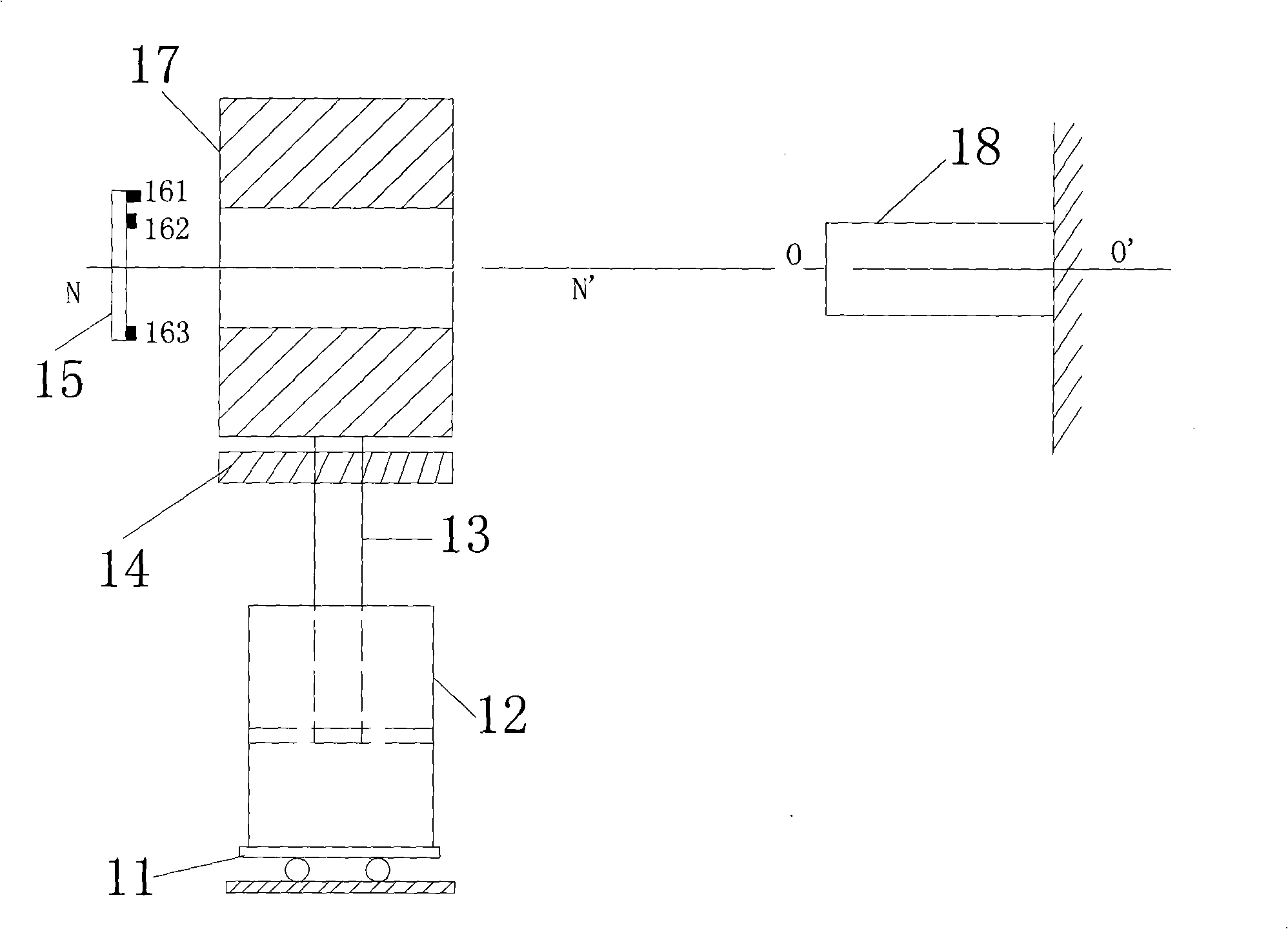

Embodiment 1

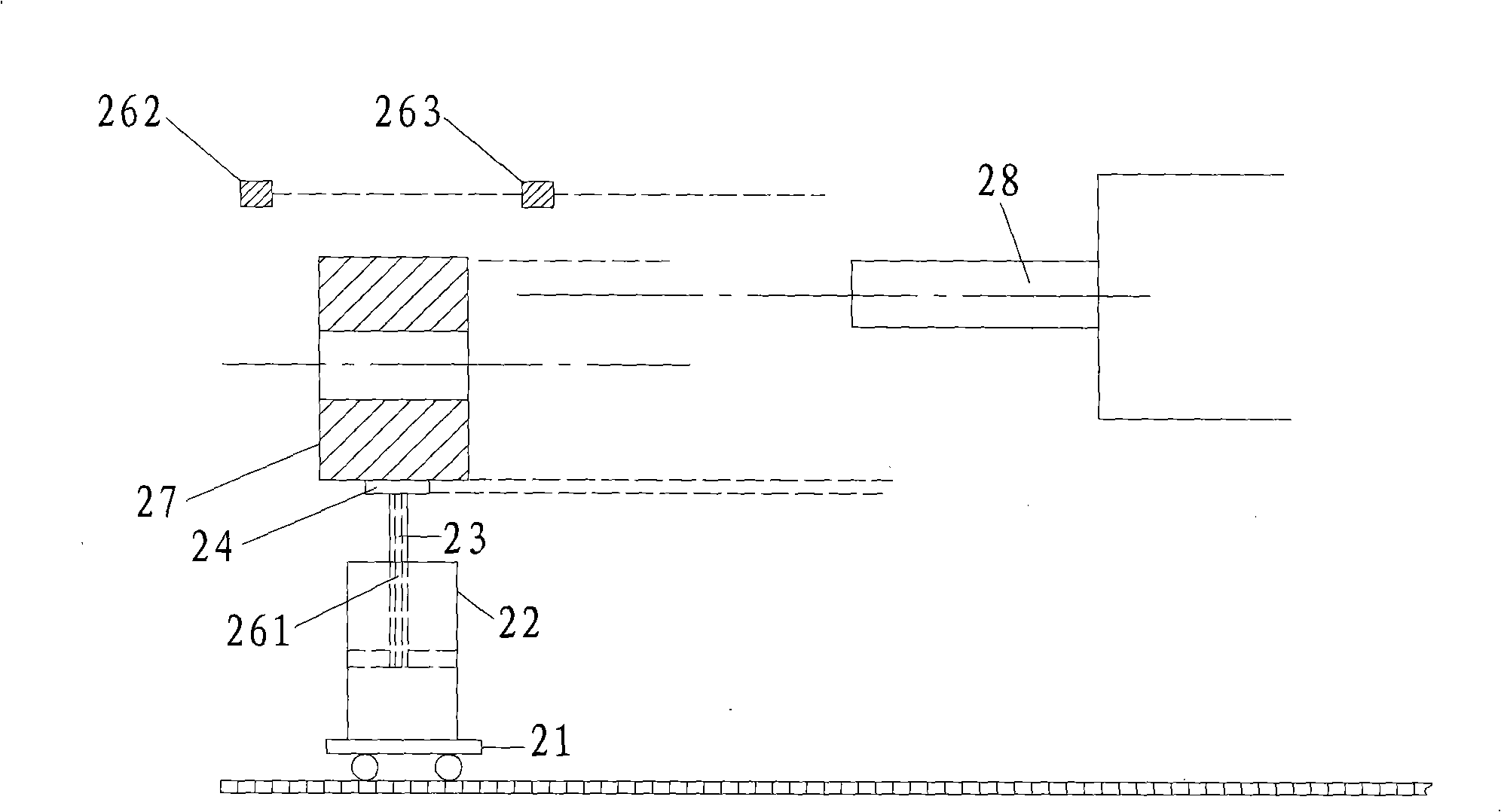

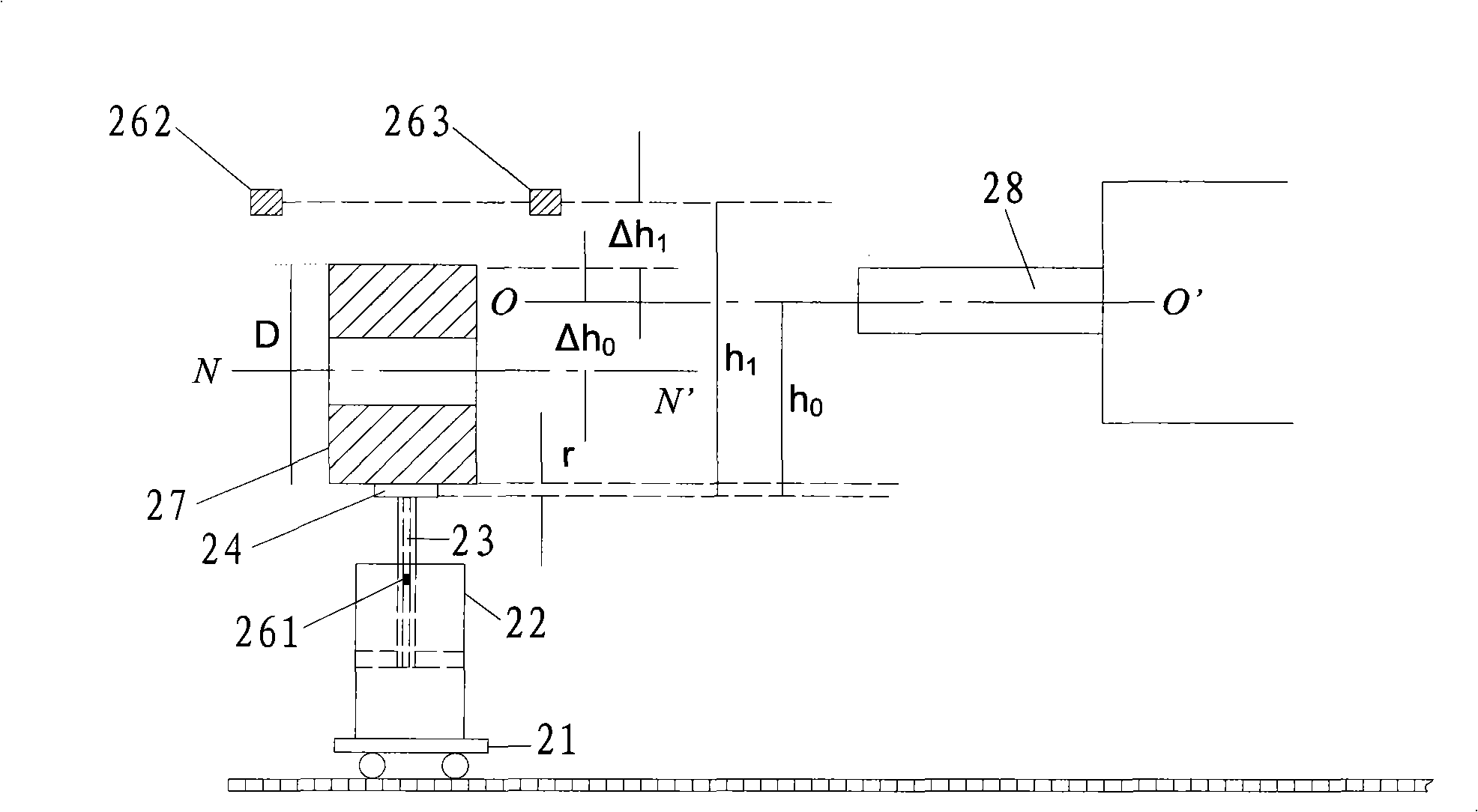

[0021] A coil centering diameter measuring device, comprising a trolley 21, a hydraulic cylinder 22, a push rod 23, a bracket 24, a displacement sensor A 261, a photoelectric sensor B 262, a photoelectric sensor C 263, an analog / digital converter 29 and a PLC 30, The specific structure is: a hydraulic cylinder 22 is fixed on the trolley 21 that can move left and right, a push rod 23 is fixed on the piston of the hydraulic cylinder 22, a bracket 24 is fixed on the top of the push rod 23, and a displacement sensor A 261 is fixed inside the push rod 23 , the position signal generated by the displacement sensor A 261 has a linear relationship with the moving distance of the ejector rod 23, the photoelectric sensor B 262 and the photoelectric sensor C 263 are fixed directly above the bracket 24, and the photoelectric sensor B 262 and the photoelectric sensor C 263 are on the same horizontal line Above, the displacement sensor A 261, the photoelectric sensor B 262 and the photoelectr...

Embodiment 2

[0027] A coil centering diameter measuring device, comprising a trolley 21, a hydraulic cylinder 22, a push rod 23, a bracket 24, a displacement sensor A 261, a grating B 362, a grating C 363, an analog / digital converter 29 and a single-chip microcomputer 40, specifically The structure is: a hydraulic cylinder 22 is fixed on the trolley 21 that can move left and right; The position signal generated by the displacement sensor A 261 has a linear relationship with the moving distance of the ejector rod 23. The grating B 362 and the grating C 363 are fixed directly above the bracket 24, and the grating B 362 and the grating C 363 are on the same horizontal line. The displacement sensor A 261, grating second 362 and grating third 363 are all connected with single-chip microcomputer 40 through analog / digital converter 29.

[0028]When using this embodiment for centering and diameter measurement, the steel coil 27 is fixed on the bracket 24, and the piston of the hydraulic cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com