U-shaped hybrid type radiation boiler

A hybrid, U-shaped technology, used in steam boilers, lighting and heating equipment, steam generation, etc., can solve problems such as boiler contamination and difficult removal of boiler heating surfaces, reduce dust accumulation, ensure continuous operation, Solve the effect of coking and heating surface in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

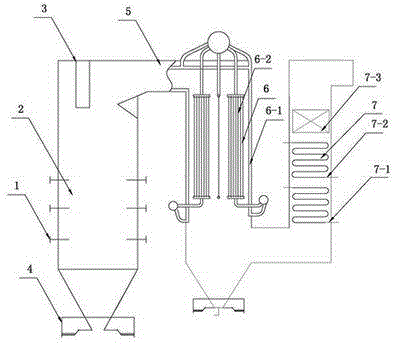

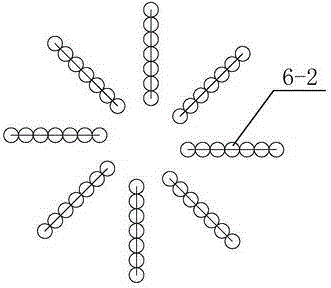

[0028] Such as Figure 1-2 As shown, a U-shaped hybrid radiant boiler includes a pulverized coal furnace and a heat recovery device. The pulverized coal furnace is located on the left side of the heat recovery device. The heat recovery device is a hybrid heat recovery device, including a flue gas inlet 5, a Heat exchange assembly 6, convection heat exchange assembly 7, radiation heat exchange assembly 6 is on the left side of convection heat exchange assembly 7, radiation heat exchange assembly 6 and convection heat exchange assembly 7 form a U shape; the radiation heat exchange assembly 6 includes radiation Water-cooled wall 6-1 and radiation screen 6-2; the radiation water-cooled wall 6-1 is a cylindrical structure formed by splicing a plurality of vertical slender tubes, and the inside of the cylinder is a cavity structure; the radiation screen 6 -2 is located in the cavity structure of the radiation water wall 6-1. The radiation screen 6-2 includes a plurality of vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com