Automatic splicing device for broken yarn of weaving cotton cloth

A yarn breaking and automatic technology, applied in the direction of textiles, textiles, papermaking, weaving auxiliary equipment, etc., can solve the problems of increasing the cost of fabric textiles, increasing the labor intensity of workers, and reducing the efficiency of textile machinery, so as to improve work efficiency and ensure The effect of continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with embodiment the present invention is further described:

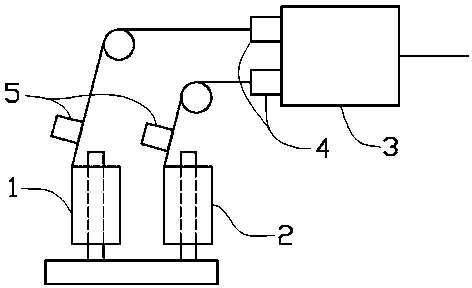

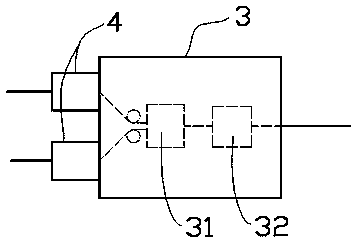

[0013] Such as figure 1 As shown in the embodiment, the device for automatically connecting broken yarns in weaving is installed on the loom, and includes a junction box 3, a main spindle 1, and an auxiliary spindle 2, and the front end of the junction box 3 is equipped with two , secondary spindles 2 respectively connected to the incoming line connector 4; said main spindle 1, secondary spindle 2 and said incoming line connector 4 are respectively equipped with detectors 5; said detectors 5 are respectively connected to the main control device , only one of the main spindle 1 and the auxiliary spindle 2 is connected to the textile fabric; the detector 5 can respond the broken yarn signal to the main control device, and the main control device controls the junction box 3 to Another way of yarn is connected to the loom.

[0014] When the weaving broken yarn automatic continuation device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com