Chain bar type permanent magnet filter

A filter and chain-rod technology, which is applied in the field of chain-rod permanent magnet filters, can solve the problems of difficult processing, difficult implementation of track installation, and high failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

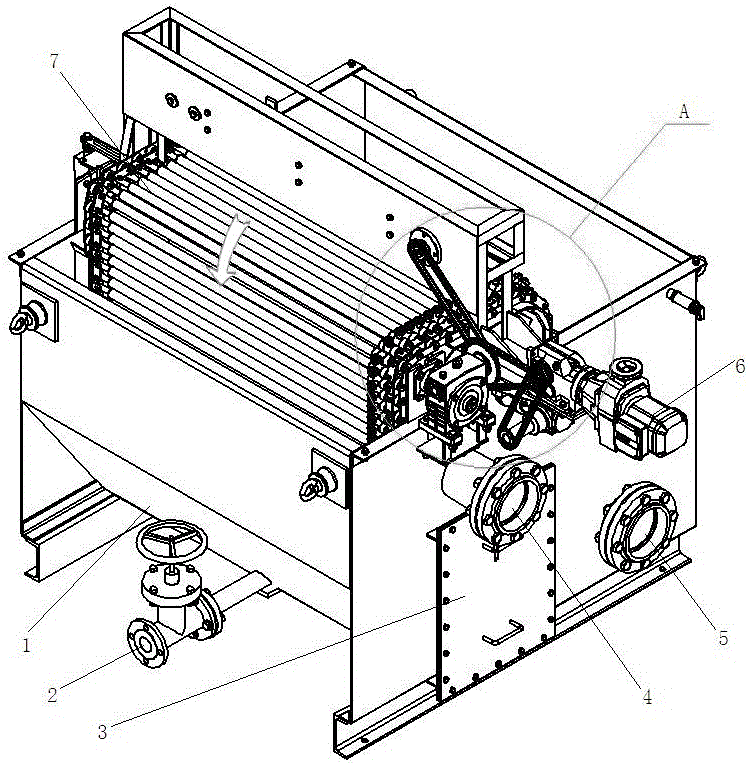

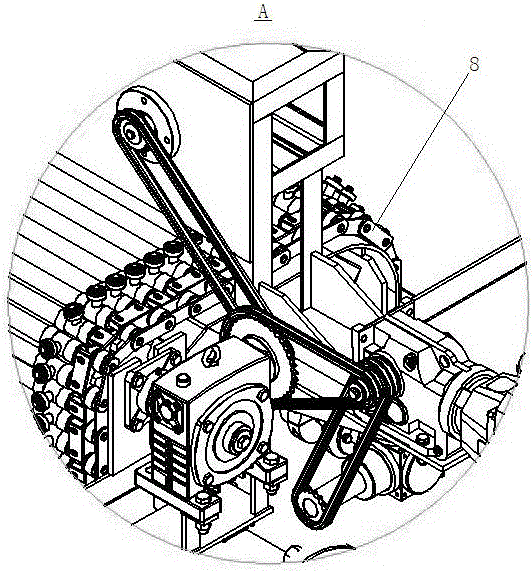

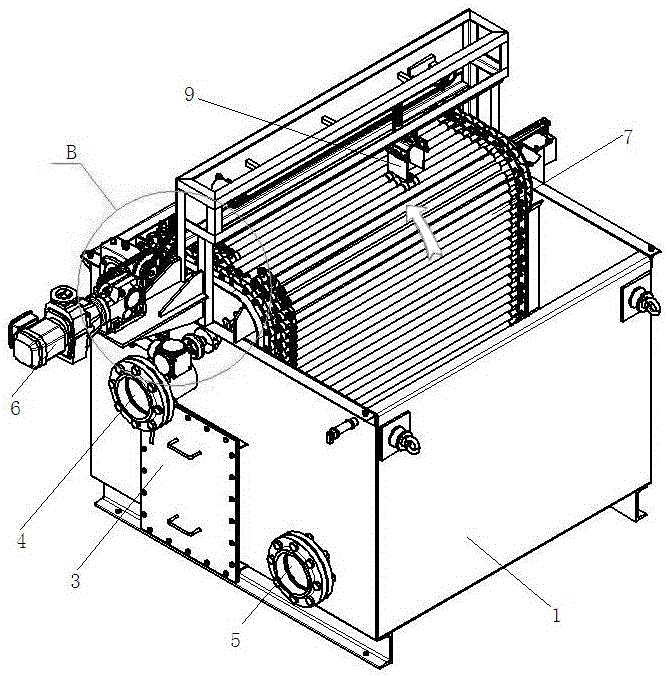

[0029] Such as Figure 1 to Figure 4 Shown, a kind of chain bar type permanent magnet filter, comprises box body 1, is located at the magnetic bar chain 7 that can revolve around itself in box body 1, is located at the mud scraping mechanism above magnetic bar chain 7, is located at scraper mud Below the mechanism and at the sludge tank 19 inside the magnetic bar chain 7, a sludge conveying mechanism is arranged in the sludge tank 19, and each magnetic bar 10 of the magnetic bar chain 7 is fitted with a wiper sleeve 11 to wipe The mud mechanism includes a moving block 15 capable of reciprocating axially along the magnetic rod 10. The lower part of the moving block 15 is hinged with two scrapers 9 that can only swing in the axial direction of the magnetic rod 10 (torsion springs are provided at the hinges). A scraper 9 can swing and reset to the side cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com