Patents

Literature

288results about How to "No stuck phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

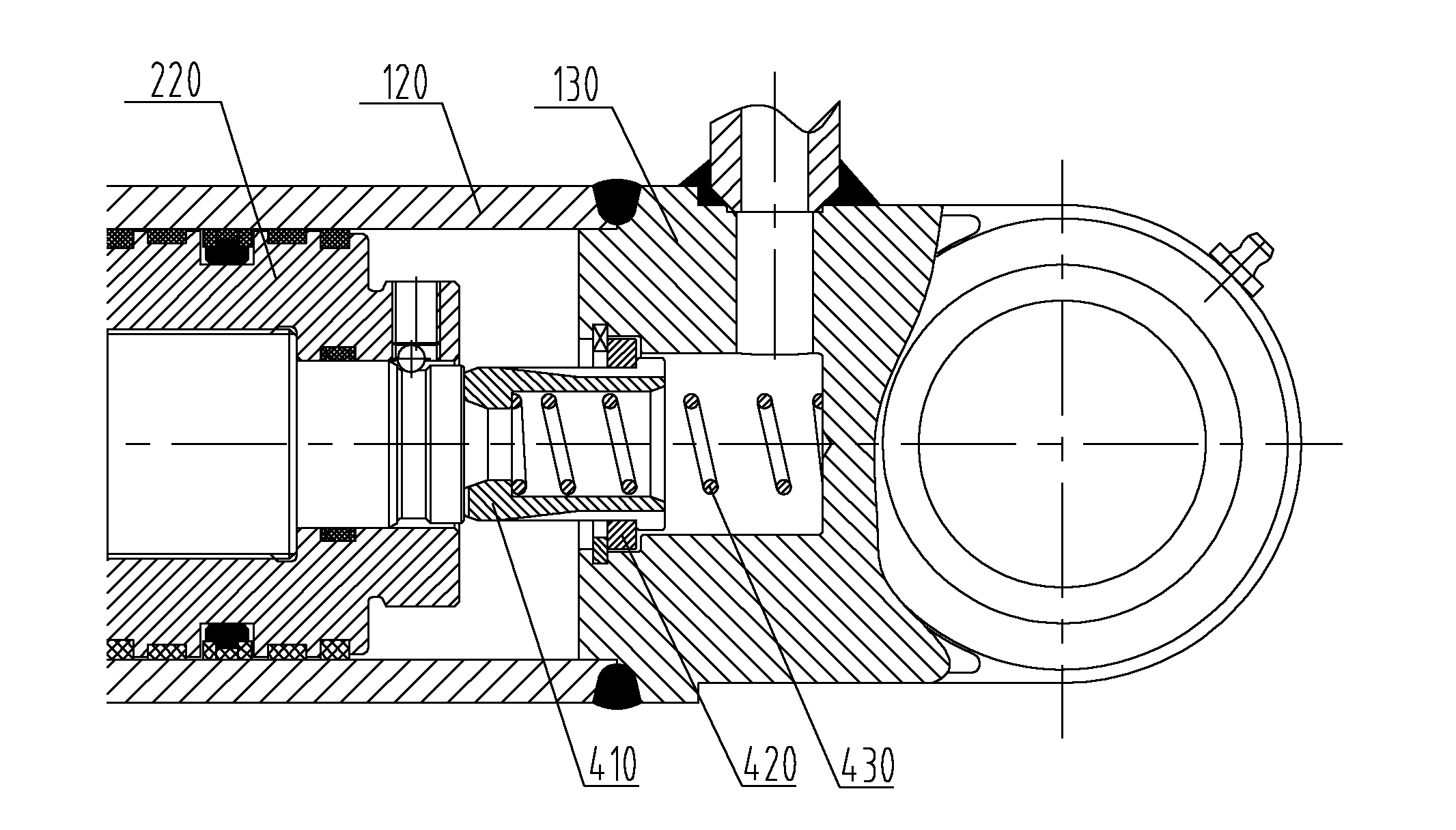

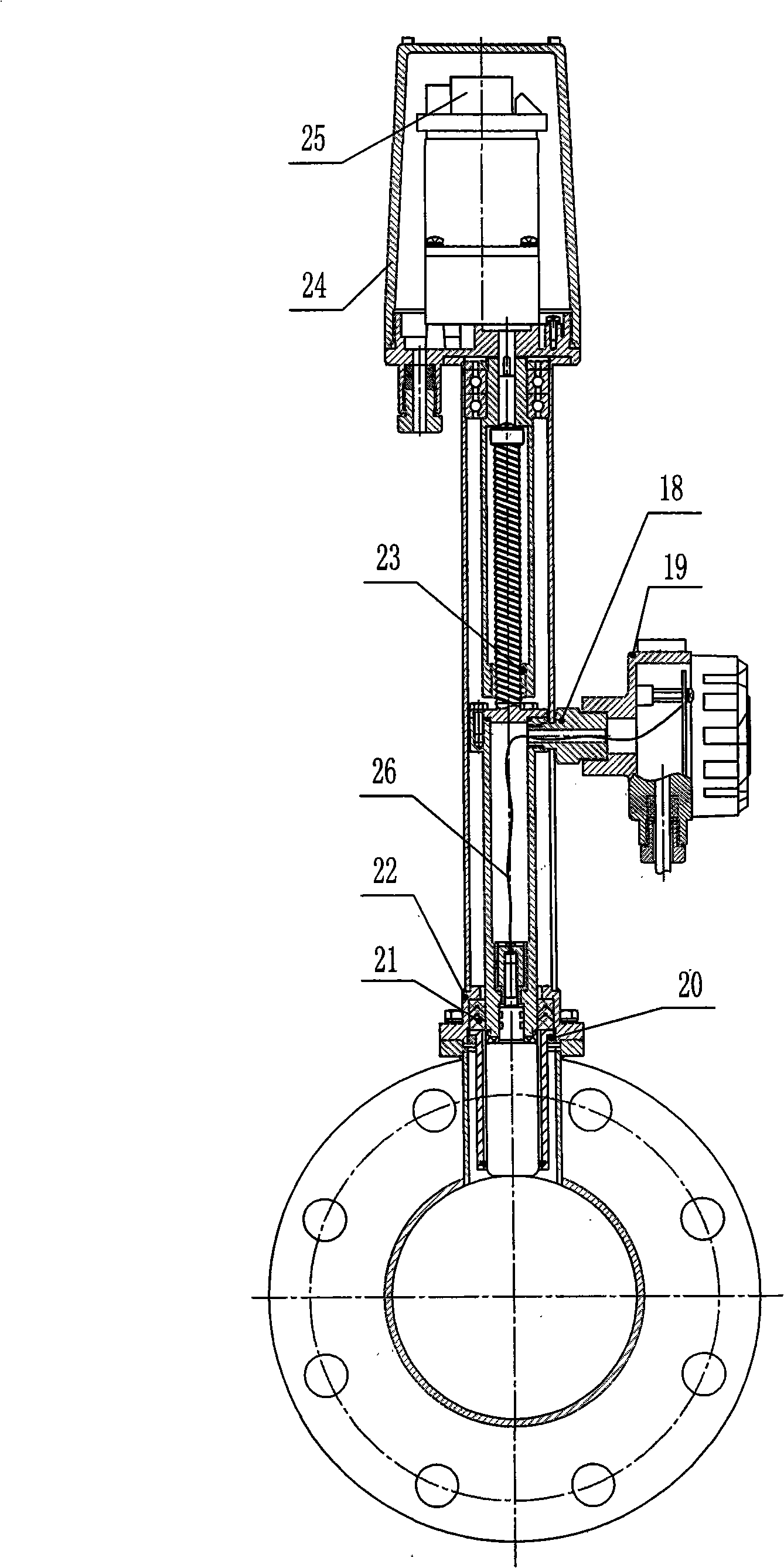

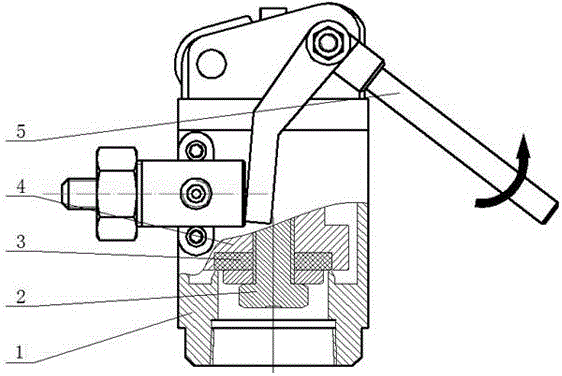

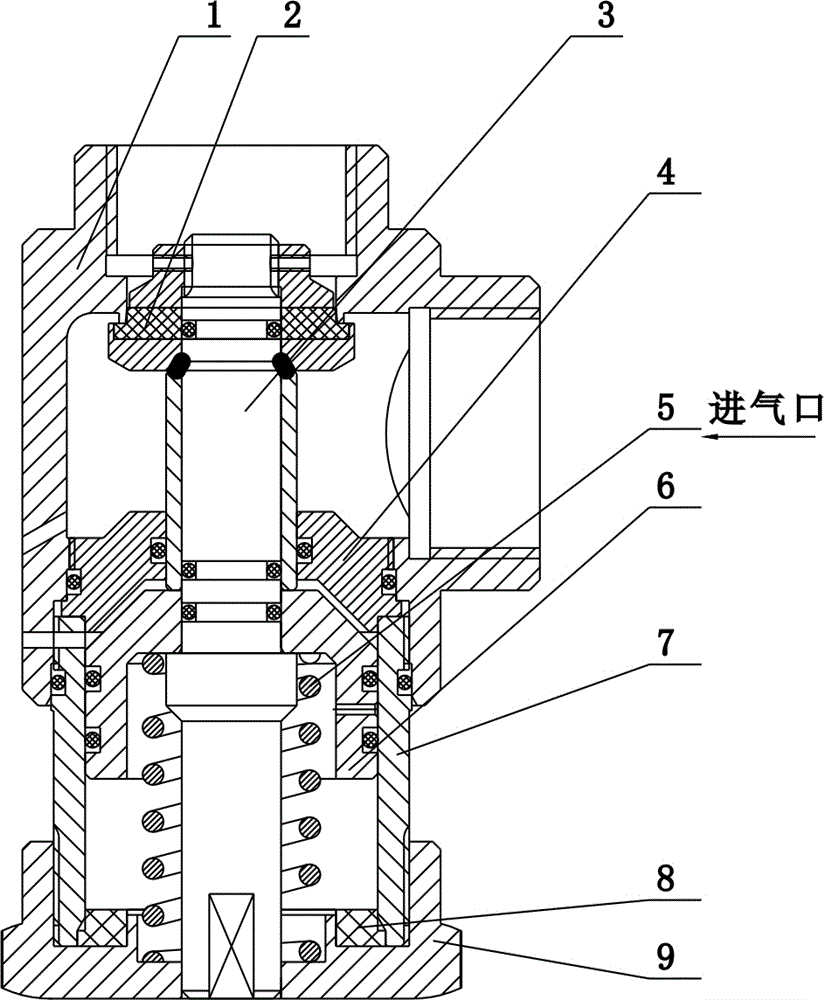

Integrated electro-hydraulic actuator capable of carrying out quick action and adjustment

ActiveCN1865746ACompact structureReduce volumeOperating means/releasing devices for valvesServomotorsElectric machineHydraulic pump

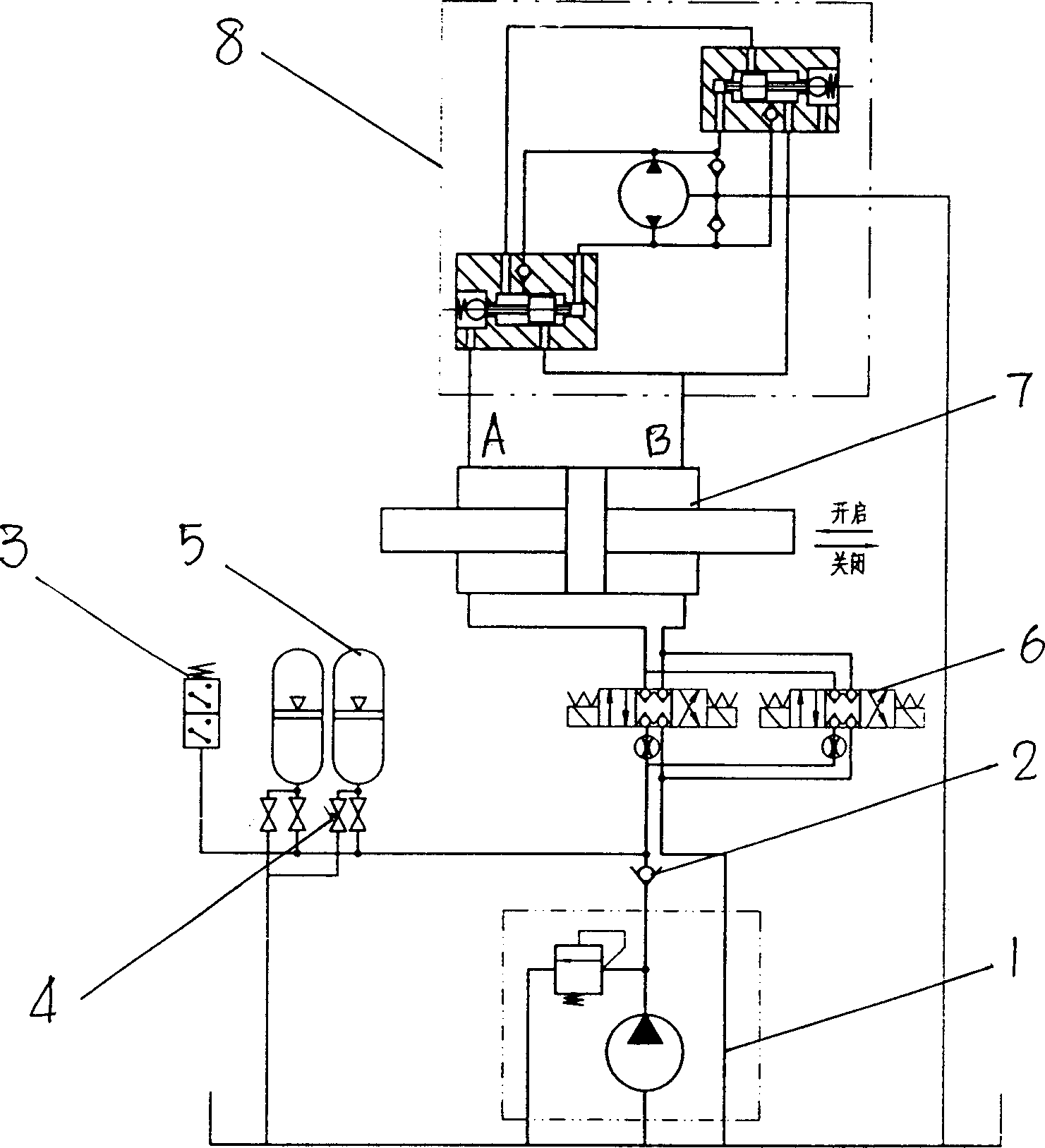

The invention discloses an integrated electric hydraulic executer with quick motion and adjustment. Wherein, present hydraulic executer needs external hydraulic station, to increase the volume and relative maintenance. The invention is characterized in that: it comprises a hydraulic cylinder, an integrated power source and a quick power source. Wherein, the quick power source comprises that: the hydraulic pump group via one-way valve feeds hydraulic oil to the accumulator; there is a check valve between the accumulator and the cylinder; the accumulator as the indirect oil source, via two electromagnetic steering valves, provides power oil to the cylinder; the electro voltage switch controls the voltage of accumulator; said integrated power source is formed by a servo motor, a step motor, a bidirectional hydraulic pump and a hydraulic control valve. The invention has the advantages that: it has itself oil source, with compact structure, small volume, lower weight, long service life, and reliable control, while it can be used to control the flux and pressure of tube.

Owner:SHENYANG NORTHEAST ELECTRIC POWER CONTROL

Brushless electric steering control unit and method based on functional safety design

ActiveCN106945720AGuaranteed reliabilityWill not short circuitElectrical steeringElectric machinePermanent magnet synchronous motor

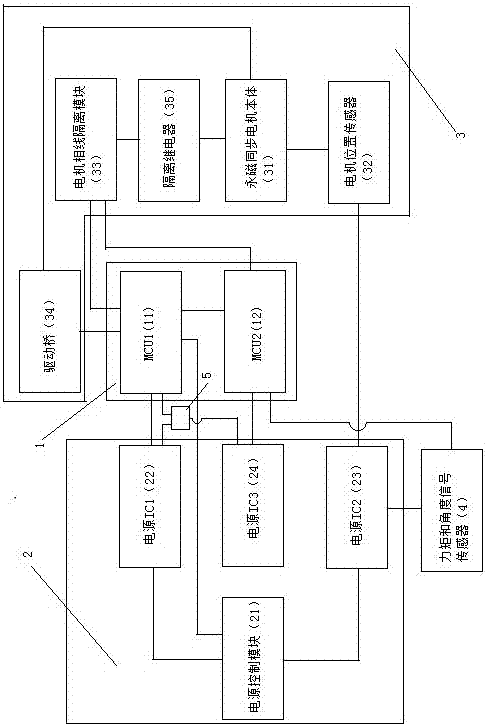

The invention discloses a brushless electric steering control unit based on functional safety design. The brushless electric steering control unit comprises an EPS controller, a power redundancy module, a torque and angle signal sensor and a permanent magnet synchronous motor module. The power redundancy module comprises a power control module, a power source IC1, a power source IC2 and a power source IC3. The EPS controller comprises an MCU1 and an MCU2. The permanent magnet synchronous motor module comprises a permanent magnet synchronous motor body and a motor position sensor which are connected with each other. The power control module is connected with the power source IC1 and the power source IC2 at the same time. The power source IC1 is connected with the MCU1. The power source IC2 is connected with the torque and angle signal sensor and the motor position sensor at the same time. The power source IC3 is connected with the MCU2. The power redundancy module can continuously keep the working power sources of the EPS control module in the high-speed driving process of a vehicle under the condition that a rigid line IG signal or a CAN IG signal is lost, and an EPS can continuously provide the assistance to enable the vehicle to run safely.

Owner:浙江航驱汽车科技有限公司

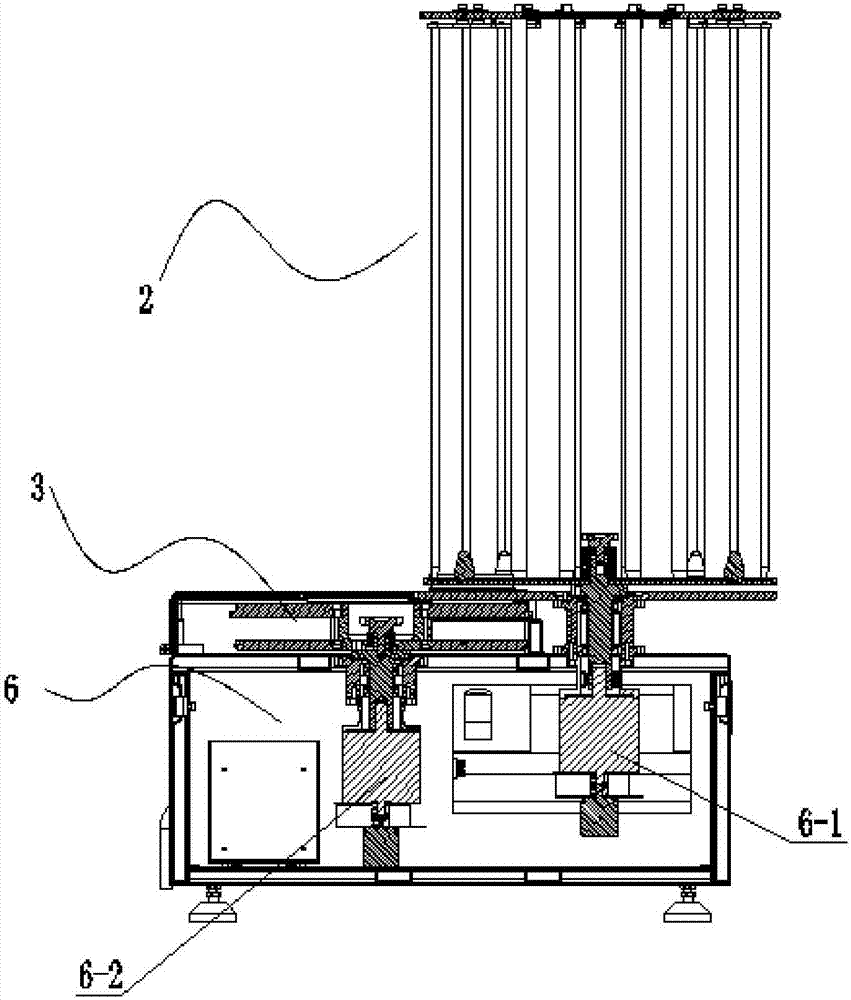

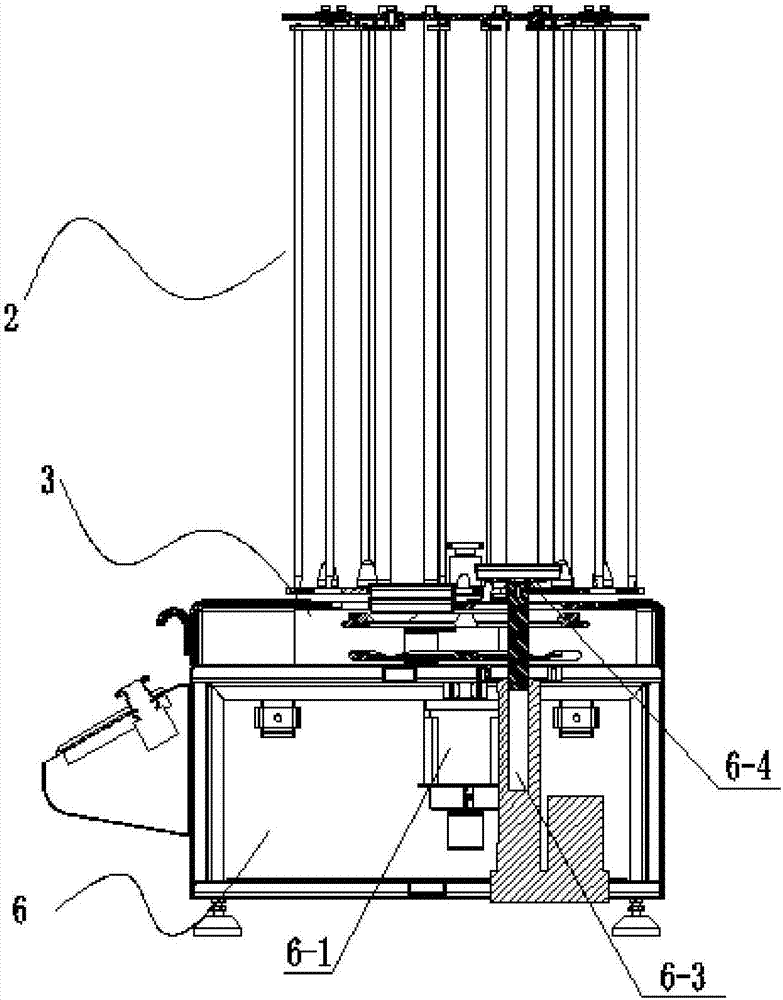

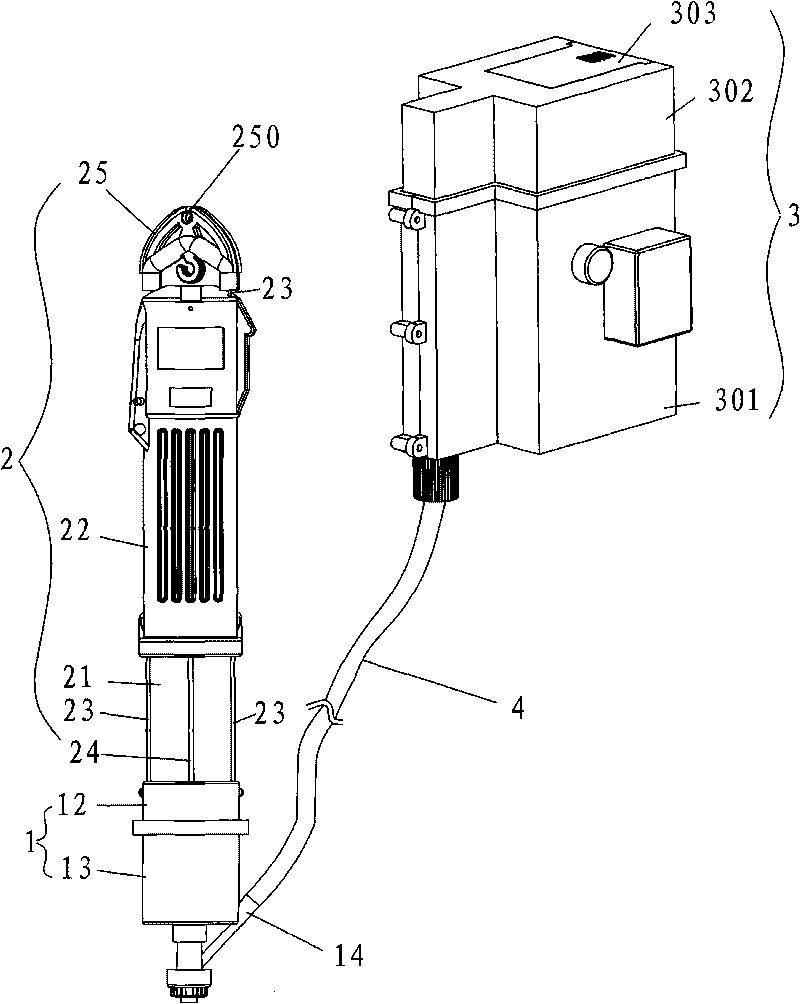

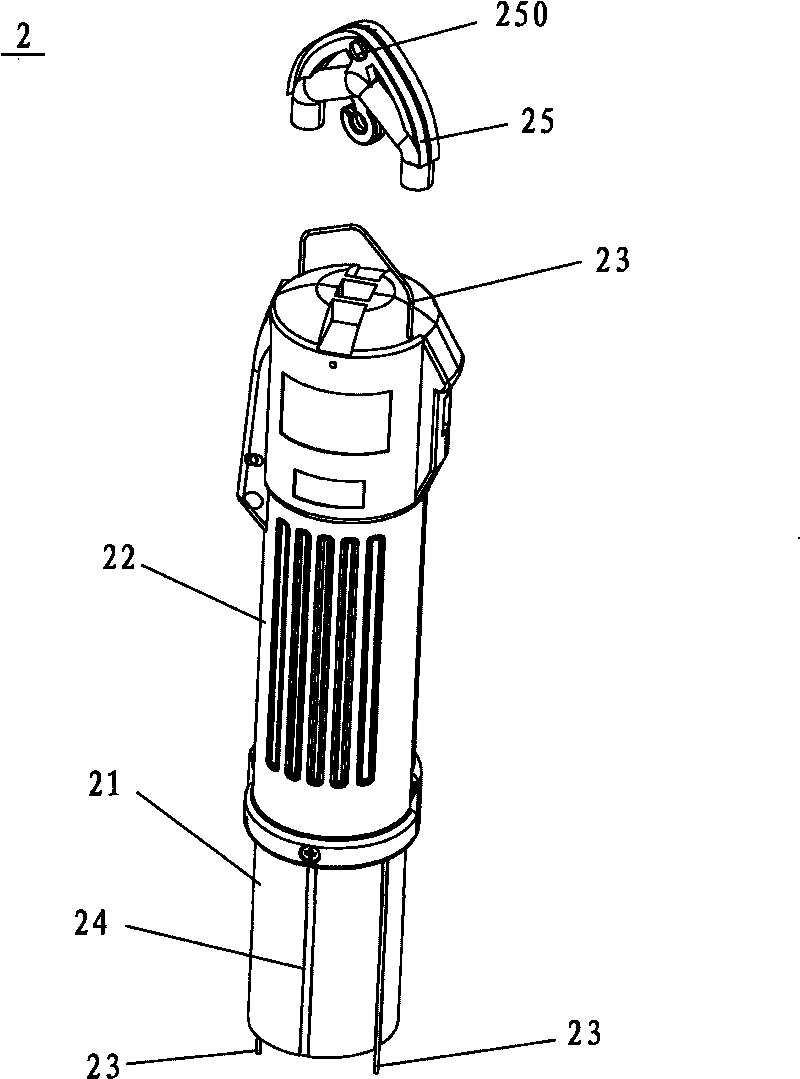

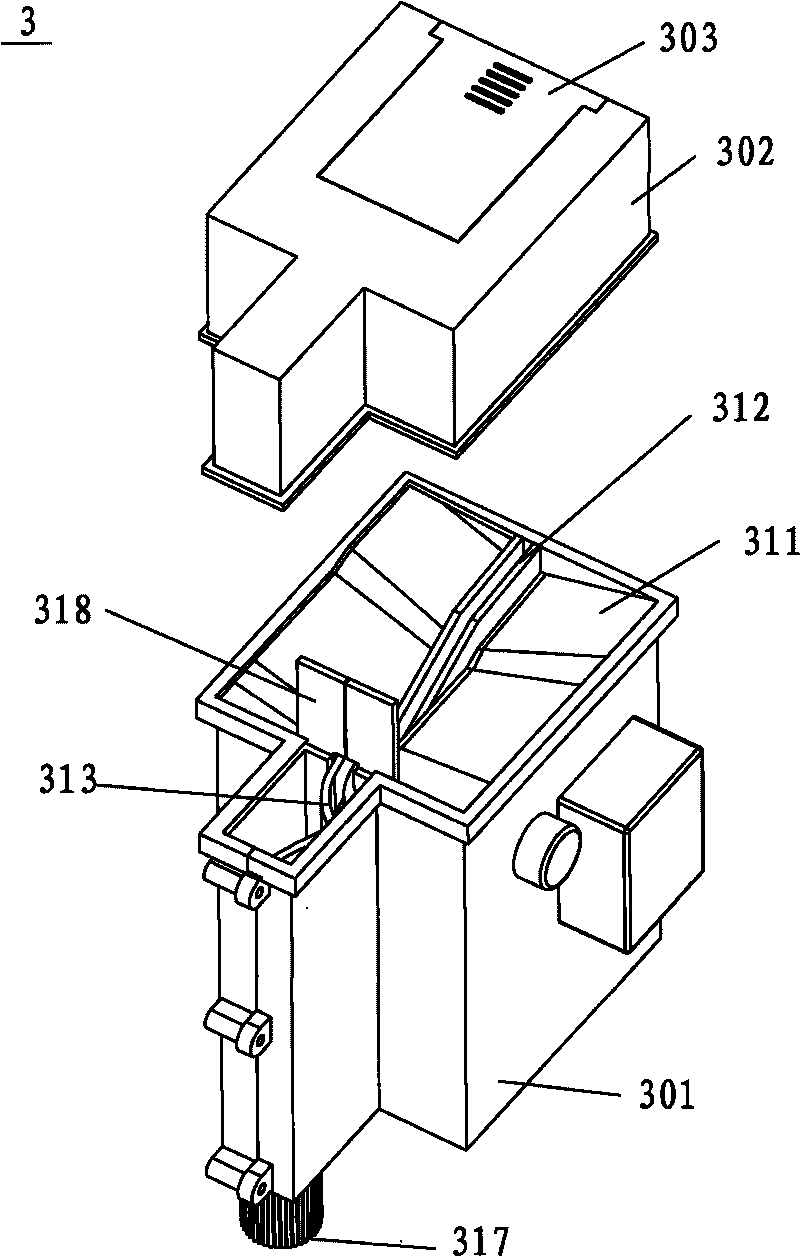

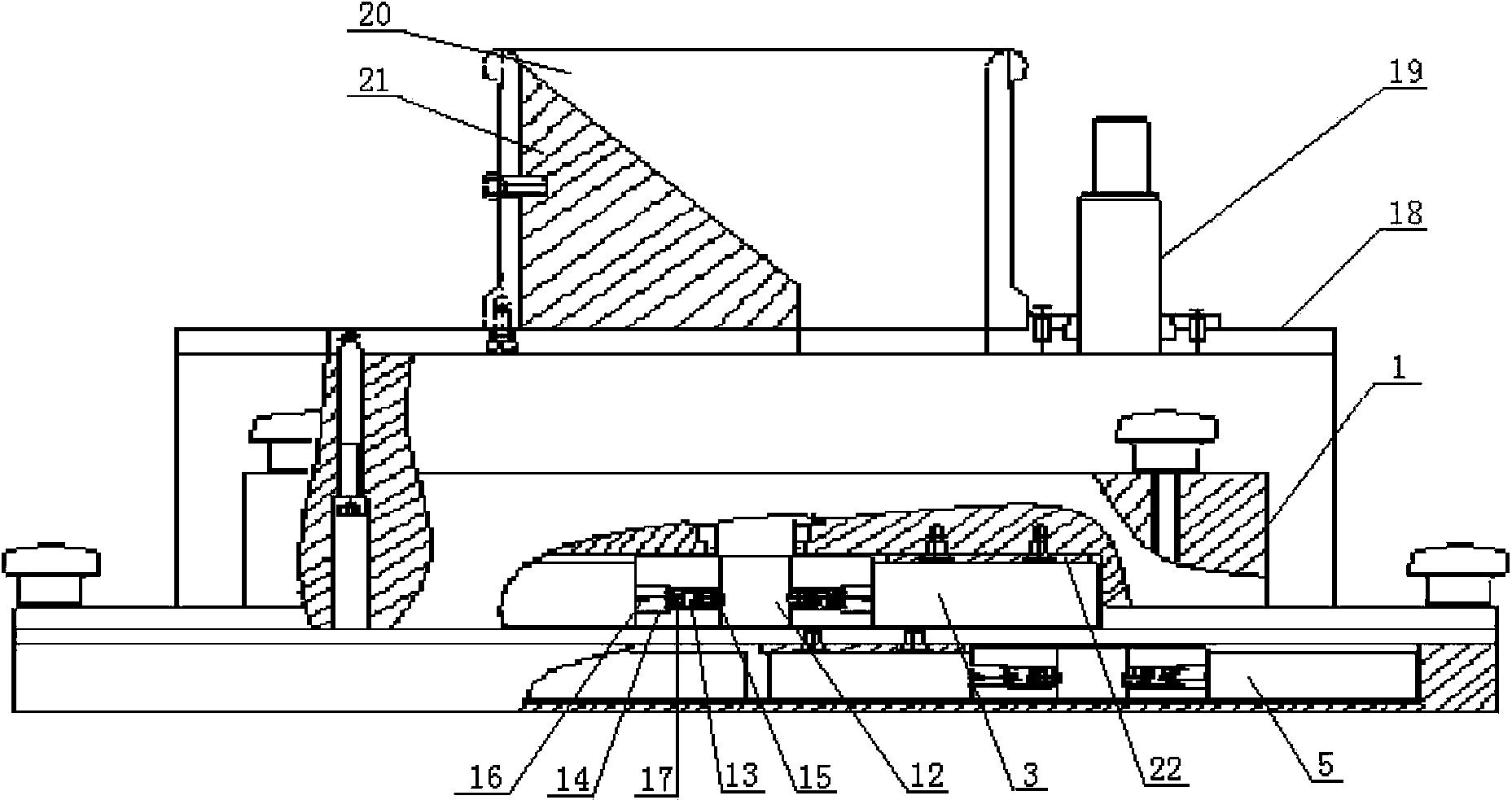

Measurement device for residual carbon quantity in fly ash

ActiveCN102012350AAvoid cloggingGuarantee smooth feedingWeighing by removing componentMeasurement deviceEngineering

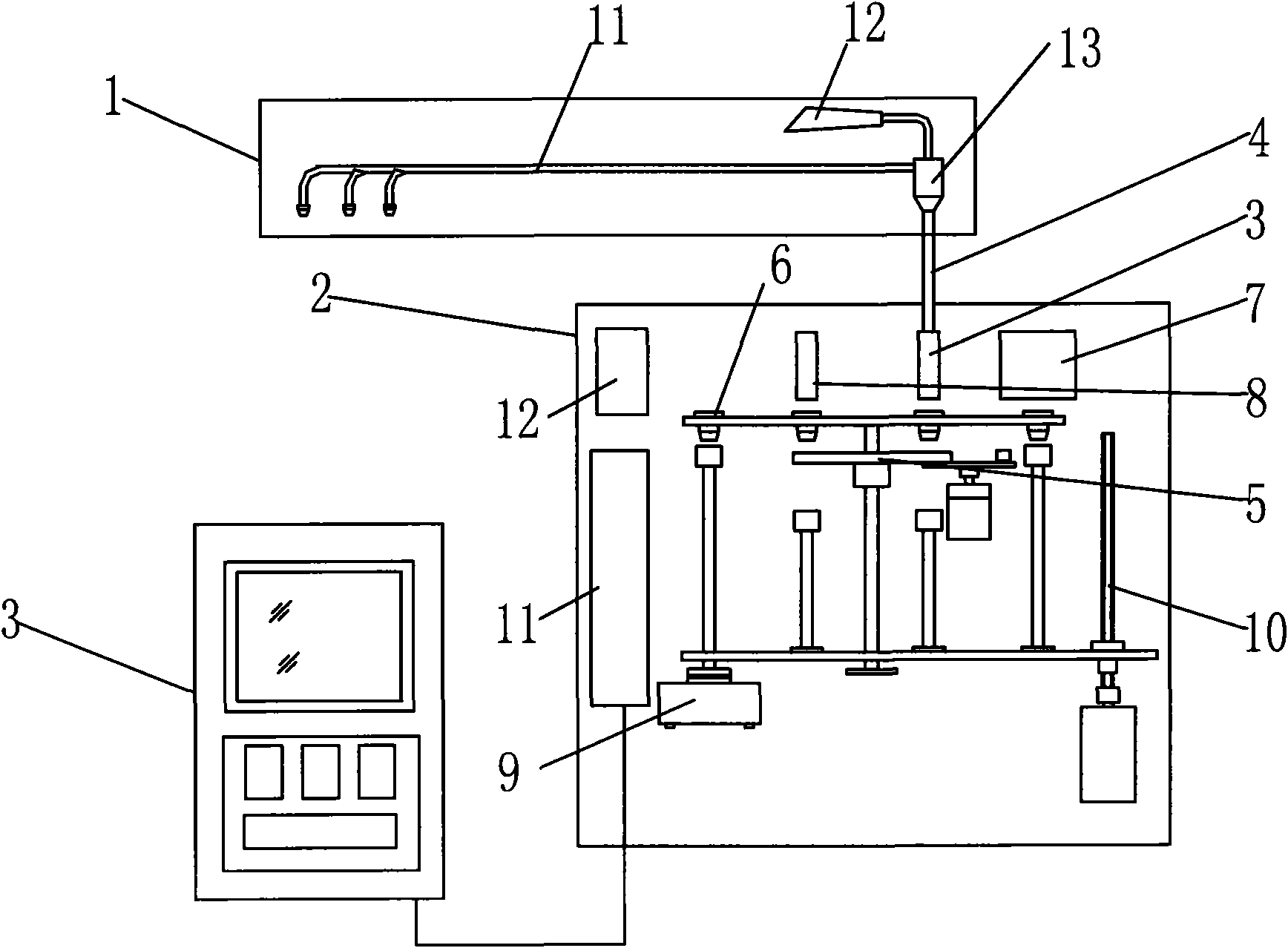

The invention discloses a measurement device for residual carbon quantity in fly ash. The device comprises a sampling unit, a measurement unit and a control unit, wherein the sampling unit is connected with an ash collecting device in the measurement unit through an ash collecting pipe; in the measurement unit, four crucibles are uniformly arranged on a rotating device along the circumference, the ash collecting device, a burning device and an ash discharge device are respectively arranged above the crucibles, a weighing device is arranged below the crucibles, an ejector rob is arranged on an elevating device, the ash collecting device, the ash discharge device, the rotating device, the elevating device and the weighing device are all connected with an electric device, and the burning device is connected with a temperature controller; and the measurement unit is connected with the control unit by the electric device. The invention has the advantages of excellent ash collection and discharge effect, high accuracy, no noise and no clamp phenomena.

Owner:NANJING ZHONGYU AUTOMATION

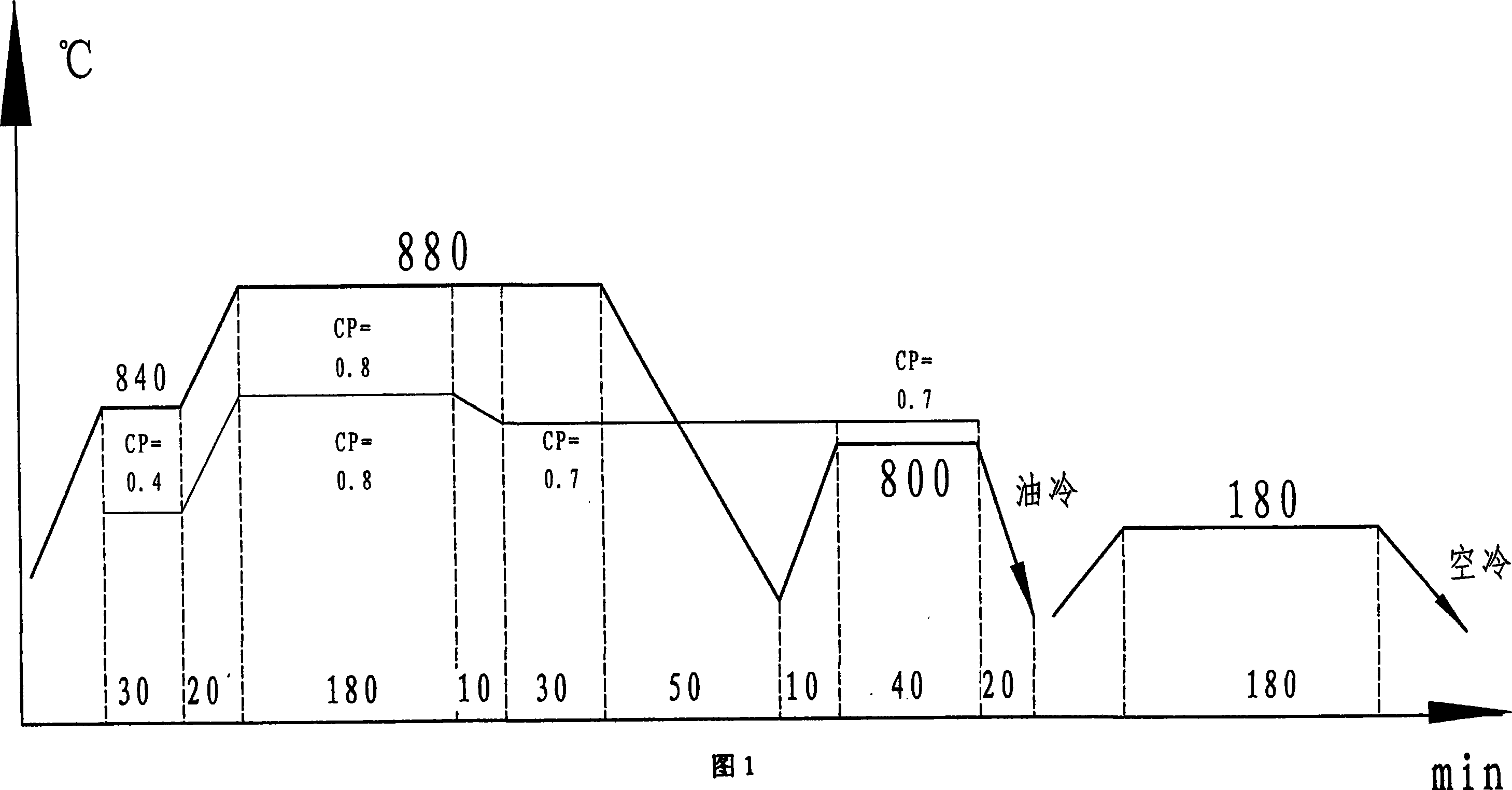

Production process of high-purity plunger piston

ActiveCN101126387AHigh precisionGuaranteed uptimePositive displacement pump componentsSolid state diffusion coatingFurnace temperatureCarbon potential

The invention relates to a manufacturing method of a high-precision plunger, the material adopts alloy steel or bearing steel and the technology adopts the flow of machining, heat treatment and grinding; the specific heat treatment steps are that: the plunger is preheated at a temperature of 350-400 DEG C for 40-50 minutes; the plunger is placed into the carburization heat treating furnace, then the temperature is raised to 840 DEG C and is kept for 30 minutes, the carbon potential (CP) is controlled to be 0.4, then the temperature is raised to 880 DEG C and the carbon potential (CP) is raised to 0.8 and kept for 20 minutes, then a surface carburization is made under the furnace temperature of 880 DEG C and the CP of 0.8 for 180 minutes, then the carbon potential is reduced to 0.7 for ten minutes, the furnace temperature is kept at 880 DEG C, then the surface carburization is made under the furnace temperature of 880 DEG C and the CP of 0.7 for 30 minutes, then is cooled to 100 DEG C for 50 minutes, and finally the temperature is raised to 800 DEG C for 10 minutes and then the plunger is removed from the furnace after keeping for 50 minutes at the temperature of 800 DEG C; is quenched in the oil for 15-25 minutes, the oil temperature is kept at 80 DEG C; the plunger is rinsed; and finally is tempered in a tempering furnace for 170-190 minutes at the temperature of 175-185 DEG C. The invention is environment-protective and the manufactured plunger has high precision.

Owner:WUXI YINGBEI PRECISION BEARING

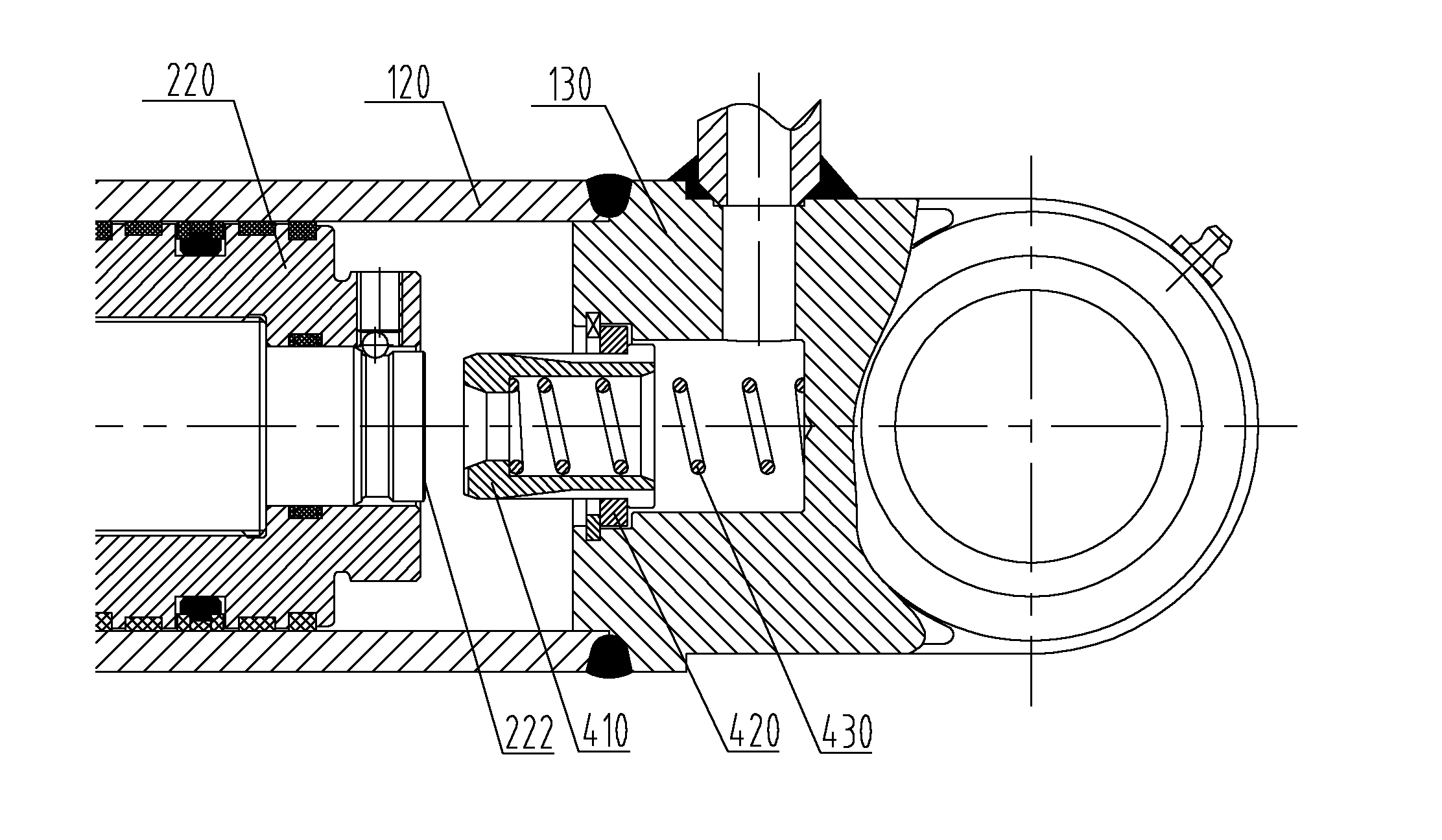

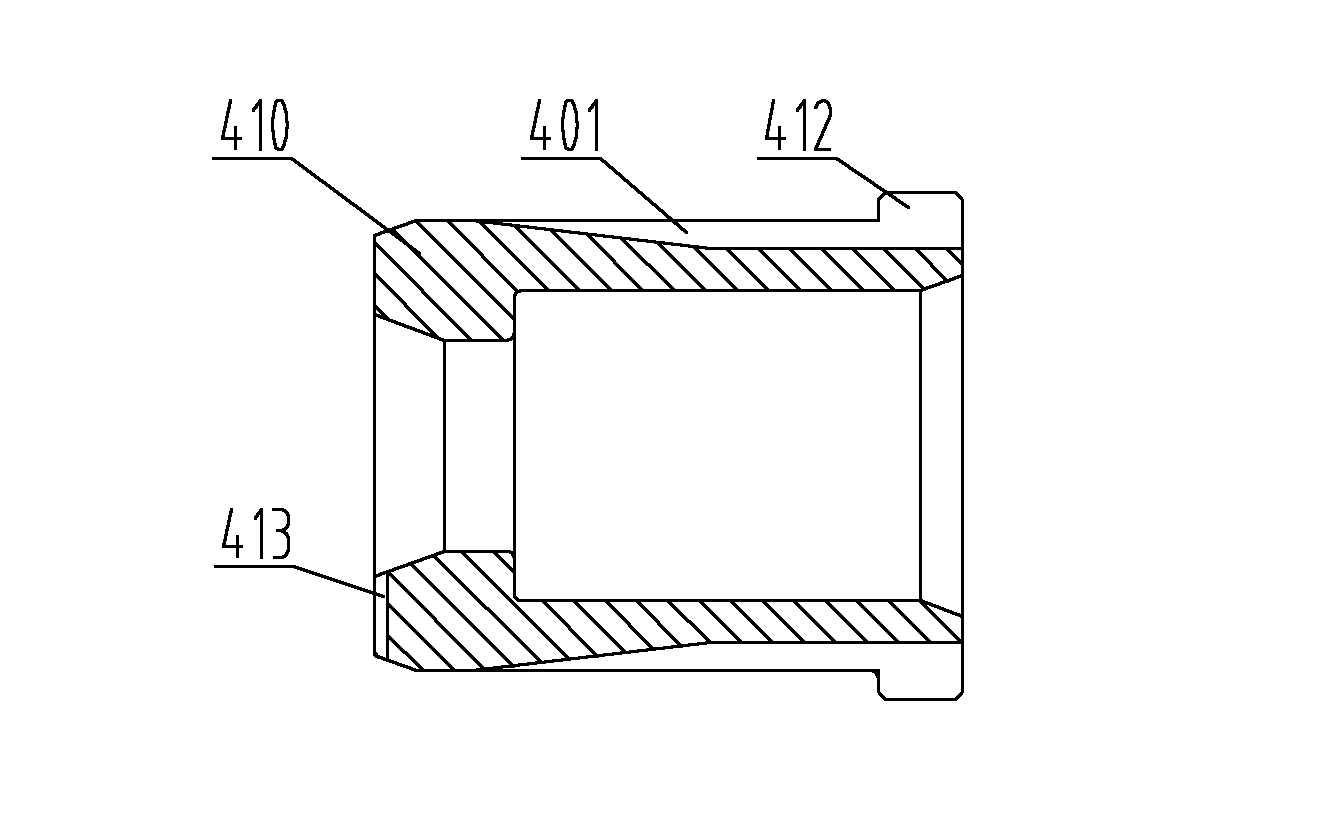

Hydraulic cylinder and cushioning device of hydraulic cylinder

InactiveCN102155468ANo stuck phenomenonEasy to processFluid-pressure actuatorsHydraulic cylinderCushioning

The invention discloses a hydraulic cylinder and a cushioning device of the hydraulic cylinder. The cushioning device comprises a cushioning sleeve, a spring and an outer cushioning component, wherein a central hole is formed on the cushioning sleeve; the outer cushioning component is fixed with a cylinder body; a throttling oil passage is formed between an outer wall face of the cushioning sleeve and an inner wall face of the outer cushioning component; the cushioning sleeve and the outer cushioning component are in sliding fit in axial direction; the spring is positioned between the cylinder body and the cushioning sleeve; in a free state, an inner end of the cushioning sleeve extends into a hydraulic chamber of the hydraulic cylinder; and an inner end face of the cushioning sleeve can be in sealing fit with a cushioning blocking face of a piston. By the cushioning device provided by the invention, the fit of the outer wall face of the cushioning sleeve and the inner wall face of a guide sleeve is not required, and the phenomenon of blocking of the cushioning sleeve caused by displacement of the cushioning sleeve cannot be generated, so that damage to a fitting face of the cushioning sleeve and the outer cushioning component can be reduced or avoided, and the reliability and cushioning effect of the cushioning device are guaranteed.

Owner:SANY HEAVY IND CO LTD (CN)

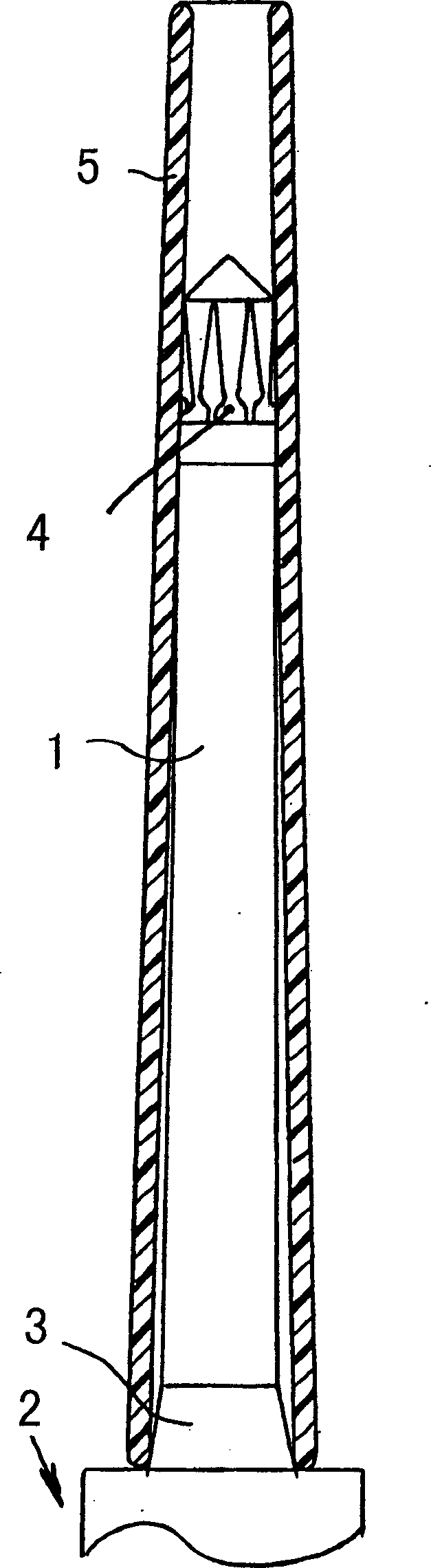

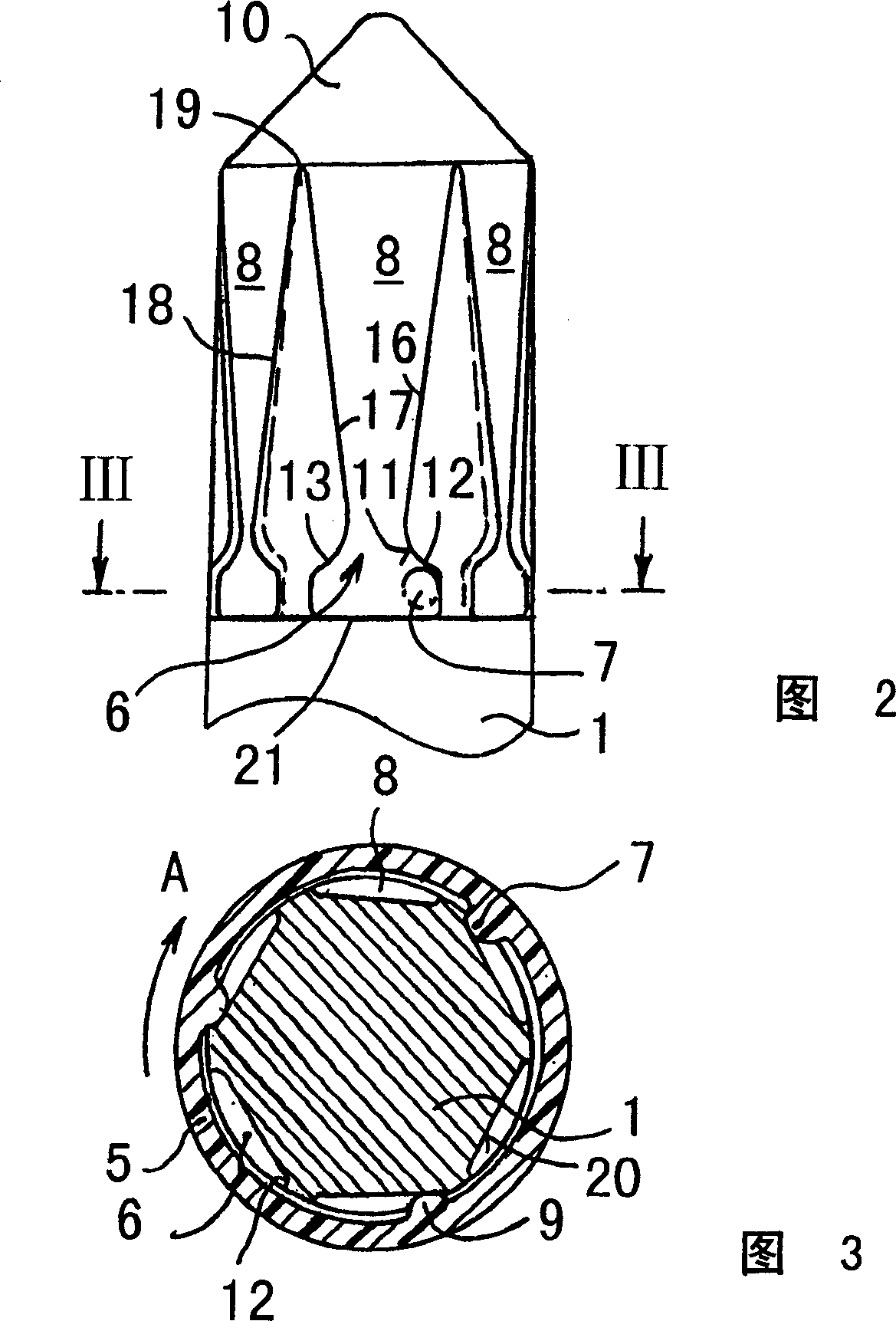

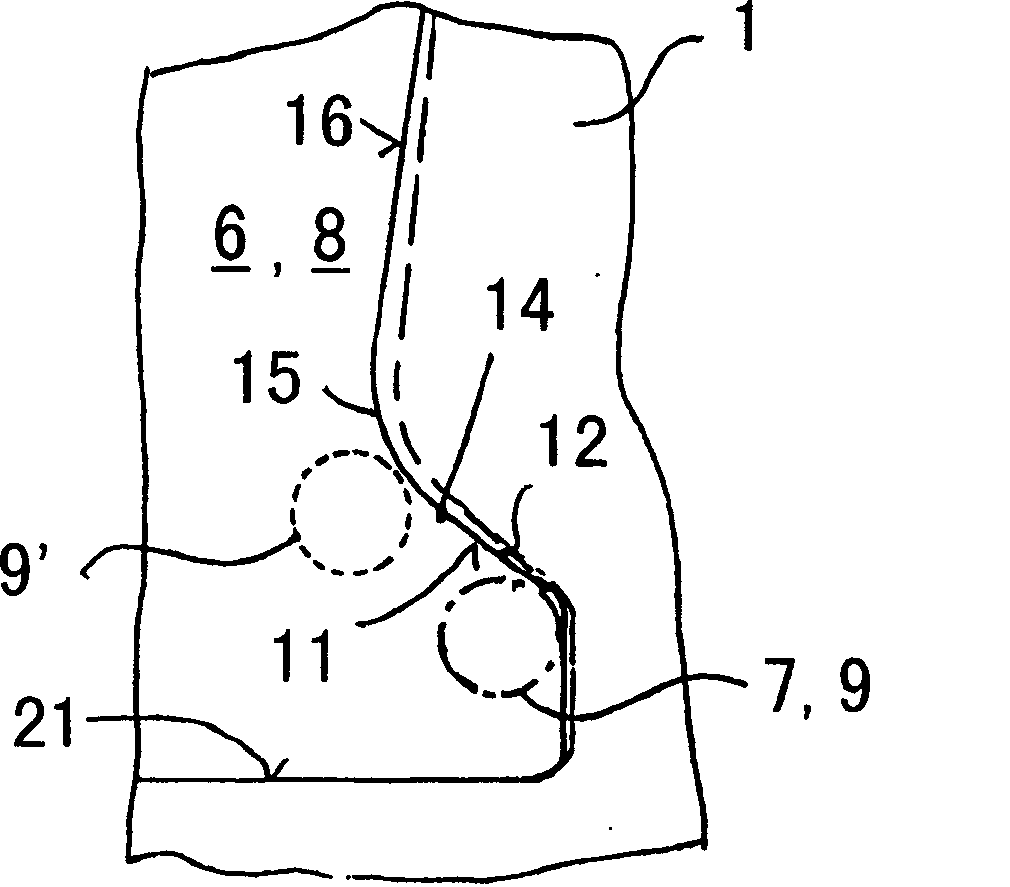

Bobbin connector for spinning spindle or silk throwing spindle

InactiveCN1490447AGuaranteed Continuous Side LimitsEasy to manufactureFilament handlingTextiles and paperBobbinVertical channel

The winder tube coupling for a spinning or twisting spindle is so structured that gripping of a winder tube with an upper part of the spindle is realized by a joining part of a positive motion coupling composed of (two or more) recessed parts and (two or more) protrusions. The recessed parts are arranged on the upper part of the spindle and formed into vertical channels, and the protrusions are arranged on the winder tube and formed into cylindrical pegs, so that the pegs are engaged with the vertical channels. While the spindle is operating, the pegs are arranged in the direction of the top of the spindle on stopping surfaces where the vertical channels are made to be narrowed. A cap having the vertical channels is preferably mounted on the upper part of the spindle.

Owner:NOVIBRA

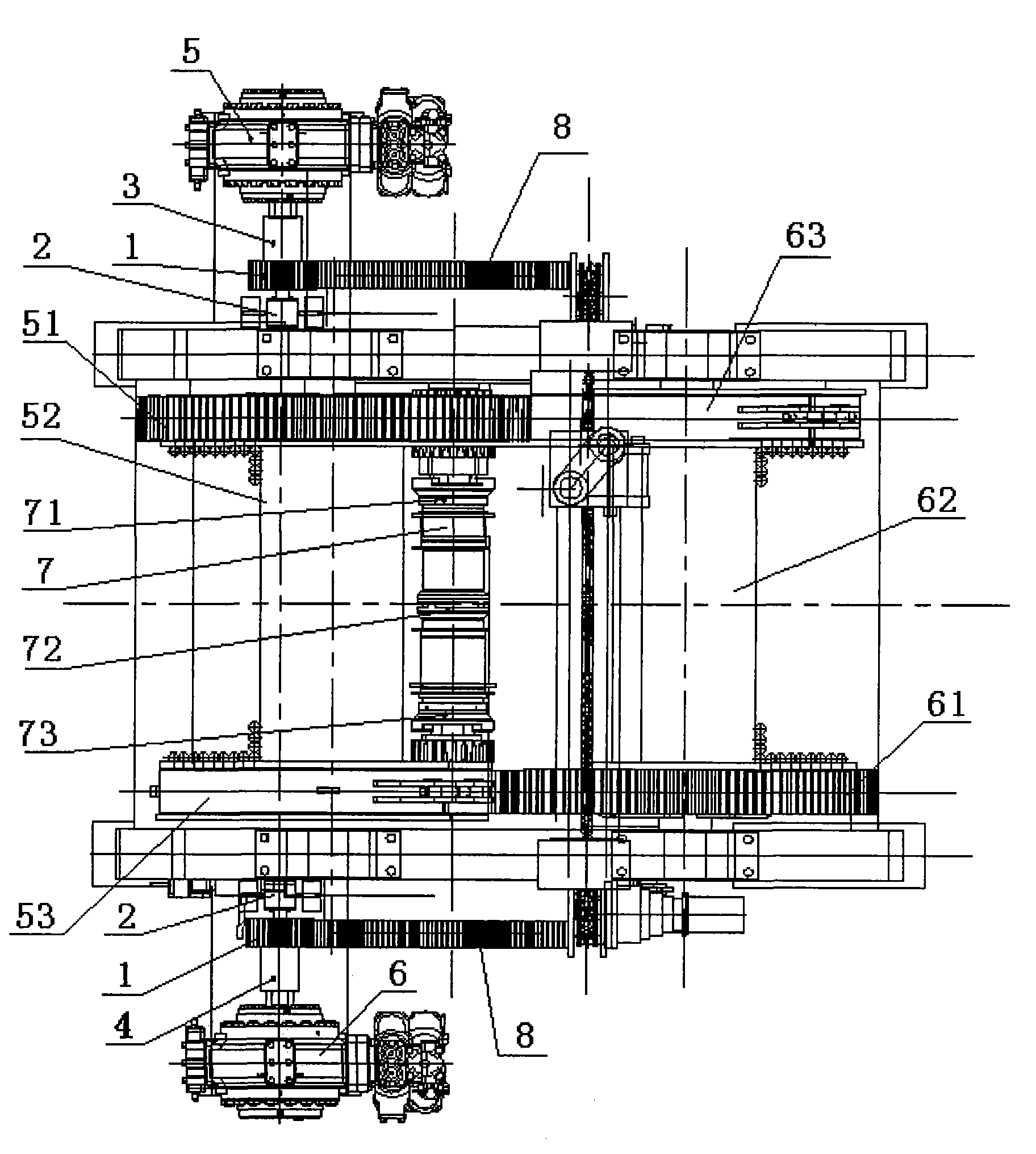

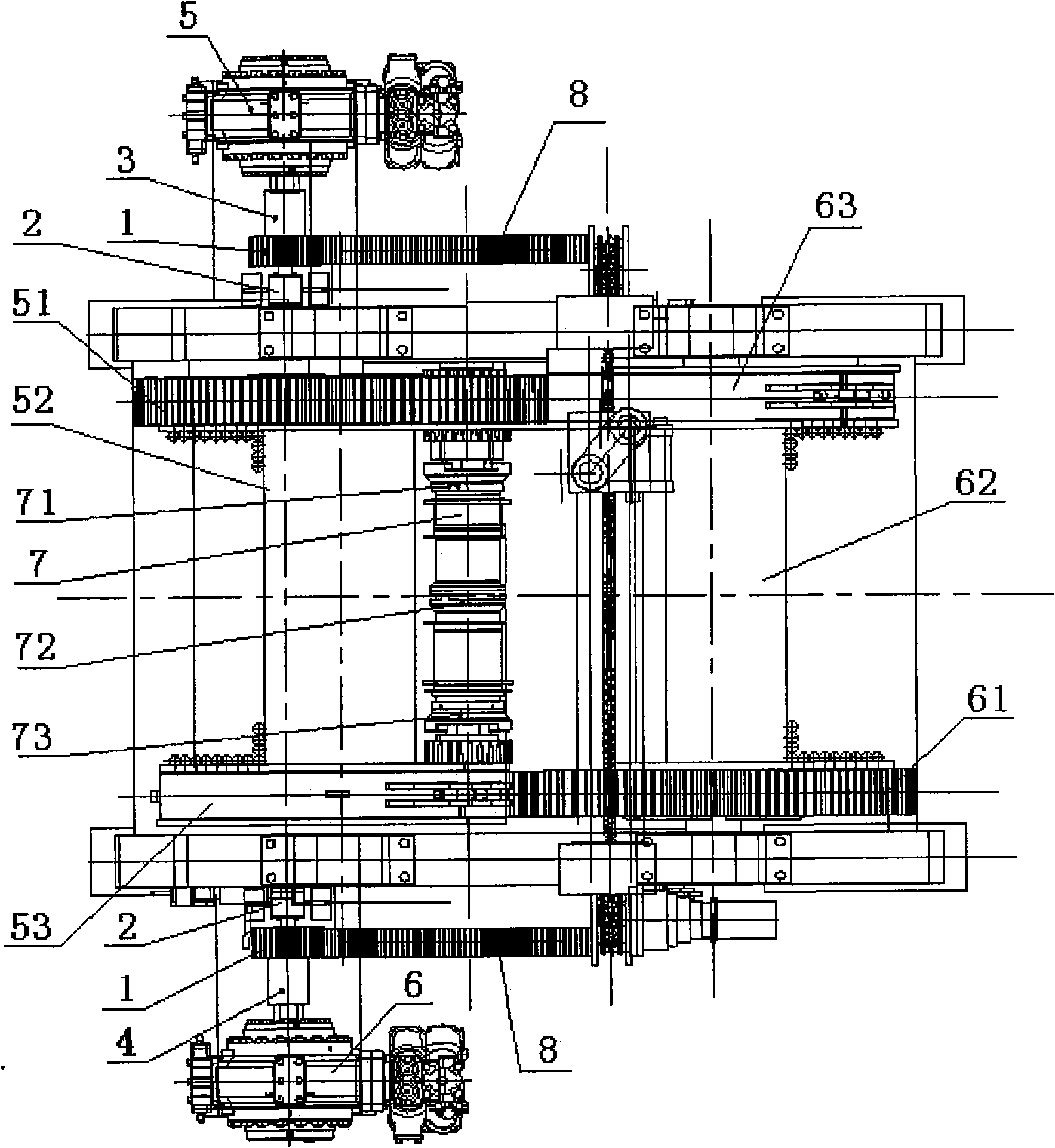

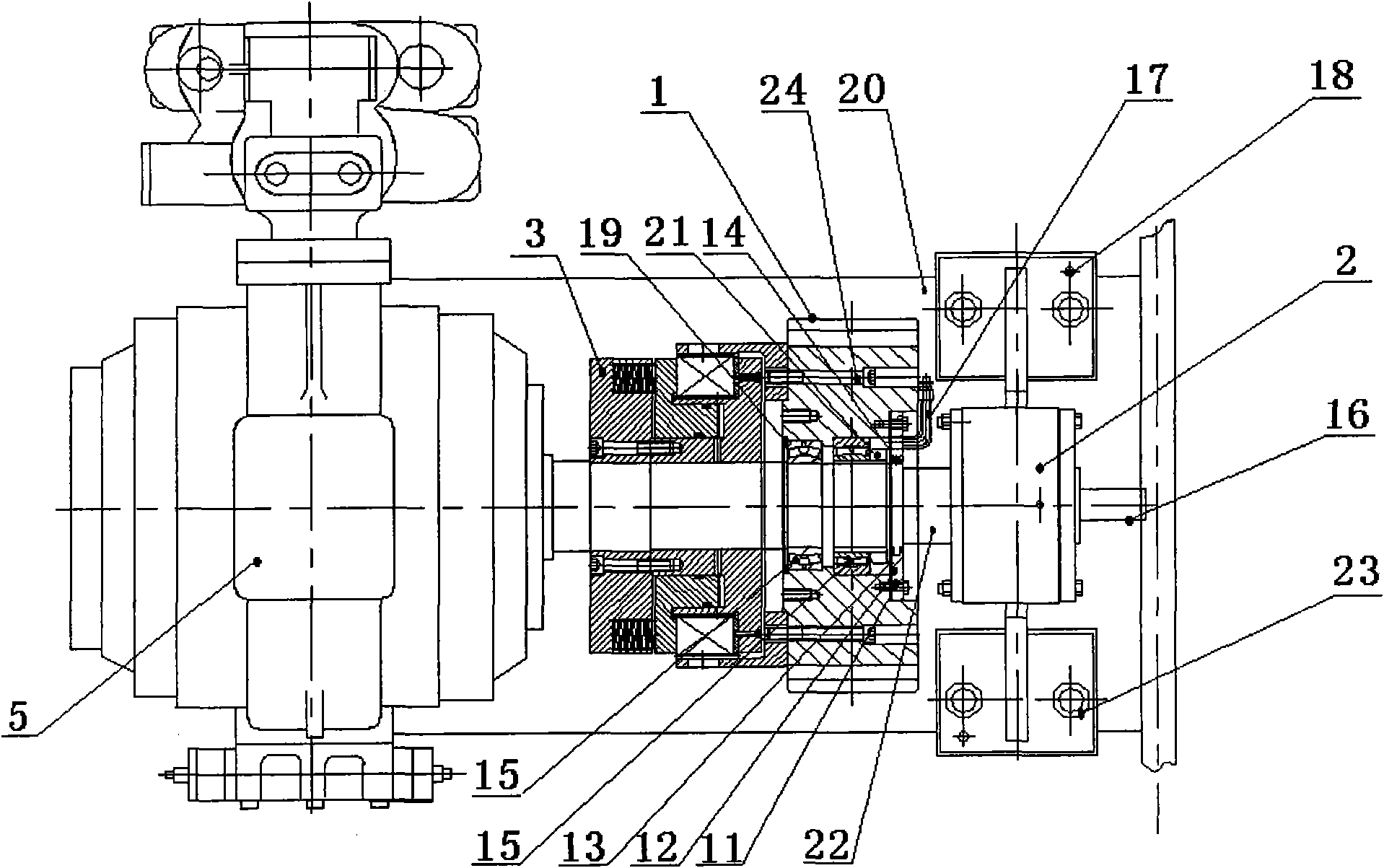

Marine haulage device and emergency release method thereof

The invention relates to a marine haulage device and an emergency release method thereof, which belong to the technical field of marine machines. An upper roller clutch (3) is mounted on the output shaft of an upper roller-driving motor (5), a lower roller clutch (4) is mounted on the output shaft of a lower roller-driving motor (6), the output ends of the upper roller clutch (3) and the lower roller clutch (4) are respectively and fixedly connected with small gears (1), the control end of the upper roller clutch (3) is connected with an upper roller clutch controller (54), and the control end of the lower roller clutch (4) is connected with a lower roller clutch controller (64). The upper roller clutch (3) and the lower roller clutch (4) can be synchronously disengaged to carry out emergency release. The transmission torque of the clutches is low, action is quick, sensitivity is high, the clutches can be quickly engaged and disengaged, operation is flexible and reliable, and thereby the invention can fully meet the requirement of International and domestic emergency release action standards.

Owner:WUHAN MARINE MACHINERY PLANT +1

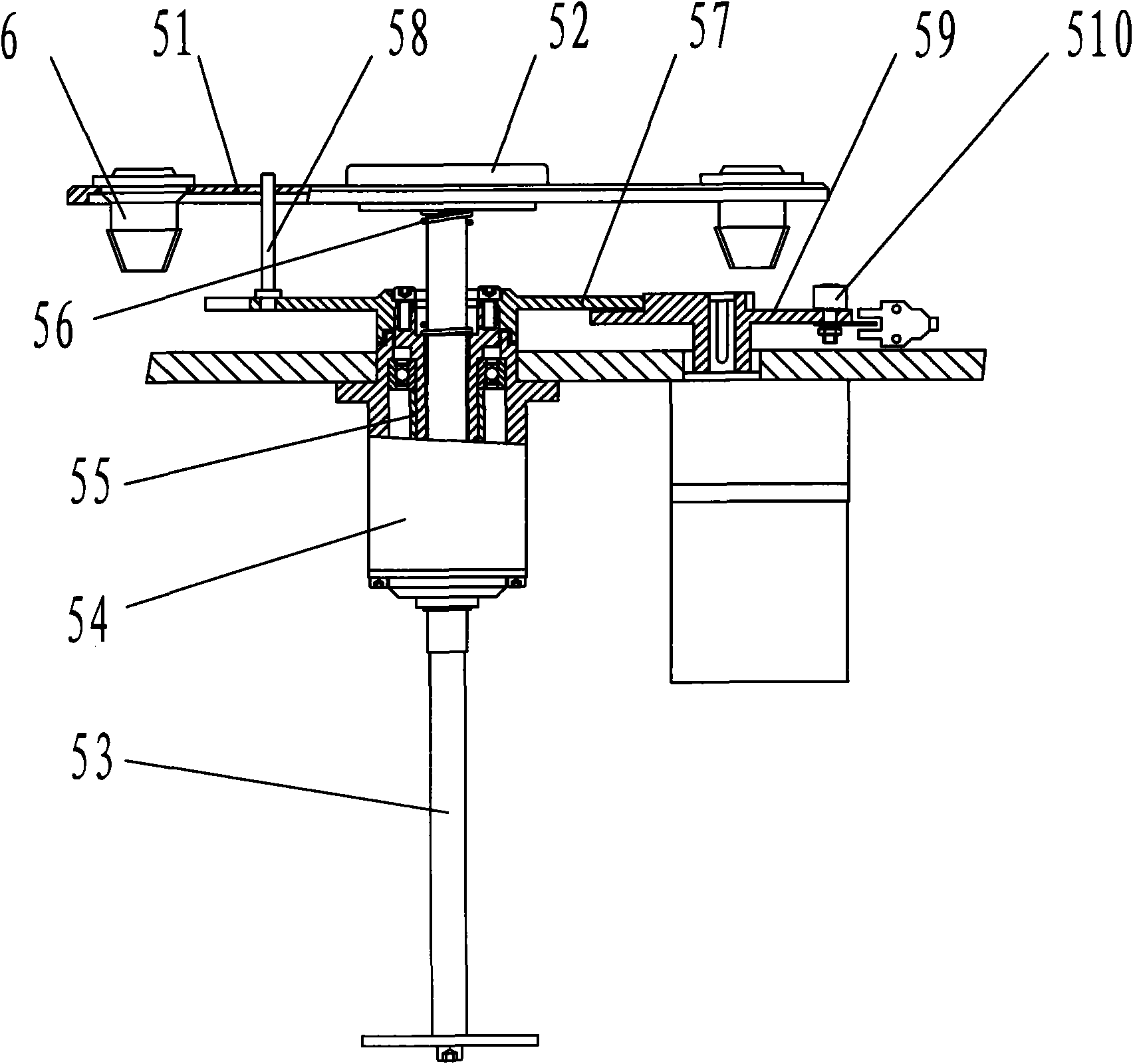

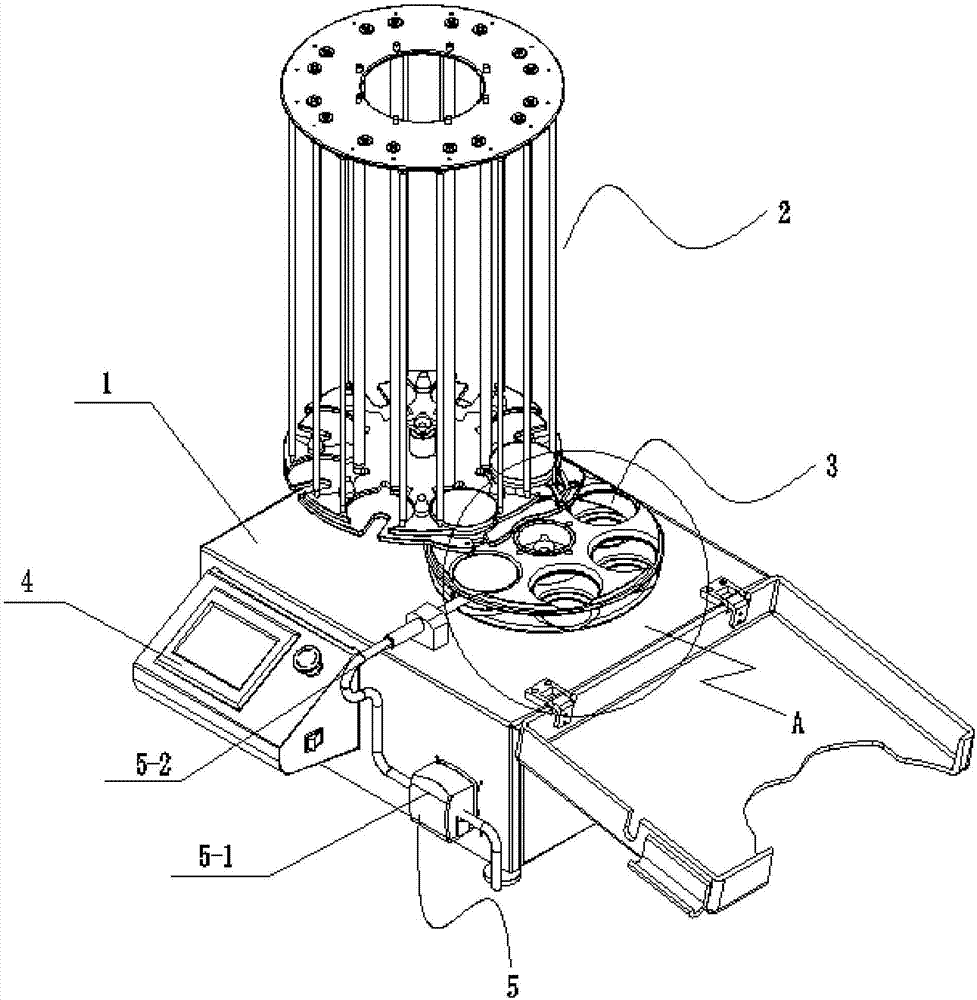

System for automatically dispensing medium

PendingCN107083318AReduce pollutionReduce work intensityBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpEngineering

The invention provides a system for automatically dispensing a medium. The system comprises a cabinet, a driving mechanism is arranged in the cabinet, a vessel sending mechanism, a dispensing mechanism and a liquid injecting mechanism are matched and arranged above the cabinet, and the cabinet is also provided with a control unit for controlling the driving mechanism to operate; a driving mechanism comprises a main motor and an auxiliary motor; the vessel sending mechanism comprises a circular base plate and a dish library rack, the base plate is fixed above the cabinet, the dish library rack is installed on the base plate, and a main motor outputs power to the dish library rack; the dispensing mechanism comprises an upper bracket plate and a lower bracket plate which is under the upper bracket plate, and the central parts of the upper bracket plate and the lower bracket plate are fixedly connected, and the auxiliary motor outputs power to the dispensing mechanism. The liquid injecting mechanism comprises a peristaltic pump and a liquid injecting pipe, the liquid injecting pipe is installed on the peristaltic pump, and one end of the liquid injecting pipe is inserted in a container which is equipped with medium, and the other end of the liquid injecting pipe is positioned between the upper bracket plate and the lower bracket plate. The system reduces manpower cost, improves work efficiency, and substantially reduces risk of medium pollution.

Owner:HANGZHOU GEEVO TECH

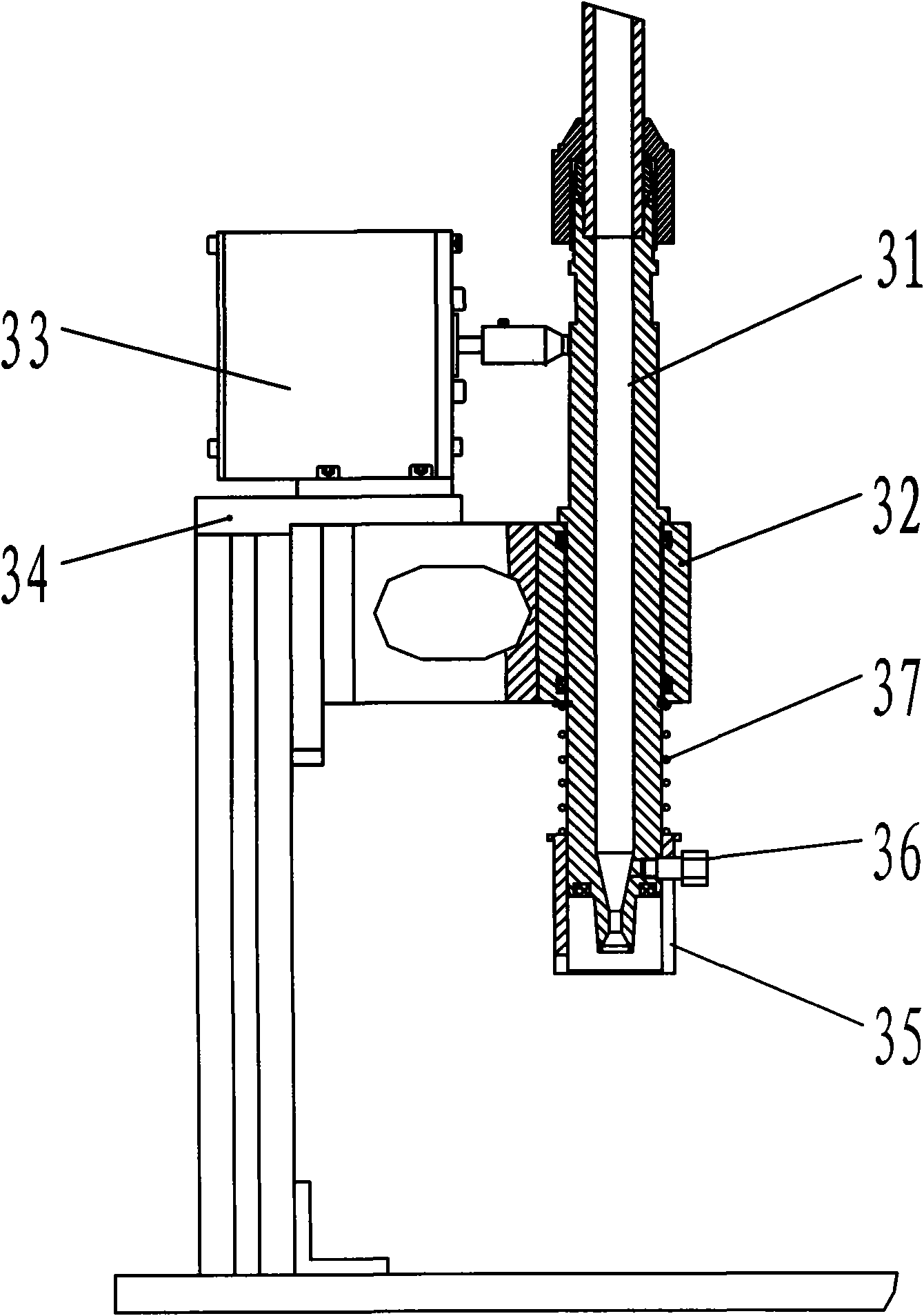

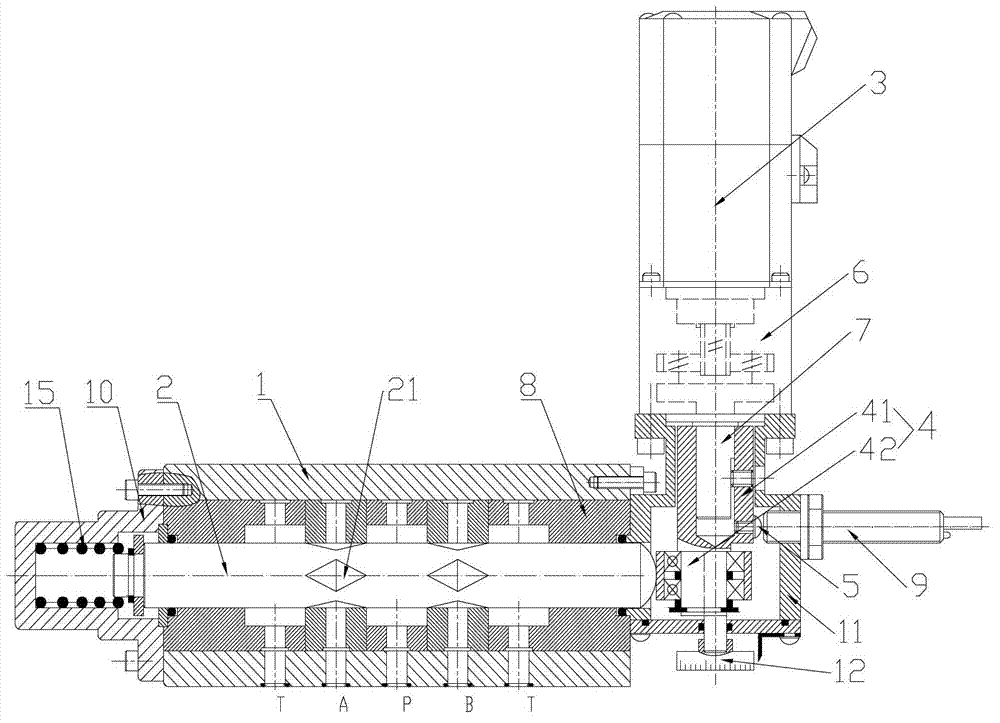

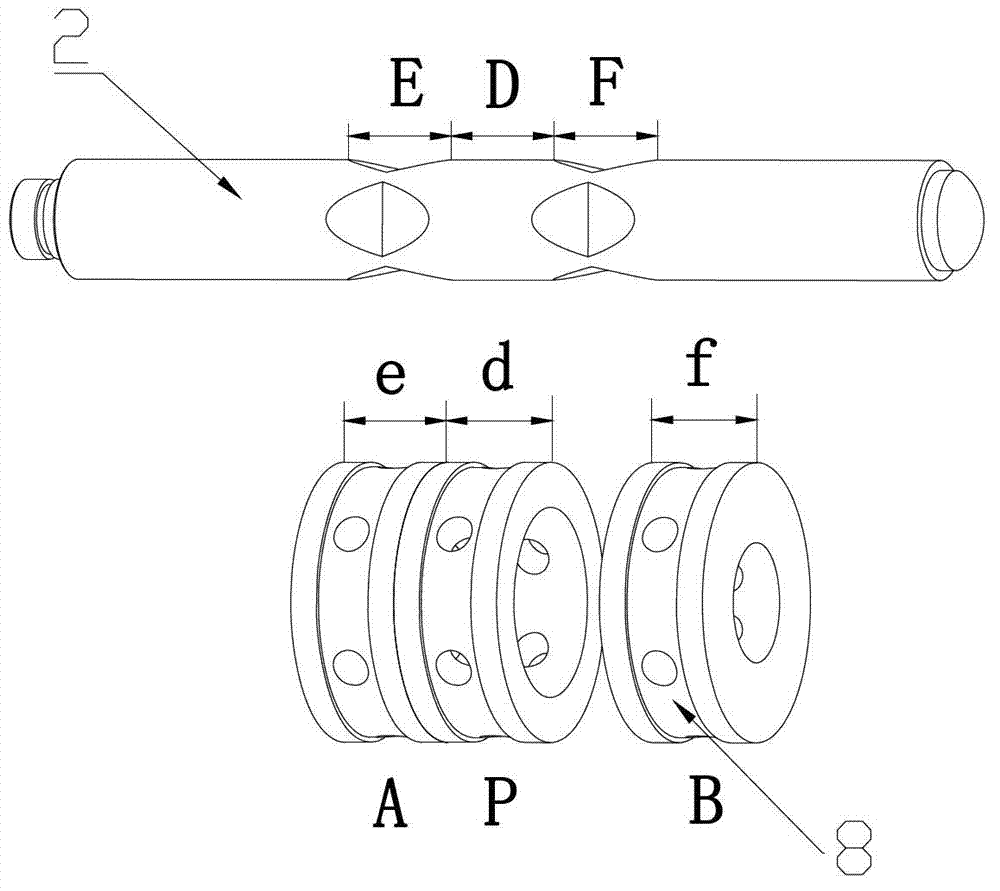

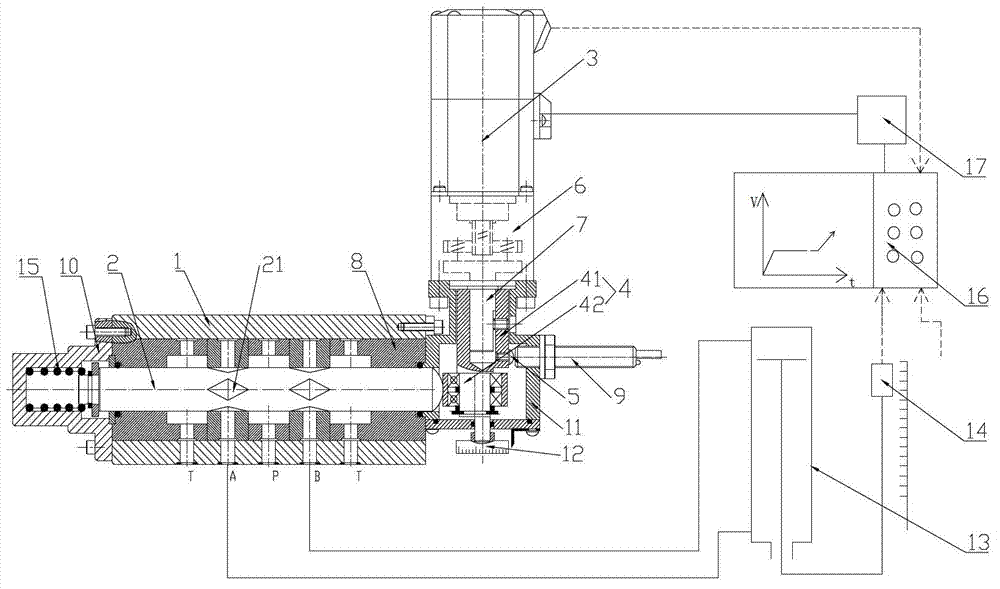

Directly moving type high-flow directional flow servo valve and control system using servo valve

The invention discloses a directly moving type high-flow directional flow servo valve and a control system using the servo valve. A valve core of the servo valve is pushed by a cam shaft driven by a servo motor; the cam shaft comprises an eccentric section and a driving section; one end of the valve core is pressed and leaned against a shaft surface of the eccentric section; a zero position sensing head is arranged on the shaft surface of the driving section; an inductive sensor which is matched with the zero position sensing head is arranged on a cam box; the inductive sensor is connected with a controller; and the controller is used for receiving a signal of the inductive sensor, controlling the servo motor to rotate back and forth in a small scope and performing the zero position positioning on the valve core. The servo valve is high in response speed and high in control precision. Meanwhile, the zero position positioning of the valve core is high in accuracy, is free from temperature null shift and is high in repeating precision. The adjusting time for the zero position positioning is short and a hydraulic system is relative stable when the zero position is adjusted.

Owner:北京润菲利德科技有限公司

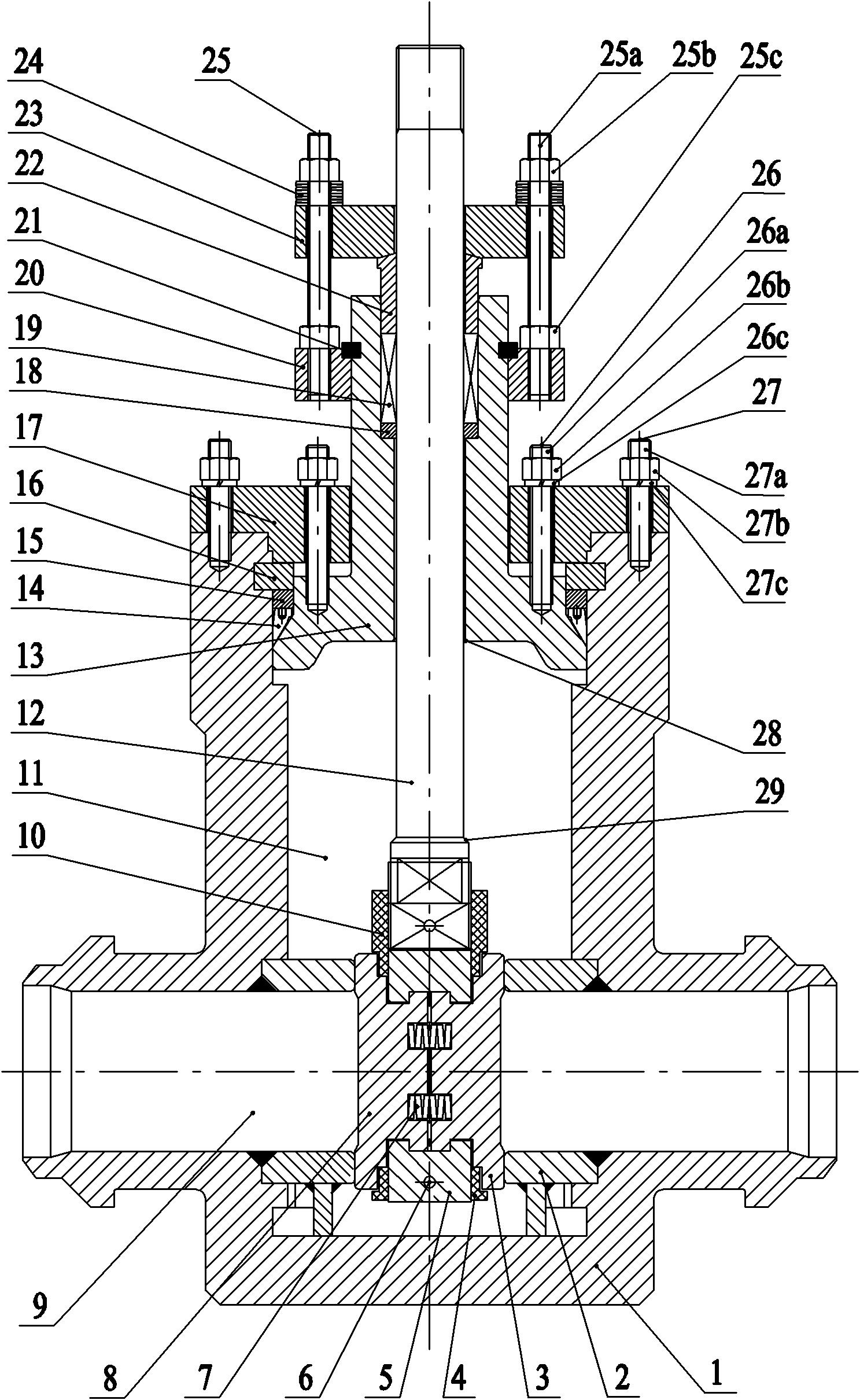

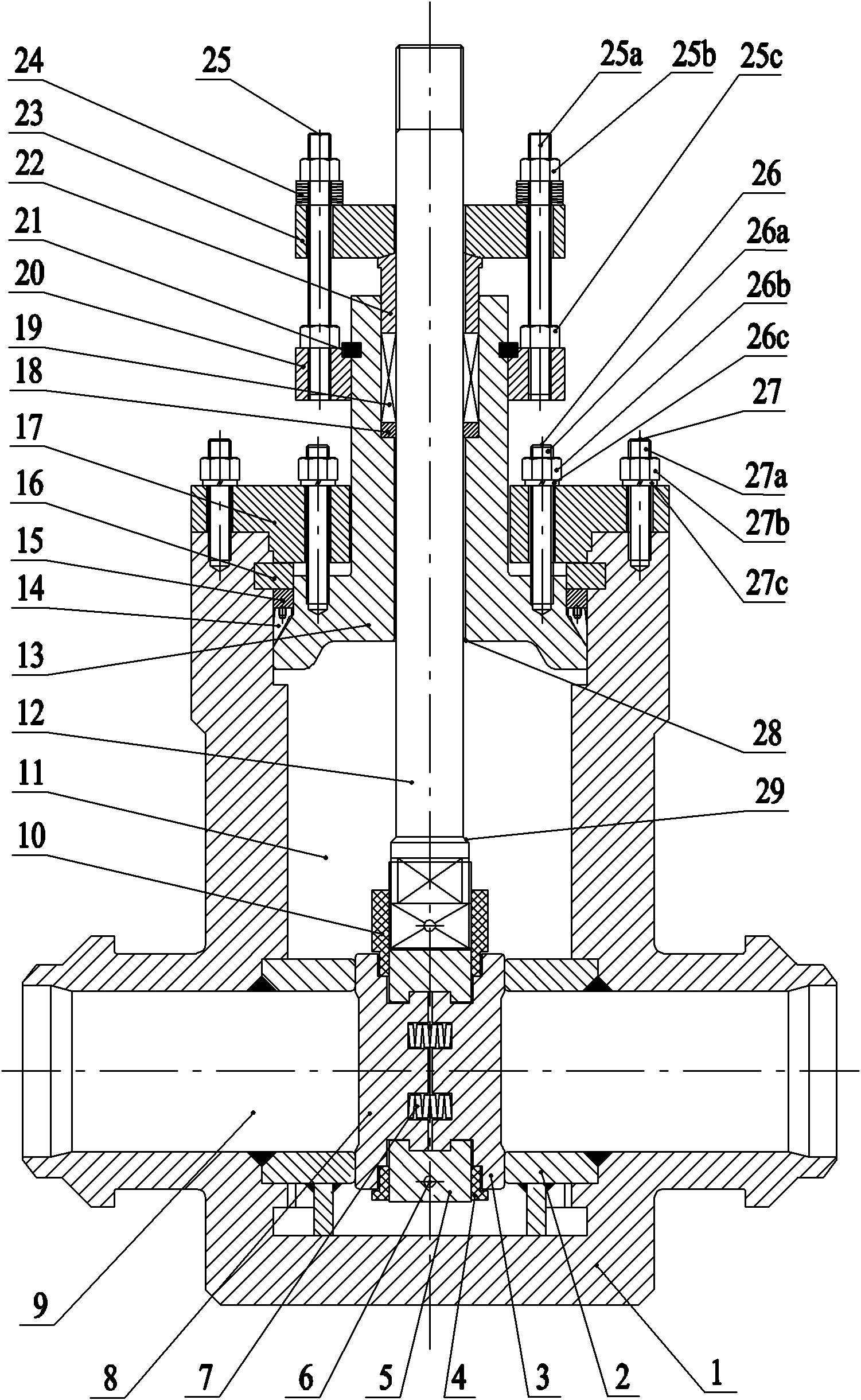

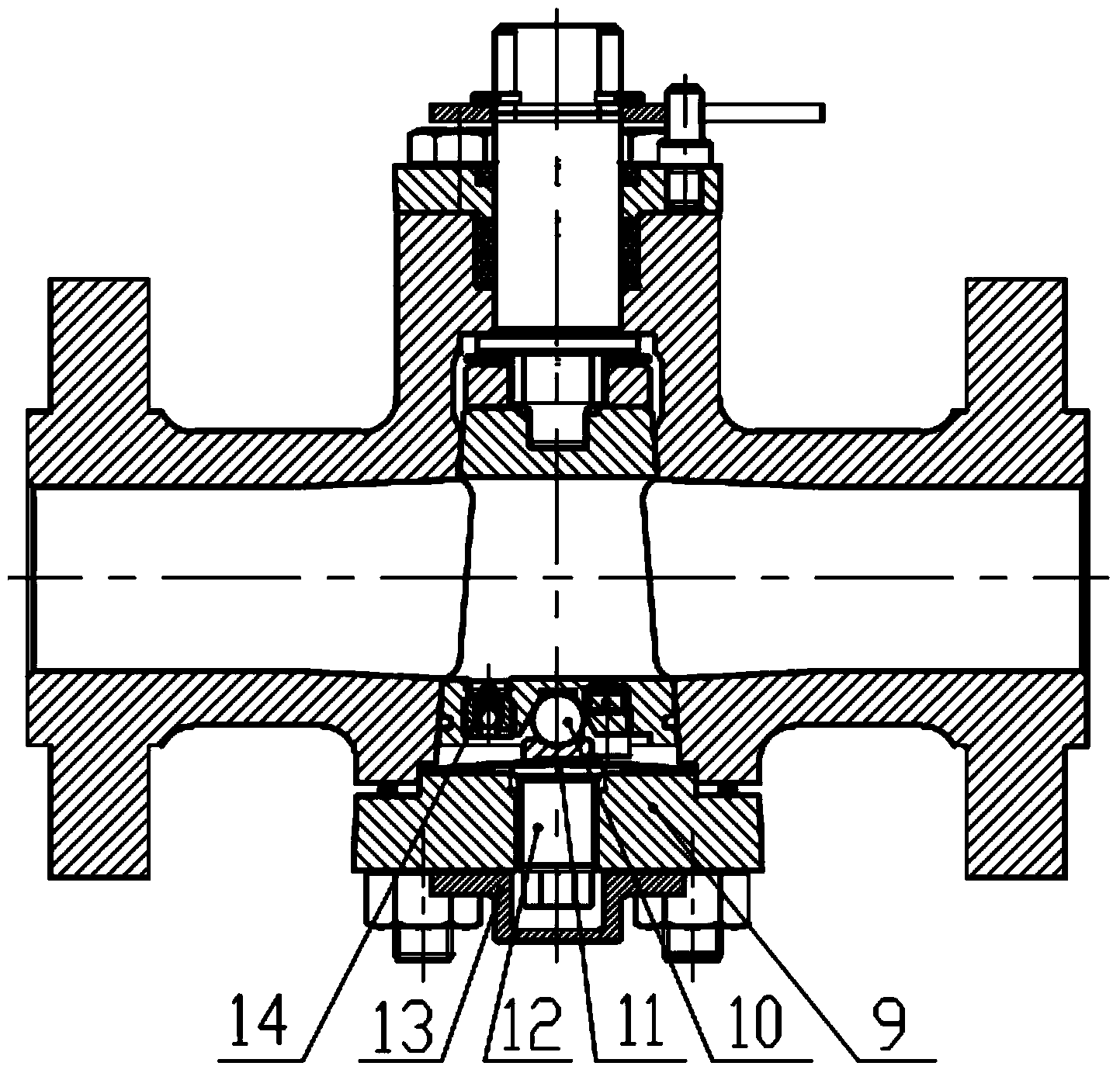

Parallel gate valve

ActiveCN102094988AIngenious structureOvercoming the splay at the topSpindle sealingsSlide valveGate valveValve seat

The invention relates to a parallel gate valve comprising a valve body, a valve cover, a valve seat, a valve rod and a valve plate assembly, wherein the valve cover is arranged on the top of the valve body; the upper part of the valve body is provided with an upper cavity, and the lower part of the same is provided with a flow passage; the valve seat is arranged in the flow passage and provided with a valve plate groove matched with the valve plate assembly; the valve plate assembly is arranged in the valve plate groove; the valve rod penetrates through the upper cavity from the valve cover; the valve rod and the valve cover are sealed by utilizing a sealing structure; and the lower end of the valve rod is connected with the upper part of the valve plate assembly. The parallel gate valve is characterized in that the valve plate assembly comprises a left valve plate, a right valve plate, a middle spring, a valve plate sleeve, an upper fixing ring and a lower fixing ring, wherein the left valve plate and the right valve plate are symmetrically arranged; the abutted surface of the left valve plate and the right valve plate is provided with a spring cavity; and the middle spring is arranged in the spring cavity. The invention has the advantages of ingenious, compact and reasonable structure, long service life, better sealing effect and low manufacture and maintenance cost, and can not generate the top opened phenomenon of the valve plate assembly when the valve plate assembly is opened, thereby preventing the drag mark phenomena of the valve plate assembly and the valve seat.

Owner:WUXI YADI FLUID CONTROL TECH CO LTD

Multifunctional filtration type two-way telescoping anti-theft gate valve

ActiveCN104879560AWith magnetic anti-theft functionWith anti-theft functionAdjustable jointsSlide valveInlet channelFiltration

The invention discloses a multifunctional filtration type two-way telescoping anti-theft gate valve. The multifunctional filtration type two-way telescoping anti-theft gate valve comprises a valve body, a valve deck, a rotary cover, a lower valve deck, a valve rod and locking nuts. The valve deck is arranged above the valve body, a square hole is formed in the other end of the valve rod, and a locking blind hole and a positioning blind hole are formed in the upper end face of the valve deck in a spaced mode. A rotatable functional plate is arranged between the rotary cover and the valve deck, and a locking hole which a piece of locked magnetic steel can pass through, and a positioning hole matched with a piece of movable magnetic steel are formed in the functional plate. A circular groove is formed in the side wall of the lower end of the rotary cover, and a magnetic conduction iron ring is arranged in the circular groove. A positioning groove and a hexagonal hole used for opening and closing are formed in the upper end face of the rotary cover. A fixing hole is formed in the outer side wall of the valve deck. An O-type ring is further arranged in the outer side wall of the valve deck and below the rotary cover. The valve body is located at a gate plate water flow control port, and filter screens are arranged between the valve body and a water inlet channel and between the valve body and a water outlet channel. A sliding telescopic pipe is arranged between a water inlet and a water outlet of the valve body. The multifunctional filtration type two-way telescoping anti-theft gate valve is reasonable in structural design, convenient to install and detach and low in cost, has the two-way telescoping movable connection and filtration functions and can compensate for a pipeline. The multifunctional filtration type two-way telescoping anti-theft gate valve can be used as either an anti-theft valve or an ordinary gate valve and is flexible to use and wide in application range.

Owner:LIANGGANG VALVE GRP

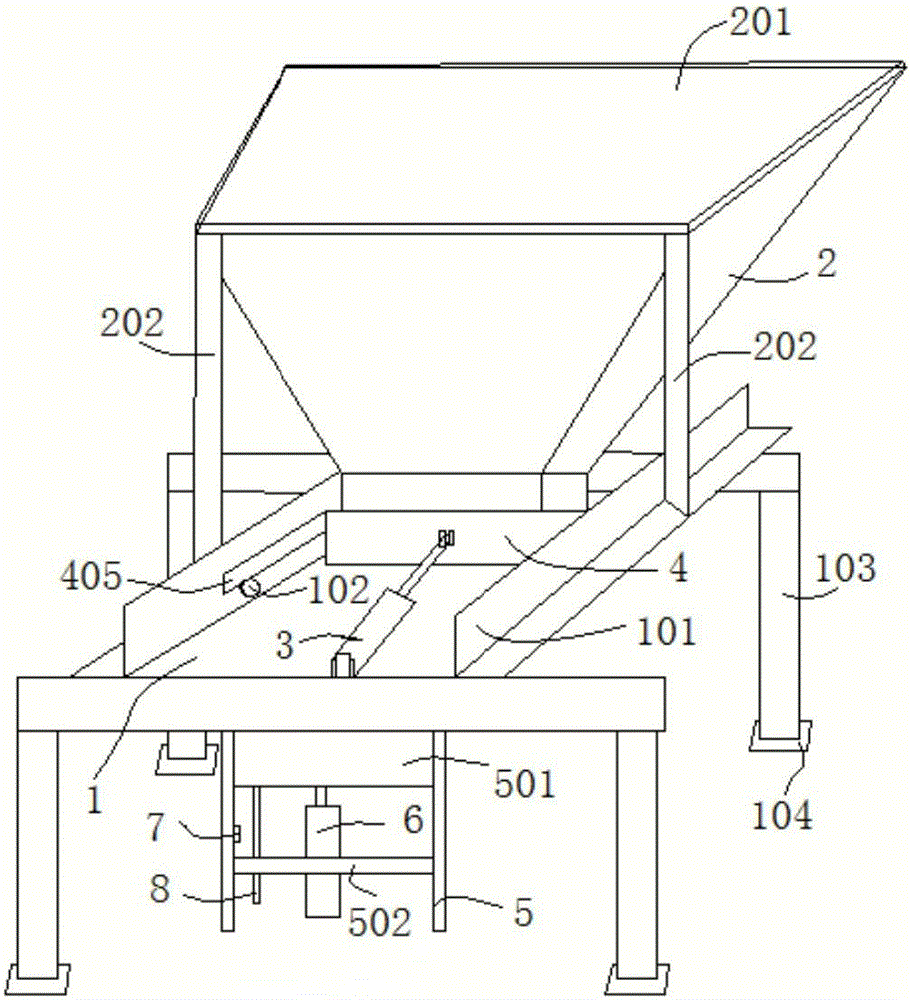

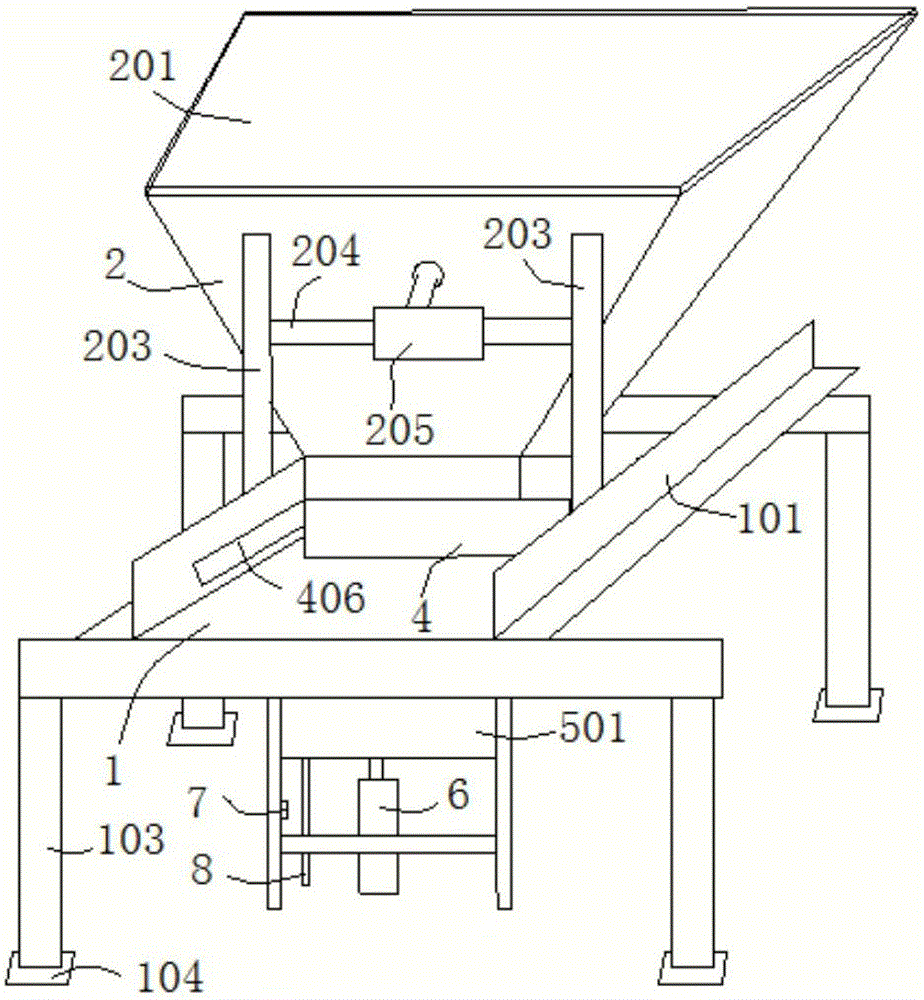

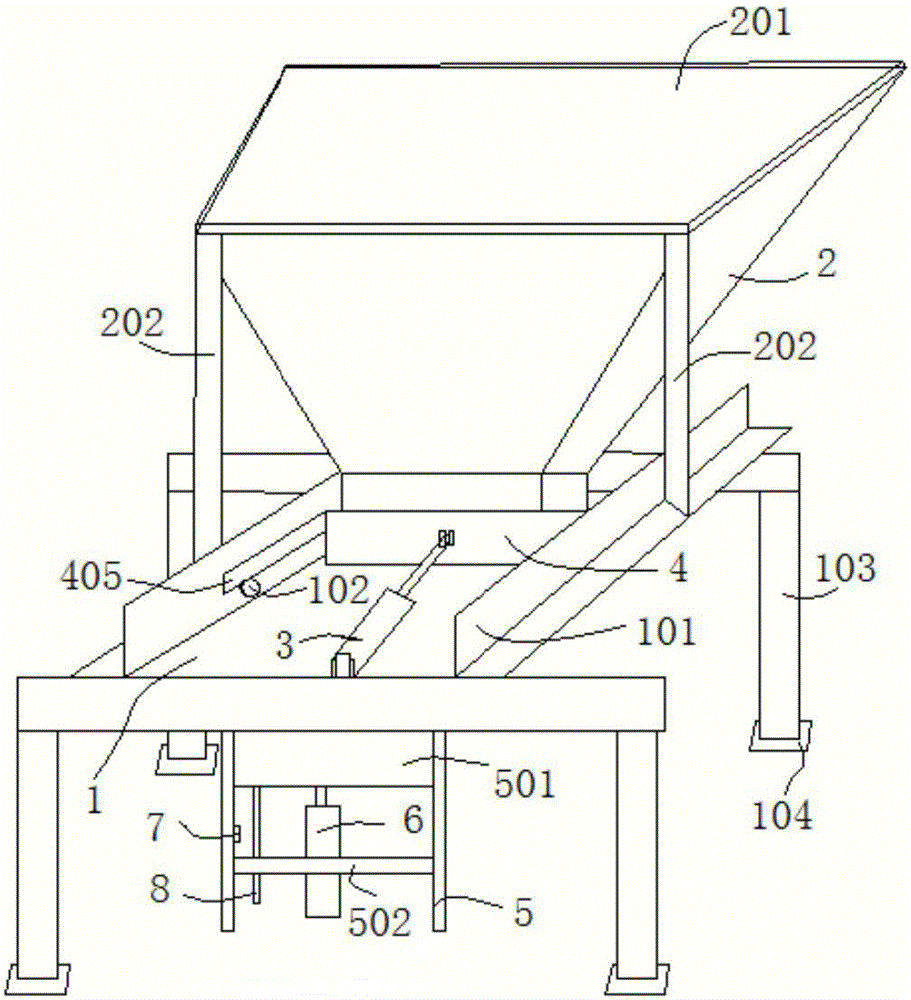

Automatic forming device for producing baking-free bricks

ActiveCN106313297AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses an automatic forming device for producing baking-free bricks, and belongs to the field of brick making machines. The automatic forming device comprises a frame, a blanking opening is formed in the frame, a forming material pushing mechanism is arranged above the blanking opening and connected with a first hydraulic cylinder, a forming mechanism is arranged below the blanking opening and connected with a second hydraulic cylinder, raw materials penetrate the forming material pushing mechanism, enters the forming mechanism and squeezed into bricks by the second hydraulic cylinder, the bricks are pushed onto the frame by the second hydraulic cylinder, and the first hydraulic cylinder drives the forming material pushing mechanism, so that the bricks are pushed onto a delivery mechanism and conveyed. The automatic forming device helps to solve the problems of complicated structure and cumbersome production process of an existing brick making machine, the bricks can be continuously squeezed and formed, production efficiency is improved, the automatic forming device is simple in structure and low in machining cost, and productive benefits of enterprises can be improved.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

Full-automatic accessory screwdriver

The invention relates to the technical field of screwdrivers, in particular to a full-automatic accessory screwdriver which comprises an electric screwdriver, a coordination machine, a delivery pipe for delivering screws and a screw transmitting device, wherein the screw transmitting device is provided with a decelerating bent groove and a guide tube. In the invention, mechanical motility is mainly utilized, full automation during the delivering process is realized by a tilting structure and the self gravity of the screw, not only the time for manually grabbing the screw and the use cost are saved, but also the screws entering a material bearing space can be delivered to the entrance for the screw completely, and especially, nail clamping phenomenon is avoided during the continuous delivery process; and the screw transmitting device is internally provided with an electronic automatic monitoring energy-saving device, and when the delivery pipe for delivering the screws is filled with screws to the monitoring position, the device can automatically cut off the power, and then restore to work in the set time, thus saving energy source.

Owner:STATE GRID CORP OF CHINA +1

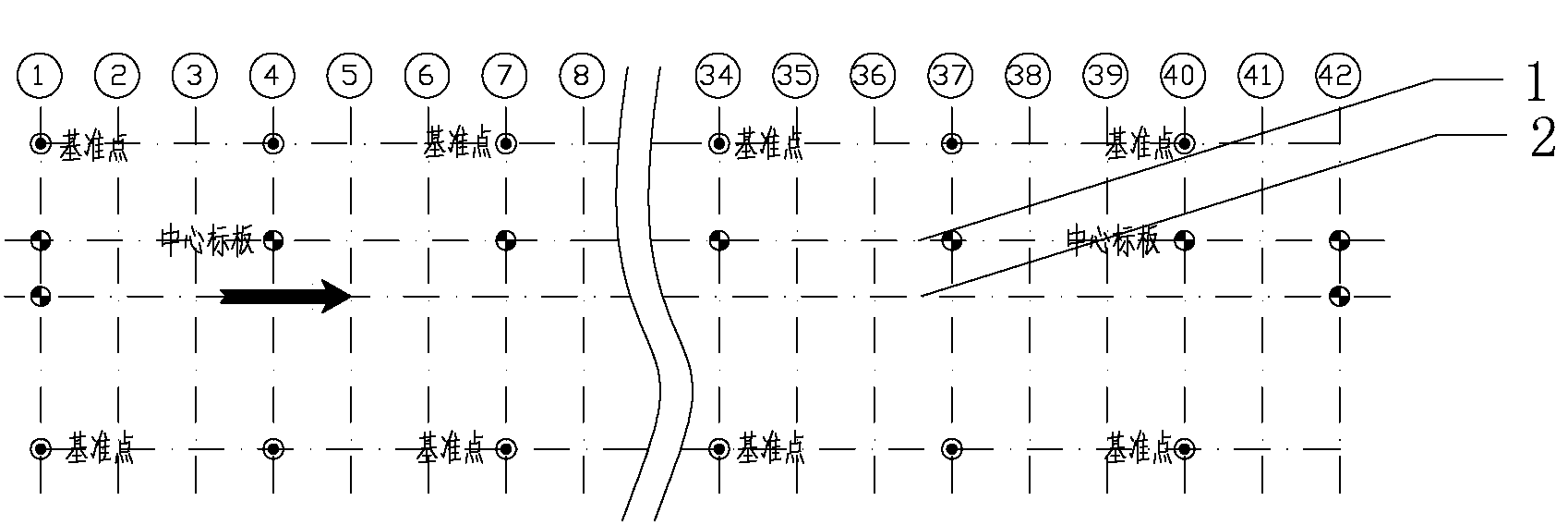

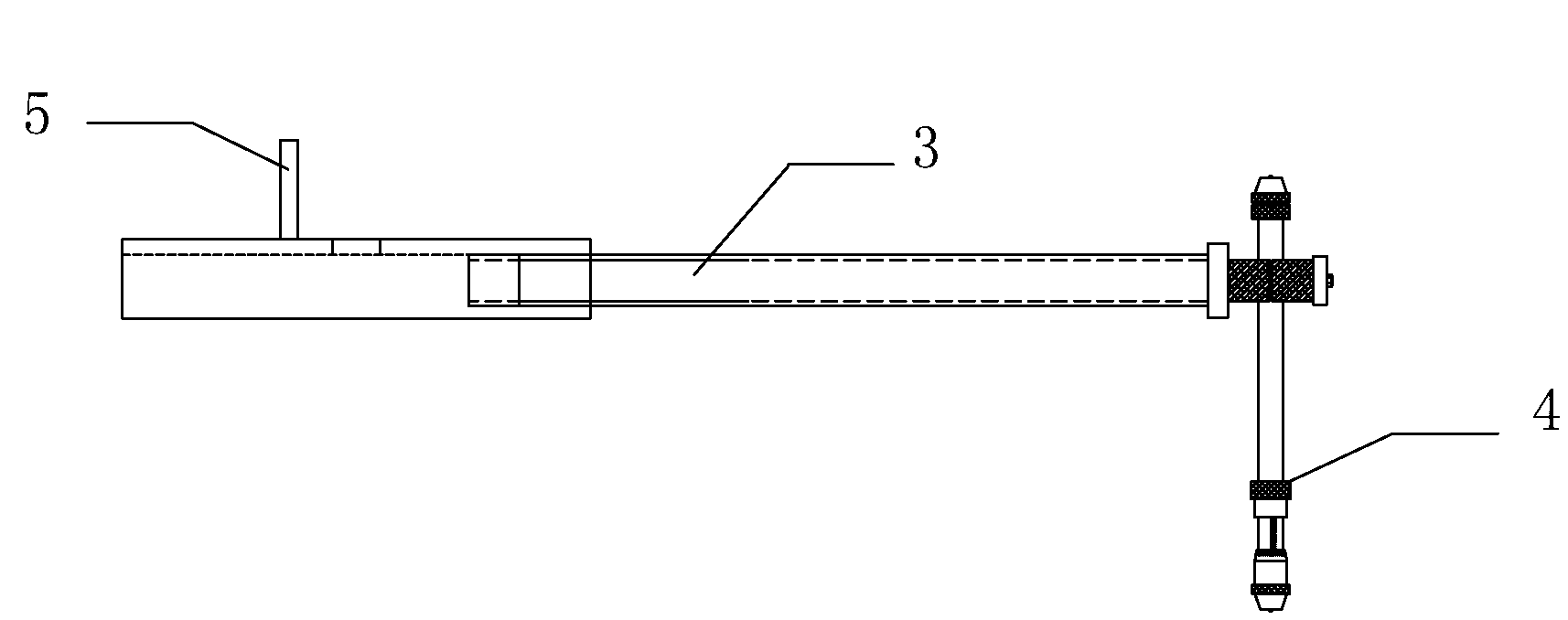

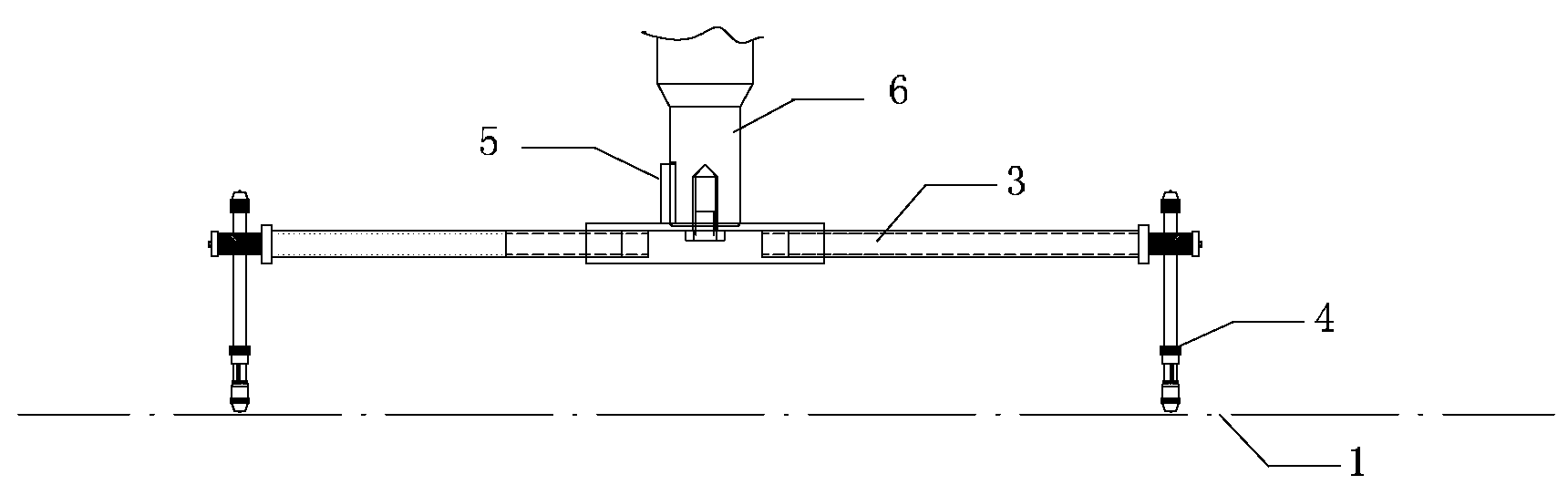

Control method of installation precision of centralized transmission roller table of oriented silicon steel annealing furnace

ActiveCN103388066AReasonable designEasy to operateFurnace typesHeat treatment furnacesControl setProcess engineering

A control method of installation precision of a centralized transmission roller table of an oriented silicon steel annealing furnace is disclosed; and the control method is characterized by comprising the following steps: a) positioning control of a center line, b), adjusting control of the centralized transmission roller table, c), control for preventing roller constraint, d) checking control of a furnace roller flange and e) inspection of installation effect of the centralized transmission roller table. The control method of the installation precision of the centralized transmission roller table of the oriented silicon steel annealing furnace has the advantages that: the step of adjusting control is reasonable in design and simple to operate, the installation construction time is shortened, the installation precision of the roller table of the furnace body can be effectively improved, the run deviation of product running can be within 10mm, and the method passes thermal state production examine, has no blocking phenomenon, greatly extends the use and the maintenance cycle of the roller table, can ensure the control of the run deviation of strip steels, and can fully meet the use requirements of production.

Owner:MCC5 GROUP CORP SHANGHAI

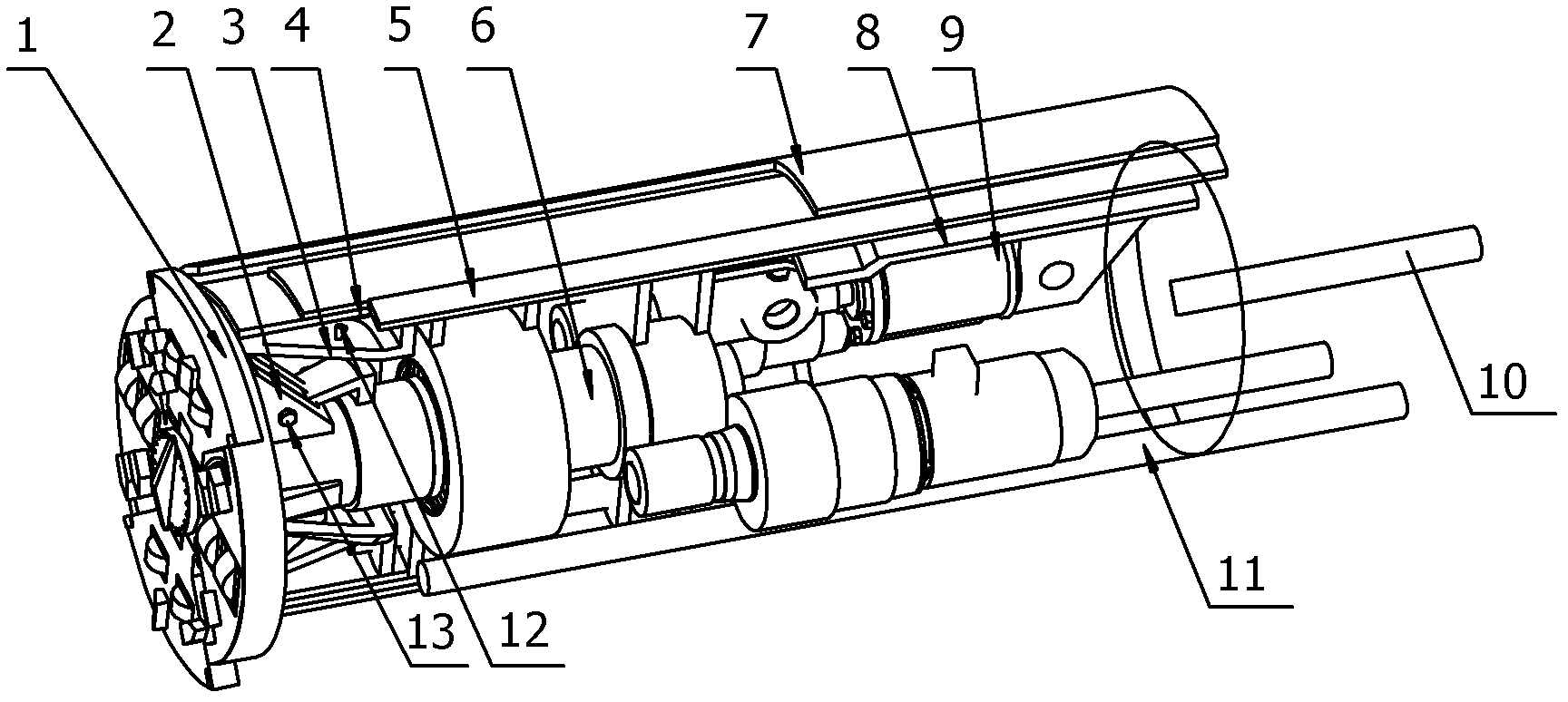

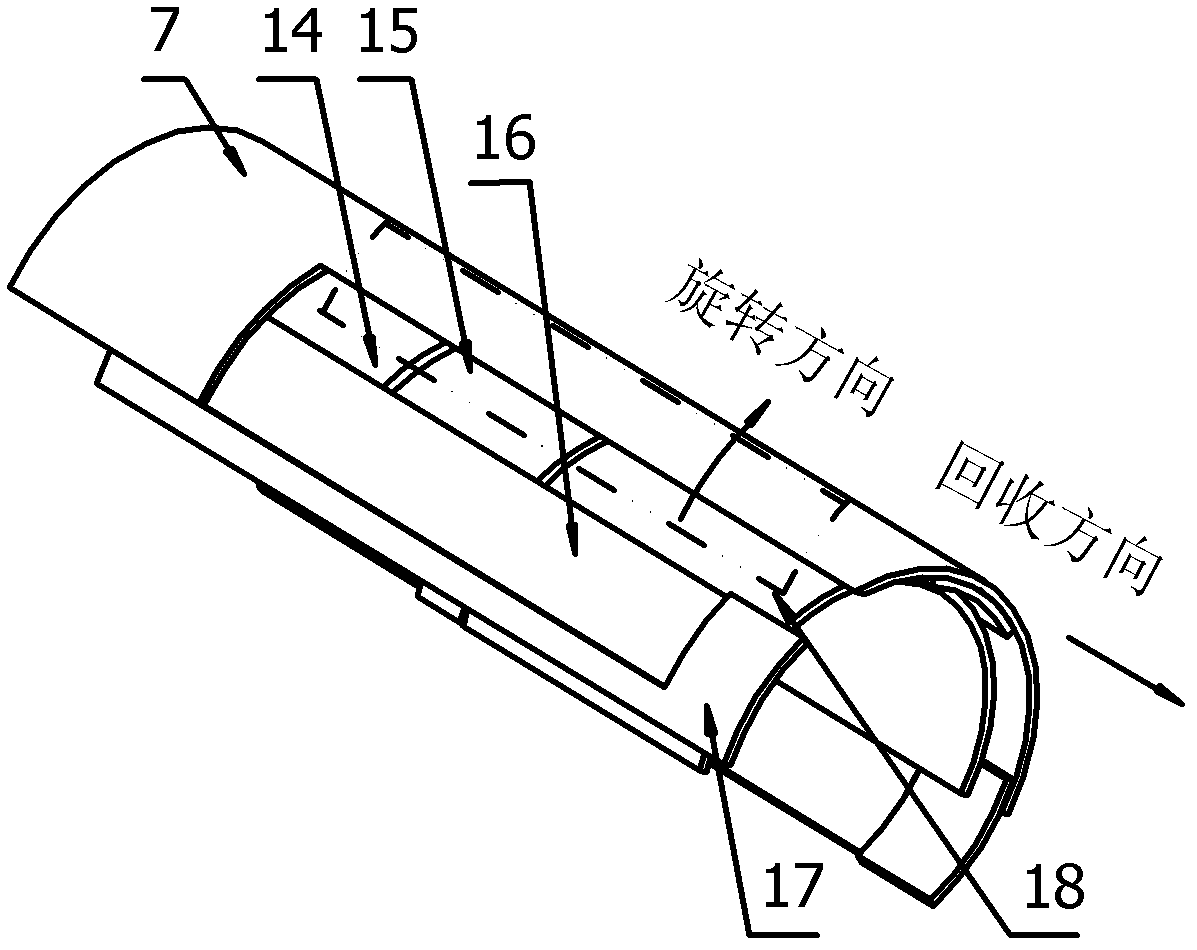

Flexible tunneling machine for installing sleeve

ActiveCN102587833AReasonable structural designThe installation position is accurateDrilling machines and methodsAgricultural engineeringSlurry

The invention discloses a flexible tunneling machine for installing a sleeve, belonging to the technical field of underground oil-gas reservoir exploitation. The tunneling machine comprises a flexible cutter head, a cutter head supporting plate, a conical crushing device, a front shell, a fixing device, a dynamic system, a rear shell, oil cylinders, a recovery system, a slurry inlet / outlet pipe, a slurry nozzle and a cutter head positioning pin, wherein the flexible cutter head is connected with the cutter head supporting plate through the cutter head positioning pin; the flexible cutter head is connected with a rotary main shaft of the conical crushing device; the rotary main shaft of the conical crushing device is connected with the main shaft of the dynamic system; the conical crushing device is welded in the front shell; the recovery system is arranged at the tail part of the rear shell; the oil cylinders are arranged on the front shell and the rear shell through fixing seats; the slurry inlet / outlet pipe is fixed below the inner part of the rear shell; and the slurry nozzle is arranged on the conical crushing device. The flexible tunneling machine for installing the sleeve is reasonable in structural design, correct and efficient in steel sleeve mounting position, free of end part sinking phenomenon, simple and reliable in recovery scheme and free of clamping phenomenon.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

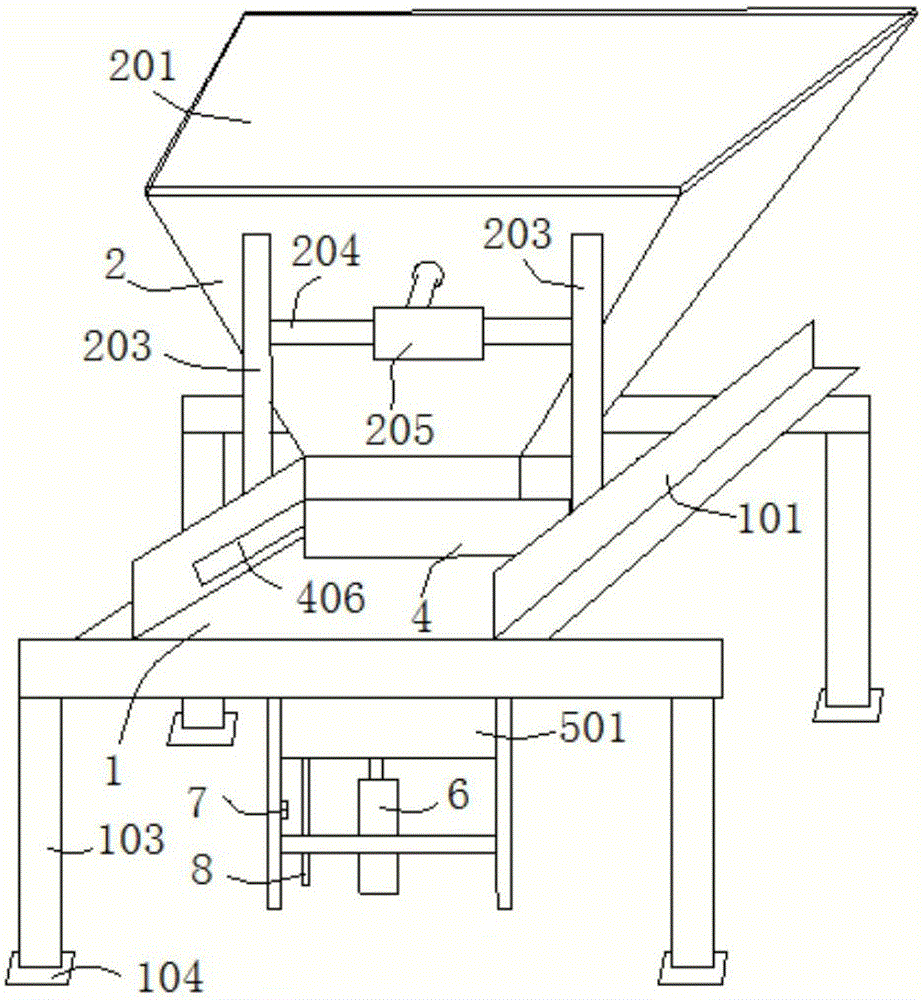

Processing method for baking-free brick extrusion forming

ActiveCN106626003AAchieve automationRealize continuous productionDischarging arrangementFeeding arrangmentsHydraulic cylinderBrick

The invention discloses a processing method for baking-free brick extrusion forming and belongs to the technical field of brick making. By means of a continuous hydraulic brick making system, the processing method includes the following steps of feeding, wherein raw materials are added into a feeding hopper, penetrate through a feeding cavity and a feeding opening and enter a forming cavity; extrusion forming of the raw materials, wherein a first hydraulic cylinder drives a forming and pushing mechanism to move, so that a buffer cavity moves to the position under the feeding hopper, a second hydraulic cylinder drives an extrusion plate to move upward in the forming cavity, and the raw materials are extruded into bricks; pushing and conveying of the bricks, the first hydraulic cylinder drives the forming and pushing mechanism to move, and the second hydraulic cylinder drives the extrusion plate to push the bricks to a machine frame, and the first hydraulic cylinder drives the forming and pushing mechanism to push out the bricks. The defects that in the prior art, the brick continuous production degree is low and production efficiency is low are overcome easily, continuous extrusion forming of the bricks can be achieved, production efficiency is effectively improved, the operation process is simple, and the production cost is low.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

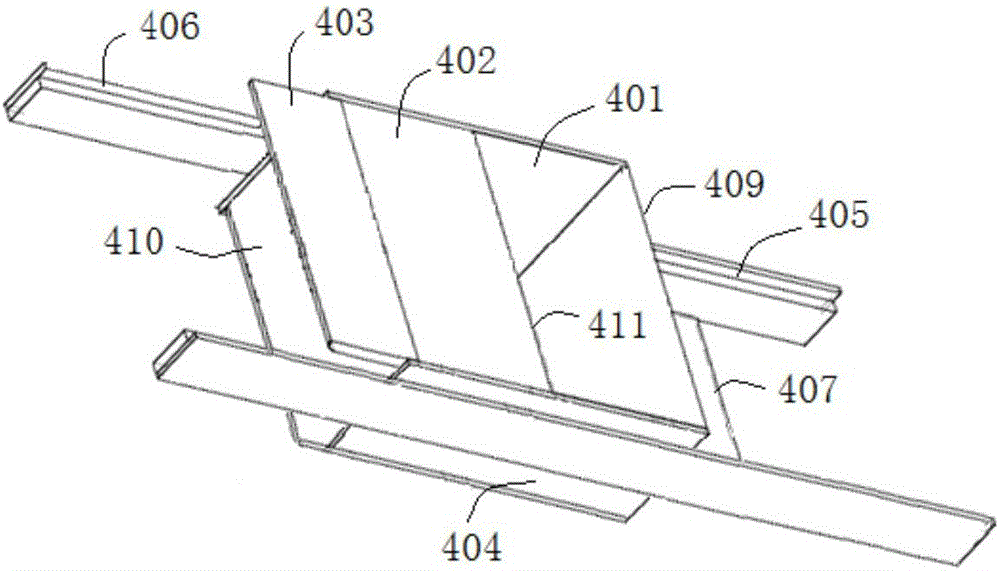

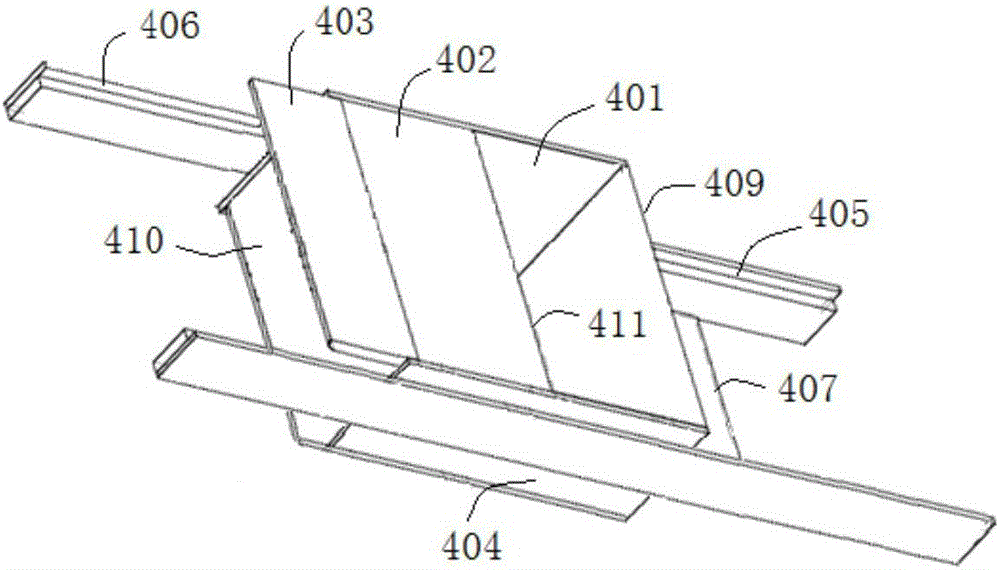

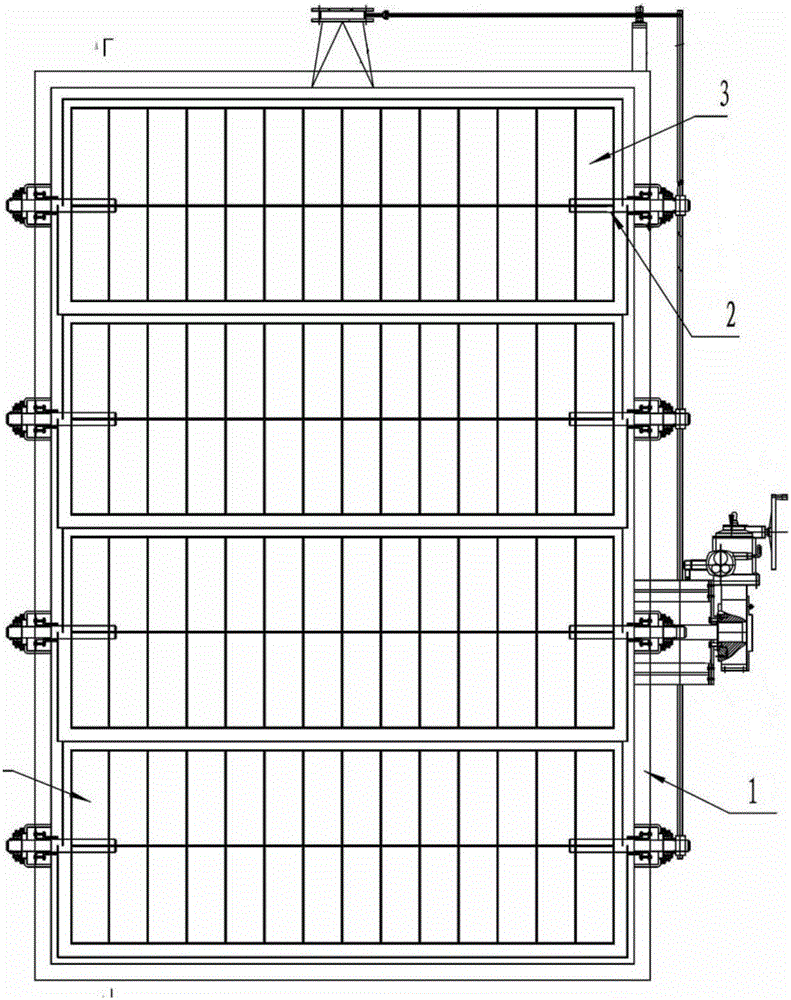

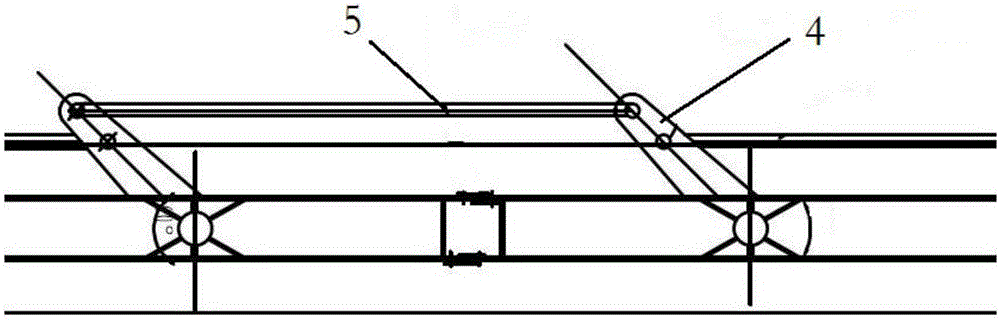

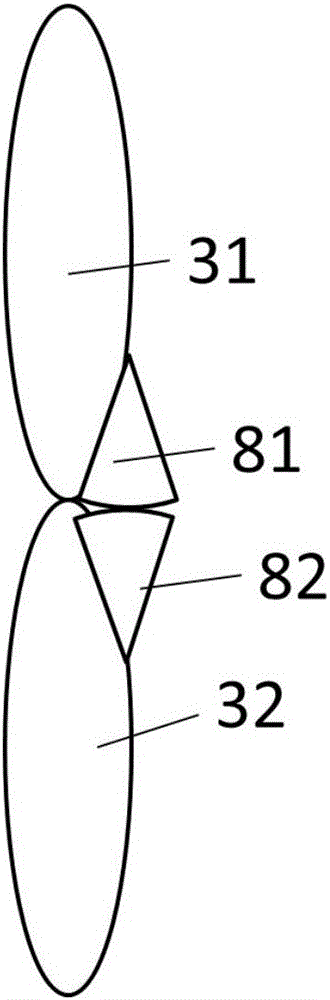

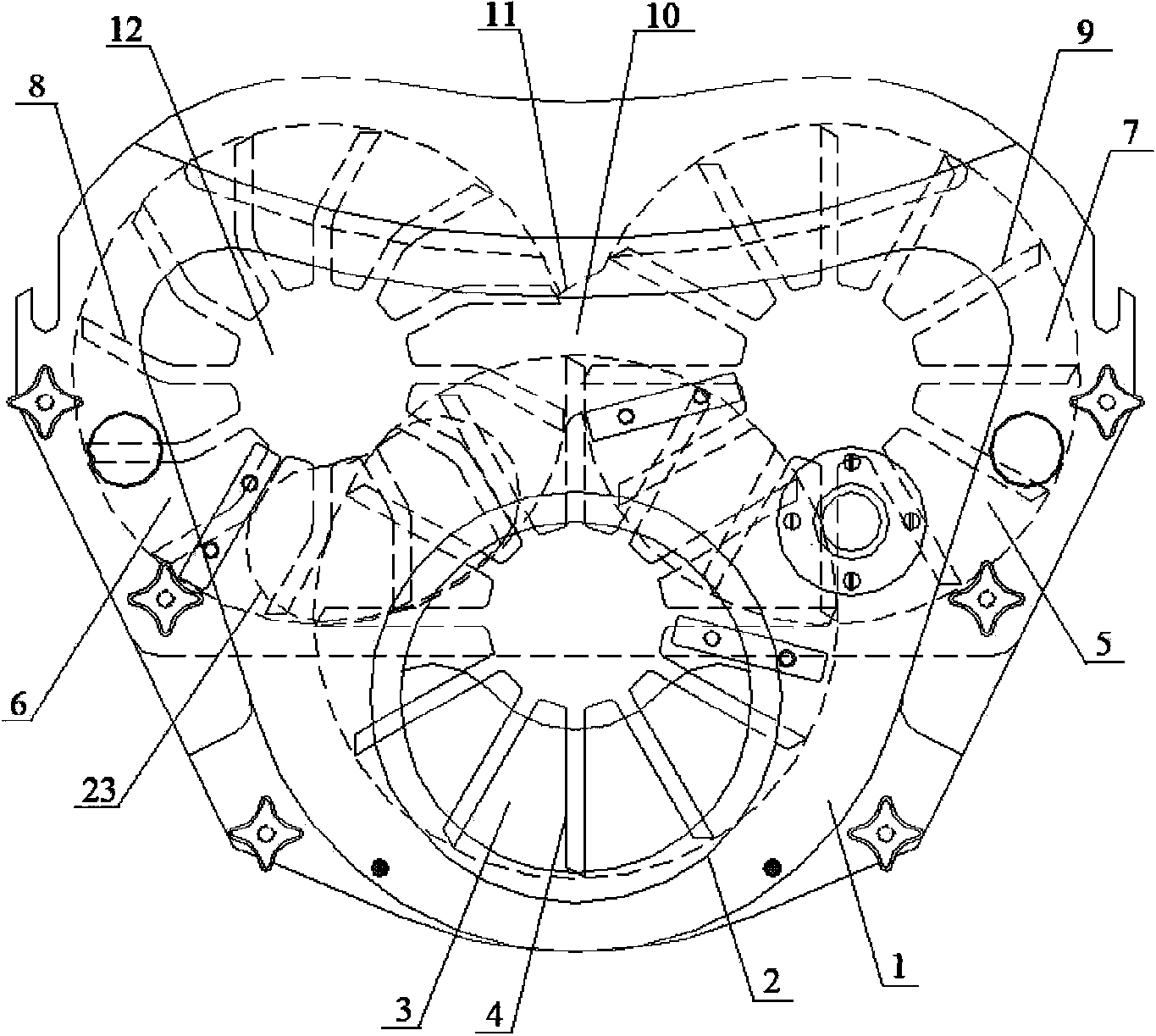

Desulphurized flue gas damper and blades

ActiveCN106090970AGood rigidityReliable operationEmission preventionChimneysAirflowComposite structure

The invention provides a desulphurized flue gas damper. The desulphurized flue gas damper comprises an outer frame, at least one shaft mounted on the outer frame and baffles fixed to the shafts, wherein the multiple shafts are mounted, the shafts are evenly distributed along the outer frame; sealing strips are arranged on the two baffles; the sealing strips are arranged on the upper edges and the lower edges of the baffles; and the sealing strips are in a fan shape, are elastic and can stretch out and retract. Each baffle is of a multi-layer composite structure, and cavities are formed in the two ends of the innermost layer correspondingly. An electromagnet is arranged in each cavity. The magnetic poles of electromagnets between the upper baffle and the lower baffle are opposite. The fan-shaped sealing strips are designed between two layers of blades, sealing air with the pressure being at least 1000 Pa higher than that of flue gas is introduced into the baffles, and a sealing air insulation layer is formed between the two layers of baffles to prevent flue gas flow from passing through. The blades are of a composite multi-layer structure so that the strength and rigidity of the blades can be improved. The sealing effect of the desulphurized flue gas damper is further improved through the electromagnet principle.

Owner:江苏汉唐环保科技有限公司

Forced feeding device

The invention discloses a forced feeding device. The forced feeding device comprises an impeller box, wherein an upper-layer impeller chamber, a lower-layer impeller chamber and a separation plate arranged between the upper-layer impeller chamber and the lower-layer impeller chamber are arranged in the impeller box; the upper-layer impeller chamber is internally provided with a material distribution impeller and the lower-layer impeller chamber comprises a feeding impeller chamber and a quantitative impeller chamber; a crossed part of the feeding impeller chamber and the quantitative impeller chamber is communicated; a feeding impeller is arranged in the feeding impeller chamber; a quantitative impeller is arranged in the quantitative impeller chamber; the rotating direction of the feeding impeller is opposite to the rotating direction of the material distribution impeller. According to the forced feeding device, the quantitative impeller chamber is arranged and surplus materials in the quantitative impeller chamber are added into the feeding impeller chamber again so that the materials flow smoothly in the forced feeding device; a material caking phenomenon is avoided so that the filling stability of the materials is ensured.

Owner:北京国药龙立科技有限公司

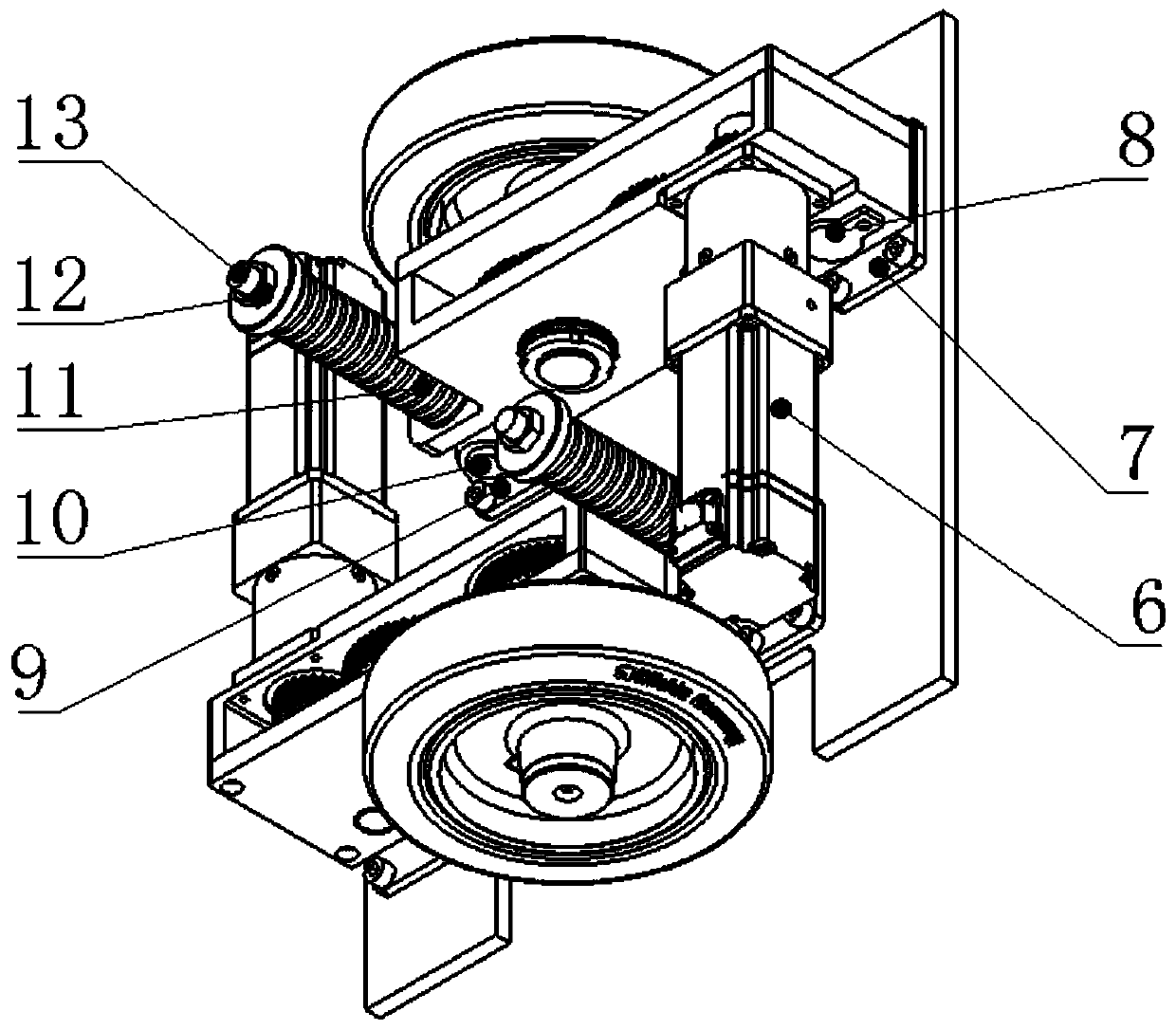

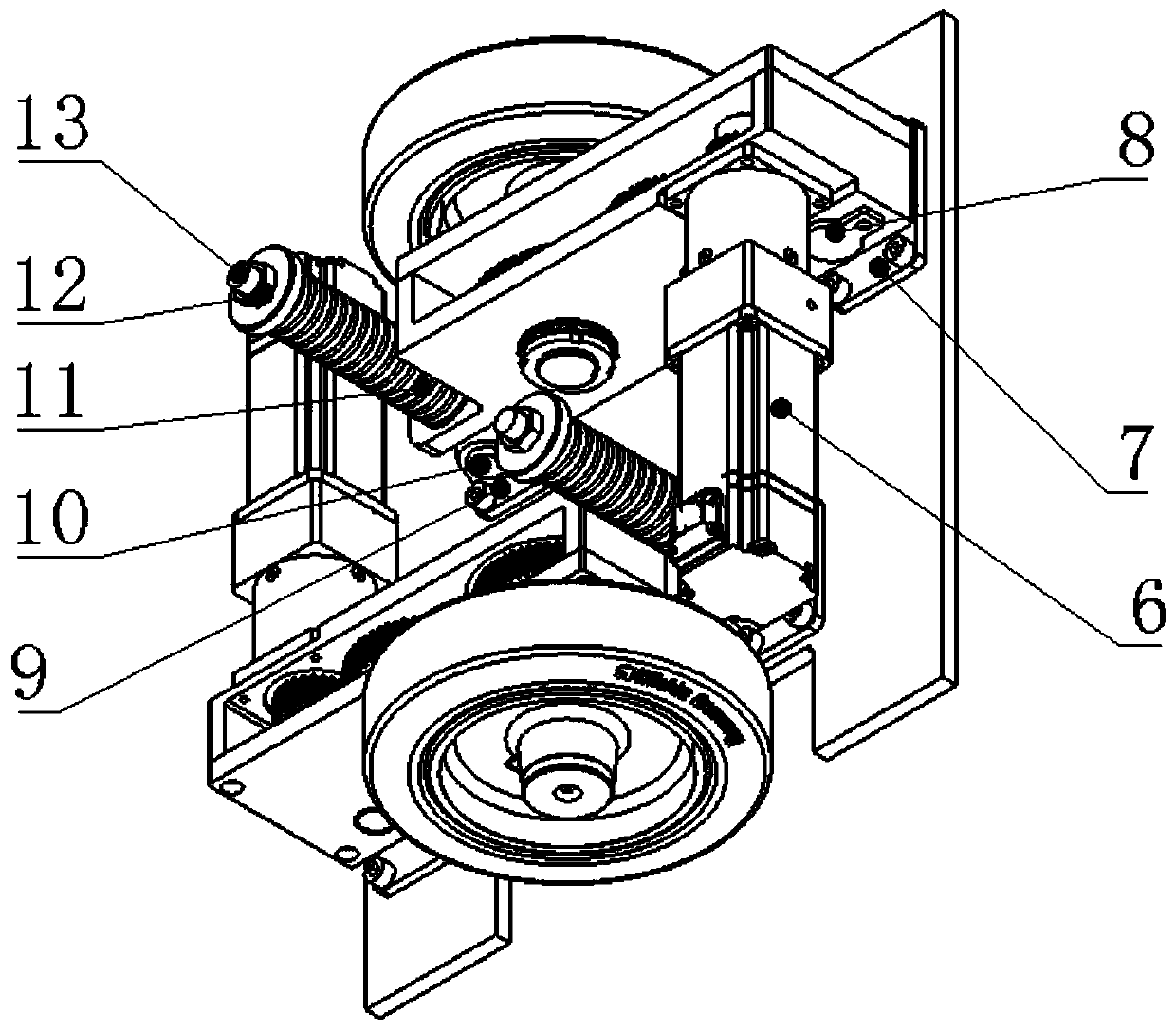

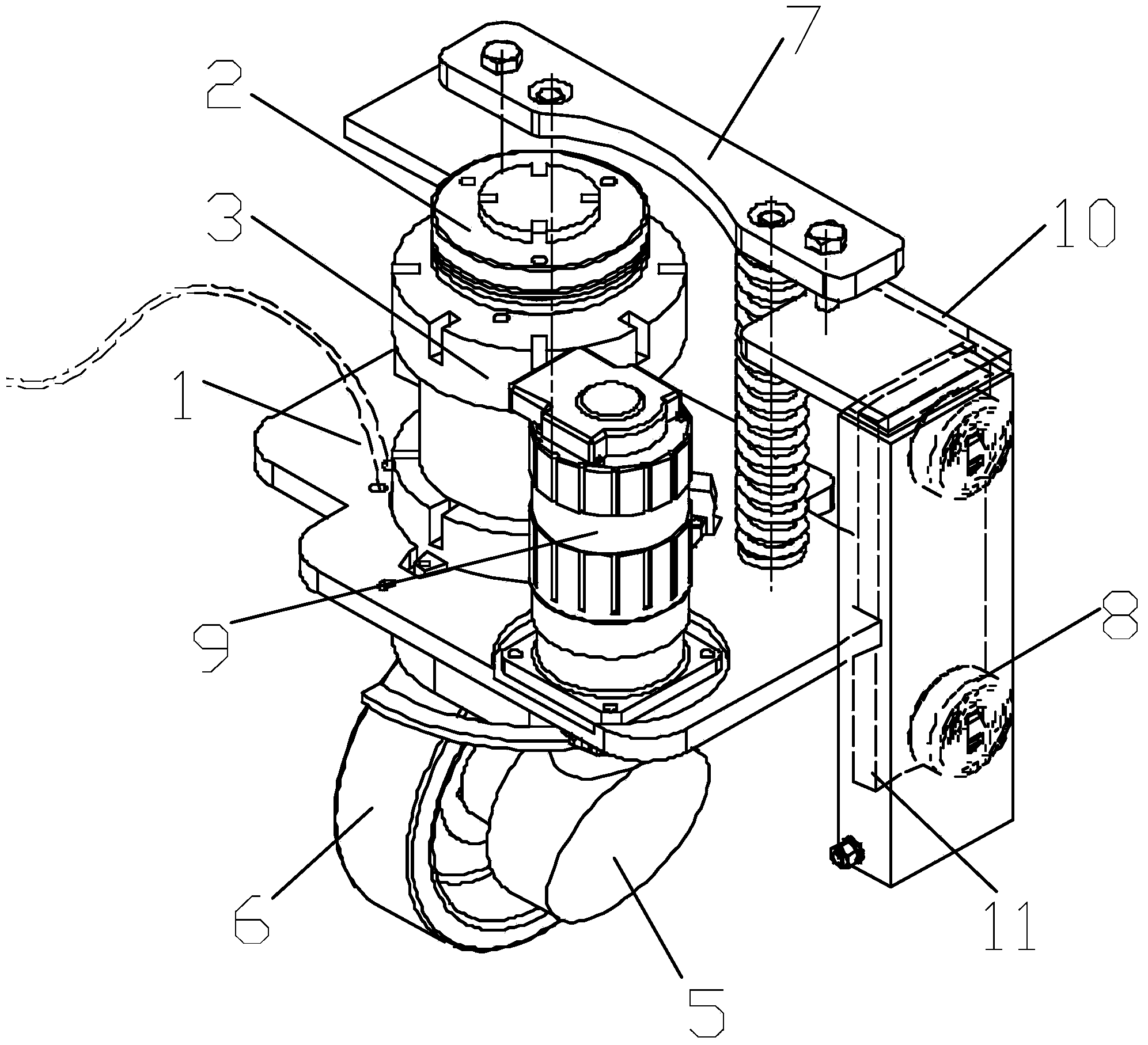

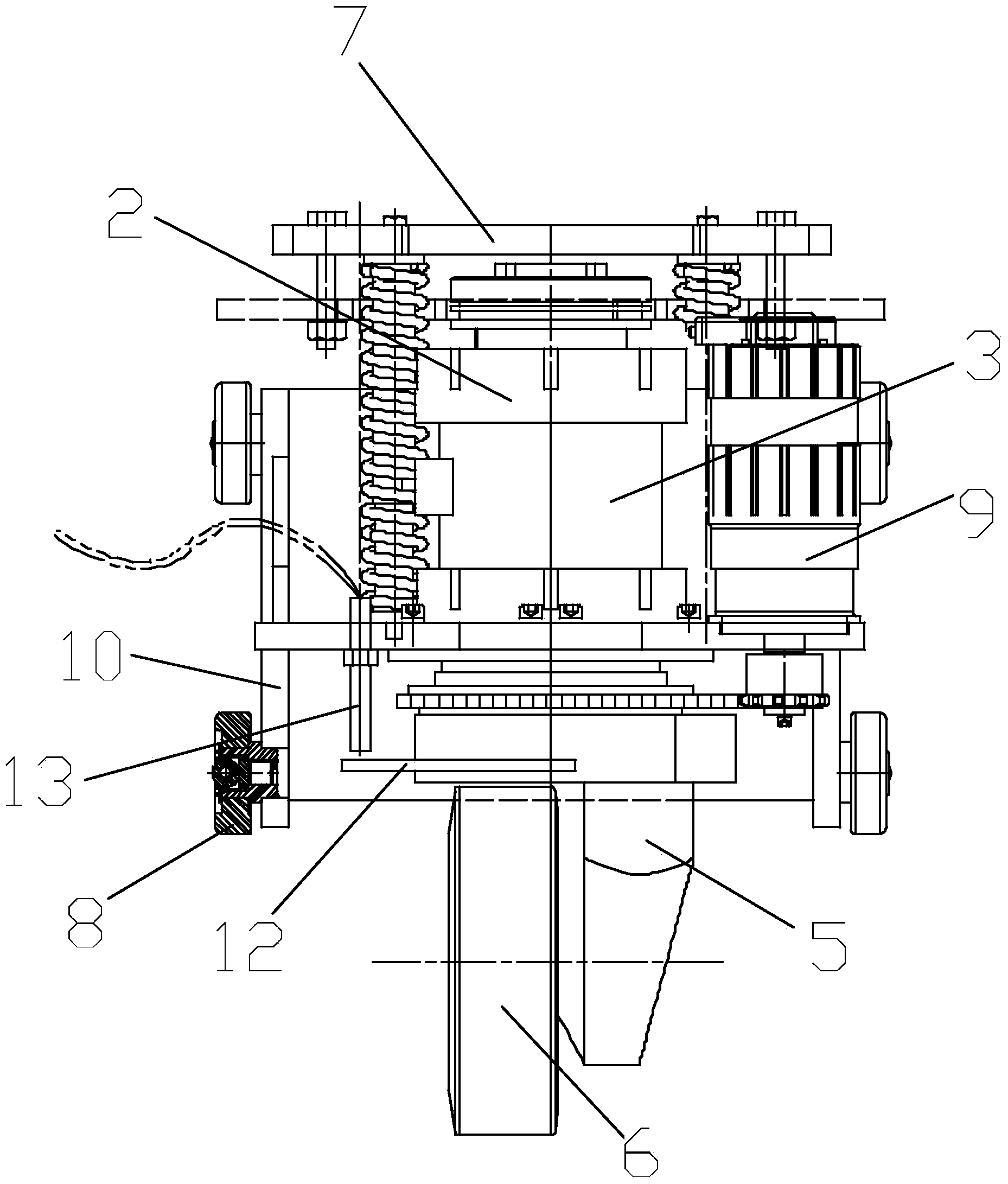

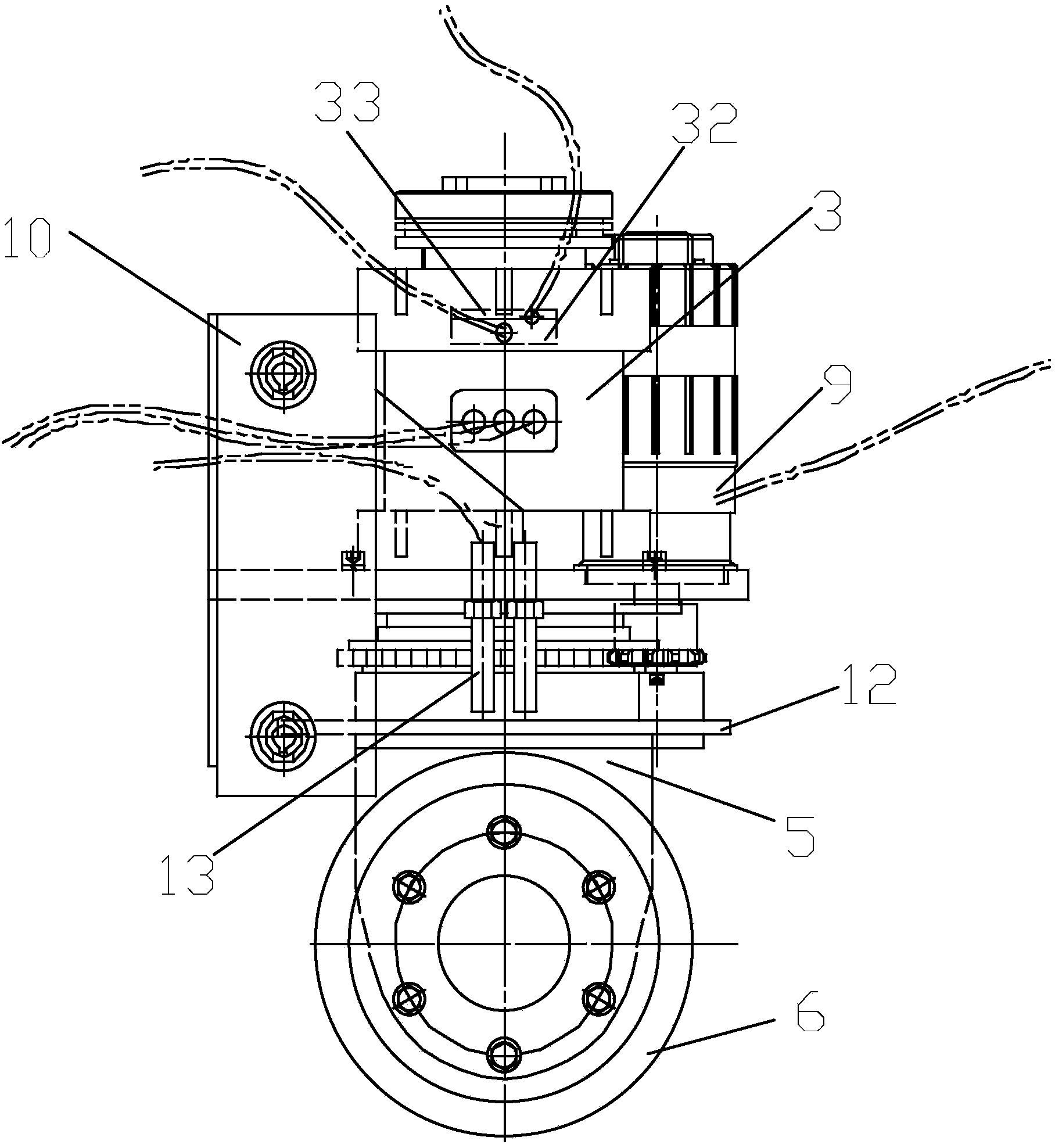

A novel transmission and suspension system and a 500 kG-loaded compact AGV (automatic guided vehicle) thereof

PendingCN109703649ACompact structureReduce wearElectric propulsion mountingVehiclesEngineeringDrive wheel

A novel transmission and suspension system comprises driving devices and a suspension device; the two same driving devices are hinged to the suspension device; the driving device comprises a direct-current servo motor, a planetary reducer, a gear box and a driving wheel; the suspension device comprises a rectangular spring, a large adjusting nut and a spring guide shaft. The direct-current servo motors in the two sets of the same driving devices are connected with driving wheels through gearboxes respectively, so that the positions of the two differential driving wheels, which are staggered from the planetary reducer through the gearboxes, are formed; the spring guide shaft penetrates through a waist-shaped hole in the left end of the gear box, and the rectangular spring penetrates throughthe spring guide shaft and is arranged between the adjusting large nut and the gear box. In addition, the invention further discloses a 500 KG-loaded compact AGV.

Owner:严格科创发展(昆山)有限公司

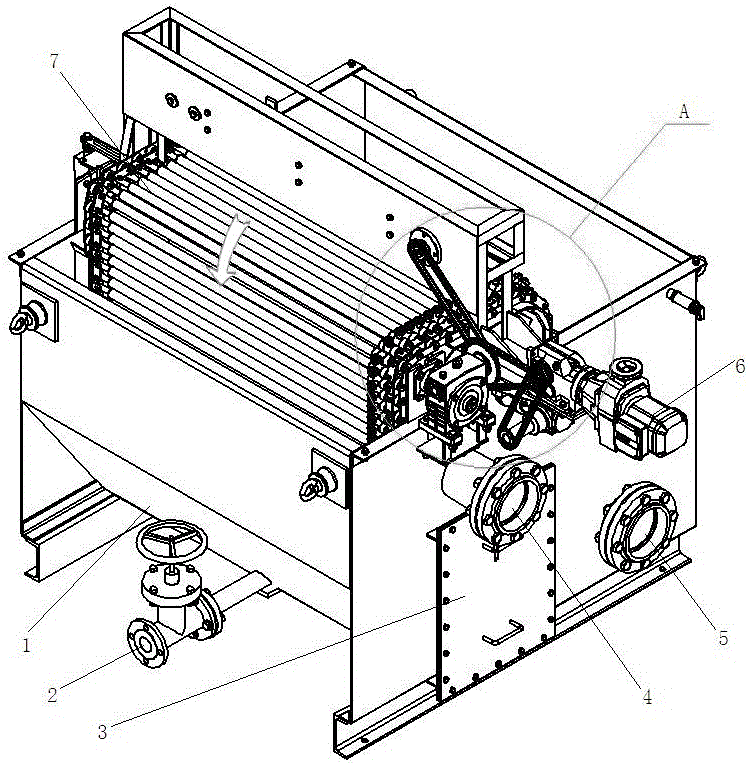

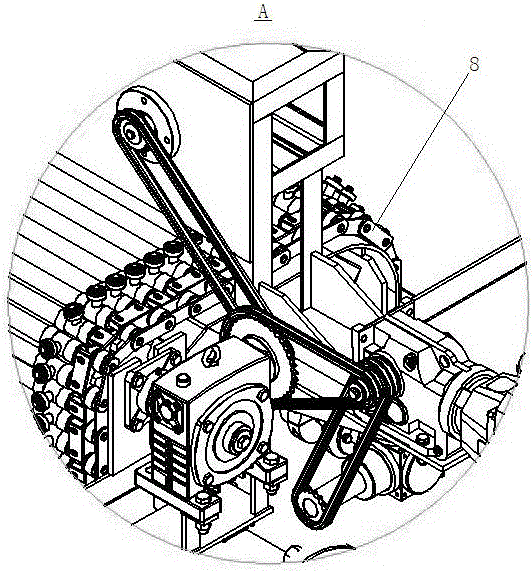

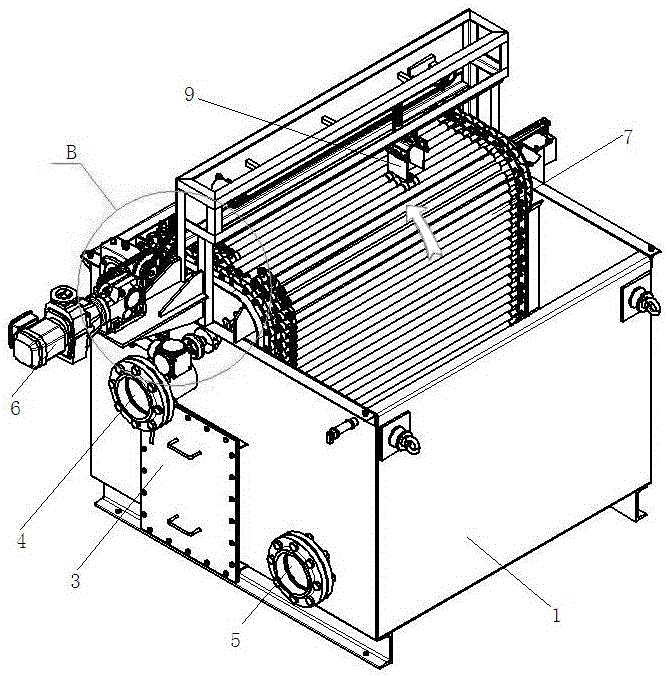

Chain bar type permanent magnet filter

The invention relates to a chain bar type permanent magnet filter. The chain bar type permanent magnet filter comprises a box, magnetic bar chains which are arranged in the box and can rotate around themselves, sludge scraping mechanisms arranged on the magnetic bar chains and sludge tanks which are arranged under the sludge scraping mechanisms and located in the magnetic bar chains; sludge conveying mechanisms are arranged in the sludge tanks, and each magnetic bar of the magnetic bar chains is sleeved with a scraping sleeve in a matched mode; each sludge scraping mechanism comprises a moving block capable of moving in the axial direction of the corresponding magnet bars in a reciprocating mode, two scrapers capable of only swinging in the axial direction of the corresponding magnetic bars are hinged to the lower portion of each moving block, can swing towards the side close to each other and reset and cannot swing to the side far away from each other, and the bottoms of the scrapers are lower than the tops of the scraping sleeves when the scrapers do not swing. The filter is simple in structure, low in cost, capable of ensuring continuous operation, good in scraping effect and convenient to maintain.

Owner:WISDRI ENG & RES INC LTD

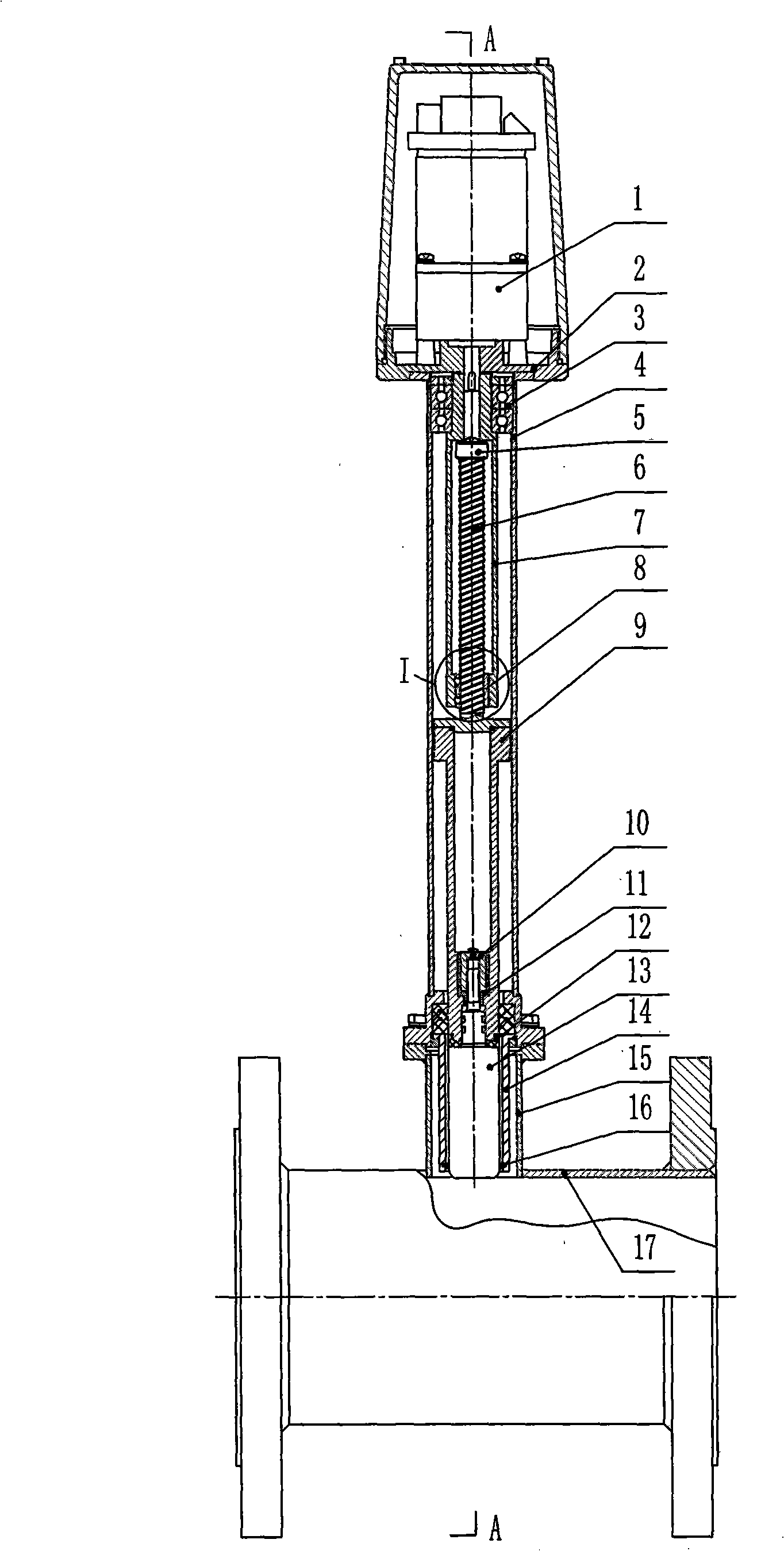

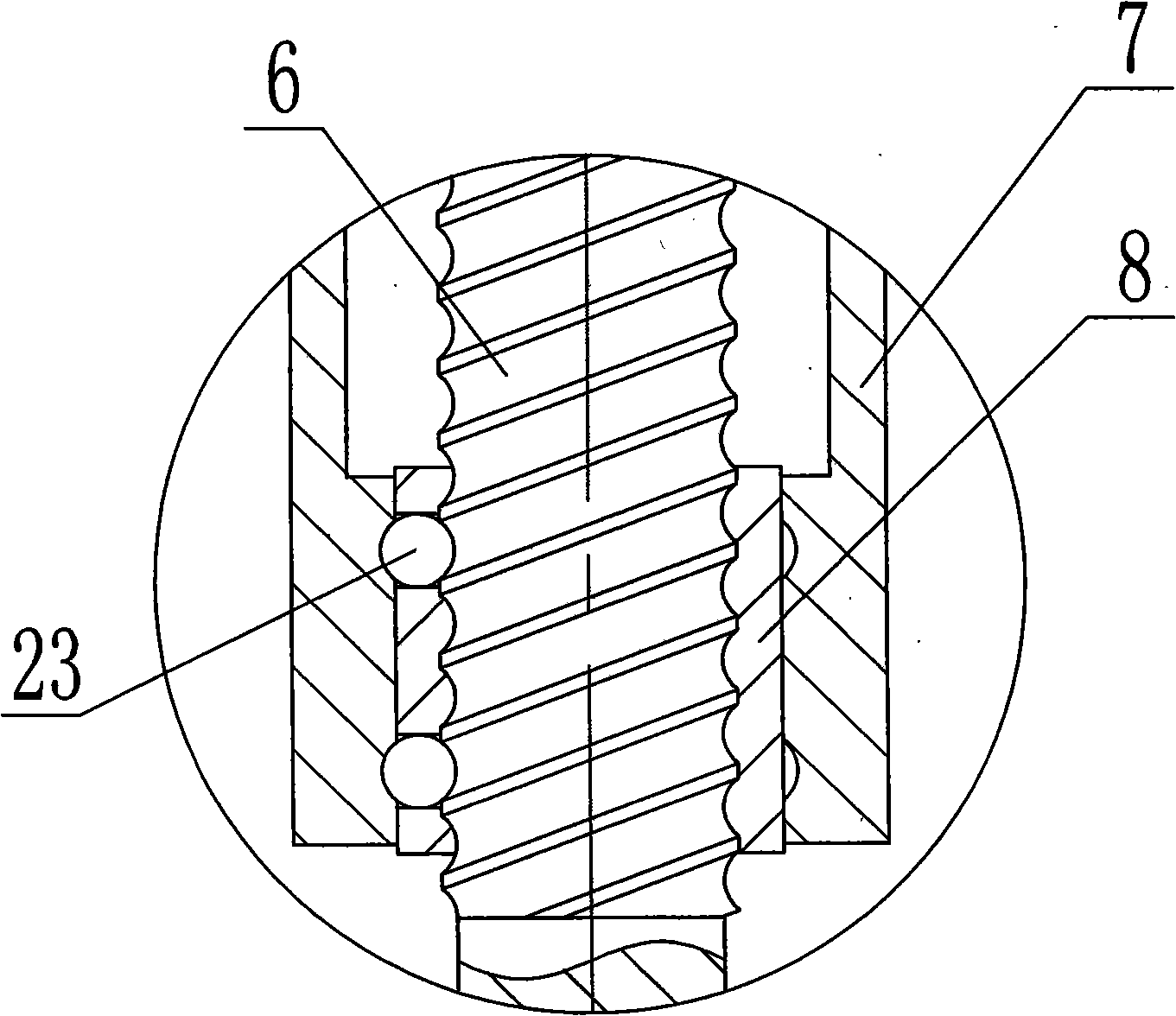

Pipeline section type automatic erasing moisture analyzer

The invention discloses a tube segmental automatic erasing moisture analyzer which comprises a supporting sleeve and a signal processing unit, wherein the lower end of the supporting sleeve is connected with tube segments; the supporting sleeve is provided with a micromotor connected with a control unit; a reciprocating mechanism is arranged in the supporting sleeve; a probe and an erasing sleeve are arranged under the reciprocating mechanism; and the probe or the erasing sleeve is connected with the reciprocating mechanism. The analyzer is characterized in that: the reciprocating mechanism consists of a master screw outer sleeve, a master screw, a screw rod, a ball bearing, a limit regulating sleeve and a connector body, wherein the master screw outer sleeve is arranged on a shaft of the micromotor; the master screw, the screw rod and the ball bearing are arranged in the master screw outer sleeve; the limit regulating sleeve is arranged at the upper end of the screw rod and the connector body is connected with the lower end of the screw rod. The tube segmental automatic erasing moisture analyzer has the advantages of simple structure, easy assembly and use, low production cost, reliable work, accurate measuring data and reasonable assembly position of each part.

Owner:JINZHOU JINYAN TECH

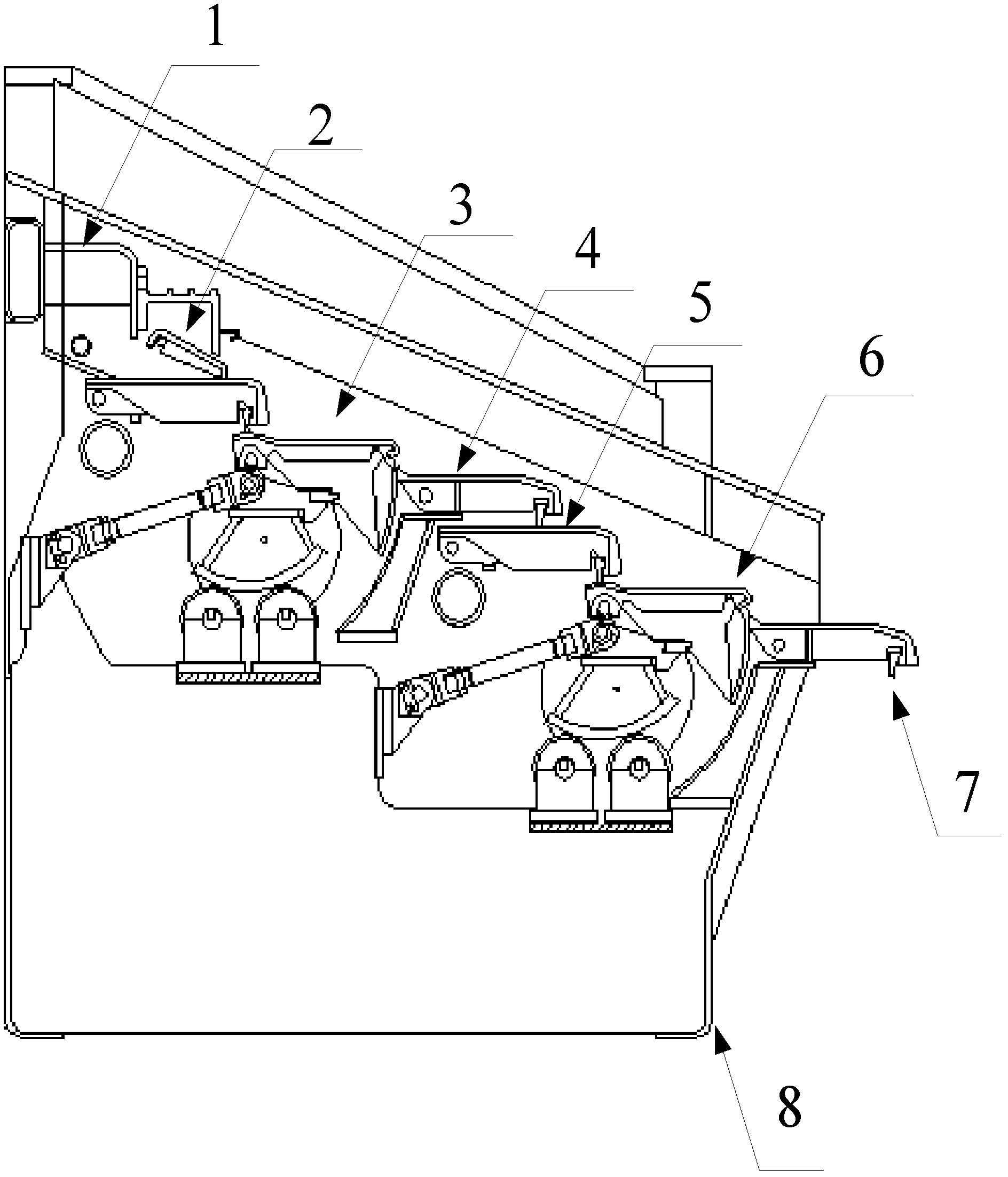

Driving and steering device for unmanned vehicle

ActiveCN103434391ACompact structureEasy to manufactureElectrical steeringResilient suspensionsDrive wheelVehicle frame

The invention provides a driving and steering device for an unmanned vehicle. The driving and steering device for the unmanned vehicle comprises a driving wheel frame and a driving wheel assembly. The driving wheel frame is connected with a frame through a shock absorption mechanism, composite idler wheels are arranged on the two sides of the driving wheel frame, rail grooves are formed in the two side edges of the frame, and the composite idler wheels roll up and down in the rail grooves. A shell body of a gearbox is fixedly connected with a connecting cover which is supported against the inner portion of a cavity hole of the driving wheel frame through a conical bearing, the connecting cover is fixedly connected with an upper pressing cover and can rotate inside the cavity hole, meanwhile, a big gear wheel is arranged on the outer circumference of the connecting cover, and the big gear wheel is meshed with a small gear wheel arranged on an output shaft of a steering motor. An electromagnetic detection device is arranged on the driving wheel frame. The driving and steering device for the unmanned vehicle is simple and compact in structure and convenient to manufacture, install and adjust, the ground adhesive force of the driving wheel can be adjusted, and the condition that the driving wheel slips due to the insufficient adhesive force is avoided. The driving and steering device for the unmanned vehicle is smooth in running, good in shock absorption and free of the stuck phenomenon. The service life of electric wires is effectively prolonged, and the safety performance of the vehicle is improved. The steering is accurately controlled.

Owner:宝鸡赫威特机械科技有限公司

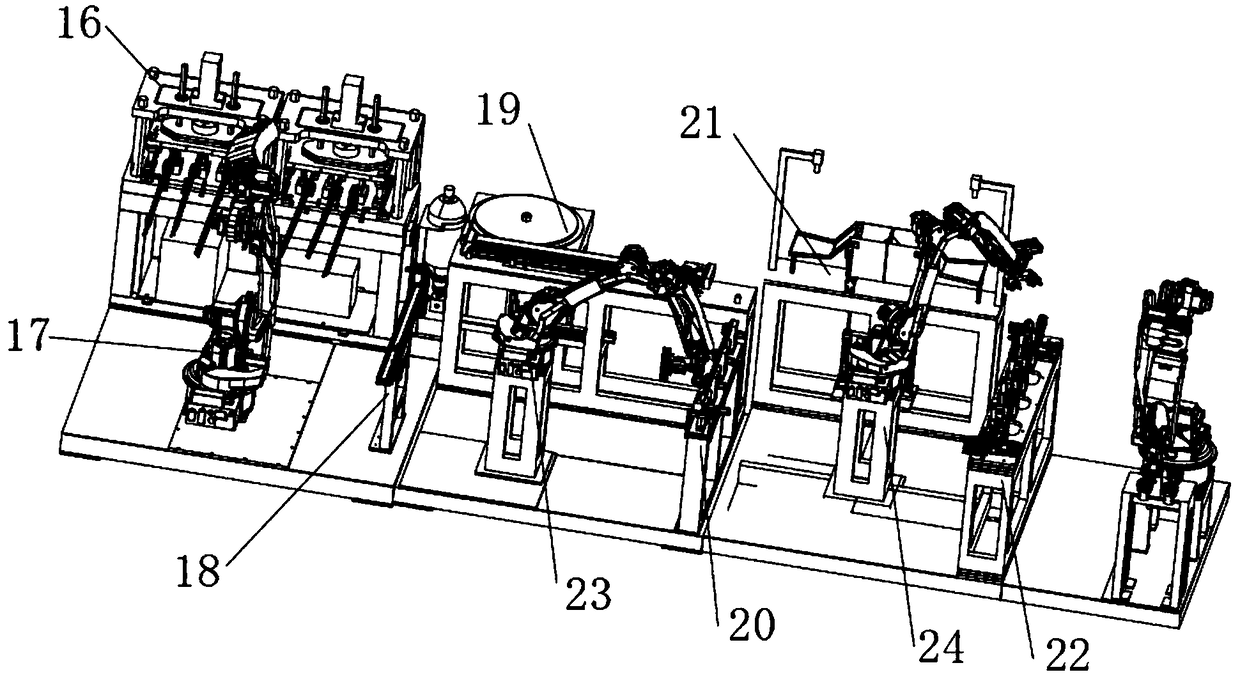

Automobile door-window frame sealing strip automatic punching cutting production line

PendingCN109049792AReduce equipment costsImprove detection accuracyDomestic articlesAutomationVisual screening

The invention relates to an automobile door-window frame sealing strip automatic punching cutting production line. The automobile door-window frame sealing strip automatic punching cutting productionline comprises a length detection device, a rolling pressing device and an end cover assembly tooling, wherein the length detection device, the rolling pressing device and the end cover assembly tooling are arranged from left to right in sequence, the left side of the length detection device is provided with a first motor, the rear of the first motor is provided with a punching machine and punching cutting molds matched with the punching machine, the left side of the rolling pressing device is provided with a second motor, the rear of the second motor is provided with a fixed-length shearing-off device, the left side of the end cover assembly tooling is provided with a third motor, and the rear of the third motor is provided with an end cover visual screening mechanism. The automobile door-window frame sealing strip automatic punching cutting production line is convenient to use, low in equipment cost and high in automation degree, and the labor cost is greatly lowered.

Owner:宁波齐盛智能设备有限公司

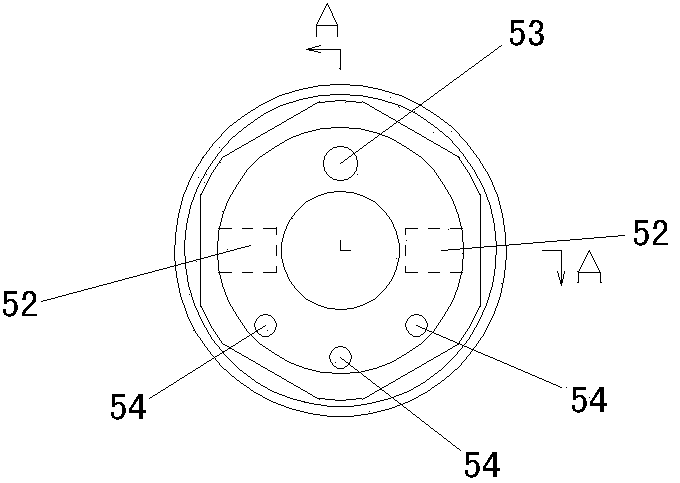

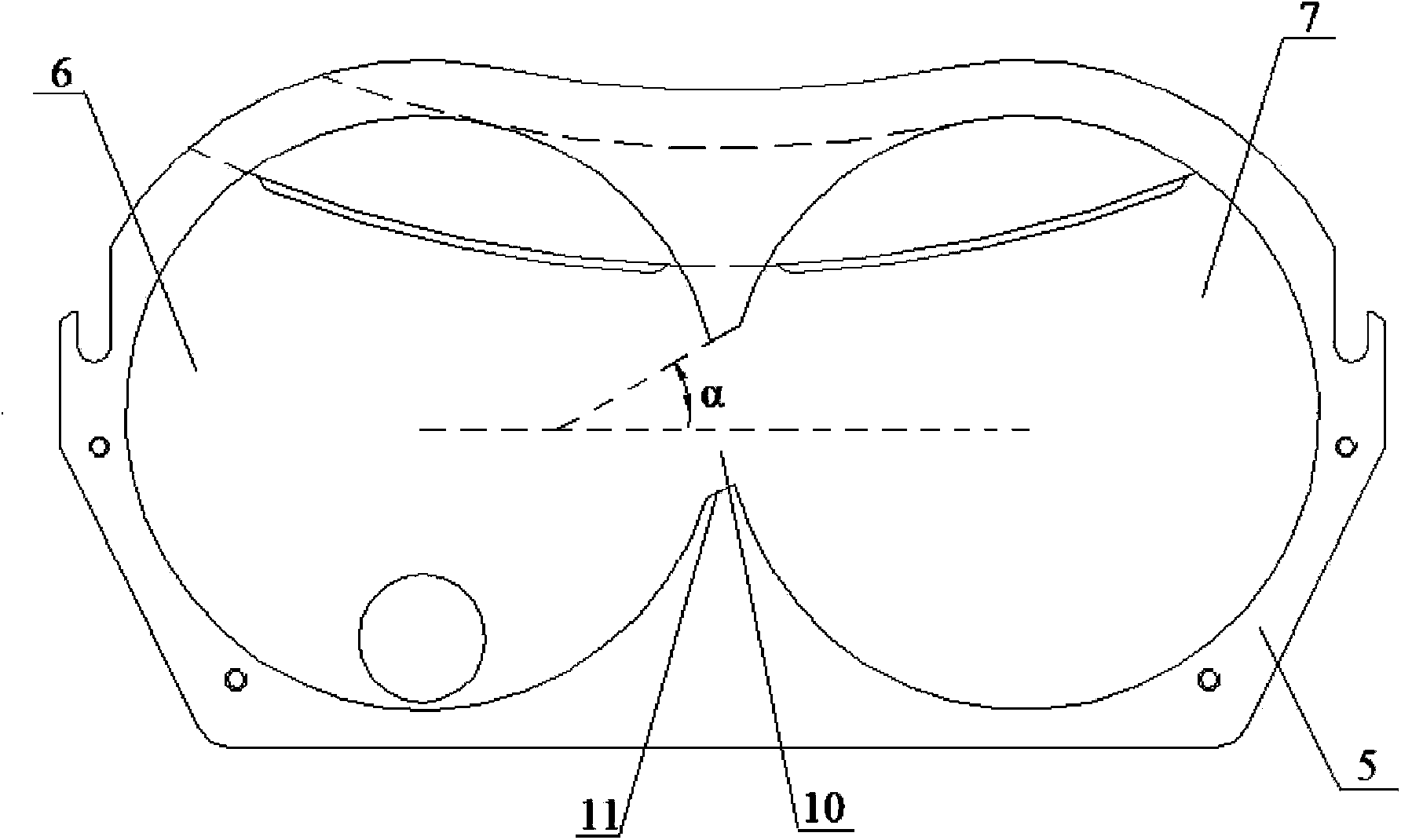

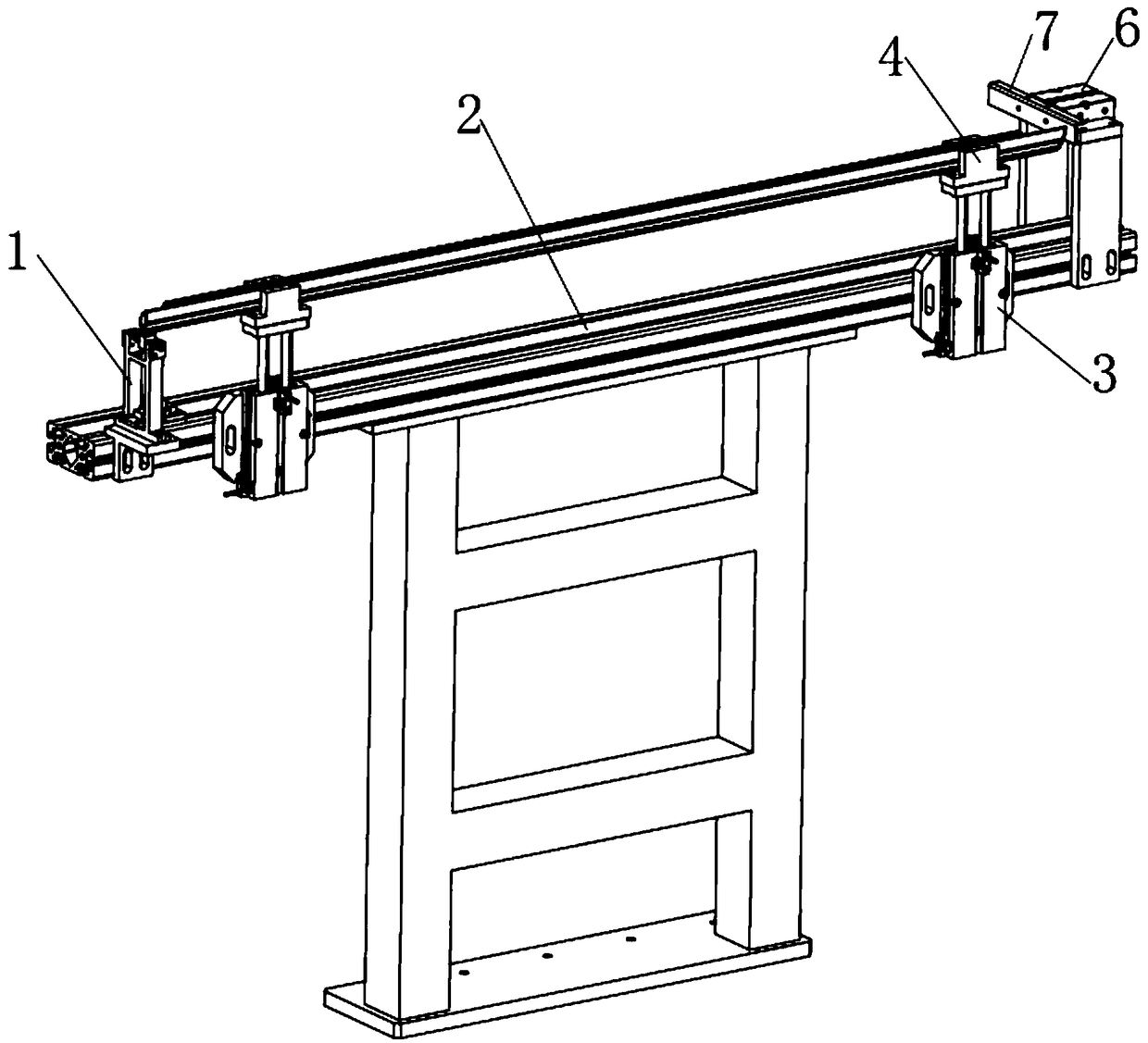

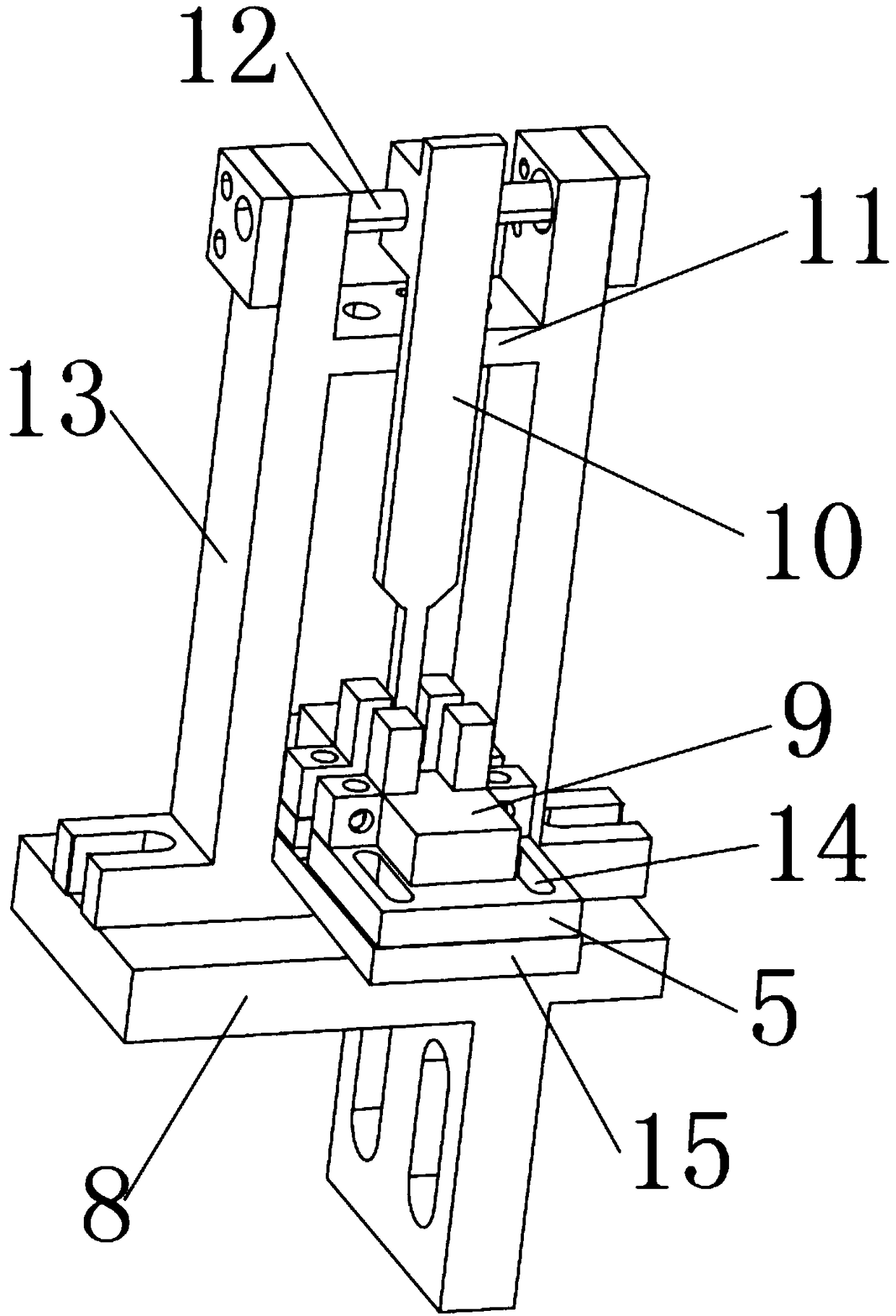

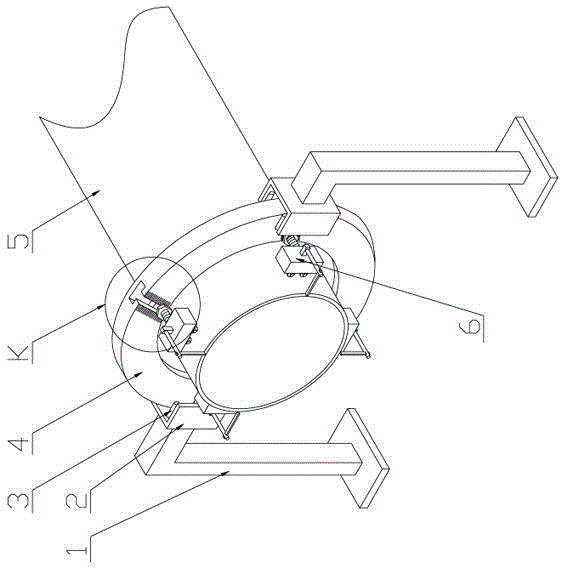

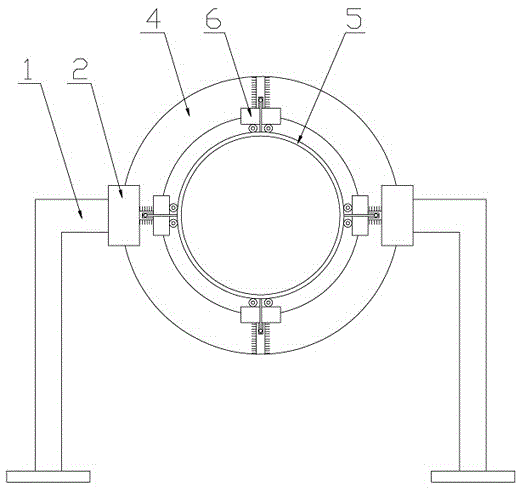

Device for manufacturing groove in large circular tube

ActiveCN105057808ANo stuck phenomenonImprove cutting efficiencyMeasurement/indication equipmentsLarge fixed membersSemi automaticEnergy consumption

The invention provides a device for manufacturing a groove in a large circular tube. The device is provided with an annular supporting plate. The symmetrical positions at the two ends of the annular supporting plate in any diameter direction are provided with positioning devices in a clamped mode. The annular supporting plate is provided with four clamp slots. The four clamp slots jointly divide the annular supporting plate into four equal regions. Each clamp slot is formed in the radial direction of the annular supporting plate and internally provided with a threaded connection rod in a clamped mode, wherein the threaded connection rod is capable of moving along an opening of the corresponding clamp slot. The front end of each threaded connection rod is provided with a sliding block. The sliding blocks can slide in the corresponding clamp slots. Nuts are assembled to the threaded connection rods. The nuts can tightly connect the annular supporting plate and the threaded connection rods when screwed. The other end of each threaded connection rod is fixedly connected with a set of semi-automatic cutting equipment. The semi-automatic cutting equipment makes rolling contact with the circular tube to be machined. The device is simple in structure, free of moving the tube, safe and convenient to operate, low in energy consumption and capable of improving groove manufacturing efficiency, the production cycle is shortened, and enterprise efficiency is improved beneficially.

Owner:HUBEI HONGLU STEEL STRUCTURE

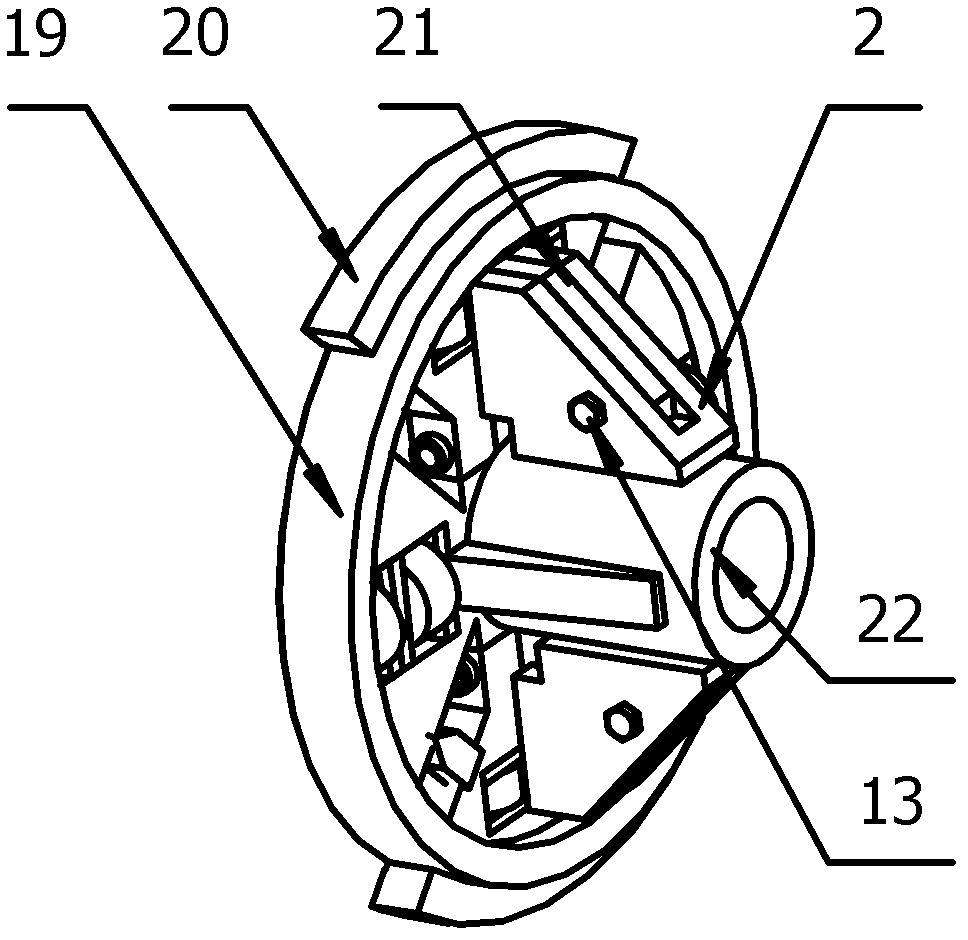

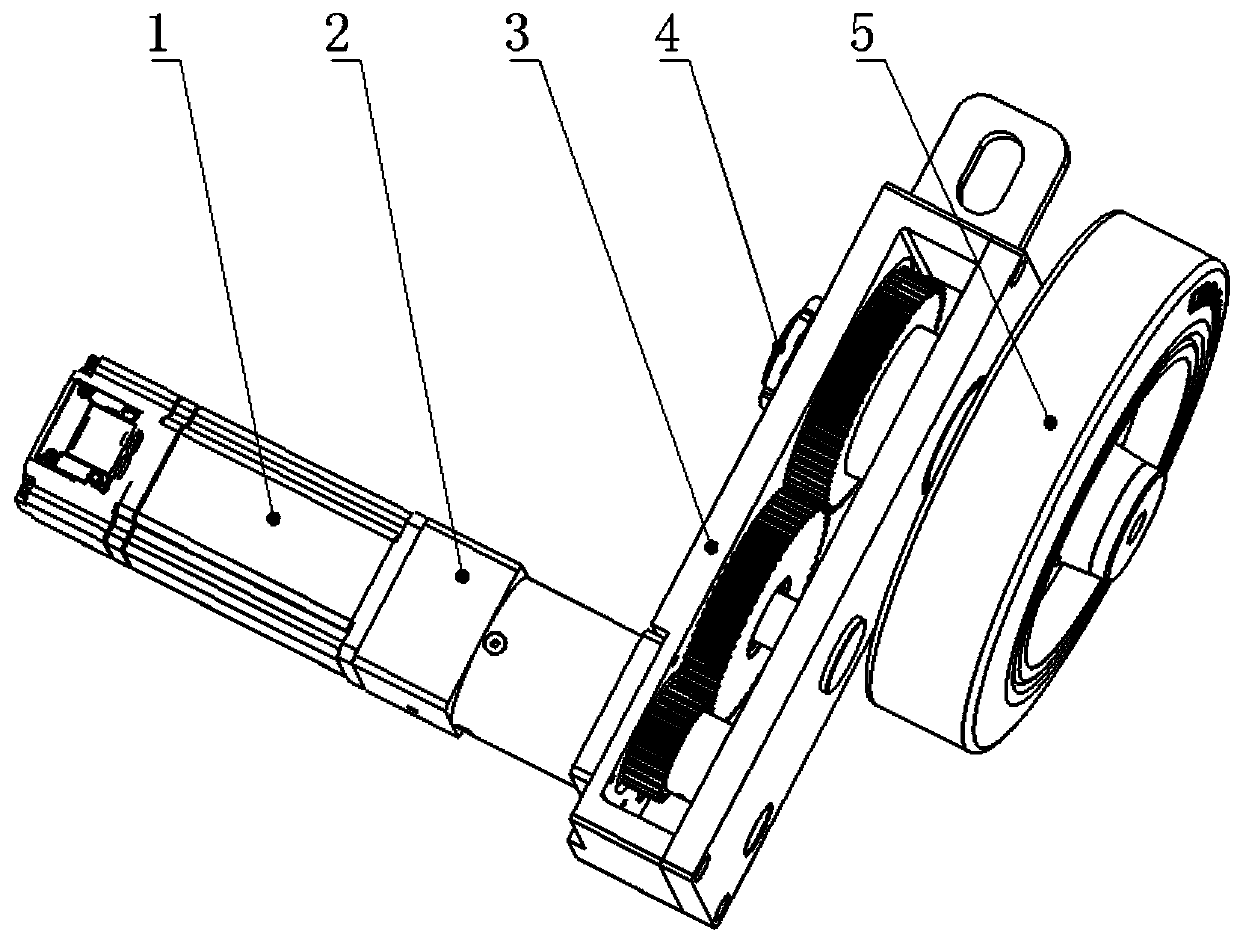

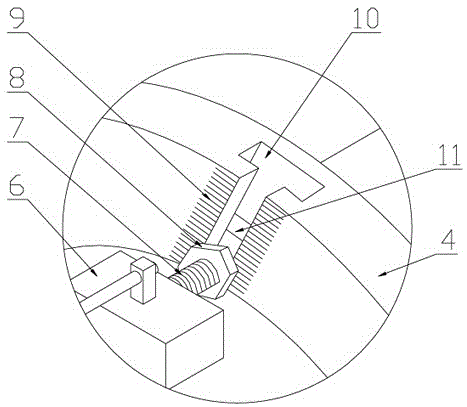

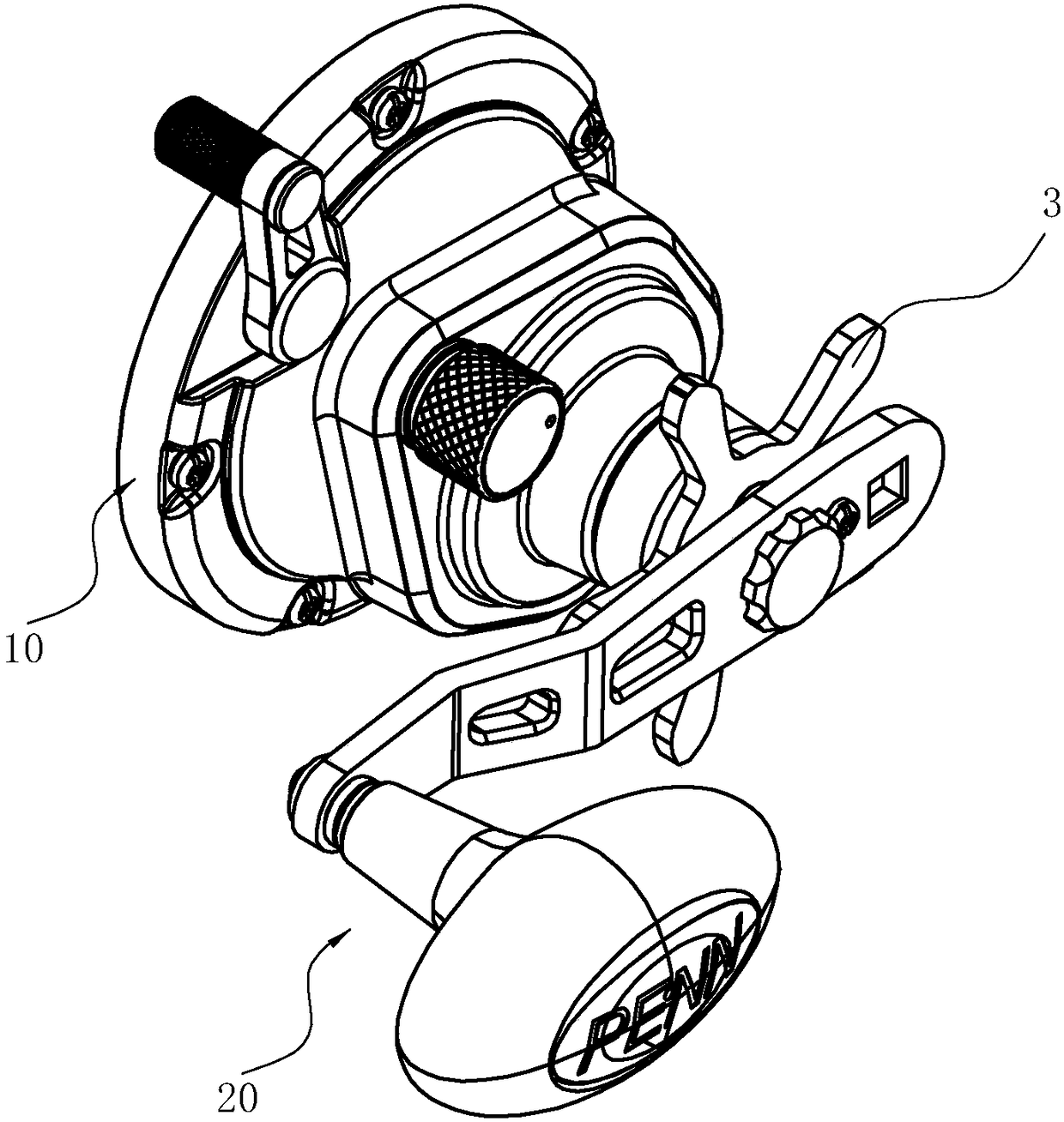

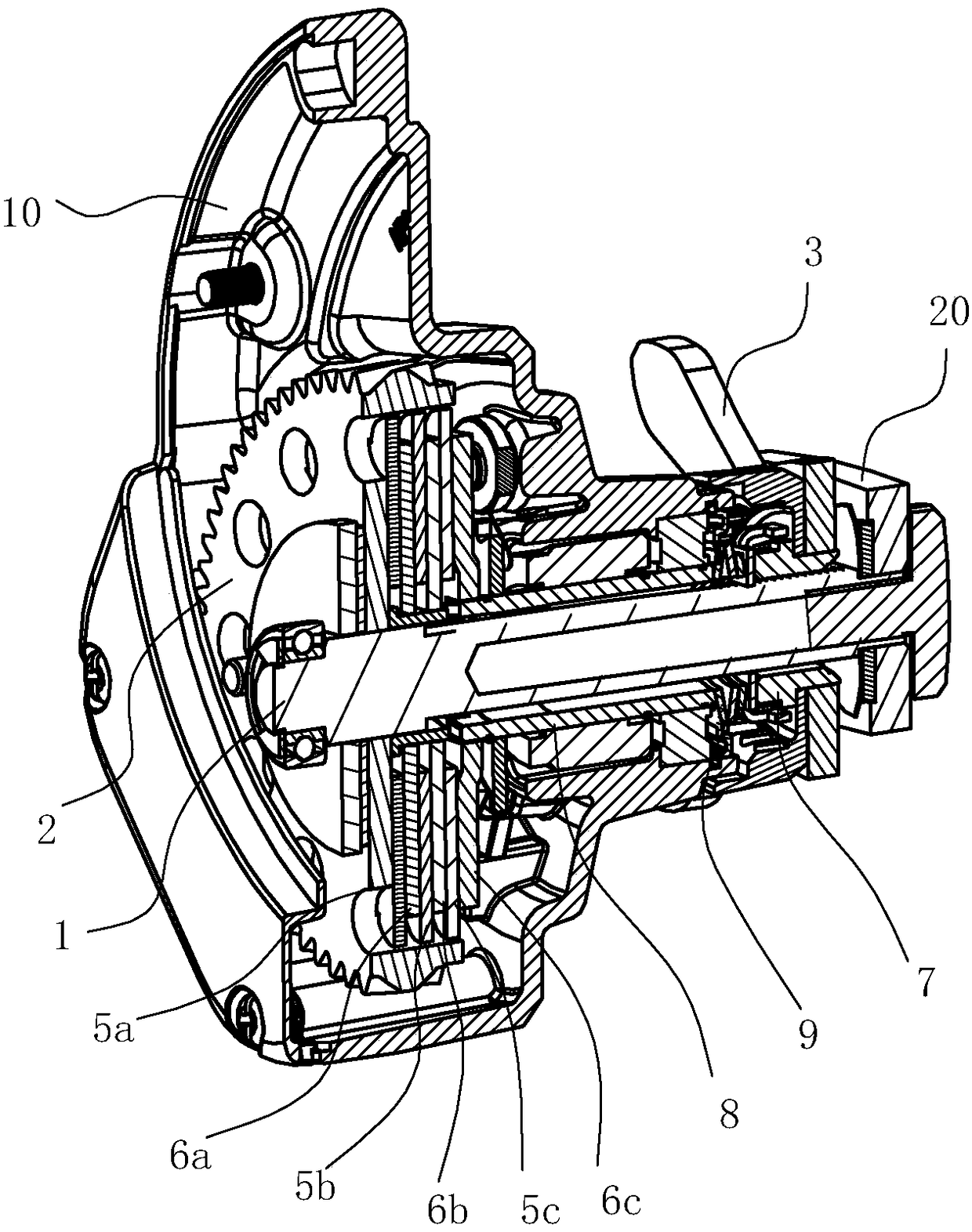

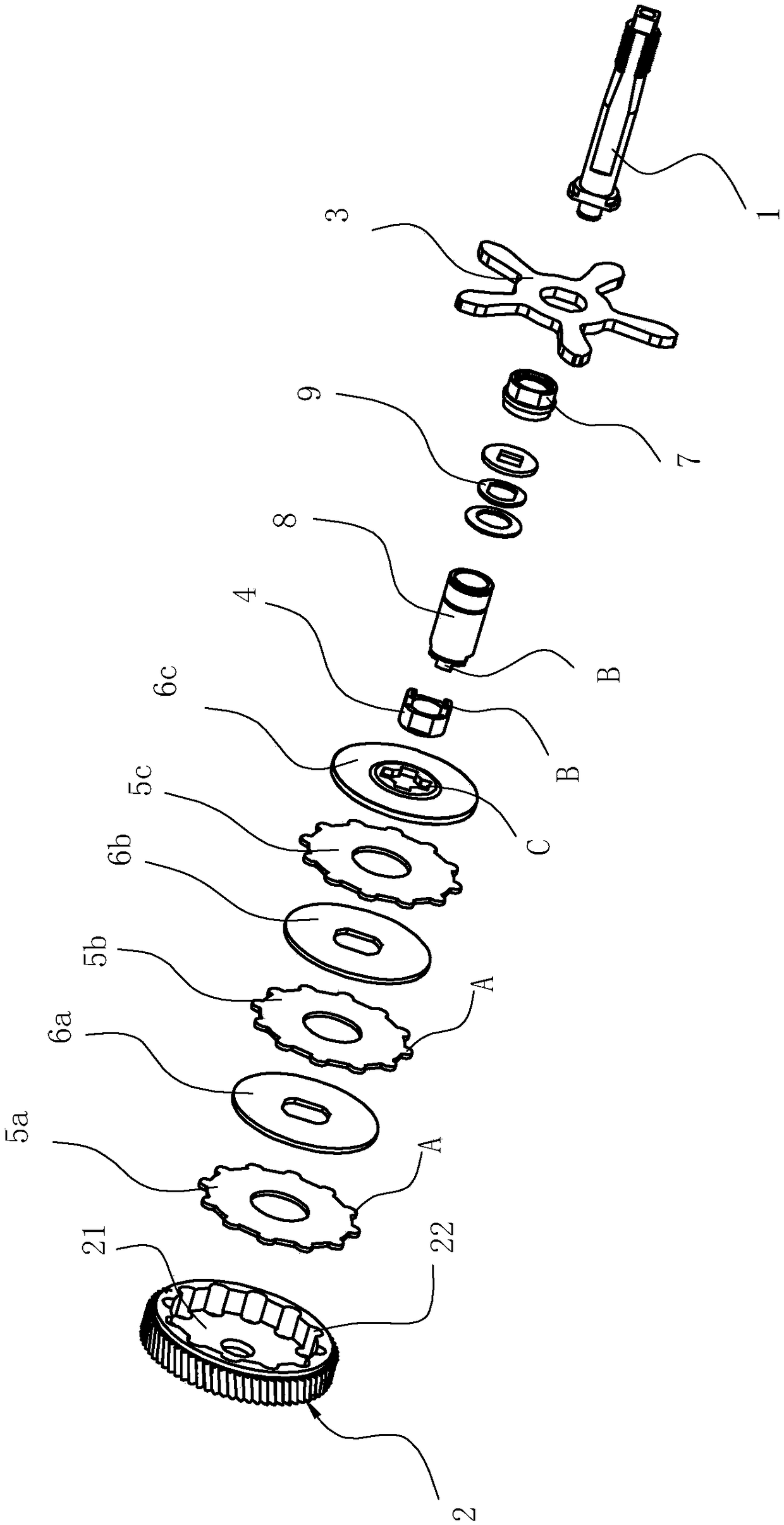

Braking device for fishing reel

The invention relates to a braking device for a fishing reel. The device comprises a rotating shaft, a moving part which is capable of rotating relative to the rotating shaft and sleeves the rotatingshaft, a brake pad group located in the inner cavity of the moving part, one end of the rotating shaft is provided with an operation member capable of axially pressing the brake pad group, the brake pad group includes a plurality of brake washers and a plurality of key washers, and the device is characterized in that the rotating shaft is tightly provided with a shaft sleeve corresponding to the inner cavity, the brake washers loosely sleeve the shaft sleeve, and a convex lug radially is extended on the periphery of each brake washer; and the side wall of the inner cavity of the moving part isprovided with axial guide grooves matched with the convex lugs, and each key washer can axially and movably sleeve the shaft sleeve, and can rotate with the shaft sleeve. According to the device provided by the invention, the outer diameter of the shaft sleeve can be utilized, so that a larger contact area exists between each key washer and the shaft sleeve, when force is released, each key washer can easily slide, a phenomenon of clamping with a rotating shaft in the prior art does not occur, so that the braking force can be unloaded to the minimum according to requirements to meet the requirements for use.

Owner:NINGBO HAIBO GRP CO LTD

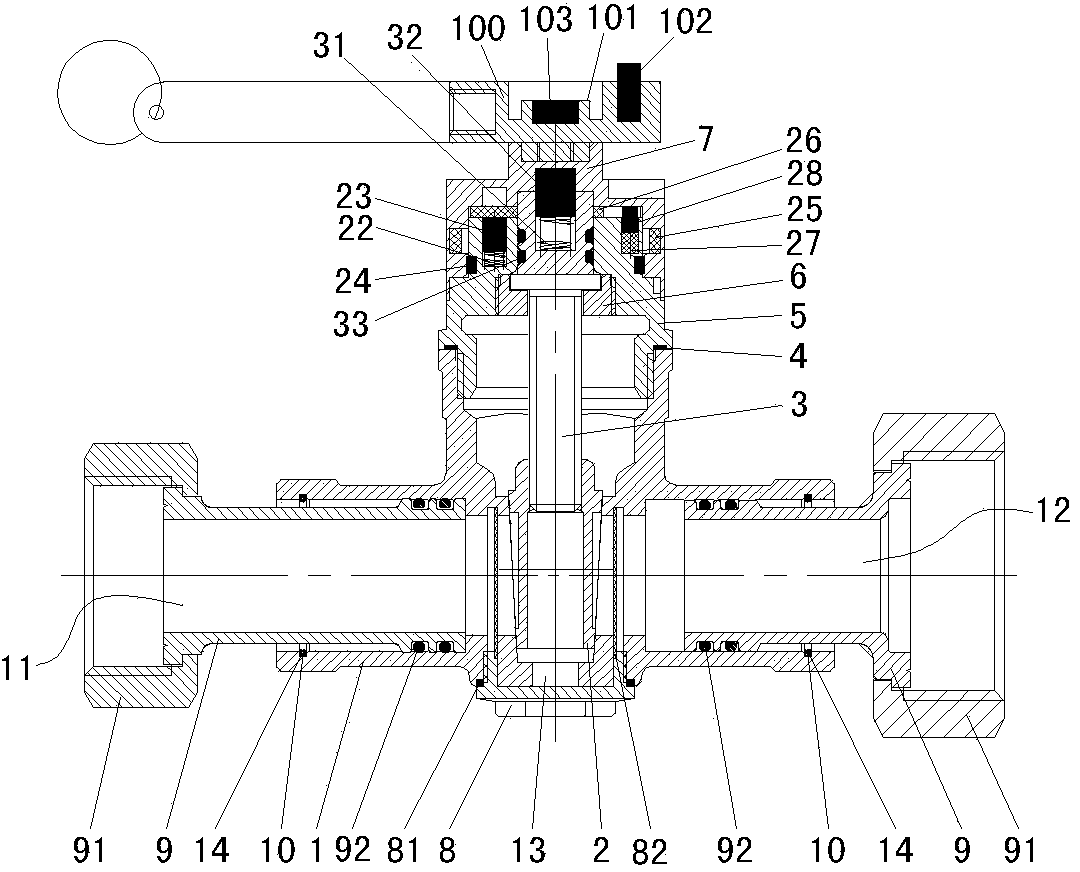

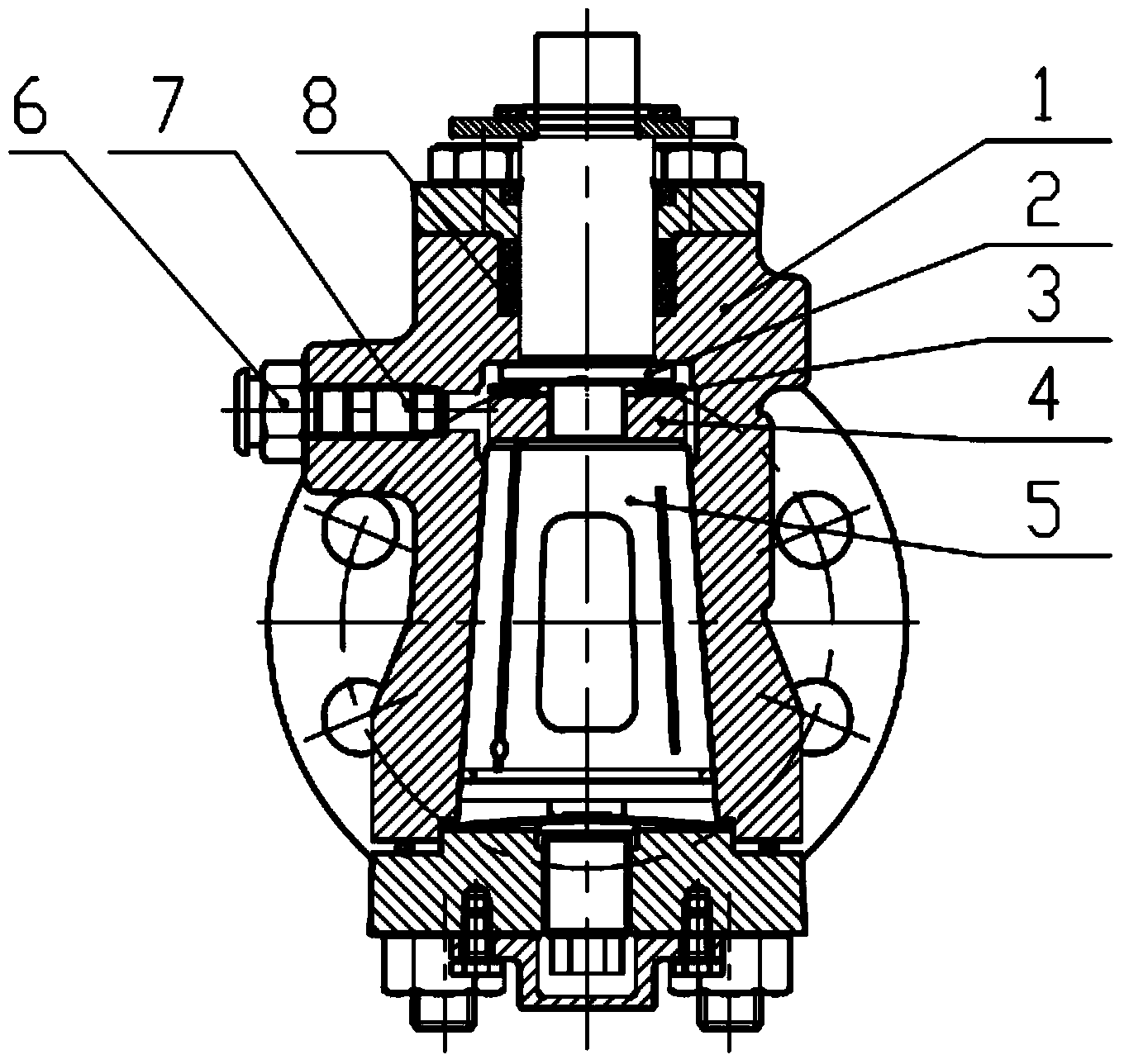

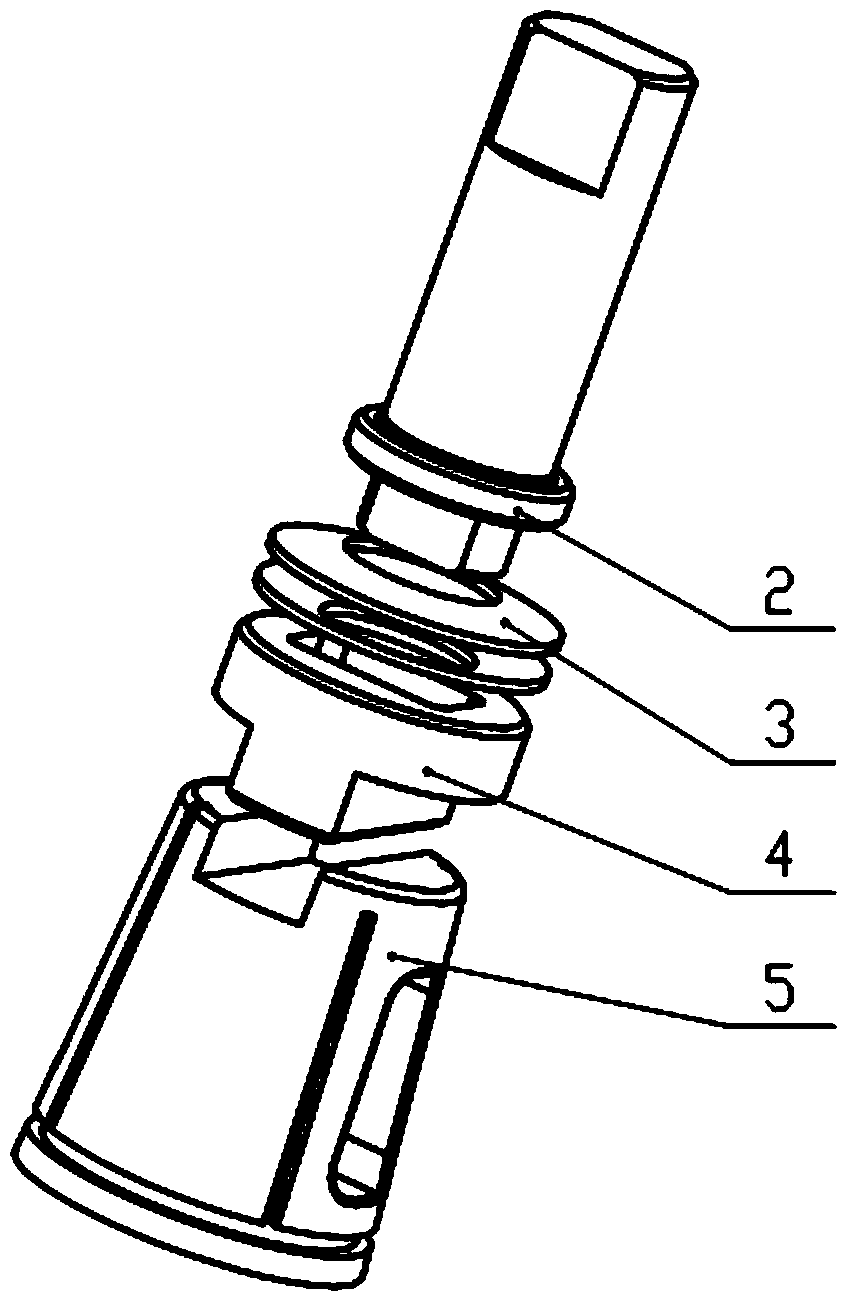

Pressure balance type inverted cock valve

The invention discloses a pressure balance type inverted cock valve which comprises a valve body, a cock, a valve rod and padding. The cock is an inverted conical cock with the lower end being larger than the upper end. The cock is arranged in an inner cavity of the valve body, the valve rod drives the cock to rotate, a sealing face of the cock is a conical face, the valve rod is connected with the cock through a cross connector, a cylindrical spring or a belleville spring is arranged between the valve rod and the cock, the lower end of the valve body is fixedly provided with a valve cover, and the valve cover is provided with an adjustment shaft. The lower end of the adjustment shaft penetrates out of the valve cover, and the upper end of the adjustment shaft abuts against the cock. the lower end of the cock is provided with a first check valve, a sealing grease groove is formed in the sealing face of the cock, an oil storage tank is arranged in the valve body, the oil storage tank of the valve body is communicated with the sealing grease groove of the cock, and an oil filling valve communicated with the oil storage tank is arranged outside the valve body. The pressure balance type inverted cock valve can be used under high temperature, high pressure and severe work conditions, and has the advantages of being reliable in sealing, small in operation torque, long in service life, and the like.

Owner:WOTAI VALVE KUSN

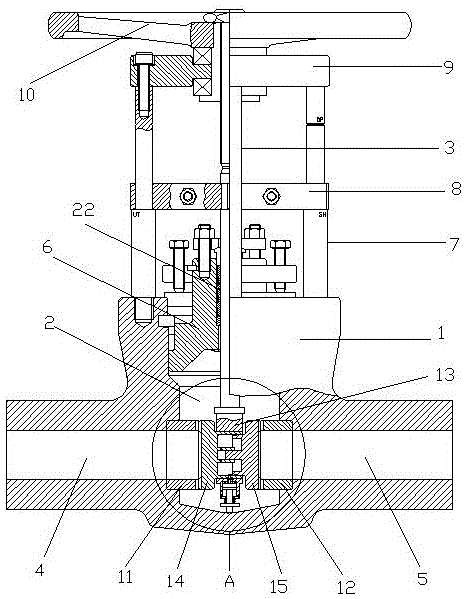

Self-sealing gate valve structure

ActiveCN105065700ANo stuck phenomenonWith sealing compensation performanceOperating means/releasing devices for valvesSlide valveGate valveValve seat

The invention relates to the technical field of valves, and discloses a self-sealing gate valve structure. The self-sealing gate valve structure comprises a valve body, a valve cavity and a valve rod, wherein a left valve seat and a right valve seat which are coaxial are arranged at the inner ends of a left passage and a right passage respectively; a gate seat fixed with the valve rod is arranged between the left valve seat and the right valve seat; a left gate and a right gate are respectively arranged on the two sides of the gate seat; the inner end of the left gate extends to form an outer connecting sleeve; the inner end of the right gate extends to form an inner connecting sleeve; the inner connecting sleeve and the outer connecting sleeve are connected in a sliding manner; the outer connecting sleeve is in clearance fit with a connection hole in the gate seat; and a closed liquid storage cavity is formed between the inner connecting sleeve and the outer connecting sleeve and filled with oil. The self-sealing gate valve structure has the benefits of being good in sealing effect, small in operation torque and anti-locking.

Owner:OUQIU VALVE CO LTD

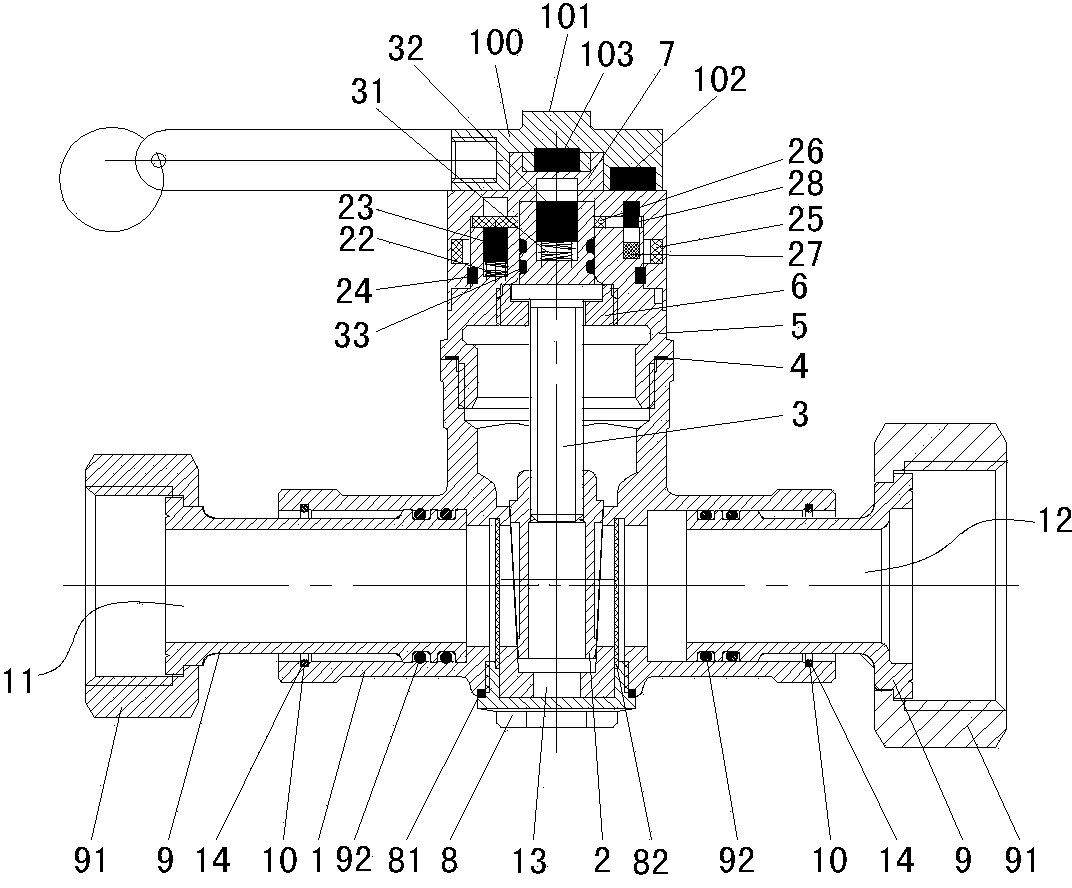

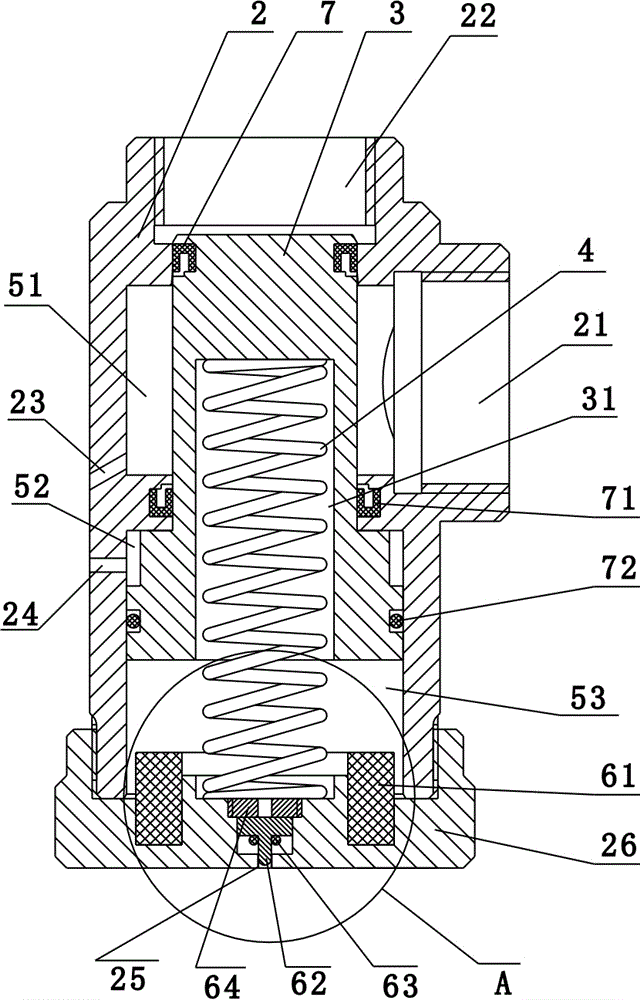

Integrated selection valve

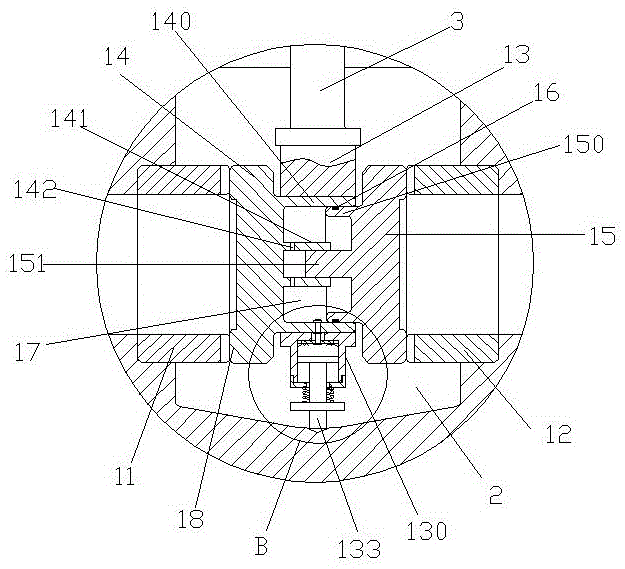

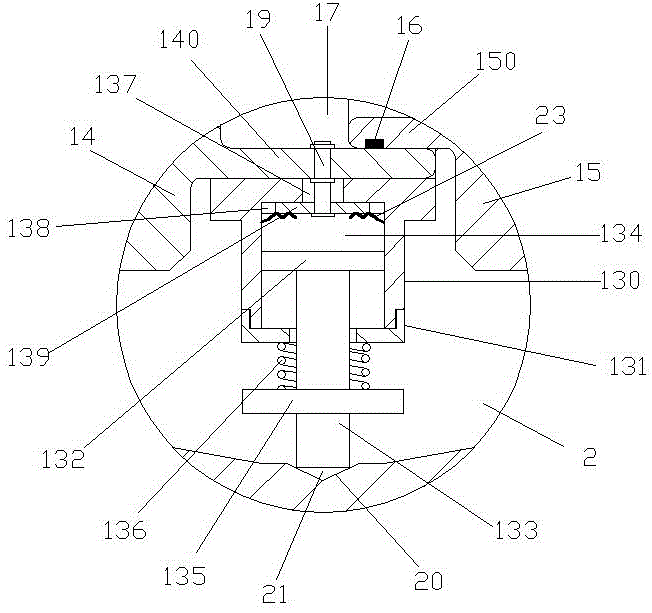

InactiveCN106090396ANo stuck phenomenonAvoid strong impactOperating means/releasing devices for valvesLift valveAssembly structurePiston

The invention discloses an integrated selection valve capable of being connected and matched with a drive device. The selection valve comprises a valve body, a piston capable of moving in the valve body and a reset piece. The valve body is provided with an air inlet and an air outlet. The piston is connected in the valve body in a sealing manner. A first space is formed between the upper portion of the piston and the inner wall of the valve body. The air inlet communicates with the first space. The valve body is provided with a first channel communicating with the first space and the drive device. A second space is formed between the lower portion of the piston and the inner wall of the valve body. The valve body is provided with a second channel communicating with the second space and the drive device. A third space is further formed between the bottom of the piston and the valve body and internally provided with a buffering structure capable of buffering the piston when the piston moves along the valve body. The integrated selection valve is small in opening force and good in sealing performance, action tests of 500 times can be achieved, the assembled structure is simple, and the service life is long.

Owner:浙江信达可恩消防股份有限公司

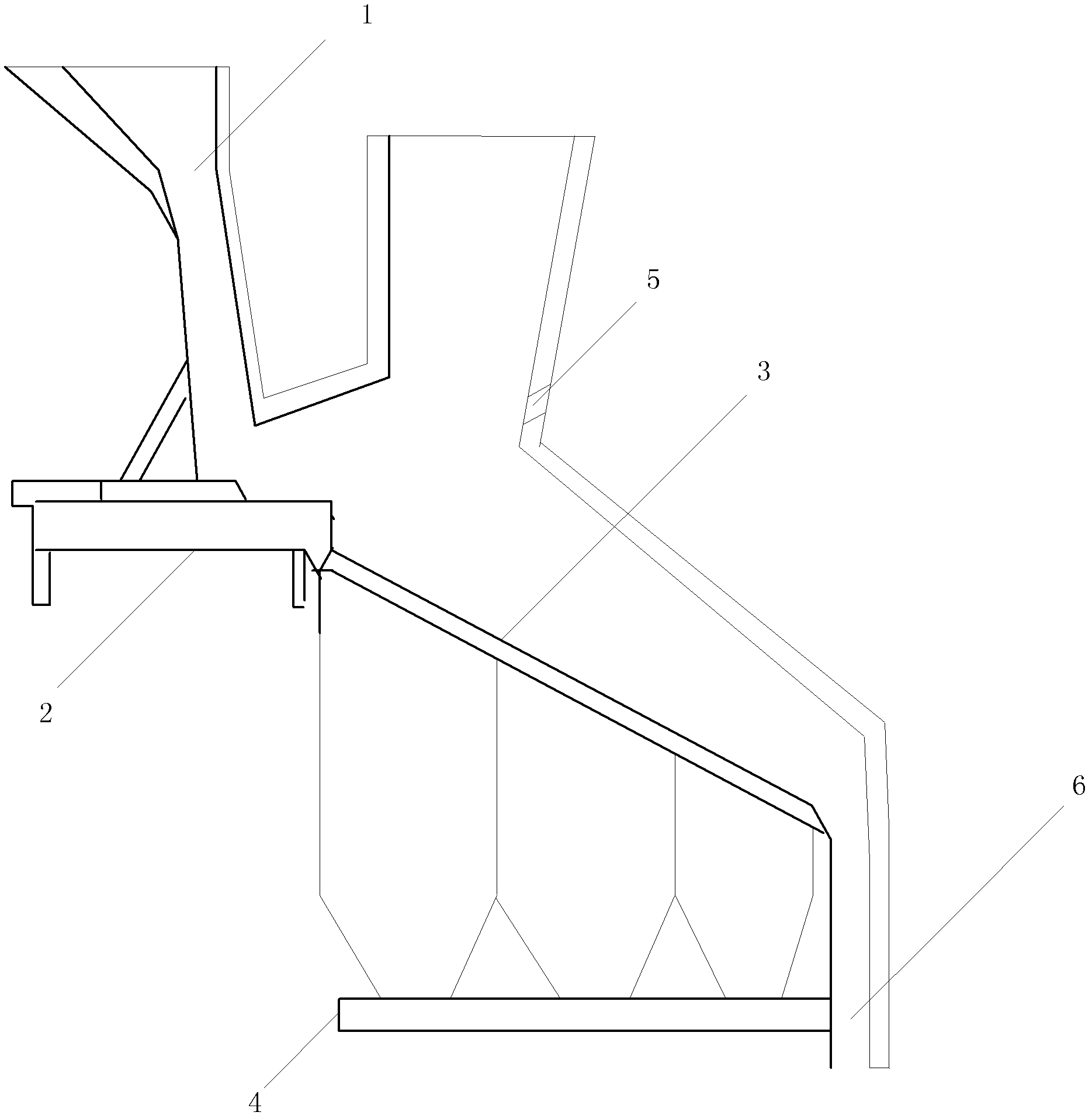

Multistage hydraulic mechanical garbage incinerator

ActiveCN102607036ASolve technical problemsGuaranteed uptimeHollow bar grateInclined grateHydraulic machineryIncineration

The invention provides a multistage hydraulic mechanical garbage incinerator, which comprises a feeding port, a feeding fire grate, an incinerating fire grate, a primary air supply system and a secondary air supply system. The incinerating fire grate is longitudinally divided into five units, wherein the first unit, the second unit, the third unit and the fourth unit are standard units, the fifth unit is a tail end lengthened unit, each unit comprises a plurality of sliding fire grate segments, turning fire grate segments and fixed fire grate segments, and the incinerating fire grate is integrally divided into a drying section, a burning section and a burnout section by the five units along the garbage moving direction. The multistage hydraulic mechanical garbage incinerator is characterized in that a limiting support device for limiting a feeding trolley to move upward is arranged on the upper surface of a tail of the feeding trolley of the feeding fire grate. By the aid of the multistage hydraulic mechanical garbage incinerator, the shortcomings of an existing garbage incinerator are improved, and burnout ratio of garbage incineration is increased.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +2

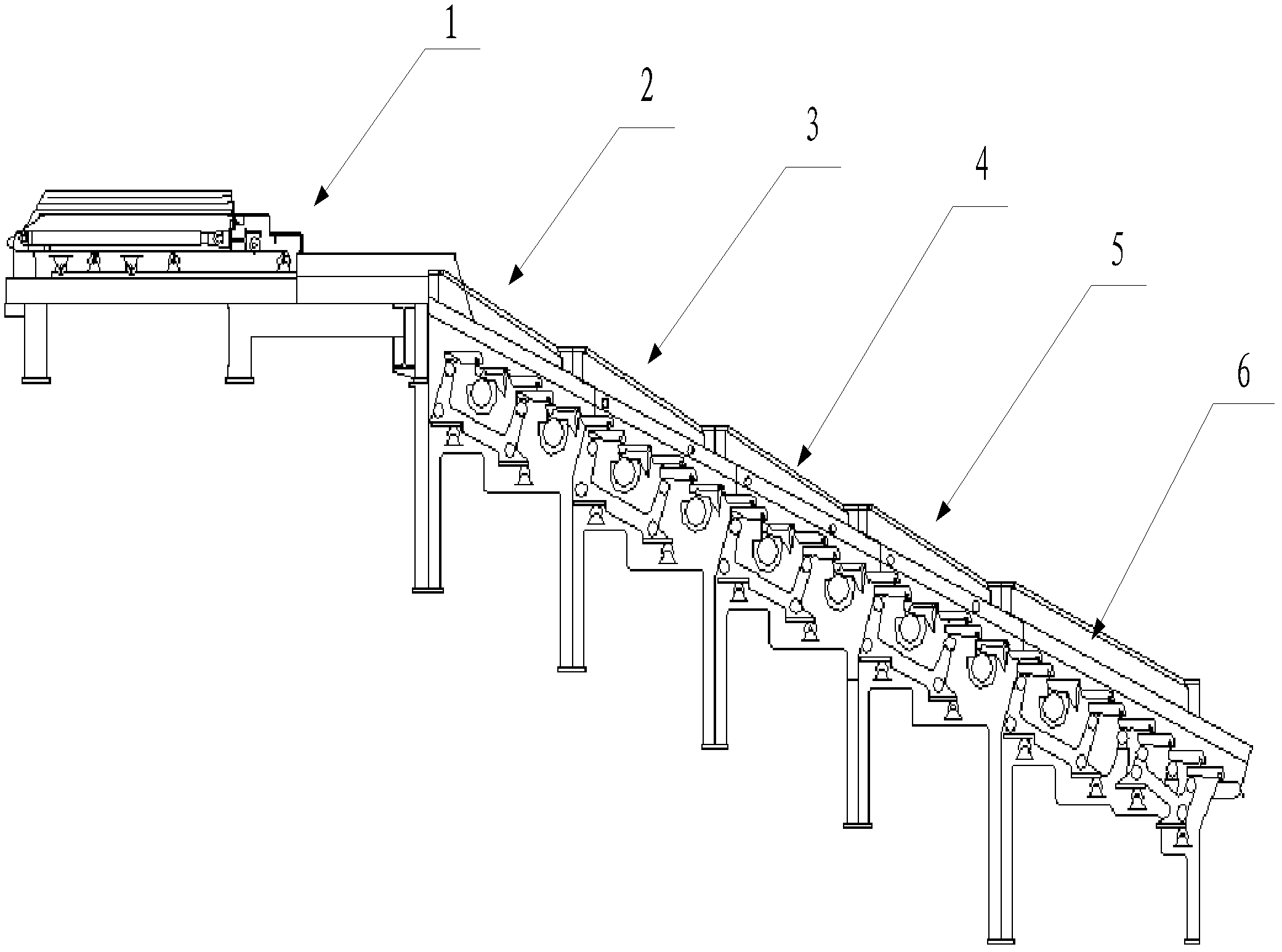

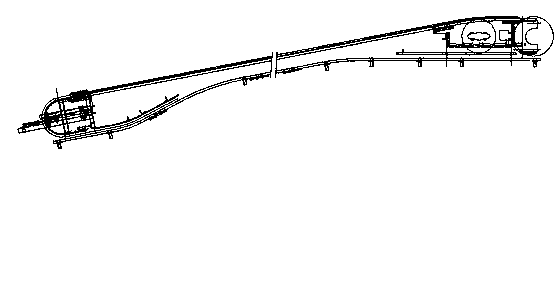

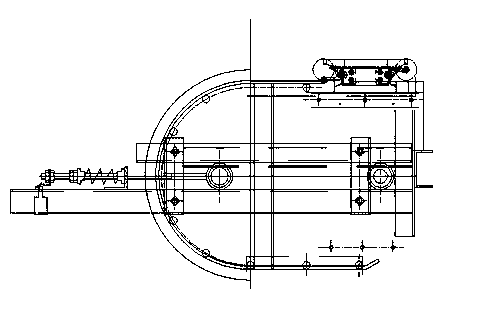

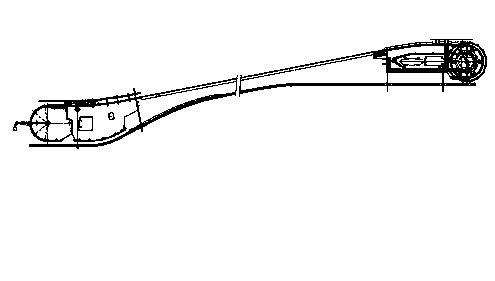

Moving pavement with biarc guide rail driving devices

Owner:SHANGHAI AIDENGBAO ELEVATOR JIANGSU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com