Control method of installation precision of centralized transmission roller table of oriented silicon steel annealing furnace

A technology of centralized transmission and installation accuracy, applied in furnaces, heat treatment furnaces, manufacturing tools, etc., can solve the problems of excessive hydrogen leakage in the furnace body, stuck furnace rollers, and inability to operate, so as to prolong the use and maintenance period and improve the installation accuracy. , The effect of meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

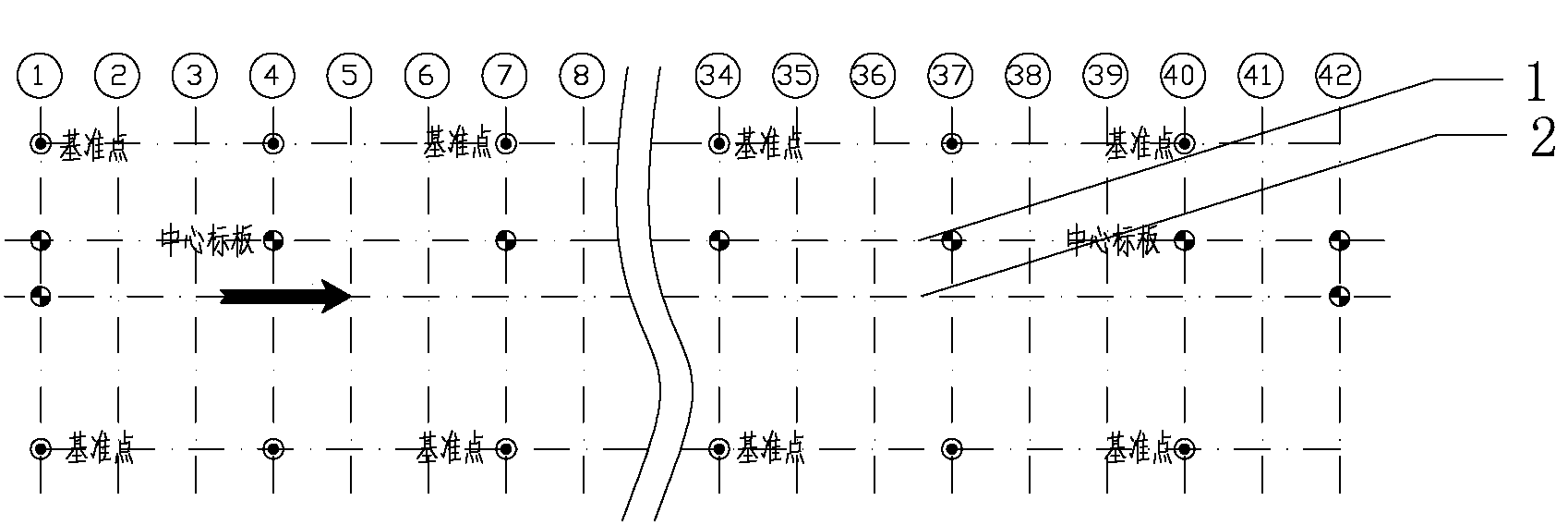

[0038] see now figure 1 , figure 1 It is a schematic diagram of the central line positioning control of the embodiment of the present invention. As shown in the figure, the centerline 1 is parallel to the centerline 2 of the unit.

[0039] The method for controlling the installation accuracy of the centralized transmission roller table of the oriented silicon steel annealing furnace of the present invention is characterized in that it comprises the following steps:

[0040] a. Centerline positioning control

[0041] Before the installation of the annealing furnace, along the length direction of the annealing furnace, set an auxiliary center line support at every 30m intervals at the position close to the furnace shell on the transmission side of the furnace, and run through the entire annealing furnace; The deviation caused by the swaying of the wire is too long.

[0042] b. Centralized transmission roller table adjustment control

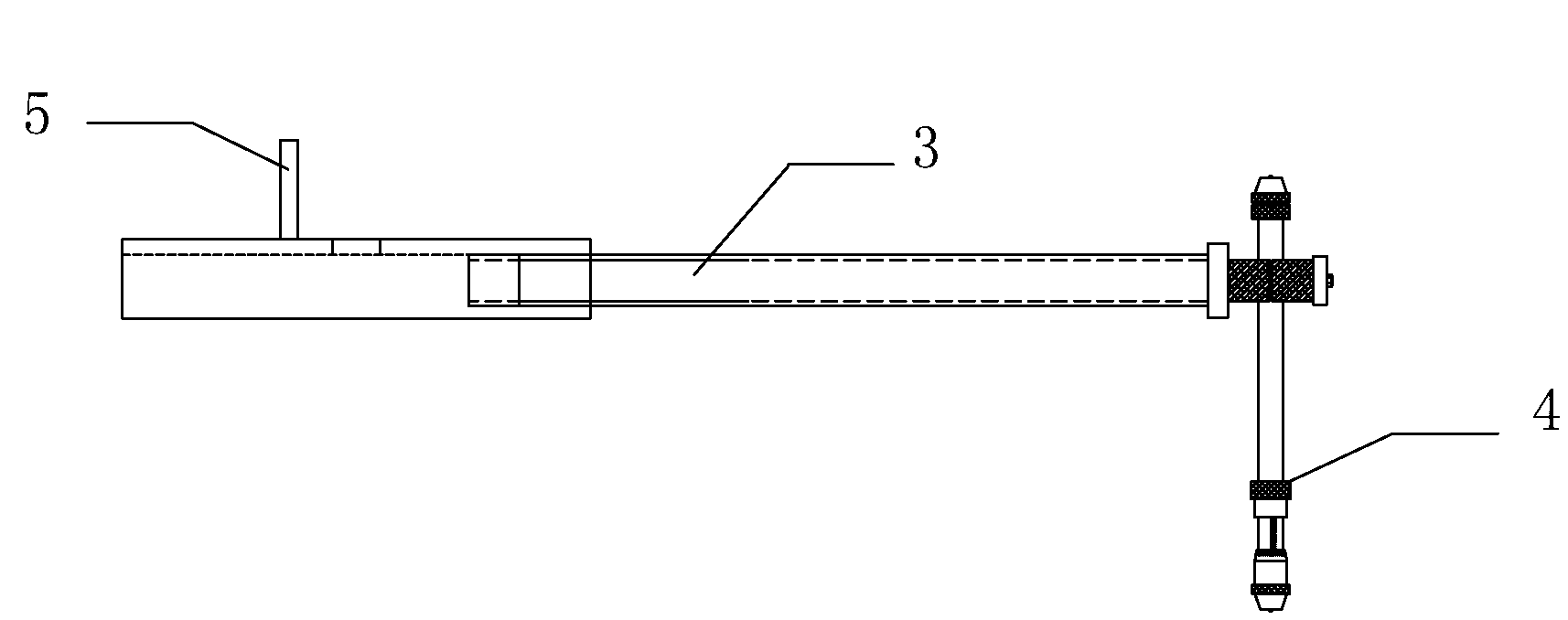

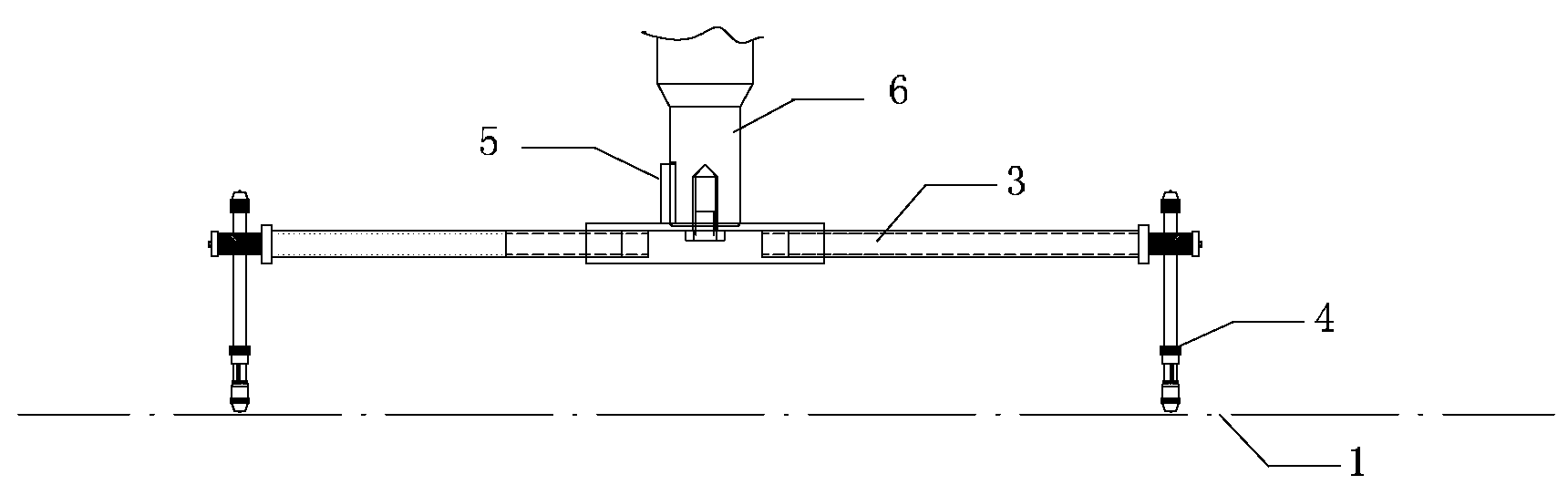

[0043] figure 2 It is a schematic dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com