Device for manufacturing groove in large circular tube

A technology for making devices and large round pipes, applied in positioning devices, large fixed members, manufacturing tools, etc., can solve the problems of expensive equipment, consuming more manpower, resources and time, and large volume, etc. Efficiency, shortened production cycle, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

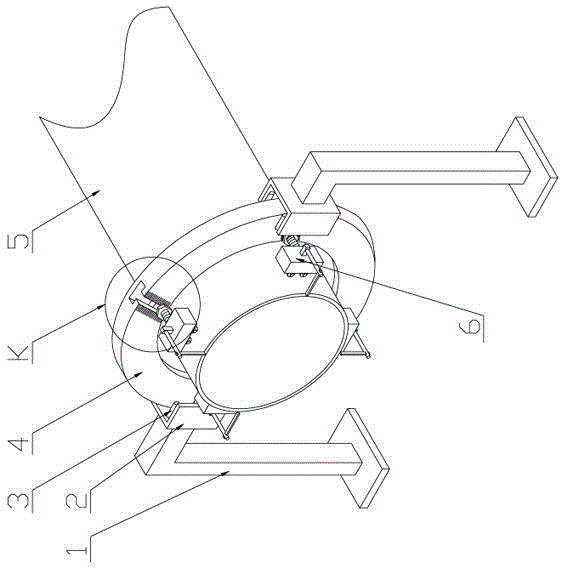

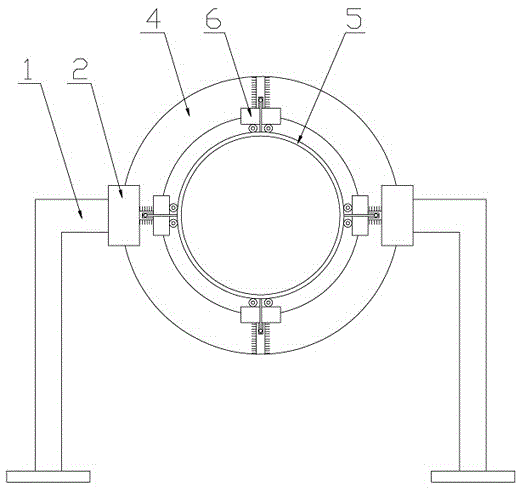

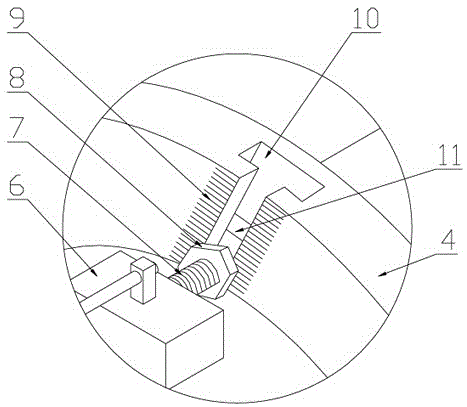

[0019] see Figure 1-Figure 3 , the present invention is a large-scale circular pipe bevel manufacturing device, which has an annular support plate 4, and positioning devices are mounted on symmetrical positions at both ends of any diameter of the annular support plate, and four clamping grooves are provided on the annular support plate 10. The four card slots jointly divide the annular support plate into four equal parts, and the direction of each card slot is opened along the radial direction of the annular support plate. The threaded connecting rod 7 that the opening of the slot moves, the front end of the threaded connecting rod is provided with a slider 11, which can slide inside the corresponding draw-in groove, and the described threaded connecting rod is equipped with a nut 8, which can be tightened when the nut is tightened. The annular support plate is tightly connected with the threaded connecting rods, and the other end of each threaded connecting rod is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com