Forced feeding device

A technology of feeder and feed port, which is applied in the field of feeding equipment, can solve the problems of unsmooth feeding and easy powder leakage, and achieve the effect of ensuring uniformity and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

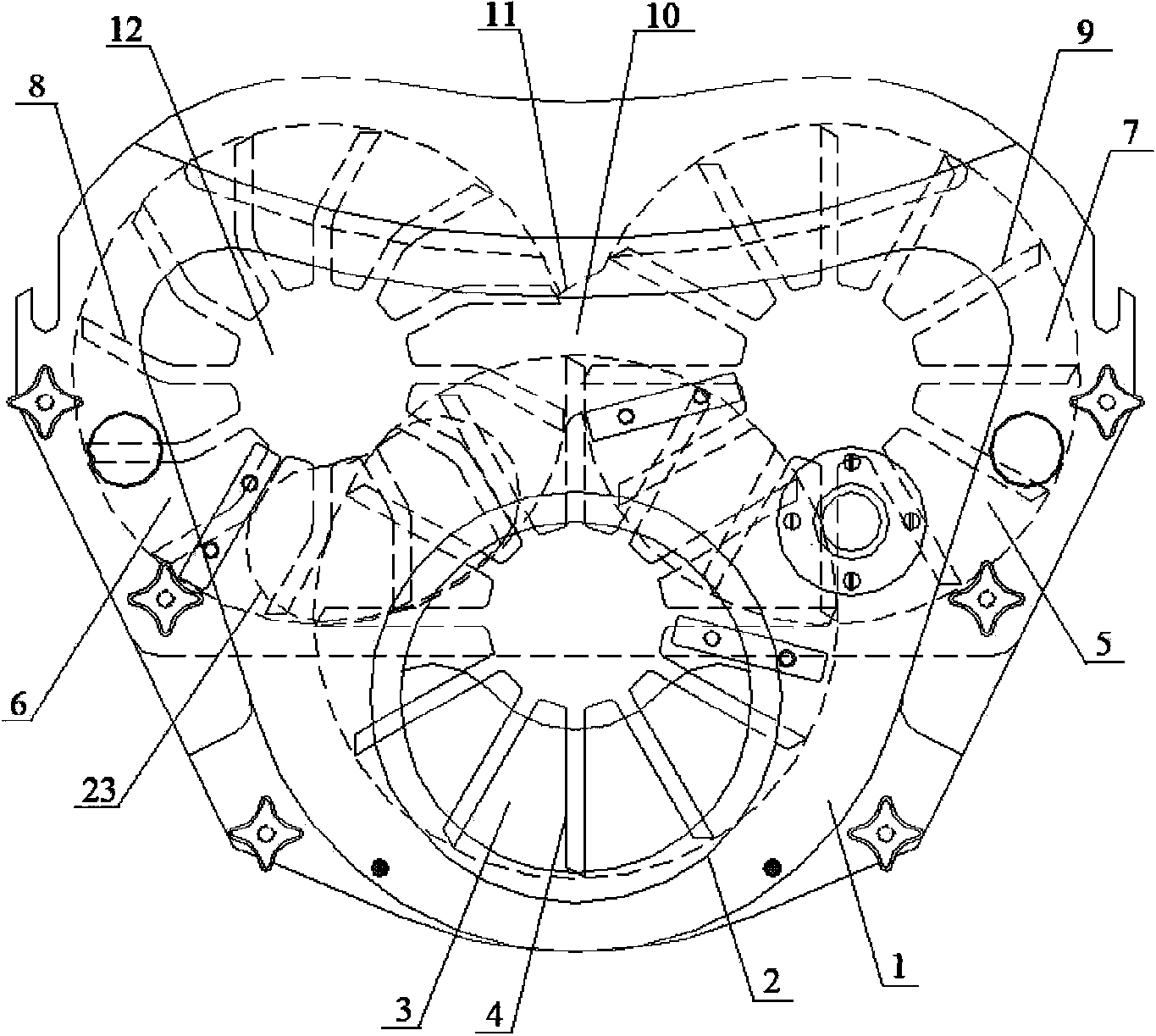

[0047] The forced feeder described in this embodiment includes an impeller box 1, and a feed inlet 2 is arranged on the upper surface of the impeller box 1; an upper impeller chamber 3 and a lower impeller chamber are also arranged in the impeller box 1. 5 and a partition between the upper impeller cavity 3 and the lower impeller cavity 5, wherein:

[0048] Such as figure 2 As shown, the upper impeller chamber 3 is communicated with the feed inlet 2, and a distribution impeller 4 is arranged in the upper impeller chamber 3, and the distribution impeller 4 is arranged below the feed inlet 2. ;

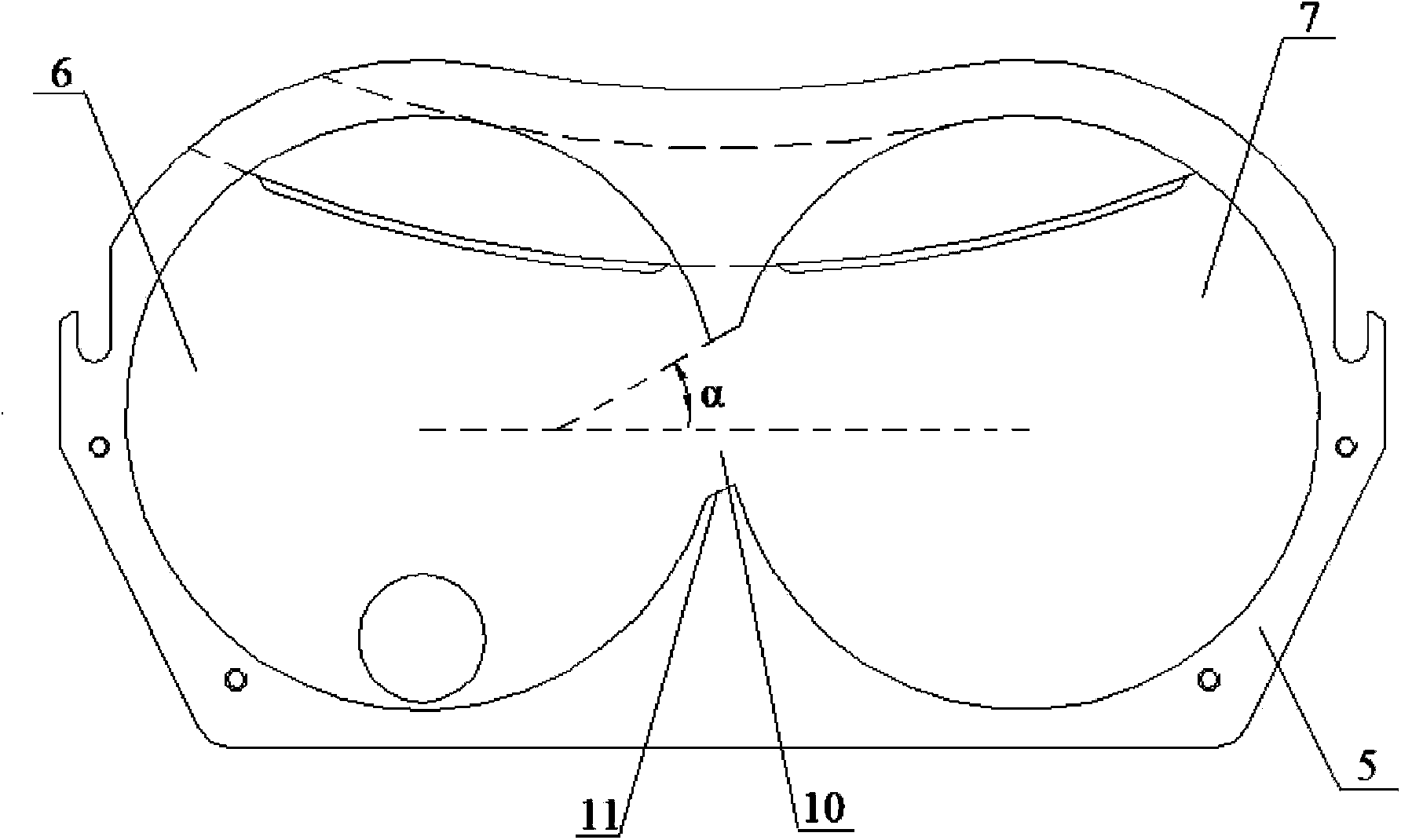

[0049] The lower impeller chamber 5 is located below the upper impeller chamber 3 and includes a feeding impeller chamber 6 and a quantitative impeller chamber 7. The junction of the feeding impeller chamber 6 and the quantitative impeller chamber 7 is communicated. A feeding impeller 8 is arranged in the impeller chamber 6, a quantitative impeller 9 is arranged in the quantitative i...

Embodiment 2

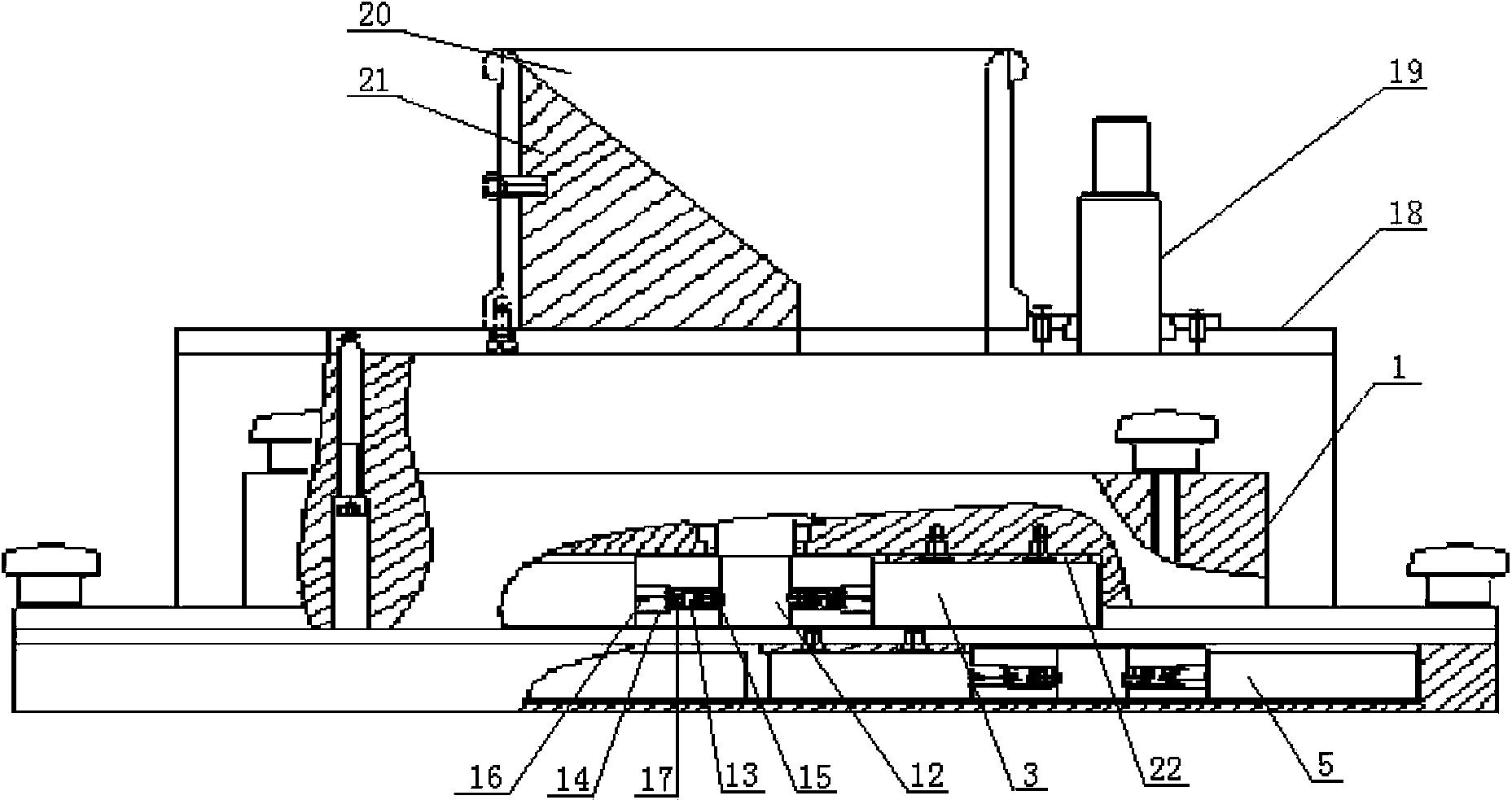

[0057] See figure 1 , the forced feeder described in this embodiment includes an impeller box 1, a gear box 18 and a feeding cylinder 20, please also refer to figure 2 , the upper surface of the impeller box 1 is provided with a feed inlet 2; in the impeller box 1, there are also: an upper impeller chamber 3, a lower impeller chamber 5, and an upper impeller chamber 3 and a lower impeller chamber. Partition between chambers 5, wherein:

[0058] The upper impeller chamber 3 is communicated with the feed inlet 2, and a distribution impeller 4 is arranged in the upper impeller chamber 3, and the distribution impeller 4 is arranged below the feed inlet 2;

[0059] The lower impeller cavity 5 is located below the upper impeller cavity 3, and includes a feeding impeller cavity 6 and a quantitative impeller cavity 7 communicated at the junction, both of which have a diameter of 168mm. Feed impeller 8, the gap between the feed impeller 8 and the wall of the feed impeller chamber 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com