Patents

Literature

44results about How to "Avoid uneven flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

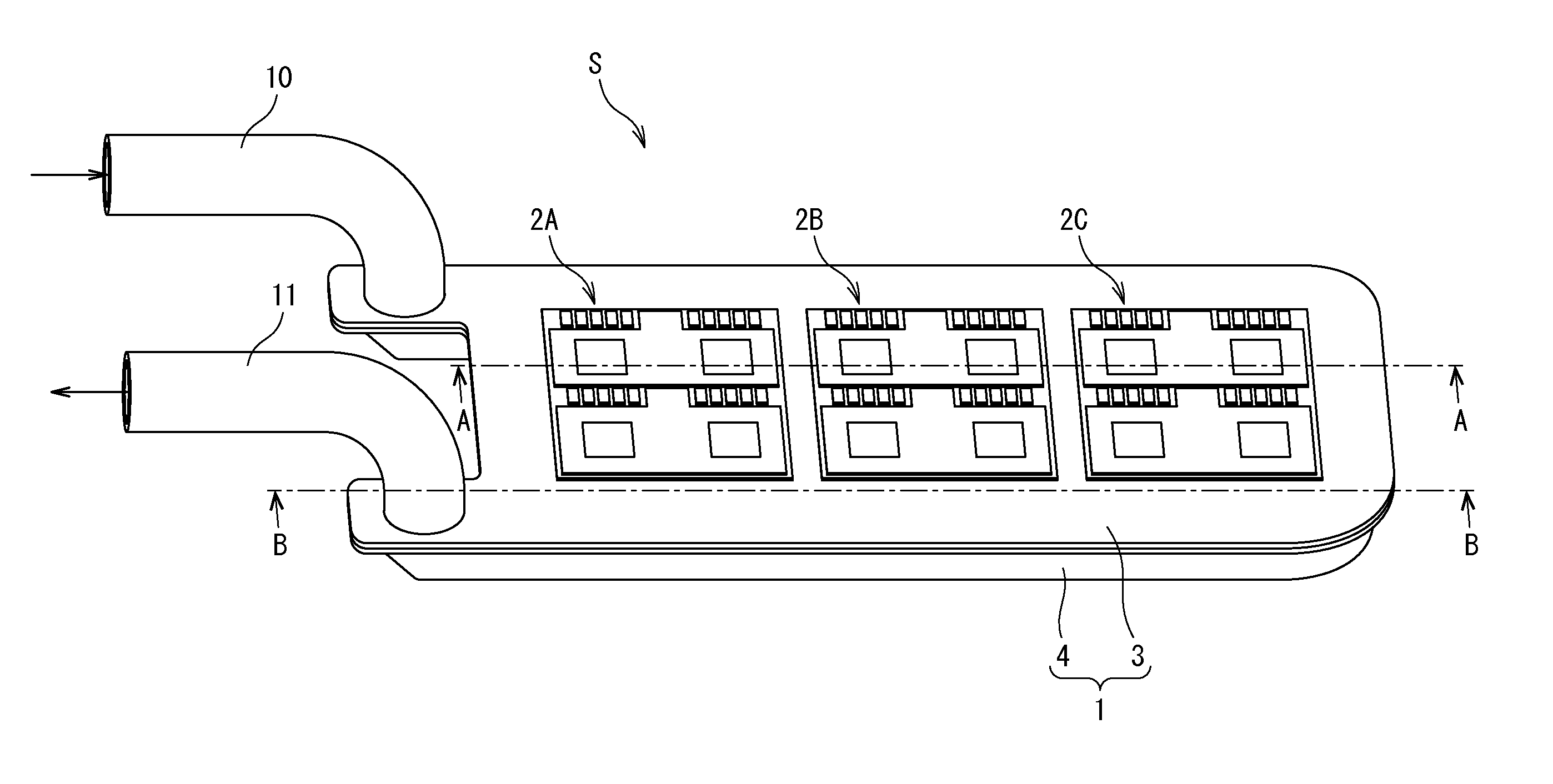

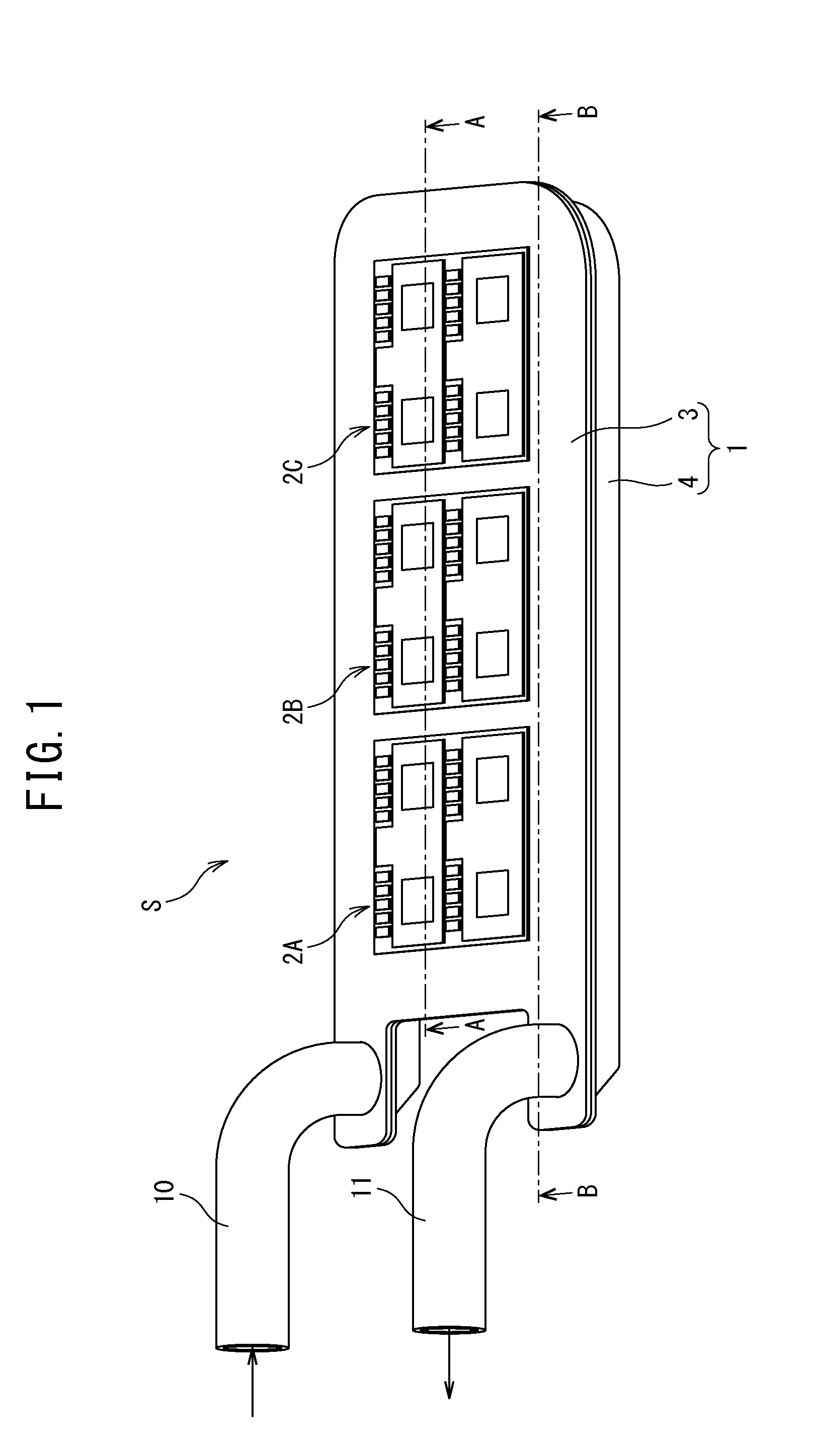

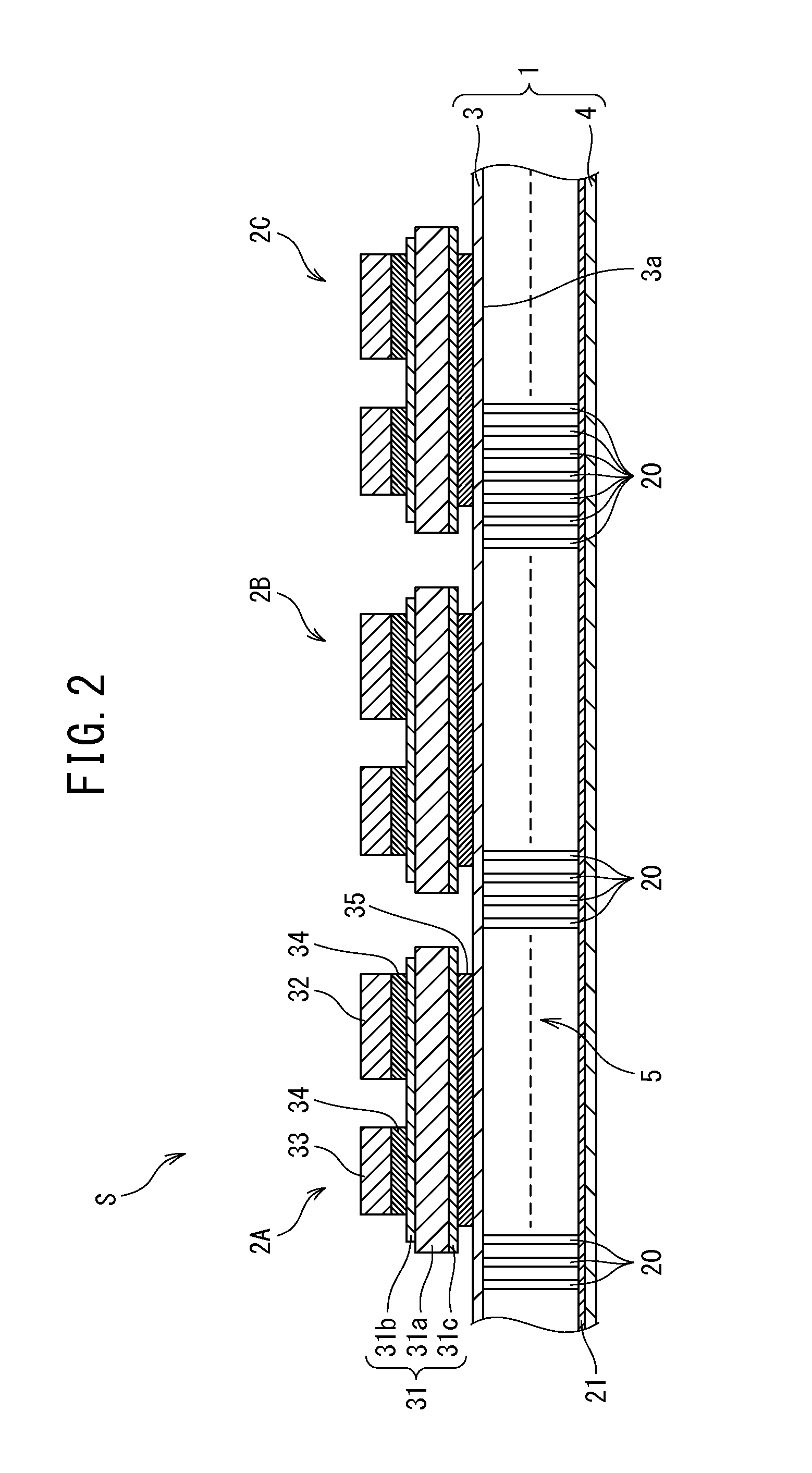

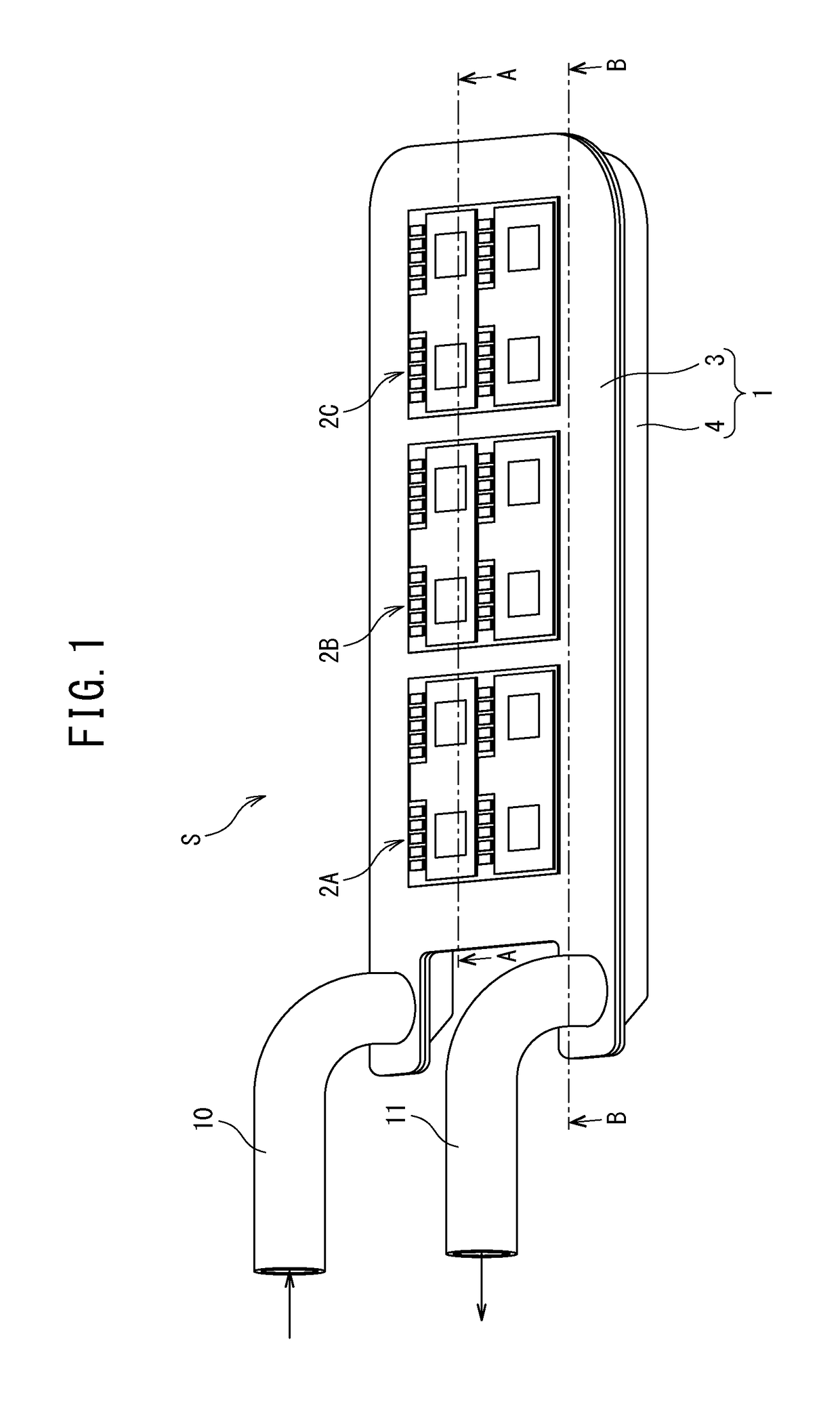

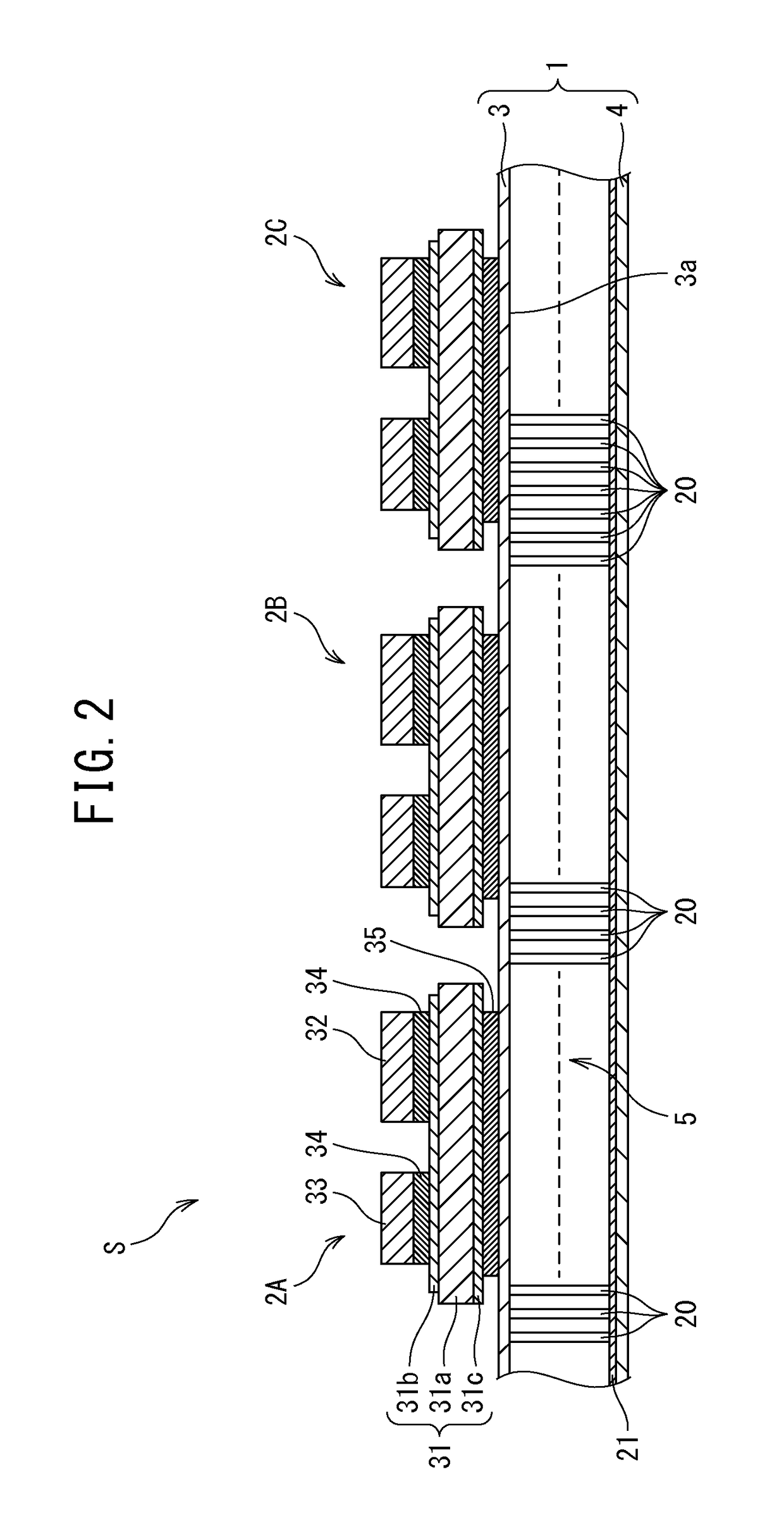

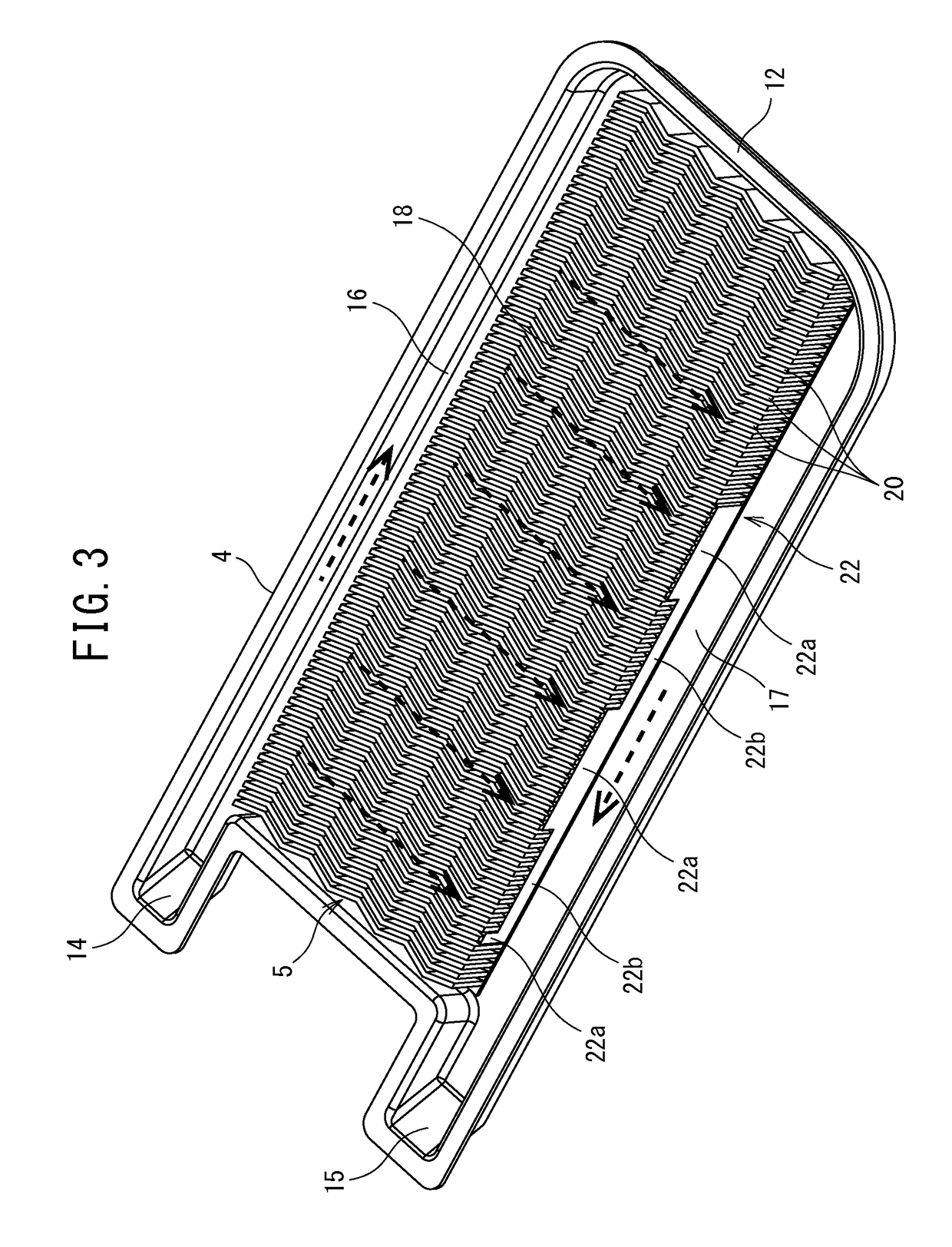

Method for manufacturing cooler for semiconductor-module, cooler for semiconductor-module, semiconductor-module and electrically-driven vehicle

ActiveUS20160129792A1Simple manufacturing processReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesComputer moduleEngineering

A cooler for a semiconductor-module includes: a heat sink which has an appearance of a cuboid structure to one side of which a flow rate control plate is fixed; a thermal radiation plate on an outer surface of which semiconductor devices are bonded; and a tray-shaped cooling jacket having: a coolant introduction channel; a coolant extraction channel extending in parallel to the coolant introduction channel; and a cooling channel provided between the coolant introduction and extraction channels. The heat sink is provided in the cooling channel of the cooling jacket so that the flow rate control plate extends in a boundary between the coolant extraction channel and the cooling channel, and channels provided for the heat sink extend orthogonally to the coolant introduction and extraction channels. The thermal radiation plate is fixed so as to close an opening the cooling jacket.

Owner:FUJI ELECTRIC CO LTD

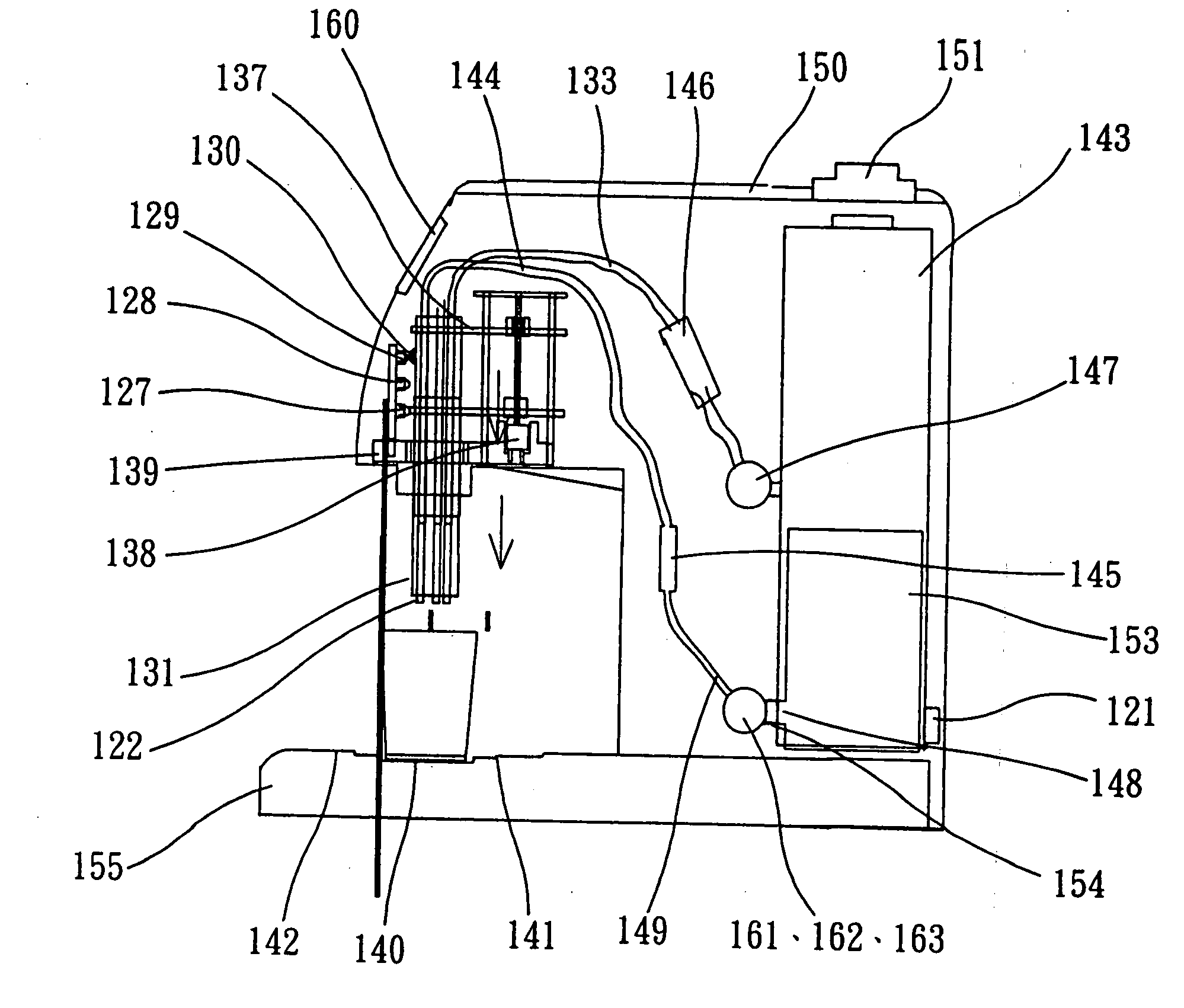

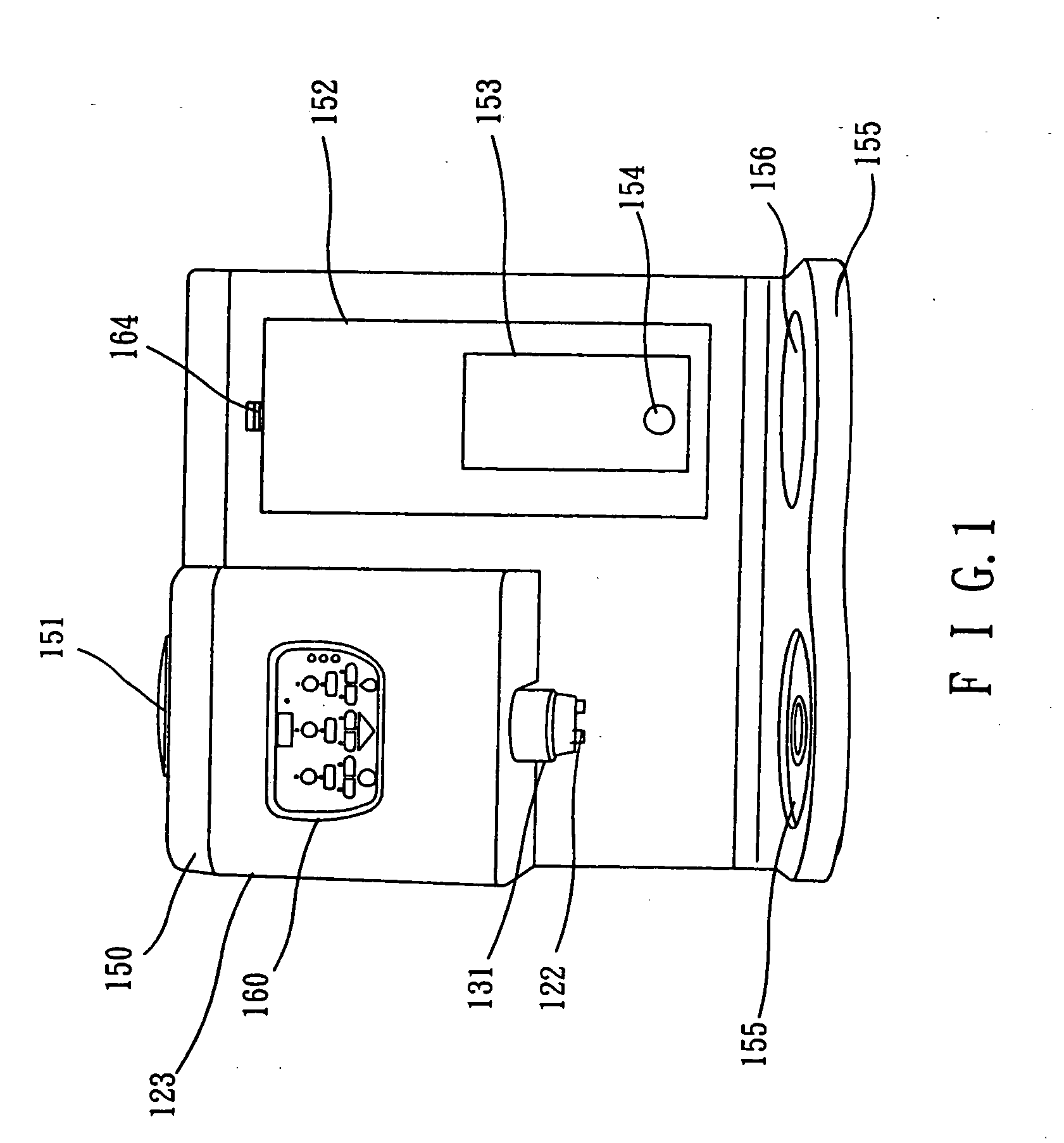

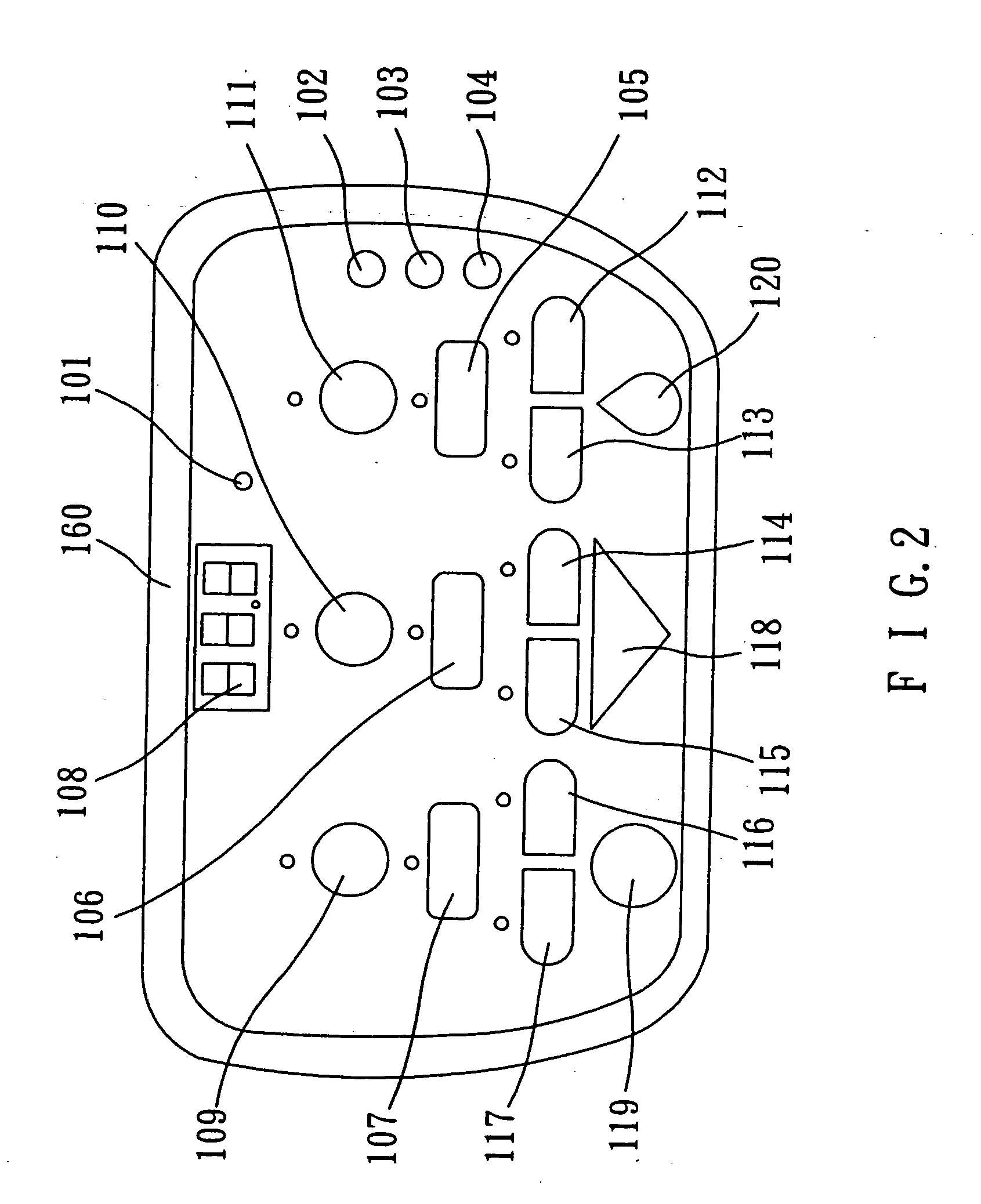

Automatic liquid metering apparatus

InactiveUS20070029005A1Uneven flow be preventGood fluidityLiquid transferring devicesSolid materialCheck valveMicroprocessor

An automatic liquid metering apparatus is disposed with at least a liquid concentrate motor pump with a tube connected thereto and at least a diluting water motor pump with a tube connected thereto where the turning of the pumps is timed by a microprocessor to control the amounts of liquid concentrate and diluting water to be dispensed. The outlet tubing of the pump is connected to the outlet of liquid concentrate and diluting water via a check valve. A lift mechanism is provided at the concentrate / diluting water outlet, which allows the choice of small cup, medium cup or large pot by ascending or descending to the proper height. The stop point of the lift mechanism is microprocessor controlled to prevent the spurting of dispensed liquid concentrate and diluting water due to great distance between their outlet and the rim of cup to ensure sanitary and smooth dispensing of fluids. This invention features precision dispensing of concentrate and diluting water and low manufacturing costs.

Owner:HUANG SHIH YEN +1

Method for manufacturing cooler for semiconductor-module, cooler for semiconductor-module, semiconductor-module and electrically-driven vehicle

ActiveUS10214109B2Simple manufacturing processReduce the number of partsSpeed controllerElectric devicesComputer moduleEngineering

A cooler for a semiconductor-module includes: a heat sink which has an appearance of a cuboid structure to one side of which a flow rate control plate is fixed; a thermal radiation plate on an outer surface of which semiconductor devices are bonded; and a tray-shaped cooling jacket having: a coolant introduction channel; a coolant extraction channel extending in parallel to the coolant introduction channel; and a cooling channel provided between the coolant introduction and extraction channels. The heat sink is provided in the cooling channel of the cooling jacket so that the flow rate control plate extends in a boundary between the coolant extraction channel and the cooling channel, and channels provided for the heat sink extend orthogonally to the coolant introduction and extraction channels. The thermal radiation plate is fixed so as to close an opening the cooling jacket.

Owner:FUJI ELECTRIC CO LTD

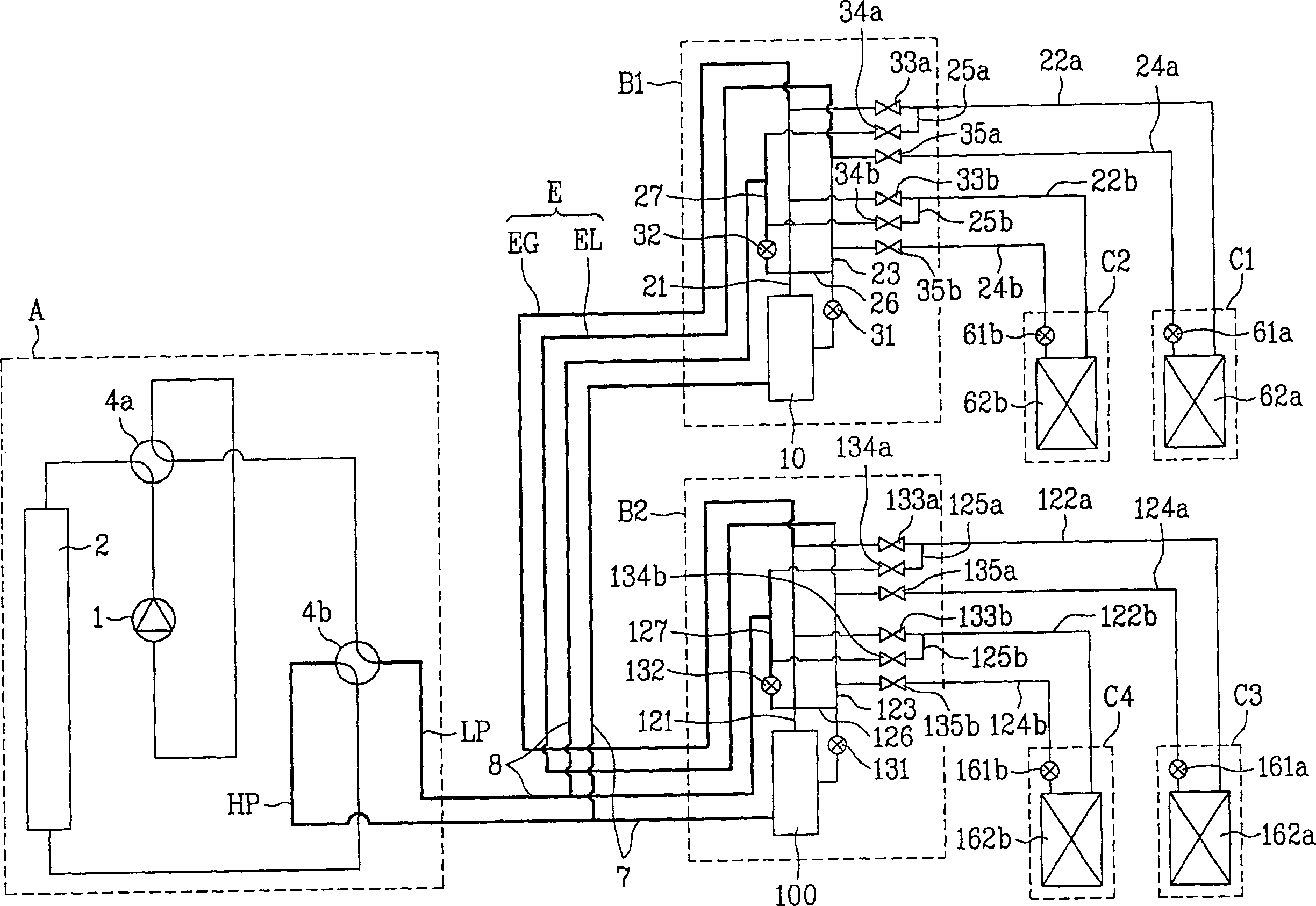

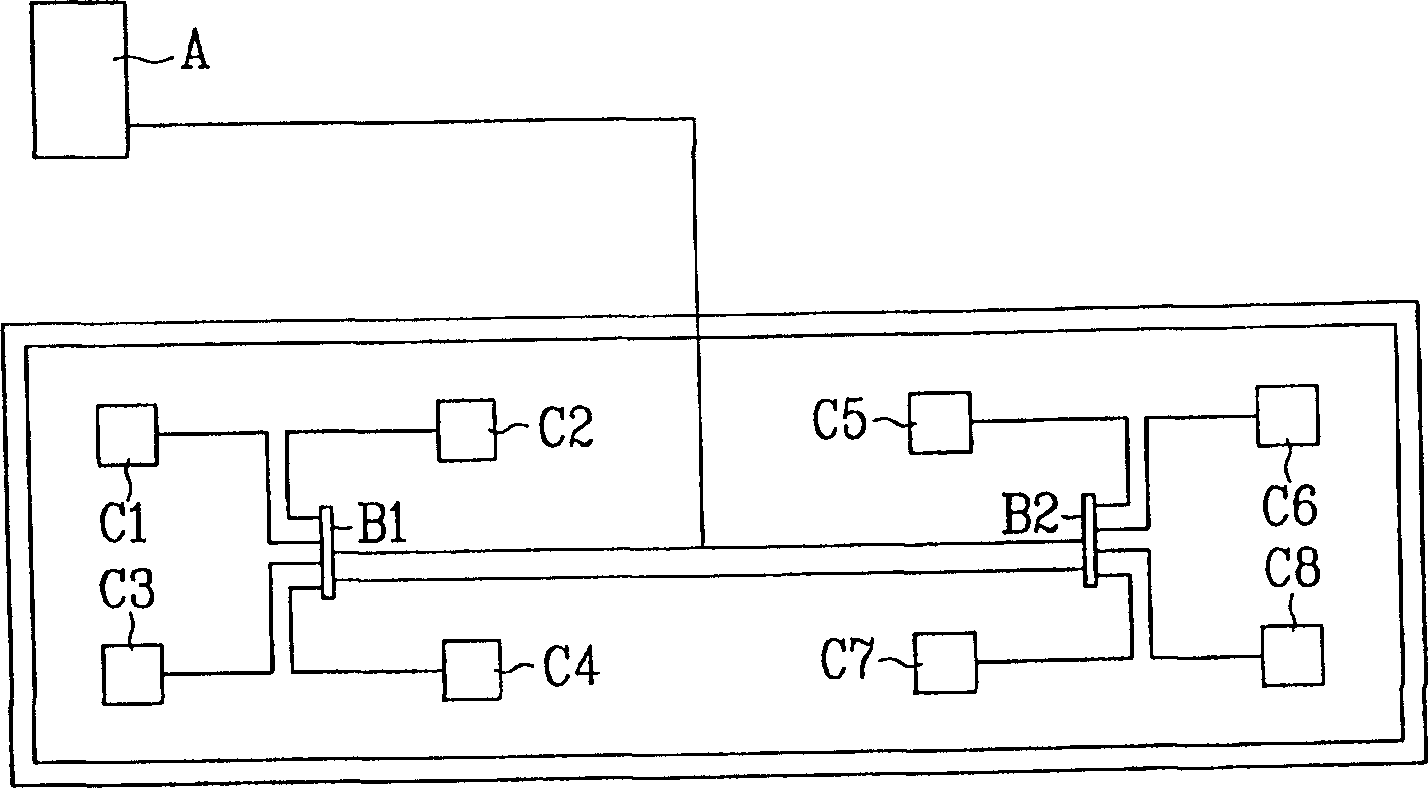

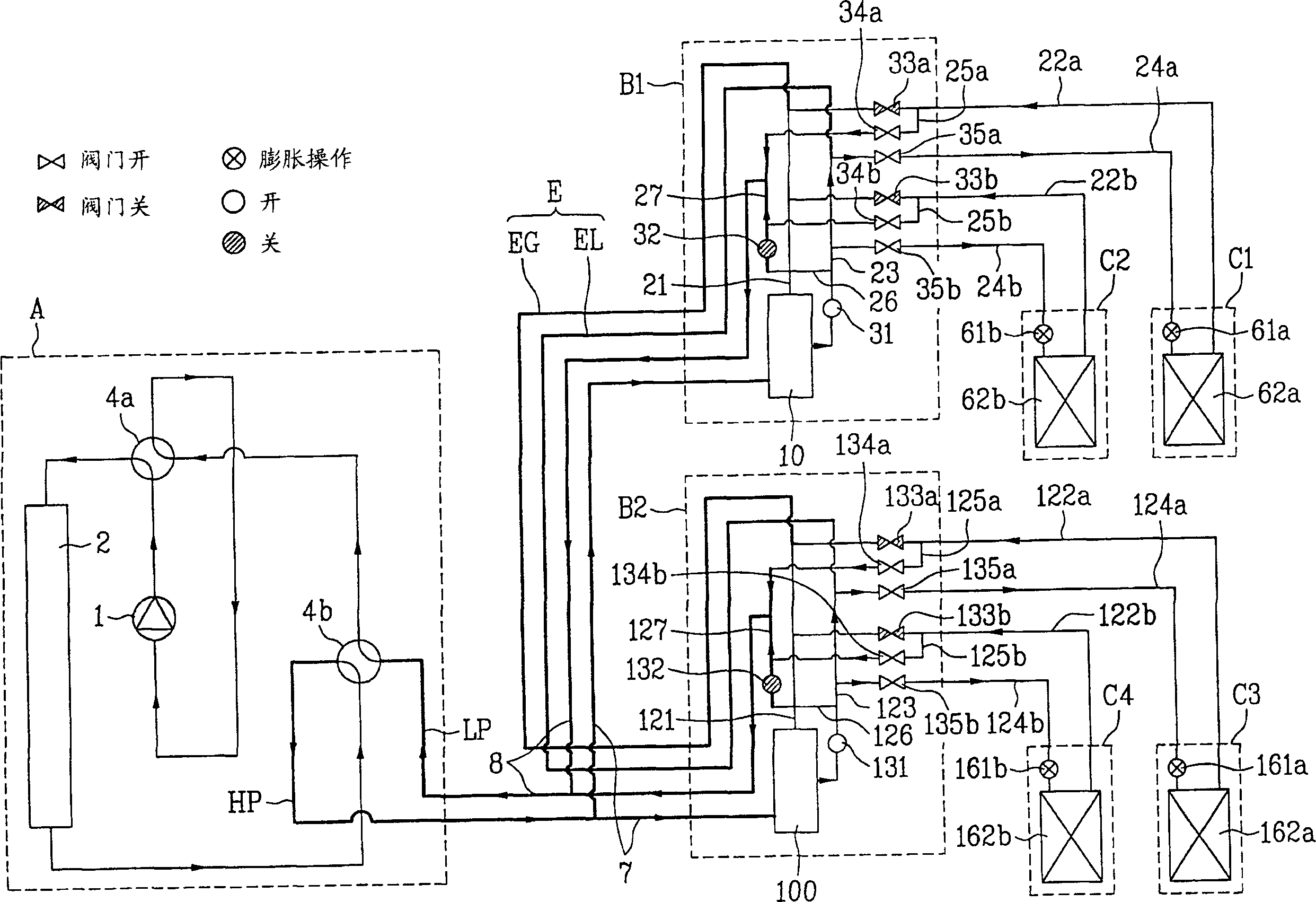

Multi-unit air conditioner

InactiveCN1483971AAvoid restrictionsEasy Tube WorkSpace heating and ventilation safety systemsSpace heating and ventilation control systemsMulti unitVapor–liquid separator

Multi-type air conditioner including a plurality of distributors each including a gas-liquid separator for separating refrigerant from the outdoor unit into gas refrigerant and liquid refrigerant, and distributor pipelines for guiding the gas or liquid refrigerant separated at the gas-liquid separator to the indoor units, and guiding the refrigerant passed through the indoor unit to the outdoor unit again, and an equalizing pipeline part for connecting the distributors for equal supply of refrigerant, thereby installing the indoor unit easily, and improving an air conditioning efficiency by supplying the refrigerant, equally.

Owner:LG ELECTRONICS INC

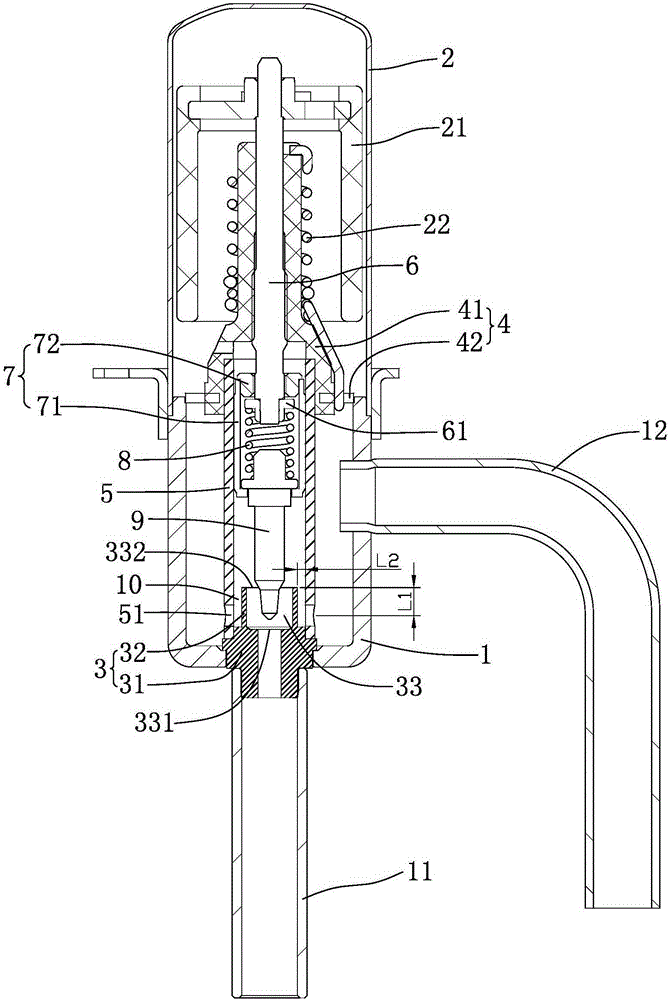

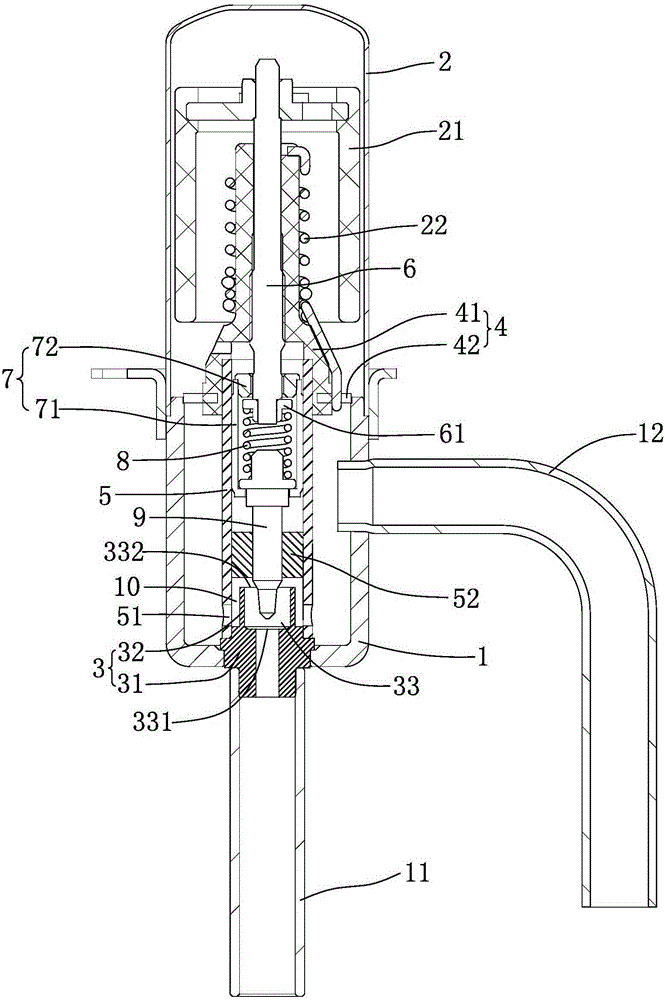

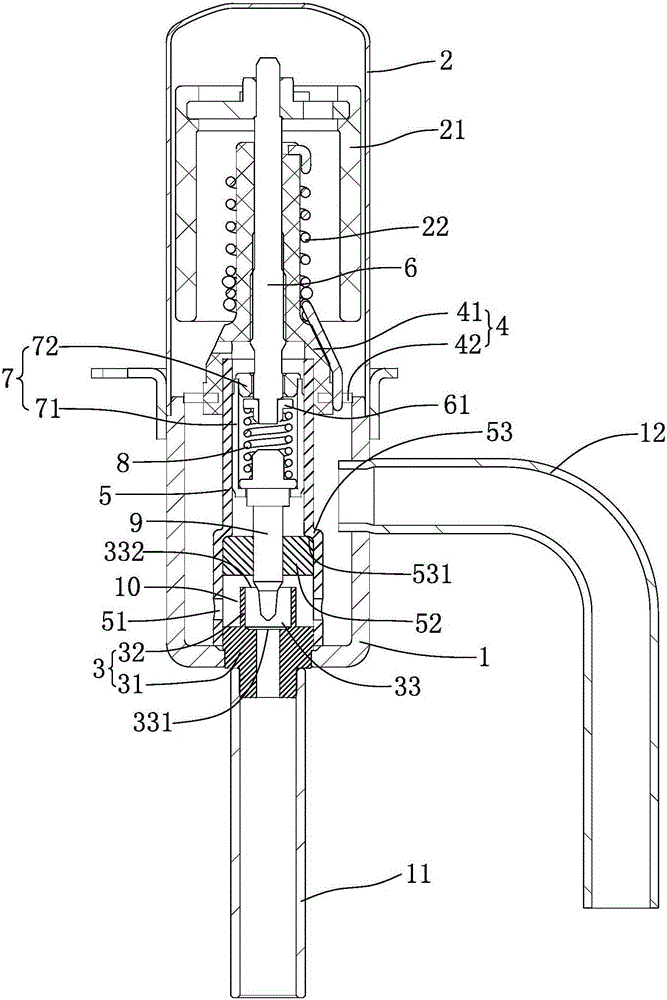

Electronic expansion valve

ActiveCN106545660AIncrease contact rateReduce surface tensionValve members for absorbing fluid energyEfficient regulation technologiesElectronic expansion valveVALVE PORT

The invention relates to an electronic expansion valve. The problem that electronic expansion valves are high in noise is solved. The electronic expansion valve comprises a valve body, a valve needle, a valve seat and a driving mechanism. The valve is arranged at the lower end of the valve body. A valve port is formed in the valve seat. The driving mechanism is arranged at the upper end of the valve body. The valve needle is connected with the driving mechanism and driven by the driving mechanism to open or close the valve port. A guiding sleeve used for guiding the valve needle to move axially is further arranged in the valve body and provided with a plurality of side wall through holes. An annular flow channel is formed between the outer side wall of the valve seat and the inner wall of the guiding sleeve. The side wall through holes are evenly distributed in the guiding sleeve mainly and correspond to the annular flow channel.

Owner:DUNAN ENVIRONMENT TECH

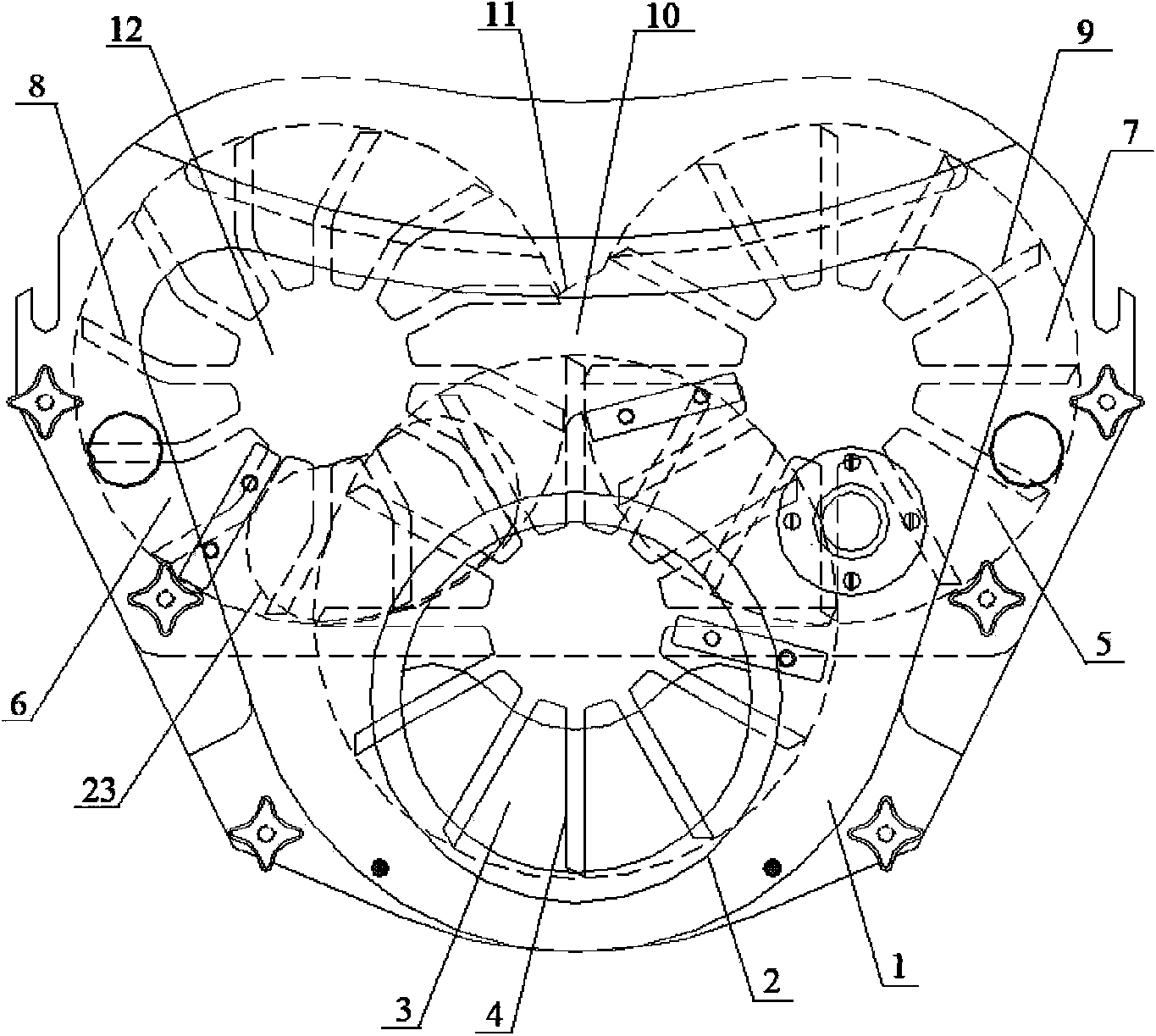

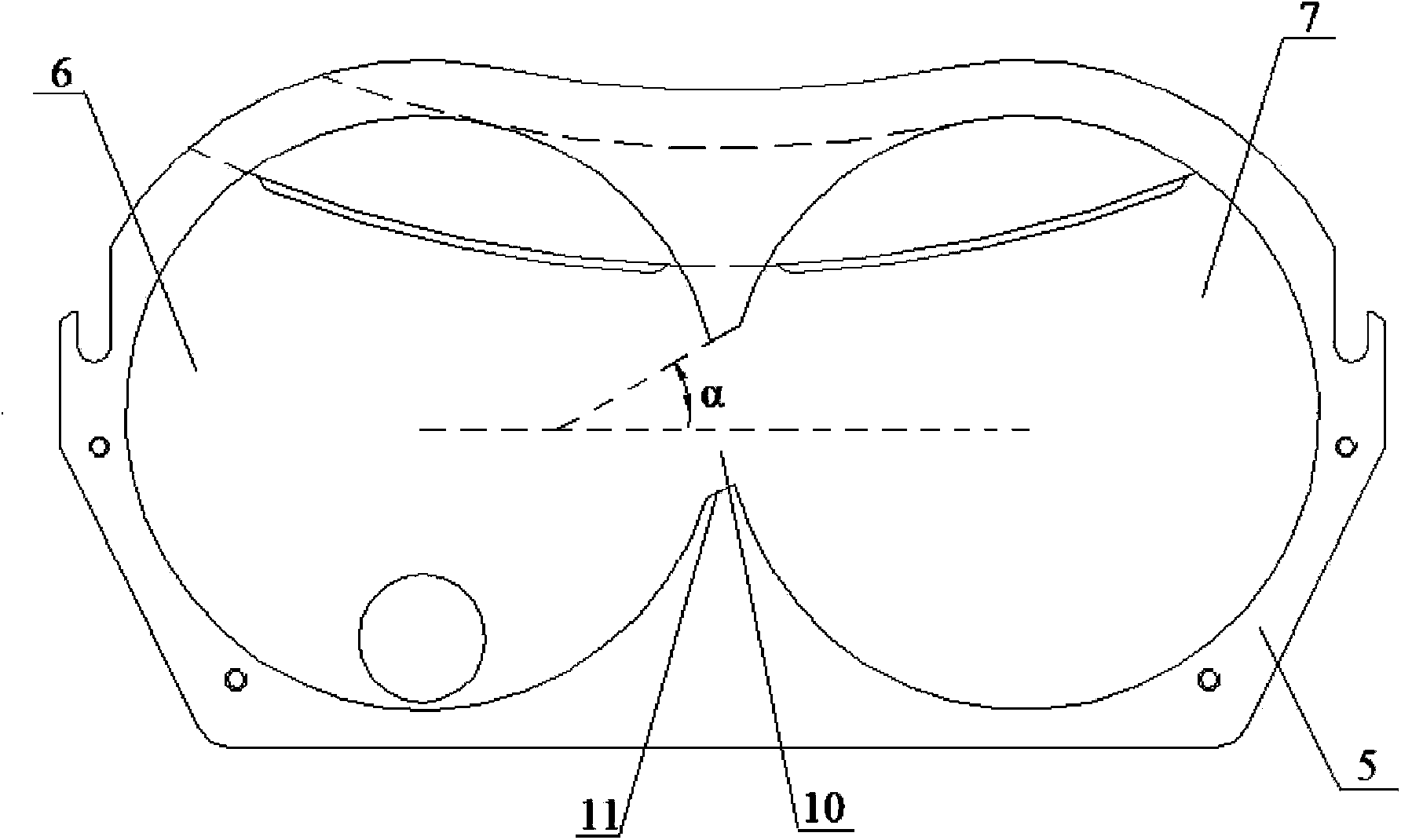

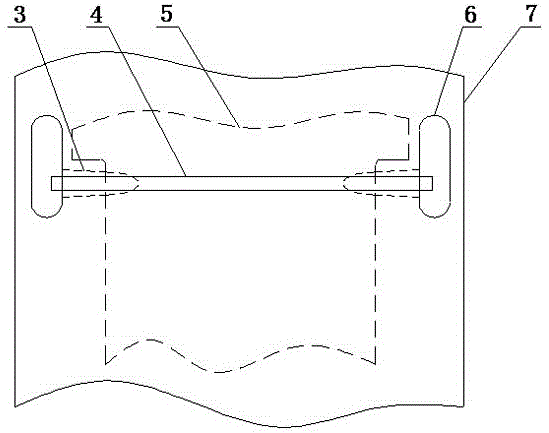

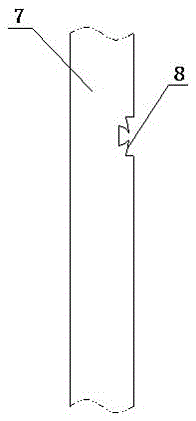

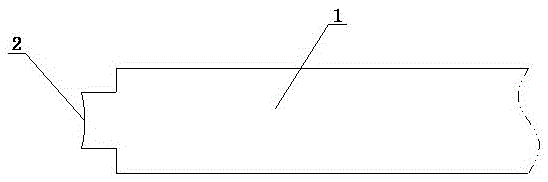

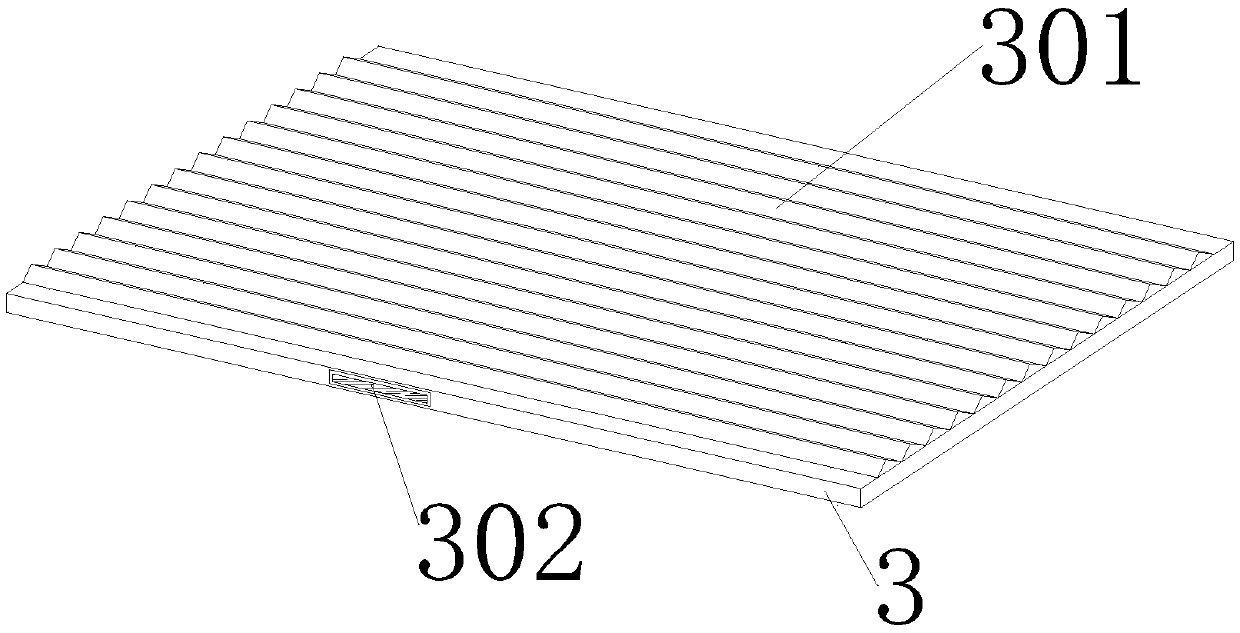

Forced feeding device

The invention discloses a forced feeding device. The forced feeding device comprises an impeller box, wherein an upper-layer impeller chamber, a lower-layer impeller chamber and a separation plate arranged between the upper-layer impeller chamber and the lower-layer impeller chamber are arranged in the impeller box; the upper-layer impeller chamber is internally provided with a material distribution impeller and the lower-layer impeller chamber comprises a feeding impeller chamber and a quantitative impeller chamber; a crossed part of the feeding impeller chamber and the quantitative impeller chamber is communicated; a feeding impeller is arranged in the feeding impeller chamber; a quantitative impeller is arranged in the quantitative impeller chamber; the rotating direction of the feeding impeller is opposite to the rotating direction of the material distribution impeller. According to the forced feeding device, the quantitative impeller chamber is arranged and surplus materials in the quantitative impeller chamber are added into the feeding impeller chamber again so that the materials flow smoothly in the forced feeding device; a material caking phenomenon is avoided so that the filling stability of the materials is ensured.

Owner:北京国药龙立科技有限公司

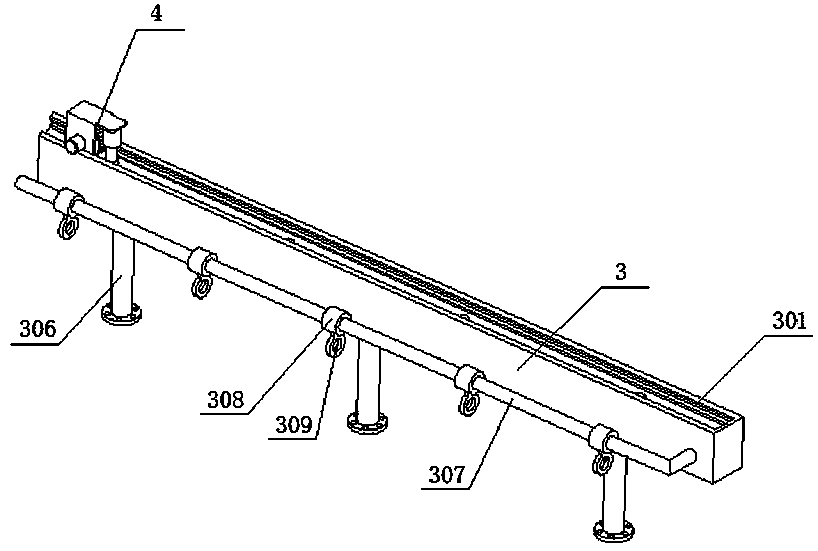

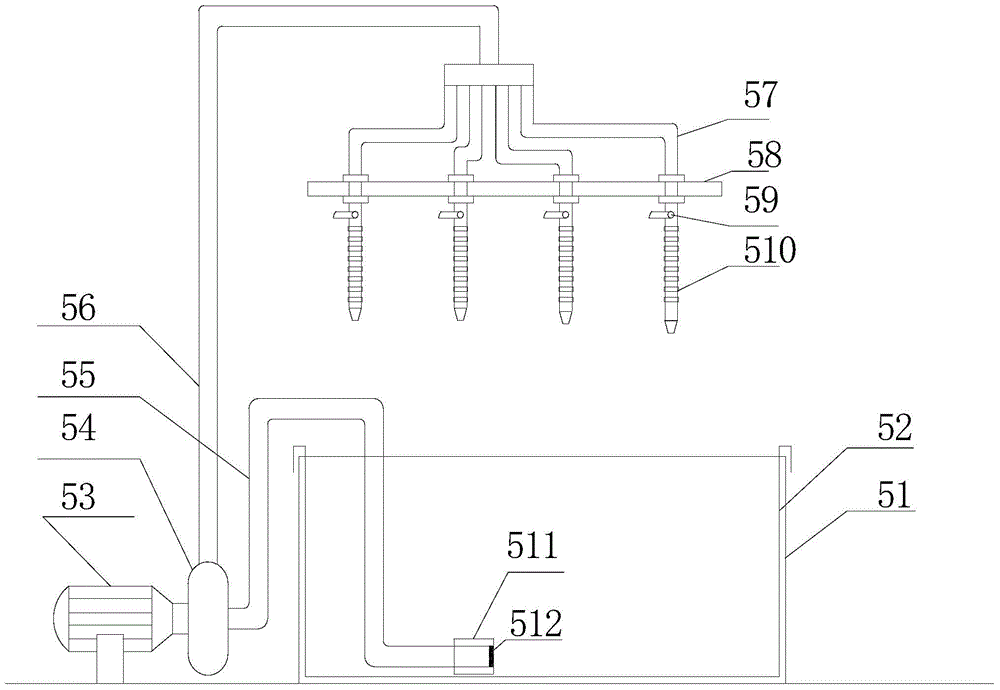

Water and fertilizer integrated automatic irrigation system based on Internet of Things

InactiveCN110226400AImprove uniformityEasy to useLiquid fertiliser regulation systemsPressurised distribution of liquid fertiliserPipingFertilizer

The invention discloses a water and fertilizer integrated automatic irrigation system based on Internet of Things and relates to the technical field of irrigation systems. The automatic irrigation system comprises a water supply device, a management center, a plurality of soil humidity sensors and a division device, wherein the water supply device comprises a water pump, a water and fertilizer tank and a solid fertilizer tank, a water delivery pipe is fixed at a water outlet of the water pump, a transfer pump is fixed on the circumferential surface of the water and fertilizer tank, a first water pipe is communicated between the water delivery pipe and the transfer pump, a first electric flow valve is arranged on the first water pipe, a mixing box is fixed on the bottom surface of the solidfertilizer tank, and a stirring mechanism is fixed in the mixing box. Partition plates are arranged in a division pipe to divide the division pipe into multiple compartments, meanwhile, slide rails are arranged on the division pipe, sliding connecting parts are arranged, water can be injected to different compartments for division irrigation, and the problem that fertilizer is not put uniformly due to longer division pipes under fertilizer-carrying irrigation condition at present is solved.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

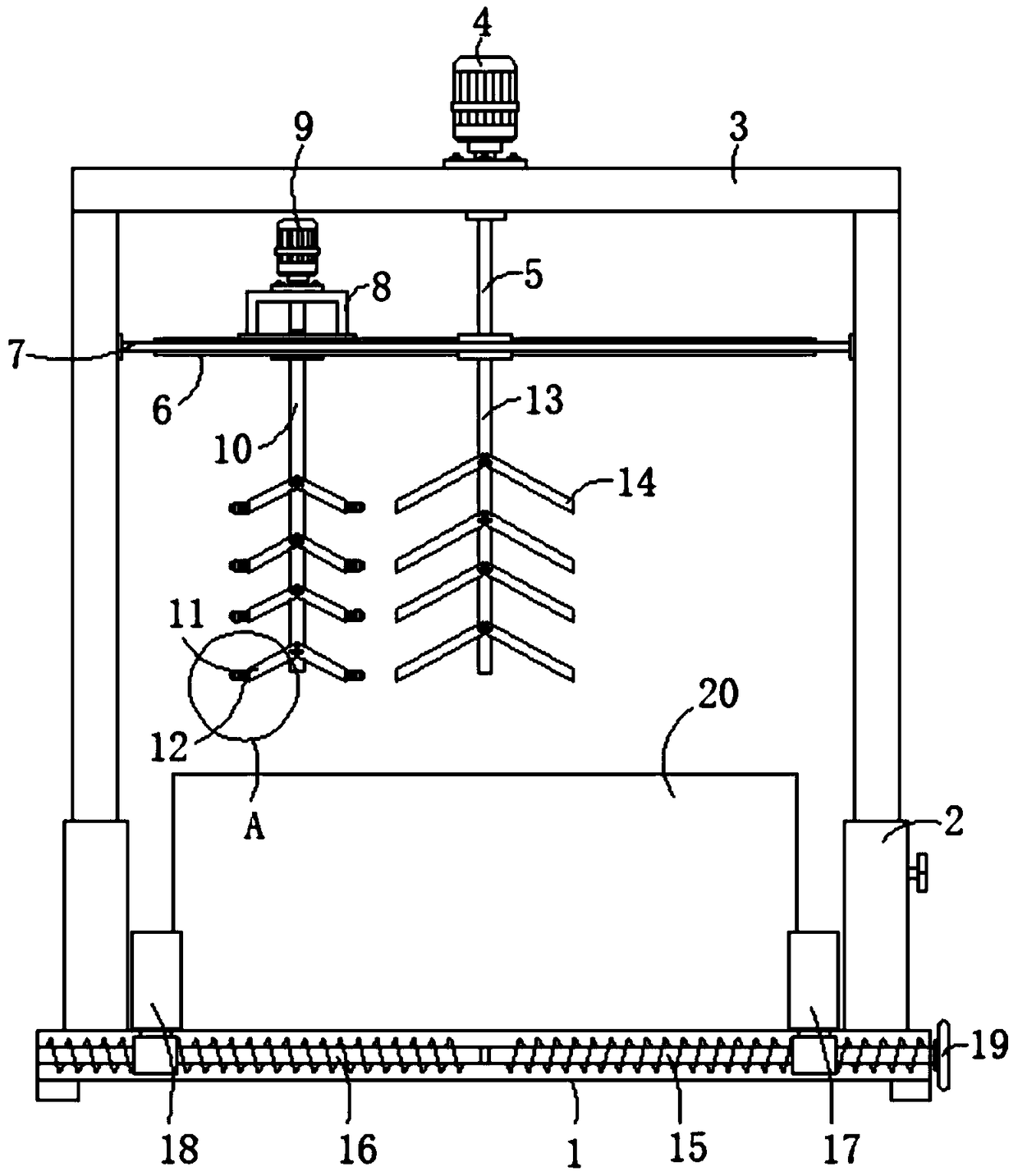

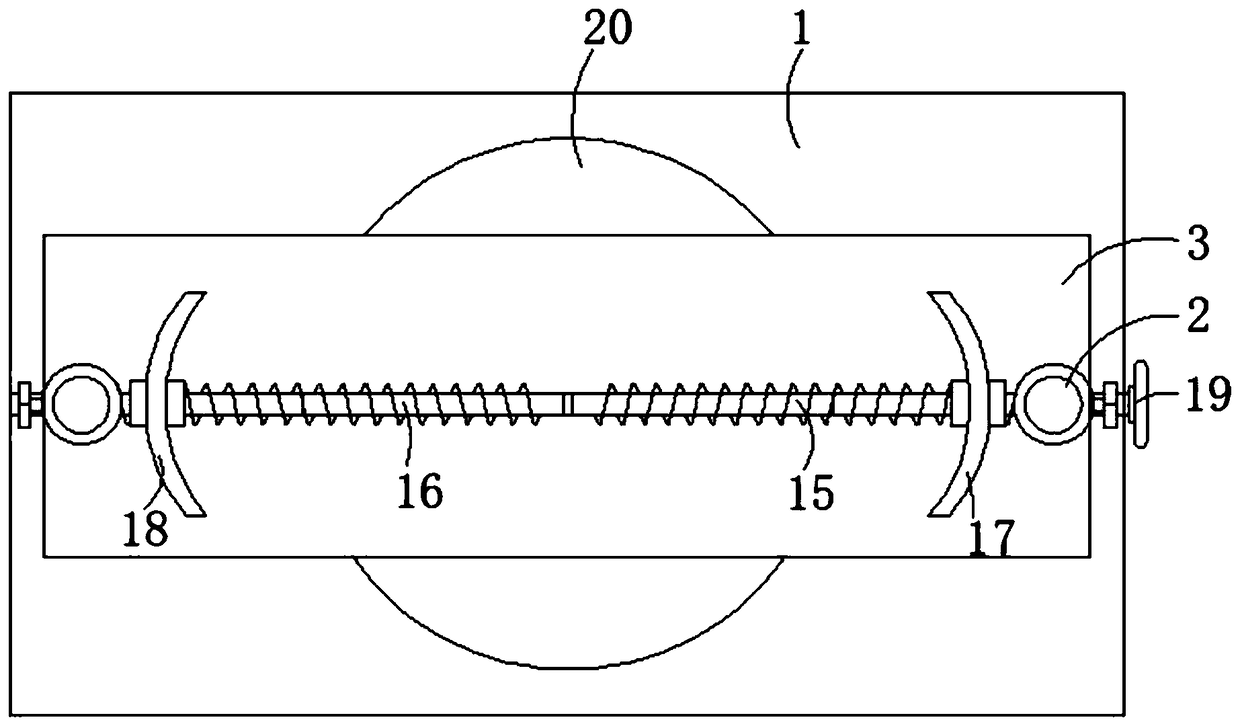

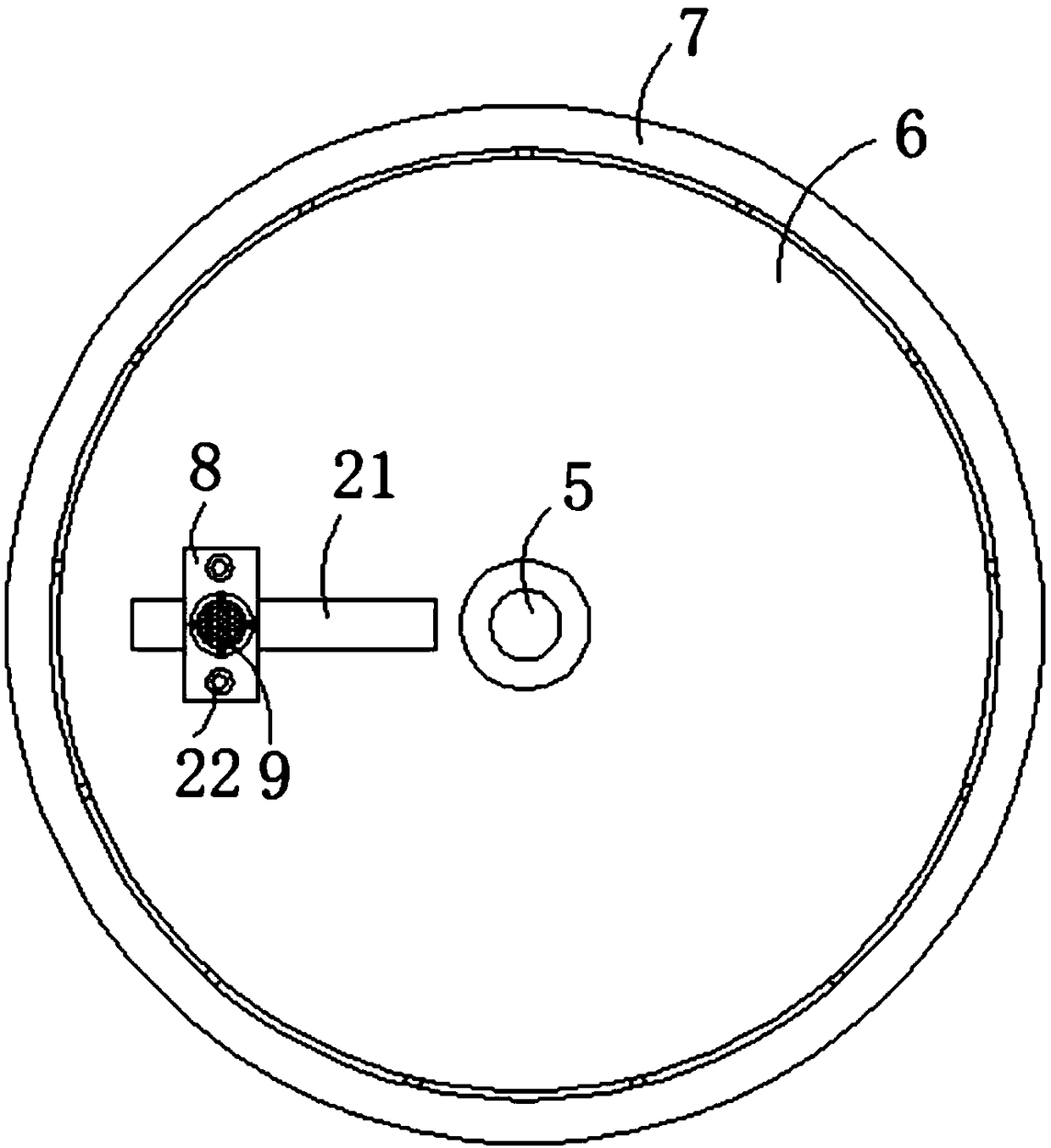

Stirring device applicable to stirring of machining lubricating oil

InactiveCN108837749AQuality improvementStir wellRotary stirring mixersTransportation and packagingDrive shaftEngineering

The invention discloses a stirring device applicable to stirring of machining lubricating oil. The stirring device comprises a base, wherein telescopic rods are fixedly connected to the top of the base through bolts; a top plate is arranged at the top ends of the telescopic rods; a first motor is fixedly connected to the central position of the top of the top plate through bolts; a turnplate is rotationally connected to one end of the first motor through a transmission shaft; fixing rings are arranged on the outer walls of one sides of the telescopic rods; the fixing rings are connected with the turnplate in a sliding manner. On one hand, through dual stirring, the lubricating oil in a stirring barrel can be uniformly stirred sufficiently, so that the problems of nonuniform stirring and nonuniform material flow caused by incapability of covering the stirring barrel due to insufficient length of stirring blades are avoided, and high efficiency and high quality of material stirring are sufficiently guaranteed; on the other hand, distance between double stirring shafts can be adjusted according to the diameters of different stirring barrels so as to be adapted to stirring in the stirring barrels with different sizes, so that the applicability is improved.

Owner:浙江荣正管业有限公司

Small-pore-diameter brass distributor for uniform distribution

InactiveCN108870812AGuaranteed tightnessThere will be no leakageMechanical apparatusFluid circulation arrangementPore diameterEngineering

The invention provides a small-pore-diameter brass distributor for uniform distribution. The small-pore-diameter brass distributor comprises a connecting end and a distribution end, wherein the connecting end comprises a distribution cavity; a threaded connector is arranged at the right side of the distribution cavity; the pore diameter of the threaded connector is greater than the pore diameter of the distribution cavity; an annular surface is formed at the right side of the distribution cavity; a circle of buffer plate fixing blocks are placed at the right side of the annular surface; a buffer plate is arranged in the middle of the buffer plate fixing block; the right side of the buffer plate fixing block is fixedly connected with a group of springs; a circle of gasket is arranged at theright side of the spring; a sealing pad is padded and arranged on the gasket; the sealing pad is abutted against the opening wall of an input connector; the connecting end and the distribution end are integrally formed. The small-pore-diameter brass distributor has the advantages that under the condition that the connecting end is not in tight connection, the sealing performance of the connectingend can also be ensured; the connecting end is enabled not to generate a liquid leakage condition; a buffer device is arranged in a flow division cavity, so that the phenomenon of flow division nonuniformity caused by great impact and too fast flow speed of refrigerants is prevented.

Owner:SUZHOU TAILONG REFRIGERATION CO LTD

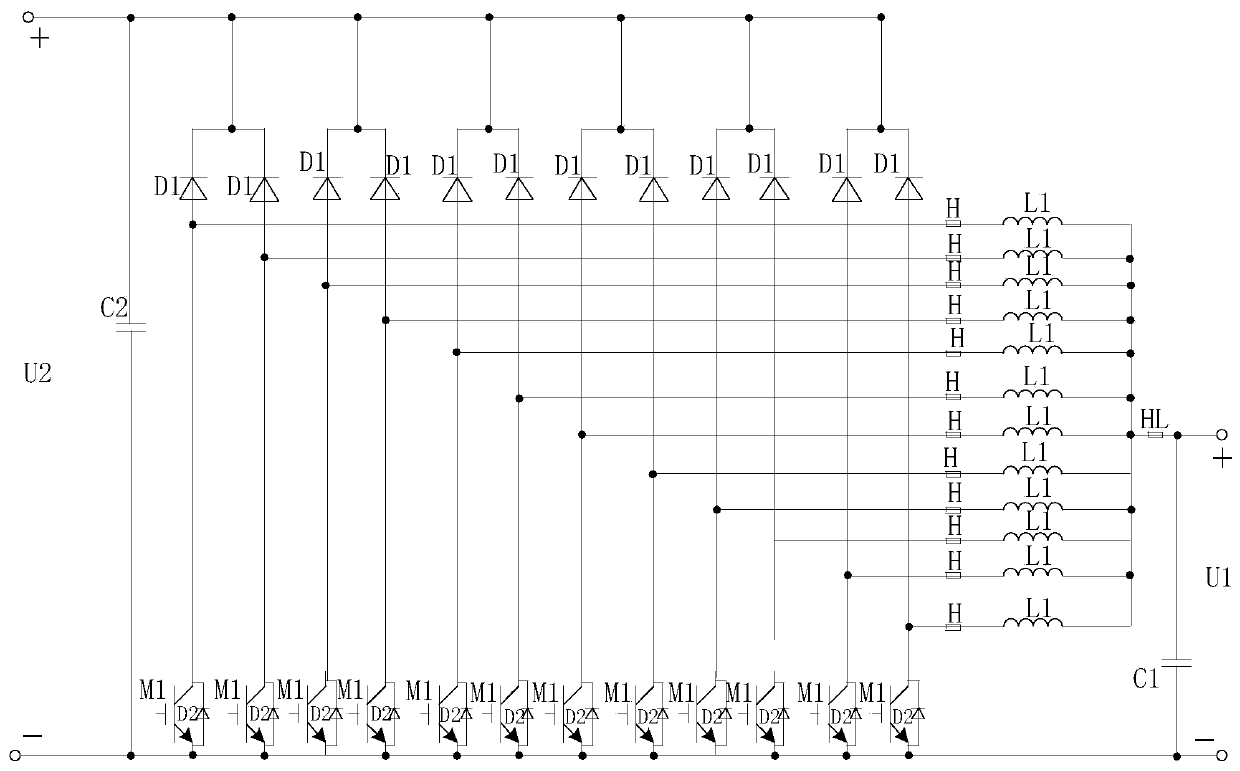

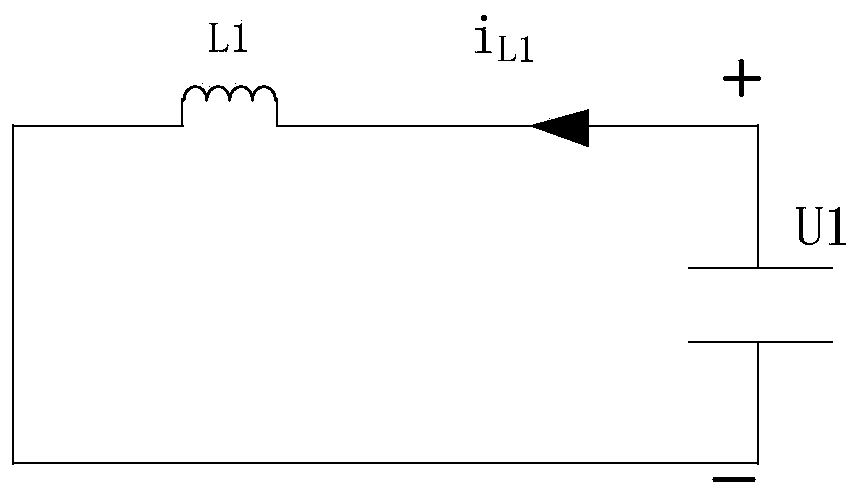

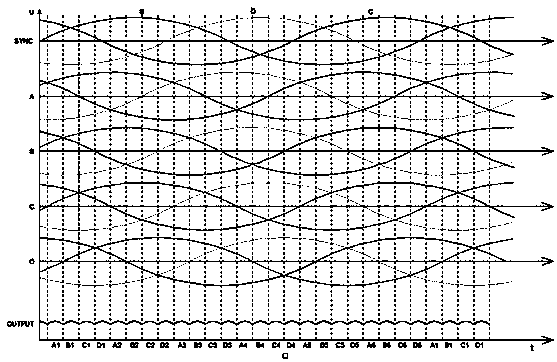

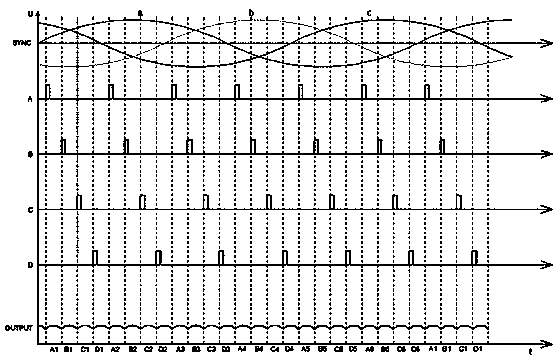

Current-sharing control method and current-sharing control device for carrier phase-shifting parallel circuit

InactiveCN111371320AAvoid uneven flowRealize the effect of multi-phase current sharing controlDc-dc conversionElectric variable regulationPhase currentsCarrier signal

The invention discloses a current-sharing control method and a current-sharing control device for a carrier phase-shifting parallel circuit. The current-sharing control method comprises the followingsteps: acquiring current of each phase of bridge arm; calculating the current change slope of each phase of bridge arm according to the PWM signal of each phase of bridge arm; and adjusting the duty ratio of the PWM signals output by the bridge arm according to the current change slope, so that the current of each phase of bridge arm is kept consistent. According to the embodiment of the invention, the current output state of each phase of bridge arm is finely adjusted according to the current change slope of each phase of bridge arm, so that output currents of all phases in the carrier phase-shifting parallel circuit can be kept completely consistent, the effect of current sharing control is achieved, the control precision of multi-phase currents in the carrier phase-shifting parallel circuit is guaranteed, and electric energy output by the carrier phase-shifting parallel circuit has high stability.

Owner:INVT POWER ELECTRONICS SUZHOU CO LTD

a forced feeder

The invention discloses a forced feeding device. The forced feeding device comprises an impeller box, wherein an upper-layer impeller chamber, a lower-layer impeller chamber and a separation plate arranged between the upper-layer impeller chamber and the lower-layer impeller chamber are arranged in the impeller box; the upper-layer impeller chamber is internally provided with a material distribution impeller and the lower-layer impeller chamber comprises a feeding impeller chamber and a quantitative impeller chamber; a crossed part of the feeding impeller chamber and the quantitative impeller chamber is communicated; a feeding impeller is arranged in the feeding impeller chamber; a quantitative impeller is arranged in the quantitative impeller chamber; the rotating direction of the feeding impeller is opposite to the rotating direction of the material distribution impeller. According to the forced feeding device, the quantitative impeller chamber is arranged and surplus materials in the quantitative impeller chamber are added into the feeding impeller chamber again so that the materials flow smoothly in the forced feeding device; a material caking phenomenon is avoided so that the filling stability of the materials is ensured.

Owner:北京国药龙立科技有限公司

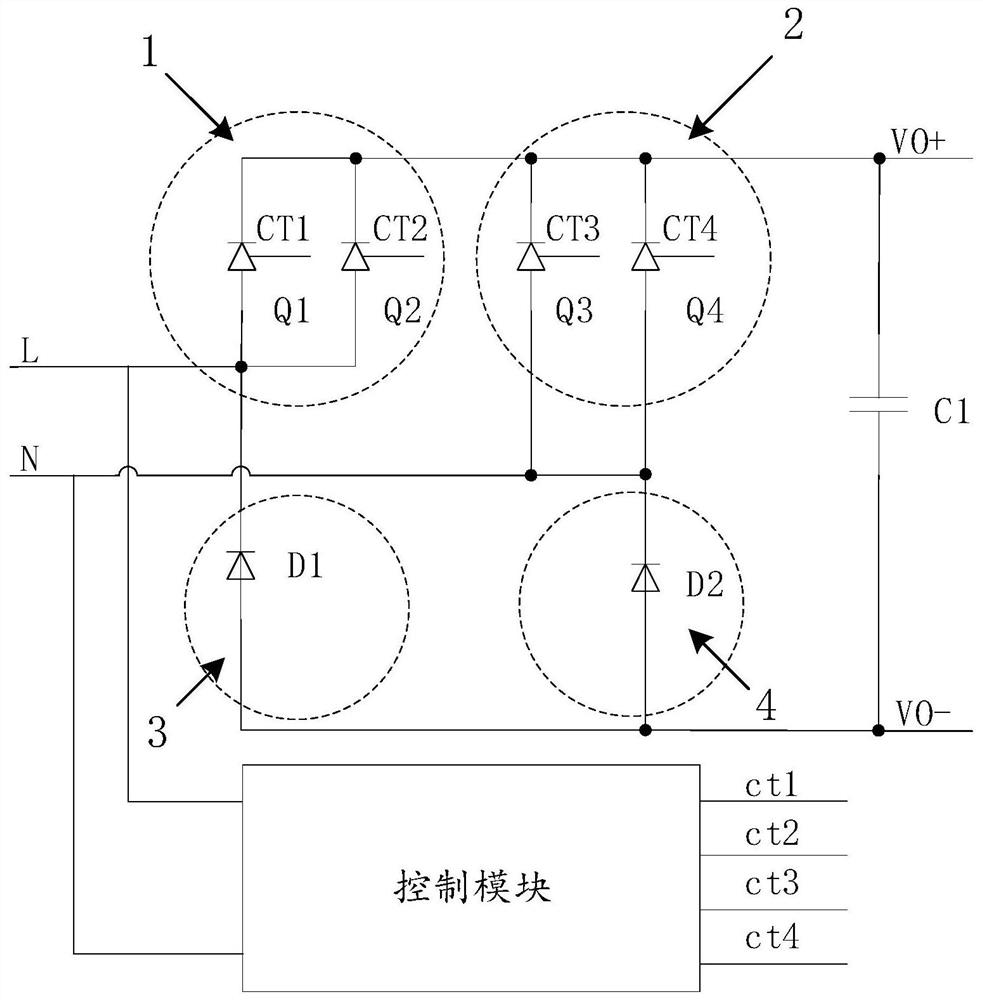

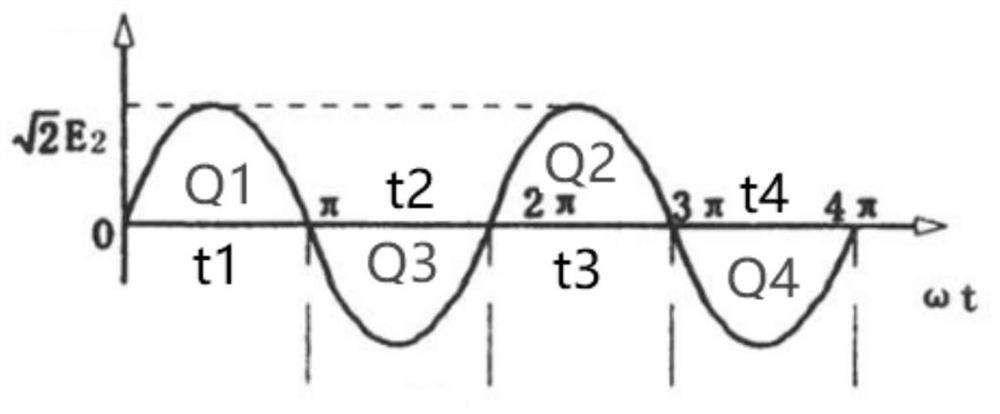

Thyristor parallel connection alternate conduction rectifying circuit silicon controlled rectifier/thyristor

InactiveCN112187070AAvoid uneven flowAvoid damageAc-dc conversion without reversalSilicon-controlled rectifierCapacitance

The invention provides a thyristor parallel connection alternate conduction rectifying circuit. The thyristor parallel connection alternate conduction rectifying circuit comprises a rectifying circuitand a control module, the control module is connected with the rectifying circuit through a control end and is used for controlling alternate conduction of thyristors connected in parallel in the rectifying circuit; a first bridge arm and a second bridge arm of an upper half bridge of the rectifying circuit are respectively composed of two thyristors which are connected in parallel. A third bridge arm and a fourth bridge arm of the lower half bridge are respectively composed of at least one diode; cathodes of the two thyristors connected in parallel on the first bridge arm and the second bridge arm are positive output ends of the rectifying circuit. The anodes of the diodes on the third bridge arm and the fourth bridge arm are the negative output ends of the rectifying circuit; the positive output end and the negative output end of the rectifying circuit are connected with the two ends of the capacitor respectively. The invention realizes the current sharing function of the two thyristors by controlling the thyristors used in parallel to conduct alternately.

Owner:SHANGHAI JUNTAO POWER EQUIP CO LTD

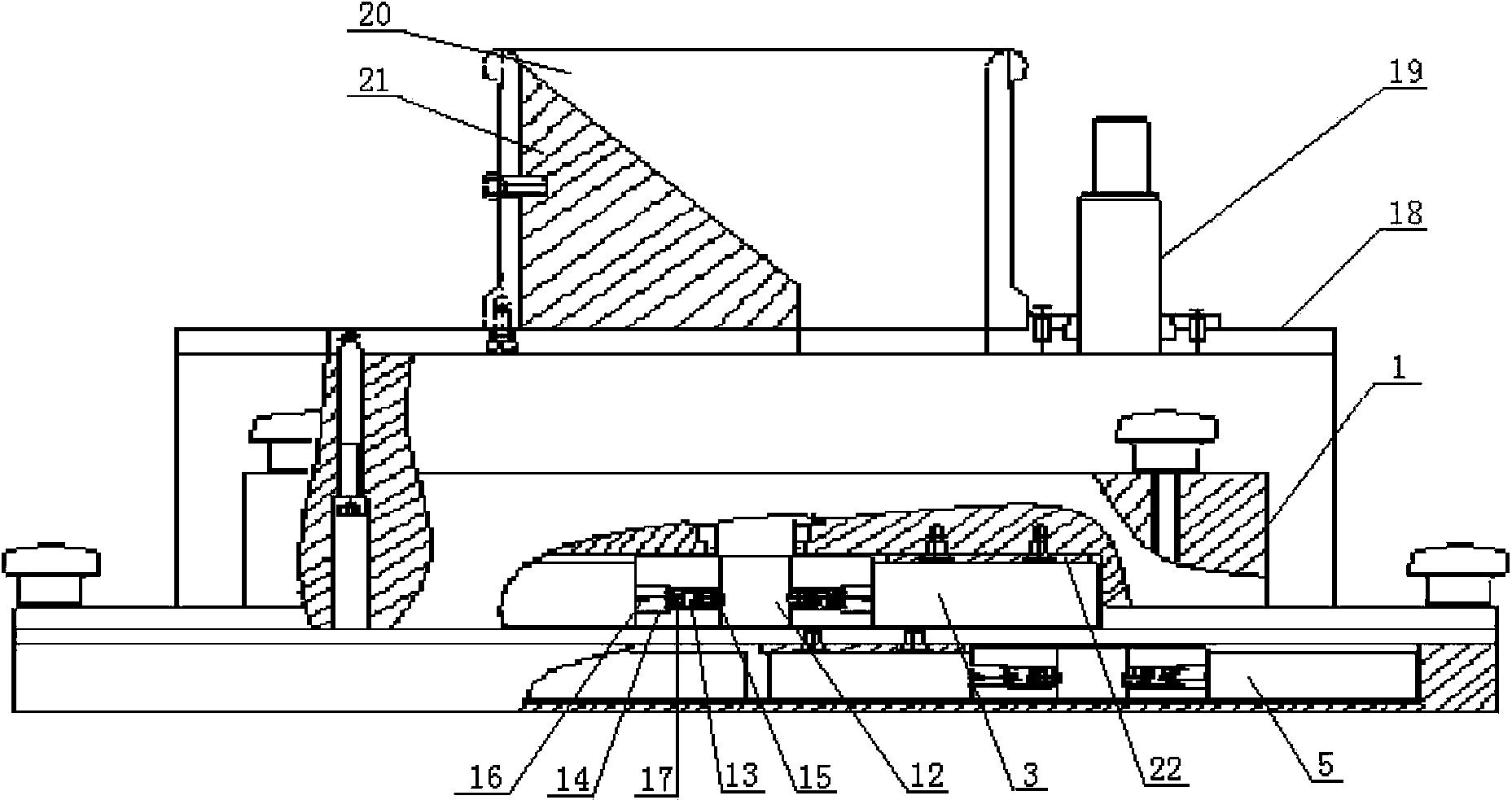

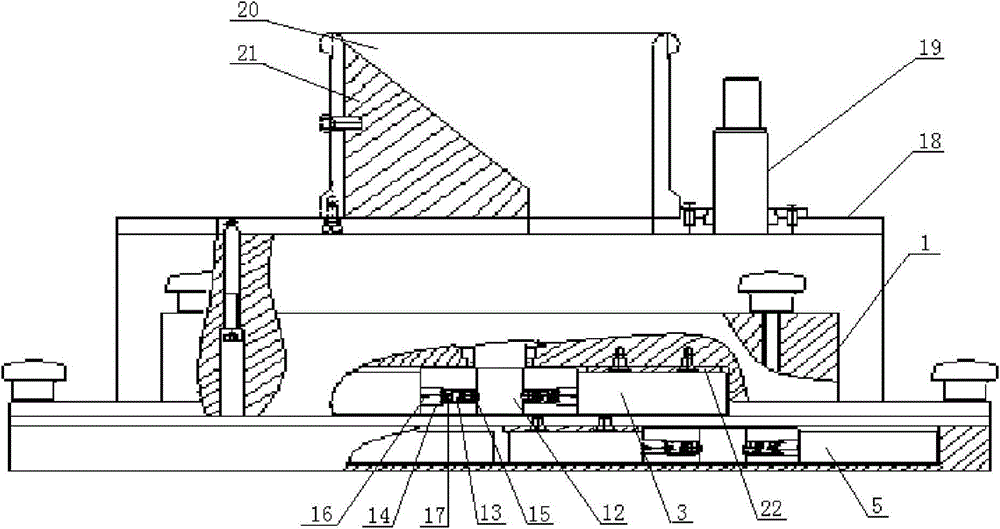

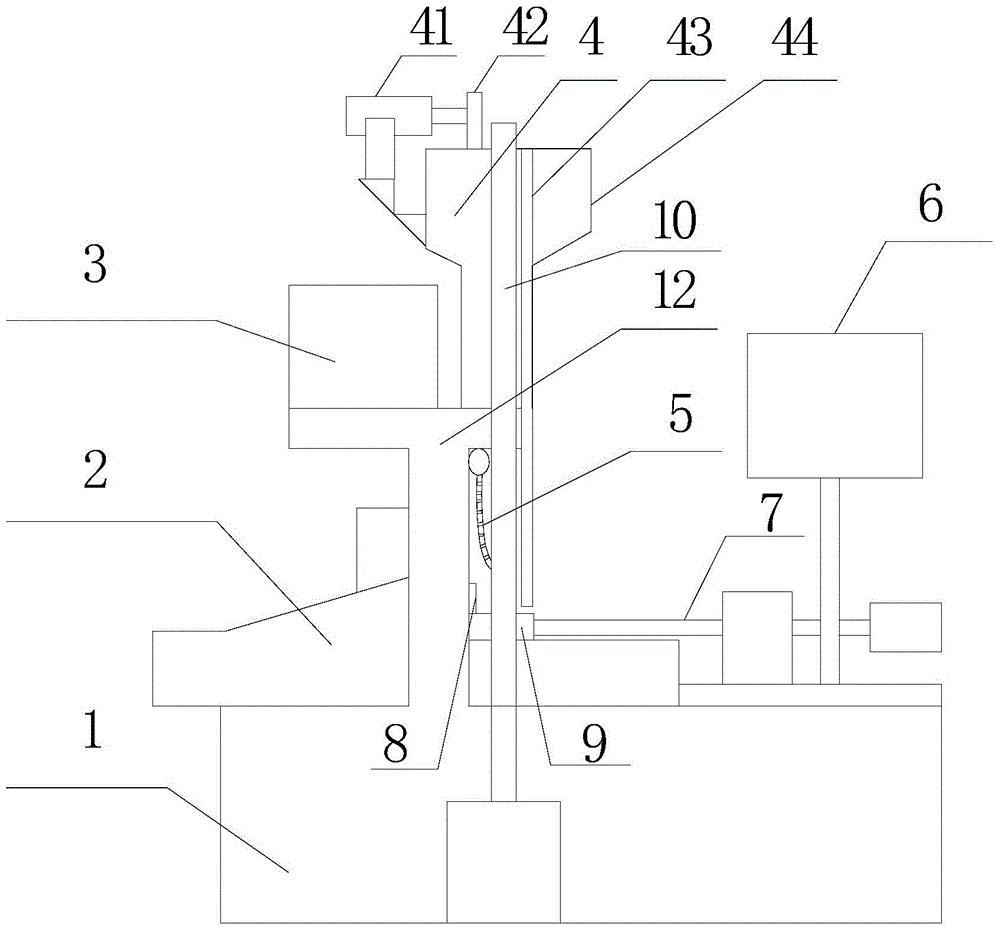

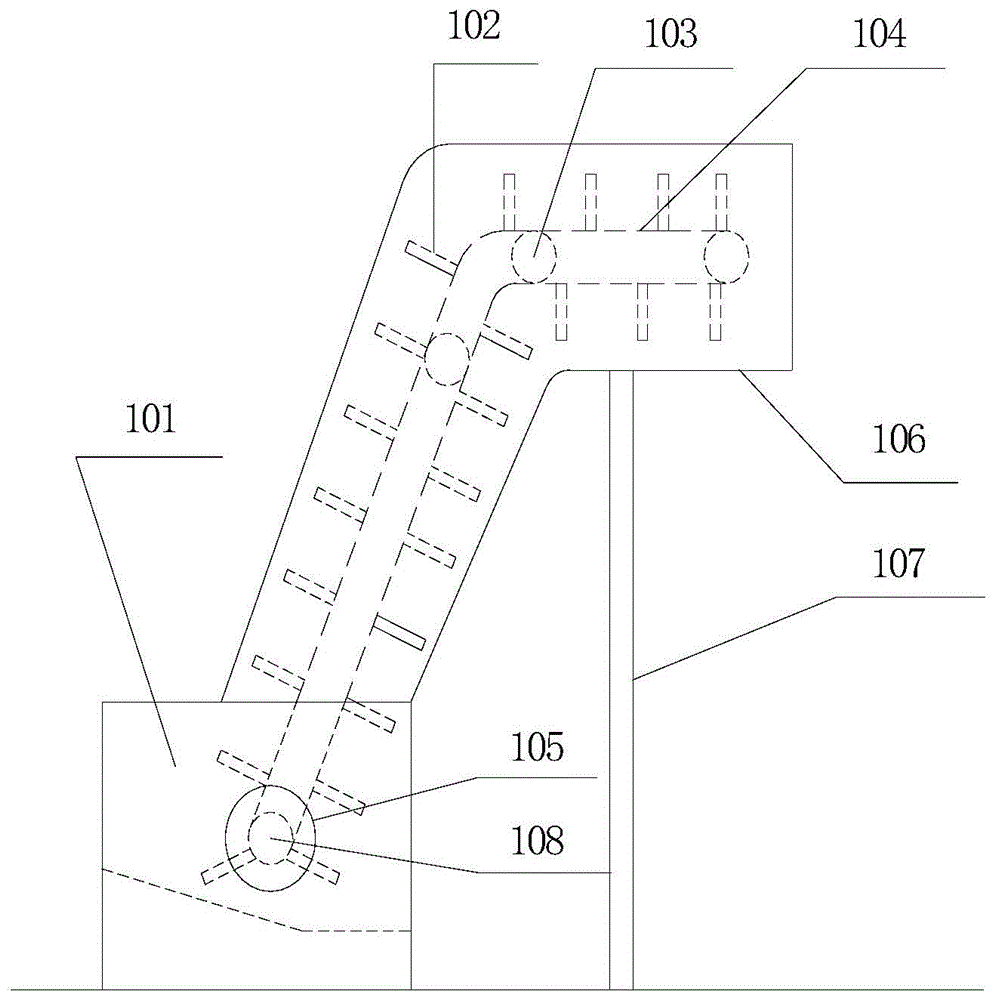

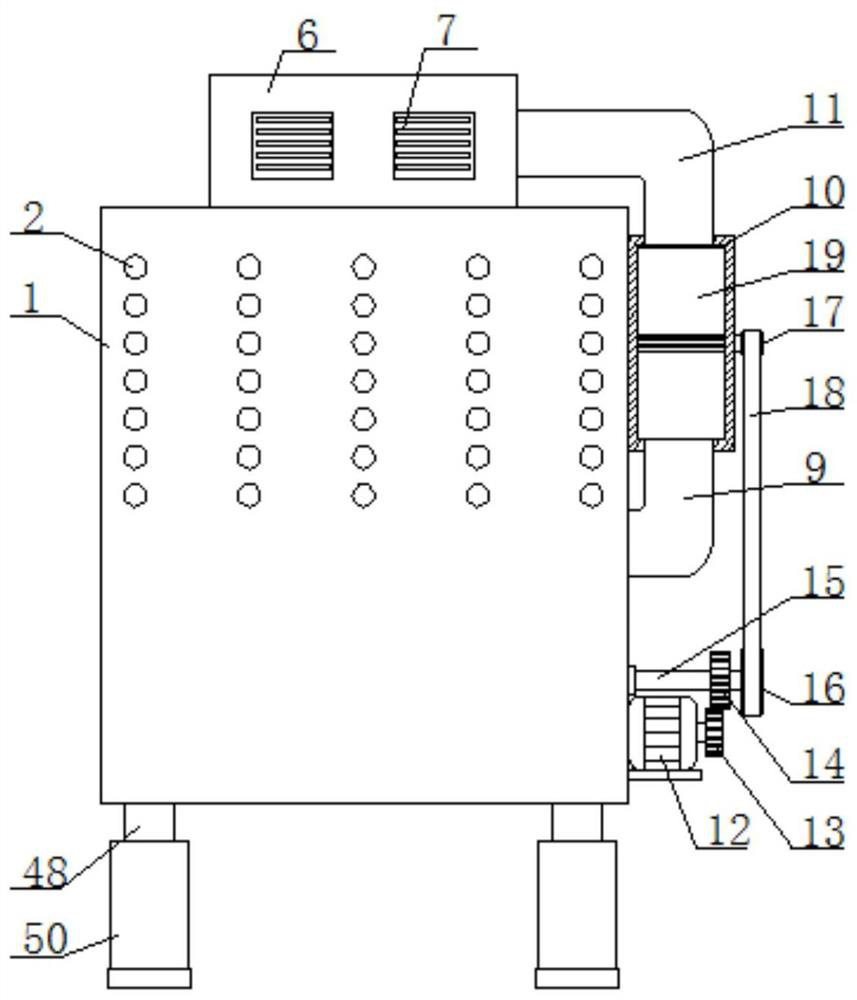

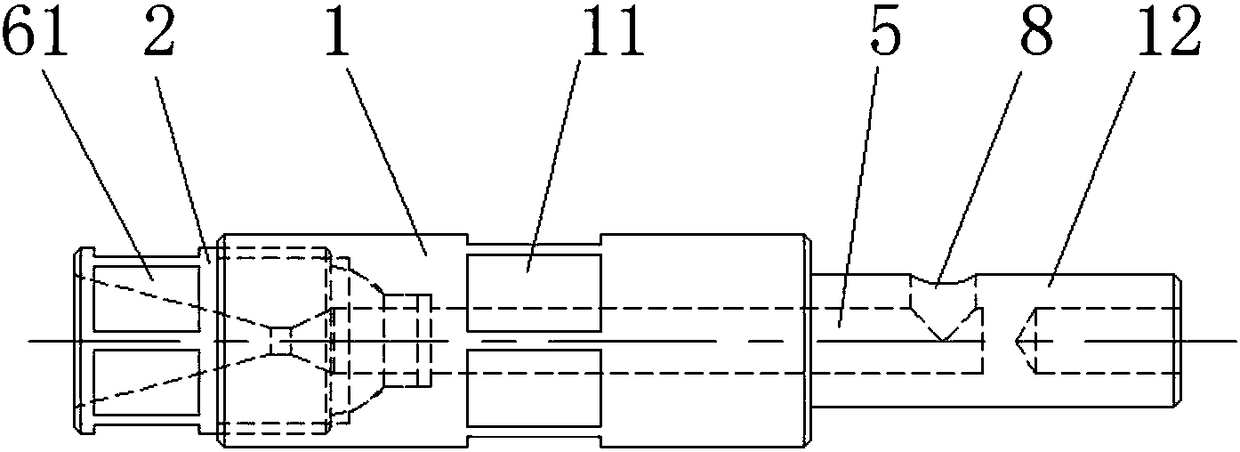

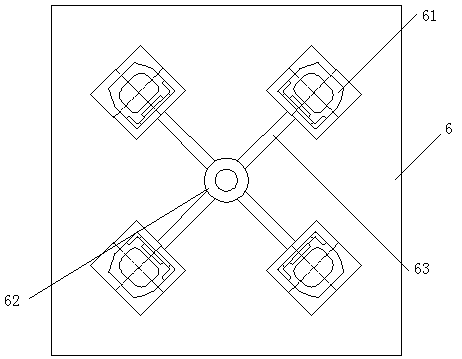

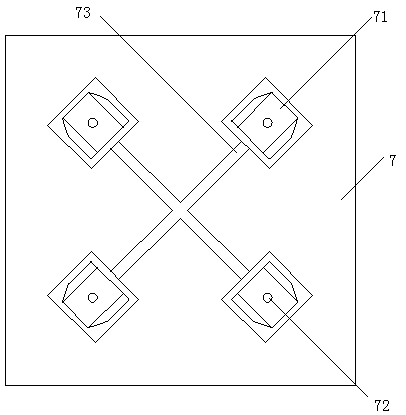

Energy-saving full-automatic four-axle horizontal tapping machine

ActiveCN104959682AConvenient feeding workReduce manufacturing costThread cutting feeding devicesThread cutting machinesOil distributionCoolant

The invention discloses an energy-saving full-automatic four-axle horizontal tapping machine, comprising a rack, a discharging device, an engine body protective cover, an arrangement device, a coolant oil circulating device, a control device, a pneumatic material pushing device, a tapping device, a material guiding device, and feeding devices. Through adding the coolant oil circulating device on a conventional four-axle horizontal tapping machine, the machine greatly reduces production cost of a nut tapping production process. Four oil distribution pipes of the machine are in a parallel structure, so phenomenon that flow of the four oil distribution pipes is not uniform is prevented. Through adding two feeding devices beside a conventional four-axle horizontal tapping machine, feeding operation of the conventional four-axle horizontal tapping machine is more convenient and easy. Through directly fixing the arrangement device on an arrangement device fixing boss, the arrangement device is fixed more firmly, and material feeding and guiding of the arrangement device are more accurate.

Owner:海盐机械设备制造有限公司

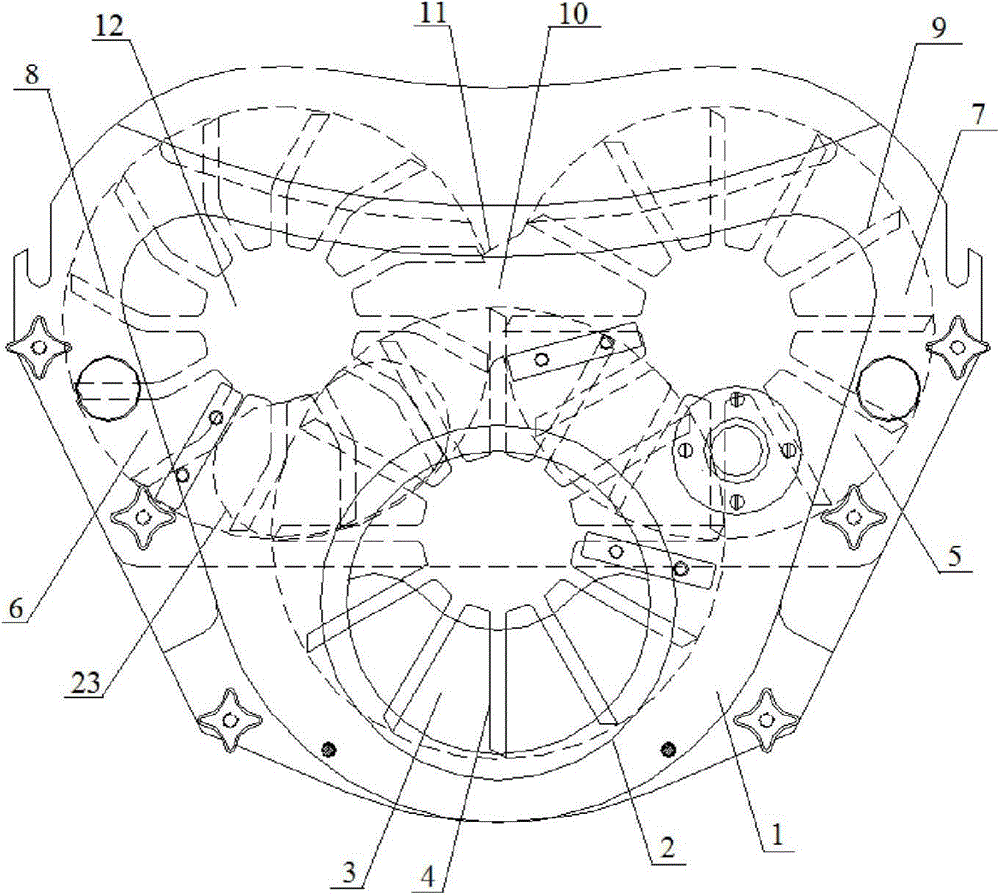

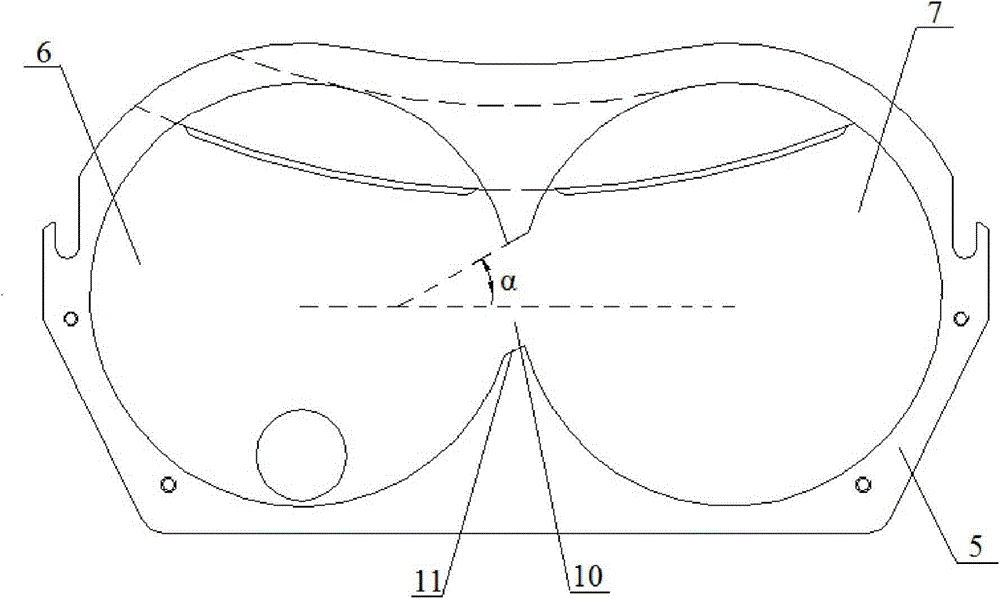

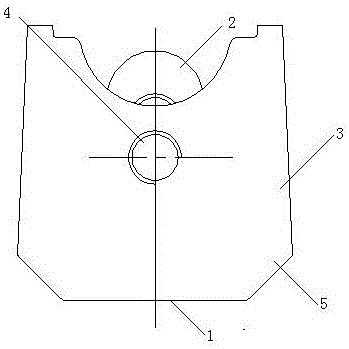

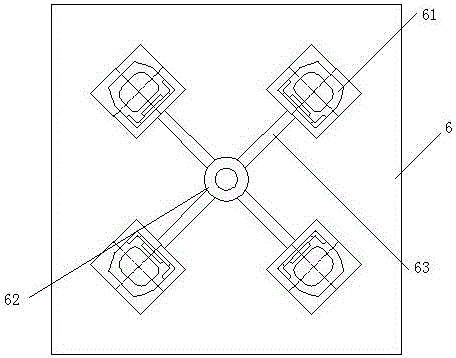

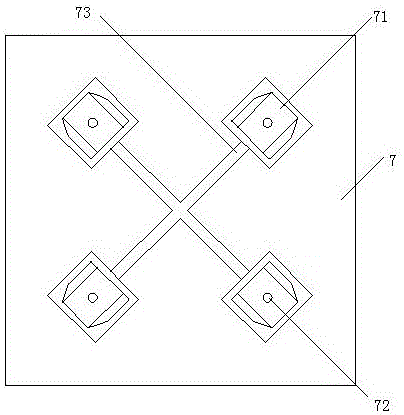

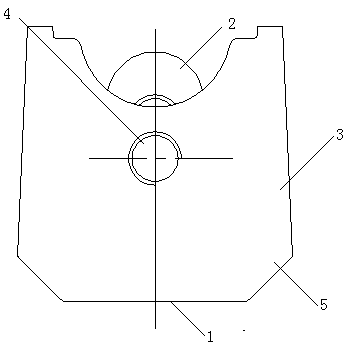

Die-casting forming die for bottom corner of antenna support

The invention relates to a die-casting forming die for a bottom corner of an antenna support. The die-casting forming die comprises an upper die body and a lower die body. Connecting section A grooves are obliquely and symmetrically formed in the four corners of the lower die body, a raised thread connecting hole structure A is arranged at the center of each connecting section A groove, and the two center connecting lines of the diagonal connecting section A grooves and the diagonal lines of the lower die body are overlapped. Connecting bulges are obliquely and symmetrically arranged on the four corners of the upper die body, and the connecting bulges and the connecting section A grooves are matched to form die cavities of the bottom corner of the antenna support. Raised thread connecting structures B are arranged at the centers of the two sides in the diagonal line extending directions of the connecting bulges correspondingly, and the two center connecting lines of the diagonal connecting section bulges and the diagonal lines of the upper die body are overlapped. The die-casting forming die has the advantages that a plurality of products can be produced through the die, thus the production efficiency of the products is improved, meanwhile, the utilization rate of the die is also increased, and the production cost can be reduced greatly; and meanwhile, uniform force-bearing is also guaranteed, and the quality of the products is improved.

Owner:江苏中伟业通讯设备有限公司

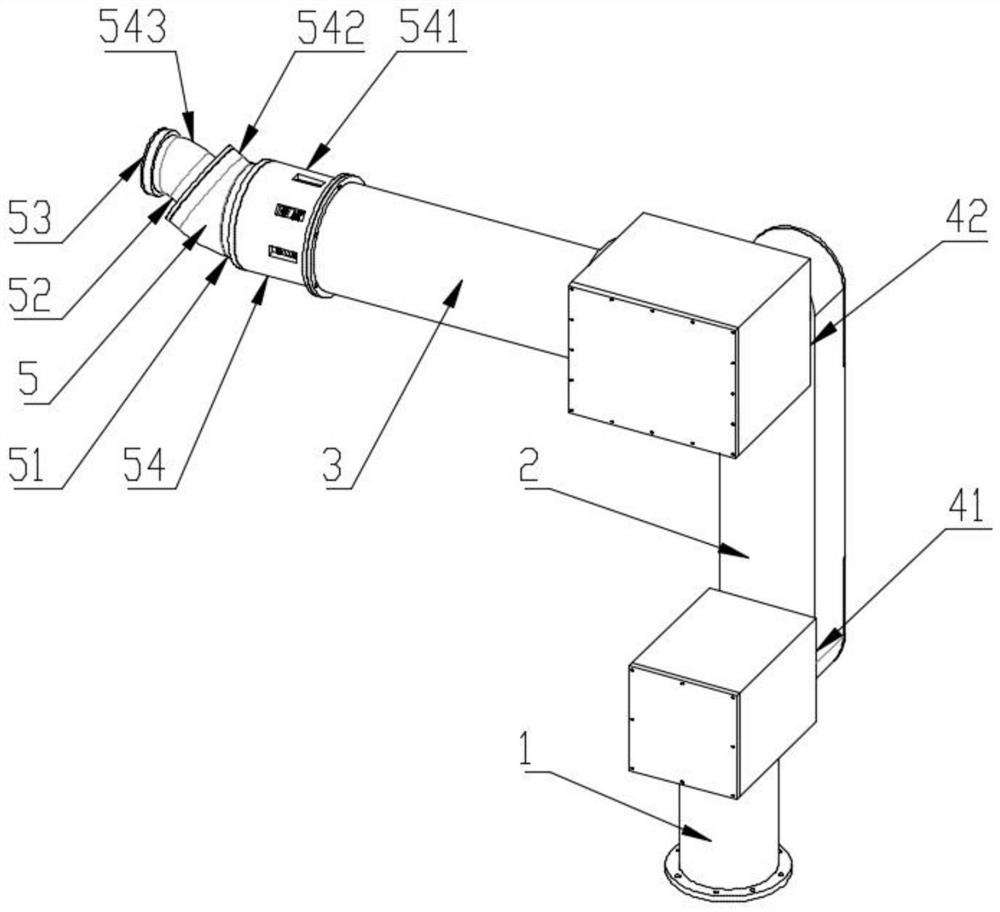

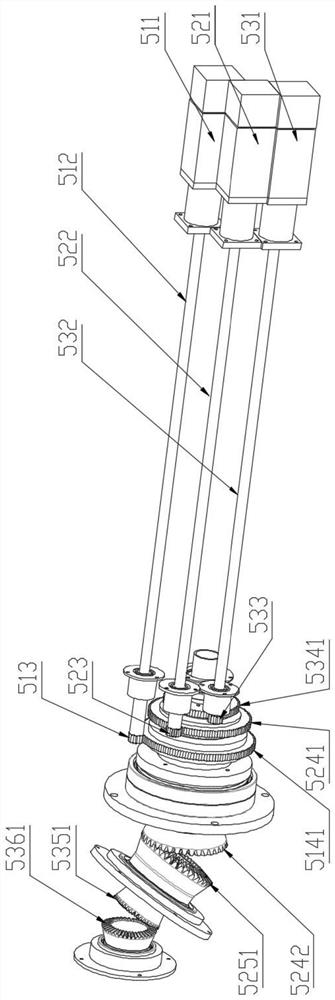

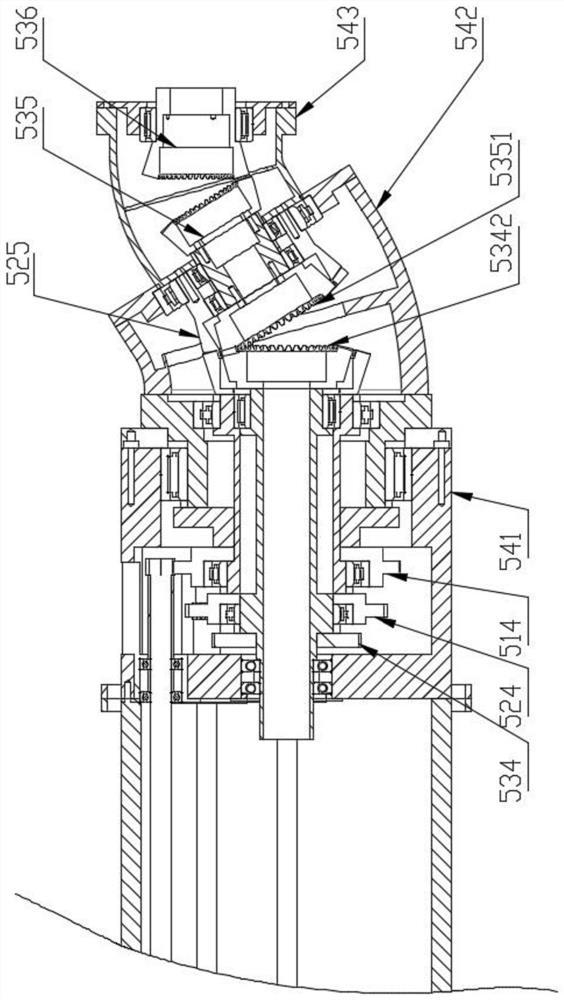

Wrist structure of spraying robot

ActiveCN112894772AIncrease coverageGood exercise flexibilityProgramme-controlled manipulatorJointsControl engineeringStructural engineering

The invention discloses a wrist structure of a spraying robot, and relates to the technical field of spraying robots. The front end of a large arm is rotationally connected with a support through a first connecting part to form a two-degree-of-freedom revolute pair; the tail end of the large arm is rotationally connected with a small arm through a second connecting part to form a one-degree-of-freedom revolute pair; the structure further comprises a wrist mechanism installed at the tail end of the small arm through the second connecting part; wrist joints comprise a first joint, a second joint, a third joint and a shell structure which are independently driven and move; and a three-degree-of-freedom rotation pair is formed in total. According to the invention, the axes of revolute pairs of the first joint, the second joint and the third joint of the wrist structure have no common intersection point and are in a novel oblique-crossing non-spherical motion mode; each joint is independently driven and transmitted; circumferential rotation can be achieved respectively; the motion flexibility is good; the motion trail coverage is comprehensive; and the device is particularly suitable for spraying operation of large components in narrow and complex environments.

Owner:HEFEI UNIV OF TECH

Method for punching dovetail groove in front surface of lead frame of semiconductor

ActiveCN105575822AAvoid uneven flowAvoid pittingSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

The invention discloses a method for punching a dovetail groove in the front surface of a lead frame of a semiconductor, and relates to the technical field of manufacturing of electronic components of the semiconductor. The method comprises the following contents: (A) processing and fabricating a lead frame blank, precutting two sides of the lead frame blank once and punching a strip-shaped hole in each of two sides of the lead frame blank; (B) pressing a rectangular groove, namely pressing materials through a mold and vertically extruding the lead frame blank with a convex mold I with a rectangular section to obtain a rectangular groove with the rectangular section; (C) punching the dovetail groove, namely vertically extruding the central position of the rectangular groove molded in the previous step with a convex mold II with a concave arc top part in the section and molding the dovetail groove; (D) precutting the dovetail groove, namely cutting off excessive materials at two sides of the dovetail groove; and (E) accurately cutting the dovetail groove, namely accurately cutting two ends of the dovetail groove. Through the steps, the dovetail groove with good strength and an optimal structure is obtained; and meanwhile, the problem of poor flatness of the surface after the dovetail groove is formed in the lead frame of the semiconductor is solved.

Owner:SICHUAN JINWAN ELECTRONICS

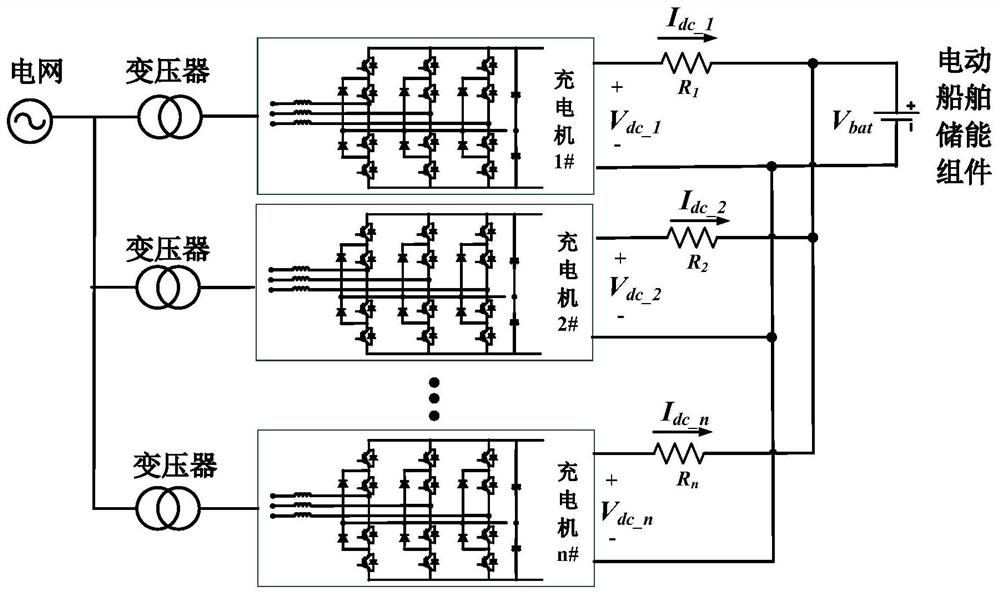

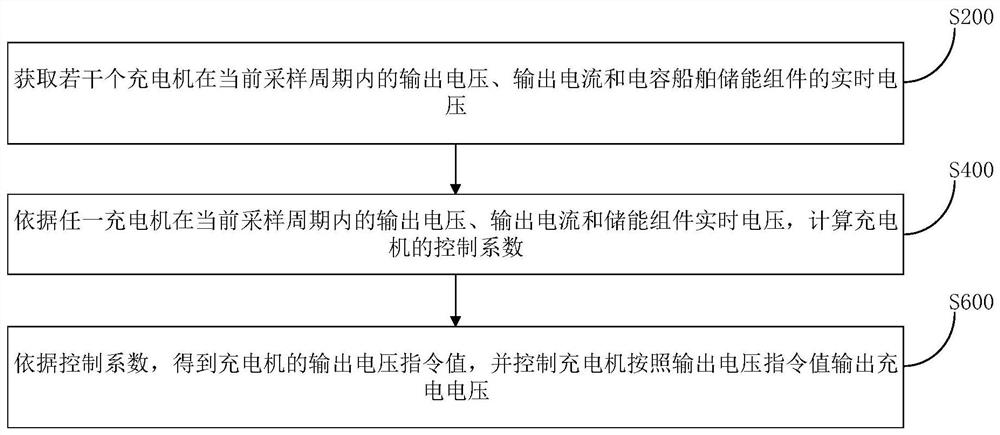

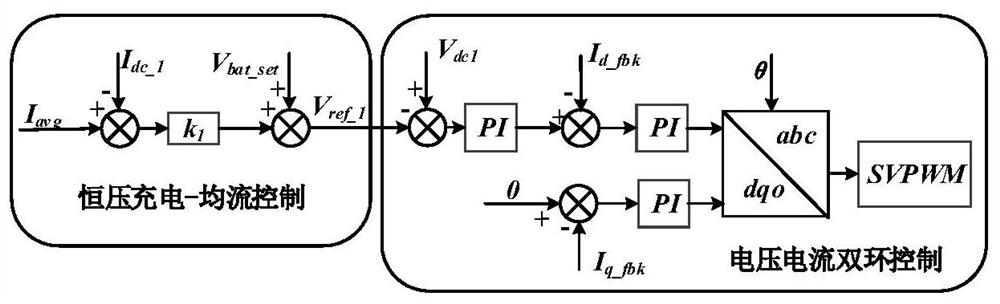

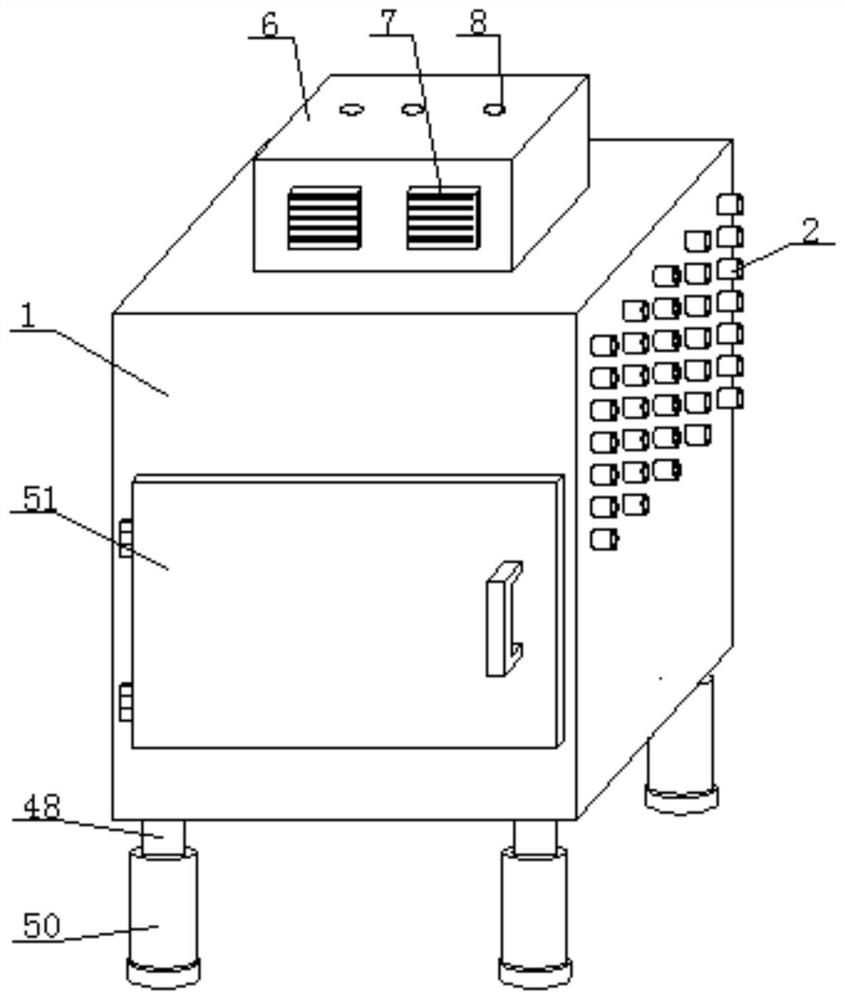

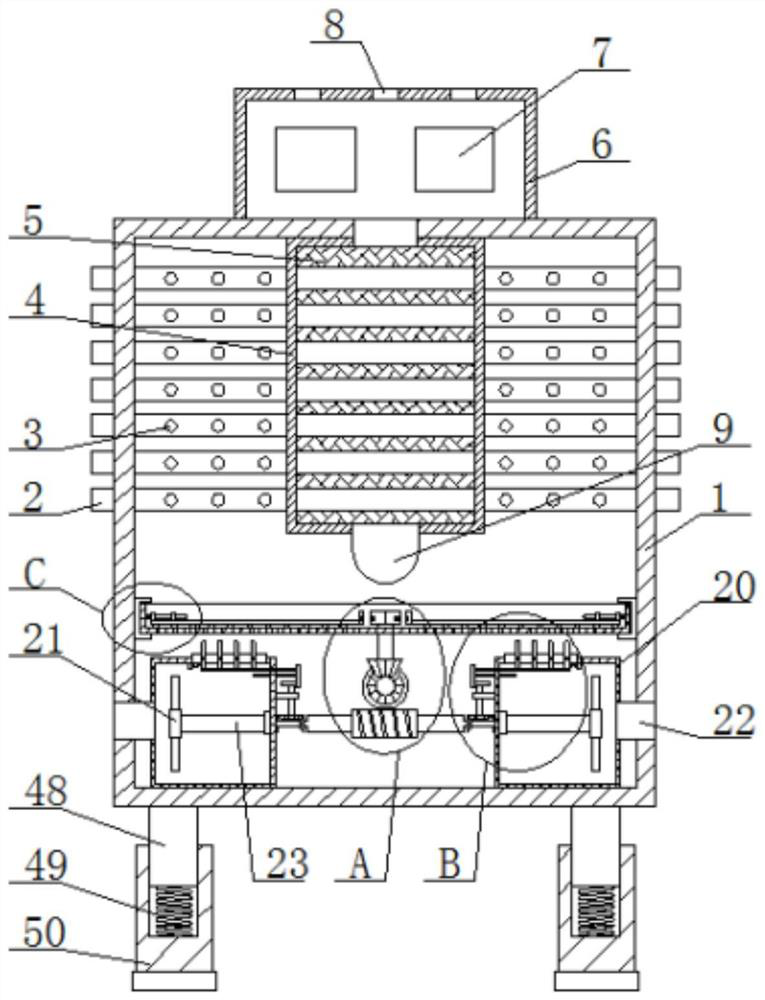

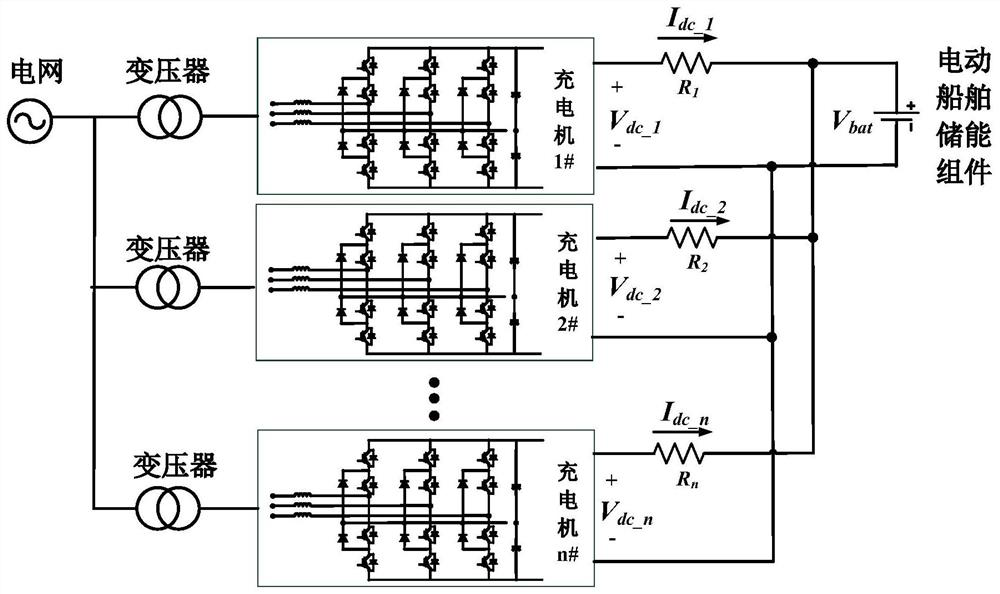

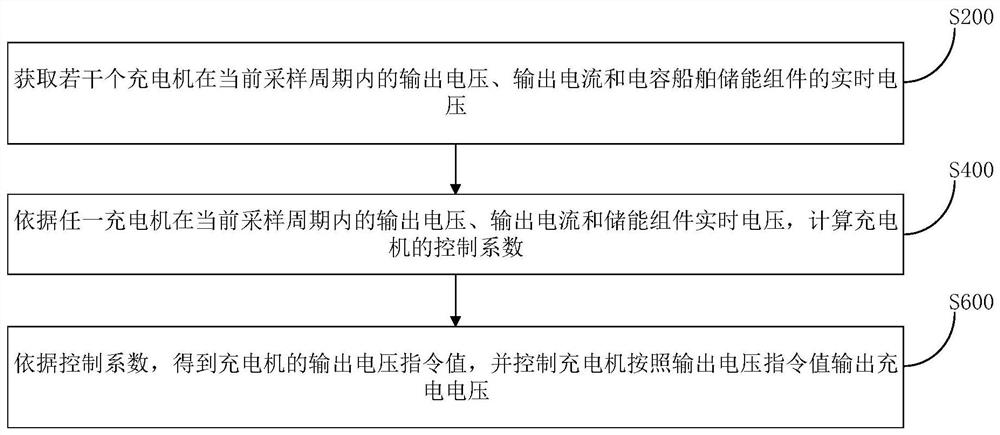

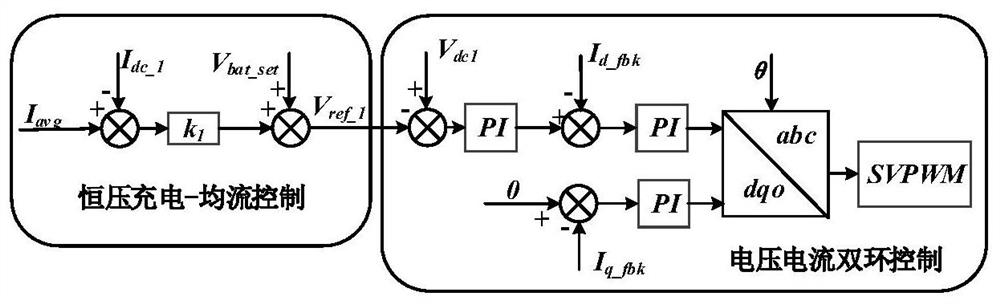

Multi-machine parallel constant-voltage current-sharing control method and device for electric ship chargers

ActiveCN111791738AAvoid circulationAvoid uneven flowBatteries circuit arrangementsCharging stationsCharge currentElectrical battery

The invention discloses a multi-machine parallel constant-voltage current-sharing control method for electric ship chargers. The method comprises the steps of acquiring output voltages and output currents of a plurality of chargers in a current sampling period and a real-time voltage of an electric ship energy storage assembly; calculating a control coefficient of any charger according to the output voltage and the output current of the charger in the current sampling period and the real-time voltage of the energy storage assembly; and obtaining an output voltage instruction value of the charger according to the control coefficient, and controlling the charger to output the charging voltage according to the output voltage instruction value. The invention further discloses a multi-machine parallel constant-voltage current-sharing control device for the electric ship chargers. The control coefficient of each charger is obtained by detecting the output voltages and the output currents ofthe plurality of chargers and the battery voltage of the electric ship energy storage assembly, and then the output voltage instruction value of the charger is adjusted, so that the output current ofthe plurality of chargers tends to the average charging current, and the loop current and the non-uniform current among the plurality of chargers are avoided.

Owner:XIAN XJ POWER ELECTRONICS TECH +3

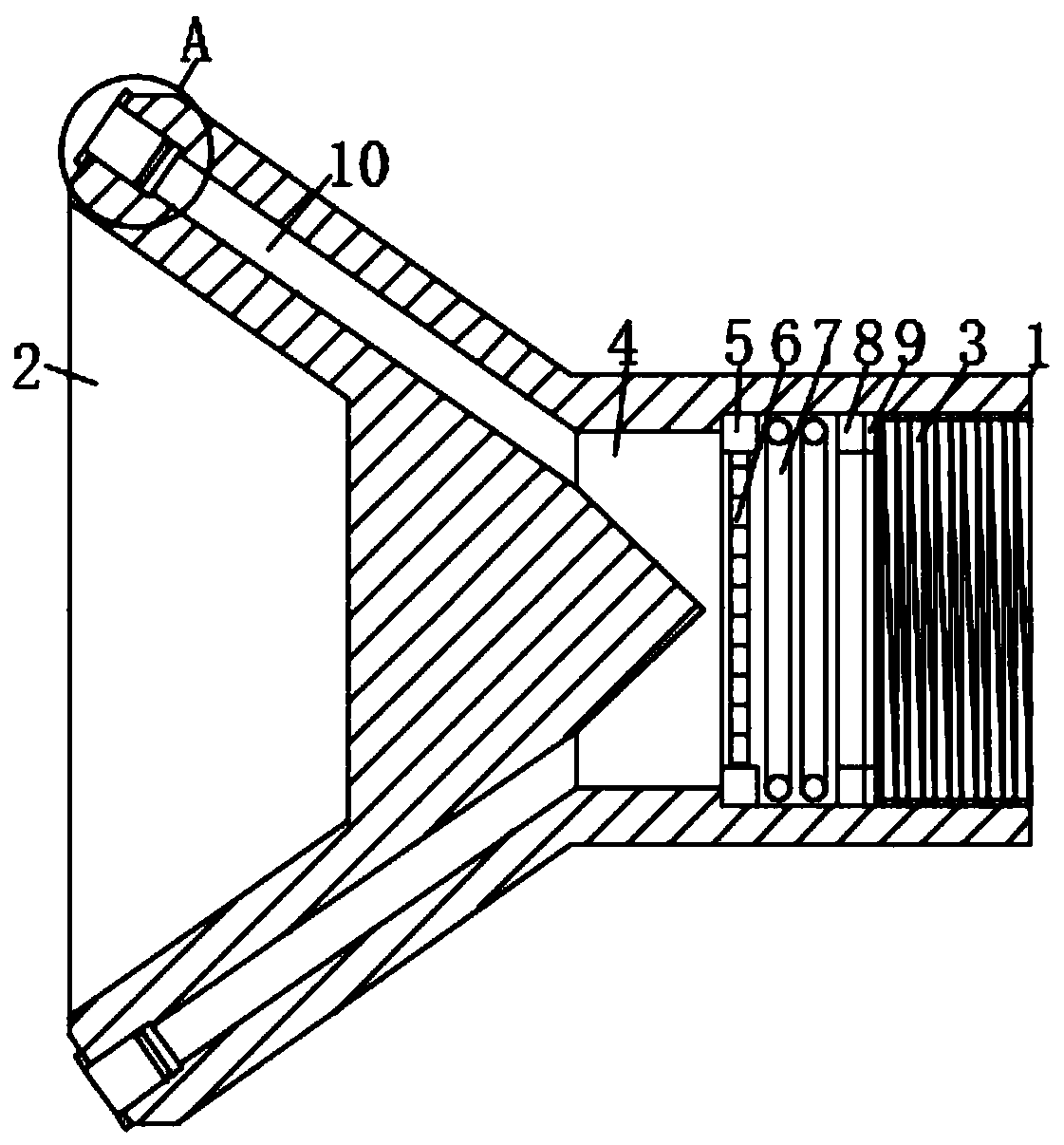

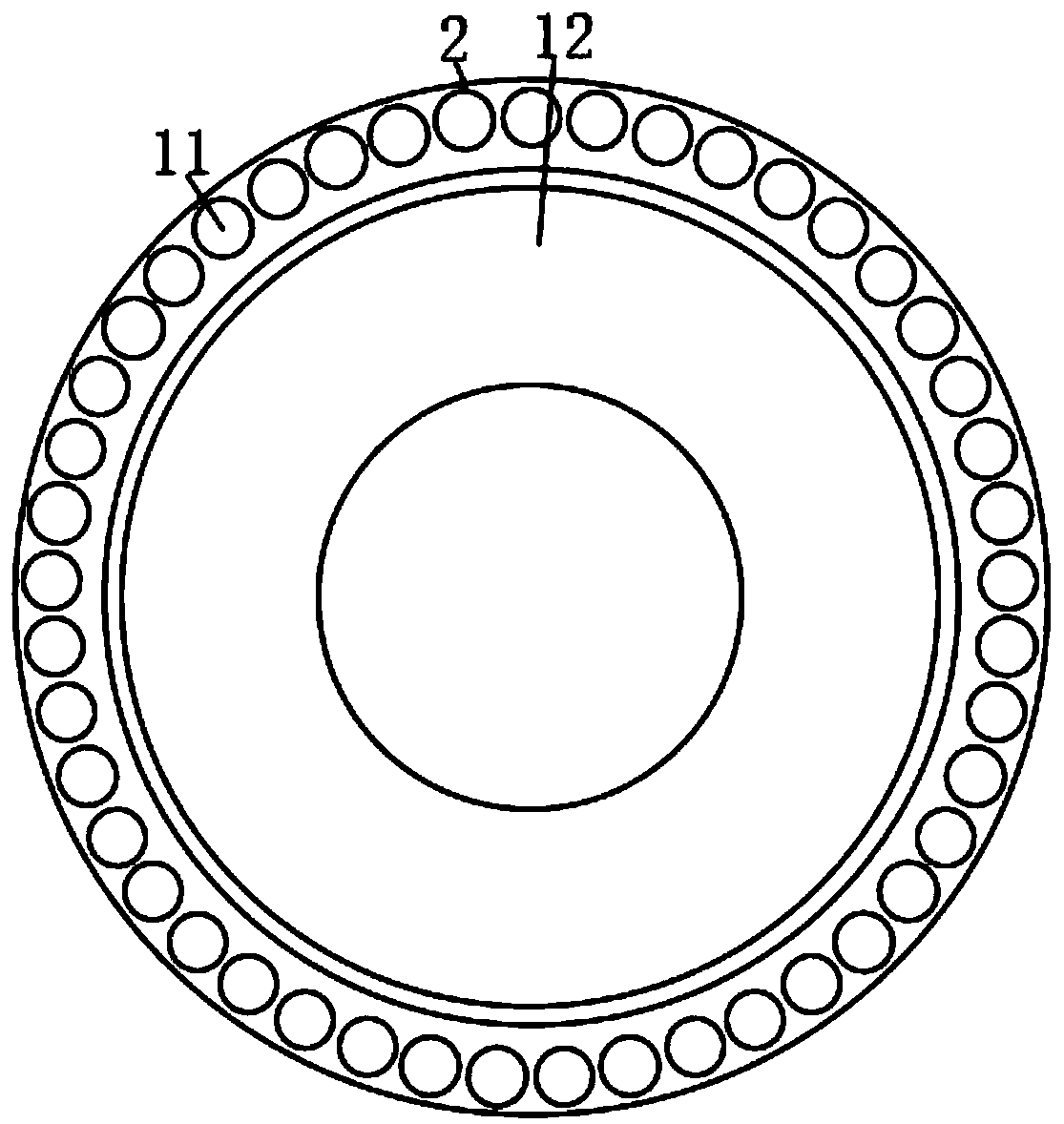

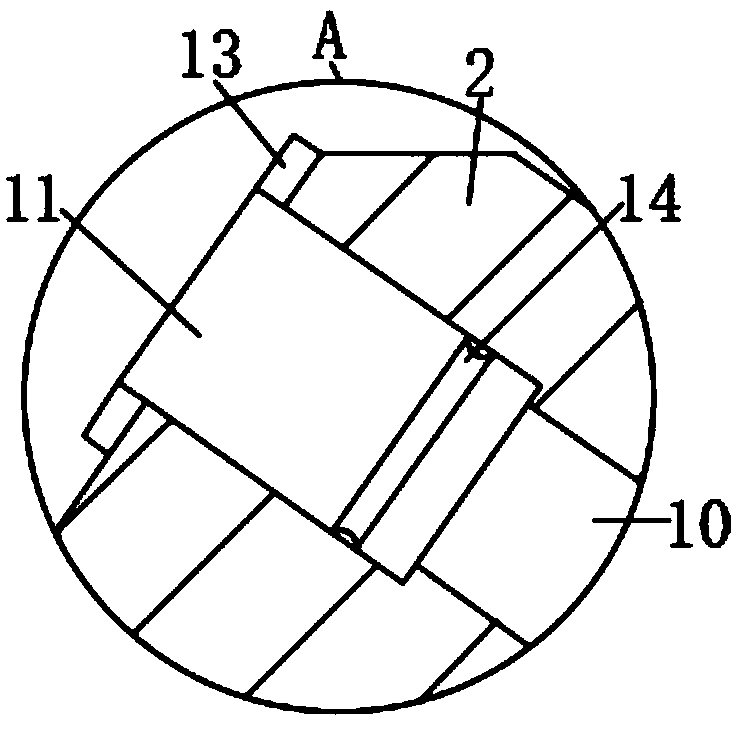

Suction cooling device for production of polyester and nylon composite filaments

ActiveCN113669988AUniform coolingImprove cooling effectTextile/flexible product manufactureMachines using electric/magnetic effectsPolyesterEngineering

The invention belongs to the technical field of cooling of polyester and nylon composite filaments, particularly relates to a suction cooling device for production of polyester and nylon composite filaments. The problems that an existing suction cooling device is poor in refrigeration effect and cannot perform dust collection and environmental protection on the composite filaments are solved. According to the following scheme, the suction cooling device comprises a refrigeration cabinet, and a box cover is rotationally mounted on the front surface of the refrigeration cabinet; a plurality of wire guide pipes are arranged in the refrigeration cabinet, a cooling box is arranged in the refrigeration cabinet, the wire guide pipes are all located in the cooling box, the cooling box is filled with heat preservation cotton, and the outer sides of the wire guide pipes are wrapped with the heat preservation cotton; and a plurality of air holes are formed in the outer sides of the wire guide pipes, the air holes are all located in the outer side of the cooling box, the top of the cooling box communicates with a refrigeration mechanism, the outer side of the refrigeration cabinet communicates with an air suction cylinder, and a propeller is rotationally installed in the air suction cylinder. The suction cooling device is convenient to operate, the refrigeration effect is improved, cooling is uniform, dust collection can be carried out on the composite filaments, and dust collection and environmental protection are carried out.

Owner:苏州申久高新纤维有限公司

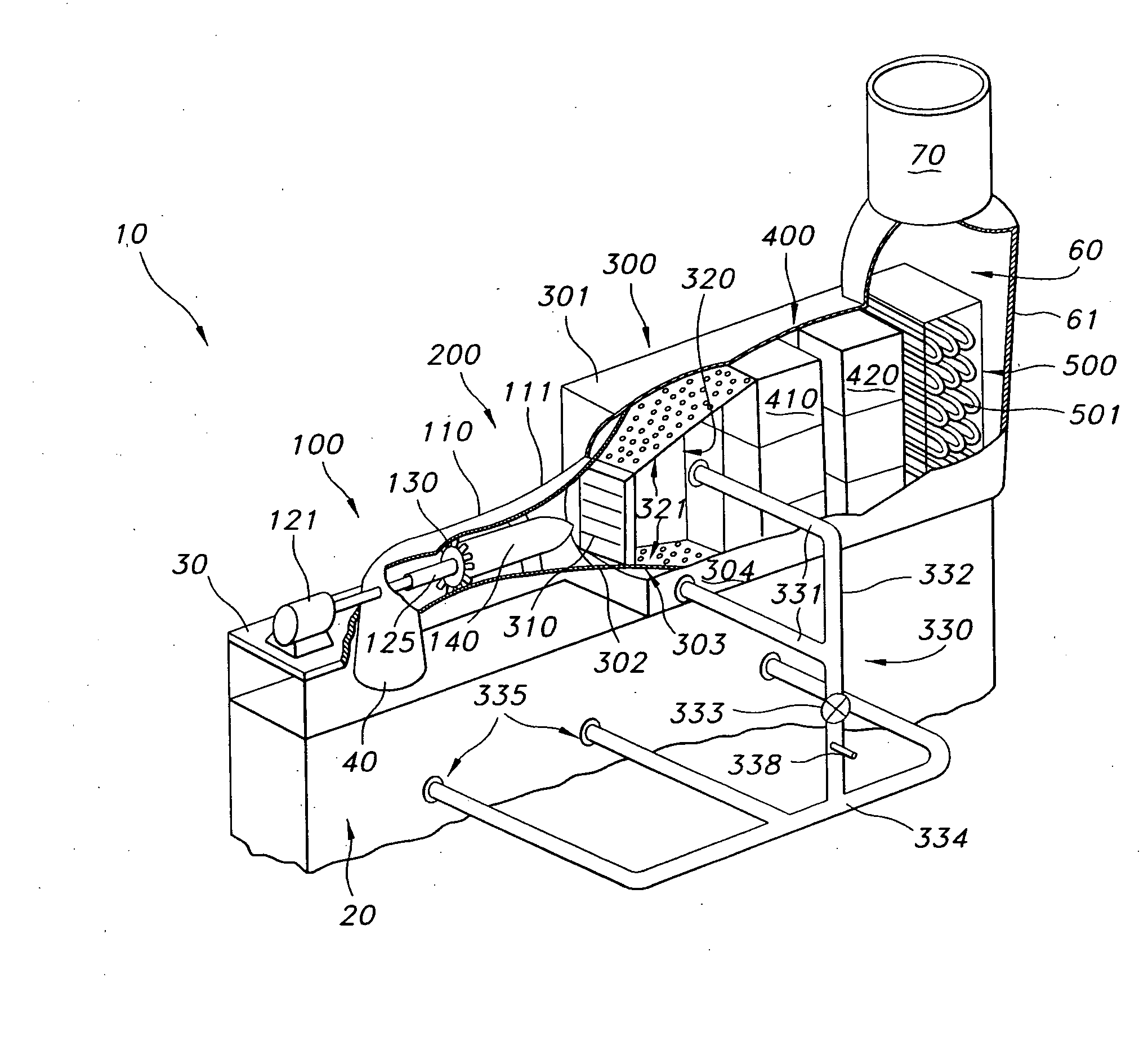

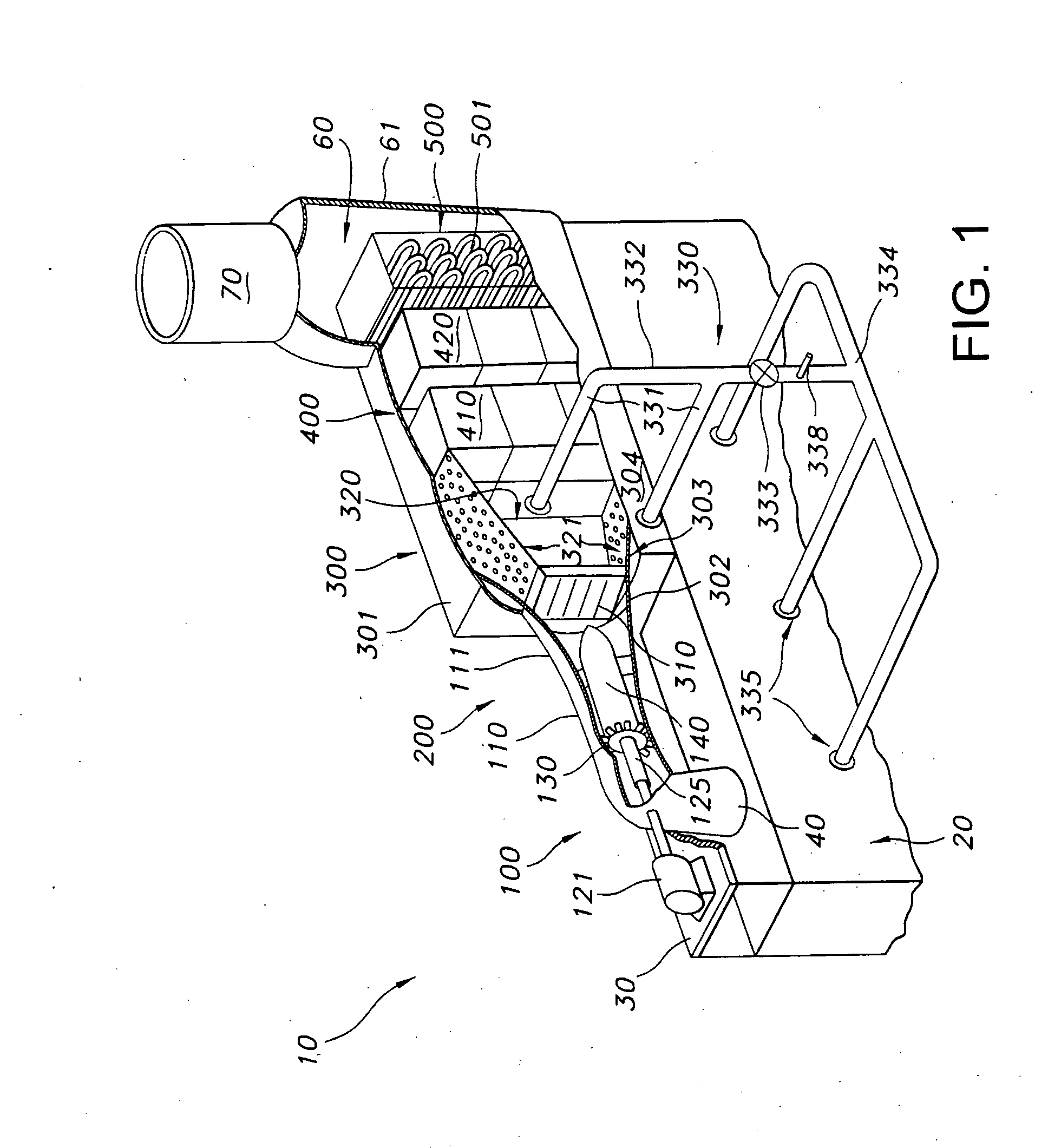

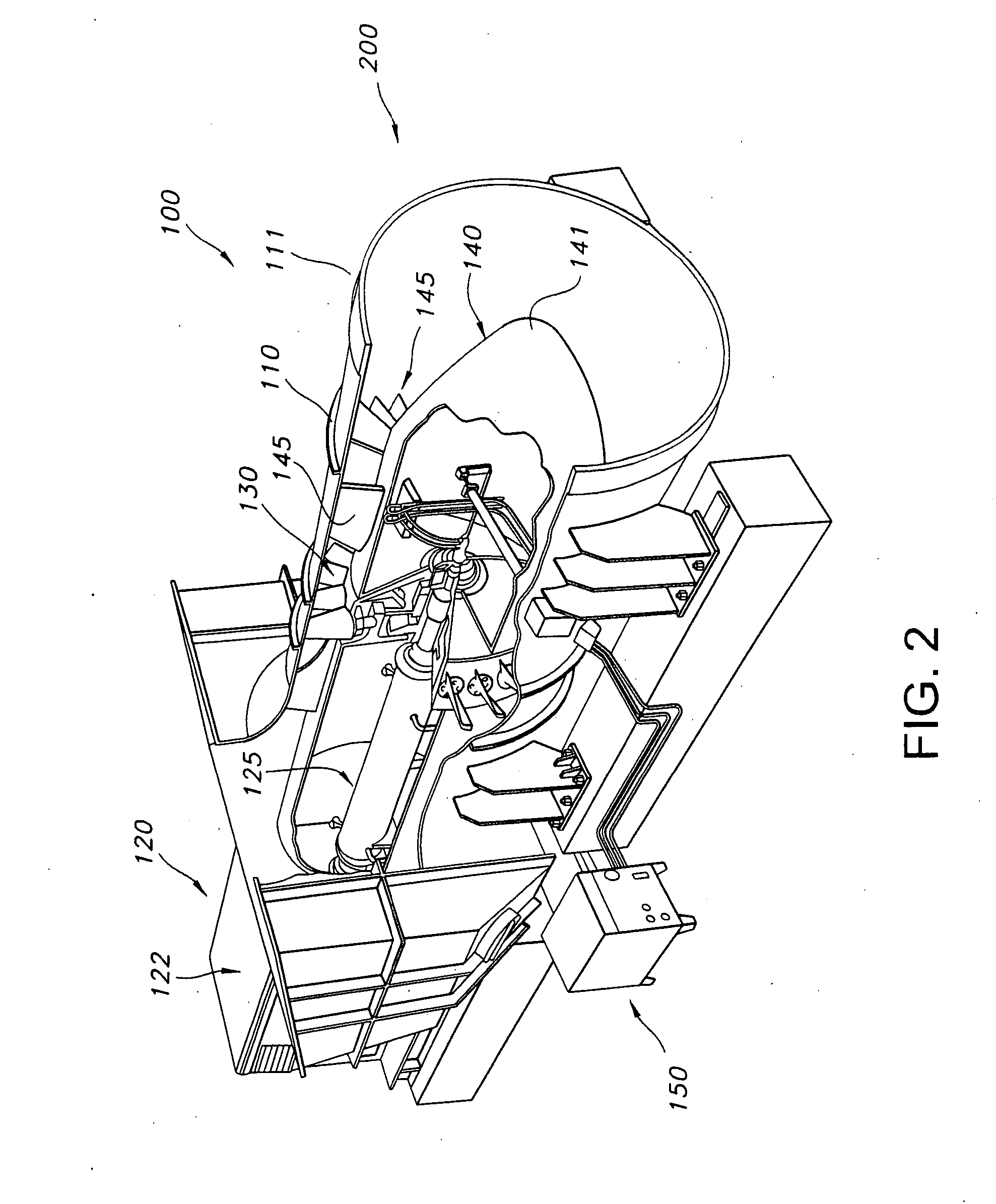

Modular system and method for the catalytic treatment of a gas stream

InactiveUS20080081010A1Shorten speedImproves airflow uniformityCombination devicesGas treatmentImpellerGas phase

A system for catalytically treating a gas stream includes a gas phase reactor containing a catalyst for the treatment of the gas stream in at least one catalyst bed having an upstream end and a downstream end, an axial fan positioned upstream of the at least one catalyst bed and having an impeller for moving the gas stream through the gas phase reactor. The gas flow is modified between the impeller and the gas phase reactor to decrease gas stream velocity and increase gas flow uniformity.

Owner:KARRS MARK +1

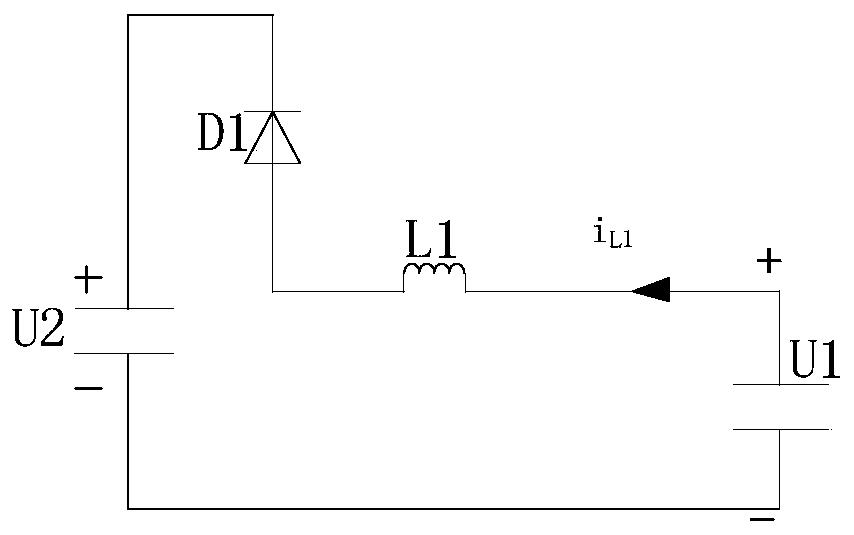

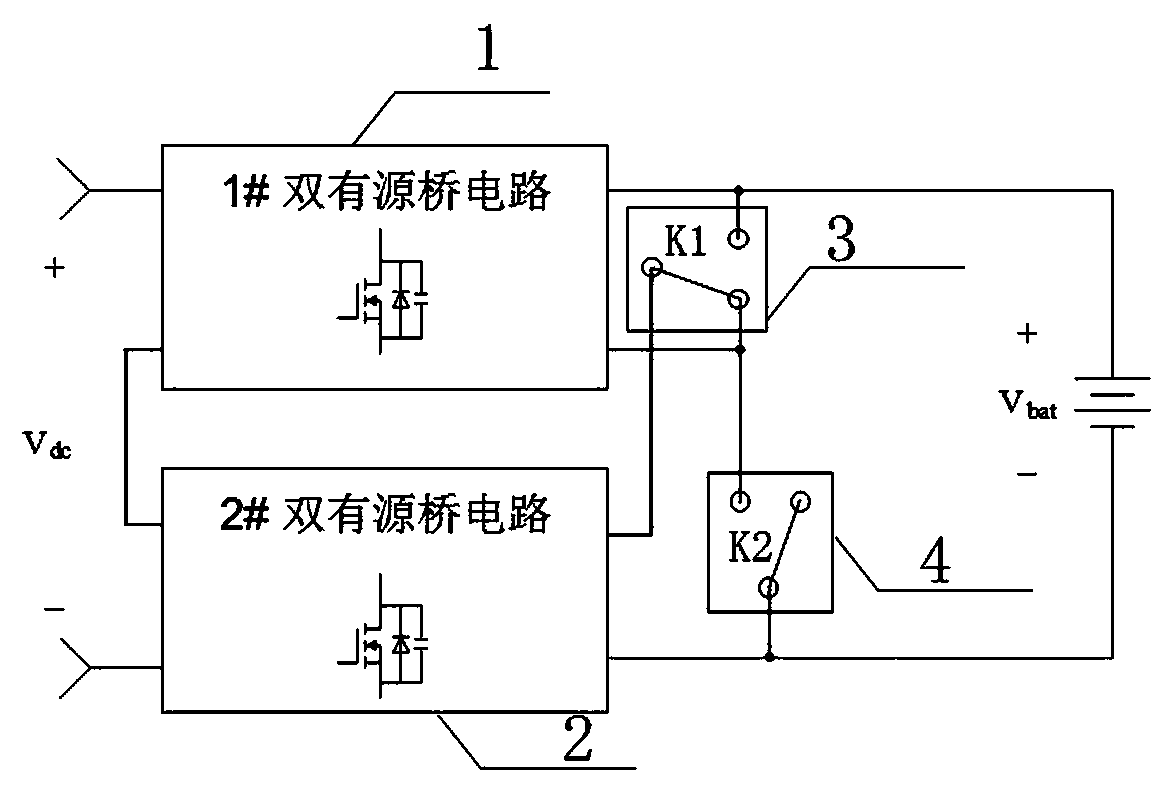

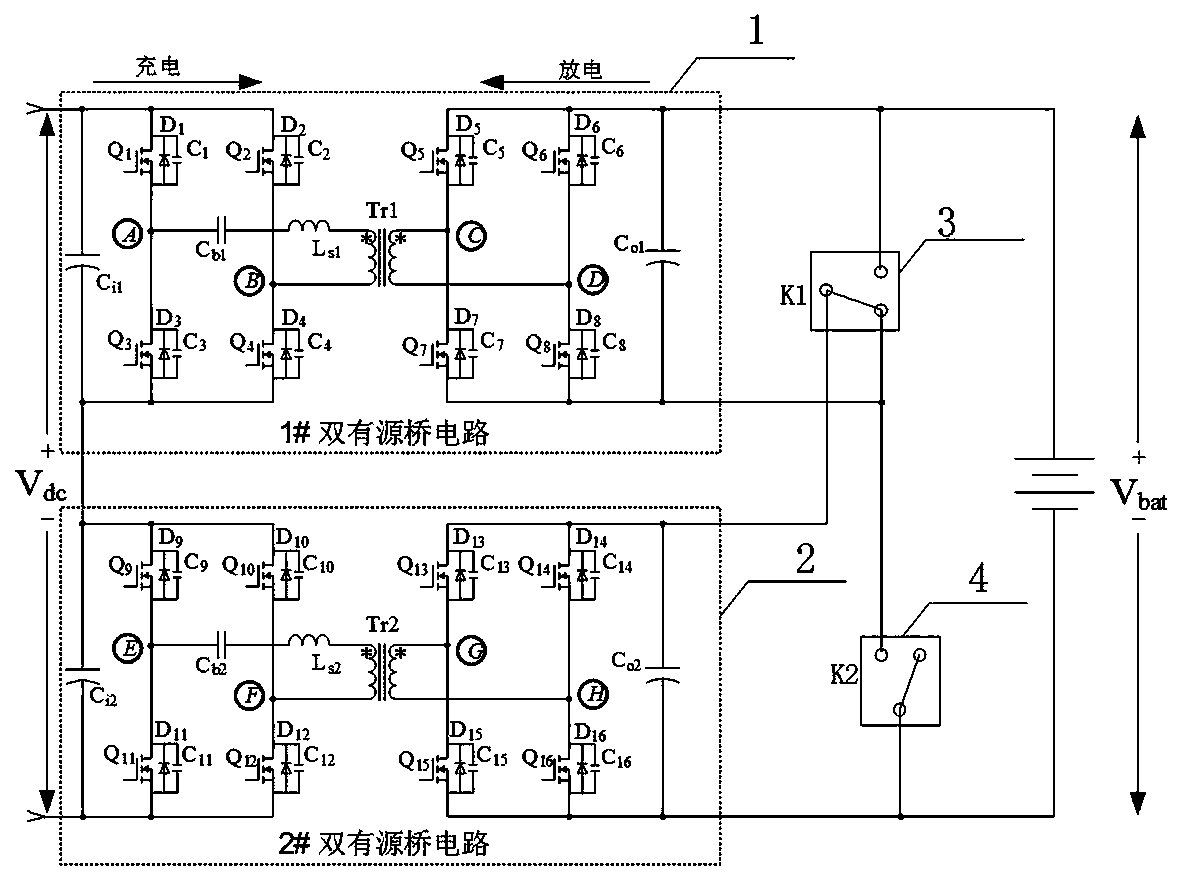

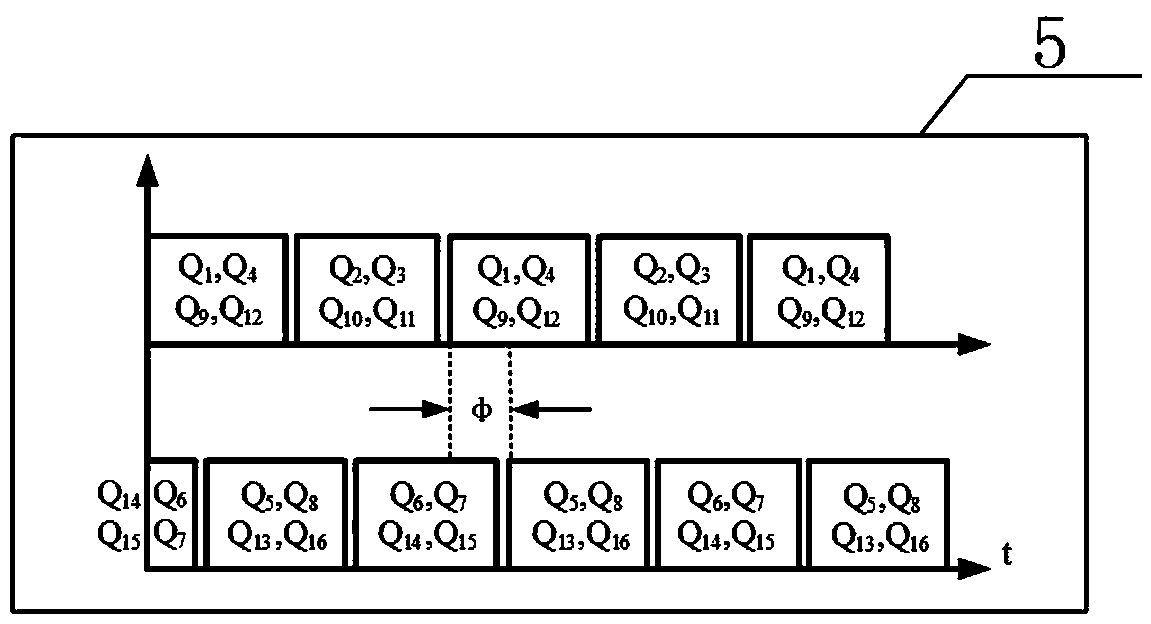

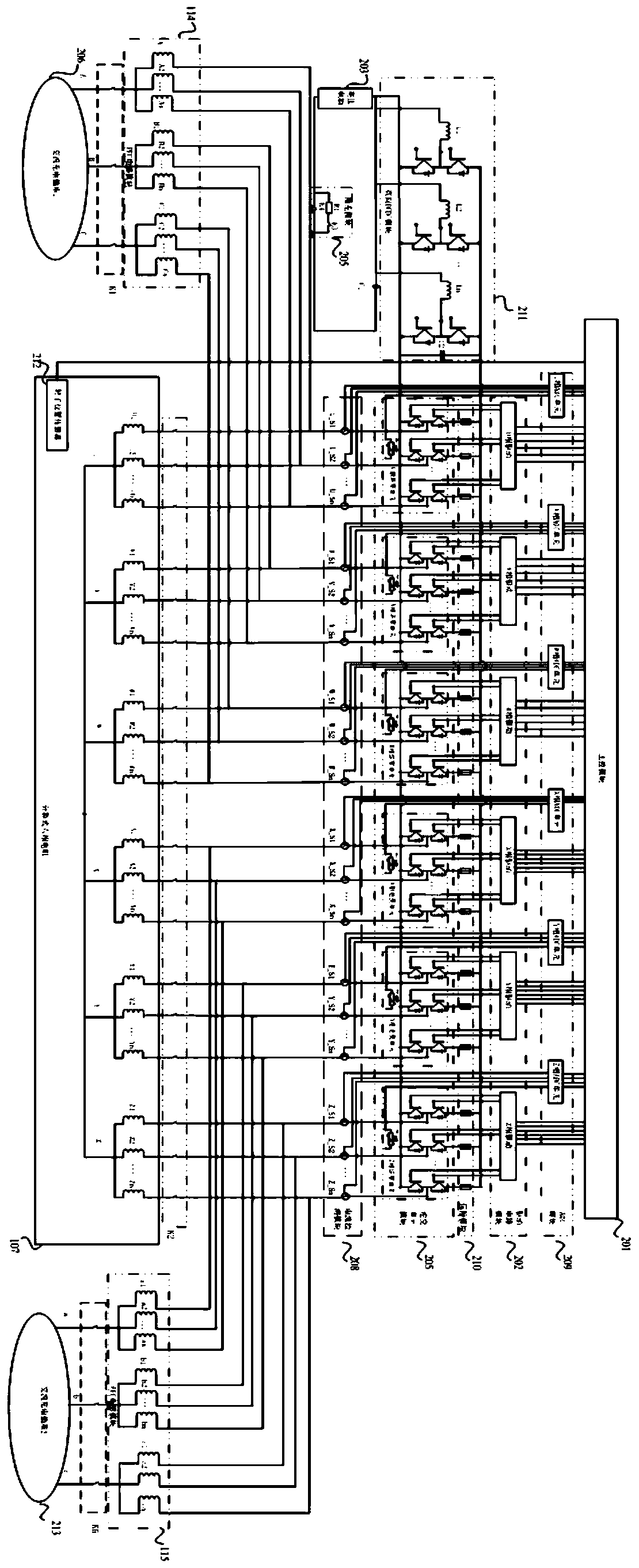

Bidirectional DC-DC circuit topology structure and control method in bidirectional charger

InactiveCN109768710AAvoid uneven pressureAvoid uneven flowBatteries circuit arrangementsDc-dc conversionOpen contactHigh pressure

The invention discloses a bidirectional DC-DC circuit topology structure in a bidirectional charger in the field of chargers. The bidirectional DC-DC circuit topology structure in the bidirectional charger comprises two dual active bridge circuits and two relays; the input sides of the first dual active bridge circuit and the second dual active bridge circuit are connected in series and then connected to a high-voltage DC side; one end output of the first dual active bridge circuit is connected to a normally open contact of the first relay and is connected to a positive pole of a battery; theother end output of the first dual active bridge circuit is connected to a normally closed contact of the first relay; one end output of the second dual active bridge circuit is connected to a commonterminal of the first relay, and the other end output of the second dual active bridge circuit is connected to the common terminal of the second relay and connected to the negative pole of the battery; and the normally closed contact of the first relay is connected to the normally open contact of the second relay. The invention adopts two dual active bridge circuits to connect in series on the high-voltage DC side, and then connects the battery after realizing series or parallel connection of the output ends through the control relays; therefore, the cost is reduced, and the power conversion efficiency is improved.

Owner:YANGZHOU UNIV +1

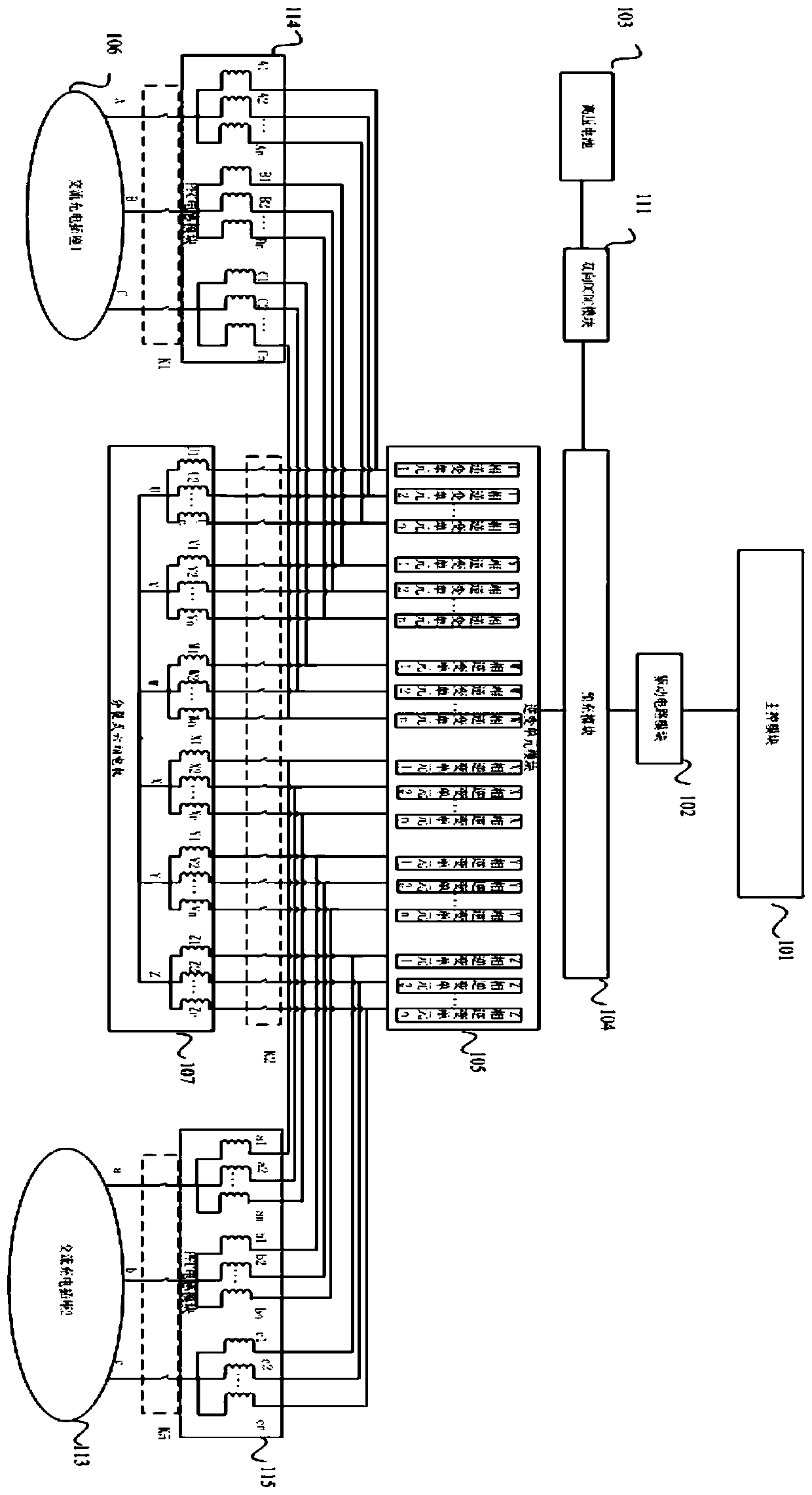

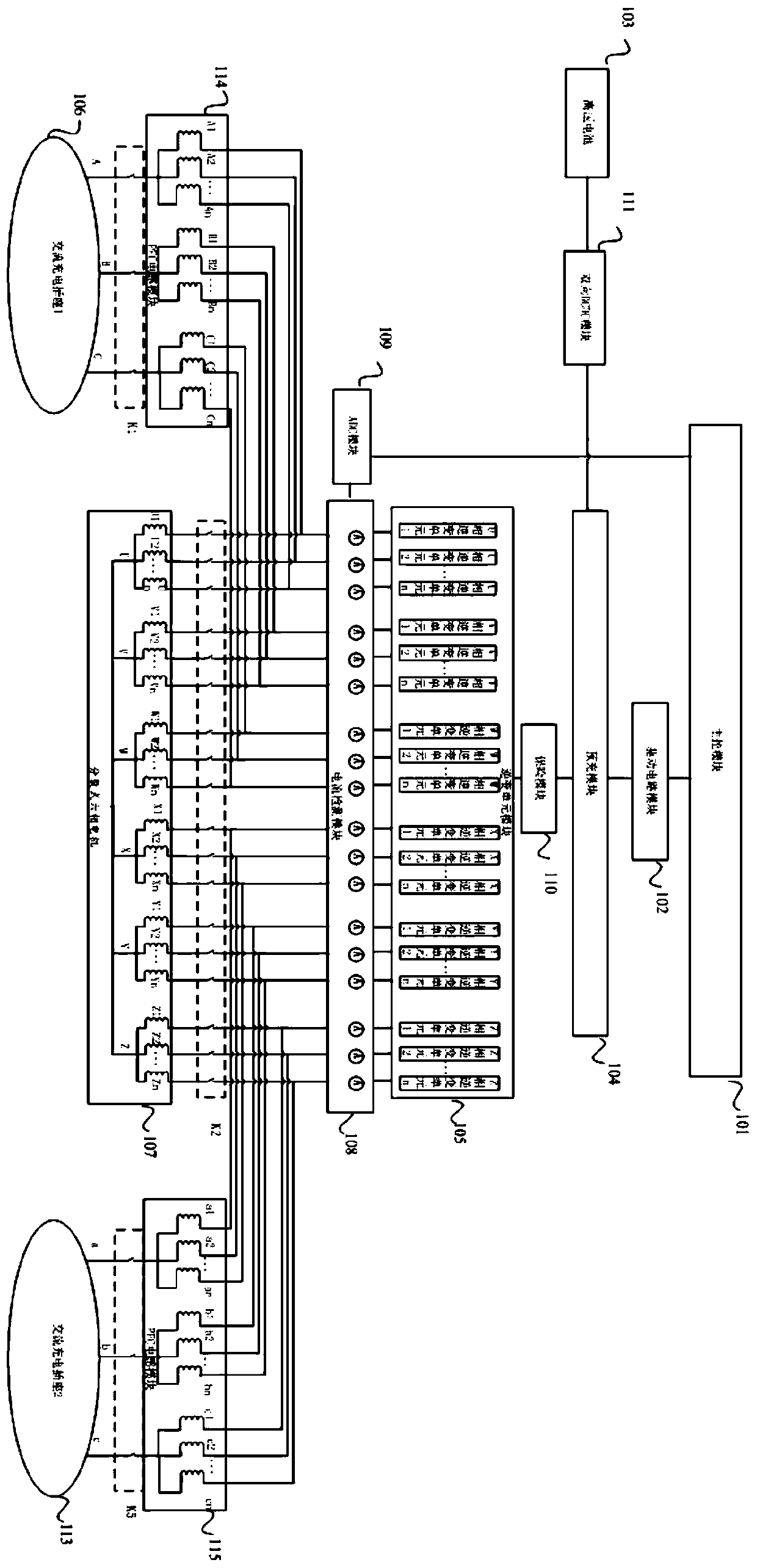

Split type six-phase motor control system integrated with alternating current charging and method thereof

PendingCN110957957AAvoid uneven flowAvoid reliabilityBatteries circuit arrangementsAC motor controlElectric machineControl system

The invention discloses a split type six-phase motor control system integrated with alternating current charging. The system comprises a main control module, a driving module, a direct current module,a pre-charging module, an inversion unit module, a split type six-phase motor and a PFC inductance module connected to an alternating current socket. An alternating current charging port and a splittype six-phase motor port of the inversion unit module drive alternating current to input voltage signals to control a six-phase motor, and the inversion unit module is electrically connected with thealternating current socket through the PFC inductance module. According to the control method disclosed by the invention, a quick charging method of the alternating-current charging is adopted, and quick electric quantity input of the six-phase motor is realized through shunting and converging control of the inversion unit, so that the purpose of quick charging of the electric automobile is achieved.

Owner:芜湖瑞来电子科技有限公司

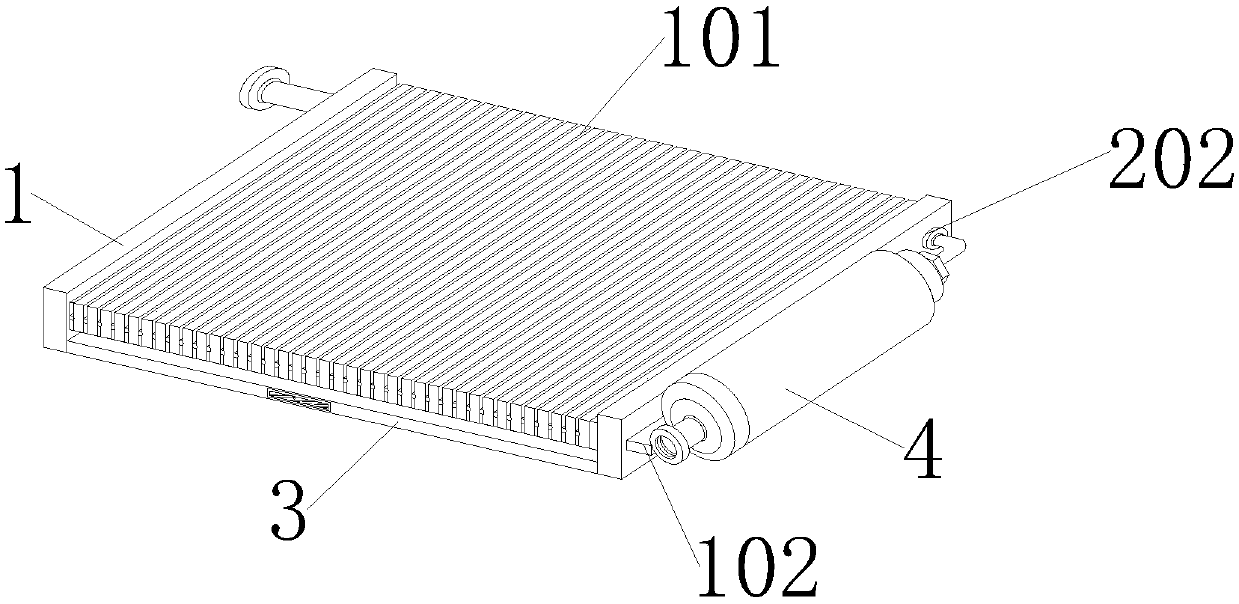

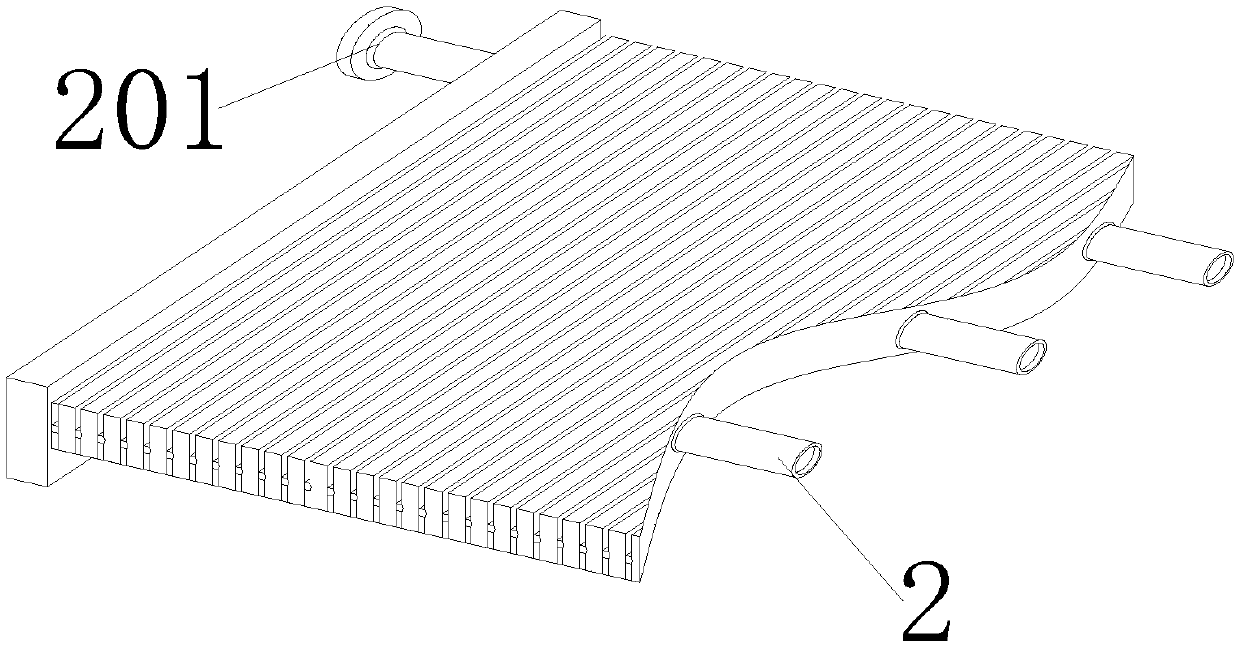

Electric car parallel flow condenser core

InactiveCN111306847AAvoid uneven flowPrevents emptying or even backflowEvaporators/condensersCorrosion preventionEngineeringStructural engineering

The invention provides an electric car parallel flow condenser core and relates to the technical field of condensers. A base plate is welded between the bottom ends of supporting plates. A plurality of fins are welded to the location, located on the base plate, between the supporting plates. An inner coil pipe is arranged inside the fins in a penetration mode. The right end of the right side of the inner coil pipe penetrates through the supporting plate on the right side. The rear end of the right side of the inner coil pipe is provided with a connector. The rear end of the left side of the inner coil pipe penetrates through the supporting plate on the left side. The rear end of the left side of the inner coil pipe is provided with an outlet. The top end of the base plate is uniformly andfixedly connected with at least ten top blocks. A drying bottle is welded to the right side of the supporting plate on the right side through soldering lugs. The upper and lower ends of the drying bottle are both provided with straight slideways, and the flow non-uniformity of condensed gas in the inner coil pipe during the later period due to inclined installation can be avoided. A user can replace the electric car parallel flow condenser core conveniently. The problems that condensed gas is prone to flow empty even backflow and a filter structure in the drying bottle is inconvenient to replace during saturation are solved.

Owner:上海晟铭汽车配件有限公司

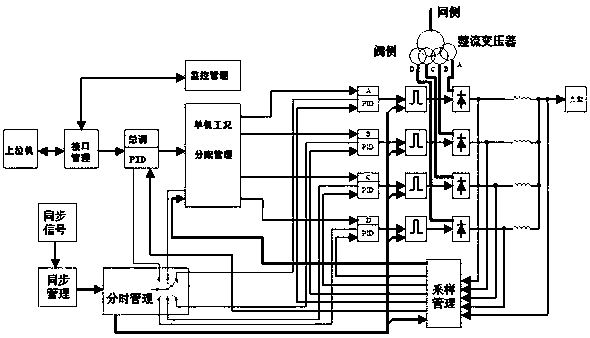

Oscillation suppression and current sharing control method for a 24-pulse phase-controlled rectifier power supply

ActiveCN105490562BAvoid oscillationAvoid uneven flowAc-dc conversion without reversalManagement unitOperating point

The invention discloses an oscillation suppression and current sharing control method of a 24-pulse wave phase-controlled rectifier power supply. Firstly, four sets of 6-pulse wave rectifier power supplies are centrally processed and time-sharing controlled, and secondly, intelligent band sampling technology and intelligent time-sharing PID control are adopted. technology, time-staggered PID control technology and multi-level PID control technology, the method of centralized processing of the four 6-pulse rectifier power supplies is as follows: given by the upper computer to the given receiving management unit; the feedback and summary of the four rectifier cabinets The feedback information is connected to the sampling management unit, and the sampling management unit centrally manages the sampling; the receiving management unit sends the given to the general adjustment PID unit, and the general adjustment PID unit adjusts according to the overall feedback, and the overall adjustment results are sent to the stand-alone working condition distribution The management unit; the single machine working condition allocation management unit uniformly dispatches and allocates the value that each rectifier cabinet should output according to the working conditions of each single machine. The oscillation suppression and current equalization control method of the 24-pulse phase-controlled rectifier power supply of the present invention avoids the occurrence of oscillation and uneven current.

Owner:深圳市力源海纳能源有限公司

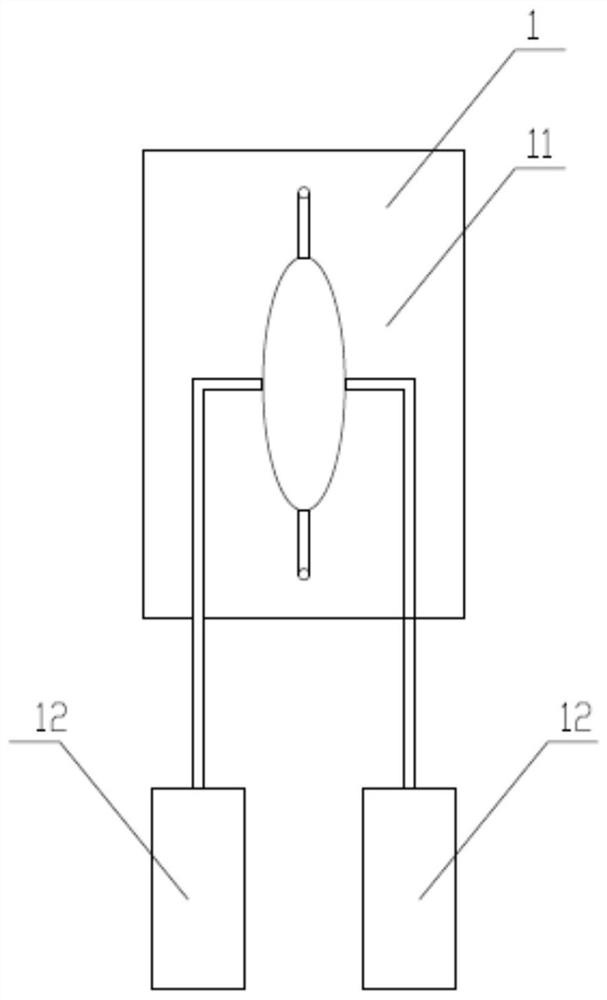

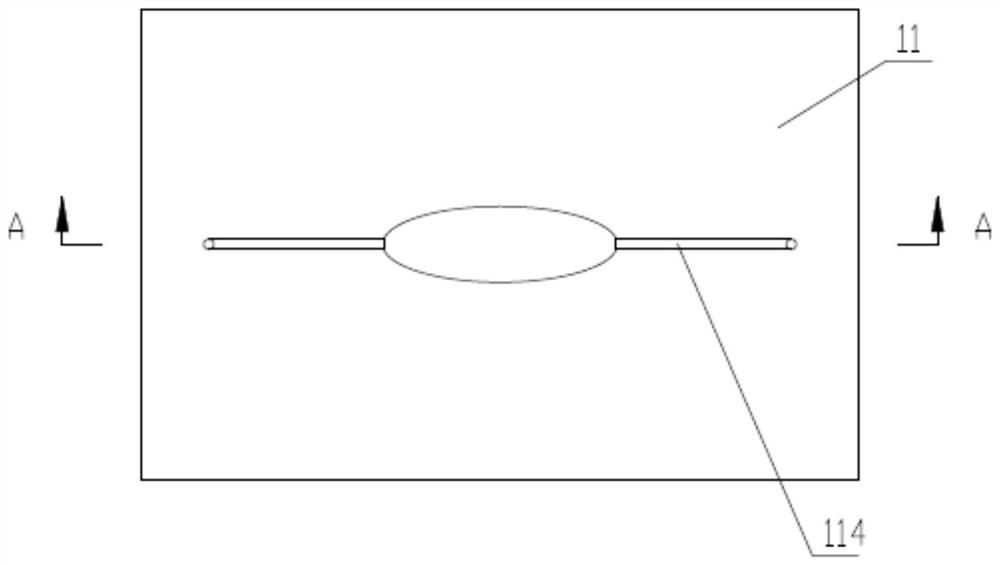

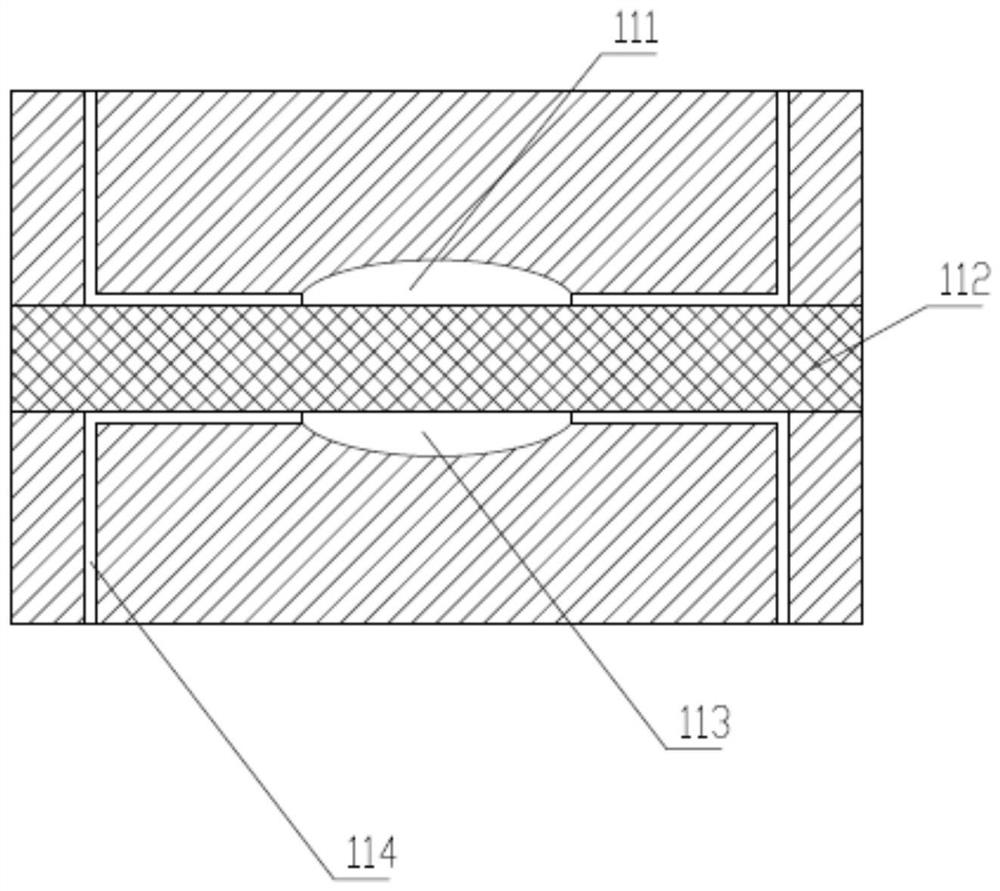

Microfluidic colon cell research model and method for researching influence mechanism of novel coronavirus on colon cells

PendingCN113416643ASimple structureLow costBioreactor/fermenter combinationsBiological substance pretreatmentsCell layerIntestinal goblet cell

The invention belongs to the technical field of in-vitro simulation analysis, and particularly relates to a microfluidic colon cell research model for researching the influence mechanism of novel coronavirus on colon cells, the microfluidic colon cell research model comprises more than one culture mechanism, one culture mechanism is selected as a control group, and other culture mechanisms are selected as experimental groups; each culture mechanism comprises a culture tank and more than one collection tank; and the inlet of the collection tank is connected with the outlet of the culture tank through a liquid channel valve. The beneficial effects are that a stimulation device is simple in structure and low in cost; a A549 cell layer and a human colon goblet cell HT29-CL.16E or HUVEC cell layer are respectively arranged, so that the structure of colon capillary vessels is effectively simulated; the rhythmic stretching of a vacuum pump is used for simulating colon contraction and relaxation caused by human respiration; the simulation device is simple to operate; an exchange cavity is in a streamline spindle shape, and fluid flowing non-uniformity is prevented by considering fluid mechanics factors.

Owner:石家庄市疾病预防控制中心

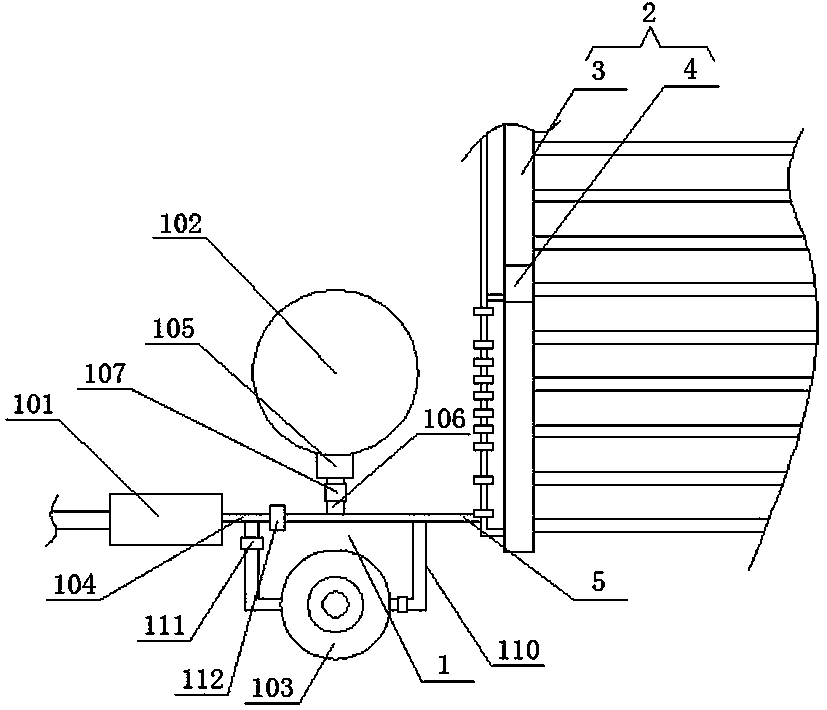

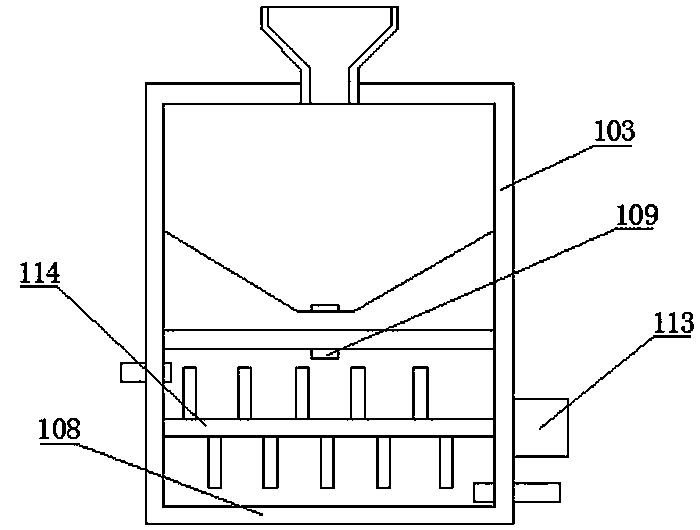

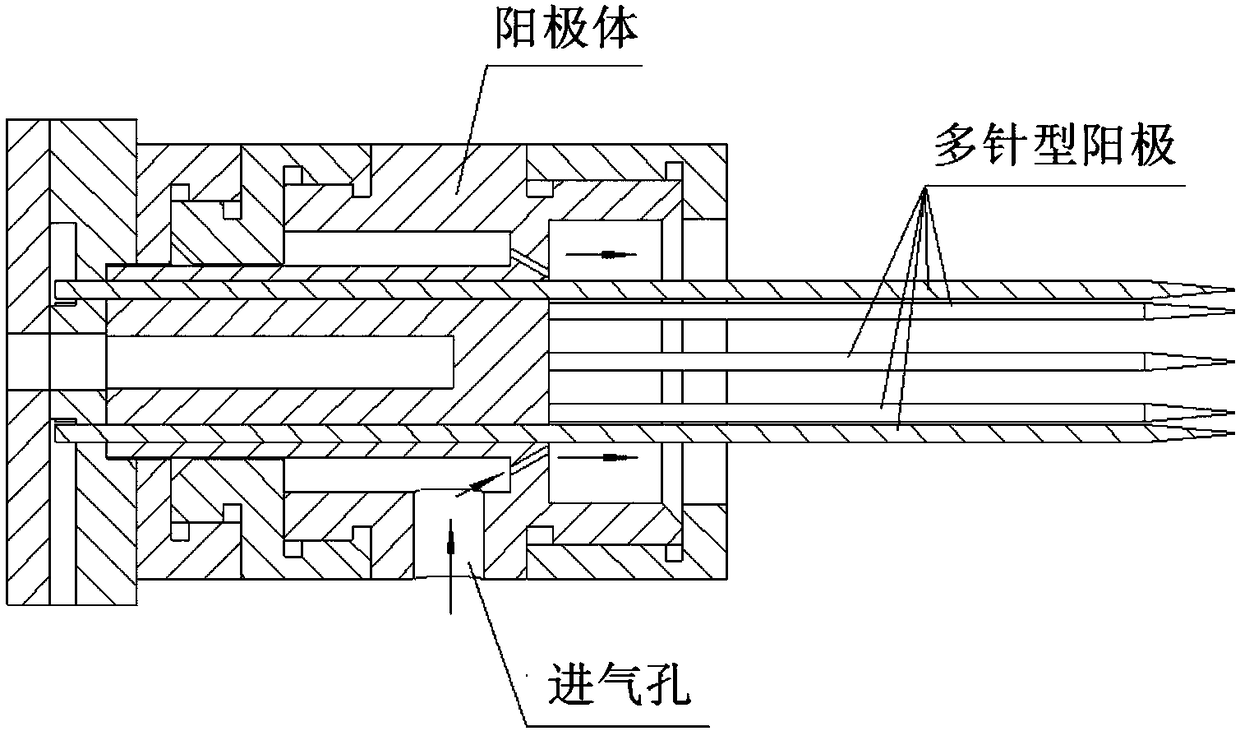

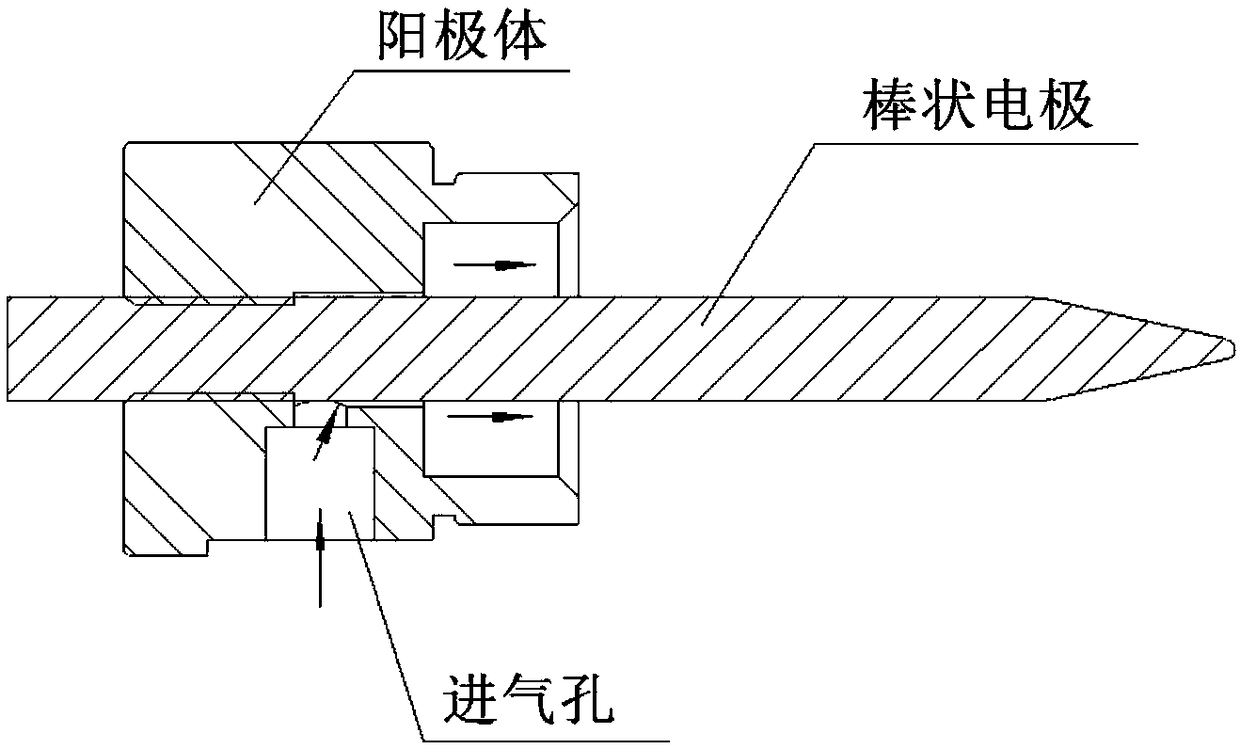

Supersonic speed anode subassembly for electrically exciting laser discharge tube

ActiveCN108336633AAvoiding ablative contamination problemsExtended service lifeLaser detailsDischarge efficiencyInlet channel

The invention discloses a supersonic speed anode subassembly for electrically exciting a laser discharge tube. The supersonic speed anode subassembly comprises a conductive vent copper tube and a supersonic speed spray tube discharging head; an air inlet channel, a positioning hole section and an internal thread hole section communicated in order are arranged in the conductive vent copper tube; the internal thread hole is arranged at the front end of the conductive vent copper tube; the supersonic spray tube discharging head comprises a positioning section and an outer thread section arrangedin front and back; the positioning section is matched with the positioning hole section, and the external thread section and the internal thread section are in thread fit; an air inlet section, a shrinking cone section, a throat and an air outlet diverging cone section communicated in order are arranged in the supersonic spray tube discharging head along an air flowing direction; and the air inletsection and the air inlet channel are communicated. The supersonic speed anode subassembly disclosed by the invention can be self-cooling, and has the advantages of being high in discharging efficiency and resistant in ablation.

Owner:NAT UNIV OF DEFENSE TECH

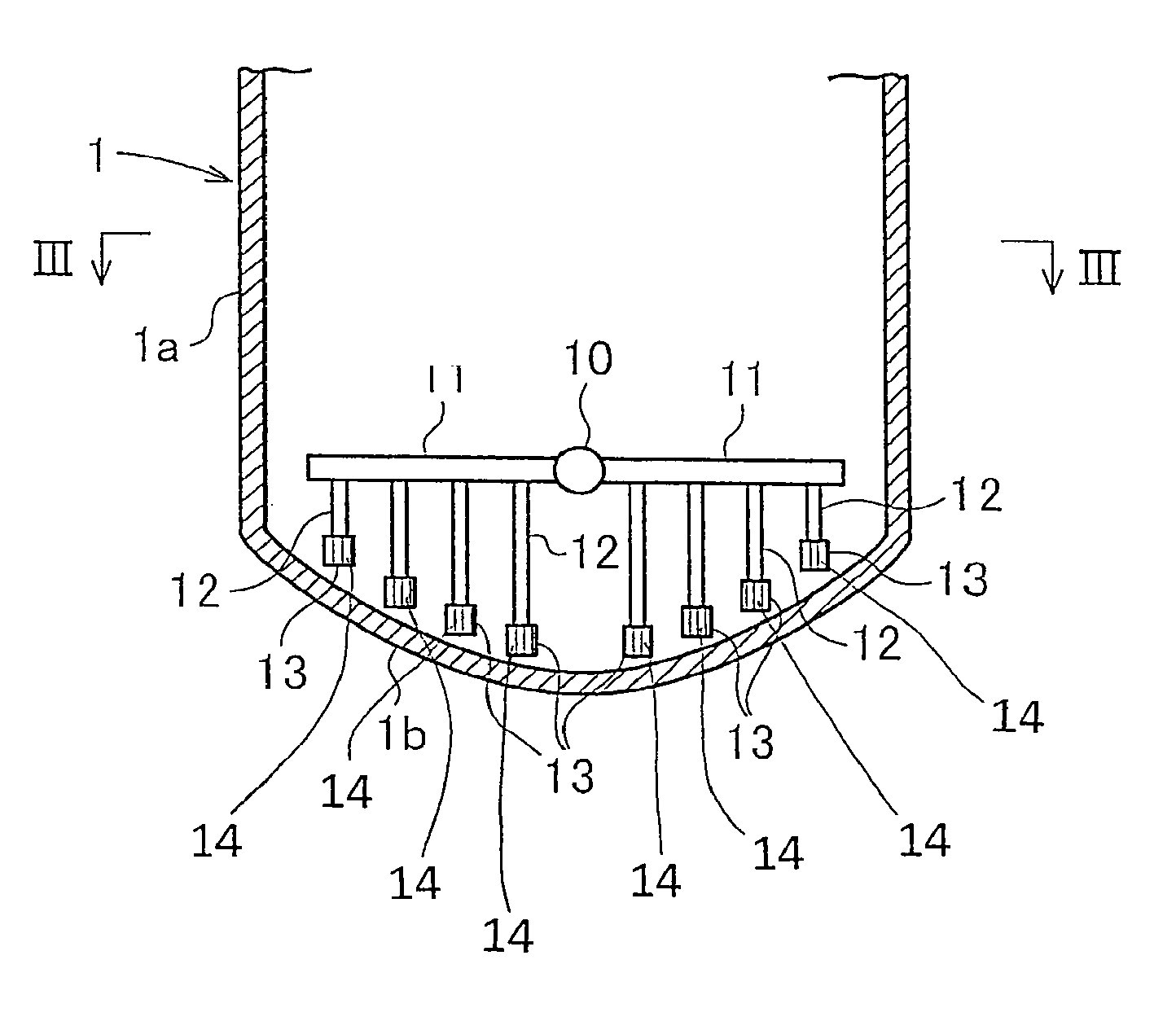

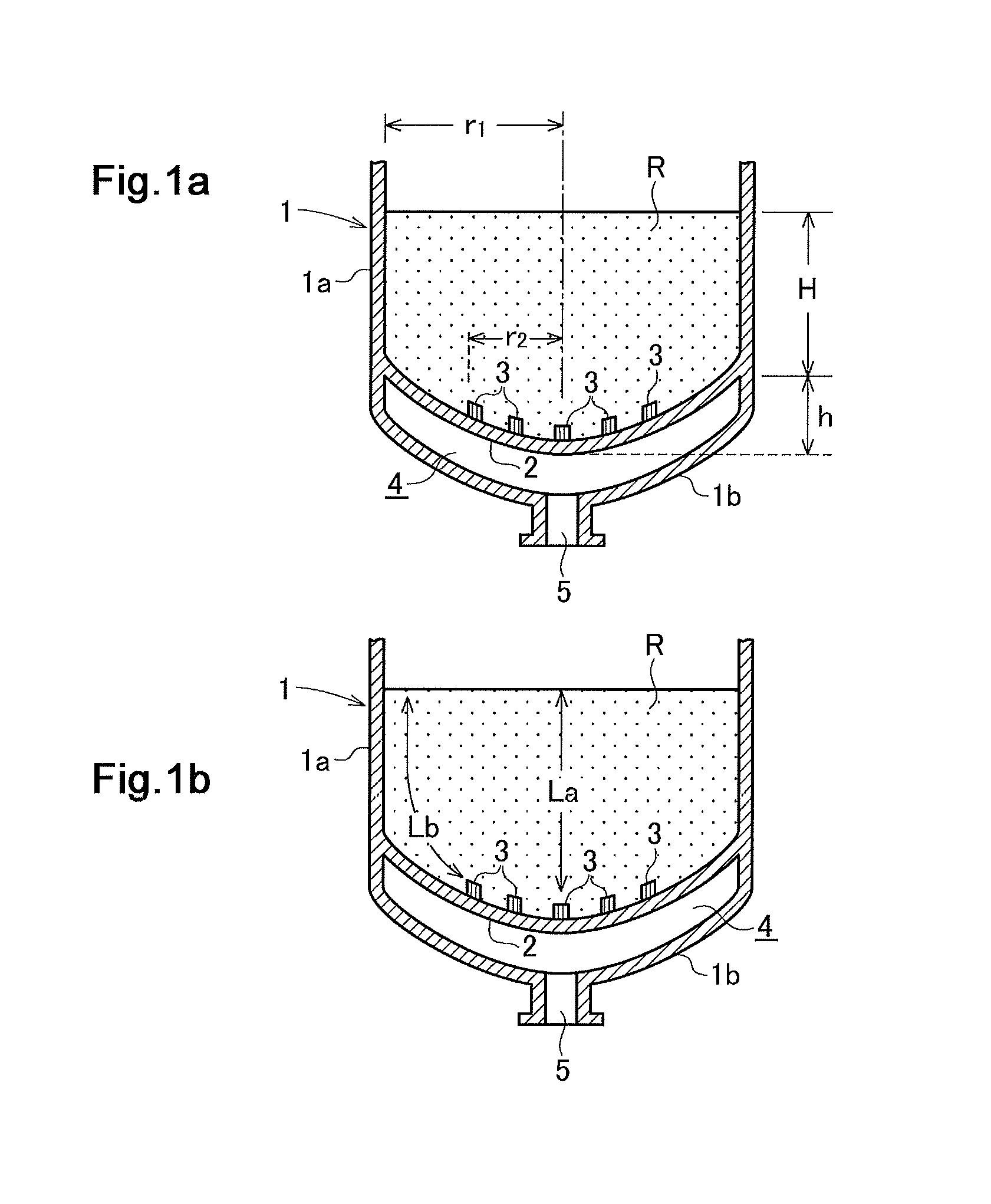

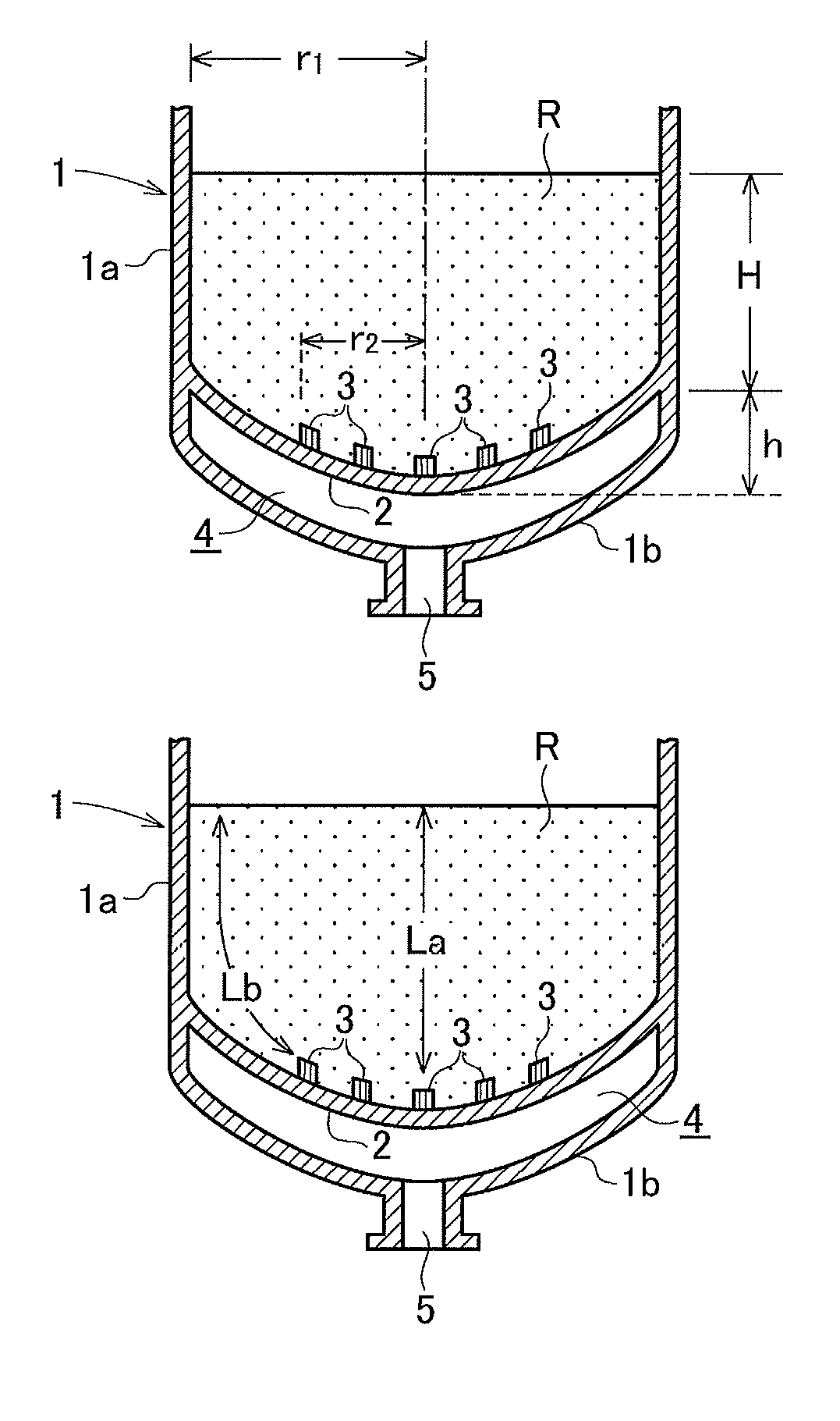

Desalting device

InactiveUS9321659B2Avoid uneven flowReduce flow rateIon-exchange column/bed processesWater/sewage treatment by ion-exchangeEngineeringIon-exchange resin

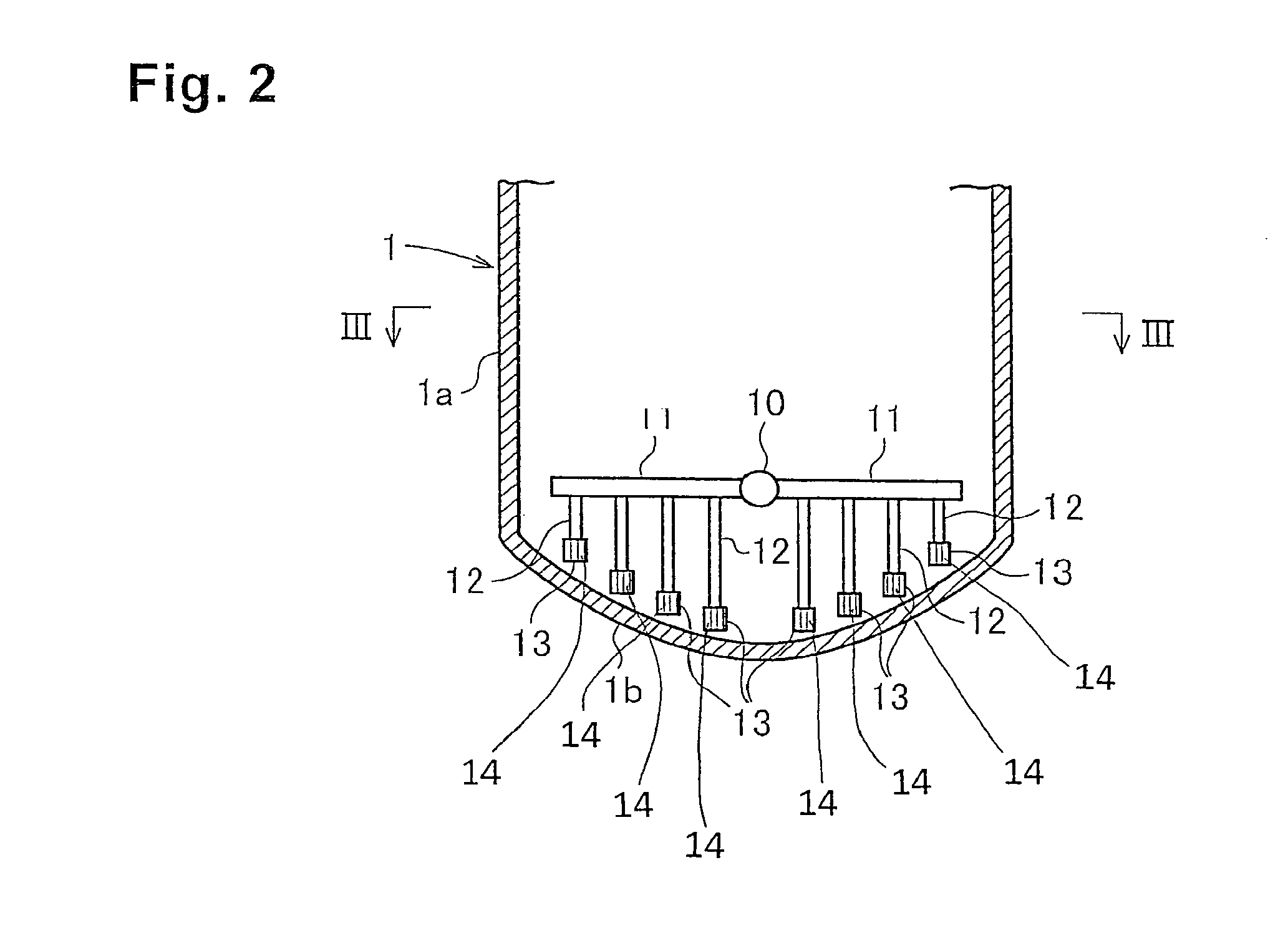

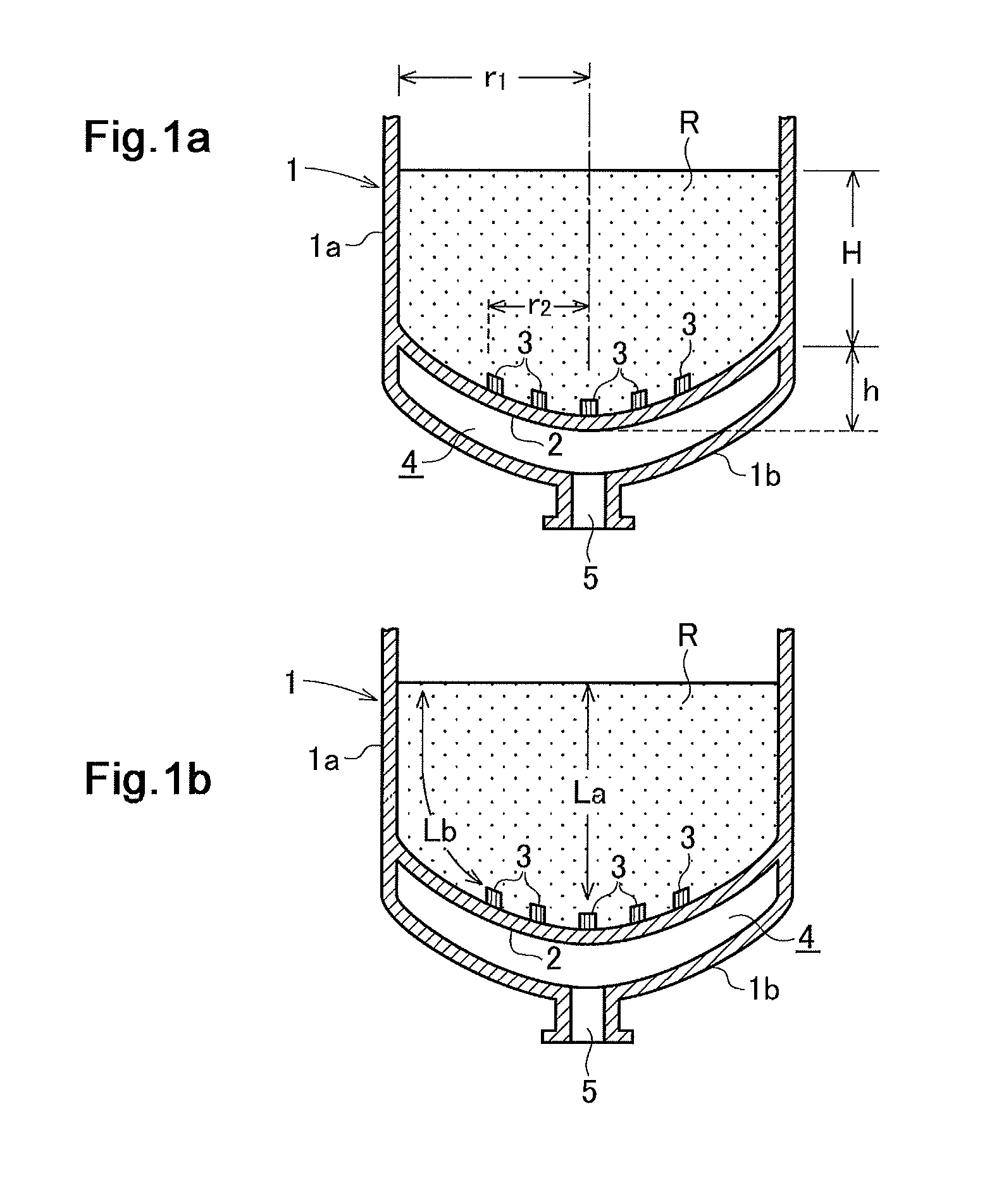

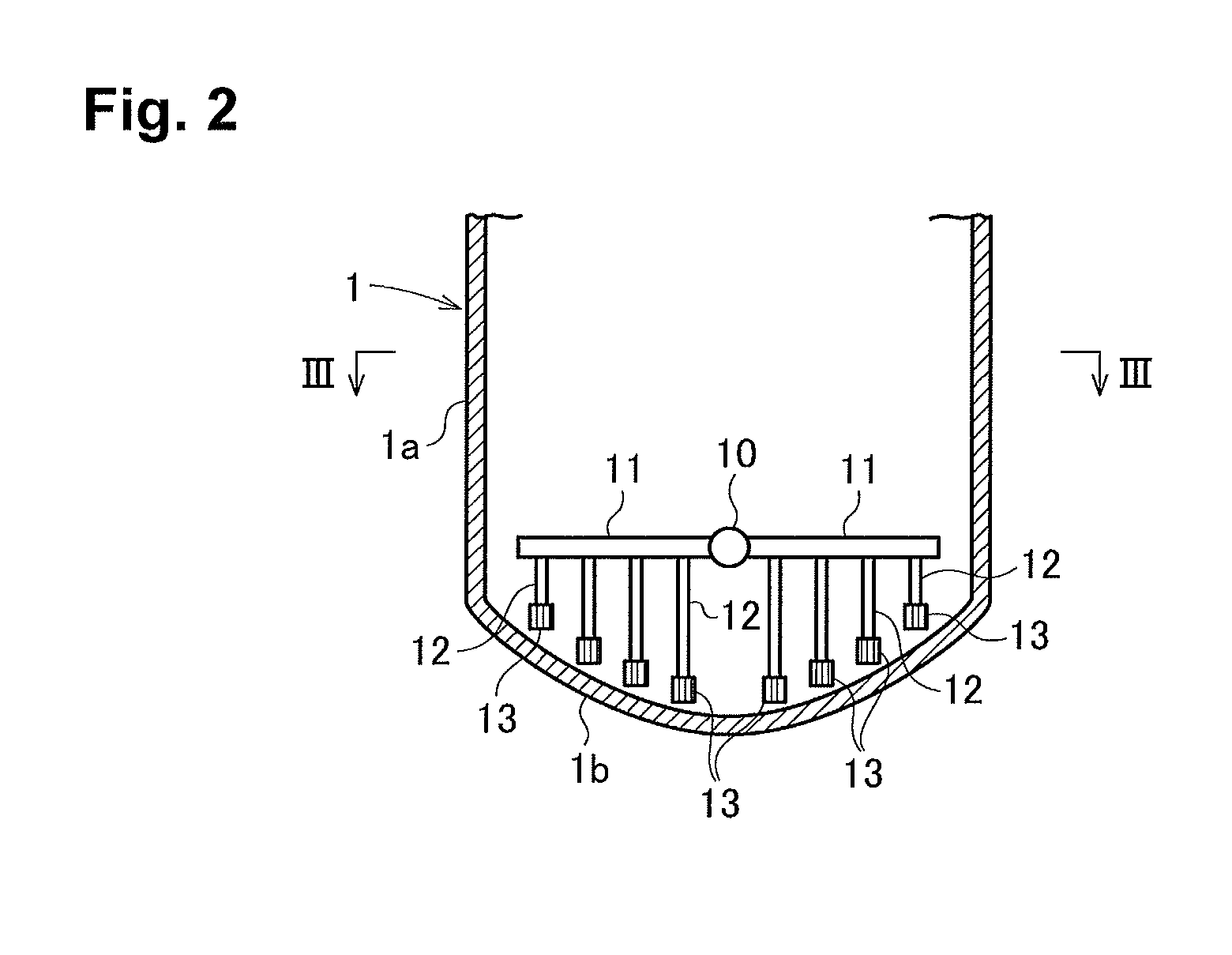

Provided is a desalting device which includes a tower body and a bulge portion bulging downward therefrom, and which prevents uneven flow and causes no dead space within the tower body. The desalting device includes a tower body having a bulge portion 1b bulging downward at a bottom portion thereof, an ion-exchange resin packed in the tower body, and a plurality of strainers 3 for collecting water being arranged within the bulge portion 1b. The strainers are arranged only in a central region of an inside of the bulge portion excluding an outer peripheral portion of the bulge portion.

Owner:KURITA WATER INDUSTRIES LTD

Die-casting mold for bottom angle of antenna bracket

The invention relates to a die-casting forming die for a bottom corner of an antenna support. The die-casting forming die comprises an upper die body and a lower die body. Connecting section A grooves are obliquely and symmetrically formed in the four corners of the lower die body, a raised thread connecting hole structure A is arranged at the center of each connecting section A groove, and the two center connecting lines of the diagonal connecting section A grooves and the diagonal lines of the lower die body are overlapped. Connecting bulges are obliquely and symmetrically arranged on the four corners of the upper die body, and the connecting bulges and the connecting section A grooves are matched to form die cavities of the bottom corner of the antenna support. Raised thread connecting structures B are arranged at the centers of the two sides in the diagonal line extending directions of the connecting bulges correspondingly, and the two center connecting lines of the diagonal connecting section bulges and the diagonal lines of the upper die body are overlapped. The die-casting forming die has the advantages that a plurality of products can be produced through the die, thus the production efficiency of the products is improved, meanwhile, the utilization rate of the die is also increased, and the production cost can be reduced greatly; and meanwhile, uniform force-bearing is also guaranteed, and the quality of the products is improved.

Owner:江苏中伟业通讯设备有限公司

A kind of electric ship charger multi-machine parallel constant voltage current sharing control method and device

ActiveCN111791738BAvoid circulationAvoid uneven flowBatteries circuit arrangementsCharging stationsCharge currentElectrical battery

The invention discloses a multi-computer parallel constant voltage and current sharing control method for electric ship chargers, which comprises the following steps: obtaining the output voltage and output current of several chargers in the current sampling period and the real-time voltage of the electric ship energy storage components; Calculate the control coefficient of the charger according to the output voltage, output current and real-time voltage of the energy storage component of any charger in the current sampling period; get the output voltage command value of the charger according to the control coefficient, and control the charger according to the output voltage The command value outputs the charging voltage. Also disclosed is a multi-unit parallel constant voltage and current sharing control device for electric ship chargers. By detecting the output voltage and current of several chargers and the battery voltage of the energy storage component of the electric ship, the control coefficient of each charger is obtained, and then the output voltage command value of the charger is adjusted to make the output current of several chargers It tends to the average charging current, avoiding the circulating current and uneven current among several chargers.

Owner:XIAN XJ POWER ELECTRONICS TECH +3

Desalting device

InactiveUS20130341263A1Avoid uneven flowReduce flow rateIon-exchange process apparatusWater/sewage treatment by ion-exchangeEngineeringCentral region

Provided is a desalting device which includes a tower body and a bulge portion bulging downward therefrom, and which prevents uneven flow and causes no dead space within the tower body. The desalting device includes a tower body having a bulge portion 1b bulging downward at a bottom portion thereof, an ion-exchange resin packed in the tower body, and a plurality of strainers 3 for collecting water being arranged within the bulge portion 1b. The strainers are arranged only in a central region of an inside of the bulge portion excluding an outer peripheral portion of the bulge portion.

Owner:KURITA WATER INDUSTRIES LTD

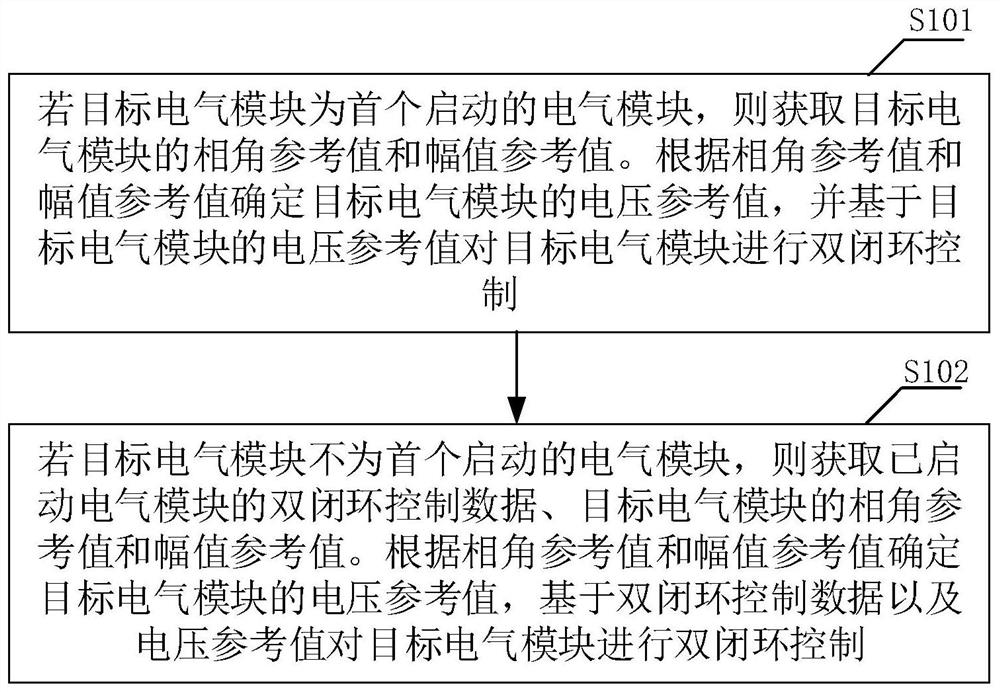

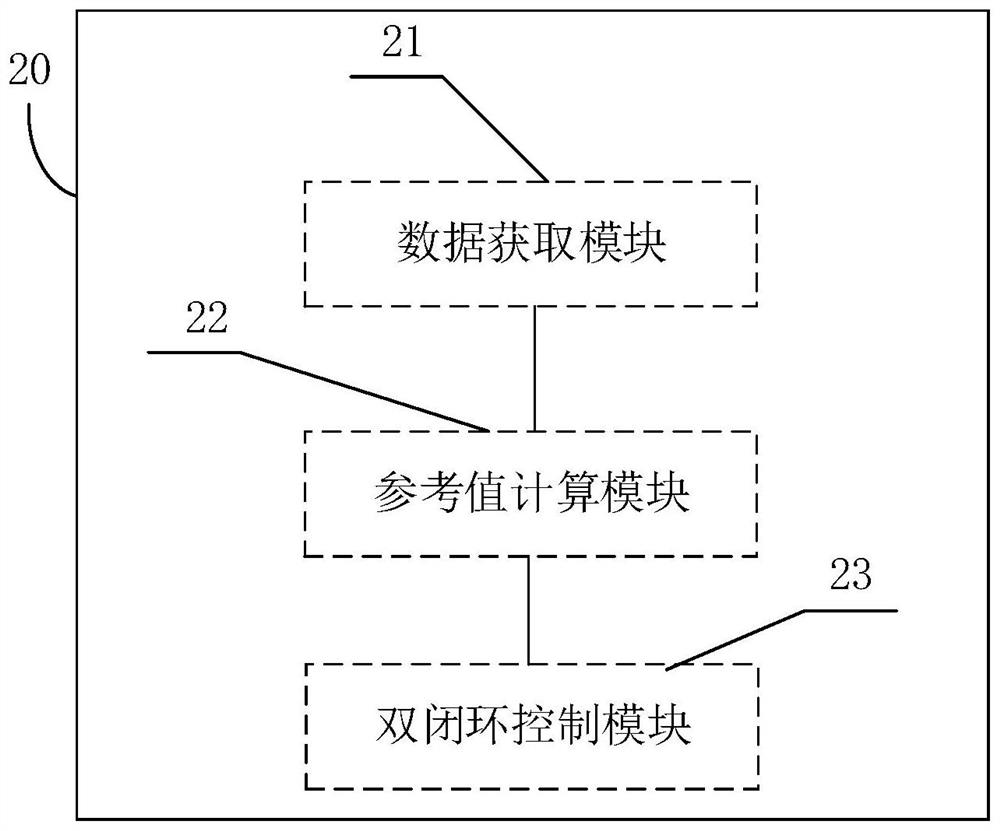

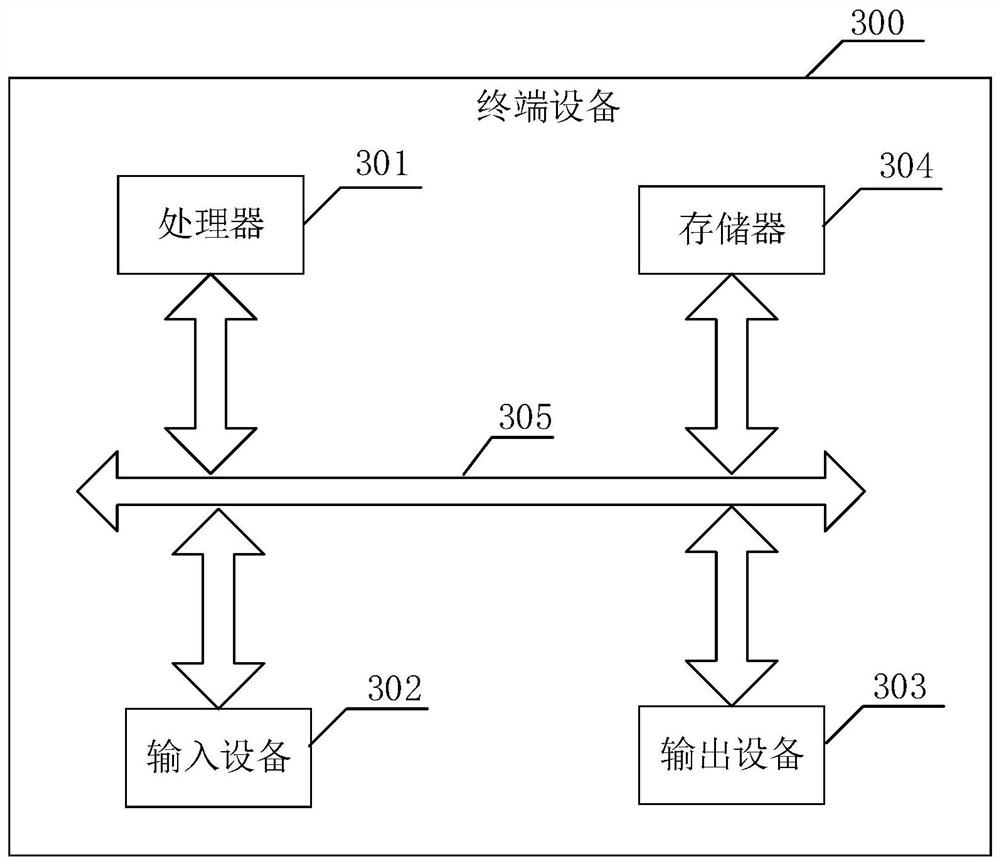

Multi-module system current sharing control method and device and terminal device

ActiveCN111984047AAvoid uneven flowRealize current sharing controlControllers with particular characteristicsElectric variable regulationVoltage referenceEngineering

The invention provides a multi-module system current sharing control method and device and a terminal device, and the method comprises the steps: obtaining a phase angle reference value and an amplitude reference value of a target electrical module if the target electrical module is the first started electrical module; determining a voltage reference value of the target electrical module accordingto the phase angle reference value and the amplitude reference value, and performing double closed-loop control on the target electrical module based on the voltage reference value of the target electrical module; if the target electrical module is not the first started electrical module, acquiring double closed-loop control data of the started electrical module and a phase angle reference valueand an amplitude reference value of the target electrical module; and determining a voltage reference value of the target electrical module according to the phase angle reference value and the amplitude reference value, and performing double-closed-loop control on the target electrical module based on the double-closed-loop control data and the voltage reference value. According to the multi-module system current sharing control method and apparatus, and the terminal device provided by the invention, current sharing control of multiple modules can be realized.

Owner:KEHUA DATA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com