Modular system and method for the catalytic treatment of a gas stream

a technology of gas stream and module system, which is applied in the direction of machines/engines, mechanical equipment, separation processes, etc., can solve the problems of reducing system efficiency, achieve the effects of increasing efficiency, decreasing gas stream velocity, and increasing gas flow uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

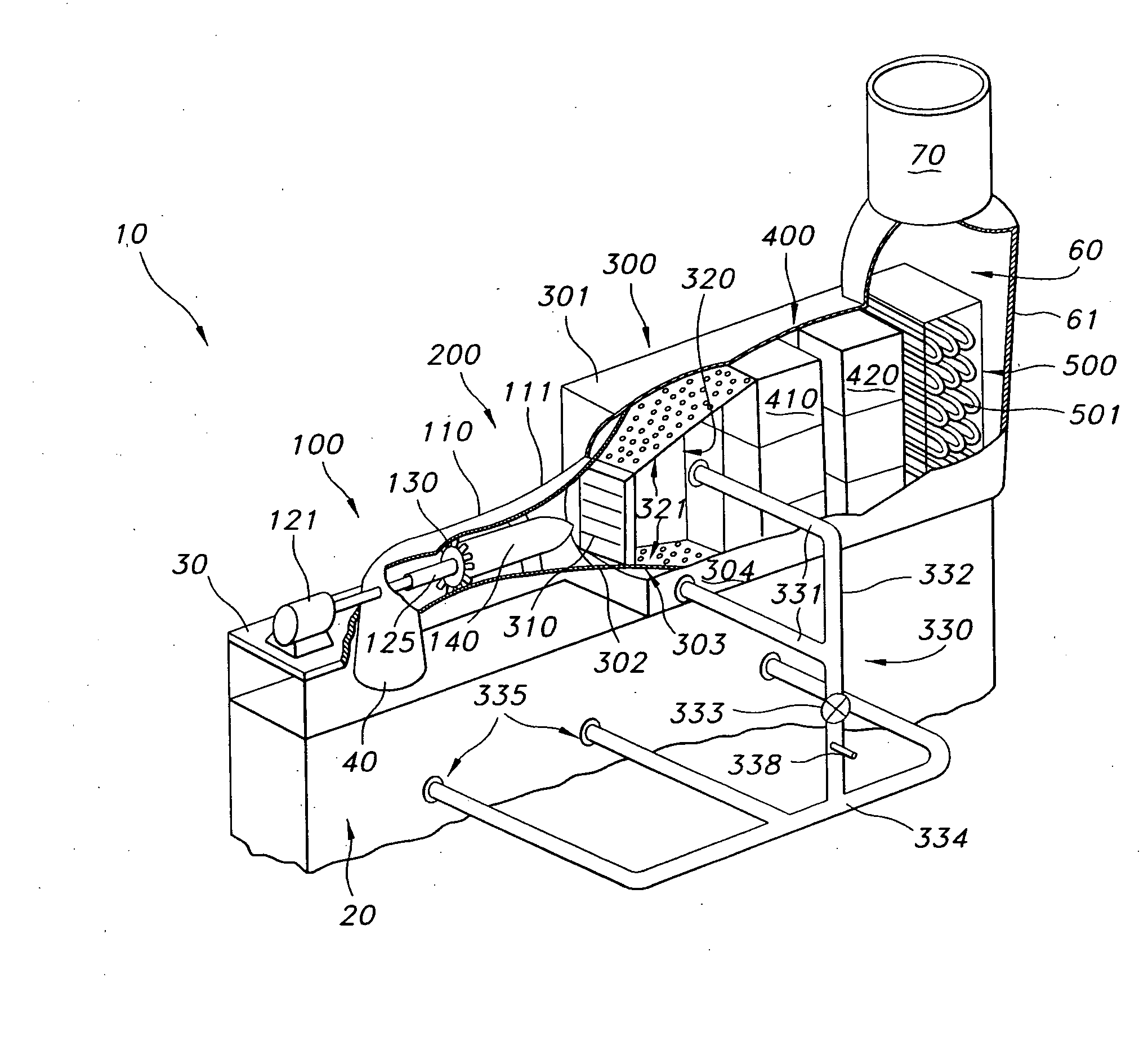

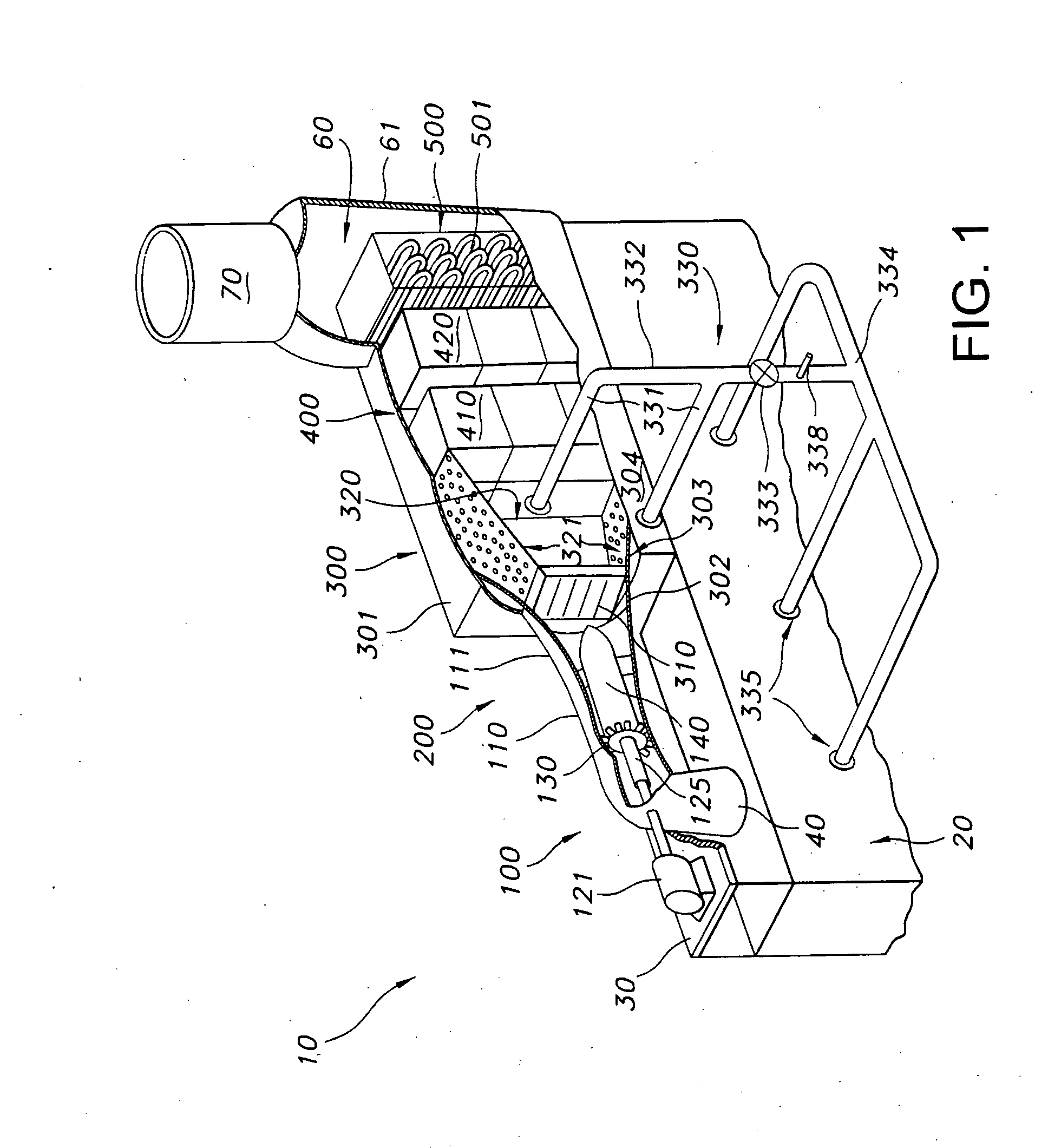

[0052] A system for the catalytic treatment of flue gas as illustrated in FIG. 1 is provided.

[0053] A flue gas is generated by a thermal cracking furnace at the rate of 272,370 lb / hr, the flue gas containing the following components:

O26.00vol. %N272.82vol. %H2O14.88vol. %CO26.30vol. %NOx30.00lb / hr

[0054] Anhydrous ammonia is added to the flue gas via the recycle grid. The ammonia flow rate to the reactor is 10.8 lb / hr.

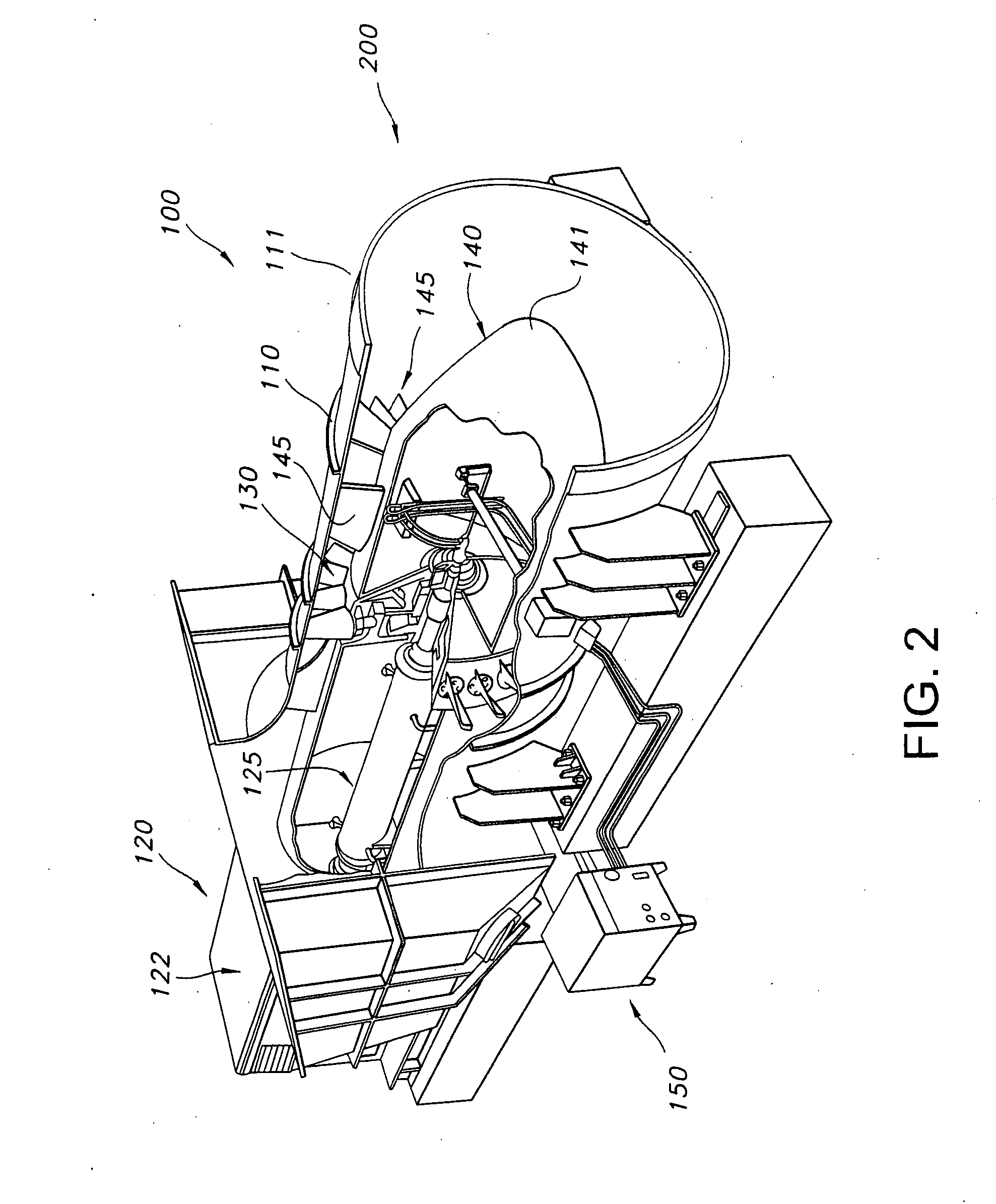

[0055] The flue gas is moved horizontally by means of the fan system described above and passes through the diffuser and transition duct into the reactor containing two modular catalyst beds in series. The catalyst for the reactor section is vanadium pentoxide on titanium dioxide honeycomb catalyst positioned for horizontal flow. The catalyst bed is operated at a temperature of 560° F. The flue gas experiences a pressure drop of 3.0″ H2O across the reactor. At the reactor exit the treated flue gas has a NOx concentration of only 2.5 lb / hr. This represents a NOx redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com