Patents

Literature

39results about How to "Improves airflow uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

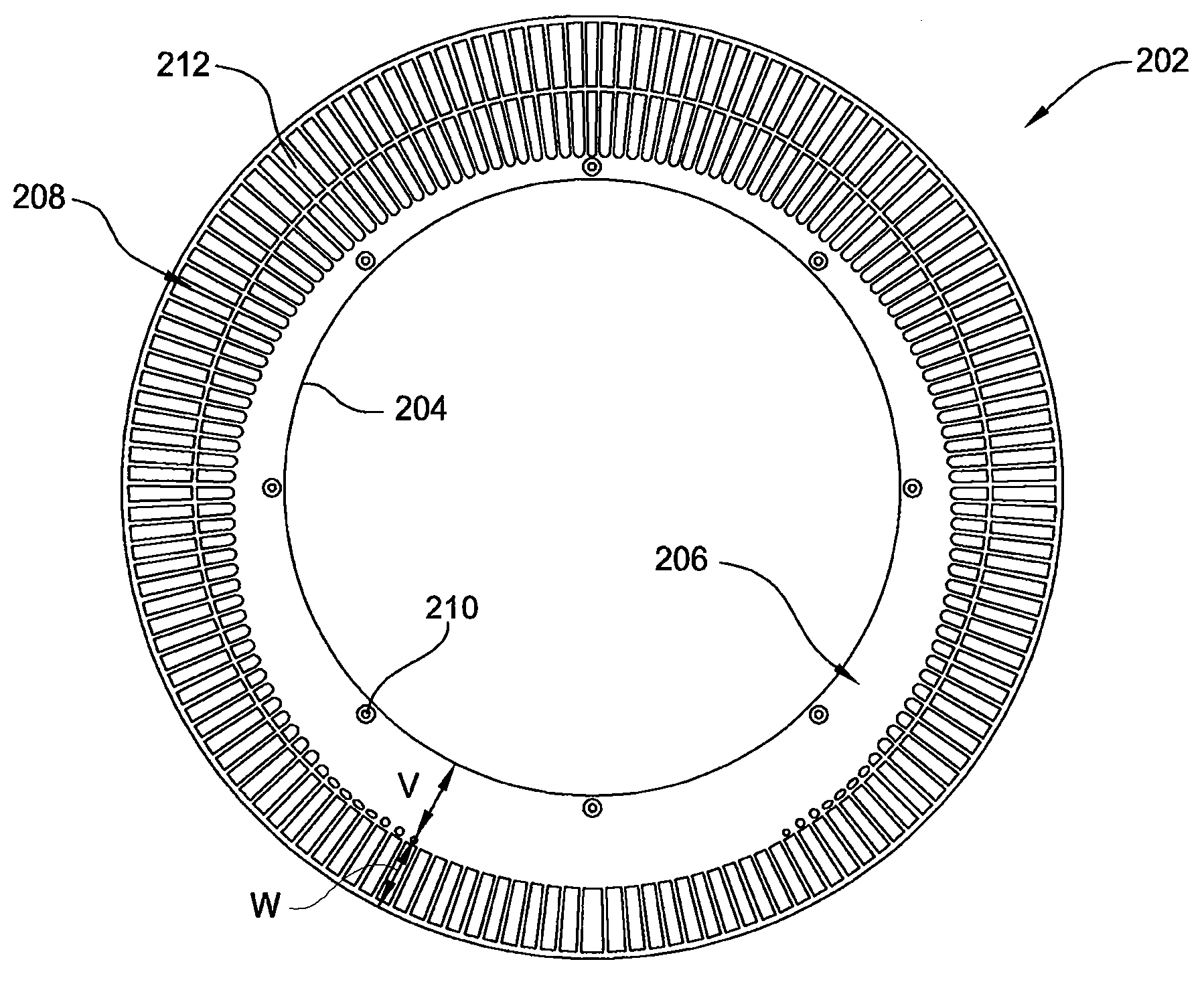

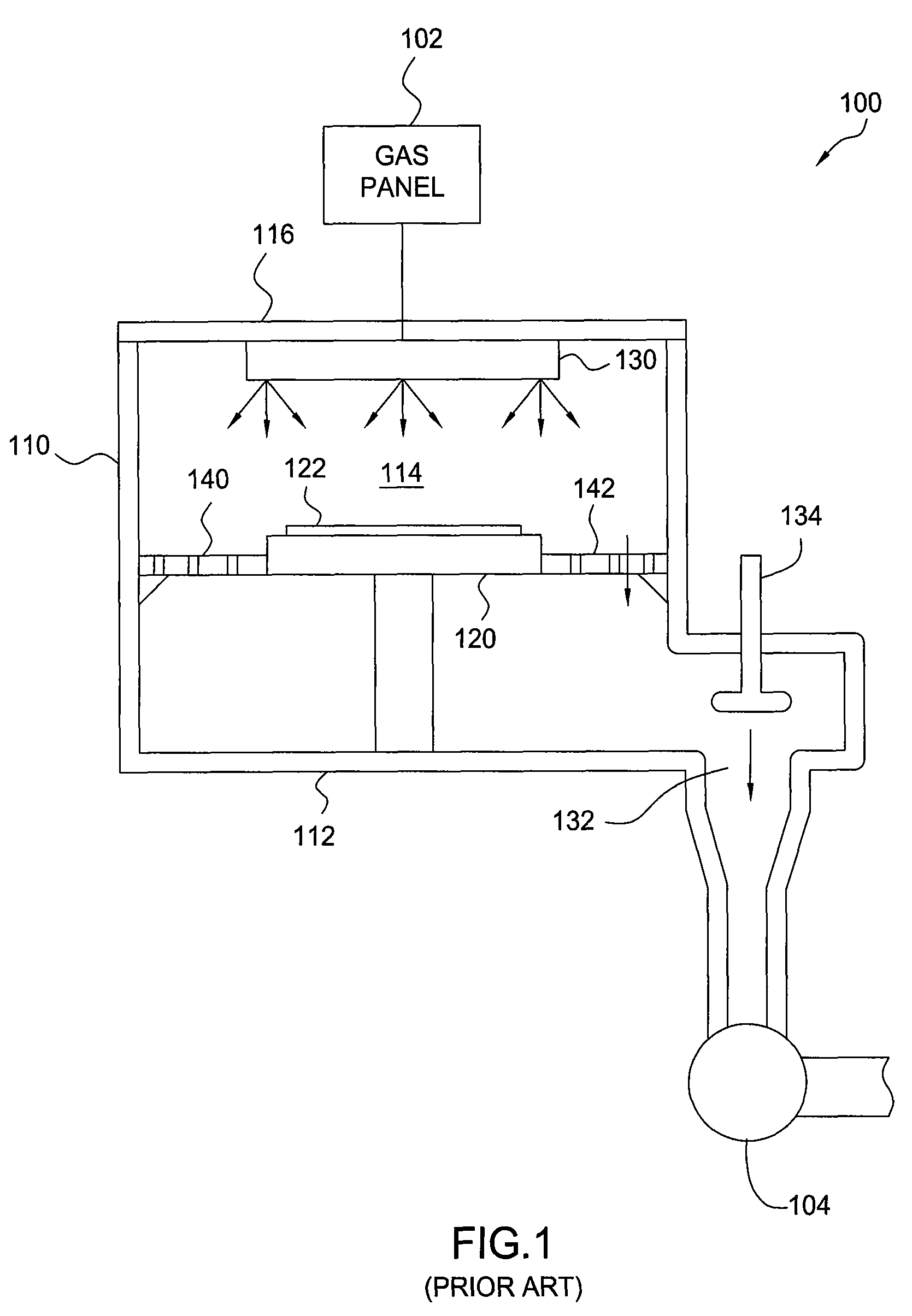

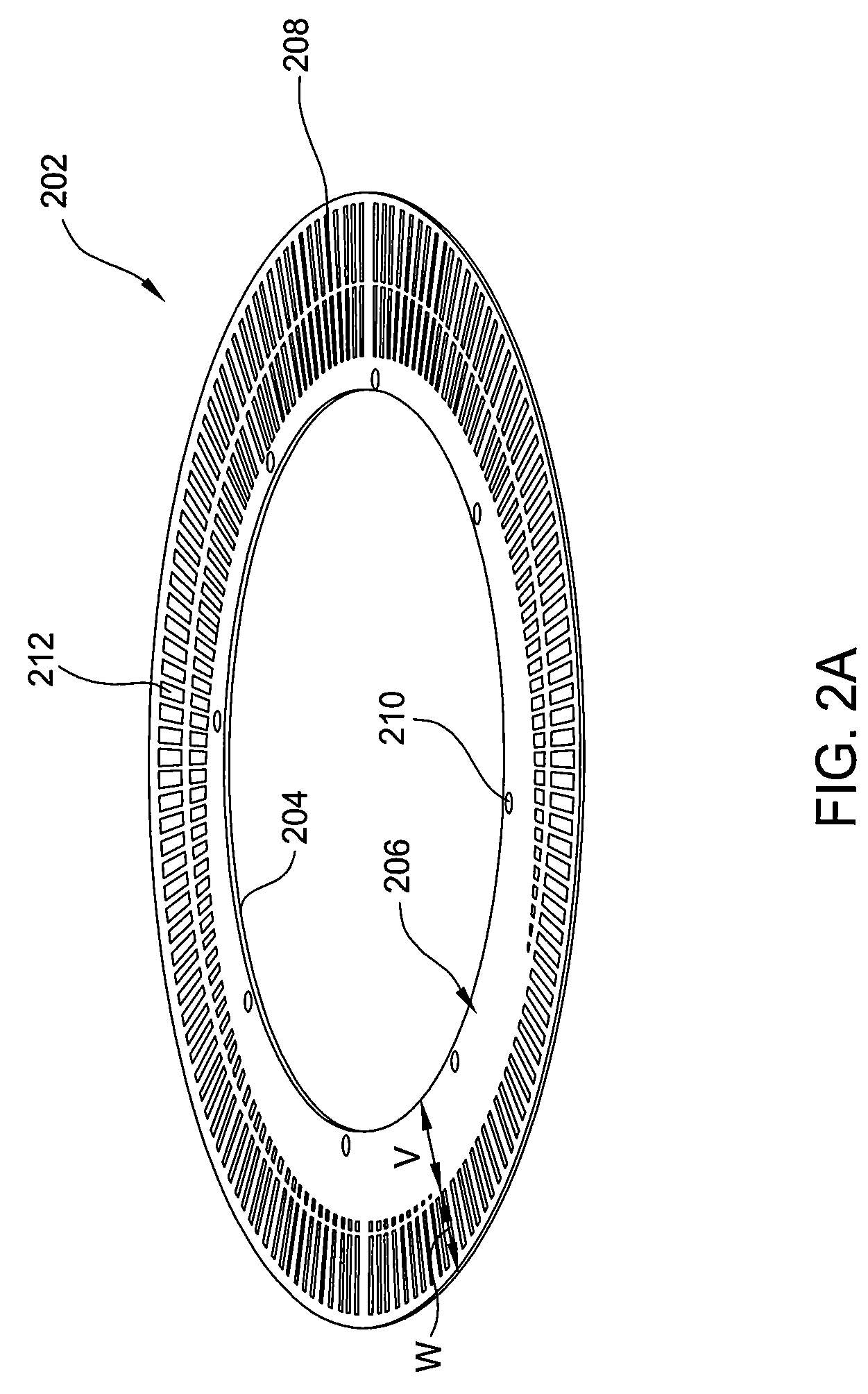

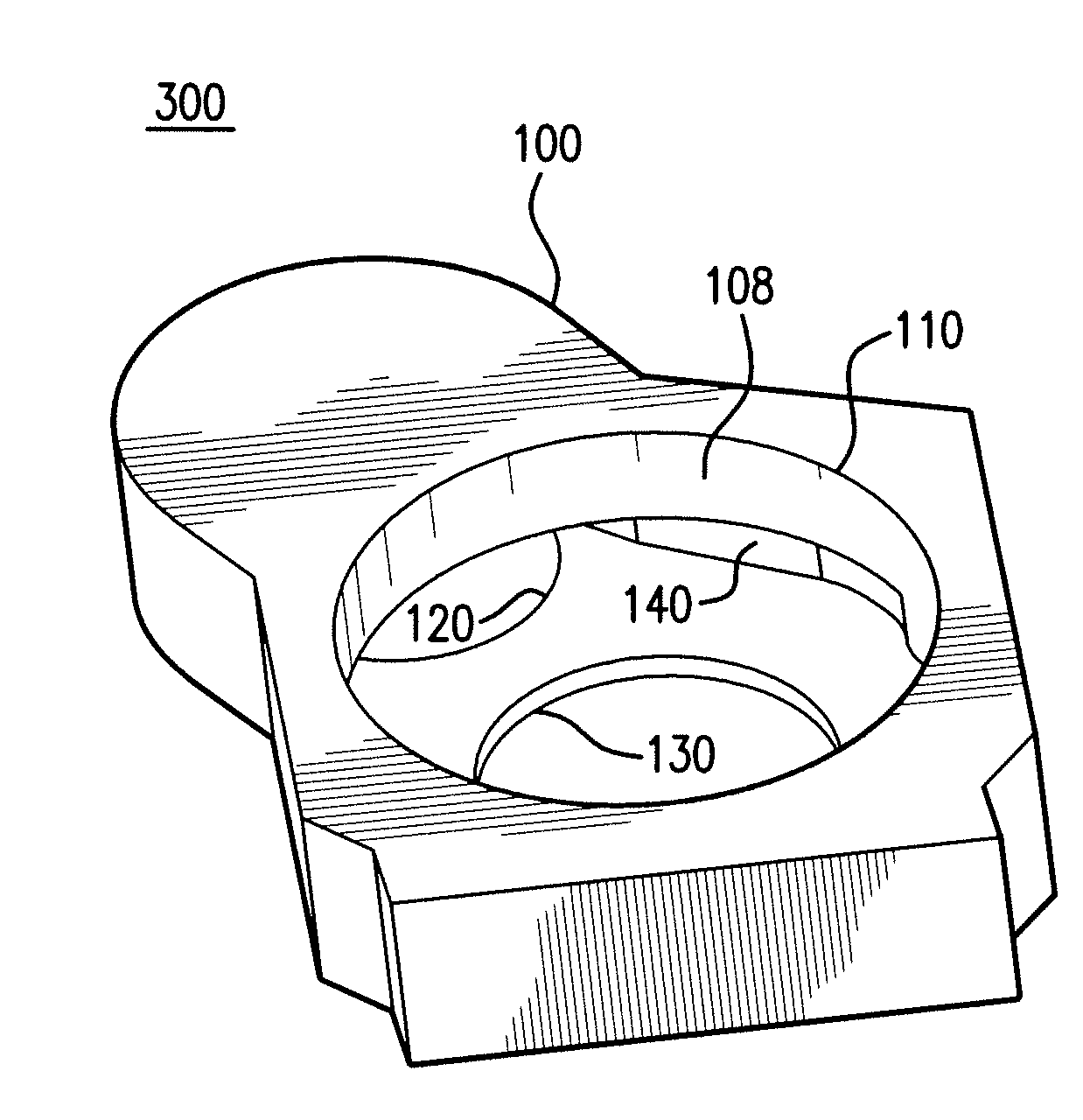

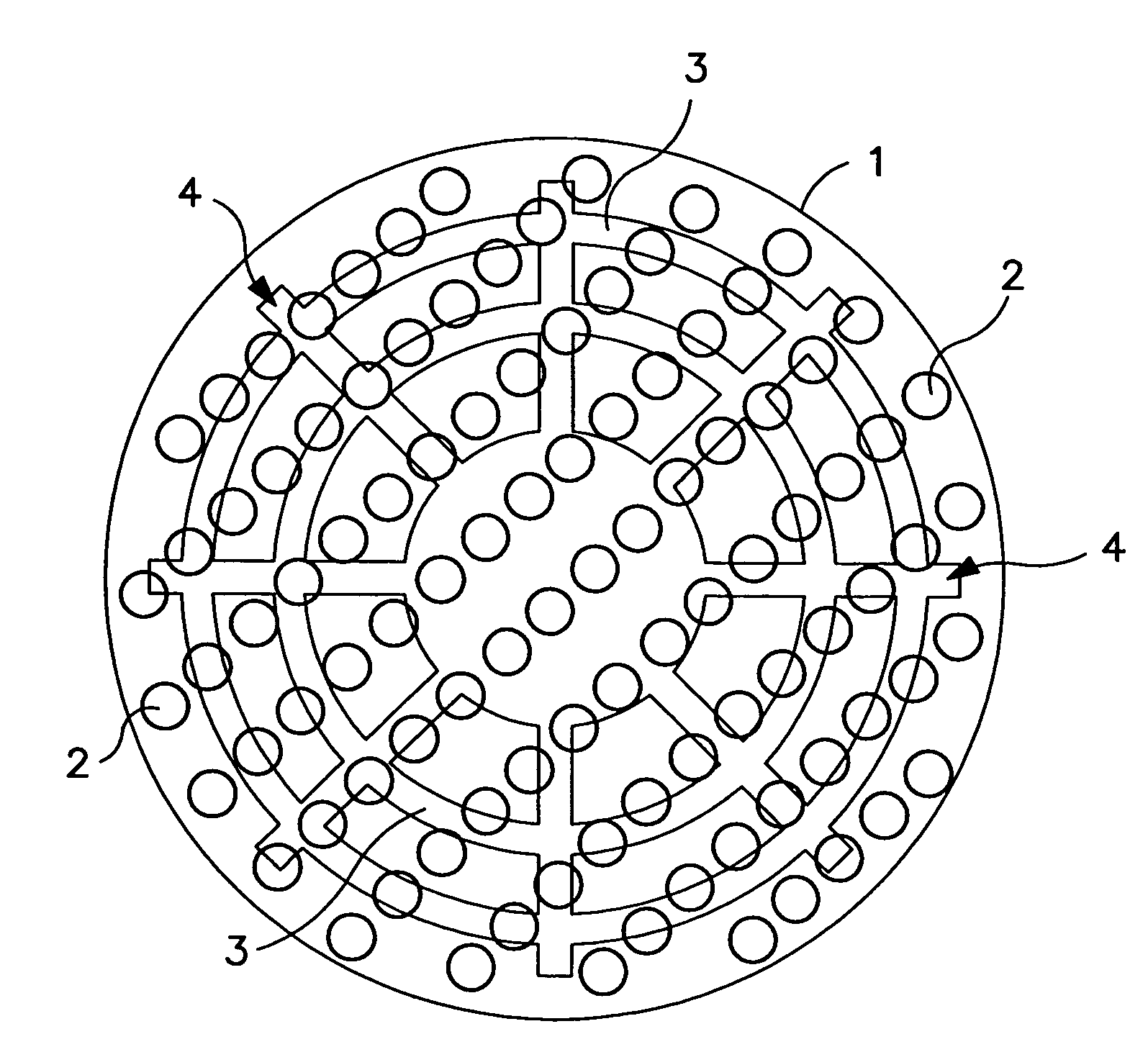

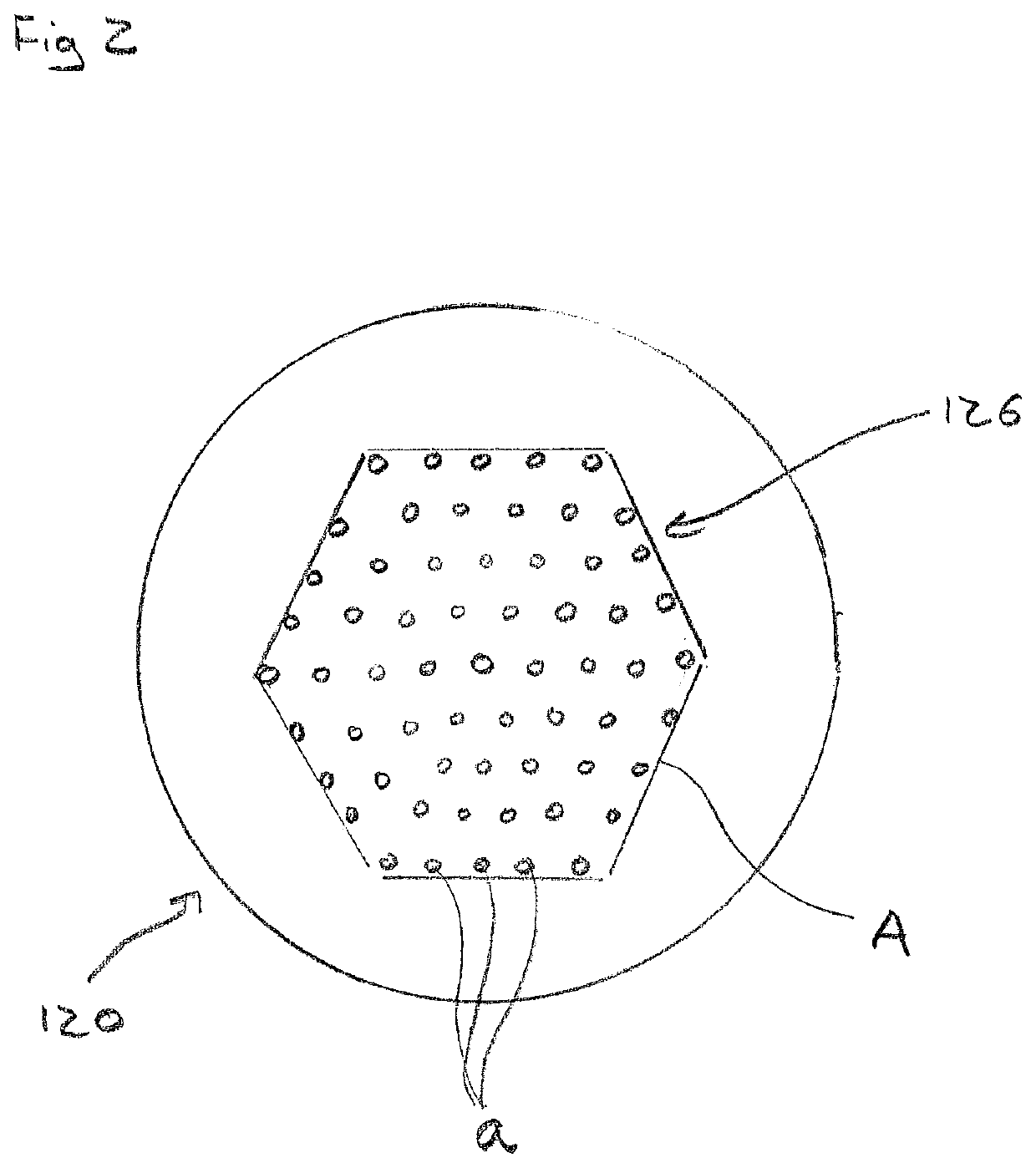

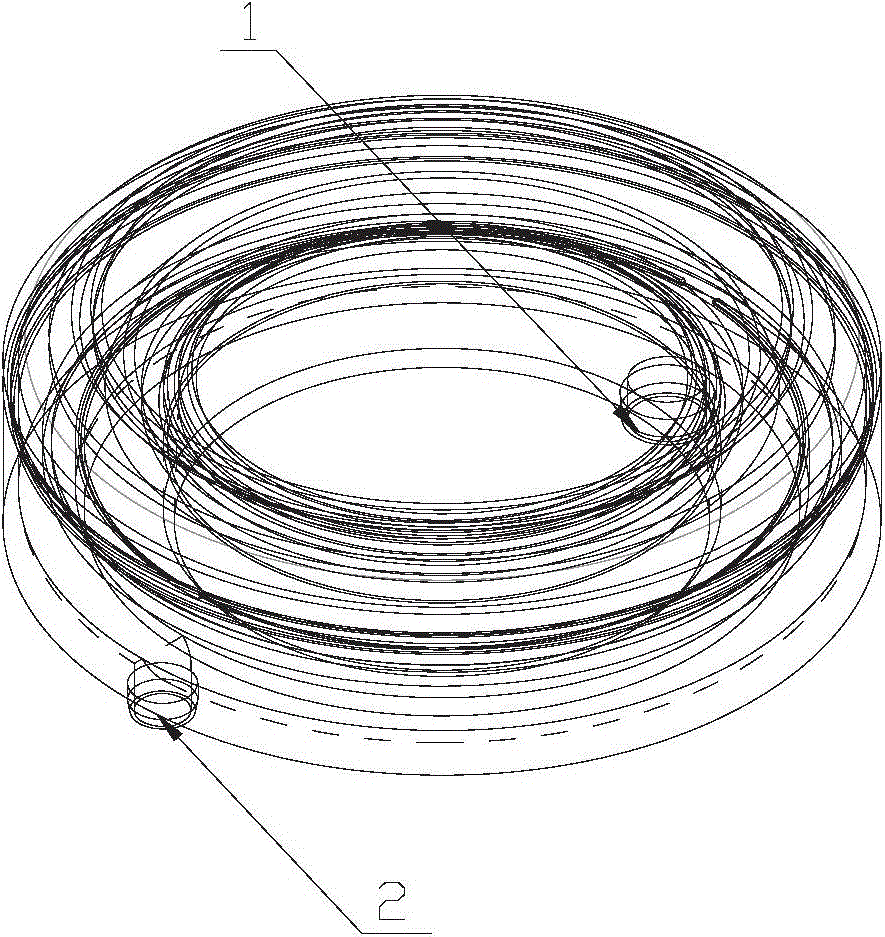

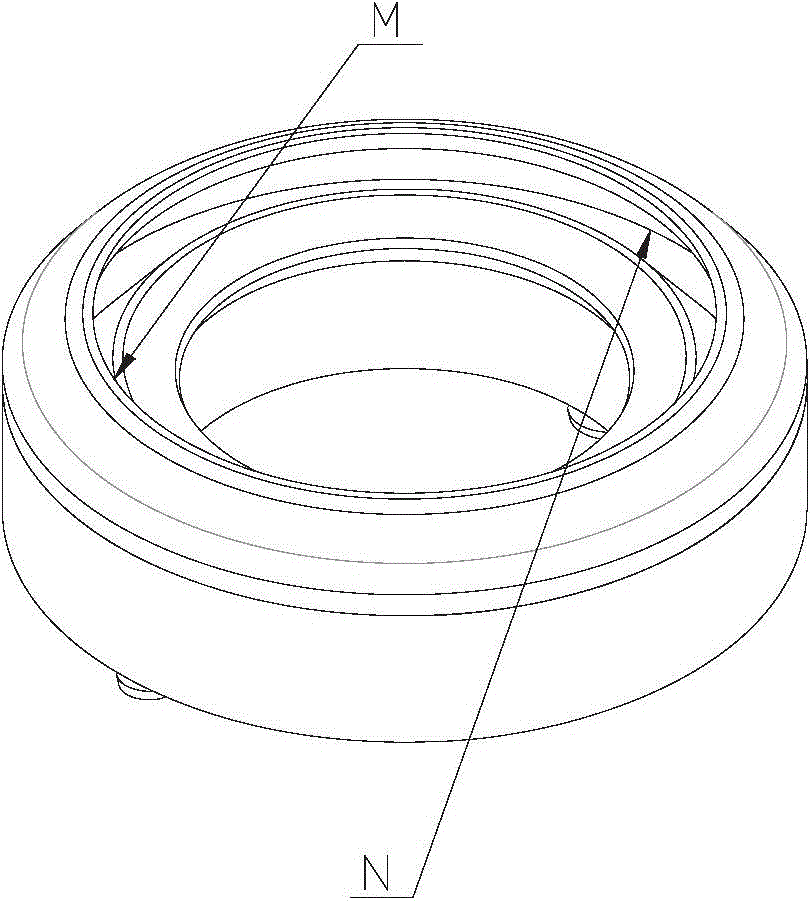

Gas flow equalizer plate suitable for use in a substrate process chamber

InactiveUS8075728B2Improves airflow uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingFlow asymmetryEngineering

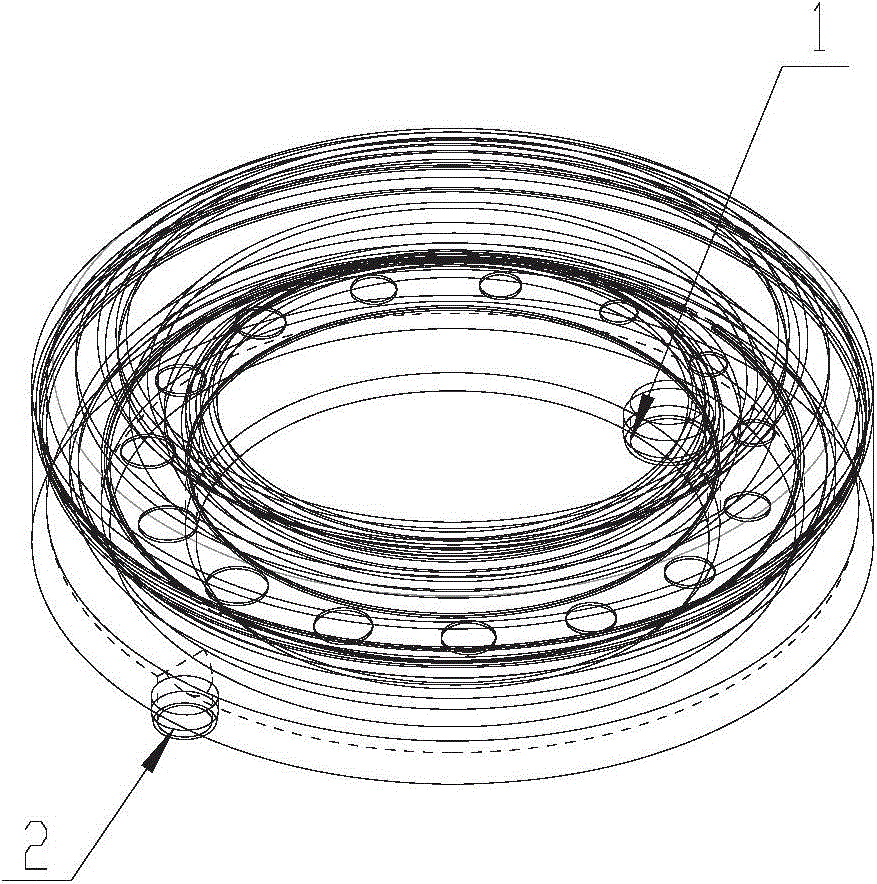

A flow equalizer plate is provided for use in a substrate process chamber. The flow equalizer plate has an annular shape with a flow obstructing inner region, and a perforated outer region that permits the passage of a processing gas, but retains specific elements in the processing gas, such as active radicals or ions. The inner and outer regions have varying radial widths so as to balance a flow of processing gas over a surface of a substrate. In certain embodiments, the flow equalizer plate may be utilized to correct chamber flow asymmetries due to a lateral offset of an exhaust port relative to a center line of a substrate support between the process volume and the exhaust port.

Owner:APPLIED MATERIALS INC

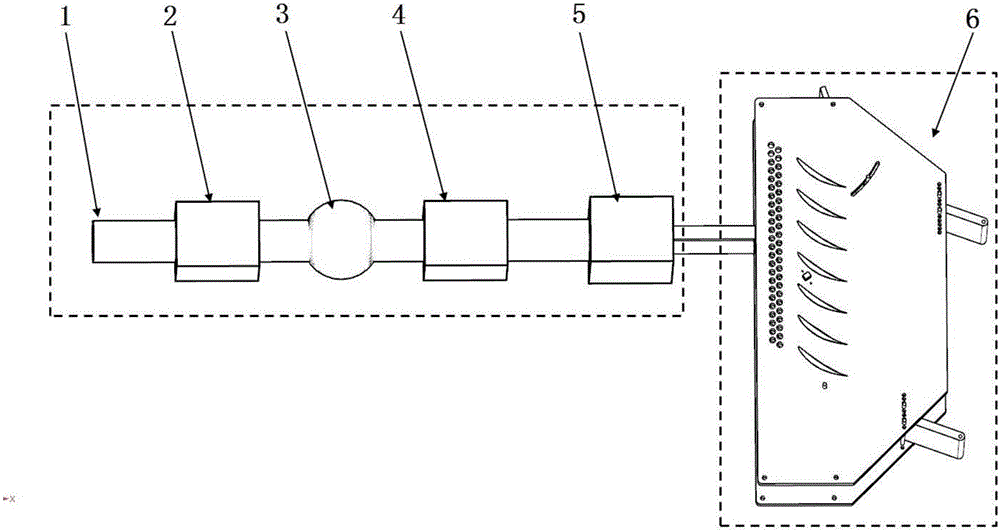

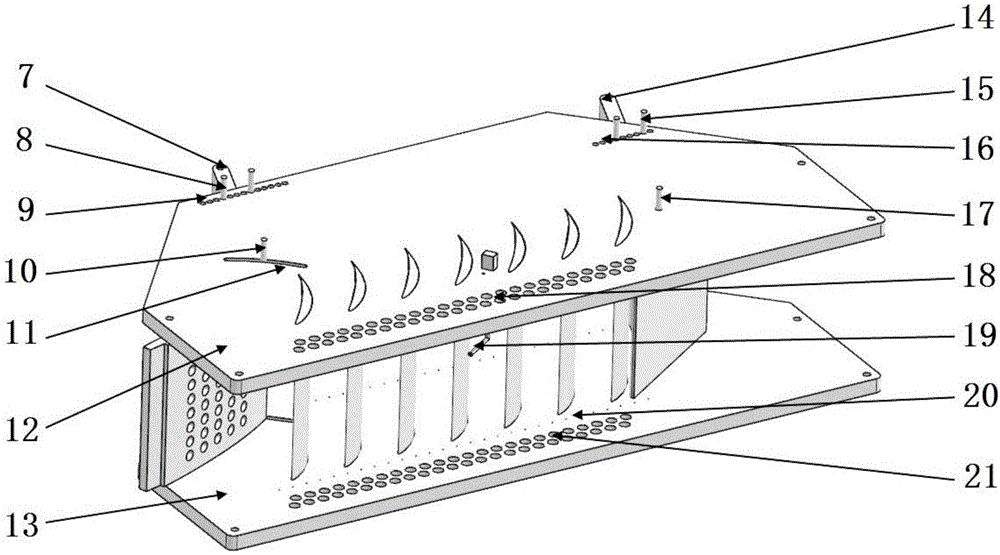

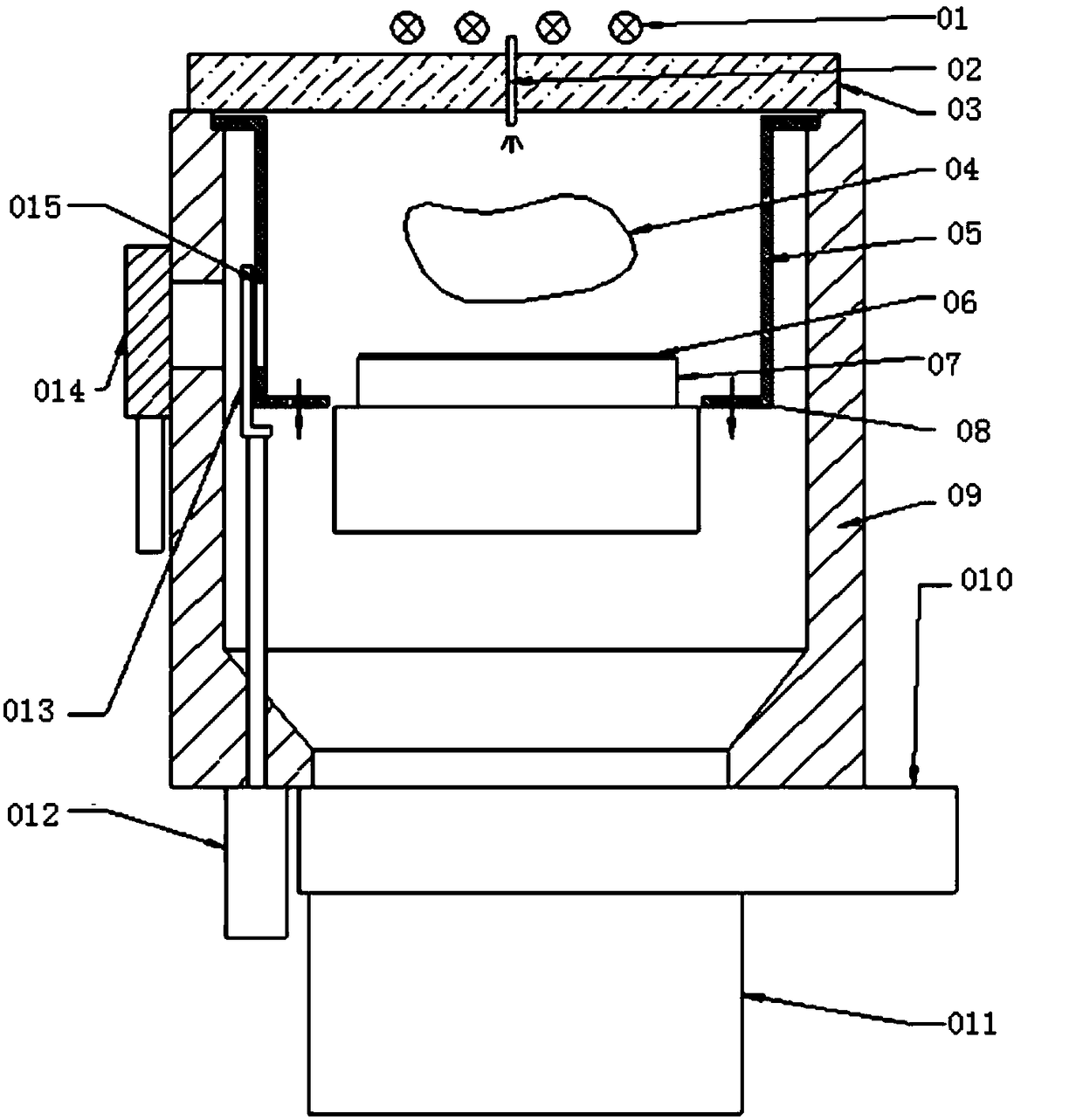

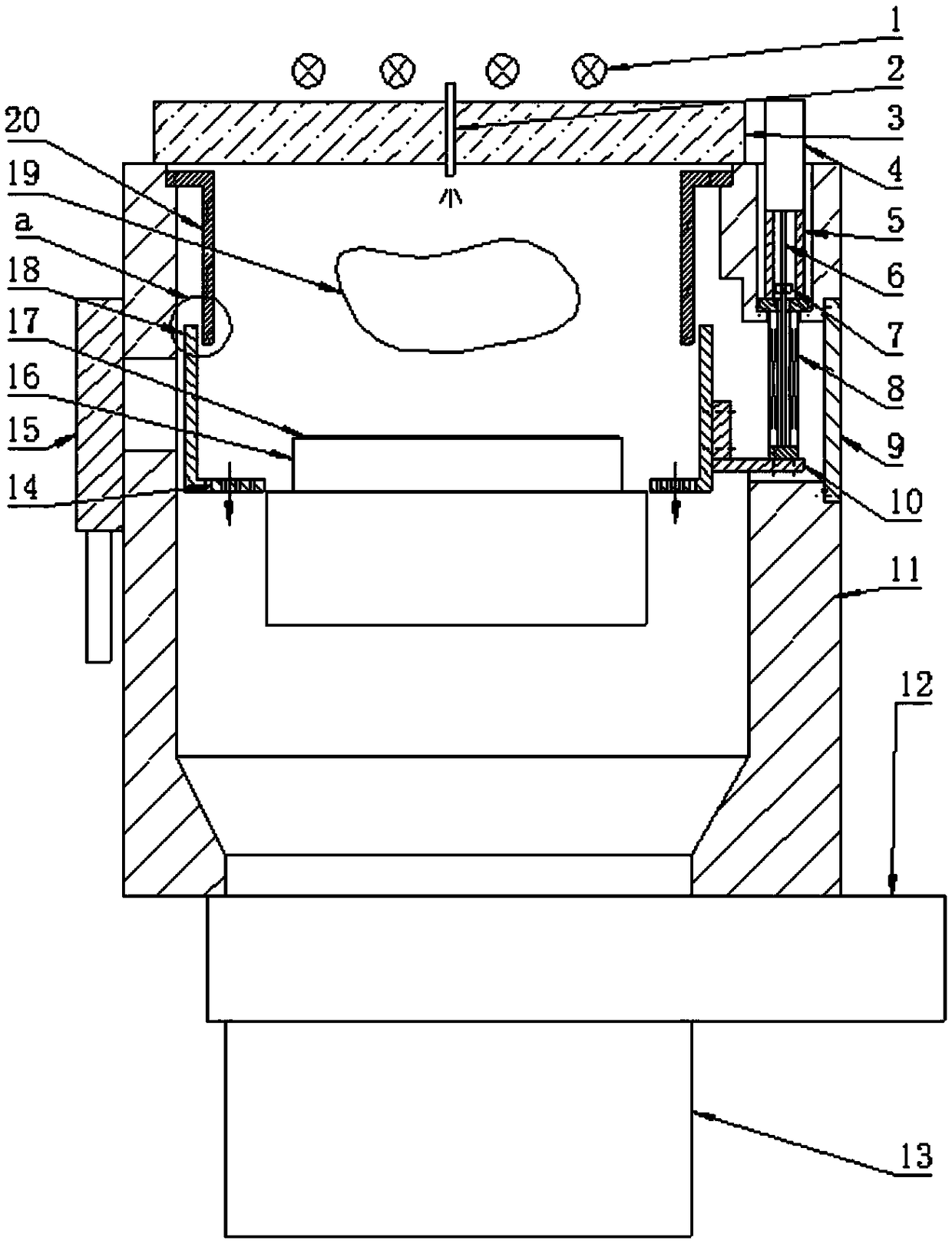

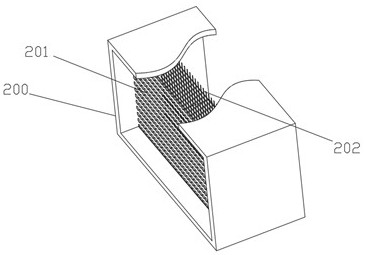

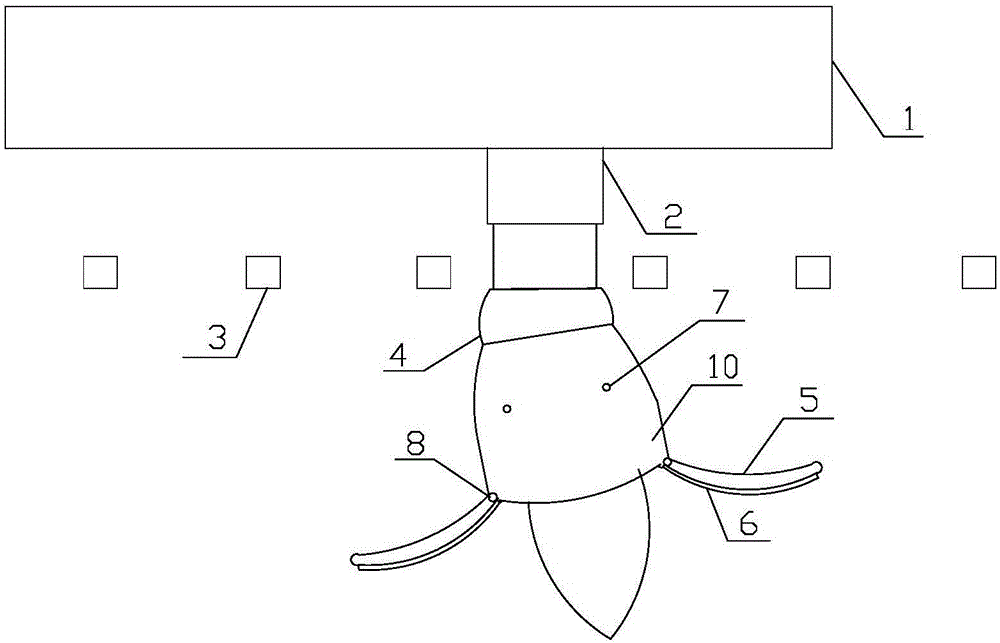

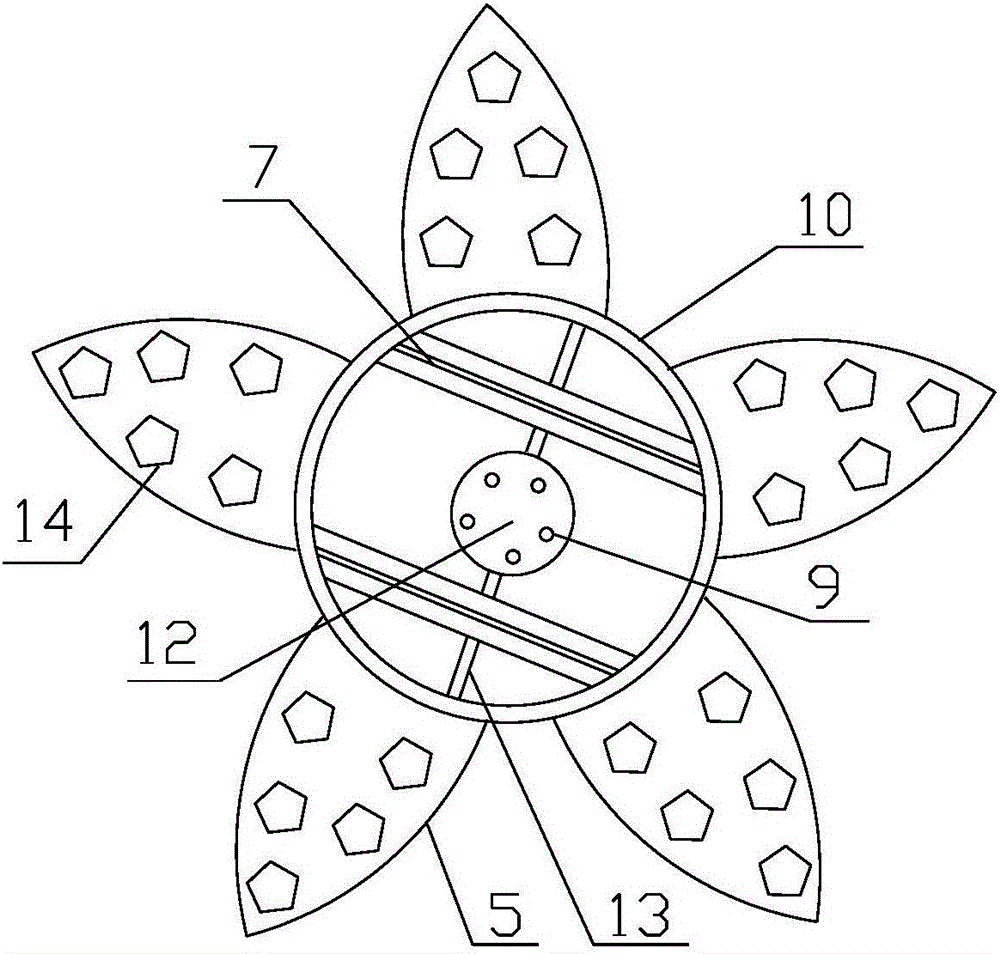

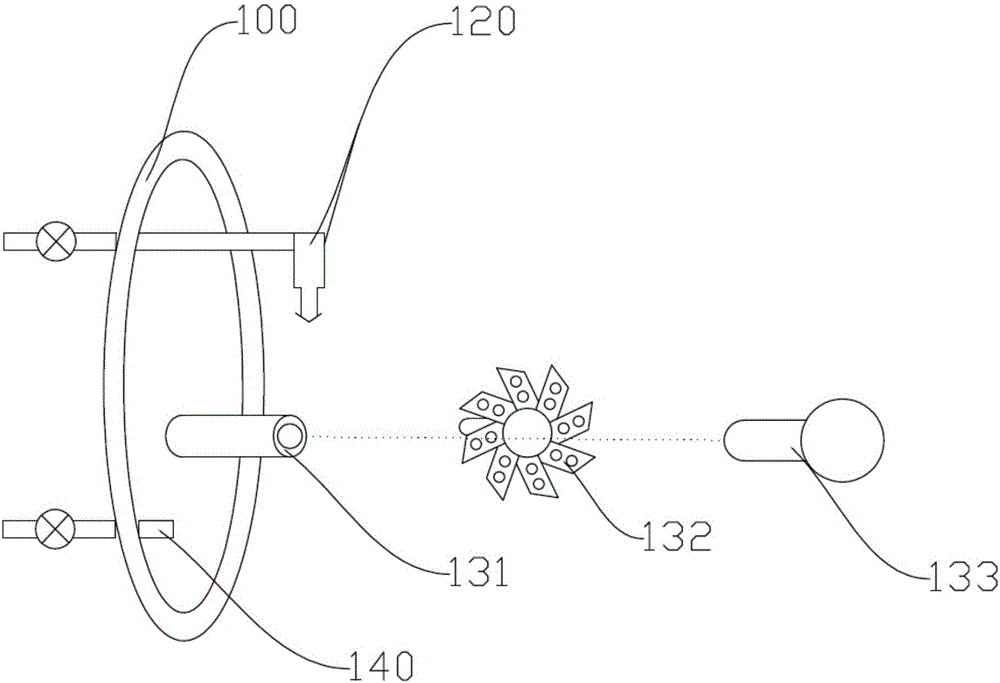

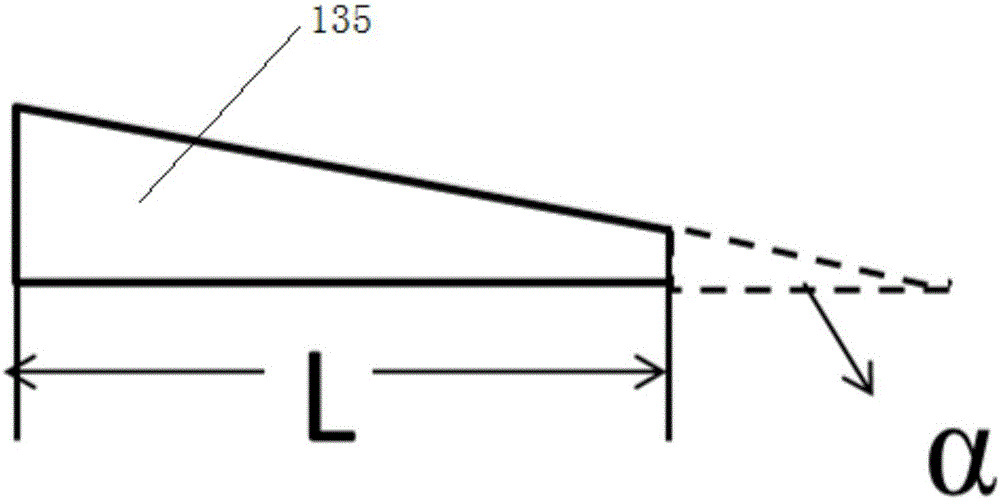

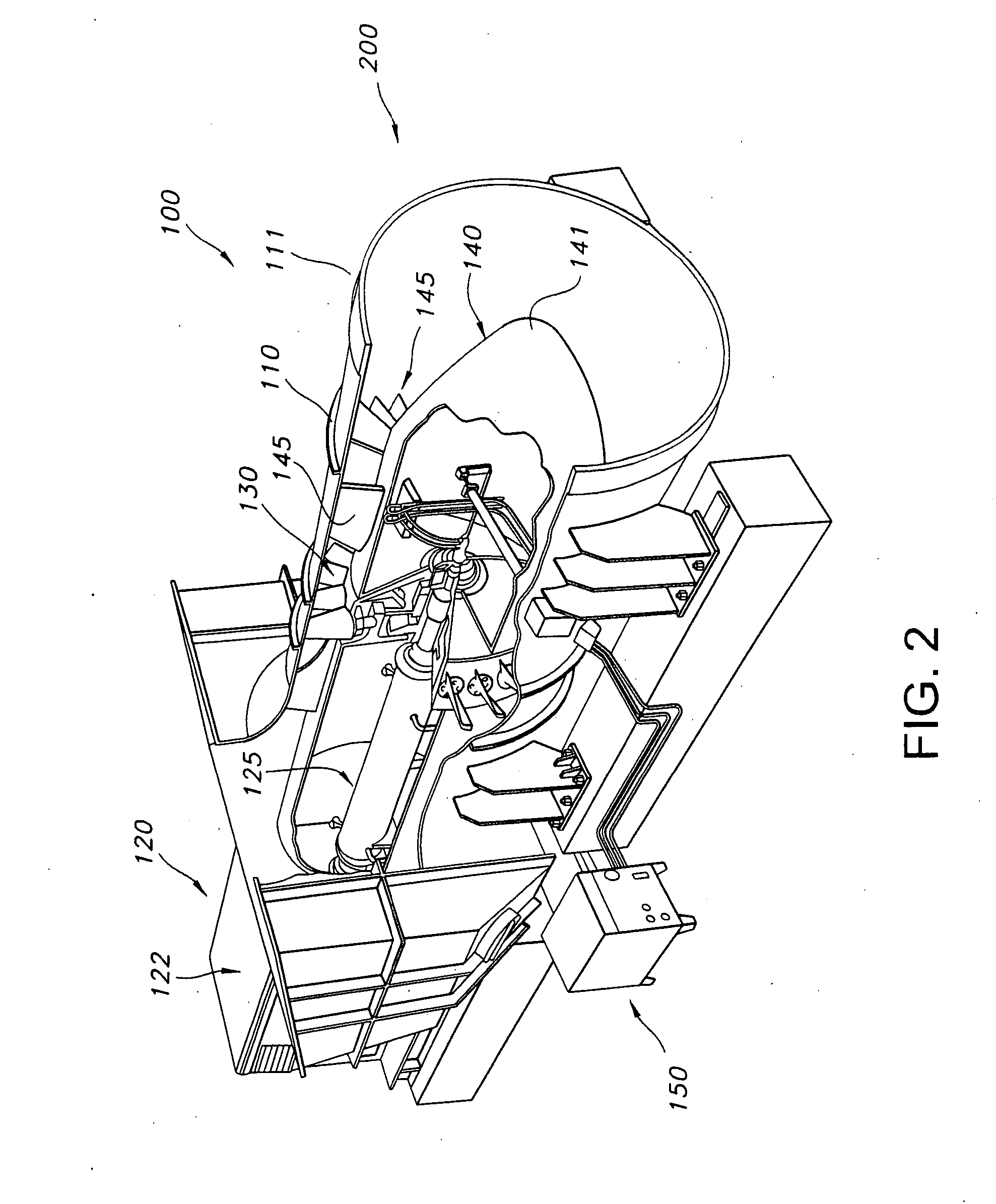

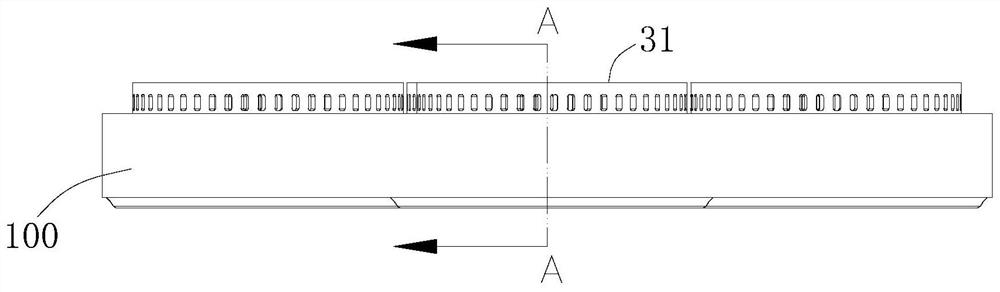

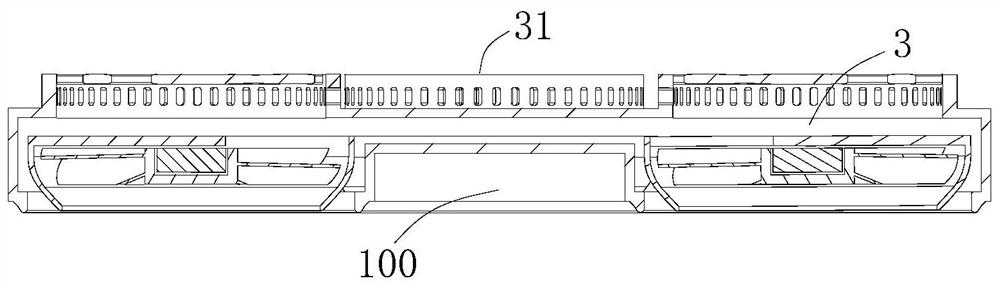

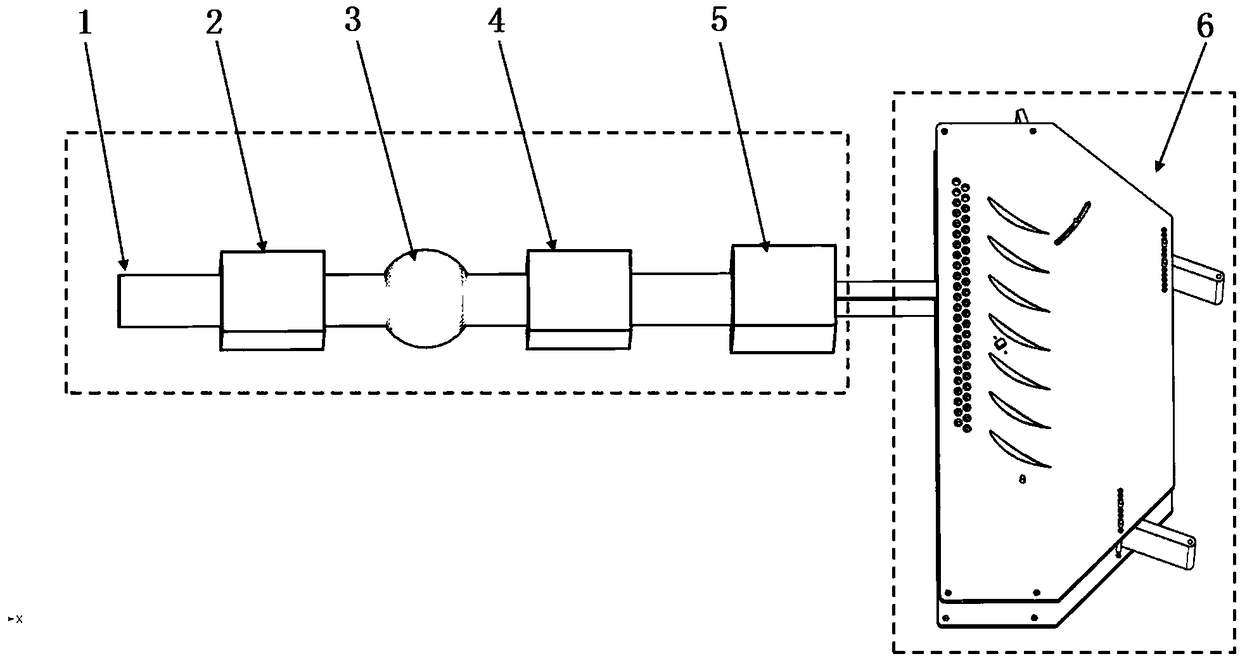

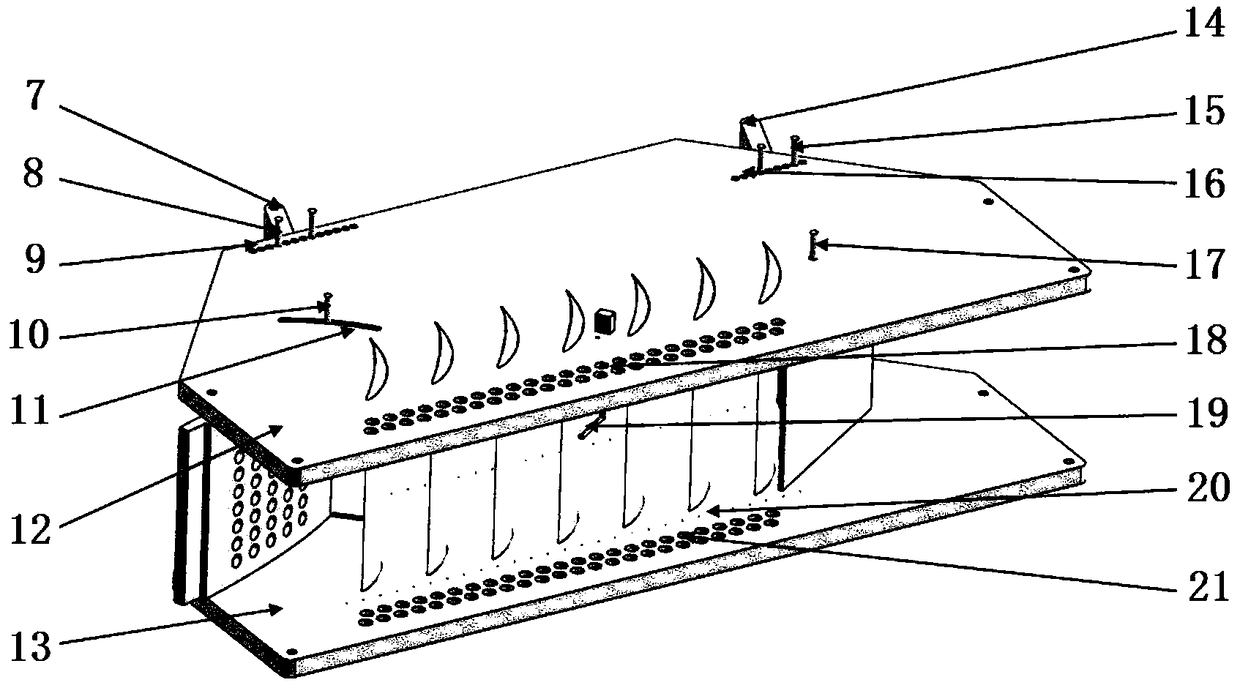

Gas compressor plane cascade experimental system with suction baffle structure

ActiveCN106640619AShort maintenance periodGood periodicityPump testingPump controlGas compressorVacuum pump

The invention provides a gas compressor plane cascade experimental system with a suction baffle structure. The gas compressor plane cascade experimental system comprises a suction device and a plane cascade experimental device. The plane cascade experimental device comprises a left end plate, a right end plate, an upper baffle, a plurality of experimental blades and a lower baffle, wherein the upper baffle is arranged between the left end plate and the right end plate, and the multiple experimental blades are distributed at intervals. The upper baffle and the lower baffle are connected between the left end plate and the right end plate through fixing shafts. The upper baffle is provided with suction holes. Left end plate suction holes are formed in the left end plate, and right end plate suction holes are formed in the right end plate. The suction holes are connected with a vacuum pump through a pipeline. A three-hole probe 1 is arranged between the left end plate and the right end plate. In the experimental process, the upper baffle and the lower baffle are adjusted so that a cascade can be good in periodicity, the boundary layer of incoming flow is sucked through the left end plate suction holes and the right end plate suction holes, the influence area of the boundary layer is reduced, and uniform incoming flow is achieved. The gas compressor plane cascade experimental system with the suction baffle structure is an effective path for exploring improvement of the performance of a gas compressor, the influence of the boundary layer of the incoming flow is reduced, and meanwhile, the periodicity of the plane cascade is improved.

Owner:DALIAN MARITIME UNIVERSITY

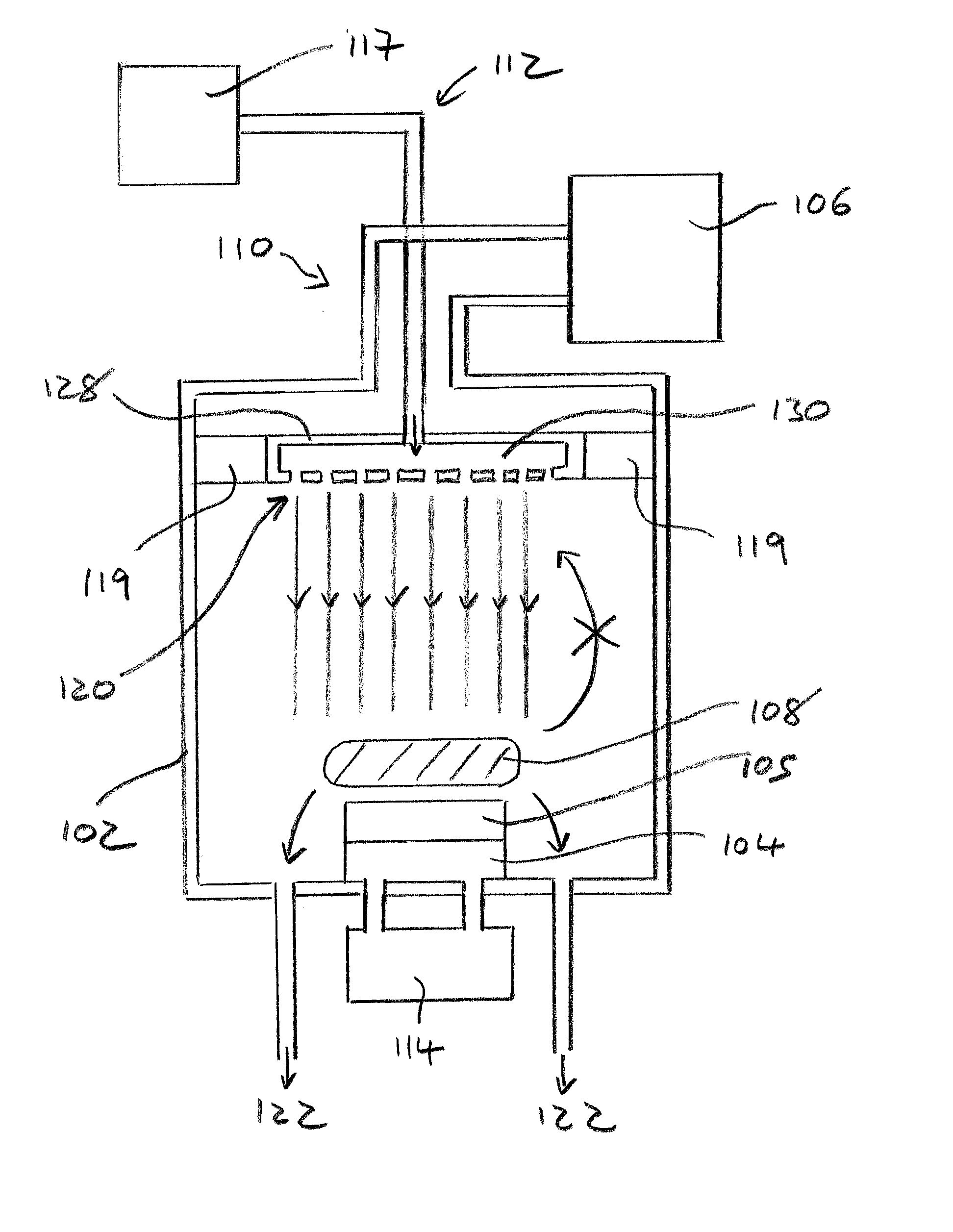

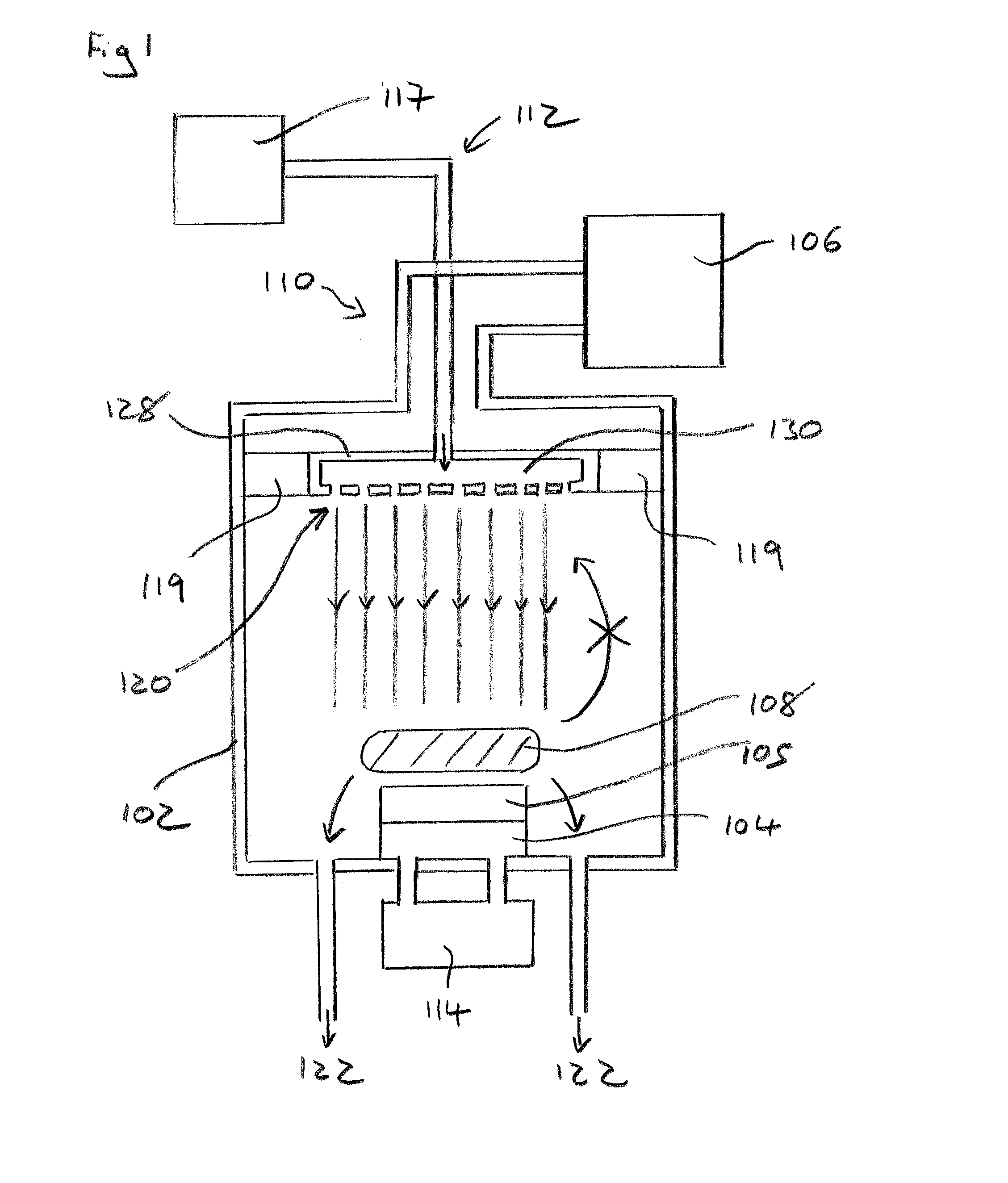

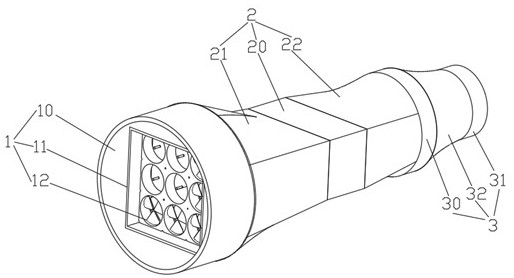

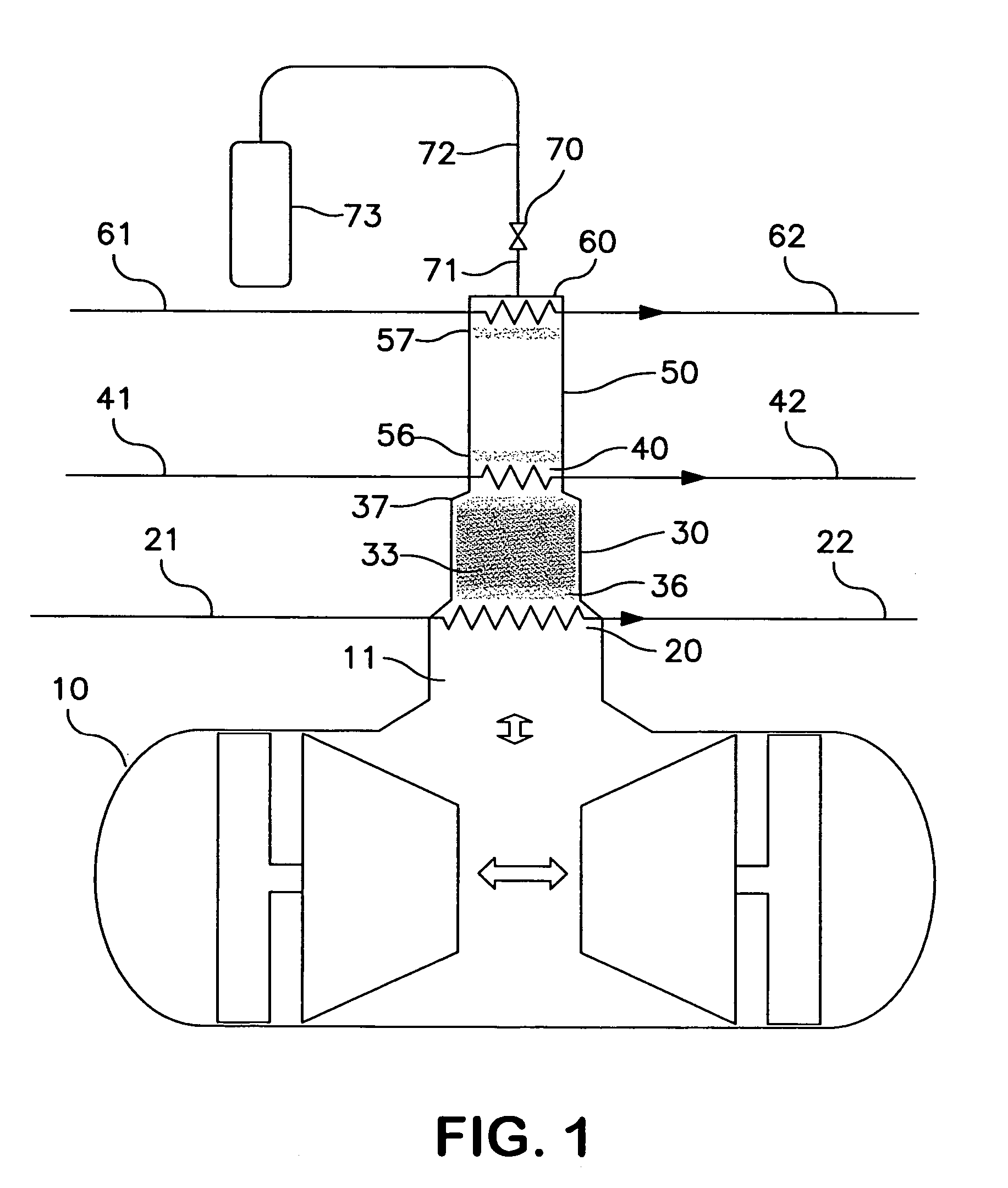

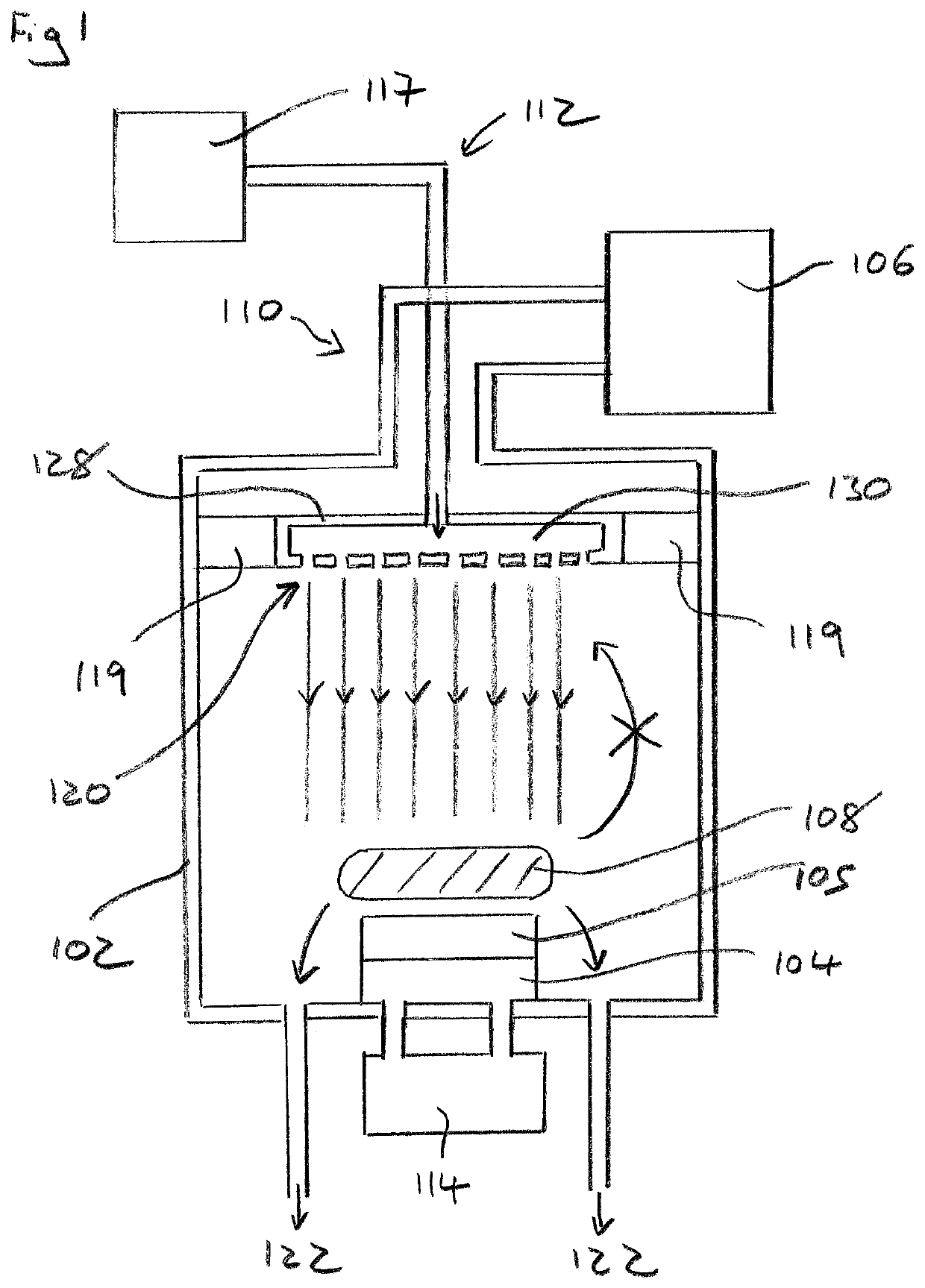

Microwave plasma reactor for manufacturing synthetic diamond material

ActiveUS20150030786A1Increase speedReduce decreasePolycrystalline material growthElectric discharge tubesSynthetic diamondPlasma reactor

A microwave plasma reactor for manufacturing synthetic diamond material via chemical vapour deposition, the microwave plasma reactor comprising: a plasma chamber; a substrate holder disposed in the plasma chamber for supporting a substrate on which the synthetic diamond material is to be deposited in use; a microwave coupling configuration for feeding microwaves from a microwave generator into the plasma chamber; and a gas flow system for feeding process gases into the plasma chamber and removing them therefrom; wherein the gas flow system comprises a gas inlet nozzle array comprising a plurality of gas inlet nozzles disposed opposite the substrate holder for directing process gases towards the substrate holder, the gas inlet nozzle array comprising: at least six gas inlet nozzles disposed in a substantially parallel or divergent orientation relative to a central axis of the plasma chamber; a gas inlet nozzle number density equal to or greater than 0.1 nozzles / cm2, wherein the gas inlet nozzle number density is measured by projecting the nozzles onto a plane whose normal lies parallel to the central axis of the plasma chamber and measuring the gas inlet number density on said plane; and a nozzle area ratio of equal to or greater than 10, wherein the nozzle area ratio is measured by projecting the nozzles onto a plane whose normal lies parallel to the central axis of the plasma chamber, measuring the total area of the gas inlet nozzle area on said plane, dividing by the total number of nozzles to give an area associated with each nozzle, and dividing the area associated with each nozzle by an actual area of each nozzle.

Owner:ELEMENT SIX TECH LTD

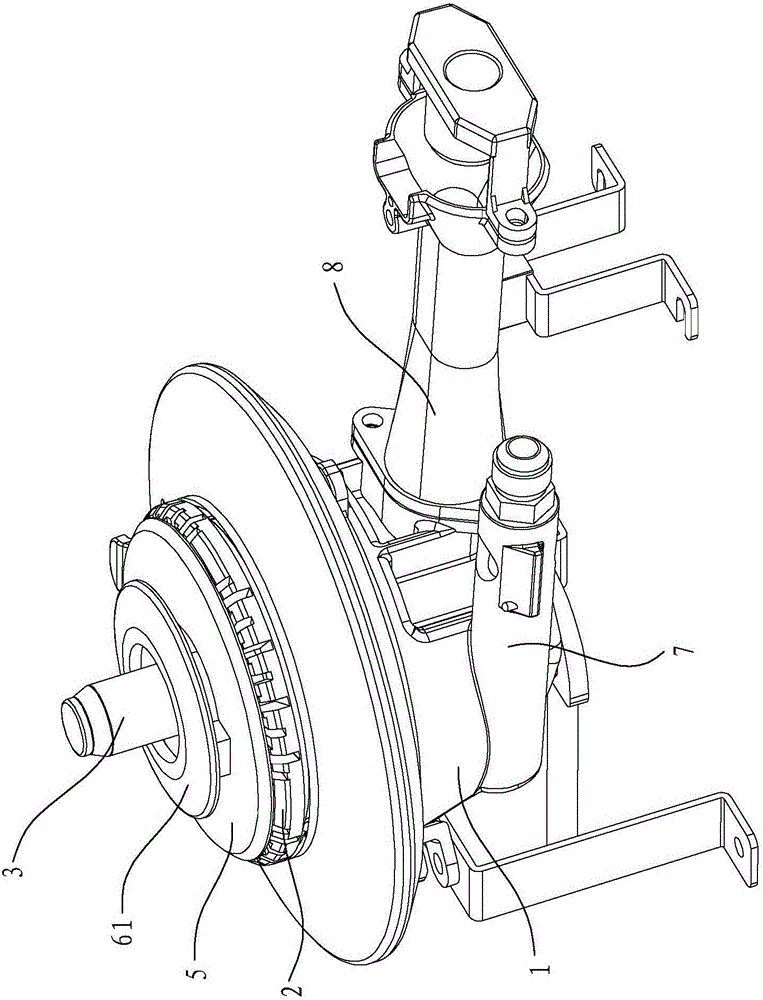

Reaction chamber and plasma apparatus

PendingCN108987237AProtect from being etchedImproves airflow uniformityElectric discharge tubesProcess regionEngineering

The embodiment of the invention discloses a reaction chamber and a plasma apparatus. The reaction chamber comprises a chamber body, an inner liner, a support assembly and a lifting driving device. Theliner includes a first liner and a second liner; The second liner is coaxially sleeved or sleeved on the first liner and has a gap between the first liner and the second liner, and the lifting and lowering driving device is used for driving the second liner up or down; When the wafer is processed, the length of the overlapping portion of the first liner and the second liner is a predetermined length such that the wafer is located in a process region surrounded by the first liner and the second liner. According to the present invention, The plasma can be confined in a certain process area in the process treatment process, the inner wall of the chamber body can be protected from etching, the gas flow uniformity in the process is improved, the process is stable for a long time, the etching result from the center to the edge of the wafer is consistent, and the yield of the product is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

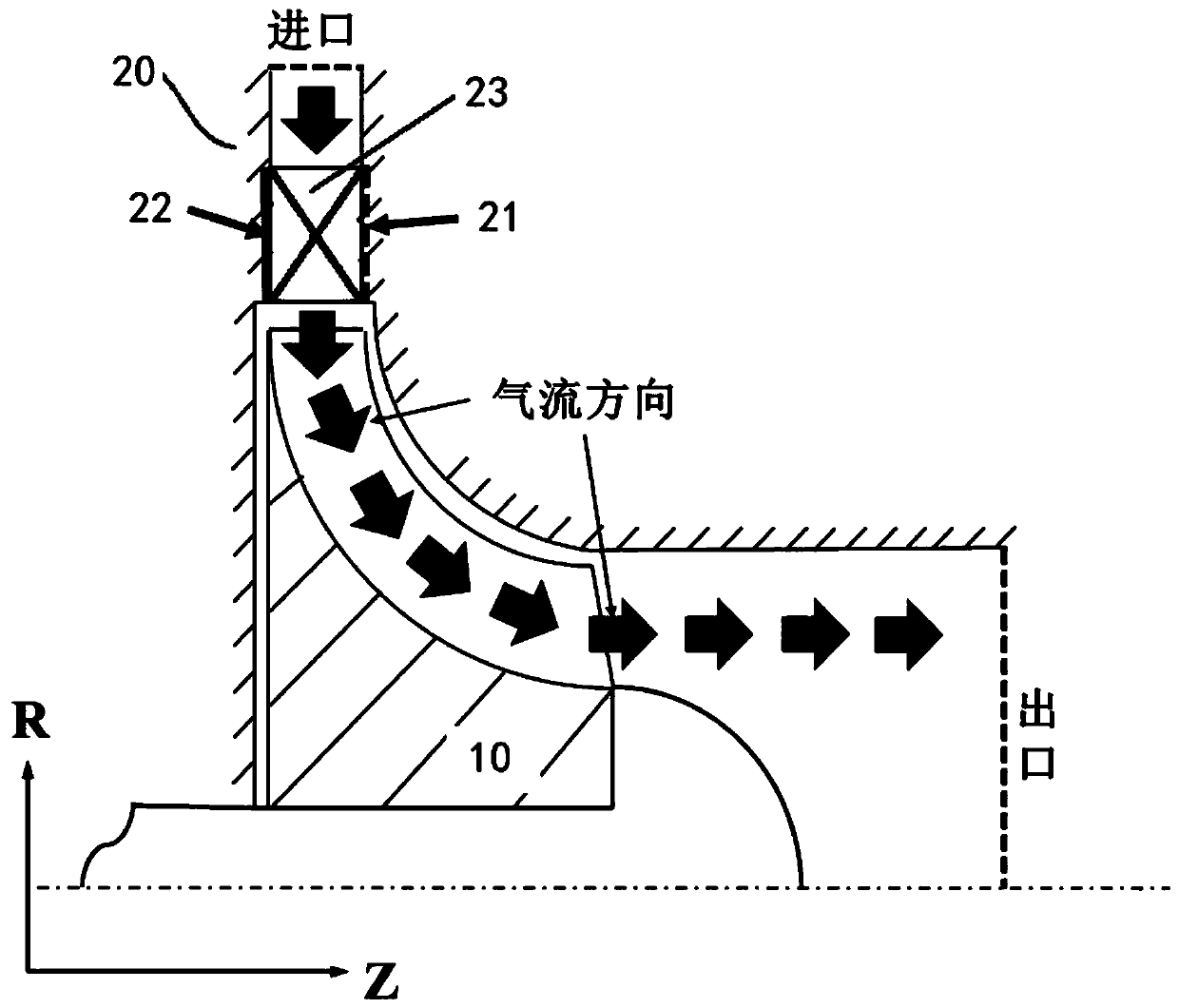

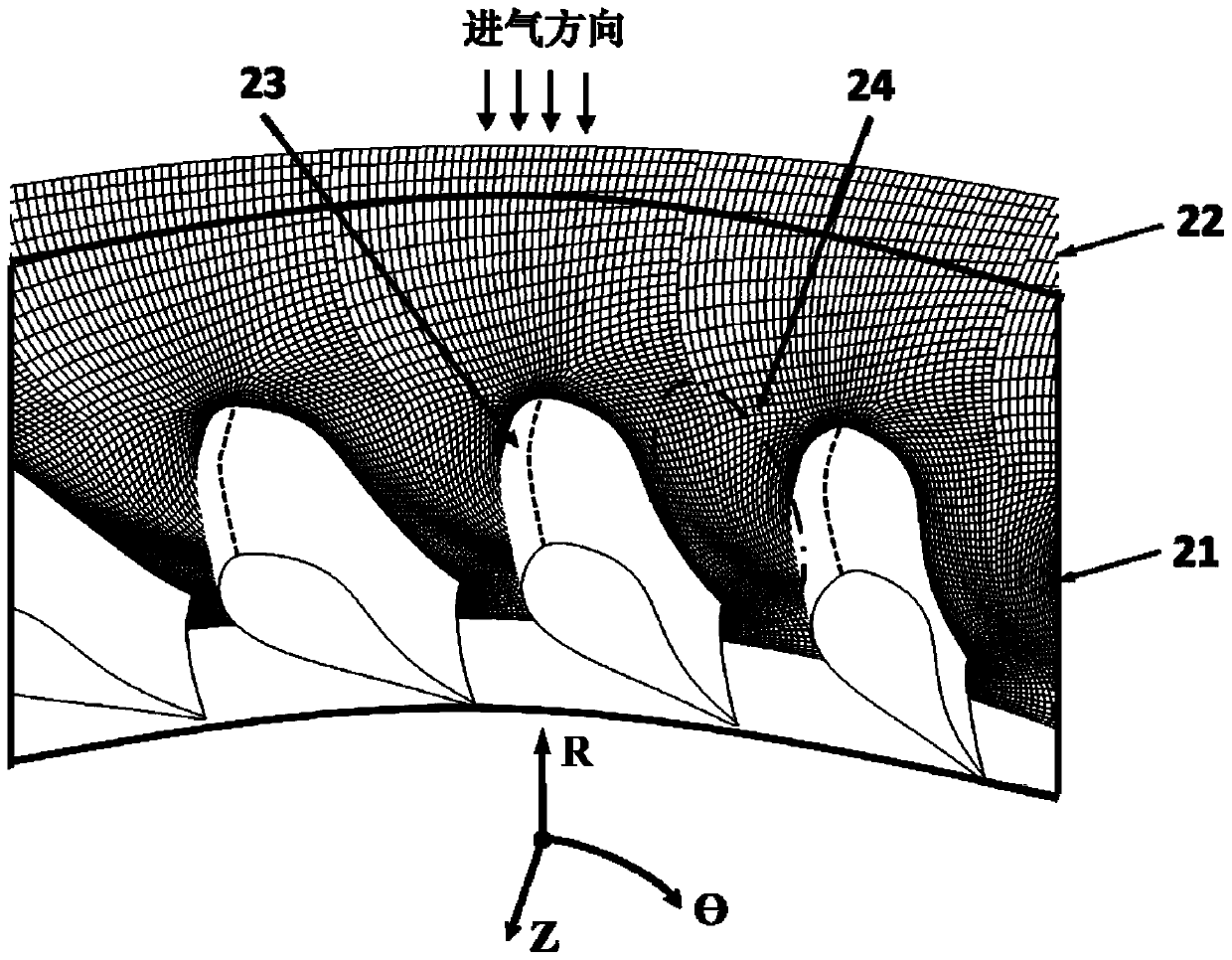

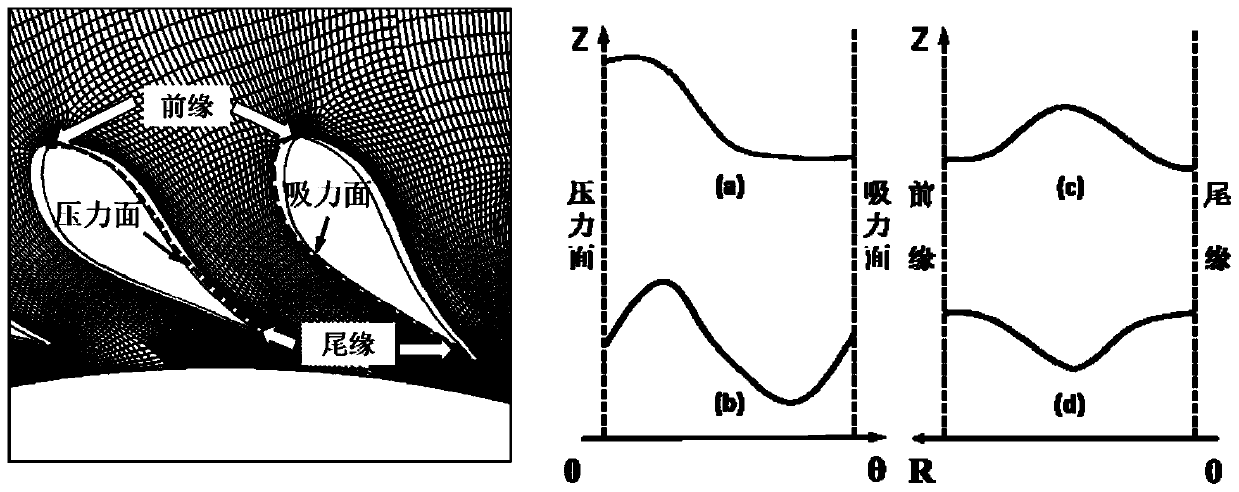

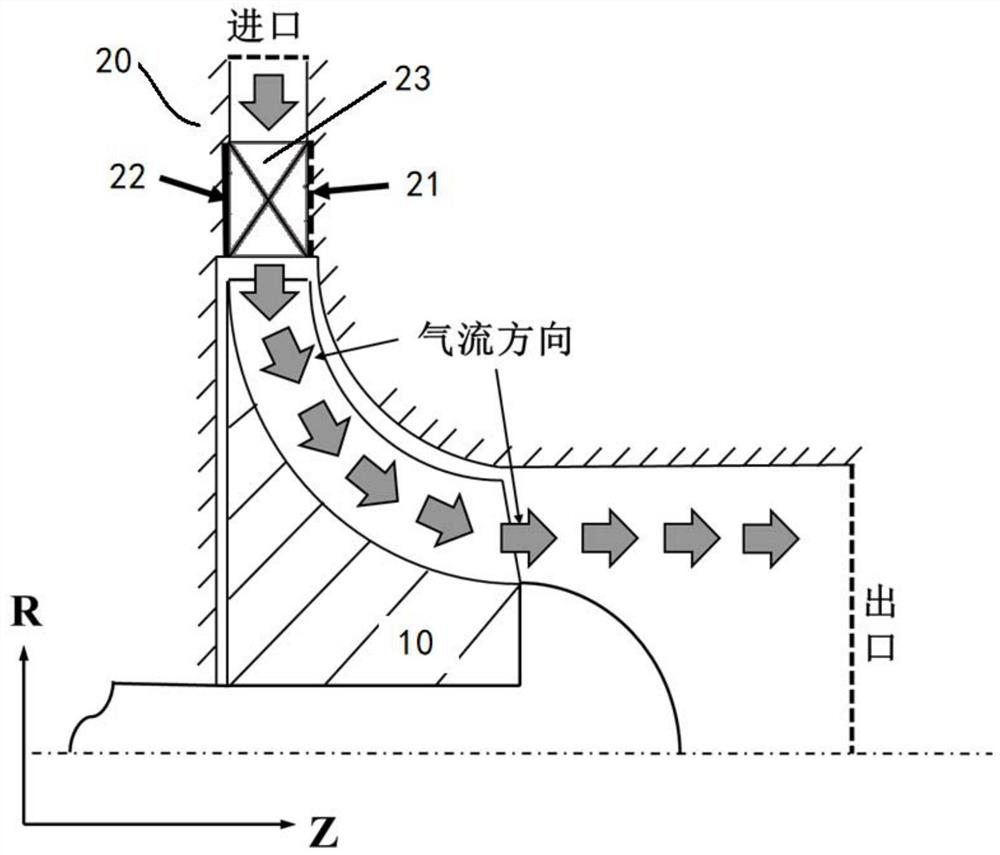

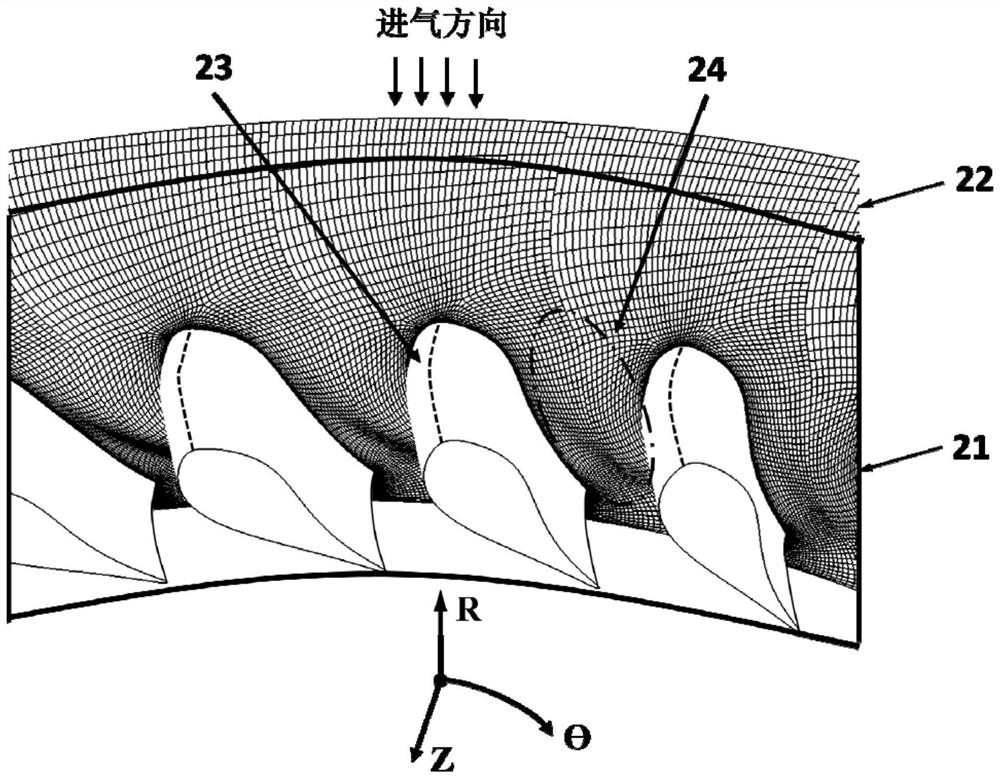

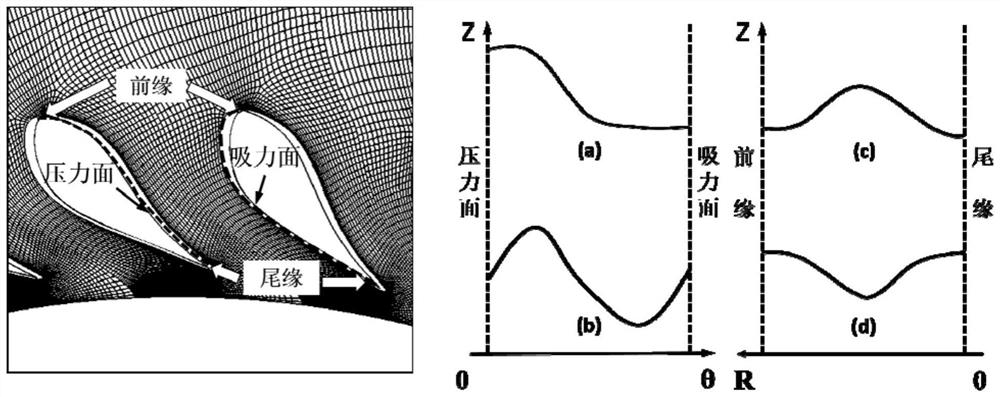

Radial flow turbine guide vane structure coupled with non-axisymmetric end walls

ActiveCN110608068ADelayed formationImproves airflow uniformityStatorsMachines/enginesEngineeringPressure difference

The invention relates to a radial flow turbine guide vane structure coupled with non-axisymmetric end walls. The radial flow turbine guide vane structure aims to solve the technical problems of remarkable secondary flow of low-span chord ratio runoff guide vane end walls, relatively large channel vortex size, poor outlet air flow uniformity and the like. A non-axisymmetric concave-convex end wallstructure is adopted at each of the front end walls and the rear end walls of radial flow turbine guide vanes and can be matched with the radial flow turbine guide vanes with the three-dimensional configuration to control the flow channel secondary flow loss more effectively. According to the radial flow turbine guide vane structure, a blade lattice is modified, and specifically, the inner surfaces of the front end walls and the rear end walls are correspondingly arranged as the non-axisymmetric concave-convex end wall structures, so that the flow area of each flow channel is changed, and theair flow pressure difference between the pressure surface on one side of each flow channel and the suction surface on the other side of each flow channel is reduced, so that the secondary flow velocity distribution is affected, the formation and development of the channel vortex are delayed, the channel vortex intensity is reduced, and the reduction of the secondary flow loss is finally realized.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

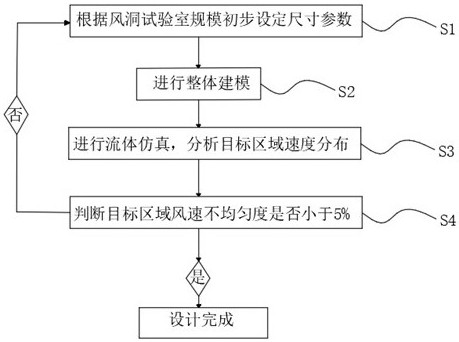

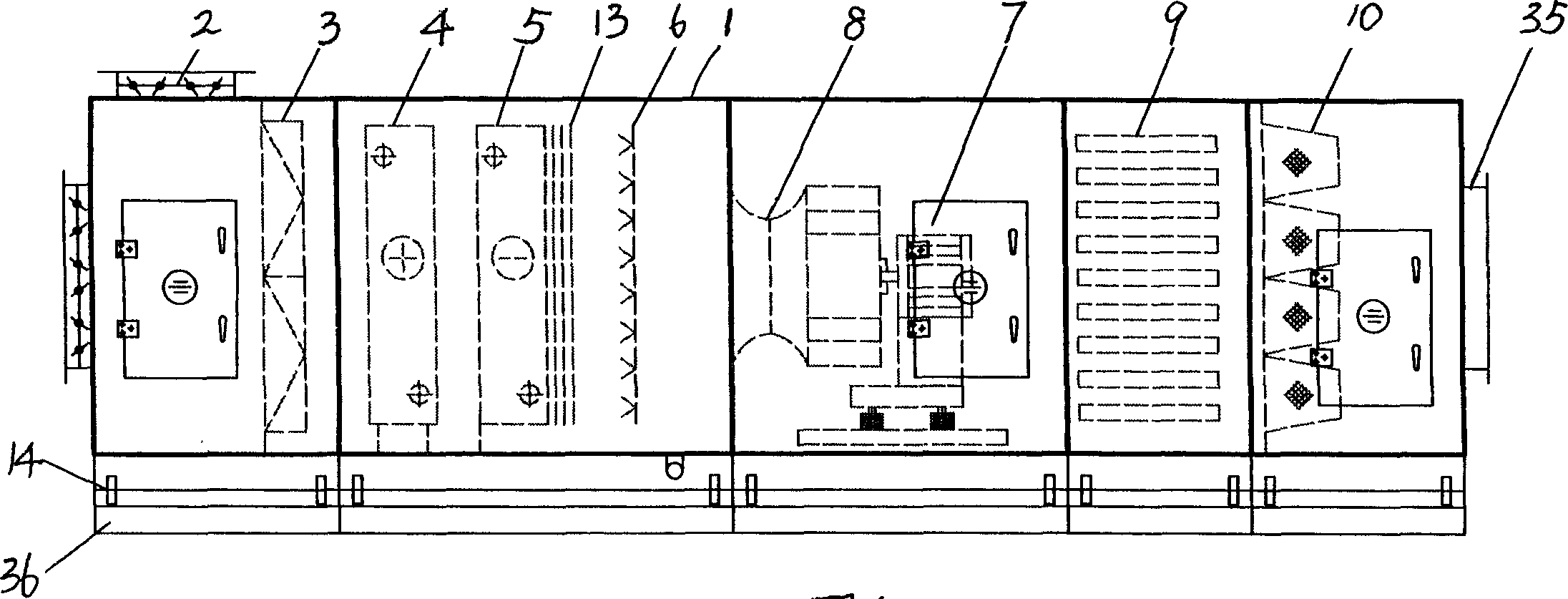

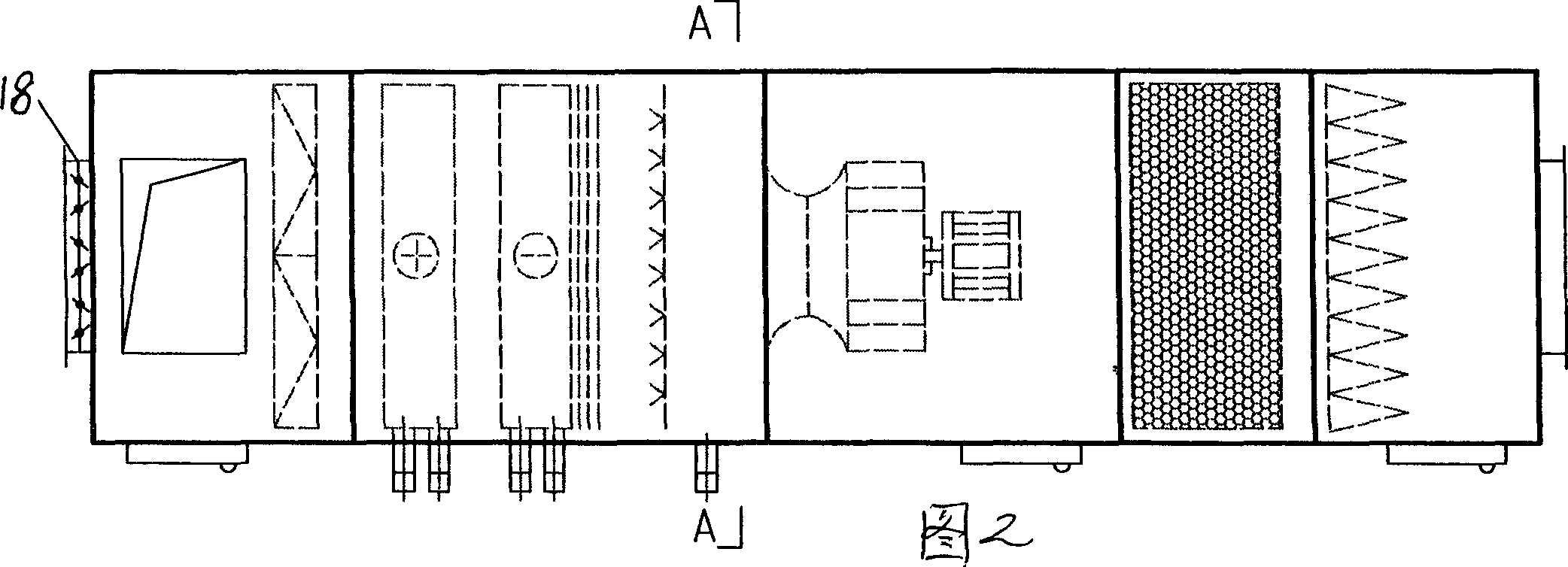

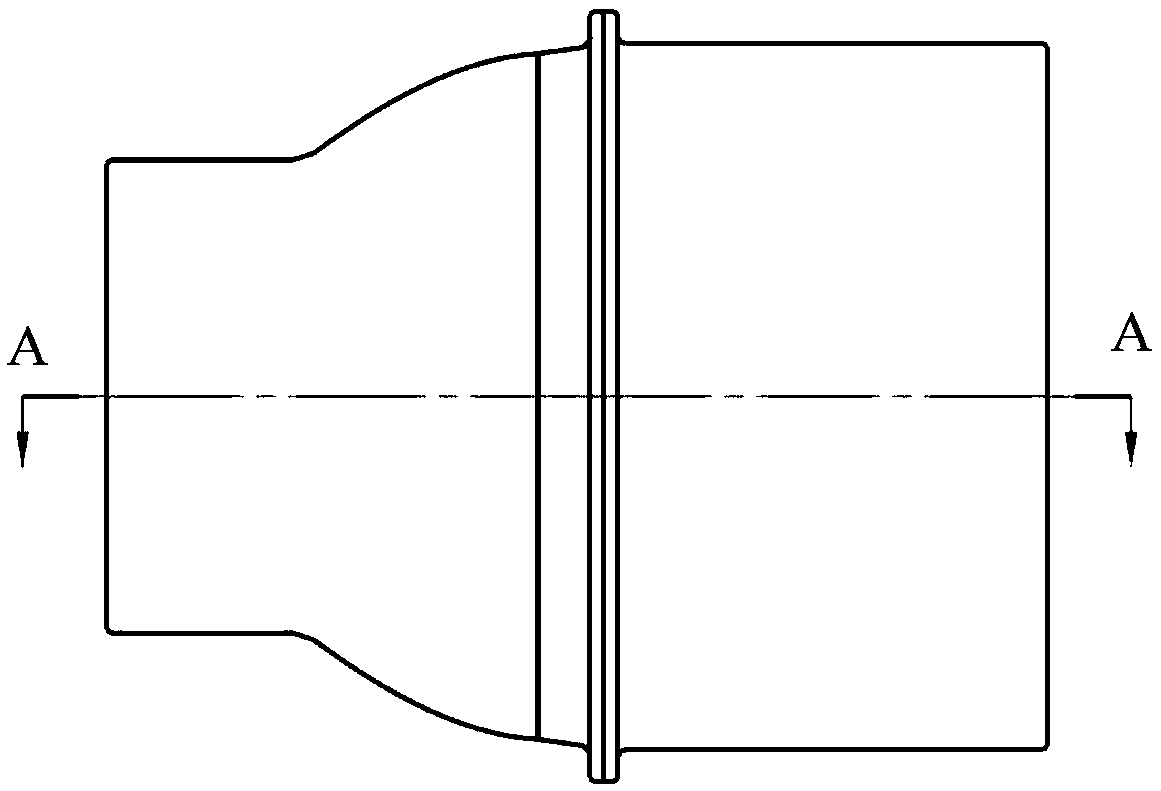

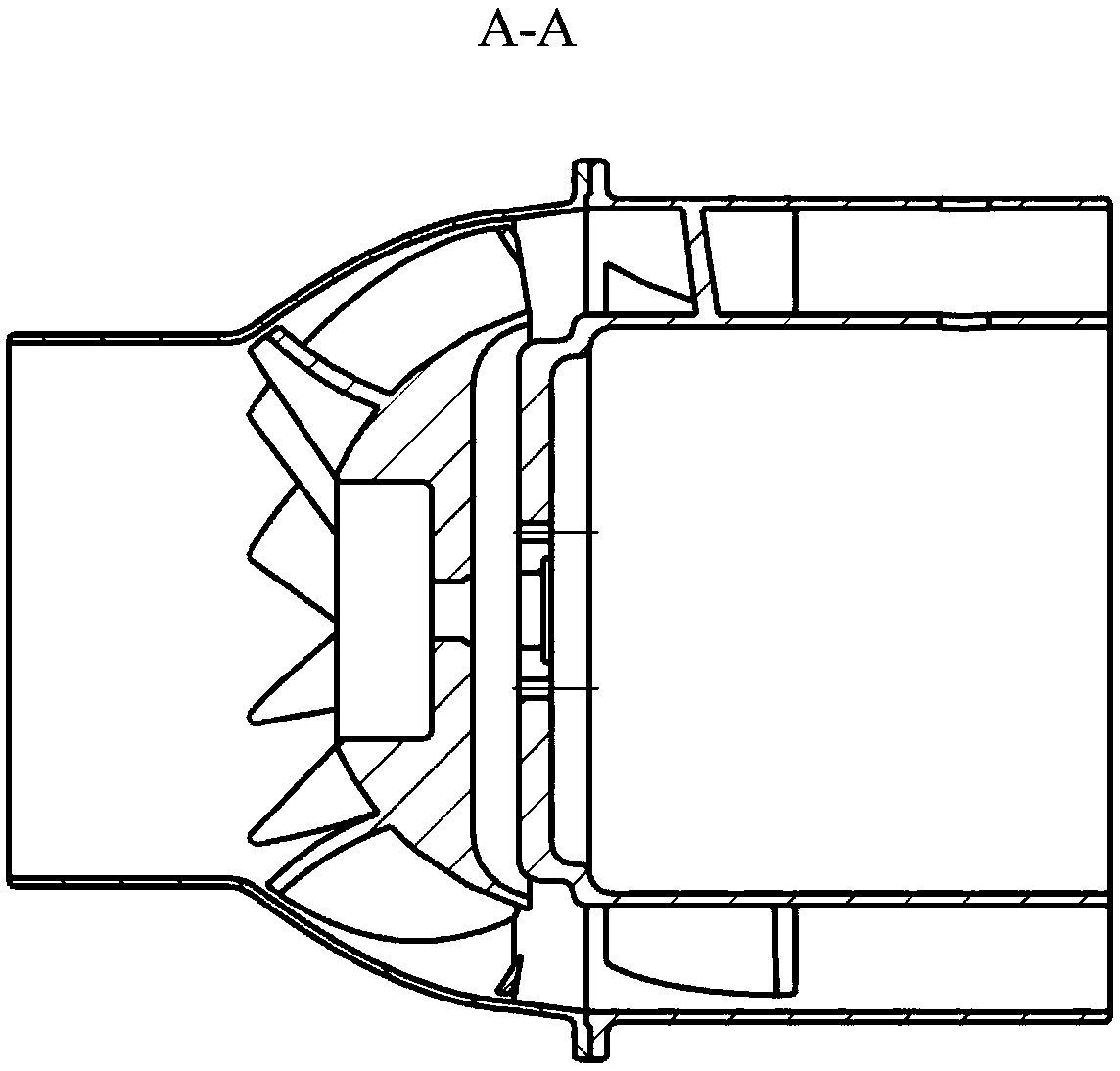

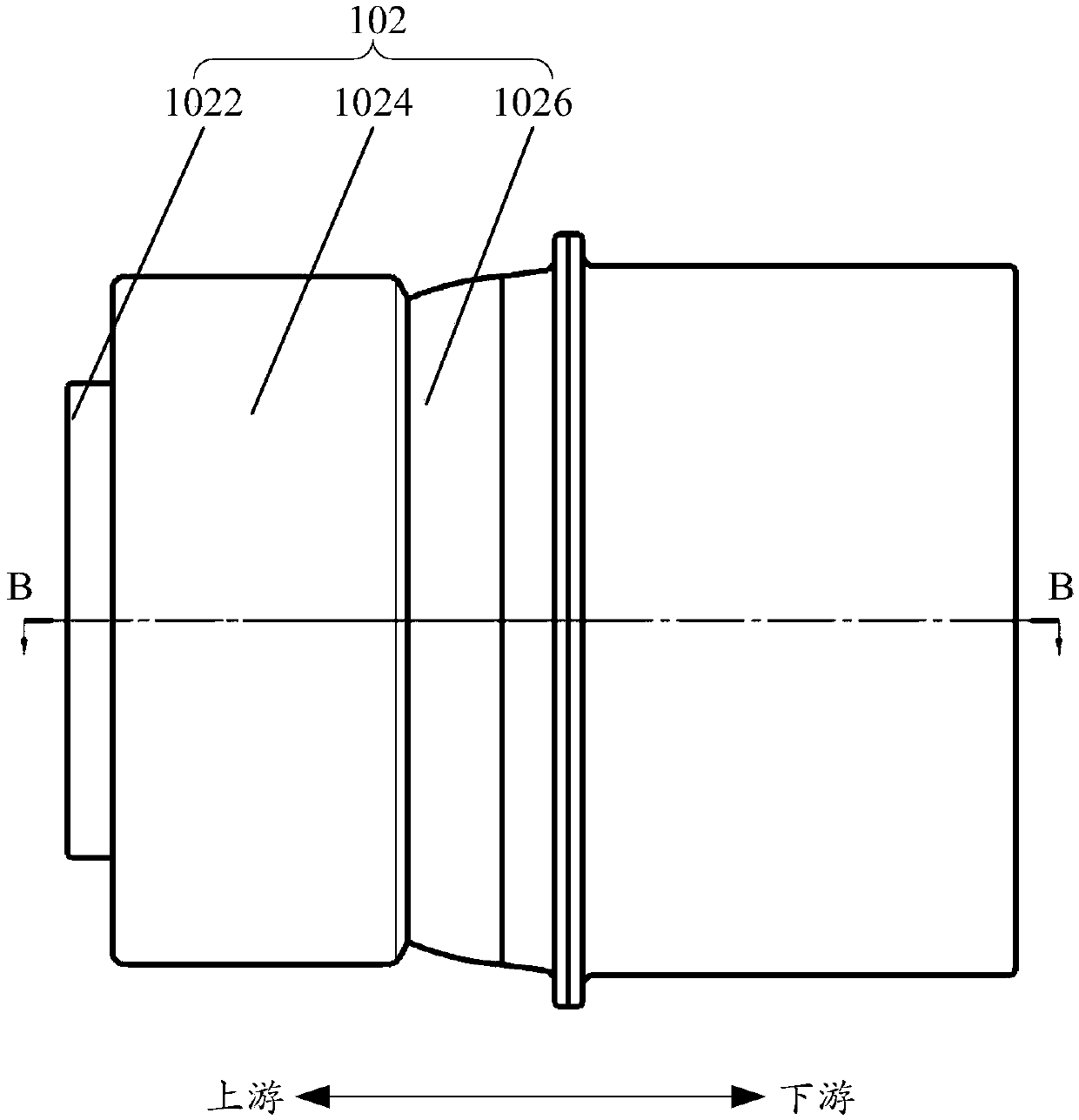

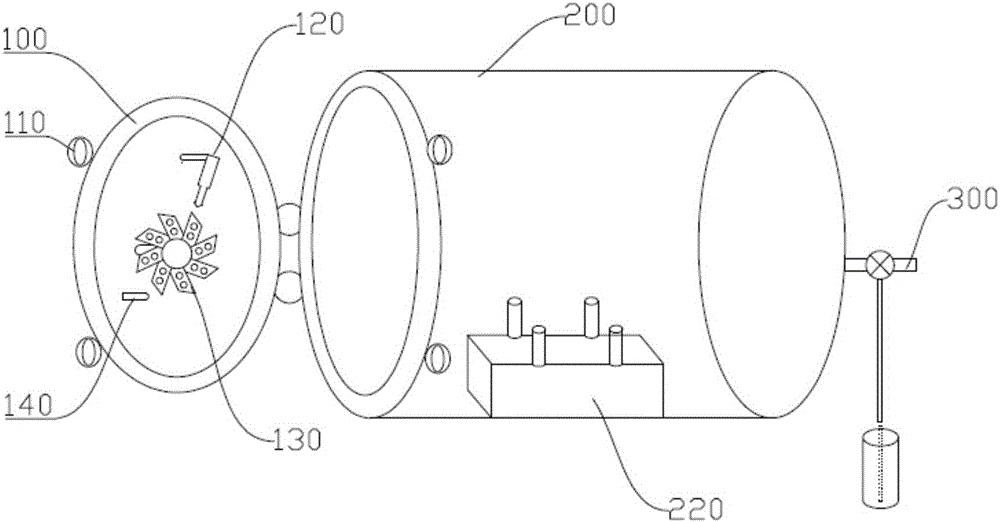

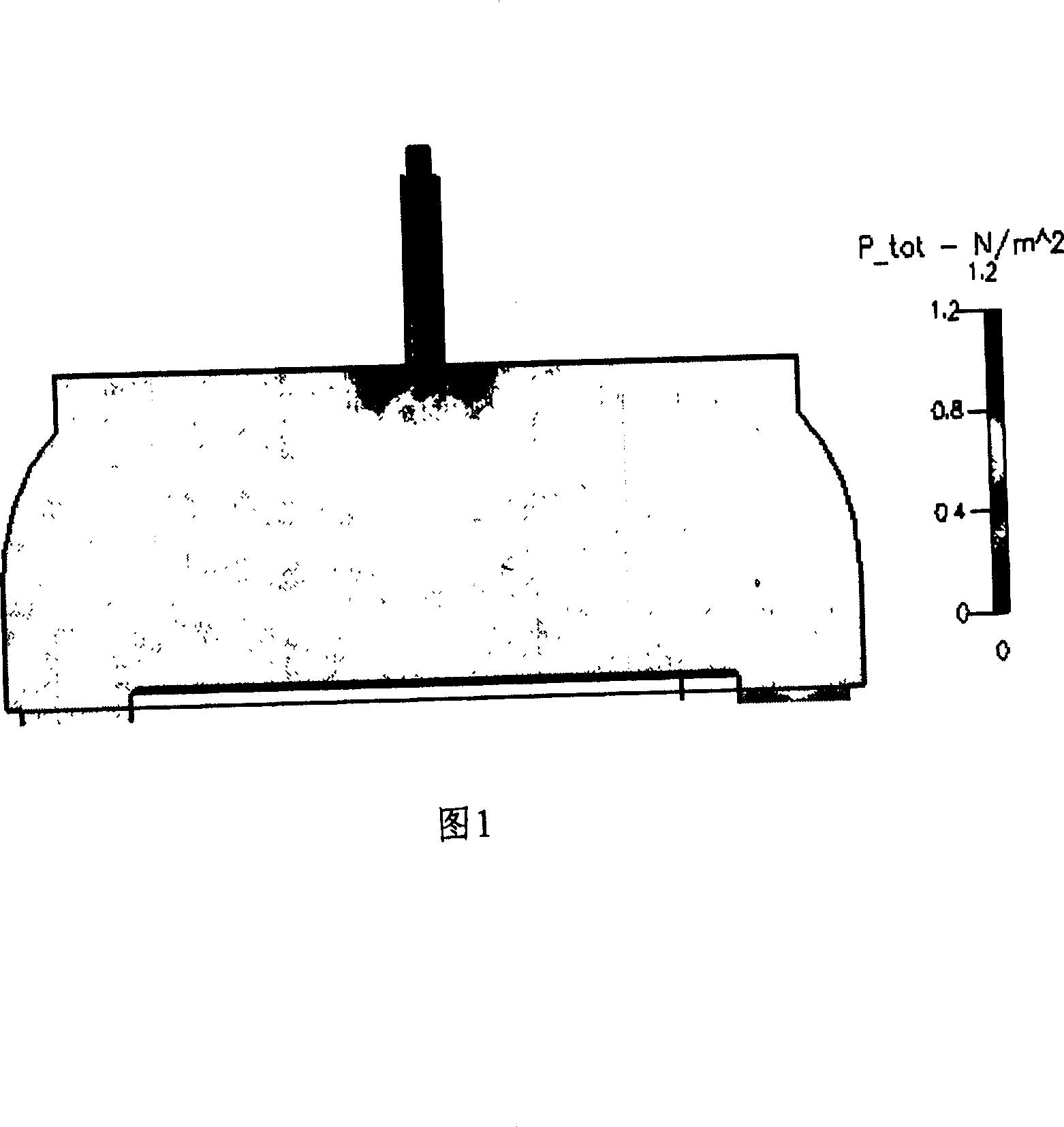

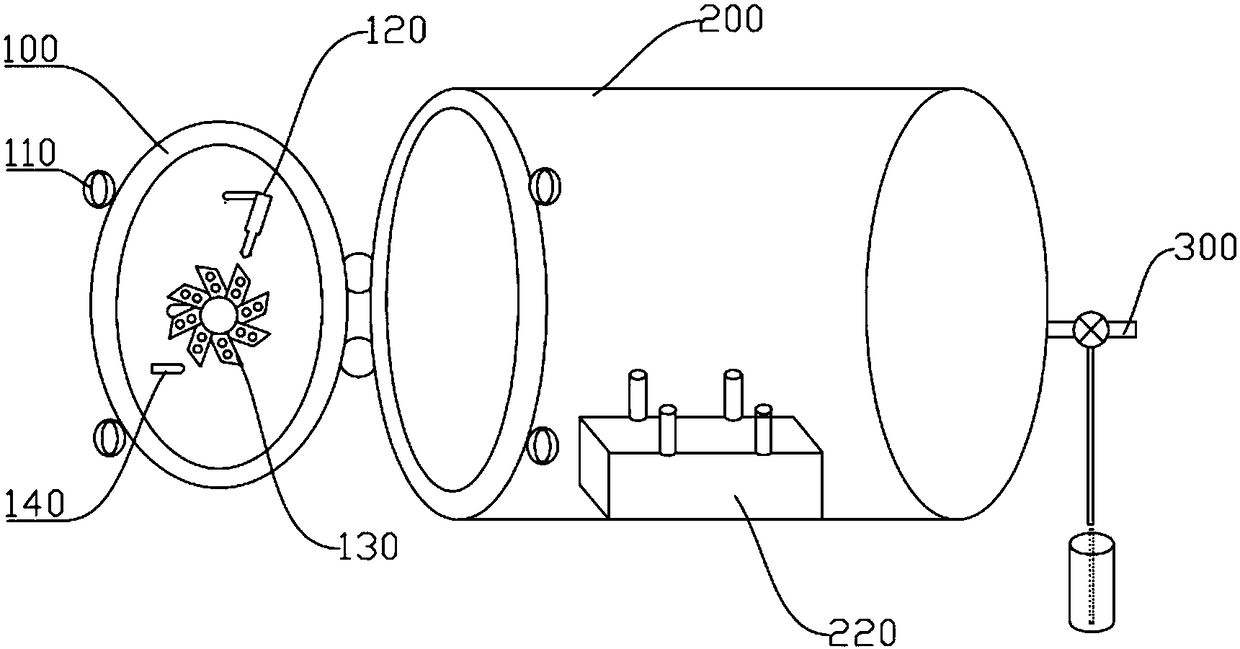

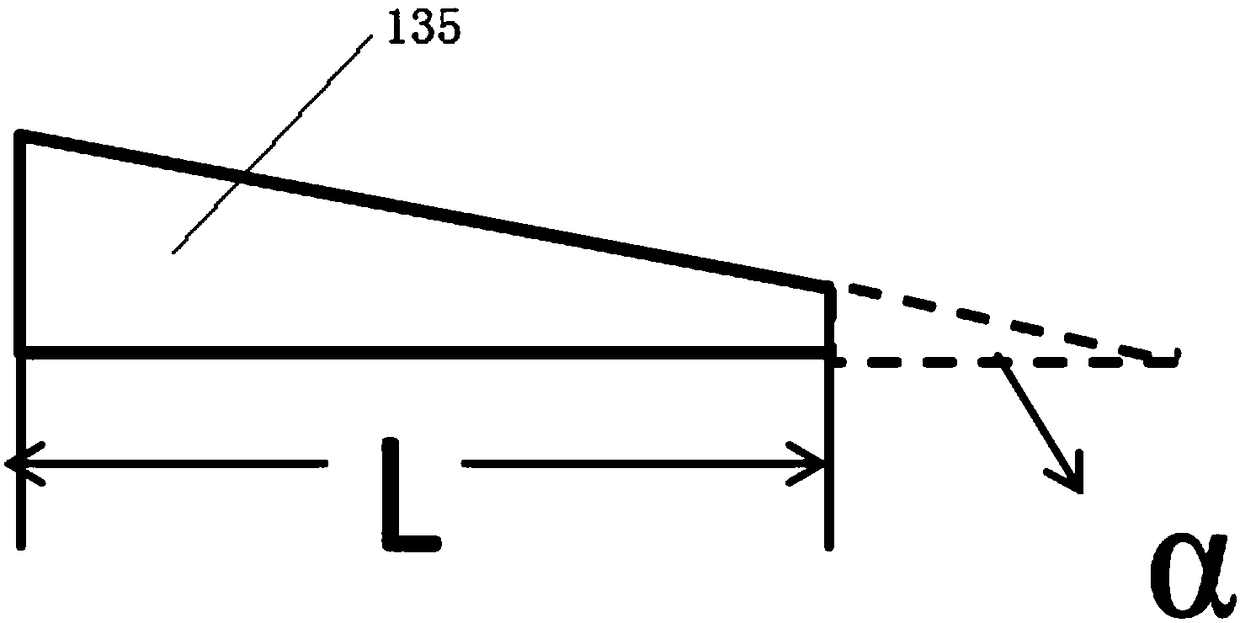

Device for improving aircraft experiment wind tunnel airflow uniformity and parameter optimization method thereof

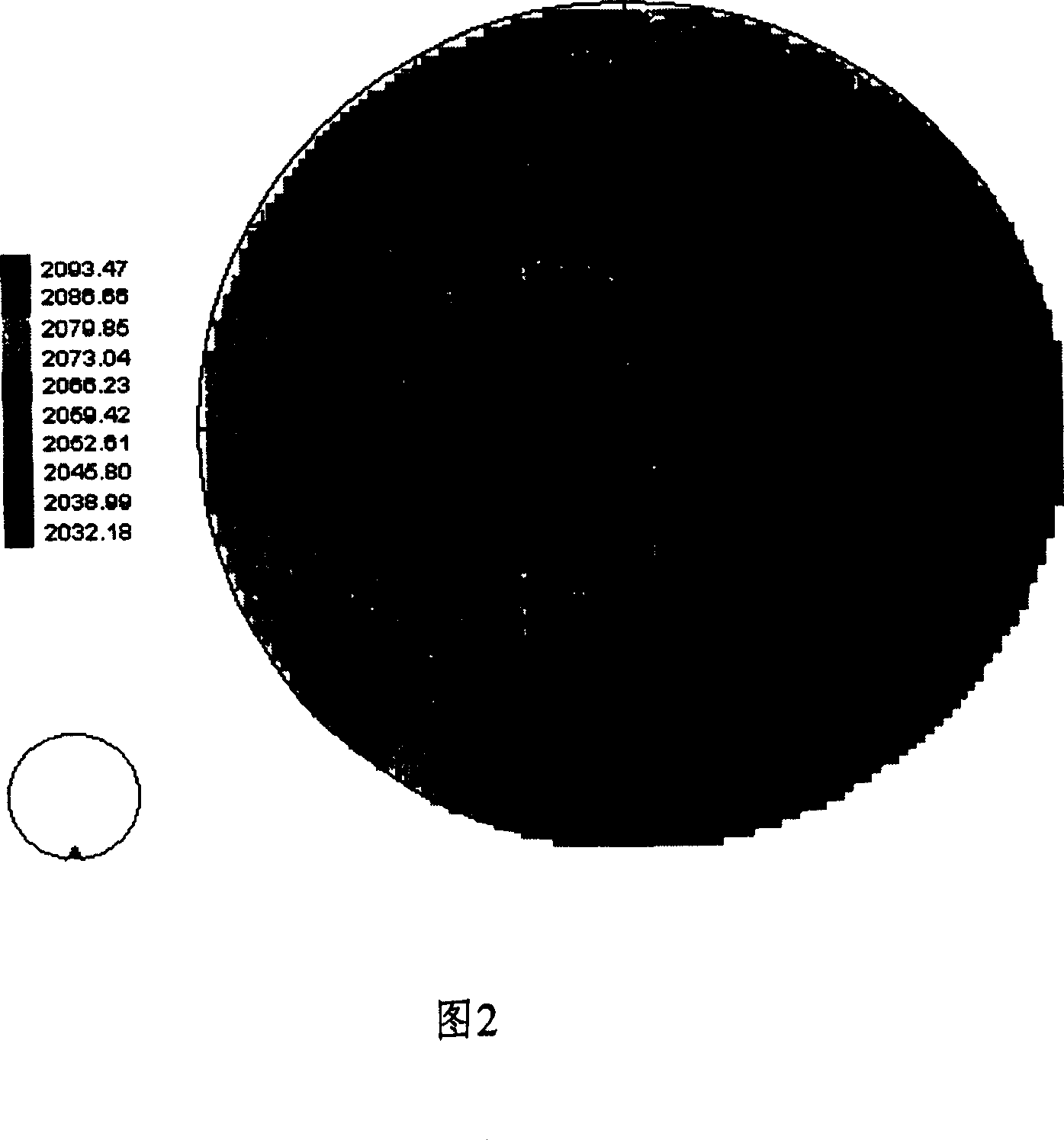

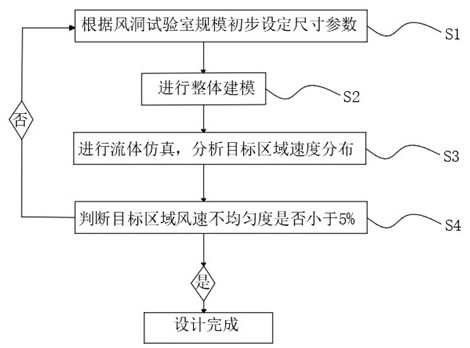

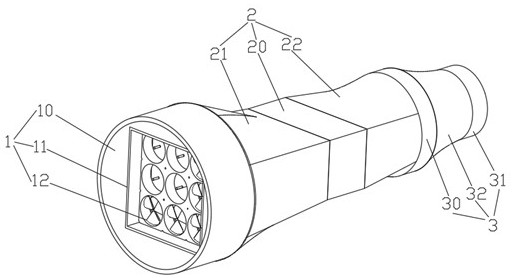

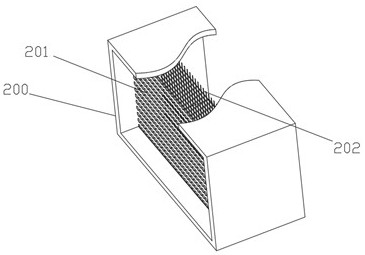

ActiveCN113916490AIncrease air capacityReduce distractionsAerodynamic testingDesign optimisation/simulationAir velocityAir volume

The invention relates to the technical field of wind tunnel experiment airflow uniformity, and discloses a device for improving aircraft experiment wind tunnel airflow uniformity and a parameter optimization method thereof. The device comprises a power section, a steady flow adjusting section and a contraction section; the power section comprises a circular-tube-shaped power main body section, a fan mounting structure arranged in the power main body section and a fan arranged on the fan mounting structure; and the method comprises the following steps: S1, preliminarily setting size parameters; S2, modeling a whole wind tunnel; S3, performing fluid simulation; and S4, judging whether the wind speed unevenness of the target area is less than 5% or not, if the unevenness is smaller than 5%, completing the design, and if not less than 5%, modifying the size parameters in the step S1, and repeating the steps S2-S4. According to the invention, the requirements of large air volume and large air speed during wind tunnel test of large aircrafts can be met, and the airflow uniformity can be improved.

Owner:CHINA AIRPLANT STRENGTH RES INST

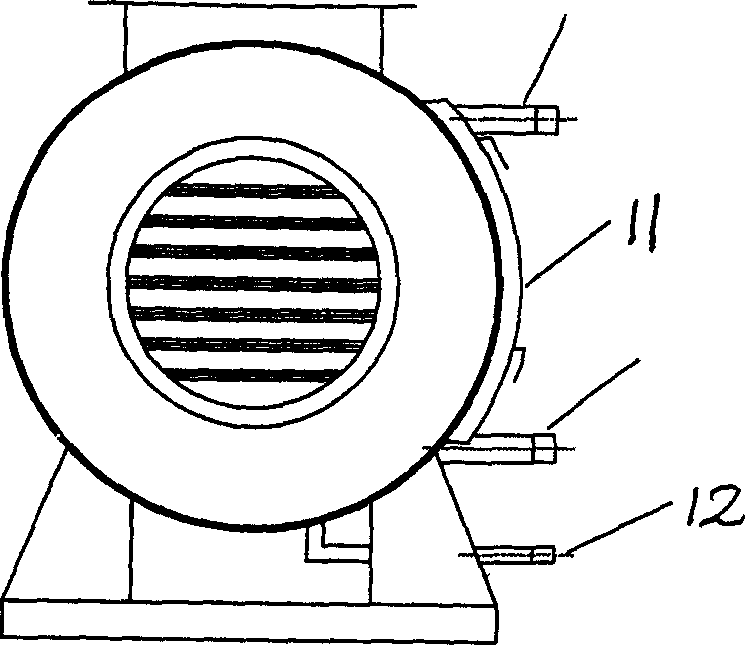

Drum type air treating machine set

InactiveCN1815095AIncrease airflowImproves airflow uniformityLighting and heating apparatusAir conditioning systemsElectric machineAir treatment

Present invention discloses a drum type air handling assembly. It includes cylinder shape horizontal shell, round multi-leaf damper, fan-shaped or tube type primary filter, round surface heater, primary filter surface air coolers, humidifier, circular arc shape service door, and condensate pipe. Said invention has reasonable structure and fine working performance.

Owner:JIANGSU FENGSHEN AIR CONDITIONING GRP

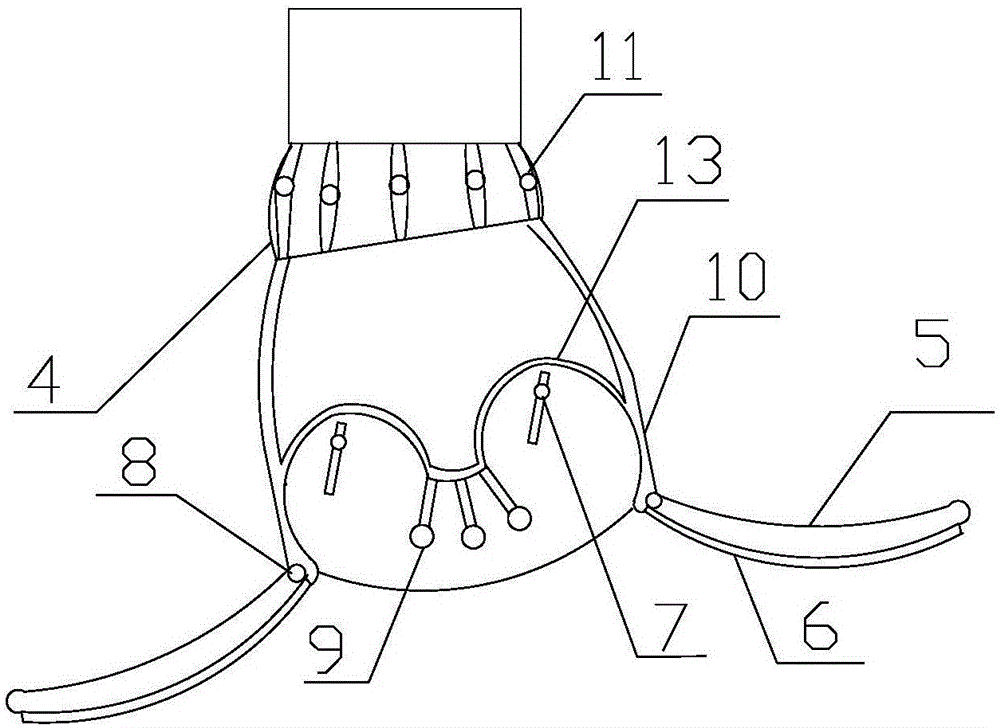

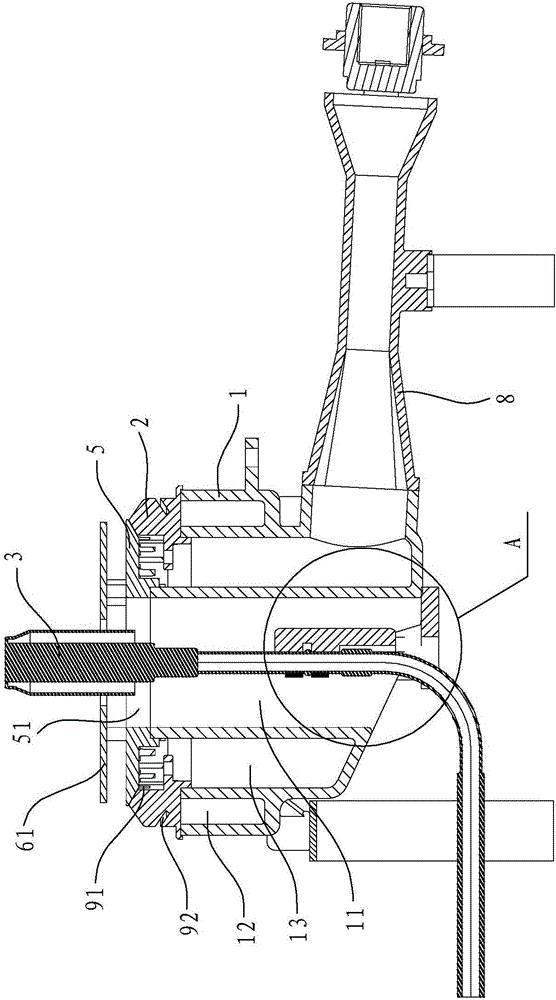

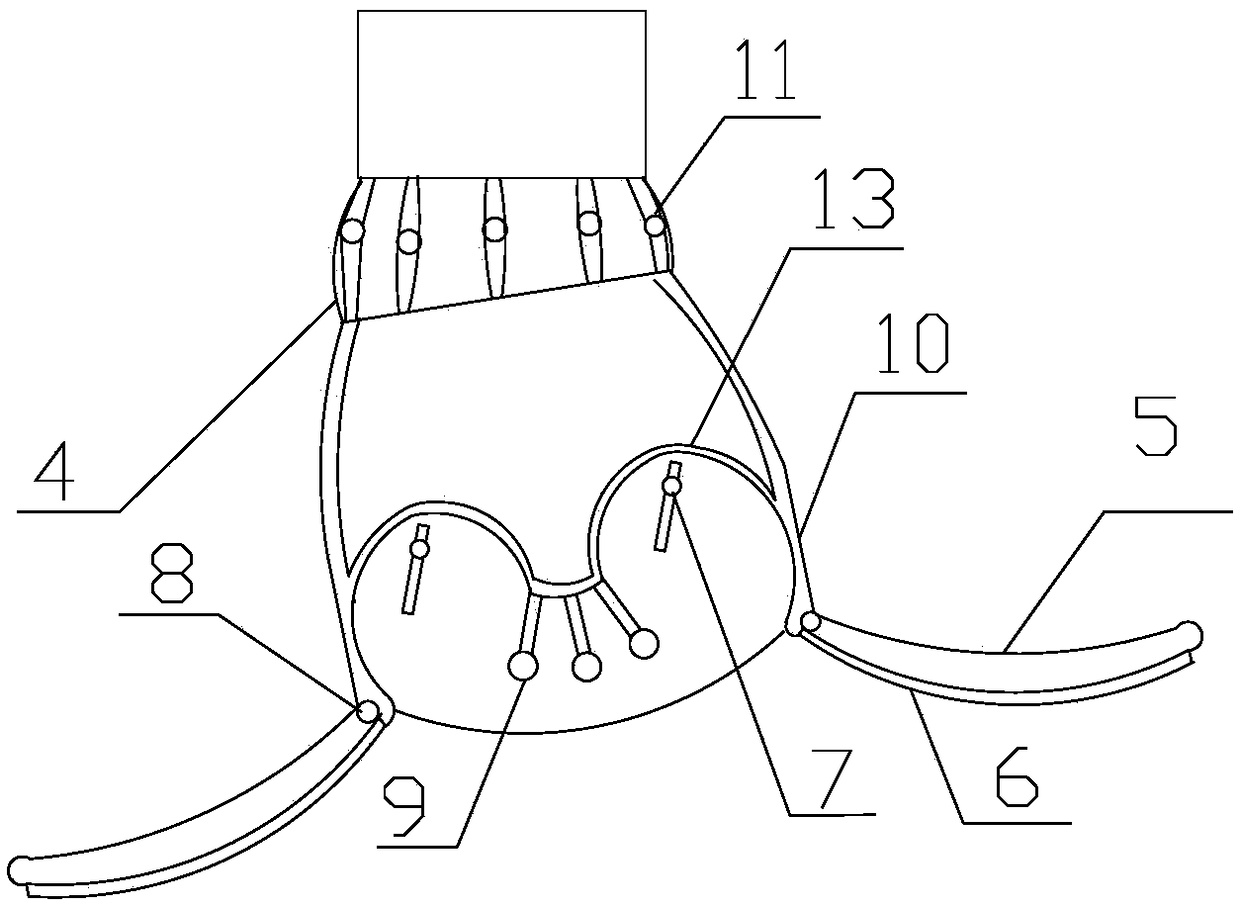

Diagonal fan and household appliance

ActiveCN110513327ARestriction formation mechanismImprove mobilityPump componentsPumpsEngineeringMechanical engineering

The invention provides a diagonal fan and a household appliance. The diagonal fan comprises a wheel cover assembly and a diagonal wind wheel. The wheel cover assembly comprises multiple sleeved wheelcovers, the wheel covers are provided with air inlets, the wheel cover located on the outer side stretches downstream relative to the wheel cover located on the inner side in any two adjacent wheel covers, a backflow passageway is formed between any two adjacent wheel covers, and the backflow passageways communicate with the air inlets. The diagonal wind wheel is partially arranged in the wheel cover on the innermost side in the multiple wheel covers. The diagonal wind wheel comprises a hub and multiple blades arranged on the hub, and the tops of the blades can correspond to inlets of the backflow passageways. By means of the technical scheme, the operating stability of the diagonal fan is improved, the pneumatic performance of the diagonal fan is improved, and meanwhile the probability that the blade frequency doubling noise is increased is reduced.

Owner:MIDEA GRP CO LTD

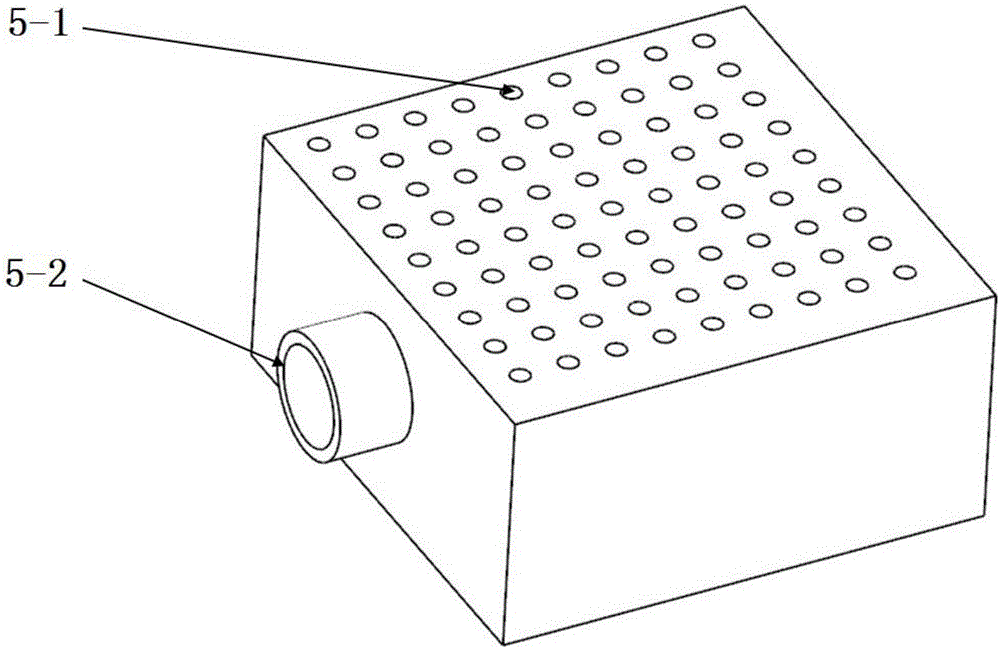

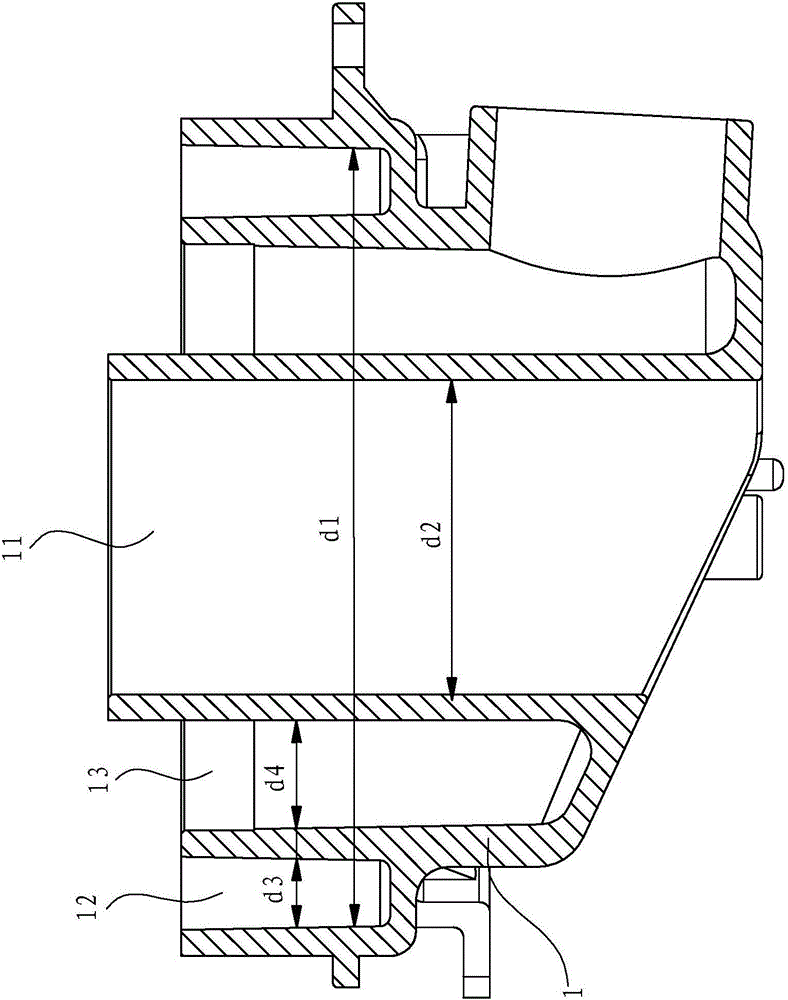

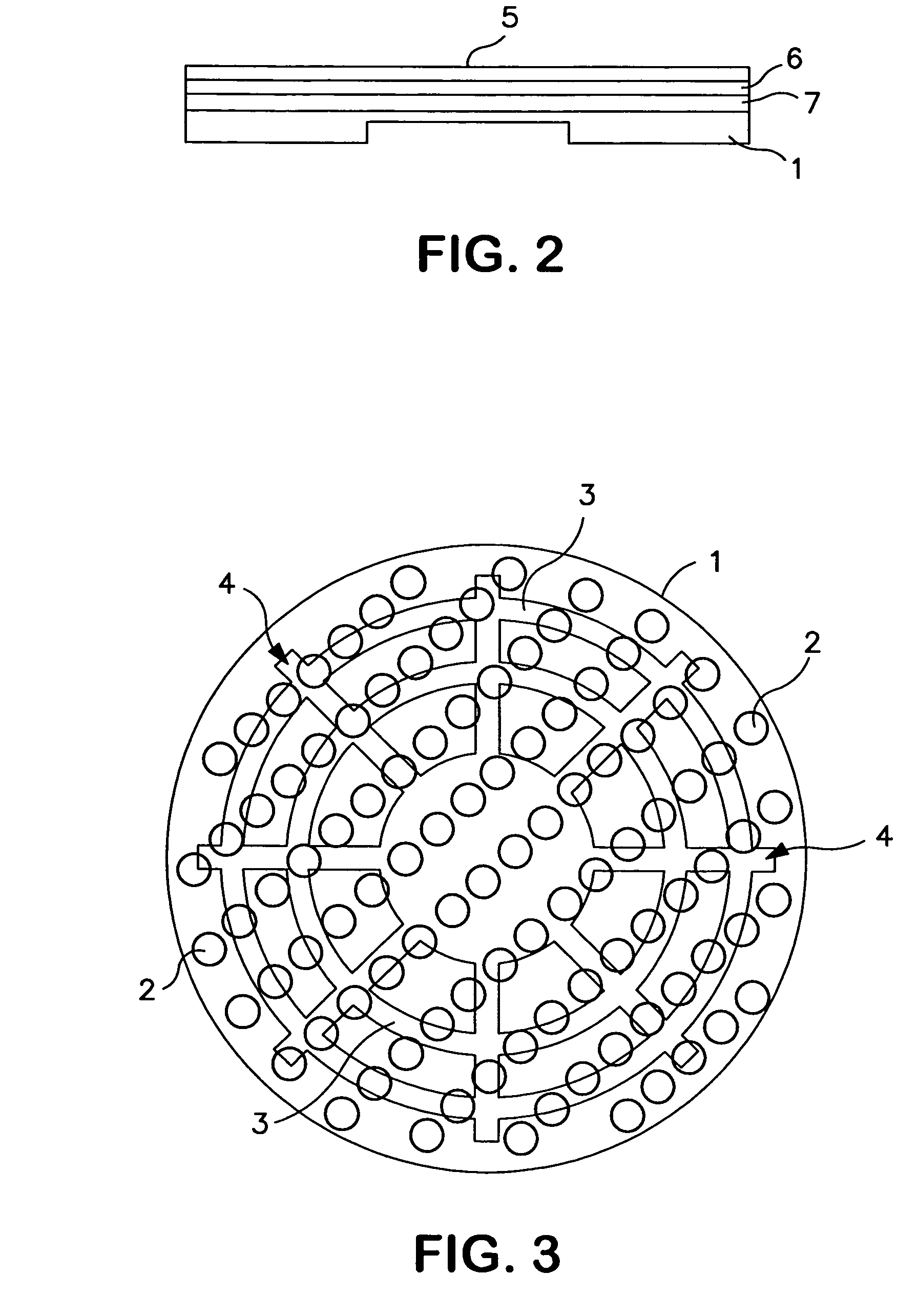

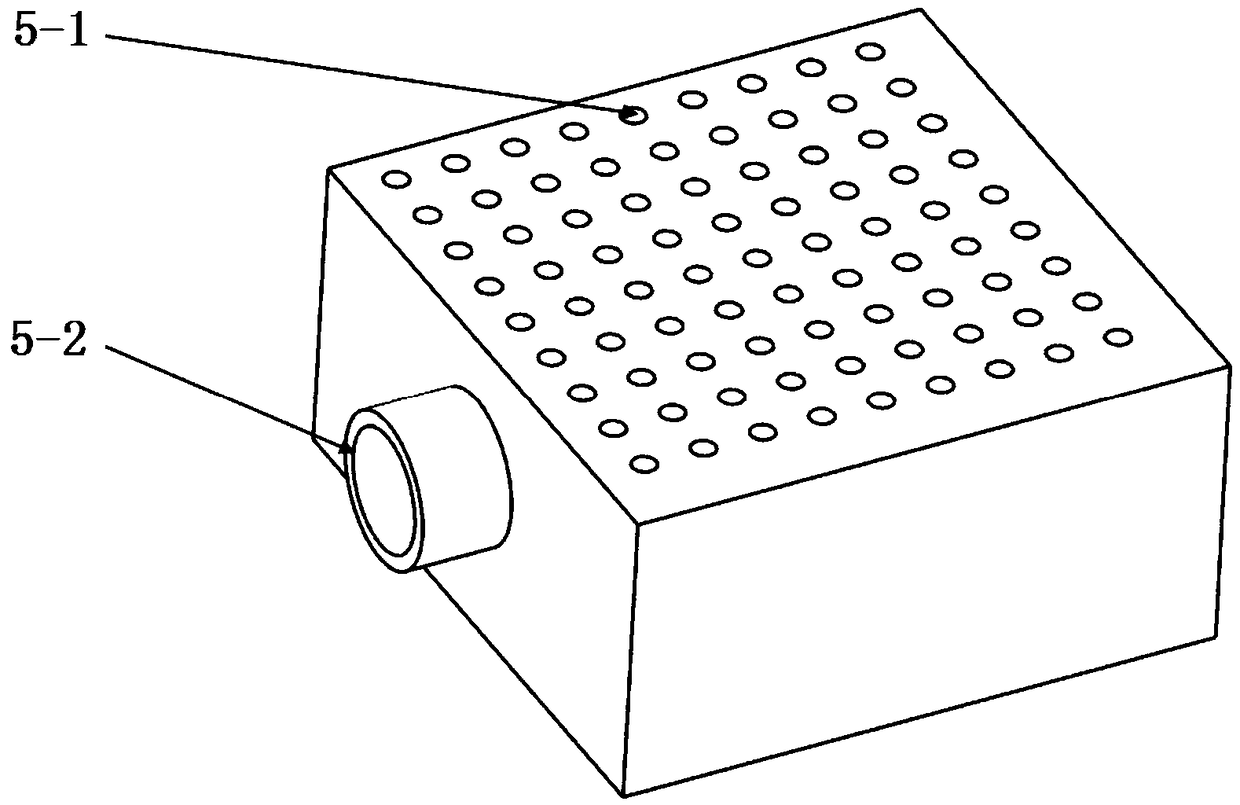

Upper electrode structure and plasma reinforced chemical vapor deposition device

ActiveCN104789947AImproves airflow uniformityImprove uniformityChemical vapor deposition coatingGas phaseGas passing

The invention provides an upper electrode structure and a plasma reinforced chemical vapor deposition device. The upper electrode structure comprises a central electrode plate and a peripheral electrode plate surrounding the central electrode plate and connected to the central electrode plate, wherein the bottom surface of the peripheral electrode plate is lower than that of the central electrode plate, and a ventilation pore passage penetrating through the upper electrode structure is formed in the upper electrode structure. The bottom surface of the peripheral electrode plate is lower than the bottom surface of the central electrode plate, and the ventilation pore passage penetrating through the upper electrode structure is formed in the upper electrode structure, so that an arch structure is formed on the bottom surface of the upper electrode structure, the airflow uniformity of process gas passing by the upper electrode structure can be improved, and a film formed by utilizing the process vapor deposition is good in uniformity; moreover, the upper electrode structure comprises the central electrode plate and the peripheral electrode plate, which are connected with each other, so that the position relation between the central electrode plate and the peripheral electrode plate can be adjusted, and the airflow uniformity of the process gas can be further optimized.

Owner:BEIJING JINGCHENG BOYANG OPTOELECTRONICS EQUIPCO

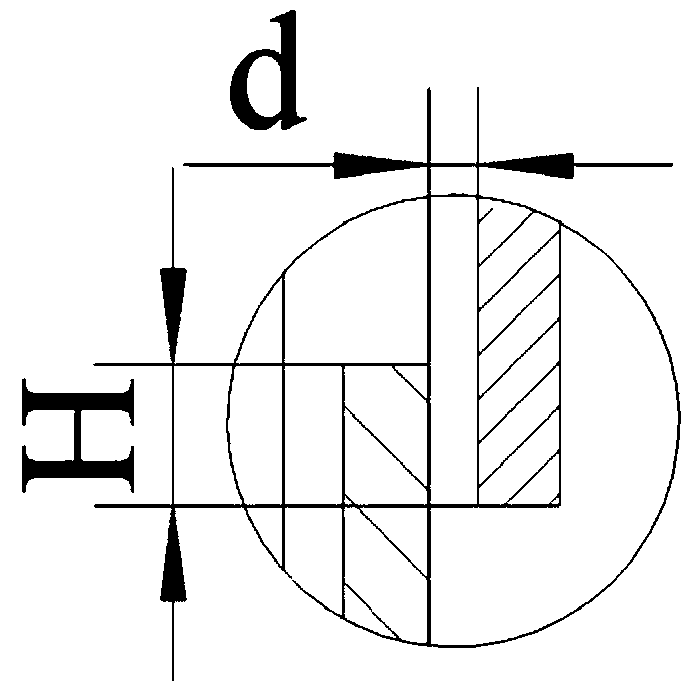

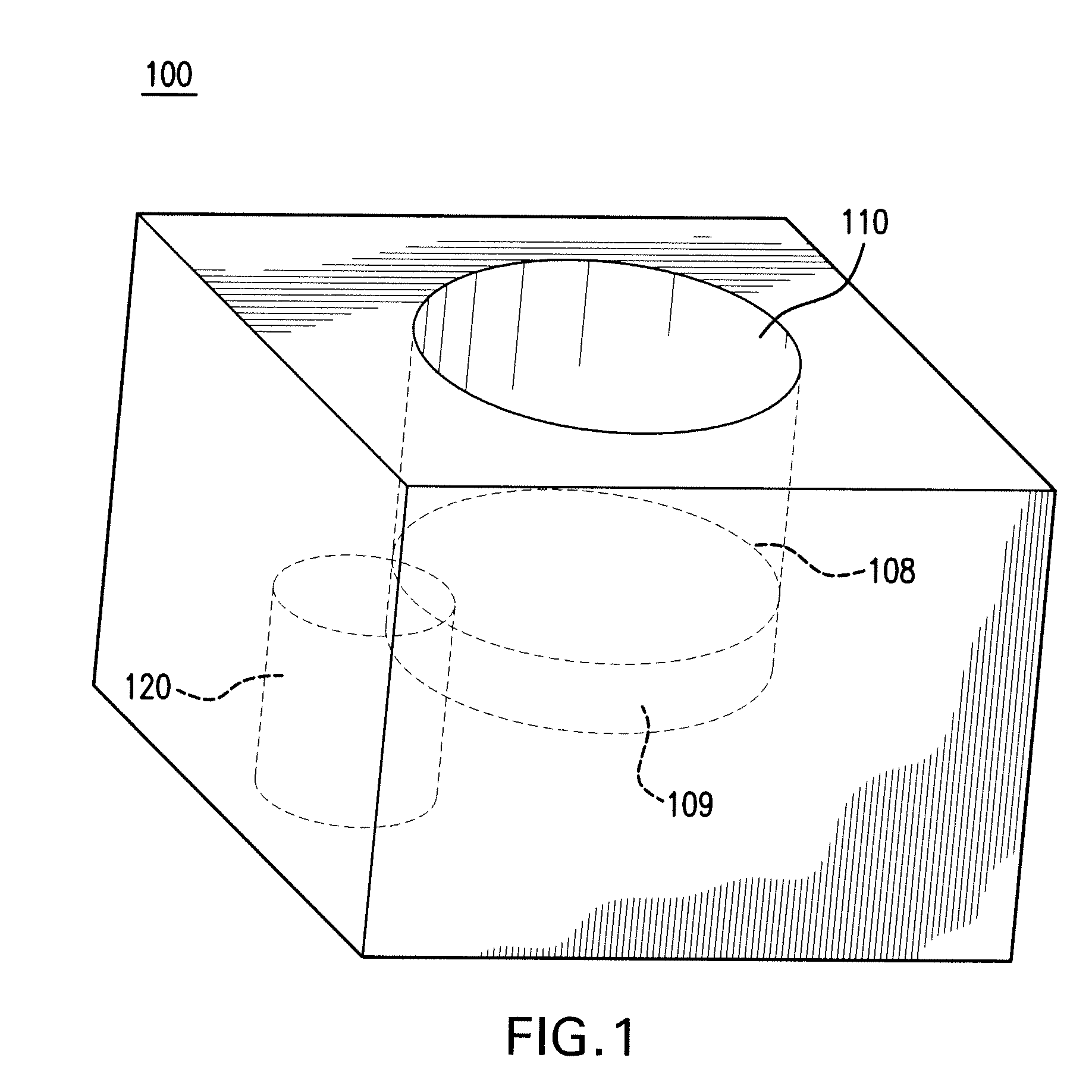

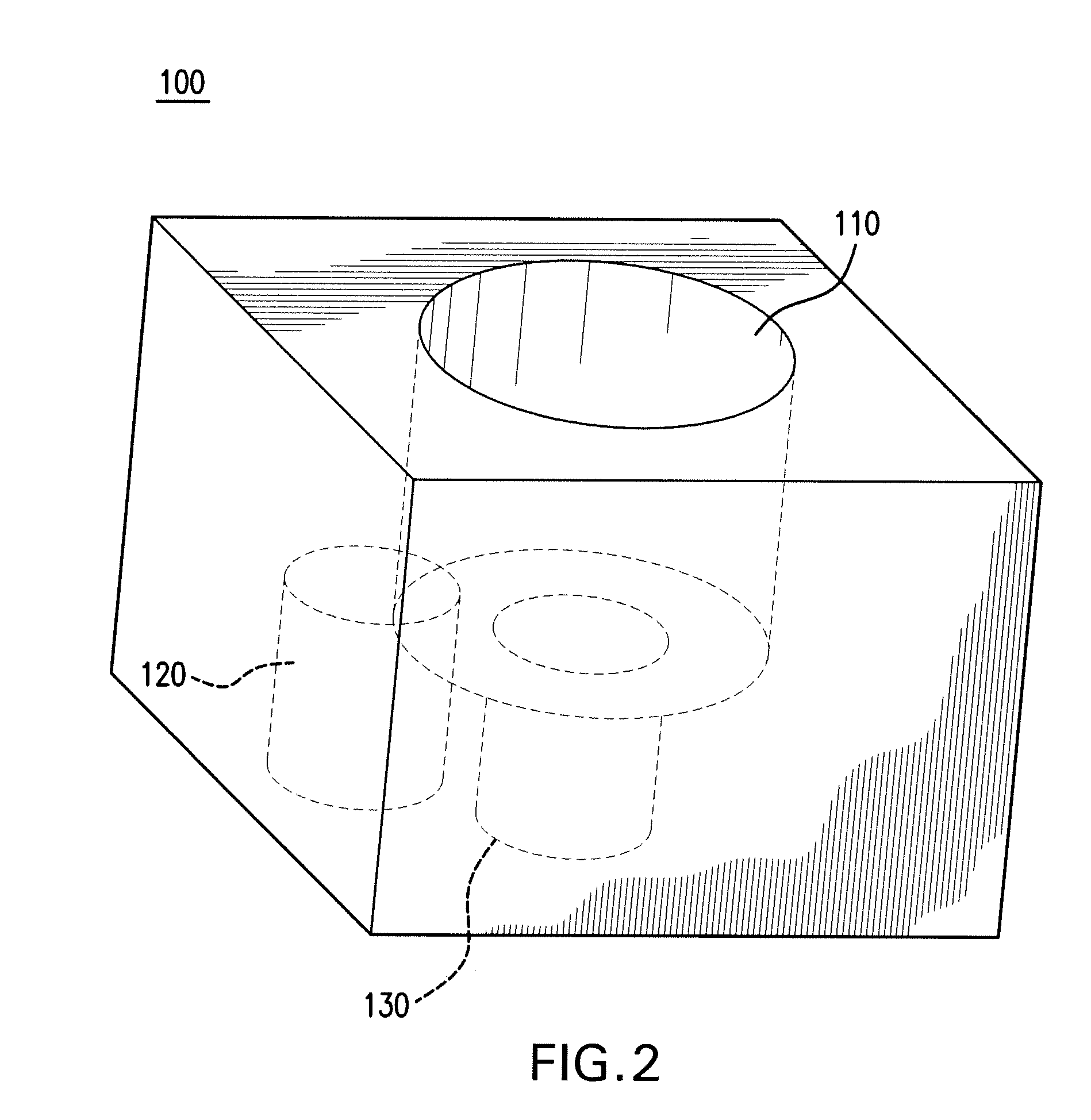

Low cost high conductance chamber

InactiveUS20090151872A1High conductanceLittle maintenanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingElectricityCircular saw

A process chamber having high conductance and a method of manufacturing the process chamber are disclosed. The process chamber is machined from a single piece of aluminum where a process cavity and a pump cavity are created by intersecting cylinders. A substrate opening is also created at a bottom of the process cavity to provide conduit for services, such as cooling gas and electrical connections. A large undercut area is formed at a top of the pump cavity between the pump cavity and the process cavity. The undercut extends past the process chamber centerline at the process cavity. A circular saw is used to remove material and create a plenum which extends beyond the process cavity centerline.

Owner:INTEVAC

Energy saving and noise reducing multifunctional decoration wind gap capable of homogenizing air currents and application method thereof

ActiveCN105910252AOptimize streamline shapeImproves airflow uniformityDucting arrangementsMechanical apparatusAirflowEngineering

The invention discloses an energy saving and noise reducing multifunctional decoration wind gap capable of homogenizing air currents and an application method thereof. The wind gap comprises a rotating extension section, a rectification section, multiple external guide plates, at least two one-layer shutters, and a wind gap probe for detecting the exhaust temperature and / or the flowing speed; one end of the rectification section is connected with the rotating extension section, and the external guide plates are uniformly mounted around the other end; the rectification section has an outward concave arched windward surface; angles between the external guide plates and the rectification section are adjustable; the one-layer shutters are arranged in the rectification section; and the rotating extension section can drive the rectification section to change a wind blowing angle. The wind gap optimizes the streamline shape of the air currents sprayed by the wind gap, can increase or reduce actual travel distance of the air currents according to the demands, and improves the uniformity of the air currents and the indoor ventilation effect. The one-layer shutters replace double-layer shutters of a traditional wind gap, so that the wind resistance is reduced, and the noise of the wind gap and the energy consumption are reduced. In addition, the wind gap has a decoration effect.

Owner:SHANGHAI INSTALLATION ENG GRP

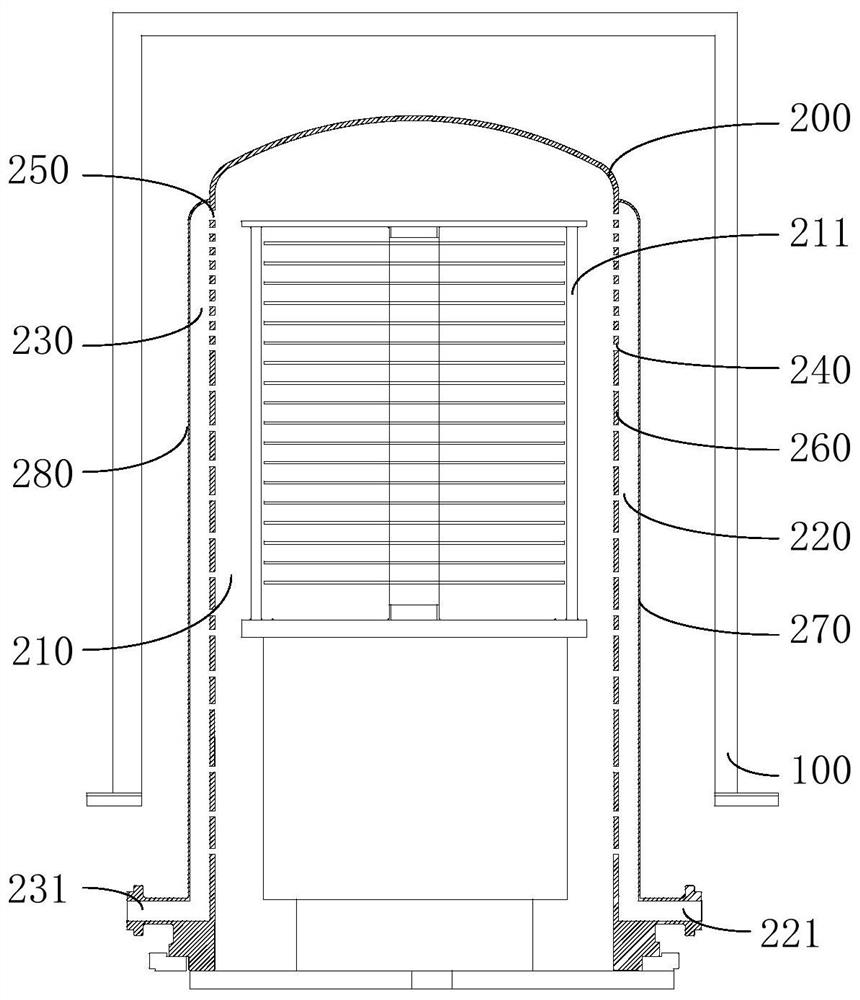

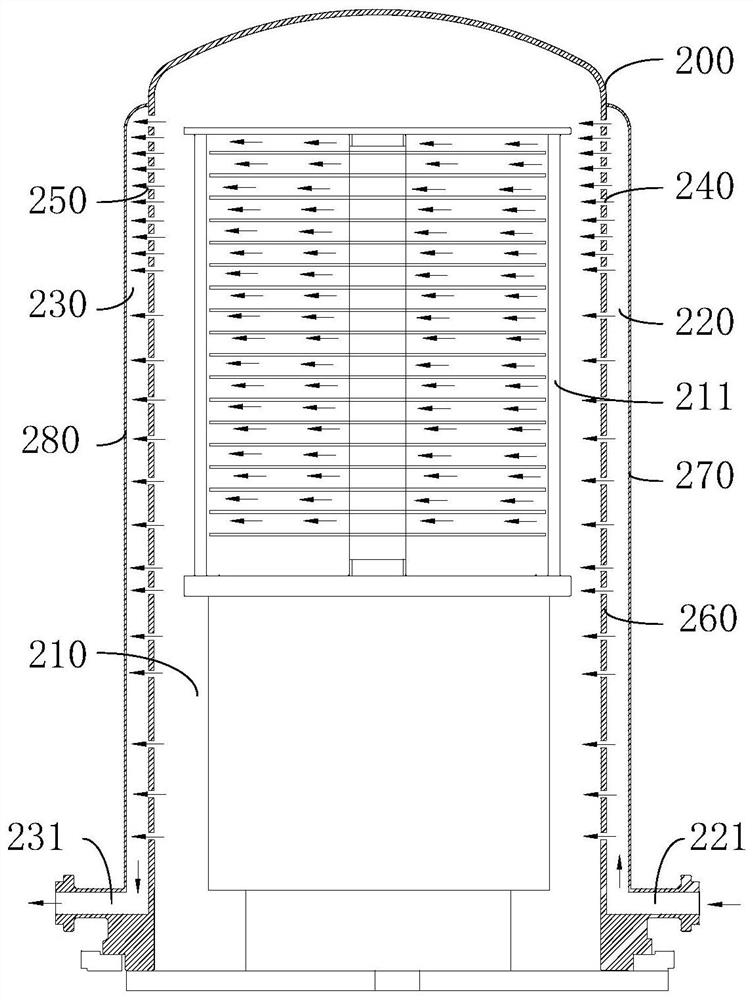

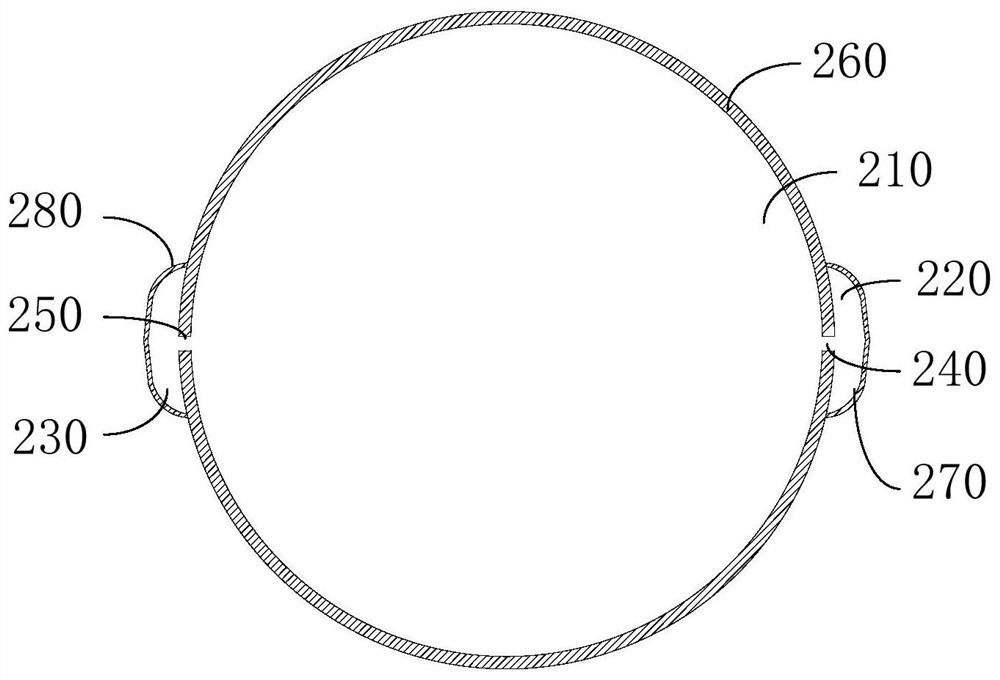

Semiconductor processing equipment

PendingCN111725108ASimple structureEasy to implementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingMechanical engineeringSemiconductor

The invention discloses semiconductor processing equipment. The semiconductor processing equipment comprises a reaction chamber and a process pipe, wherein at least part of the process pipe is positioned in the reaction chamber, the process pipe is provided with an accommodating part, an air inlet part and an air outlet part, the air inlet part is provided with an air inlet, the air outlet part isprovided with an air outlet, the process pipe is provided with a plurality of air inlets and a plurality of air outlets, the air inlets and the air outlets are distributed at intervals in the axis direction of the process pipe, the air inlets are communicated with an accommodating part, and the air outlets are communicated with the accommodating part. The semiconductor processing equipment is advantaged in that a problem that in existing semiconductor processing equipment, the effect of improving the uniformity of gas in the reaction chamber is poor can be solved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

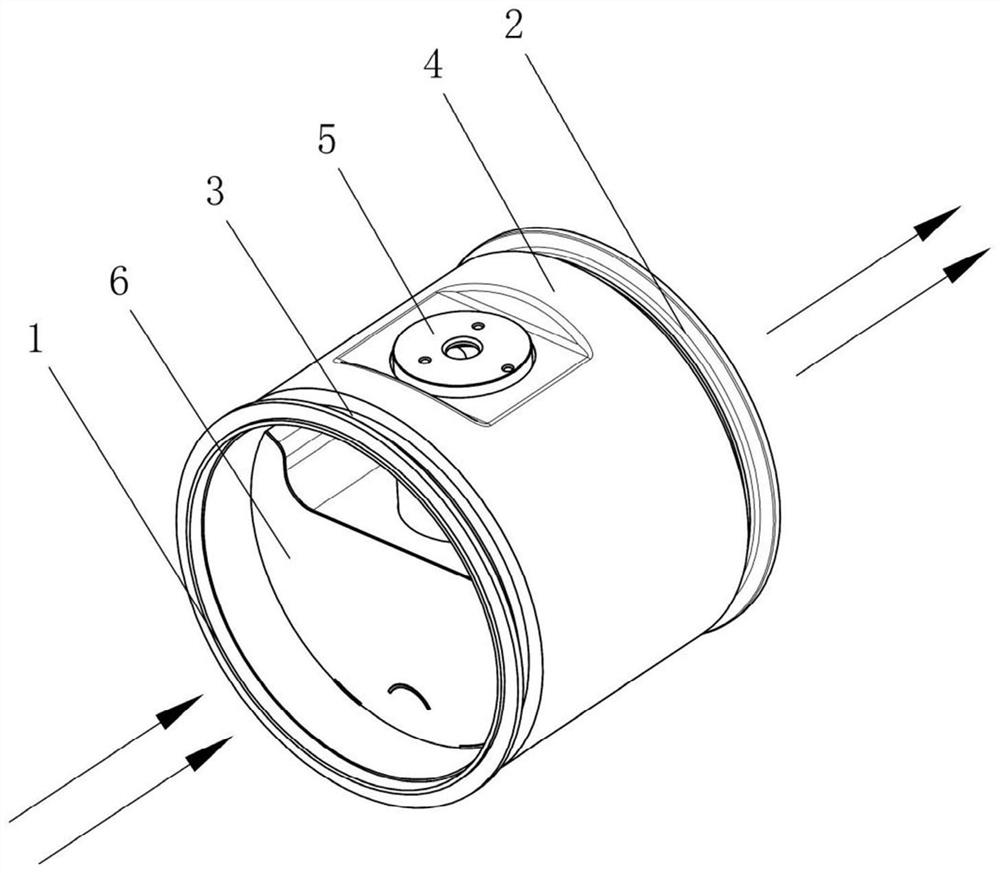

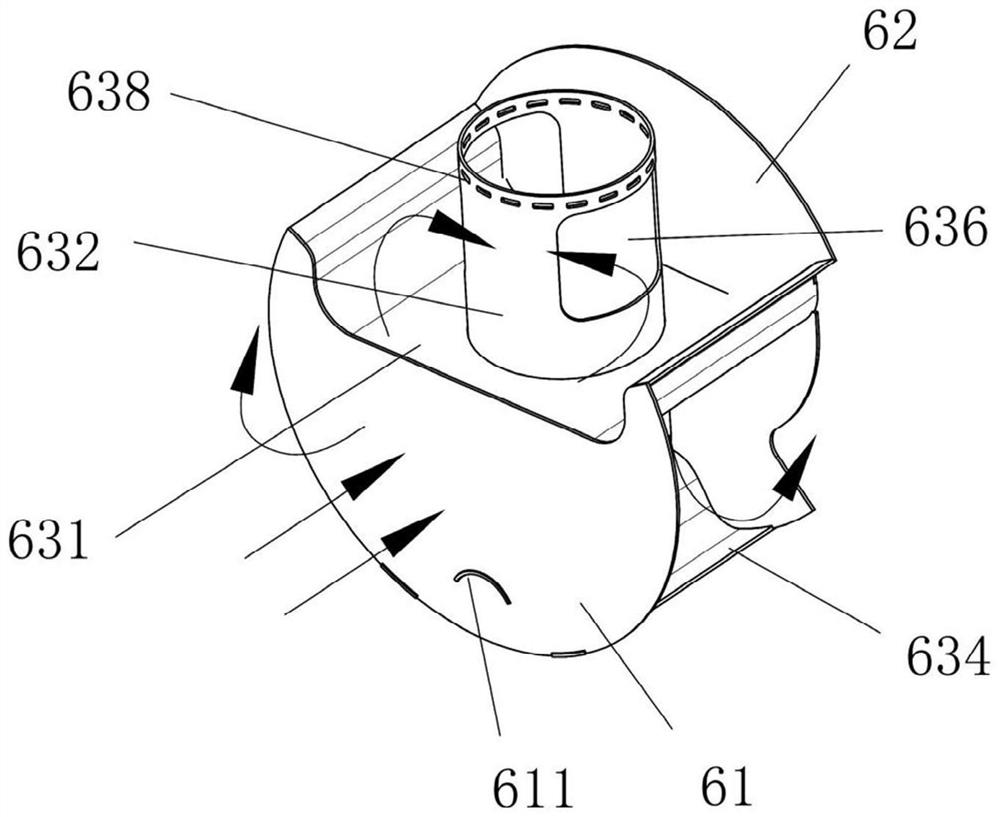

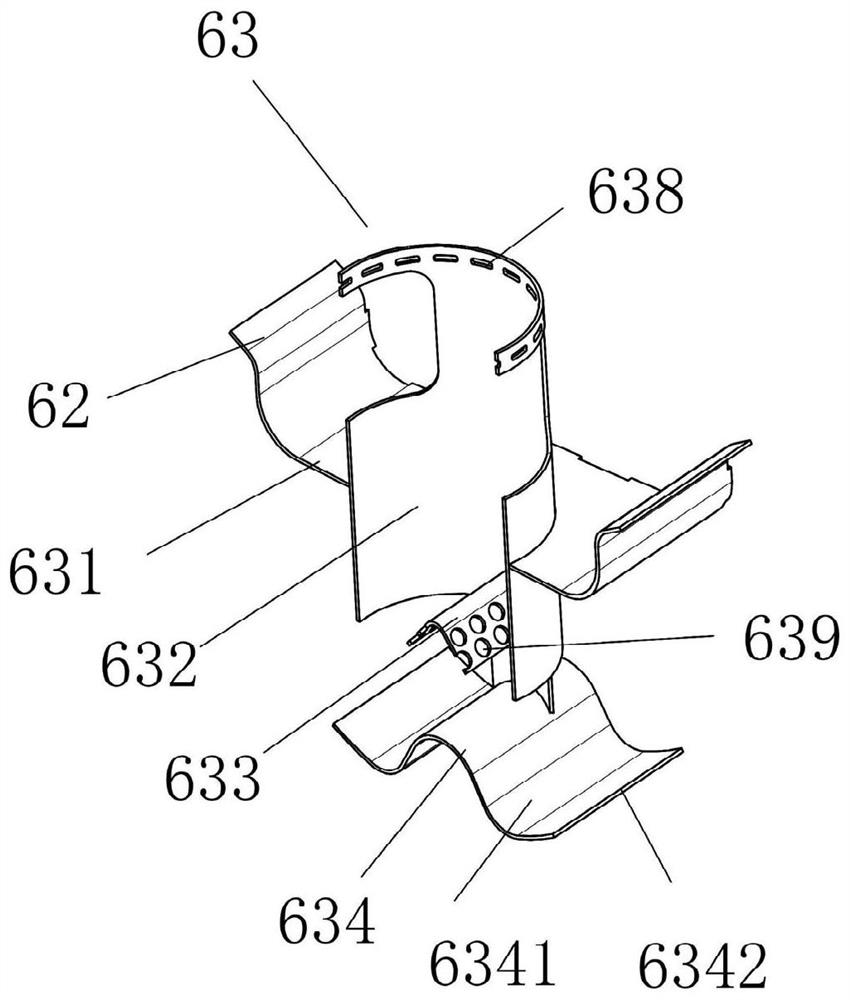

Double-vortex-flow type urea mixing device

ActiveCN113790092AImprove the mixing effectEnsure mixing uniformityInternal combustion piston enginesExhaust apparatusDieselingEngineering

The invention relates to a double-vortex-flow type urea mixing device, and belongs to the field of diesel engine tail gas after-treatment. The double-vortex-flow type urea mixing device comprises a front flange, a rear flange, a cylinder, a heat shield, a nozzle base and an in-cylinder assembly, the front flange and the rear flange are respectively welded at two ends of the cylinder, the heat shield is welded outside the cylinder, the nozzle base is welded on the cylinder, and the in-cylinder assembly is welded in the cylinder and is connected with the nozzle base; and the in-cylinder assembly comprises a front partition plate, a rear partition plate and a flow dividing pipe set, wherein the front partition plate and the rear partition plate are welded to the two sides of the flow dividing pipe set respectively. According to the double-vortex-flow type urea mixing device, a simple pipe and baffle structure is adopted to realize shunting and double-vortex rotation of urea, so that the mixing effect of urea and waste gas is improved, and the mixing uniformity of a SCR catalytic unit is ensured; and a notch in the upper end of the flow dividing pipe is used for guiding airflow to enter the flow dividing pipe from the two sides of the flow dividing pipe, so that urea sprayed from the upper portion is taken away smoothly, and the accumulation of the urea sprayed on the inner wall face of the flow dividing pipe is reduced.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

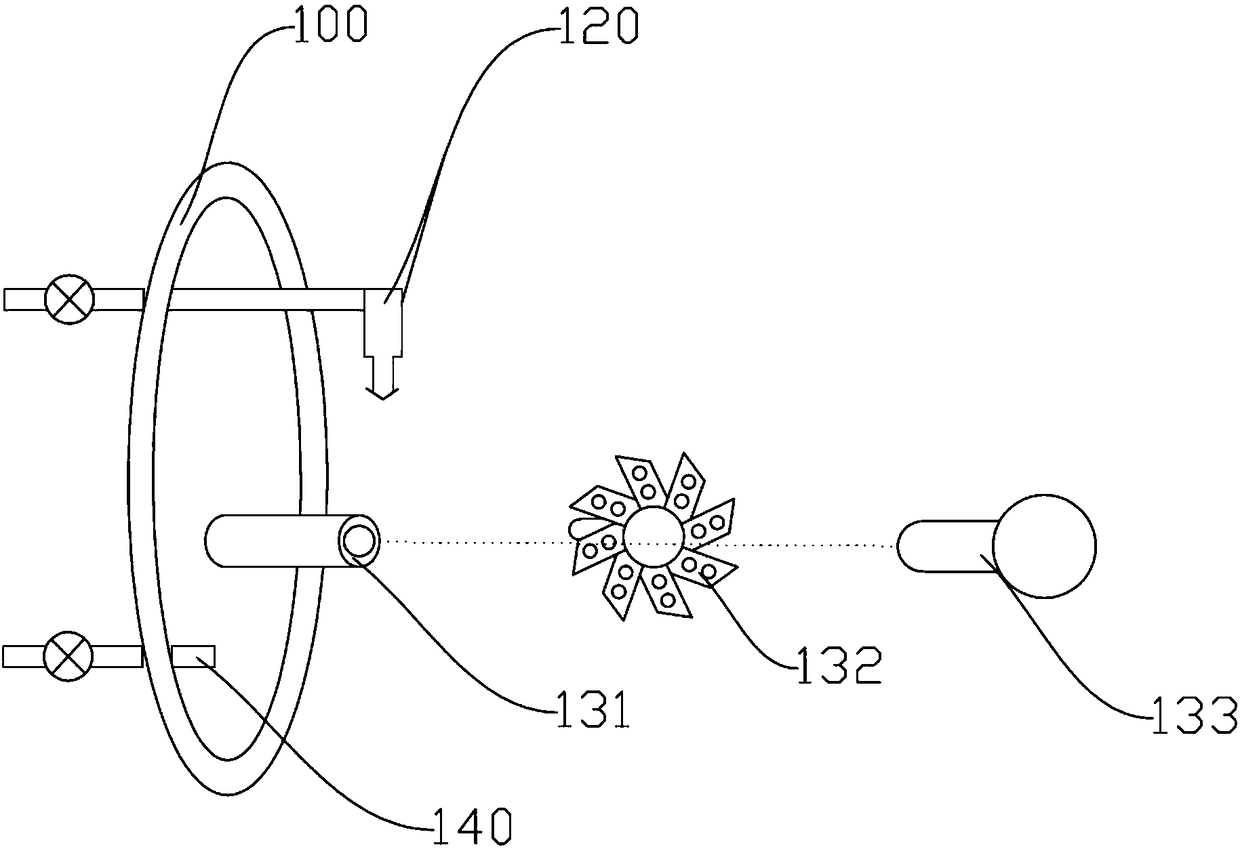

High-temperature nitridation airflow field control device and method

The invention provides a high-temperature nitridation airflow field control device and method. The control device comprises an impeller used for driving gas in a furnace body to flow, a first gas inlet used for feeding ammonia gas and a second gas inlet used for feeding power gas for driving the impeller to rotate, the first gas inlet is arranged below the impeller, the second gas inlet is arranged above the side of the impeller, and the power gas is argon. According to the high-temperature nitridation airflow field control device, the impeller driven by argon is arranged on the inner wall of a furnace door of the device, on one hand, ammonia gas and argon in the furnace are mixed to be uniform by means of rotation of the impeller; on the other hand, fed argon also can serve as diluent gas of high-purity ammonia gas to adjust the concentration of ammonia gas in the furnace.

Owner:NAT UNIV OF DEFENSE TECH

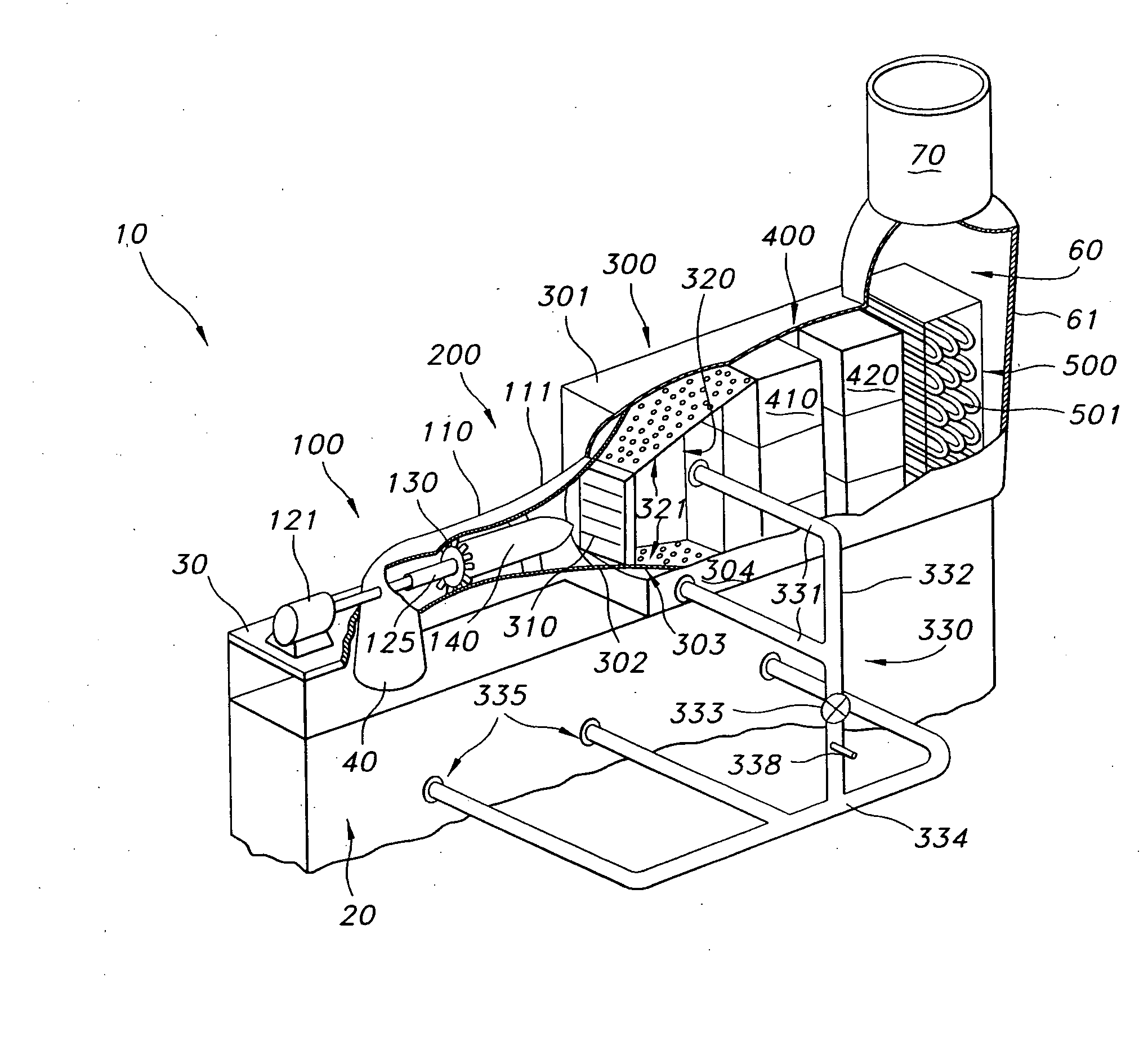

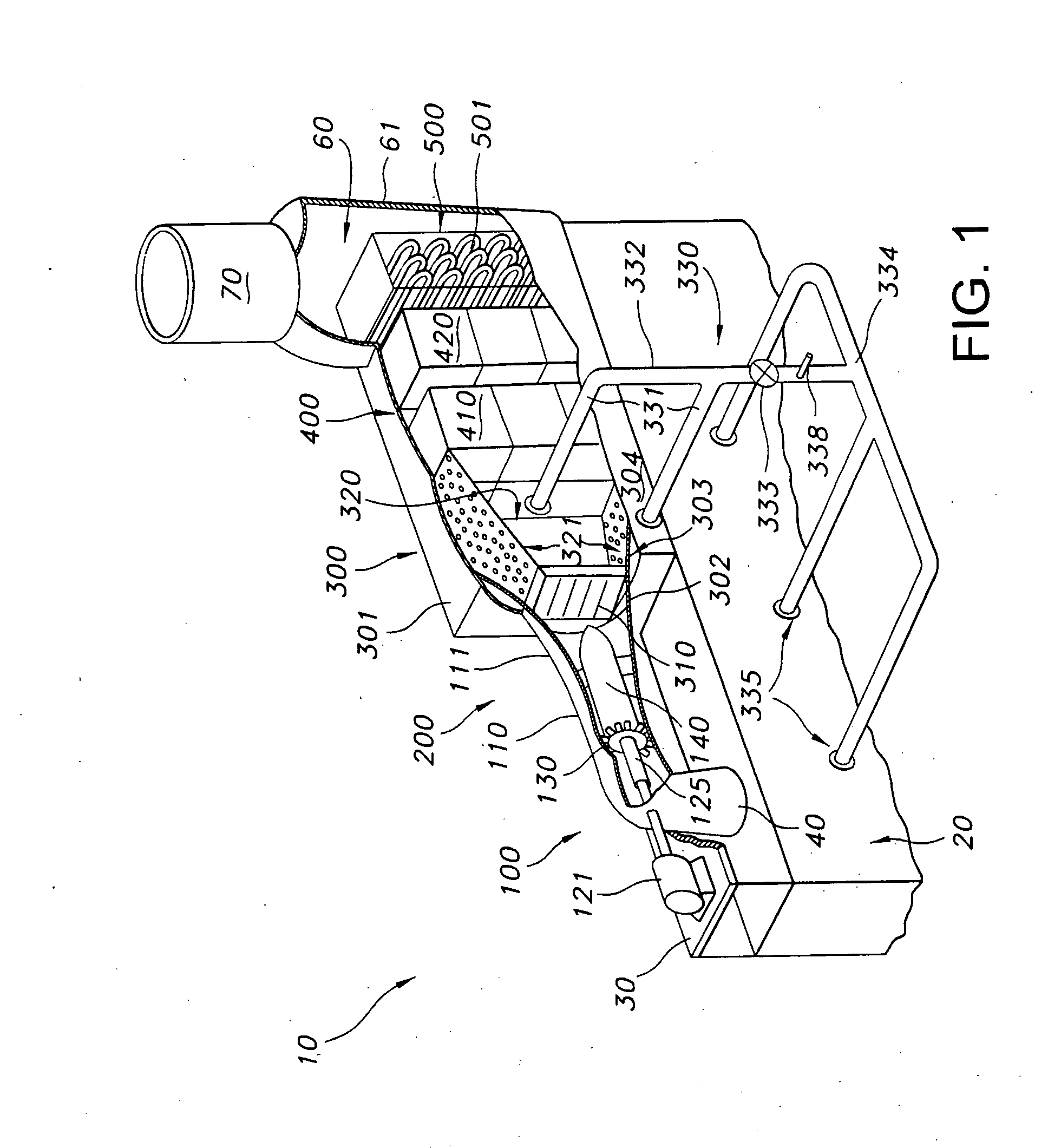

Modular system and method for the catalytic treatment of a gas stream

InactiveUS20080081010A1Shorten speedImproves airflow uniformityCombination devicesGas treatmentImpellerGas phase

A system for catalytically treating a gas stream includes a gas phase reactor containing a catalyst for the treatment of the gas stream in at least one catalyst bed having an upstream end and a downstream end, an axial fan positioned upstream of the at least one catalyst bed and having an impeller for moving the gas stream through the gas phase reactor. The gas flow is modified between the impeller and the gas phase reactor to decrease gas stream velocity and increase gas flow uniformity.

Owner:KARRS MARK +1

Stove combustor with temperature sensor

InactiveCN106123048AGood airflow uniformityGood mixing effectDomestic stoves or rangesGaseous fuel burnerAirflowEngineering

The invention discloses a stove combustor with a temperature sensor. The stove combustor comprises a base, a fire cover, the temperature sensor, an outer ring gas injection pipe and an inner ring gas injection pipe; the base is provided with an outer ring cavity and an inner ring cavity, the outer ring cavity is communicated with the outer ring gas injection pipe, the inner ring cavity is communicated with the inner ring gas injection pipe, and the stove combustor is characterized in that a mounting cavity is formed in the center of the inner ring cavity, an opening is formed in the position, located at the bottom of the base, of the mounting cavity, and the temperature sensor is mounted in the mounting cavity. Compared with the prior art, the stove combustor has the beneficial effects that the mounting cavity used for mounting of the temperature sensor is formed in the center of the inner ring cavity of the stove combustor, and can achieve the flow guide effect, the uniformity of the gas flow inside the base is better, the gas mixing effect is better, in addition, after the temperature sensor is mounted in the mounting cavity, the gas mixing effect is not affected, and a mounting structure is reasonable.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

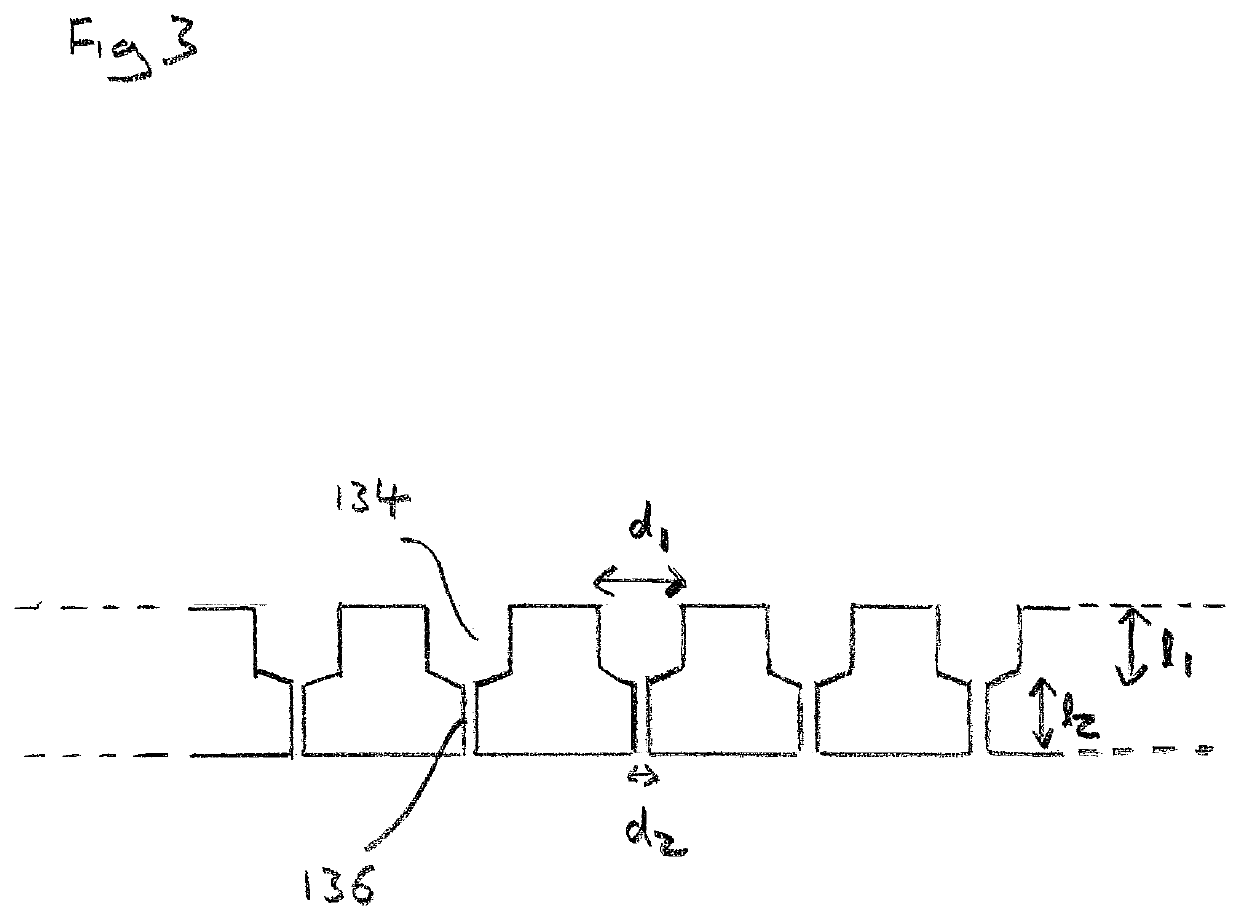

Cryocooler with grooved flow straightener

ActiveUS7234307B2Improves airflow uniformityCompression machinesGas cycle refrigeration machinesEngineeringCryocooler

A cryocooler system having at least one flow straightener which has a system of grooves on its perforated surface for enhancing gas flow uniformity through the system wherein pulsing gas which does not initially pass through the flow straightener through a perforation flows along the surface of the flow straightener within a groove prior to passing through a perforation and is effectively redistributed across the surface of the flow straightener and thus the cross section of the regenerator or thermal buffer tube.

Owner:PRAXAIR TECH INC +1

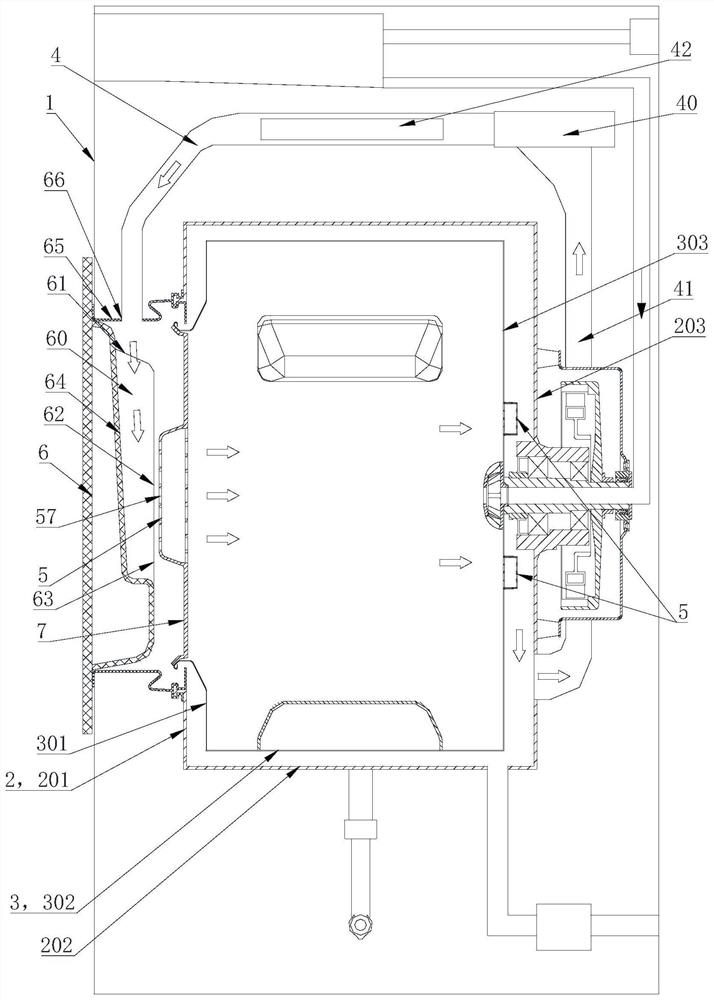

Ventilation module and clothes processing device

PendingCN114763653AEffective blockingPrevent outflowOther washing machinesTextiles and paperLaundry washing machineStructural engineering

The ventilation module comprises a shell, a hollow channel is defined by the shell, blocking ribs are arranged at the two ends of the channel respectively, the blocking ribs divide the two ends of the channel into a plurality of hollowed-out small holes respectively, and the interior and the exterior of the channel are communicated through the hollowed-out small holes respectively. By means of the arrangement, the two sides of the ventilation module can be communicated through the hollowed-out small holes of the communicating channels in the two ends, airflow on the two sides of the ventilation module can flow through the channels, and the purpose that gas on the two sides freely exchanges and flows under the action of pressure difference is achieved; meanwhile, the hollow small holes are formed in the end of the ventilation module at intervals, so that the uniformity of airflow flowing into the roller is improved, and the situation that water in the roller is discharged out of the ventilation module can be effectively prevented. Meanwhile, the invention further discloses a clothes processing device which comprises a roller which is installed in a shell and forms a sealed water container when the washing machine is in a washing state. And at least one ventilation module is arranged on the roller.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

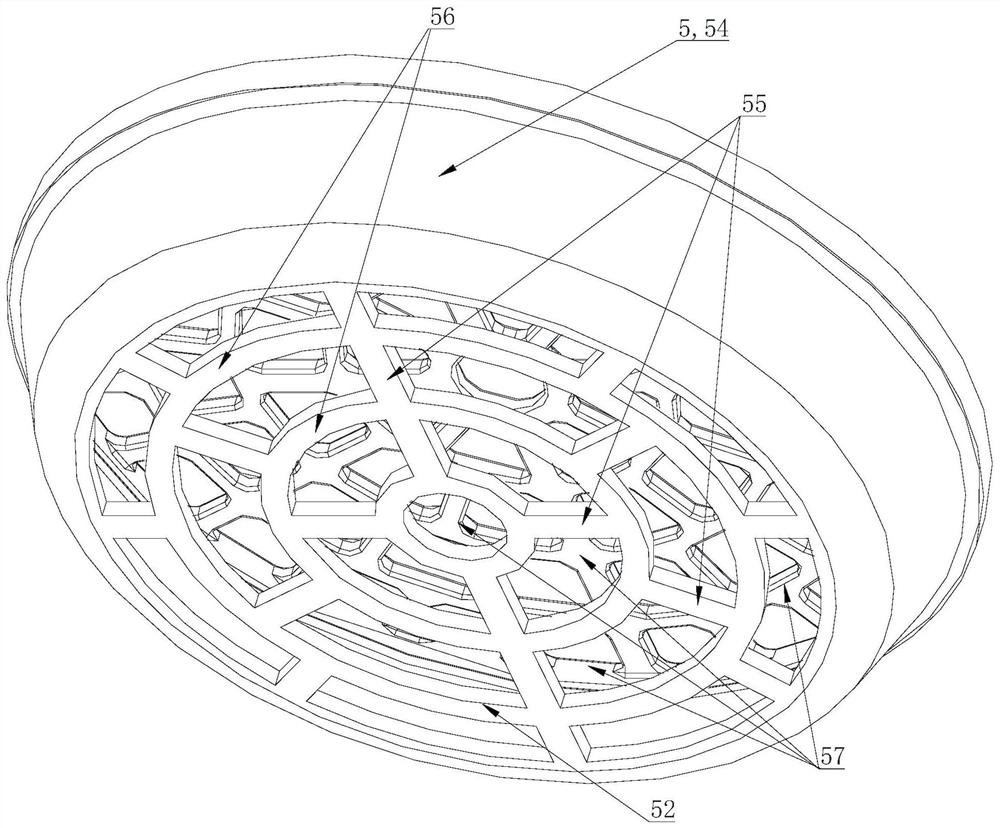

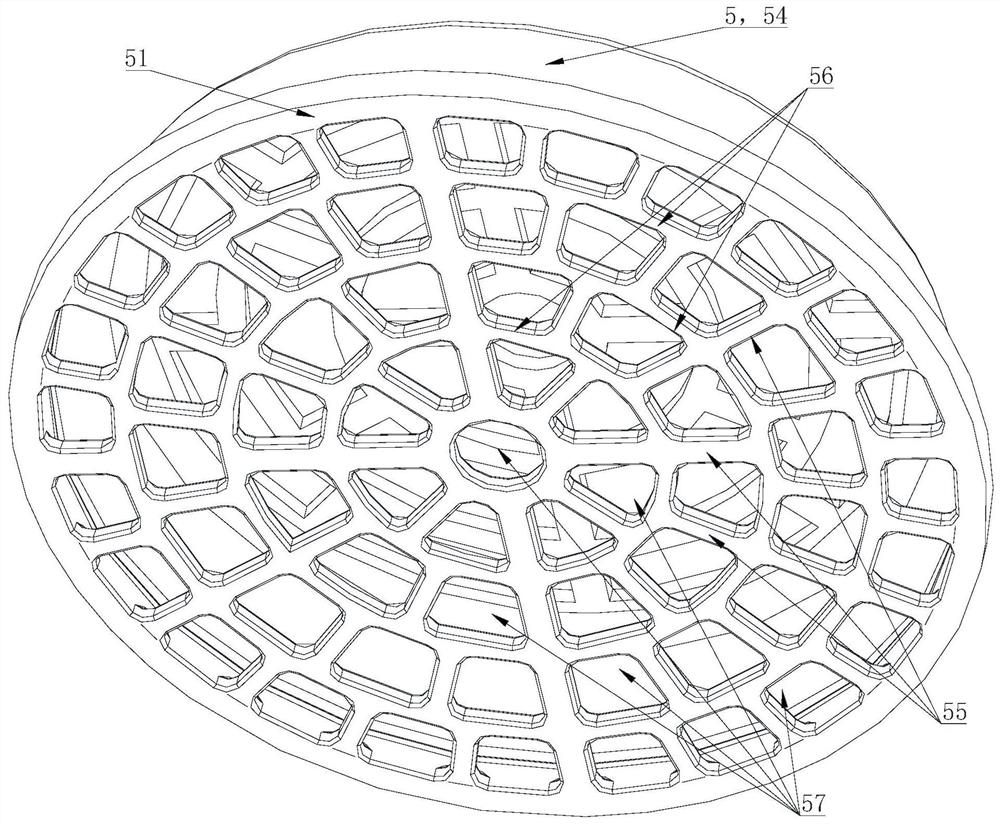

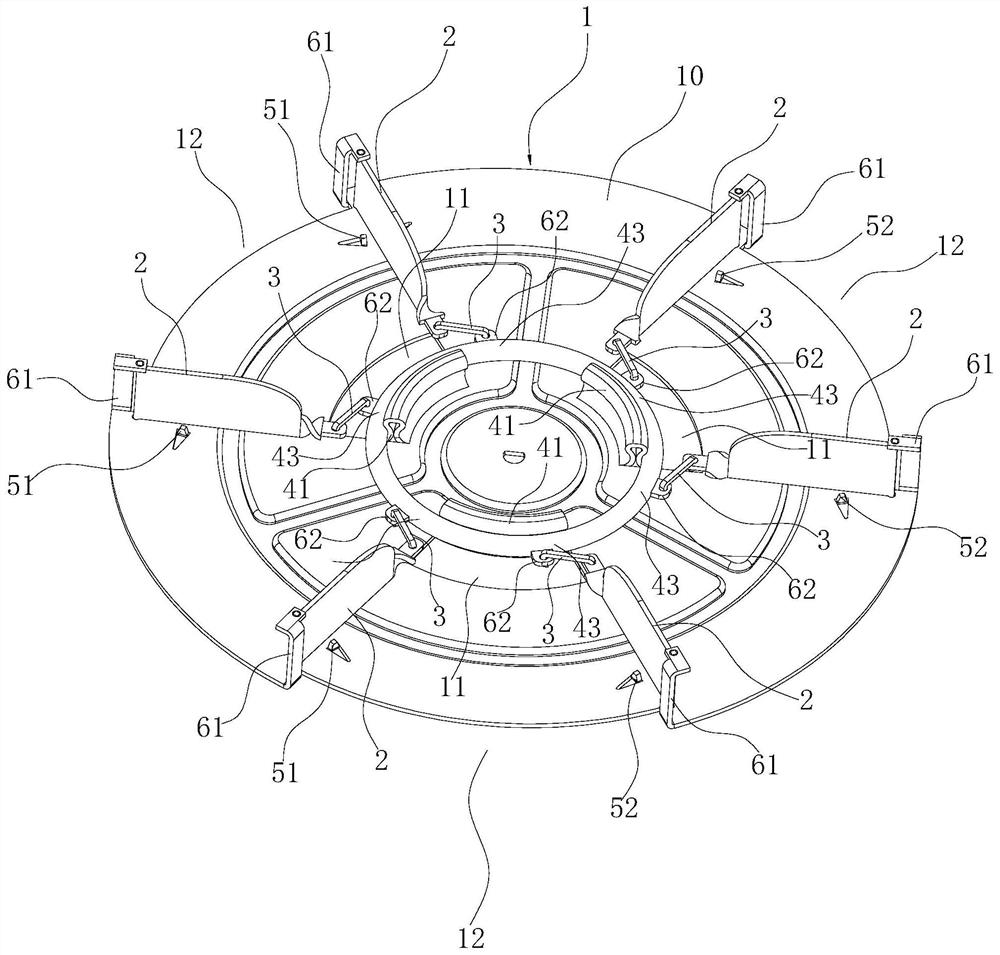

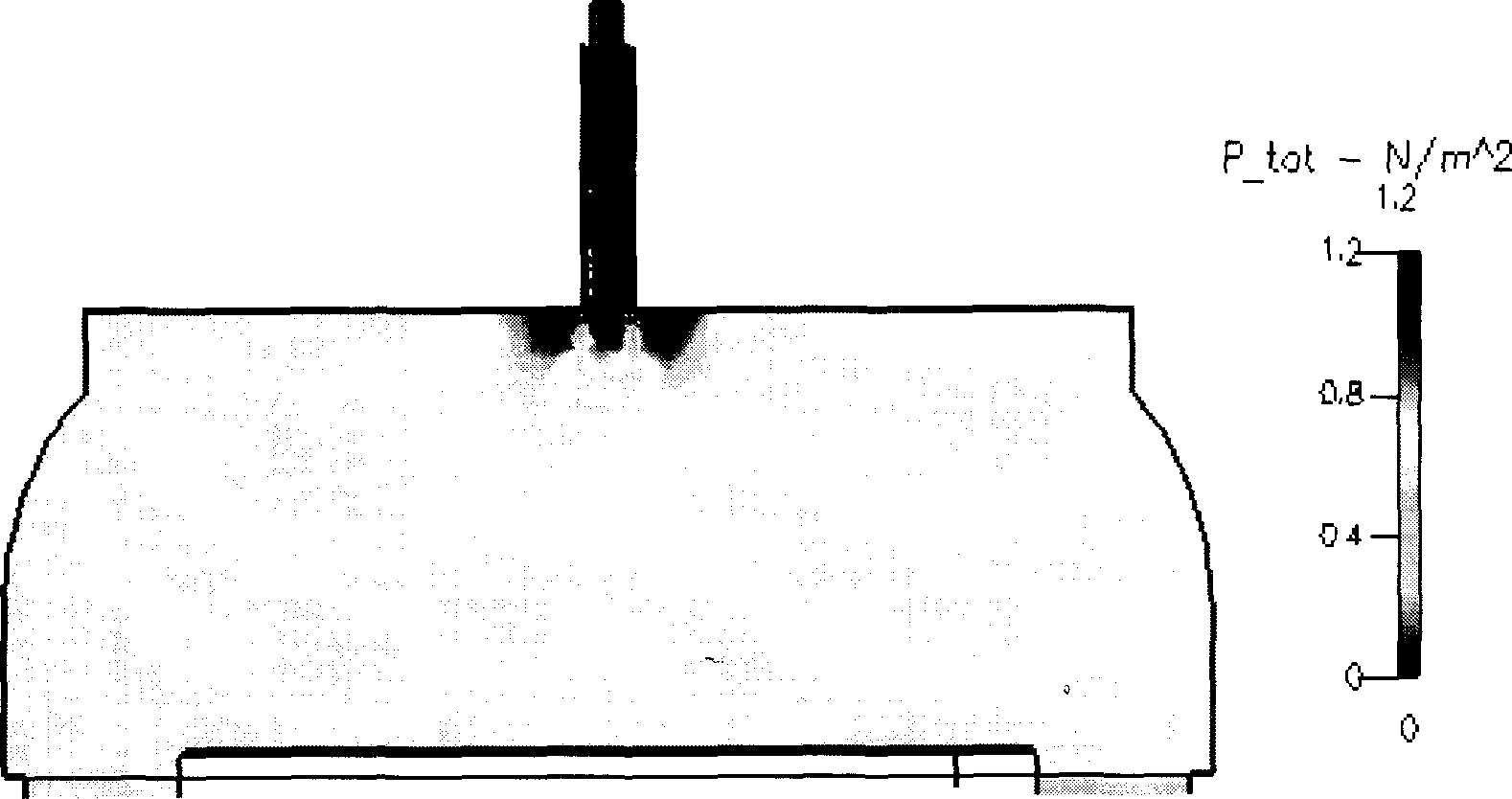

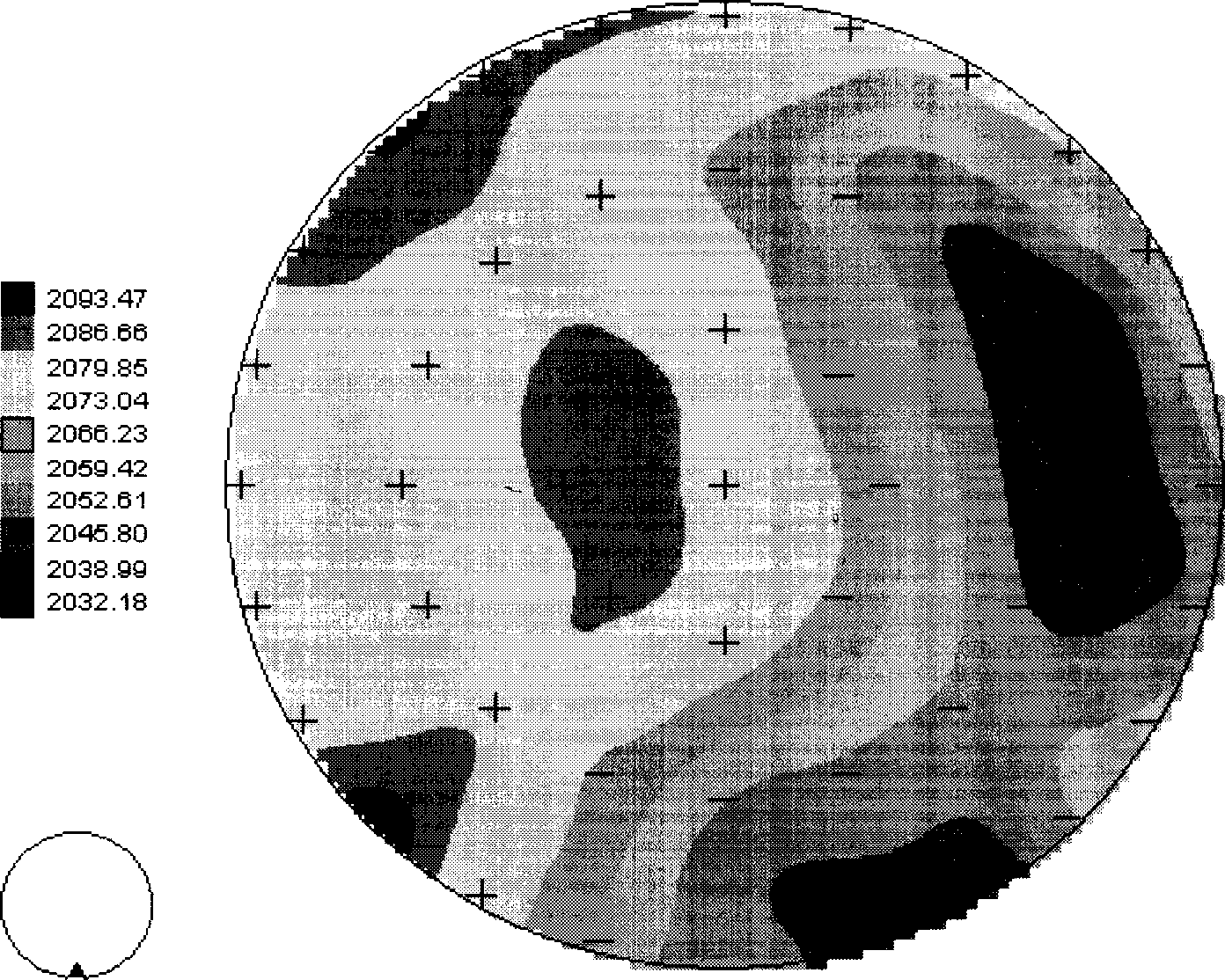

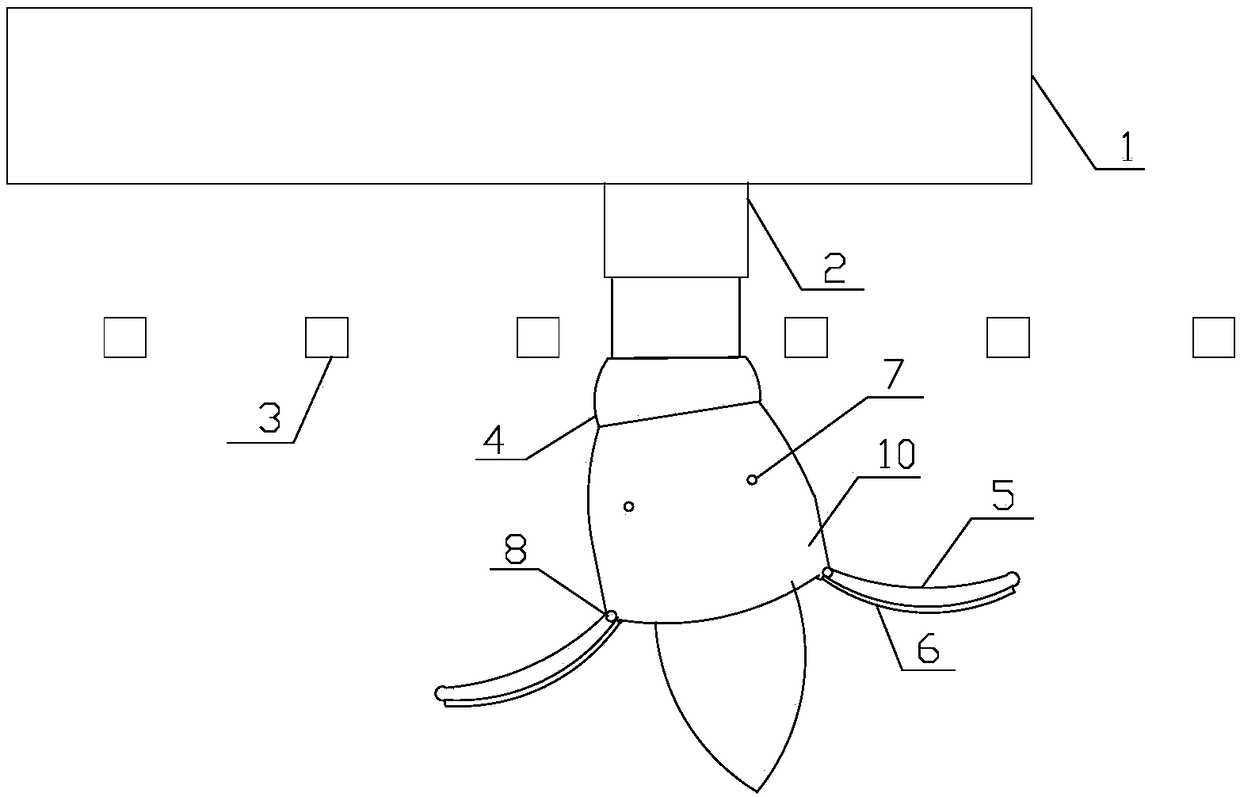

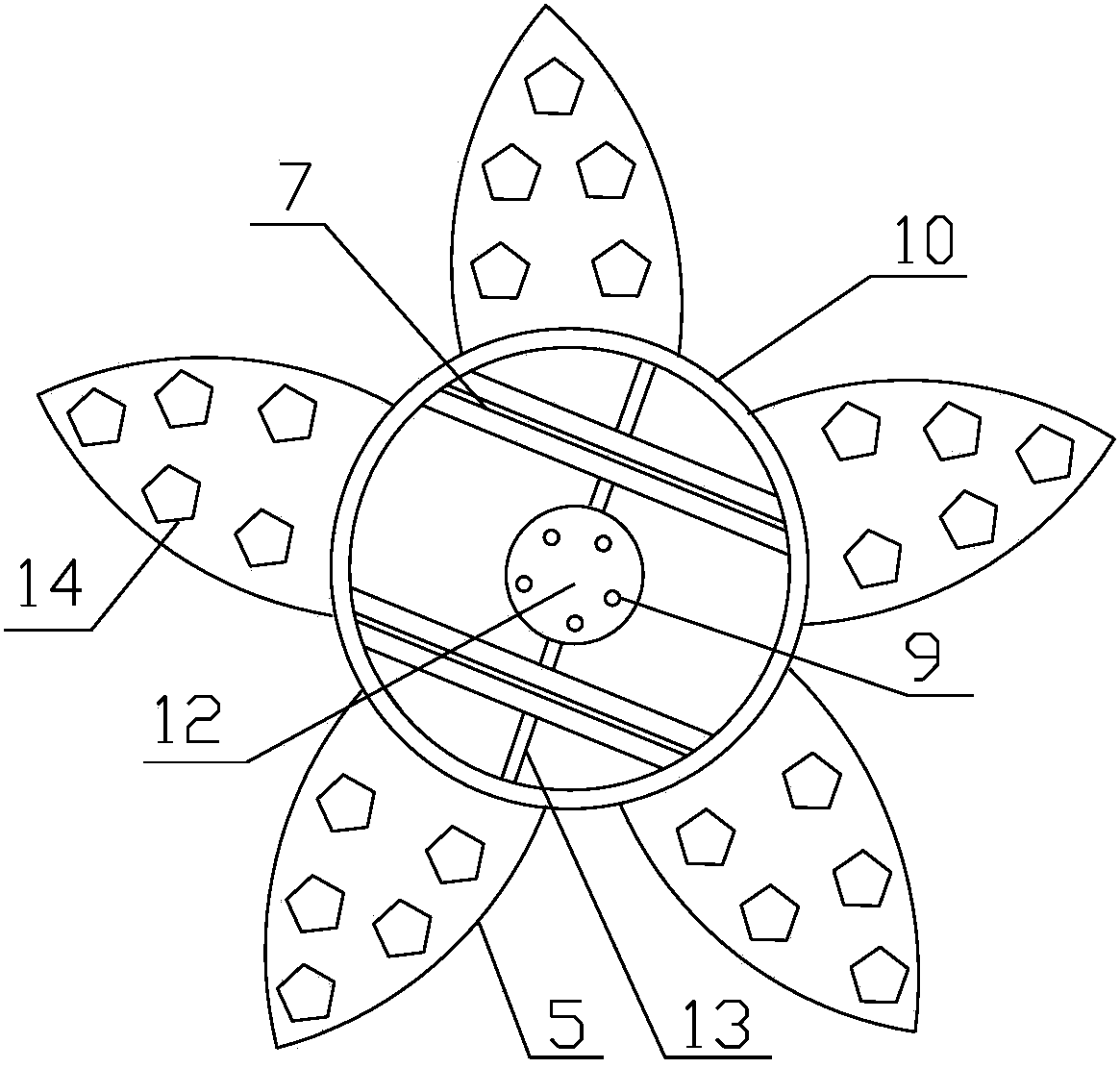

An impeller structure for cooking equipment and an oven with the structure

The invention relates to an impeller structure for cooking equipment, which comprises a disc-shaped main board, fan blades are arranged at intervals along the circumferential direction on the first disc surface of the main board, and each fan blade has a strip shape and is opposite to the The main board extends along the inner and outer directions and is arranged perpendicular to the first disk surface. The outer peripheral side of the first disk surface of the above-mentioned main board is provided with first hinge seats corresponding to the above-mentioned fan blades at intervals along the circumferential direction, and also includes the first hinge seats corresponding to the above-mentioned fan blades. One-to-one corresponding connecting rods, the first end of each fan blade is respectively rotatably connected with the corresponding first hinge seat and the second end is respectively rotatably connected with the first end of the corresponding connecting rod, and the second ends of each connecting rod are It is located on a track circle centered on the center of the above-mentioned first disk surface and can slide along the track circle circumferentially, and the track circle is located in the middle of the above-mentioned first disk surface. Compared with the prior art, the present invention can change the angle of the fan blade according to its rotation direction, so that the impeller structure can obtain better airflow uniformity in both forward rotation and reverse rotation states.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Grate etching method

ActiveCN1848386AGuaranteed stabilityImproves airflow uniformitySemiconductor/solid-state device manufacturingEtchingProduct gas

The present invention relates to a gate etching method, including BT step, main etching step and over etching step. It is characterized by that in the described main etching step the used gas contains Cl2, HBr and O2, On the premise of that its hardware design is not changed said method only can change the gas type and matching ratio of main etching step in gate etching process to raise gas flow uniformity of silicon wafer surface process gas so as to meet the requirements of advanced gate etching process.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

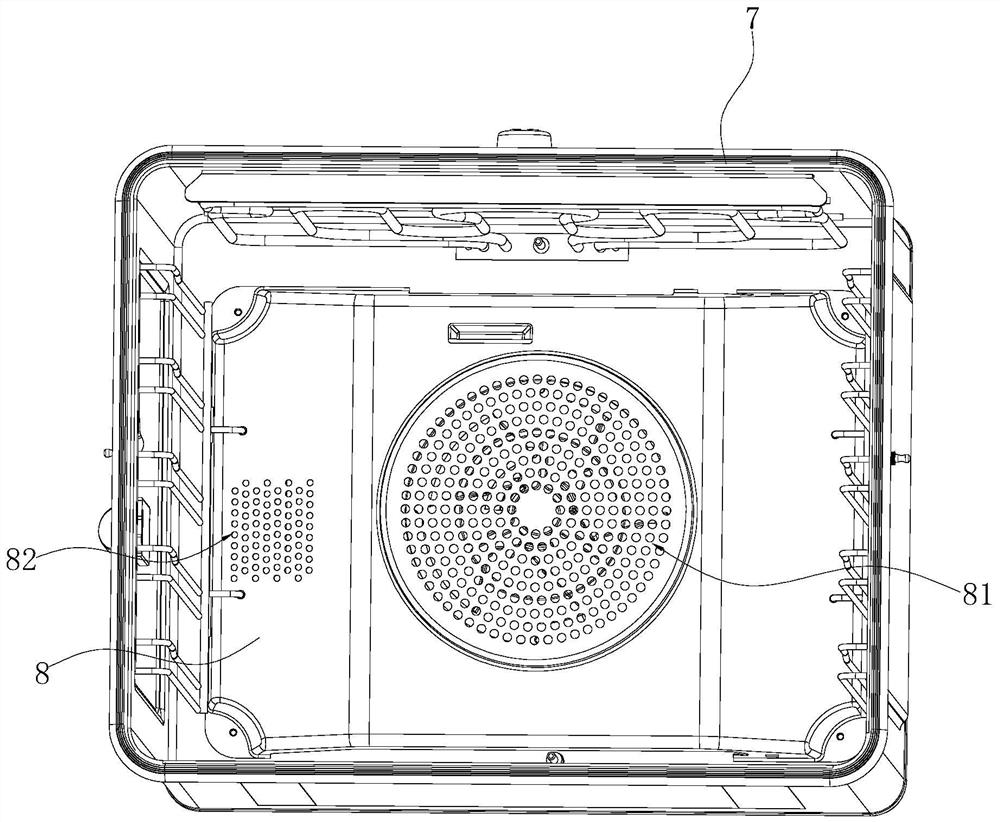

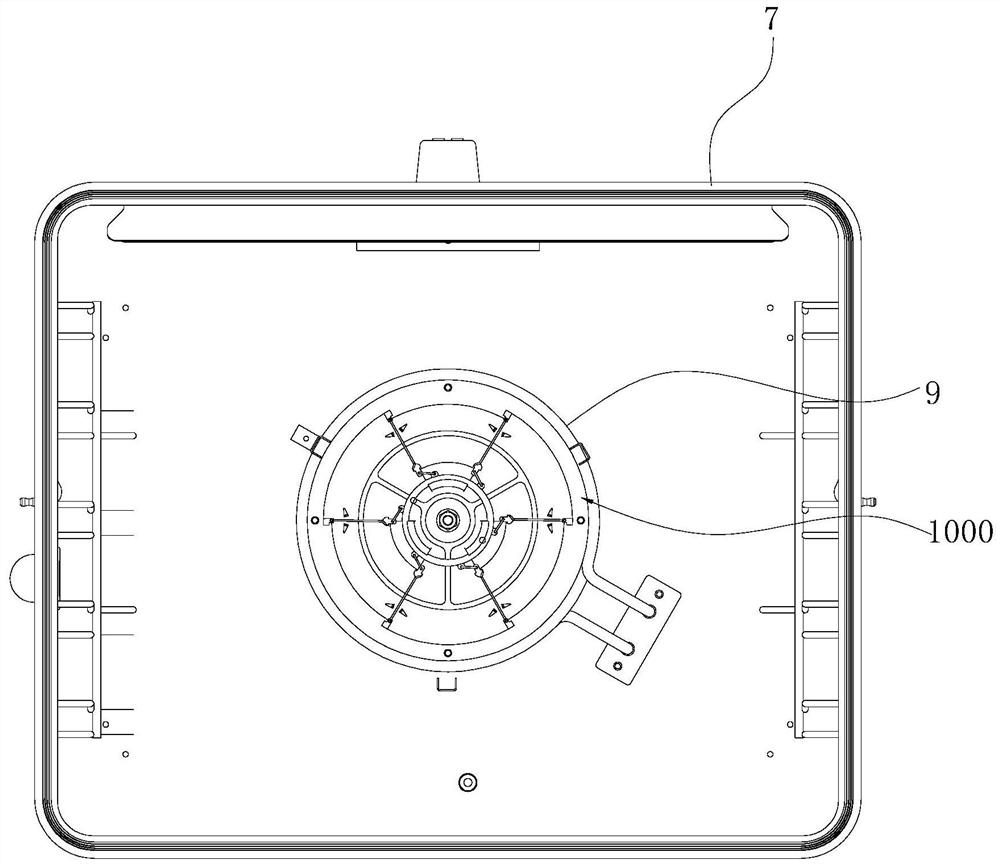

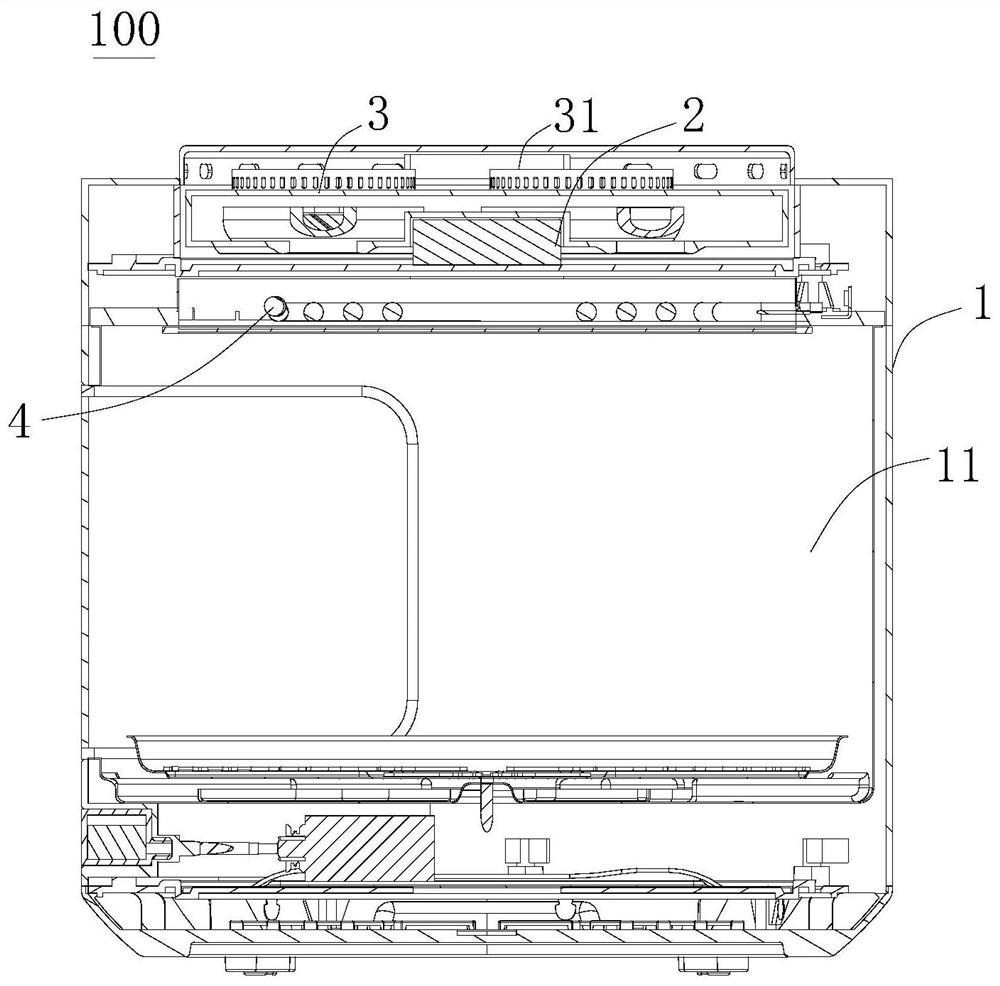

Cooking equipment

ActiveCN114521808AIncreased confusionSolve the problem of undercookingRoasters/grillsHome appliance efficiency improvementEngineeringFood material

The invention relates to cooking equipment which comprises a shell, a platform and a fan, a cooking cavity is formed in the shell, the platform is arranged in the shell, the fan is arranged on the platform, an air outlet communicates with the cooking cavity, and the platform and / or the fan can move relative to the shell so that the direction of the air outlet can change relative to the cooking cavity. By means of the mode, the confusion degree of the airflow in the cooking cavity is increased, the airflow acting on the food materials flows in all directions, then the food materials at all angles can be subjected to the airflow effect, and the airflow uniformity of the cooking equipment is improved.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

An energy-saving and noise-reducing multifunctional decorative tuyere capable of uniform airflow and its application method

ActiveCN105910252BReduce noiseReduce energy consumptionDucting arrangementsMechanical apparatusEngineeringEnergy consumption

The invention discloses an energy saving and noise reducing multifunctional decoration wind gap capable of homogenizing air currents and an application method thereof. The wind gap comprises a rotating extension section, a rectification section, multiple external guide plates, at least two one-layer shutters, and a wind gap probe for detecting the exhaust temperature and / or the flowing speed; one end of the rectification section is connected with the rotating extension section, and the external guide plates are uniformly mounted around the other end; the rectification section has an outward concave arched windward surface; angles between the external guide plates and the rectification section are adjustable; the one-layer shutters are arranged in the rectification section; and the rotating extension section can drive the rectification section to change a wind blowing angle. The wind gap optimizes the streamline shape of the air currents sprayed by the wind gap, can increase or reduce actual travel distance of the air currents according to the demands, and improves the uniformity of the air currents and the indoor ventilation effect. The one-layer shutters replace double-layer shutters of a traditional wind gap, so that the wind resistance is reduced, and the noise of the wind gap and the energy consumption are reduced. In addition, the wind gap has a decoration effect.

Owner:SHANGHAI INSTALLATION ENG GRP

An Experimental System of Flat Air Cascade of Compressor with Suction Baffle Structure

ActiveCN106640619BShort maintenance periodGood periodicityPump testingPump controlGas compressorVacuum pump

The invention provides a gas compressor plane cascade experimental system with a suction baffle structure. The gas compressor plane cascade experimental system comprises a suction device and a plane cascade experimental device. The plane cascade experimental device comprises a left end plate, a right end plate, an upper baffle, a plurality of experimental blades and a lower baffle, wherein the upper baffle is arranged between the left end plate and the right end plate, and the multiple experimental blades are distributed at intervals. The upper baffle and the lower baffle are connected between the left end plate and the right end plate through fixing shafts. The upper baffle is provided with suction holes. Left end plate suction holes are formed in the left end plate, and right end plate suction holes are formed in the right end plate. The suction holes are connected with a vacuum pump through a pipeline. A three-hole probe 1 is arranged between the left end plate and the right end plate. In the experimental process, the upper baffle and the lower baffle are adjusted so that a cascade can be good in periodicity, the boundary layer of incoming flow is sucked through the left end plate suction holes and the right end plate suction holes, the influence area of the boundary layer is reduced, and uniform incoming flow is achieved. The gas compressor plane cascade experimental system with the suction baffle structure is an effective path for exploring improvement of the performance of a gas compressor, the influence of the boundary layer of the incoming flow is reduced, and meanwhile, the periodicity of the plane cascade is improved.

Owner:DALIAN MARITIME UNIVERSITY

Microwave plasma reactor for manufacturing synthetic diamond material

ActiveUS11371147B2Increase speedReduce decreasePolycrystalline material growthElectric discharge tubesPhysical chemistryPlasma reactor

A microwave plasma reactor for manufacturing synthetic diamond material via chemical vapour deposition, the microwave plasma reactor includes a plasma chamber, a substrate holder, a microwave coupling configuration for feeding microwaves into the plasma chamber, and a gas flow system for feeding process gases into the plasma chamber and removing them therefrom. The gas flow system includes a gas inlet array having a plurality of gas inlets for directing the process gases towards the substrate holder. The gas inlet array includes at least six gas inlets disposed in a substantially parallel or divergent orientation relative to a central axis of the plasma chamber.

Owner:ELEMENT SIX TECH LTD

Grate etching method

ActiveCN100369214CGuaranteed stabilityImproves airflow uniformitySemiconductor/solid-state device manufacturingEtchingProduct gas

The present invention relates to a gate etching method, including BT step, main etching step and over etching step. It is characterized by that in the described main etching step the used gas contains Cl2, HBr and O2, On the premise of that its hardware design is not changed said method only can change the gas type and matching ratio of main etching step in gate etching process to raise gas flow uniformity of silicon wafer surface process gas so as to meet the requirements of advanced gate etching process.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Device for Improving Airflow Uniformity in Aircraft Experimental Wind Tunnel and Its Parameter Optimization Method

ActiveCN113916490BIncrease air capacityReduce distractionsAerodynamic testingDesign optimisation/simulationAir volumeAir velocity

The invention relates to the technical field of airflow uniformity in wind tunnel experiments, and discloses a device for improving airflow uniformity in an aircraft experiment wind tunnel and a parameter optimization method thereof; the device includes a power section, a steady flow adjustment section and a contraction section; the power section includes a circular tubular power The main body section, the fan installation structure arranged in the power main section, and the fan installed on the fan installation structure; the method includes: S1, initially setting size parameters; S2, modeling the whole wind tunnel; S3, performing fluid simulation; S4. Determine whether the unevenness of wind speed in the target area is less than 5%; if the unevenness is less than 5%, the design is completed; if it is not less than 5%, then modify the size parameters of step S1 and repeat steps S2~S4; the present invention can meet the needs of large aircraft. The wind tunnel test requires large air volume and high wind speed; it can improve the uniformity of airflow.

Owner:CHINA AIRPLANT STRENGTH RES INST

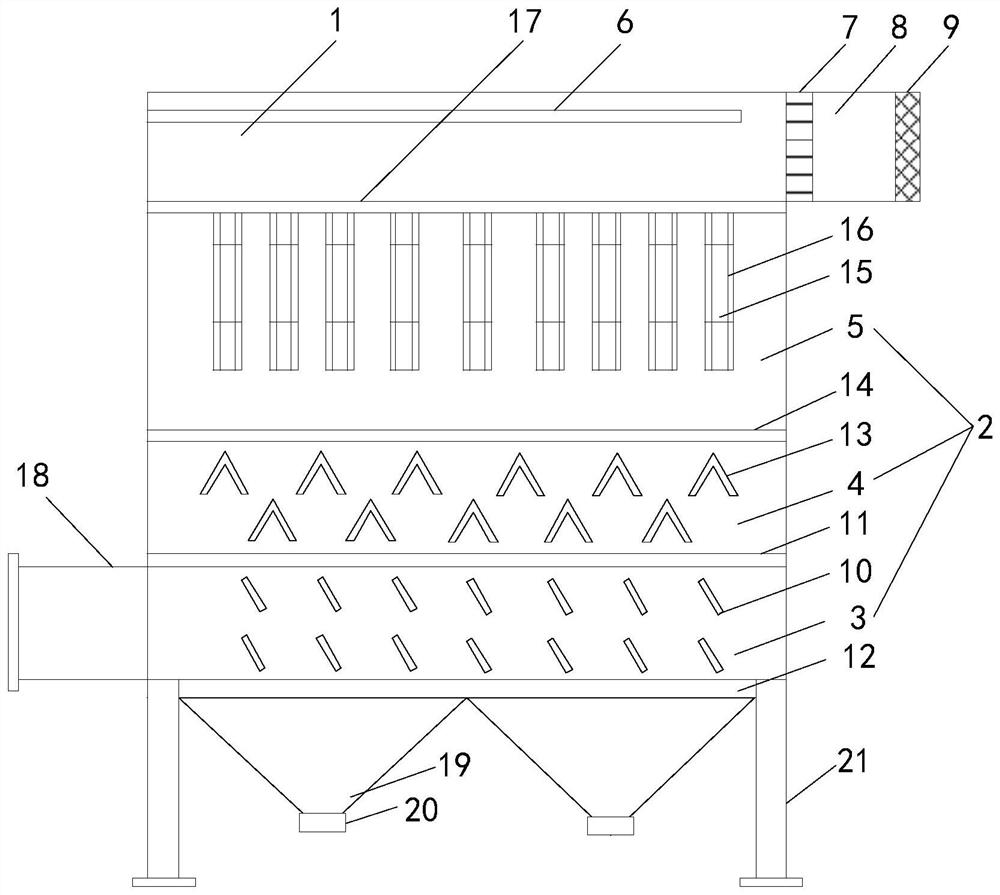

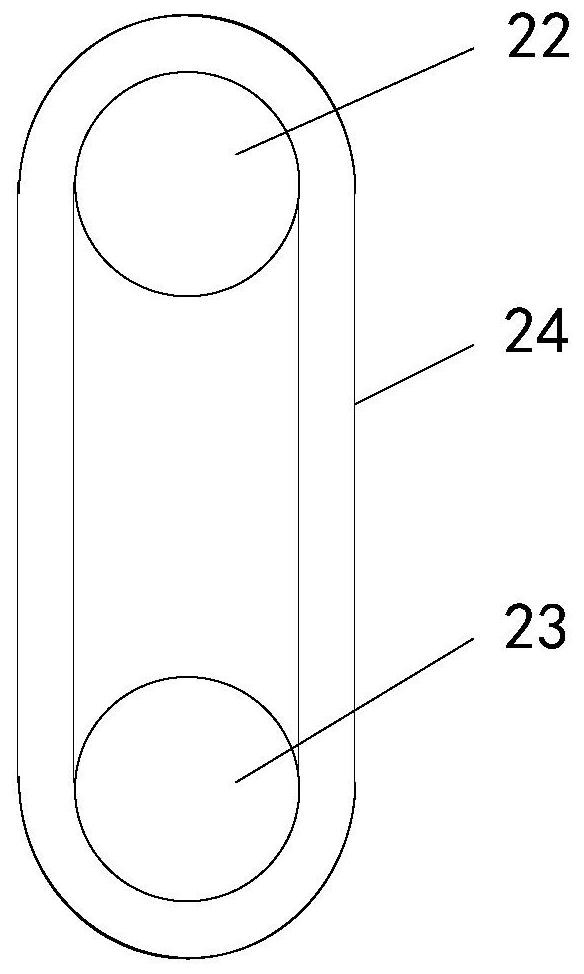

Filter cartridge dust remover

PendingCN114345057AEasy to removeEfficient separationHuman health protectionCombination devicesIron powderDust control

The invention provides a filter cartridge dust remover, which comprises a dust removal chamber, an air inlet is arranged on the outer side of the dust removal chamber, the air inlet is communicated with the dust removal chamber, a filter cartridge frame is arranged in the dust removal chamber, and a filter cartridge is arranged on the filter cartridge frame; the air purification chamber is arranged above the dust removal chamber, a tubesheet is arranged between the air purification chamber and the dust removal chamber, the dust removal chamber and the air purification chamber are separated by the tubesheet, and the filter cartridge and the filter cartridge frame are arranged on the tubesheet; the air outlet is formed in the outer side of the air purification chamber and is communicated with the air purification chamber; the dust hopper is arranged below the dust removal chamber, and a dust discharging valve is arranged at the bottom of the dust hopper; and the iron powder removing device comprises an electromagnet and is arranged between the ash bucket and the dust removing chamber. By arranging the iron powder removing device, scrap iron dust or iron ore concentrate dust can be effectively separated, electrical equipment in the dust remover is prevented from being damaged, and the problems that maintenance is difficult and maintenance cost is high due to the iron dust are solved.

Owner:无锡市凯意德干燥设备有限公司

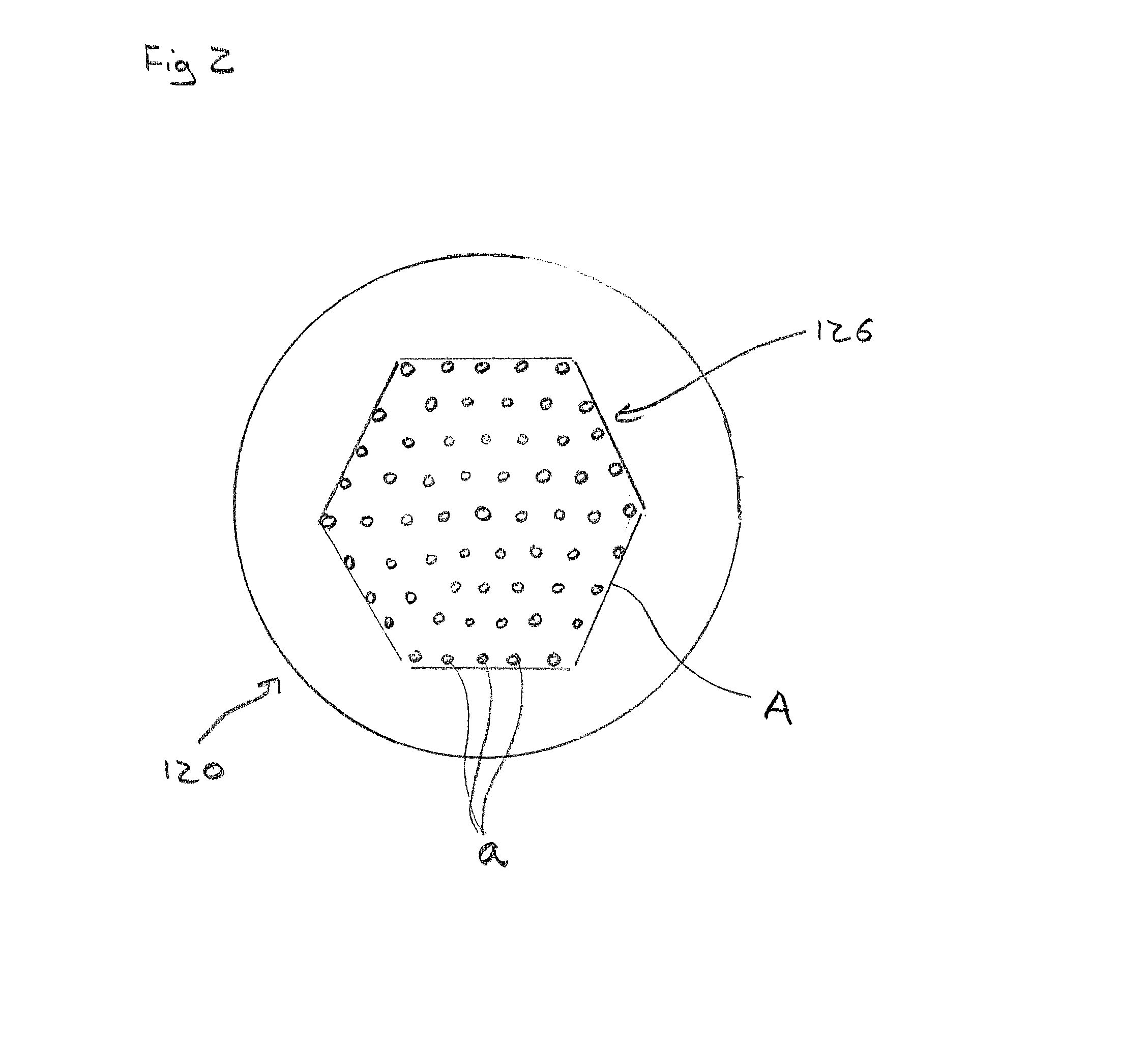

Single-air-outlet spin-coating development cavity

InactiveCN104977818AReduce in quantityImproves airflow uniformityPhotosensitive material processingSpinsEngineering

The invention relates to a spin-coating development device in the field of semiconductor manufacturing, and particularly provides a single-air-outlet spin-coating development cavity, which includes an upper spin-coating cavity, a middle spin-coating cavity, a flow reshaping board and a lower spin-coating cavity. The bottom of the lower spin-coating cavity is provided with an air outlet. The upper spin-coating cavity is disposed on the top of the lower spin-coating cavity. The middle spin-coating cavity is disposed between the upper spin-coating cavity and the lower spin-coating cavity. The flow reshaping board is arranged between the air outlet and a wafer, is in an annular shape and is provided with a plurality of holes circumferentially therein. The device is reduced in the number of air outlets and is reduced in size, and is improved in uniformity of air flow neighboring the waver.

Owner:SHENYANG KINGSEMI CO LTD

High-temperature nitriding flow field control device and control method thereof

The invention provides a high-temperature nitridation airflow field control device and method. The control device comprises an impeller used for driving gas in a furnace body to flow, a first gas inlet used for feeding ammonia gas and a second gas inlet used for feeding power gas for driving the impeller to rotate, the first gas inlet is arranged below the impeller, the second gas inlet is arranged above the side of the impeller, and the power gas is argon. According to the high-temperature nitridation airflow field control device, the impeller driven by argon is arranged on the inner wall of a furnace door of the device, on one hand, ammonia gas and argon in the furnace are mixed to be uniform by means of rotation of the impeller; on the other hand, fed argon also can serve as diluent gas of high-purity ammonia gas to adjust the concentration of ammonia gas in the furnace.

Owner:NAT UNIV OF DEFENSE TECH

A Radial Turbine Guide Vane Structure Coupled with Non-axisymmetric End Walls

ActiveCN110608068BDelayed formationImproves airflow uniformityStatorsMachines/enginesSuction forceEngineering

In order to solve technical problems such as obvious secondary flow on the end wall of the radial flow guide vane with low aspect ratio, relatively large channel vortex size, and poor outlet airflow uniformity, the present invention relates to a radial flow turbine guide vane structure coupled with non-axisymmetric end walls. The non-axisymmetric concave-convex end wall structure is adopted on the front end wall and the rear end wall of the radial turbine guide vane, and can be formed with the radial turbine guide vane having a three-dimensional configuration to more effectively control the secondary flow loss of the flow channel. In the present invention, by modifying the cascade, specifically, setting the inner surfaces of the front end wall and the rear end wall as non-axisymmetric concave-convex end wall structures, the flow area of each flow channel is changed, and the The airflow pressure difference between the pressure surface on one side of each flow channel and the suction surface on the other side is reduced, thereby affecting the secondary flow velocity distribution, delaying the formation and development of channel vortices, reducing the channel vortex intensity, and finally realizing the secondary flow velocity distribution. Reduced secondary flow loss.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com