An impeller structure for cooking equipment and an oven with the structure

A technology of cooking equipment and impeller, applied in the field of impeller structure and oven, can solve the problems of inferior two-way non-angle fan blades, inferior uniformity of temperature field in the oven inner tank, etc., and achieve the effect of good airflow uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

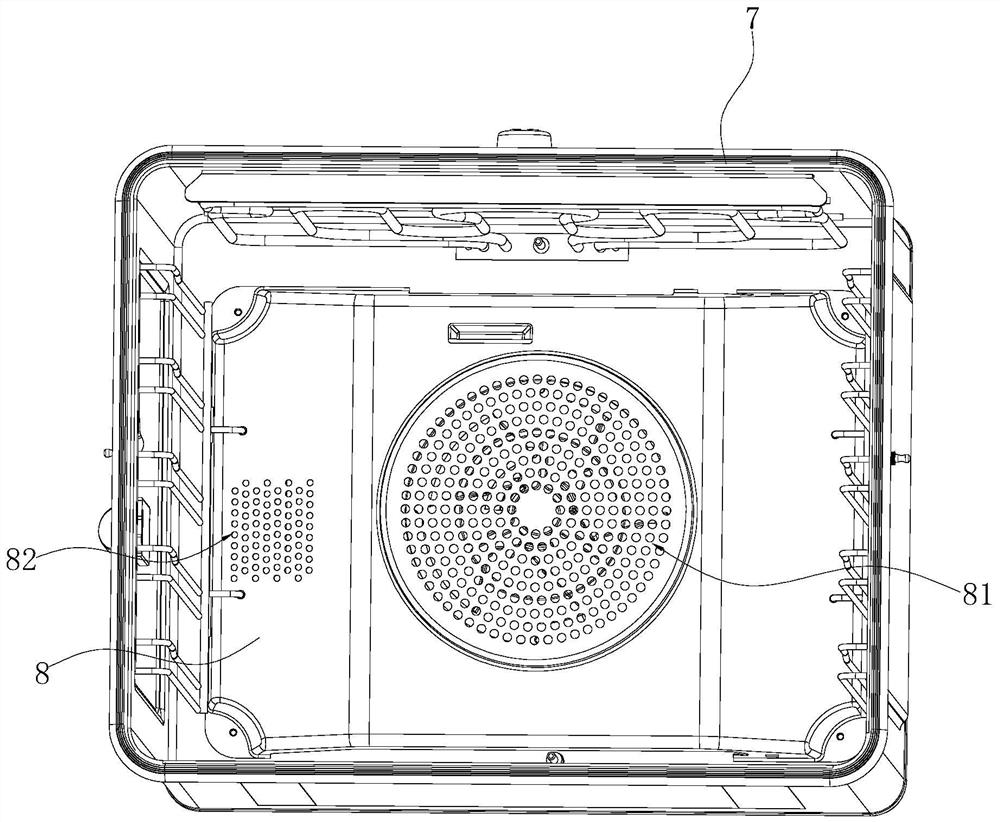

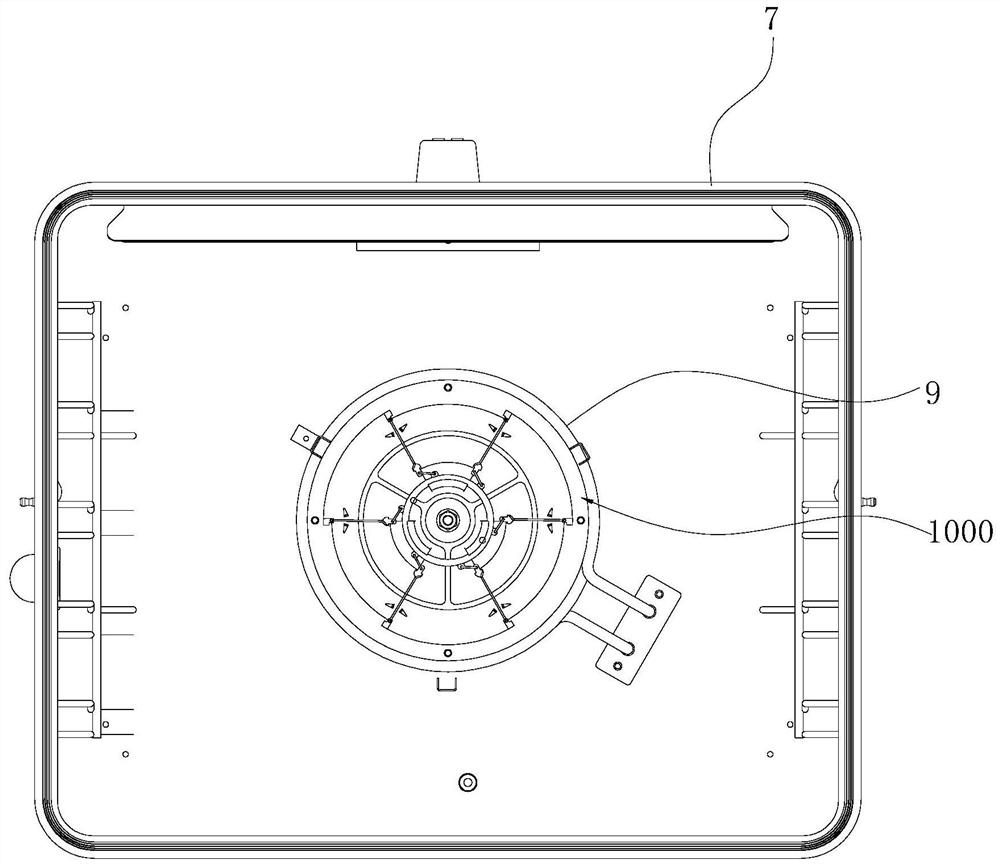

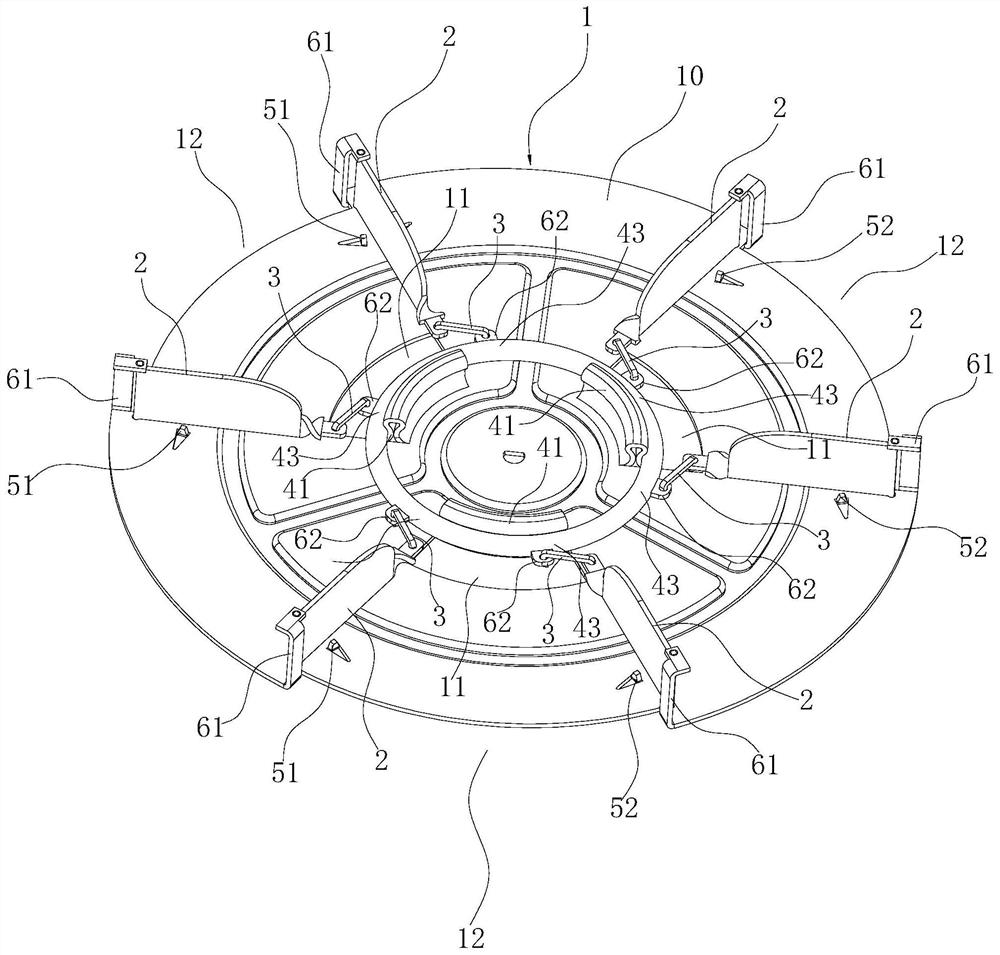

[0038] Such as Figure 1-5 As shown, a kind of oven comprises liner 7, and the rear side of this liner 7 is vertically provided with hot air baffle 8 with air inlet 81 and air outlet 82, and this hot air baffle 8 is surrounded by the back plate of liner 7 A hot air chamber 80 is formed, and an impeller structure 1000 is arranged in the hot air chamber 80 , and a back heating pipe 9 is arranged around the outer periphery of the impeller structure 1000 . When the oven works like this, the impeller structure 1000 rotates under the drive of the motor, and the cold air in the inner container 7 is sucked in the hot air chamber 80 through the air inlet 81 on the hot air baffle 8, and the hot air heated by the back heating tube 9 is in the oven. Under the action of the centrifugal force of the impeller structure 1000, it flows back into the inner container 7 through the air outlet 82 of the hot air baffle 8, and is used for toasting the food in the inner container 7, such as Figure ...

Embodiment 2

[0051] Such as Figure 6-9 As shown, the difference from Embodiment 1 is that in this embodiment, the above-mentioned sliding structures correspond to two adjacent fan blades 2 respectively, and each sliding structure 4 includes a The arc-shaped second slide rail 42 and the slide seat 44 that can slide along the second slide rail 42, the second hinge seats 62 of two adjacent fan blades 2 are respectively connected with the slide seat 44, each second slide rail 42 each extend along the aforementioned trajectory circle 100 . Arranging two adjacent fan blades 2 on one sliding seat 44 can improve the efficiency of adjusting the angle of the fan blades 2, and the two fan blades 2 on the same sliding seat 44 and the corresponding connecting rod 3 have different structures and are dead at the same time. point (that is, the angle α formed by the fan blade 2 and the corresponding connecting rod 3 is equal to 180°), so as to ensure that the angle of the fan blade 2 is automatically adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com