A Radial Turbine Guide Vane Structure Coupled with Non-axisymmetric End Walls

A turbine guide vane, non-axisymmetric technology, applied in the direction of machine/engine, stator, mechanical equipment, etc., can solve the problems of poor outlet airflow uniformity, large channel vortex size, etc., to reduce secondary flow loss and energy utilization efficiency Effects of high, delayed formation and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

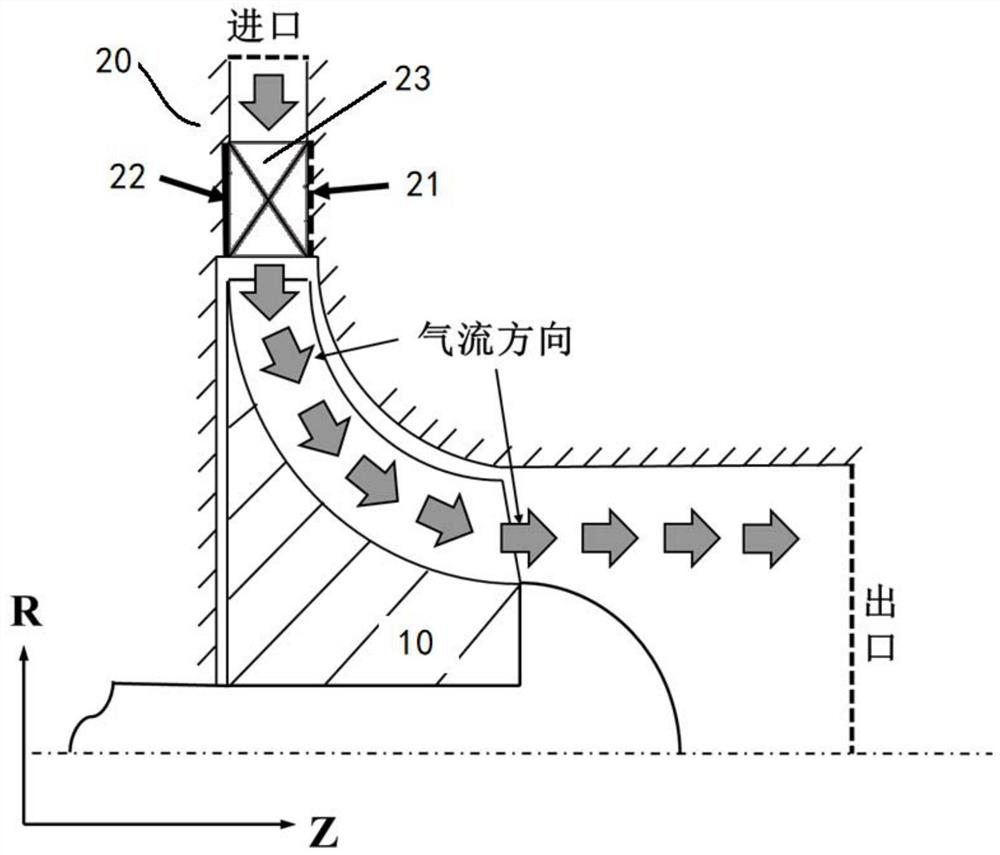

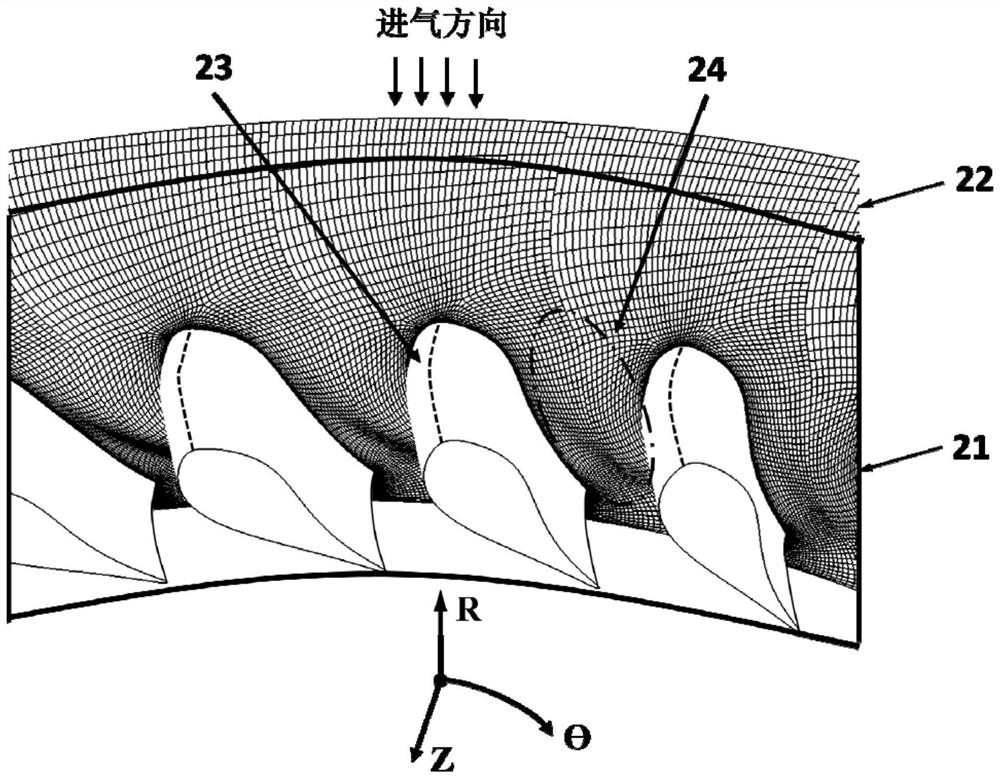

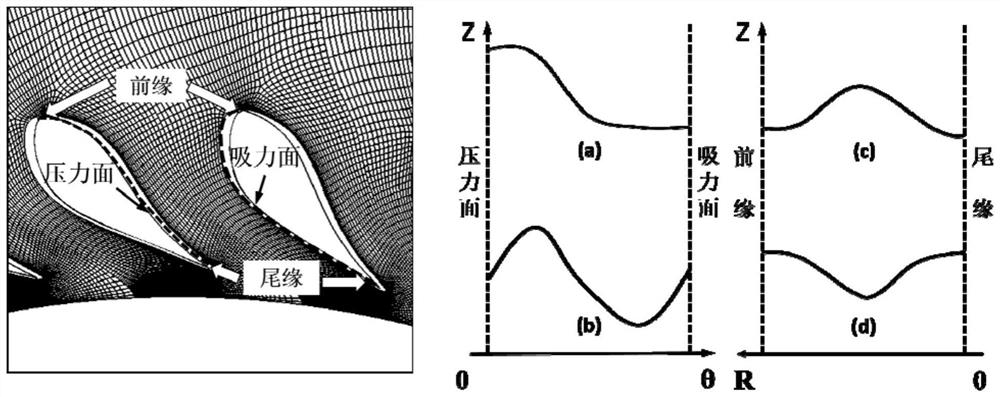

[0034] Such as figure 1 As shown, the radial turbine includes an impeller 10 and a radial turbine vane structure 20 arranged on the periphery of the impeller 10. The radial turbine vane structure 20 includes a front end wall 21, a rear end wall 22, and a front end wall 21 and a rear end wall 22. A plurality of radial flow turbine guide vanes 23 evenly arranged in the circumferential direction between them, the front end wall 21 and the rear end wall 22 are basically disc-shaped structures, and a flow channel is formed between two adjacent radial flow turbine guide vanes 23, one of the flow channels One side is the pressure surface of a radial turbine vane, and the other side of the flow channel is the suction surface of another radial turbine vane.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com