Method for operating an electrically operable suction valve

A suction valve, no current technology, applied in the direction of electrical control, engine control, fuel injection control, etc., can solve the problem of increased wear of the drive mechanism components, achieve the effect of reducing load and improving robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

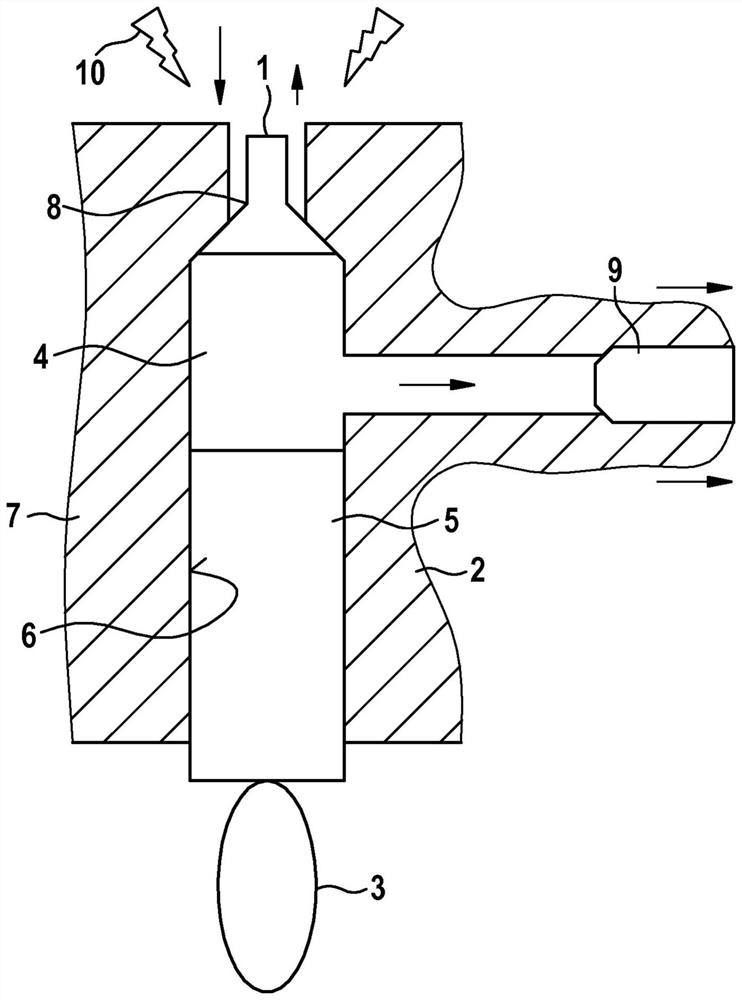

[0022] exist figure 1 A high-pressure pump 2 for a common rail injection system, shown very schematically in FIG. In the cylinder bore 6 of the housing part 7. The pump piston 5 can be driven in a stroke movement via the drive mechanism 3 , which is in the present case designed as a cam drive. During the delivery stroke of the pump piston - during which the volume in the high-pressure element chamber 4 becomes smaller - the fuel present in the high-pressure element chamber 4 is compressed and then supplied via the high-pressure outlet 9 to the high-pressure accumulator ( not shown). The high-pressure element chamber 4 is filled with fuel via an electrically actuatable suction valve 1 , which is presently designed as a valve that opens when there is no current flow. The suction valve 1 has a valve tappet 8 which can be opened into the high-pressure element chamber 4 of the high-pressure pump 2 and which can be actuated via a magnetic actuator (not shown). As a valve that op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com