Regeneration method of deactivated hydrogenation catalyst

A hydrogenation catalyst, catalyst technology, applied in catalyst regeneration/reactivation, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

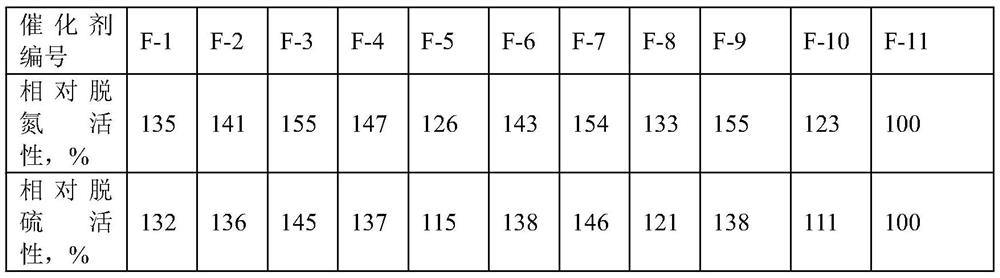

Embodiment 1

[0035] Catalyst A1 after taking by weighing a certain amount of burning charcoal (deactivated catalyst A1 active component is Mo, Ni, and the content of Mo is 23%, and the content of Ni is 3.85%, all the other are Al 2 o 3 ; The regeneration temperature is 430°C), with an aqueous solution containing glycerol for immersion, and the immersion time is 35min. The molar ratio of glycerol to Mo and Ni metal atoms in the impregnation solution is 0.5:1, the microwave power is 8W / g, the vacuum pressure is 0.07MPa, and the treatment time is 15min. Catalyst F-1 was obtained.

Embodiment 2

[0037] Catalyst A2 after taking by weighing a certain amount of burning charcoal (deactivated catalyst A2 active component is Mo, Ni, and the content of Mo is 22.5%, and the content of Ni is 4.0%, all the other are Al 2 o 3 ; the regeneration temperature is 440°C), impregnate with an aqueous solution containing maleic acid, the impregnation time is 38min, the molar ratio of maleic acid to Ni metal atoms in the impregnation solution is 0.6:1, the microwave power is 10W / g, vacuum The pressure is 0.07MPa, and the treatment time is 20min. Catalyst F-2 is obtained.

Embodiment 3

[0039] Catalyst A3 after taking by weighing a certain amount of burning charcoal (deactivated catalyst A3 active component is W, Ni, and the content of W is 22.5%, and the content of Ni is 3.75%, and all the other are Al 2 o 3; The regeneration temperature is 430°C), impregnated with an aqueous solution containing butanediol, the impregnation time is 40min, the molar ratio of butanediol to Ni metal atoms in the impregnation solution is 0.7:1, the power of the microwave is 12W / g, vacuum The pressure is 0.08MPa, and the processing time is 18min. Catalyst F-3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com