Patents

Literature

54results about How to "Delayed formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

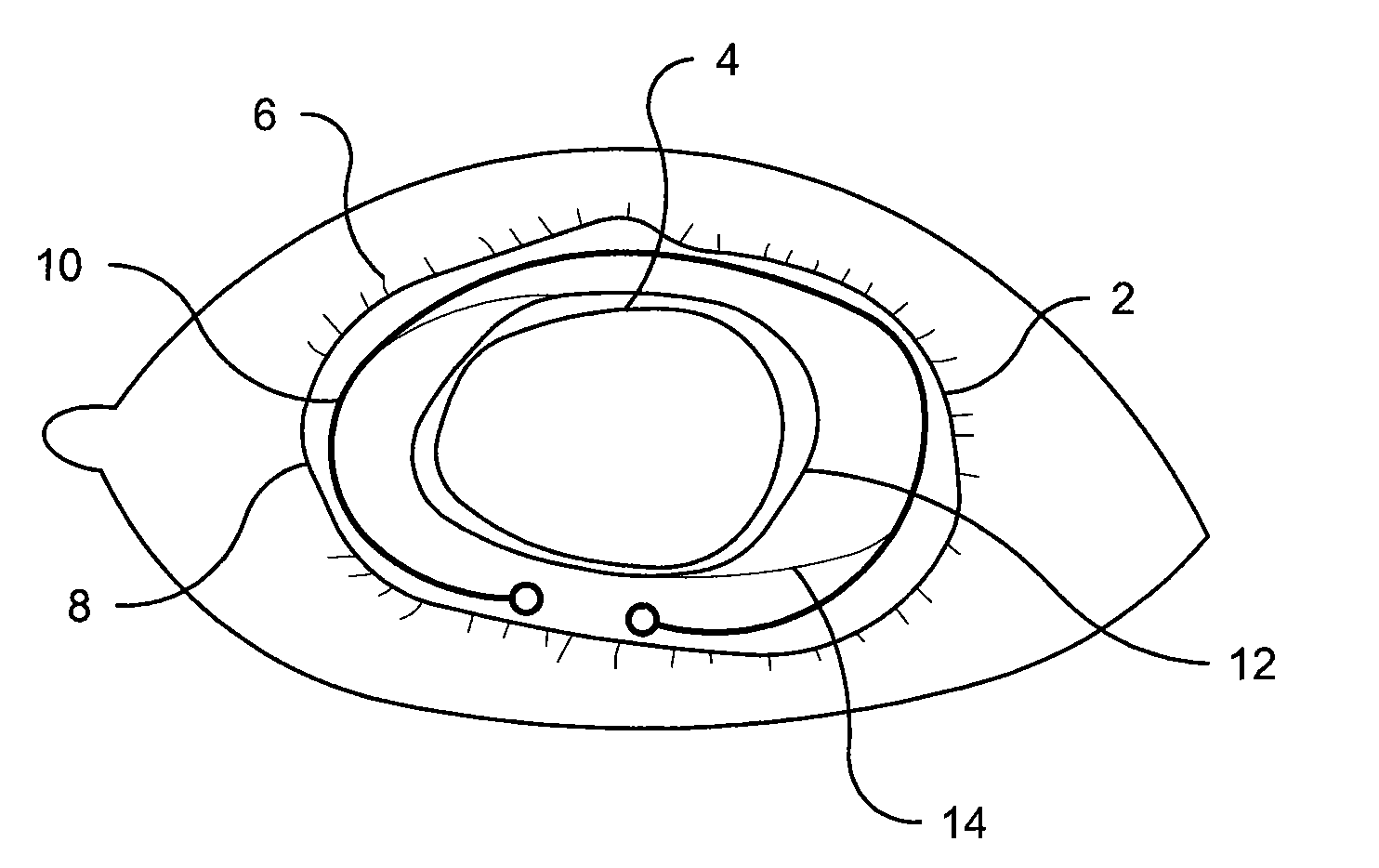

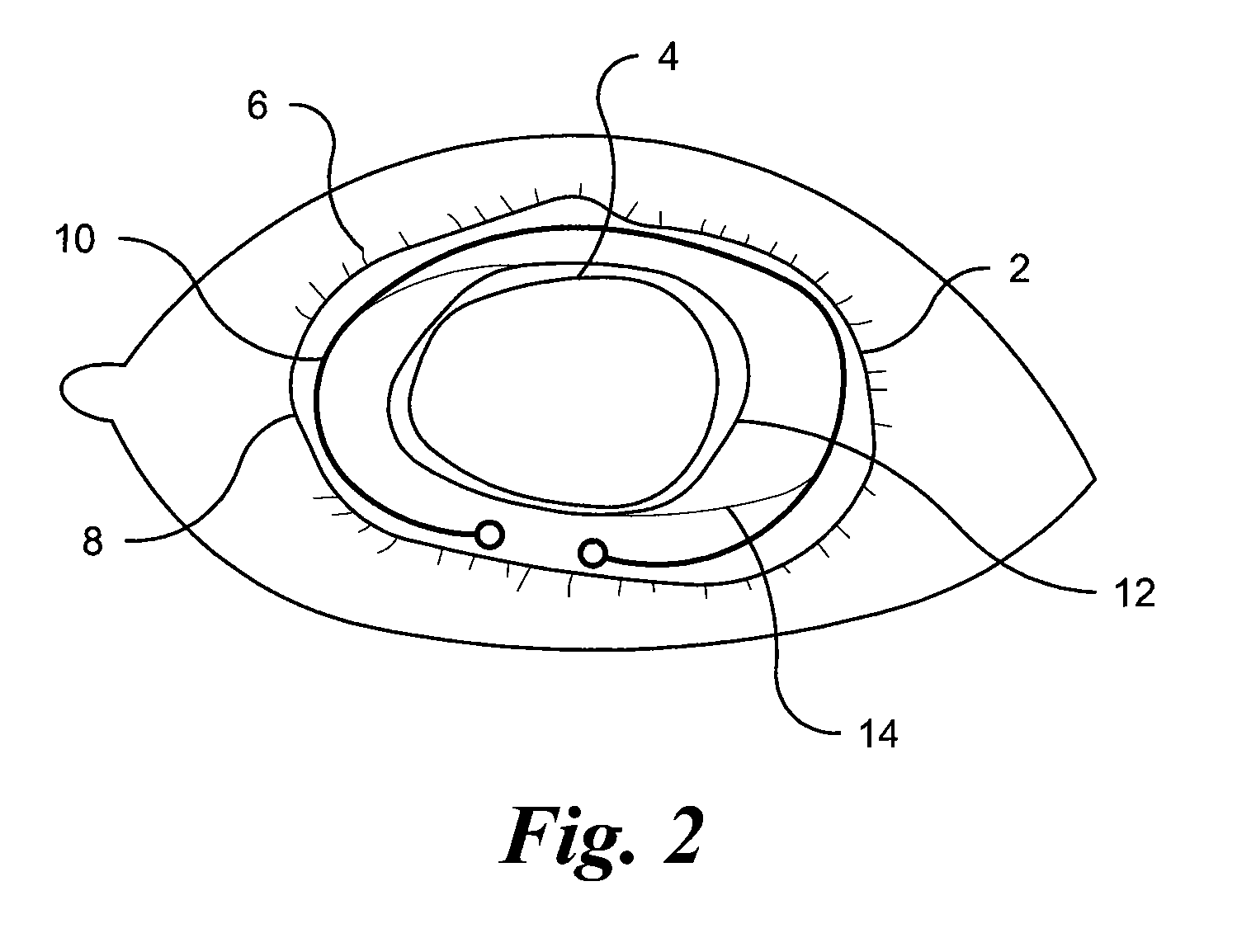

Methods and Devices for Preventing or Delaying Posterior Capsule Opacification

InactiveUS20110082543A1Prevents and minimizes and delays formationMinimize formationPharmaceutical delivery mechanismEye treatmentChemical MoietyBovine serum albumin

Several methods for preventing, minimizing, or delaying the incidence of posterior capsule opacification are provided. A first method involves chemically activating the surface of an implantable ocular device, such as an intraocular lens or a capsular tension ring, by grafting a chemical moiety onto the surface of the device, covalently attaching a non-cytotoxic inhibitor compound to the chemical moiety to produce an inhibitor implantable ocular device, and implanting this inhibitor implantable ocular device into the capsular bag of an eye of a patient during extracapsular cataract surgery. Appropriate inhibitor compounds include RGD mimetics, RGD peptides, and flavonoids. A second method involves surface modifying the exterior surface of a capsular tension ring by covalently attaching a mitotic inhibitor, preferably a conjugate of methotrexate and a bovine serum albumin, and implanting this inhibitor tension ring into the capsular bag of an eye of a patient during extracapsular cataract surgery. A third method involves surface modifying the exterior surface of a capsular tension ring by coating or grafting the exterior surface with a charged polyethylamine and implanting this inhibitor tension ring into the capsular bag of an eye of a patient during extracapsular cataract surgery. An implantable ocular device according to the invention, such as an intraocular lens or a capsular tension ring, contains a substrate with a chemical moiety grafted thereon and a non-cytotoxic inhibitor compound covalently bonded to the chemical moiety or contains a substrate modified with a mitotic inhibitor or charged polyethylamine. The inhibitor devices inhibits proliferation and migration of lens epithelial cells on the posterior capsule of the eye of the patient, thereby preventing, minimizing, or delaying the onset of posterior capsule opacification.

Owner:CLEO COSMETIC & PHARMA

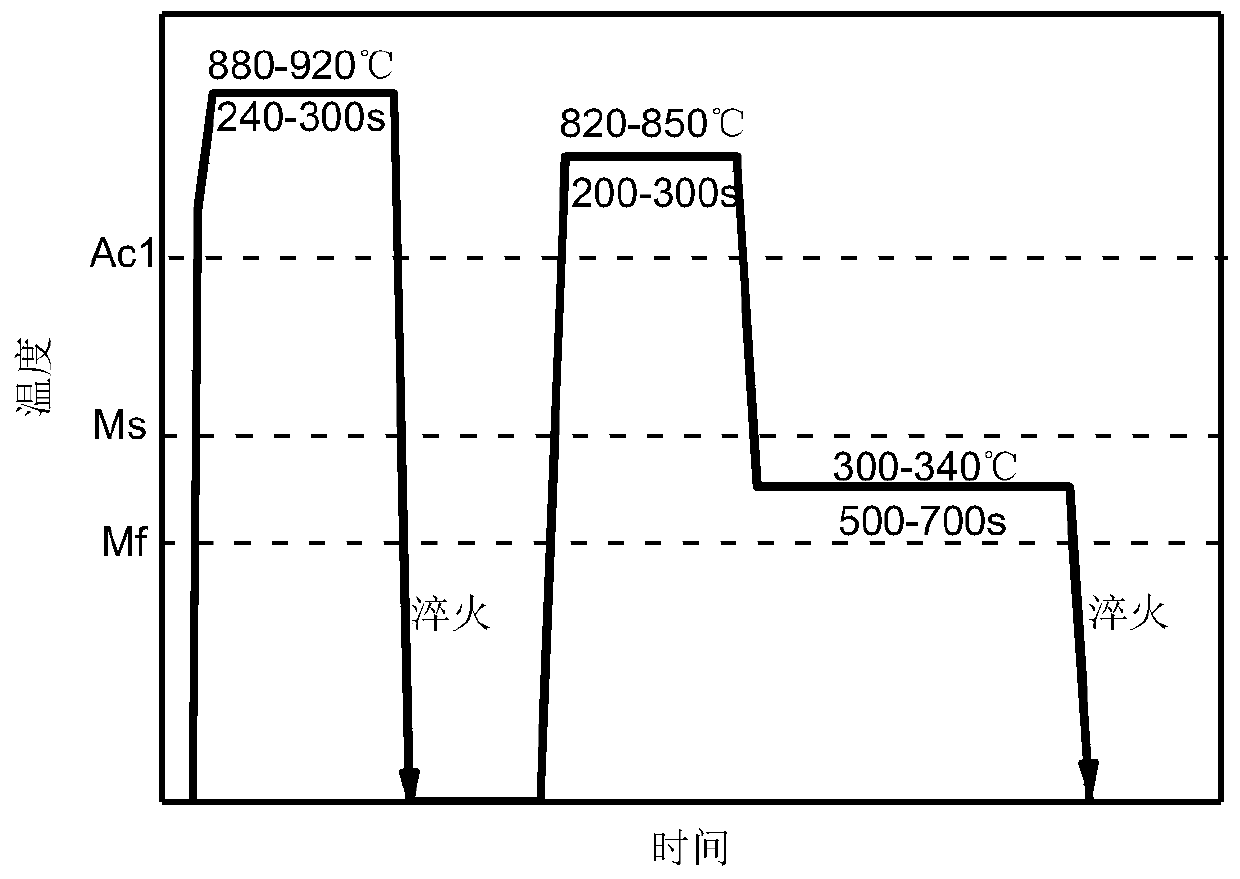

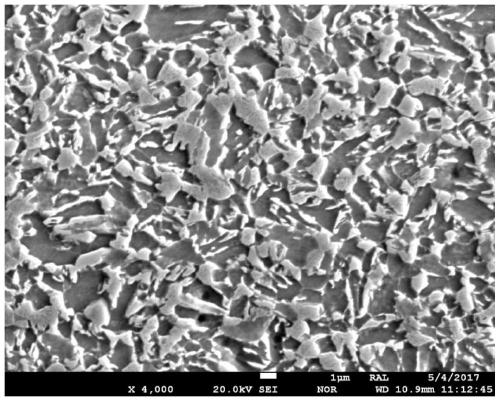

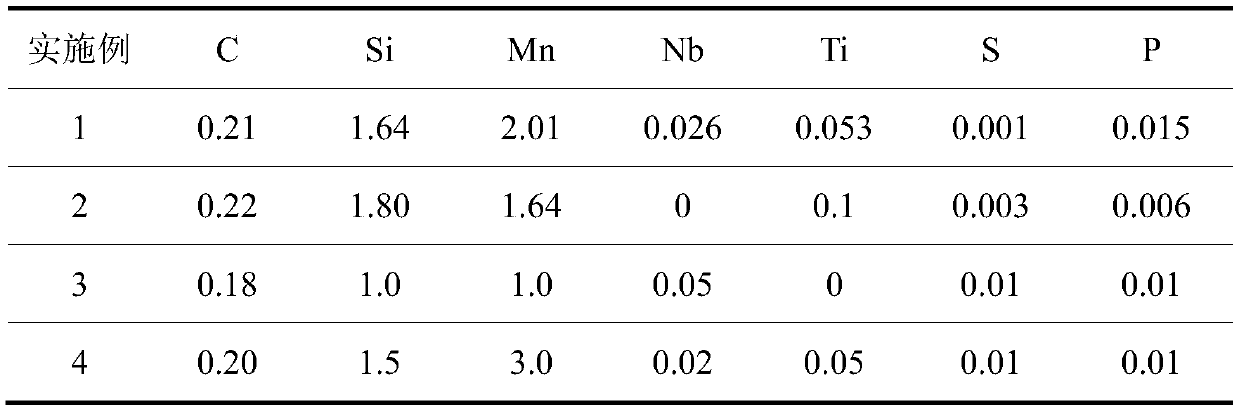

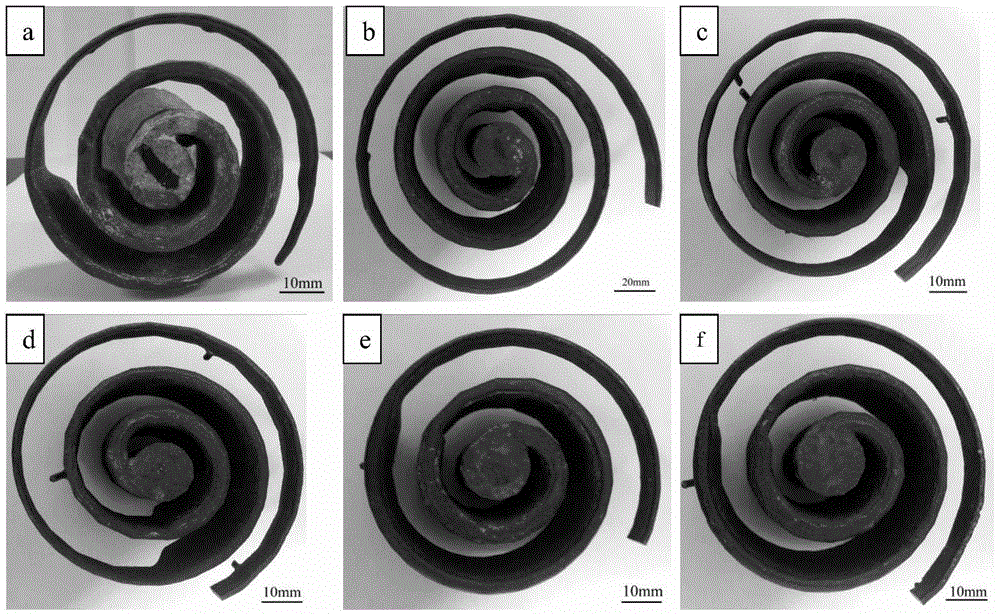

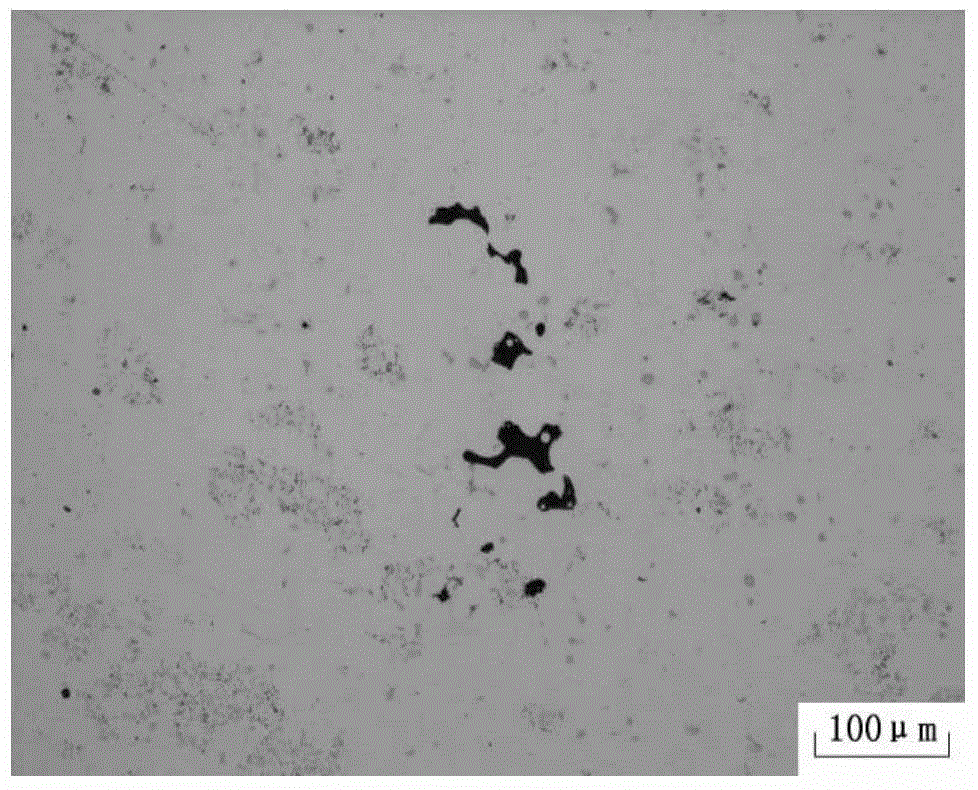

1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and manufacturing method thereof

InactiveCN110093564AIncrease contentOrganizational stabilityUltimate tensile strengthMechanical property

The invention relates to the field of third-generation advanced high-strength steel used for automobiles and discloses 1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and a manufacturing method thereof. A steel plate comprises the chemical components including, by mass percent, 0.18-0.22% of C, 1.0-3.0% of Mn, 1.0-2.0% of Si, not greater than 0.05% of P, not greaterthan 0.02% of S, 0-0.05% of Nb, 0-0.2% of Ti and the balance iron and inevitable impurities. The steel plate manufacturing method relates to the process of steel smelting, hot rolling, cold rolling,pre-quenching and heat treatment, and finally, a ferrite-bainite-martensite-retained austenite mixed structure is obtained. According to the 1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and the manufacturing method thereof, on the basis of traditional C-Mn-Si series quenched partition steel, Nb and Ti elements are added for refining the structure, pre-quenching treatment and a one-step partition process are adopted, finally the ultrahigh-strength quenched partition steel with the yield strength being 500-800 MPa, the tensile strength not smaller than 1180 MPa, the elongation after fracture not smaller than 20% and the product of strength and elongation not smaller than 24GPa.% is obtained, and the mechanical property is quite excellent.

Owner:NORTHEASTERN UNIV

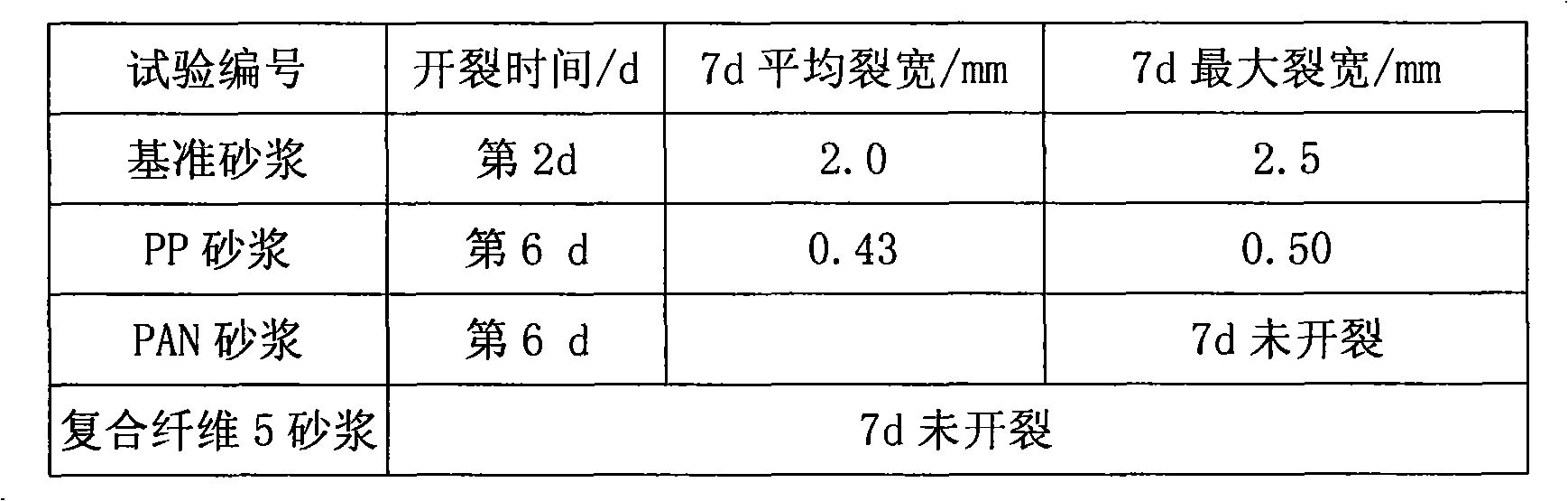

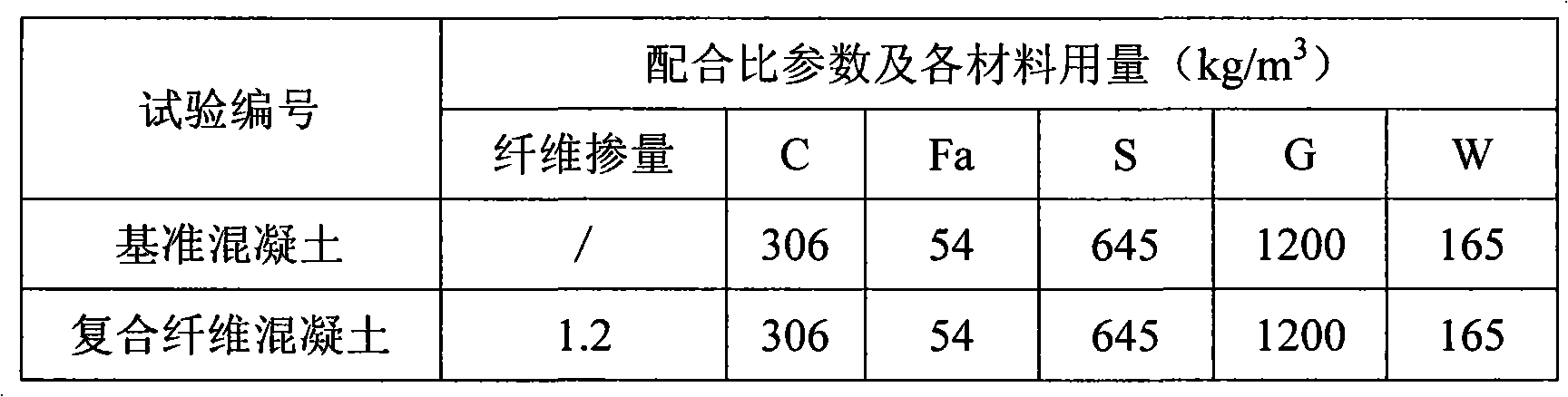

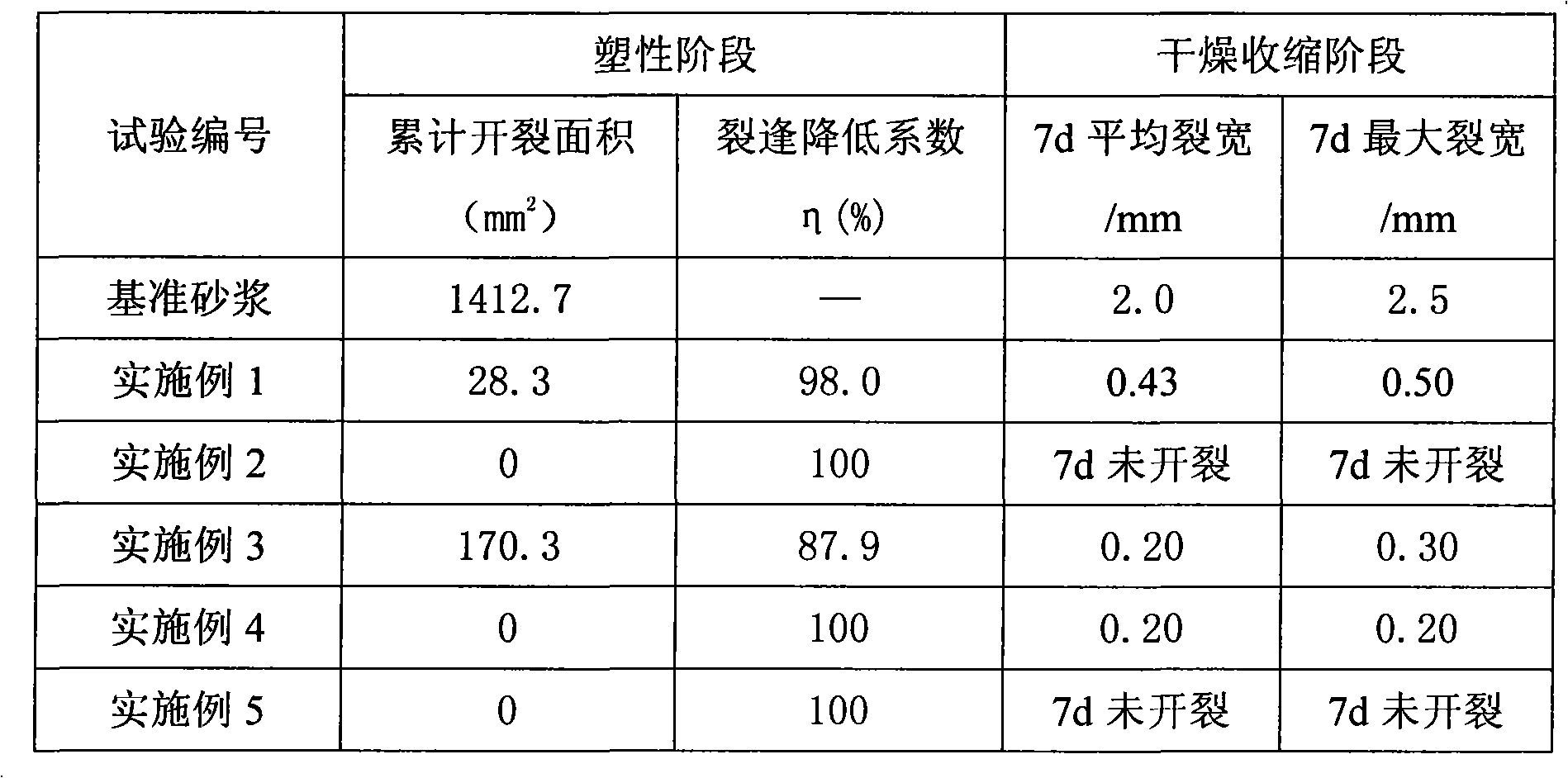

Composite fiber for whole time anti-cracking for concrete

The invention relates to duplex fiber used for resisting cracking of concrete throughout the course. The duplex fiber is prepared with the following synthetic fiber by weight: 15 to 50 percent of a high strength and high modulus synthetic fiber, 20 to 40 percent of a medium strength and medium modulus synthetic fiber, 20 to 45 percent of a low strength and low modulus synthetic fiber. The duplex fiber is prepared with fibers of different length, different elastic modulus and different strength of extension through compounding, thus forming a low strength and low modulus, medium strength and medium modulus, high strength and high modulus compound system. In this way, the duplex fiber not only has the advantages of various individual filaments but also has the superimposed effect of compounding of various fibers. Accordingly, the duplex fiber has synergistic actions in different periods when concrete is coagulated and hardened, which not only can prevent the plastic cracking of concrete, but also can effectively control the cracks during the hardening of concrete. In addition, the duplex fiber can effectively improve the toughness and the malleability of the concrete so that the durability of the concrete is significantly improved.

Owner:南京派尼尔科技实业有限公司

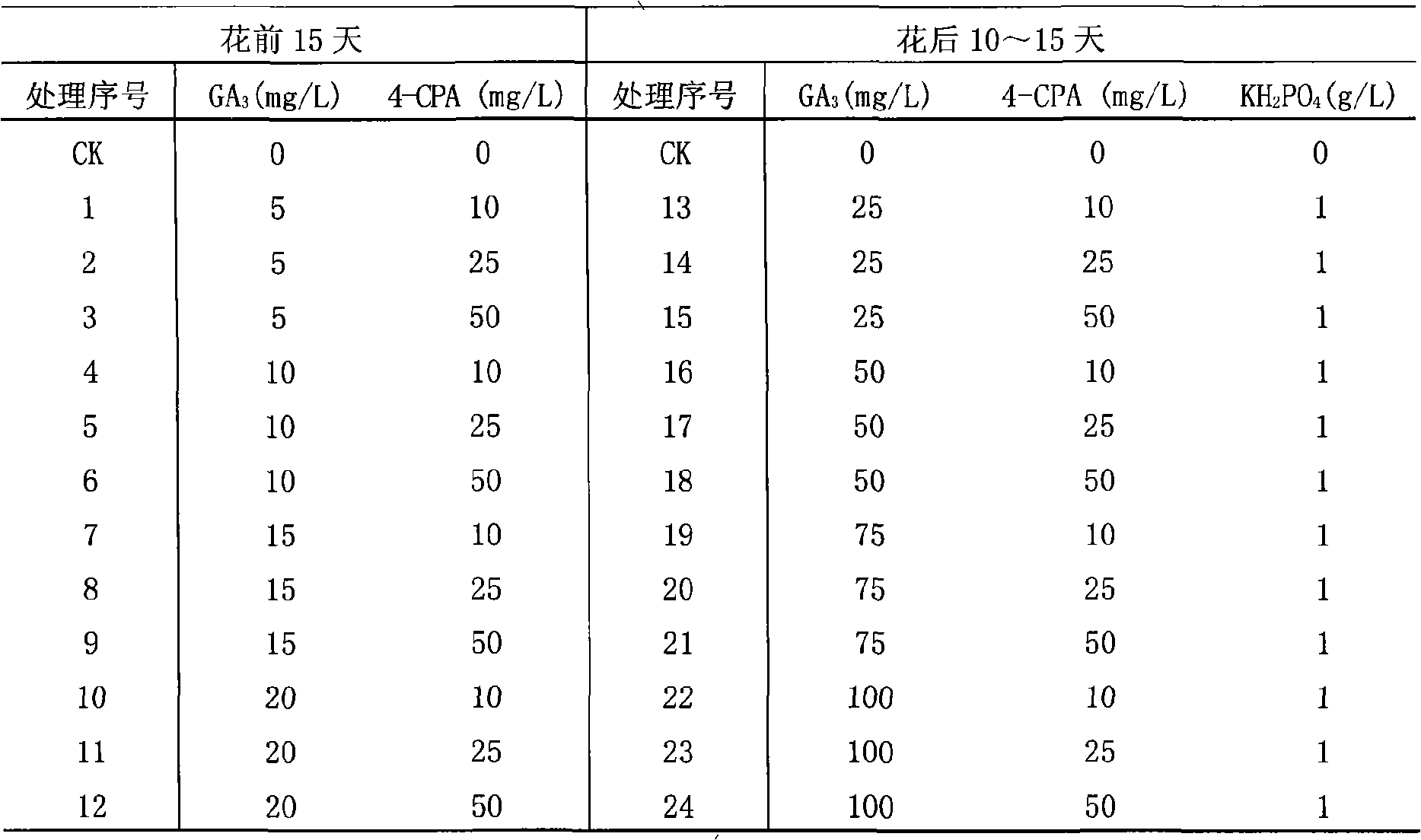

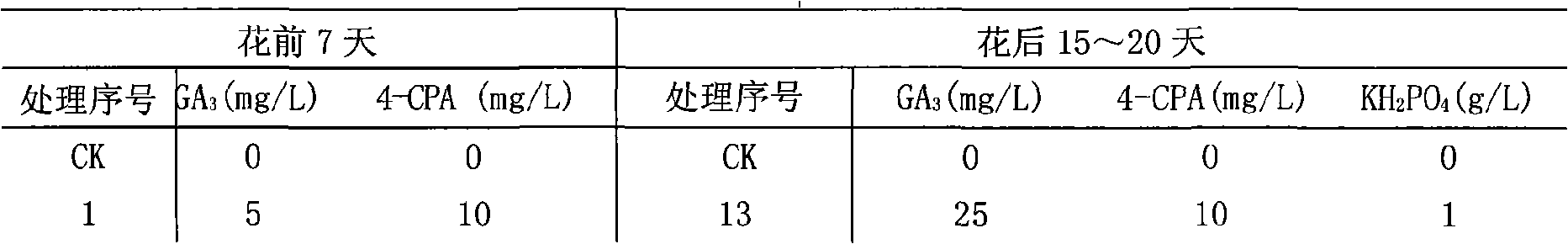

Technique for cultivating non-polluted seedless grape

InactiveCN101278639AReduce pesticide useDelayed formationCultivating equipmentsHorticulture methodsVitis viniferaEconomic benefits

The invention relates to a non-polluted grape culture technique of seedless grape; the main steps are as follows: a first step: conventional management is carried out in prophase; a second step: from 15 days before blooming to 1 week before blooming, 15-20mg / L of GA3, 10-25mg / L of 4-CPA, 1g / L of KH2PO4 and an NO.1 synergist are adopted for dipping fruit cluster; a third step: 10-20 days after blooming, 15-20mg / L of GA3, 25mg / L of 4-CPA, 1g / L of KH2PO4 and an NO.2 synergist are adopted for dipping fruit cluster; other management is operated according to conventions. By carrying out seedless treatment on seedy grape, the method can delay the formation of grape megaspore, affect the normal fertilization process, and promote seed abortion to form parthenocarpic seedless fruit; meanwhile, the method can remarkablely reduce pesticide dose, and ultimately realize the purpose of pollution-free and seedless cultivation, thus having remarkable social and economic benefits.

Owner:SICHUAN AGRI UNIV

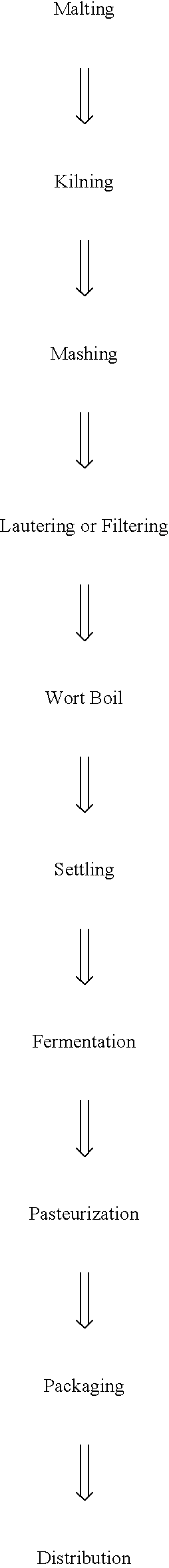

Use of Labiatae herb preparations for extending the flavor shelf life of malt beverages

InactiveUS20050058745A1Increasing flavor shelf lifeDelayed formationBeer fermentationFood preservationMalt GrainFood flavor

The present invention is concerned with a method for enhancing the flavor shelf life of beverages, including beer and other malt beverages, by incorporating Labiatae herb extracts either to the finished beverage or into a step in the manufacture of the beverage.

Owner:KALAMAZOO HLDG INC

Eye drops for cataract and its preparing method

InactiveCN1899304AGood treatment effectStop progressSenses disorderInorganic boron active ingredientsVitamin CSodium hyaluronate

The present invention relates to a kind of eye drops for cataract and its preparation process. It features the pH value of 6.0-8.0, and the osmotic pressure of 250-400 mOsm / Kg H2O, and consists of component A 100 ml and component B 1500-2400 mg, where the component A consists of taurine 600-1200 mg, sodium hyaluronate 100-500 mg, vitamin C 500-1500 mg, boric acid 500-1500 mg, borax 150-250 mg, sodium chloride 200-400 mg, EDTA disodium 100-150 mg, benzalkonium bromide 2-5 mg and water for injection for the rest in each 100 ml, and the component B is reducing glutathione. The eye drops are used in treating cataract in early stage and middle stage.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

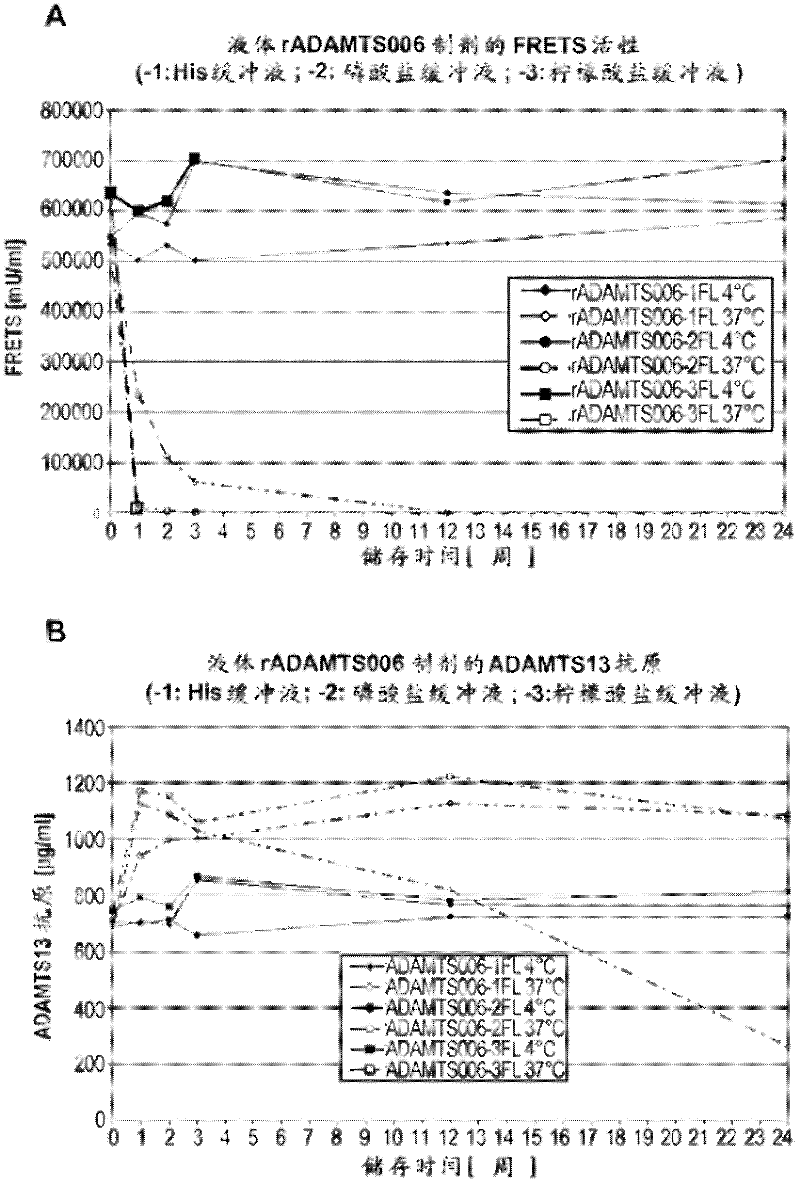

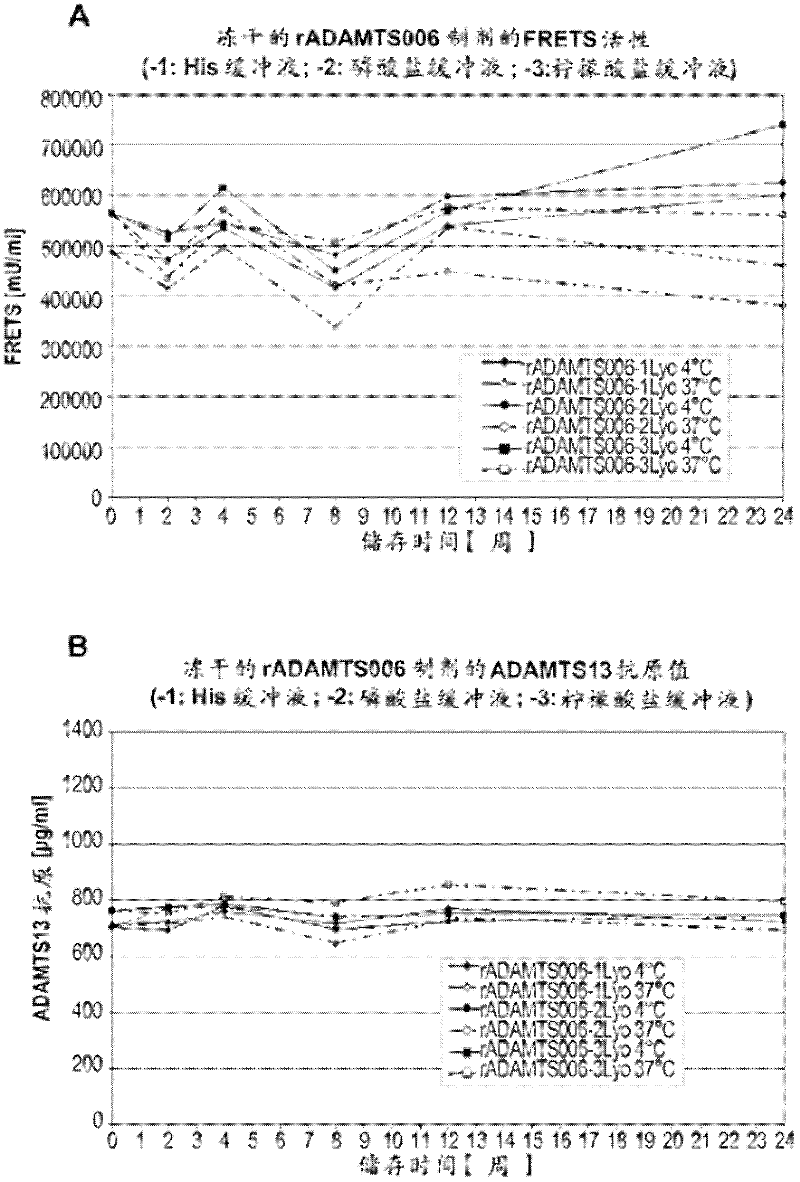

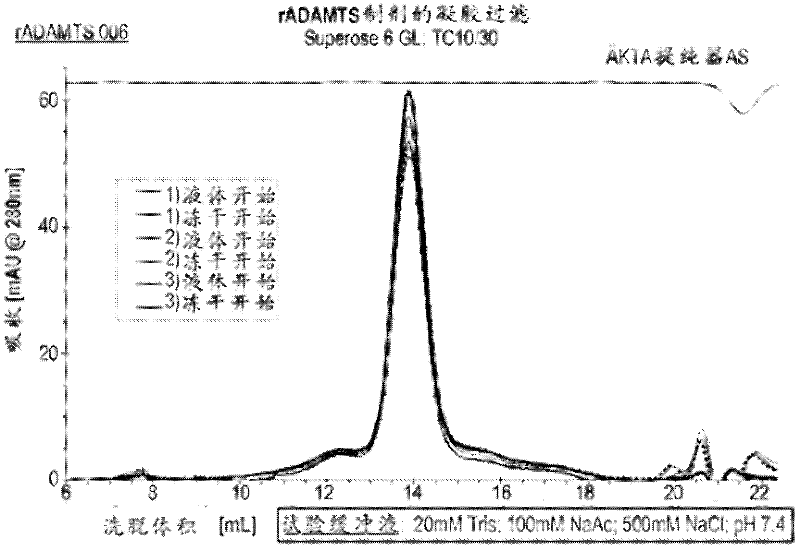

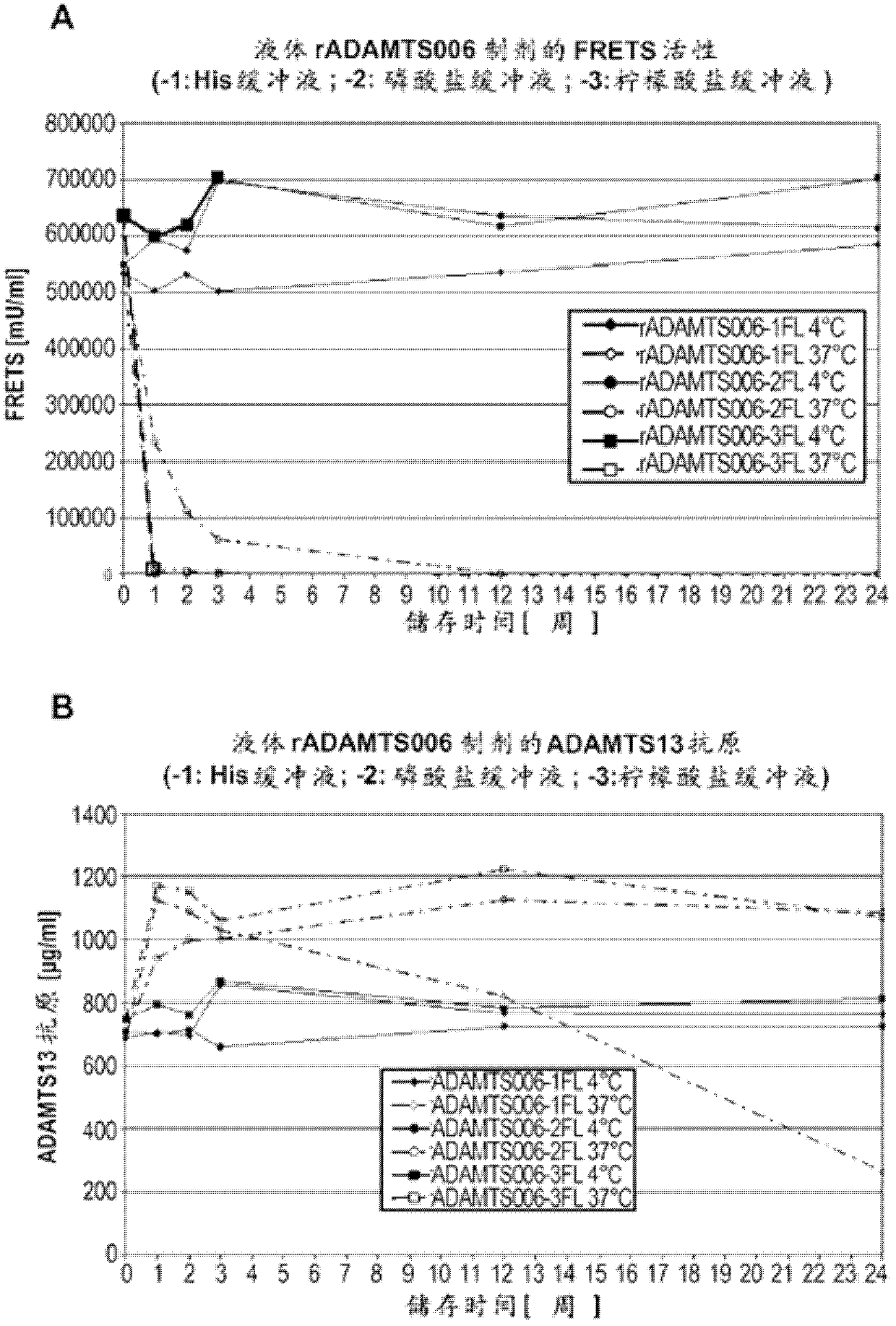

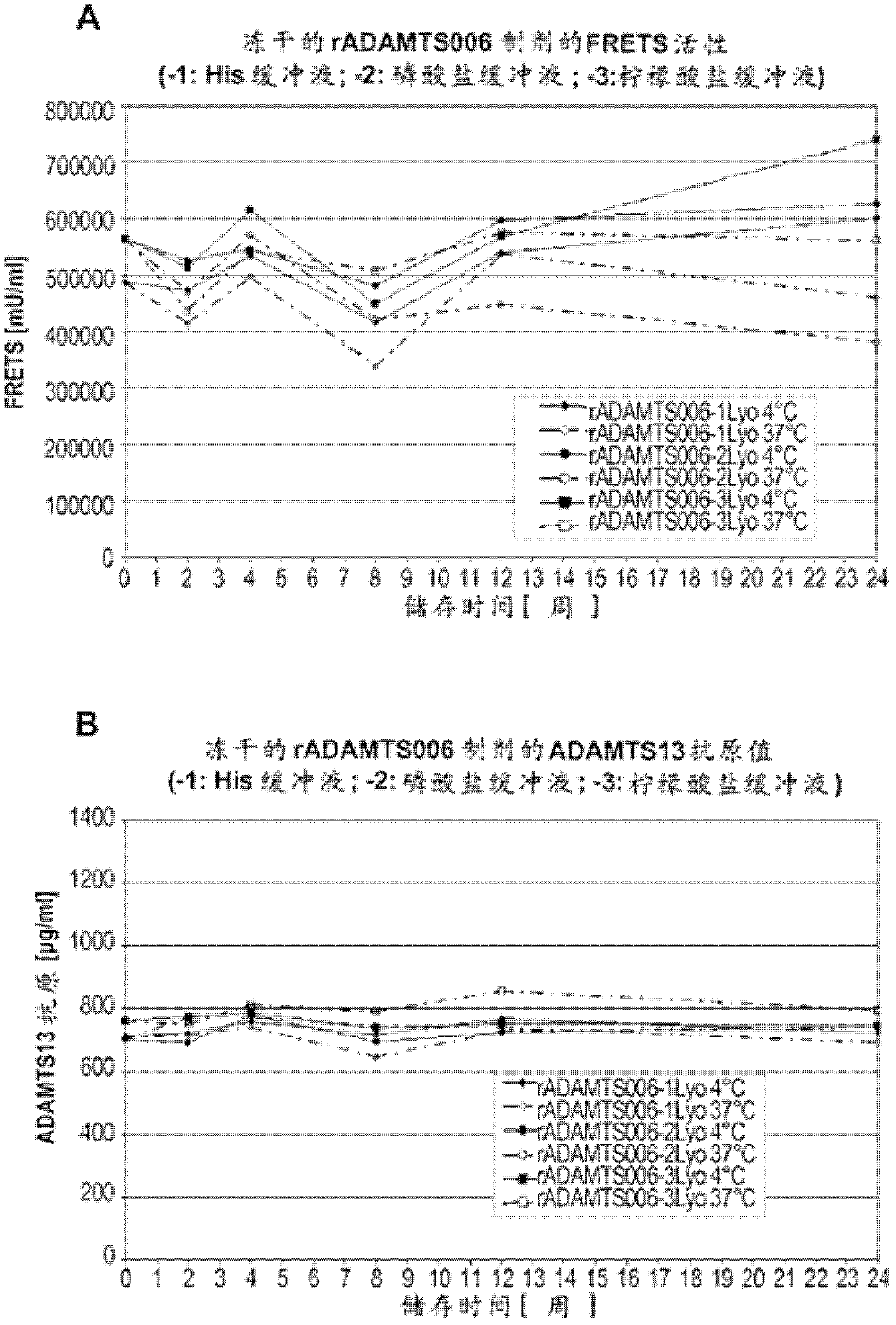

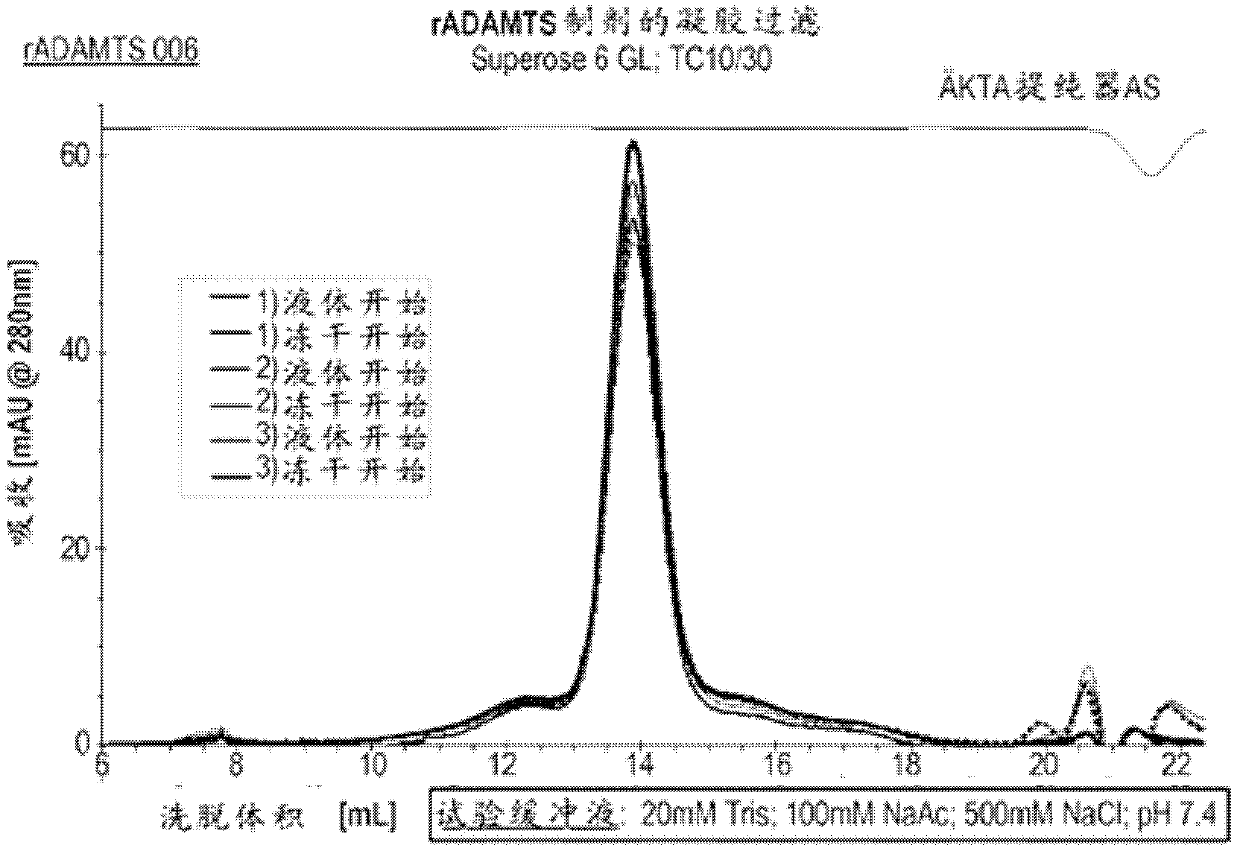

Stabilized liquid and lyophilized ADAMTS13 formulations

ActiveCN102573792AHigh specific activityDelayed formationPeptide/protein ingredientsInorganic non-active ingredientsDiseaseMedicine

Owner:TAKEDA PHARMACEUTICA CO LTD

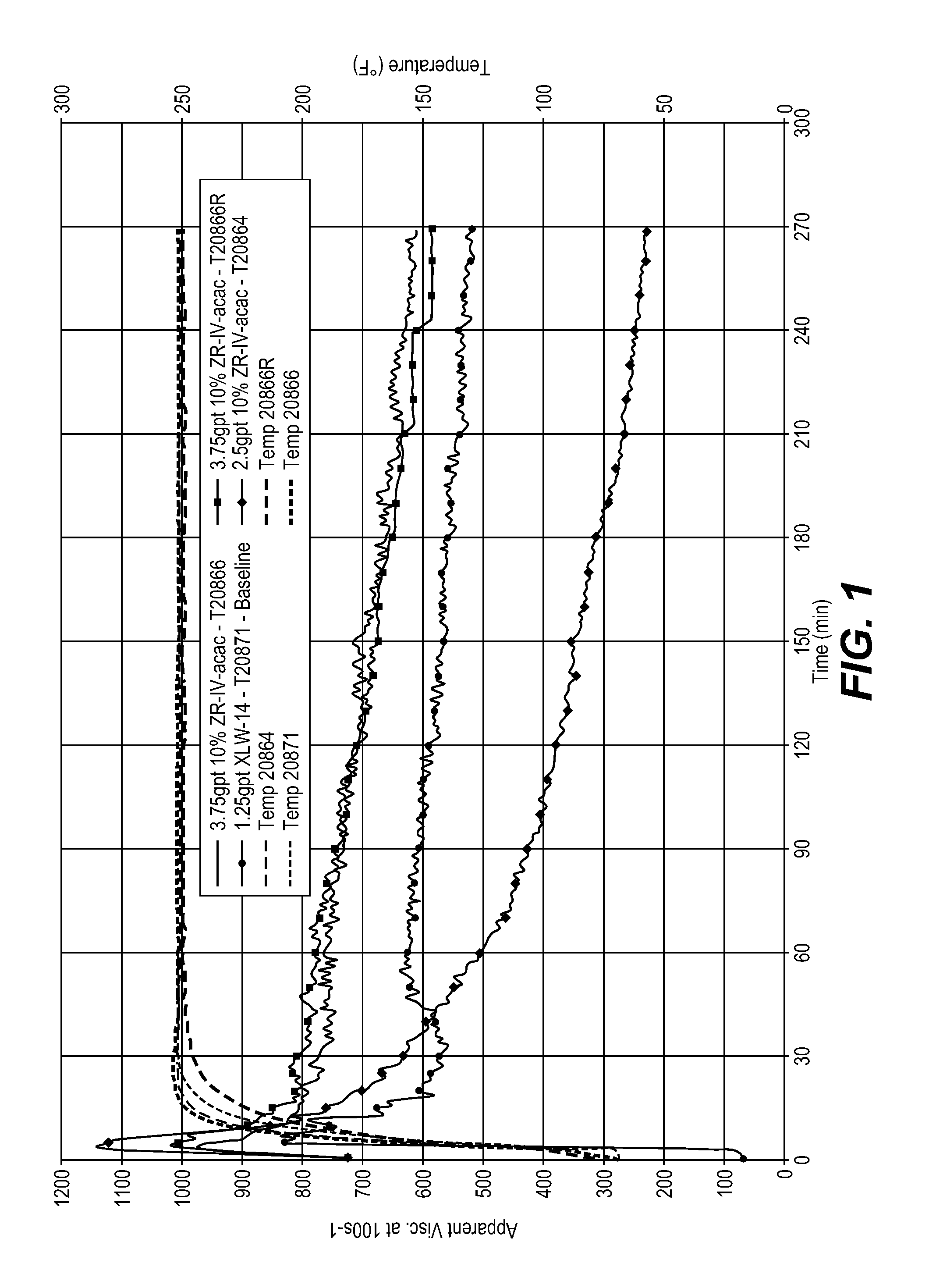

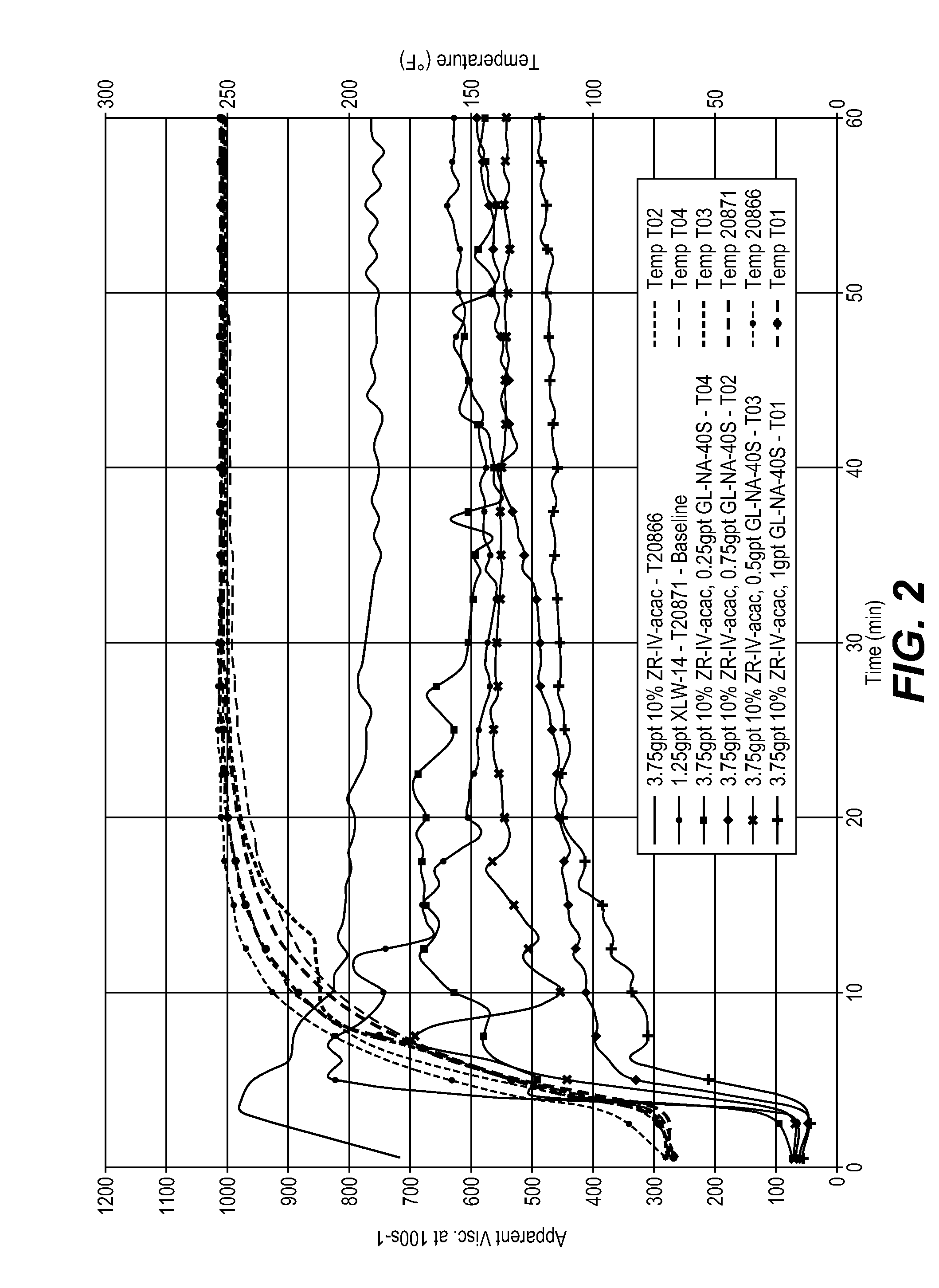

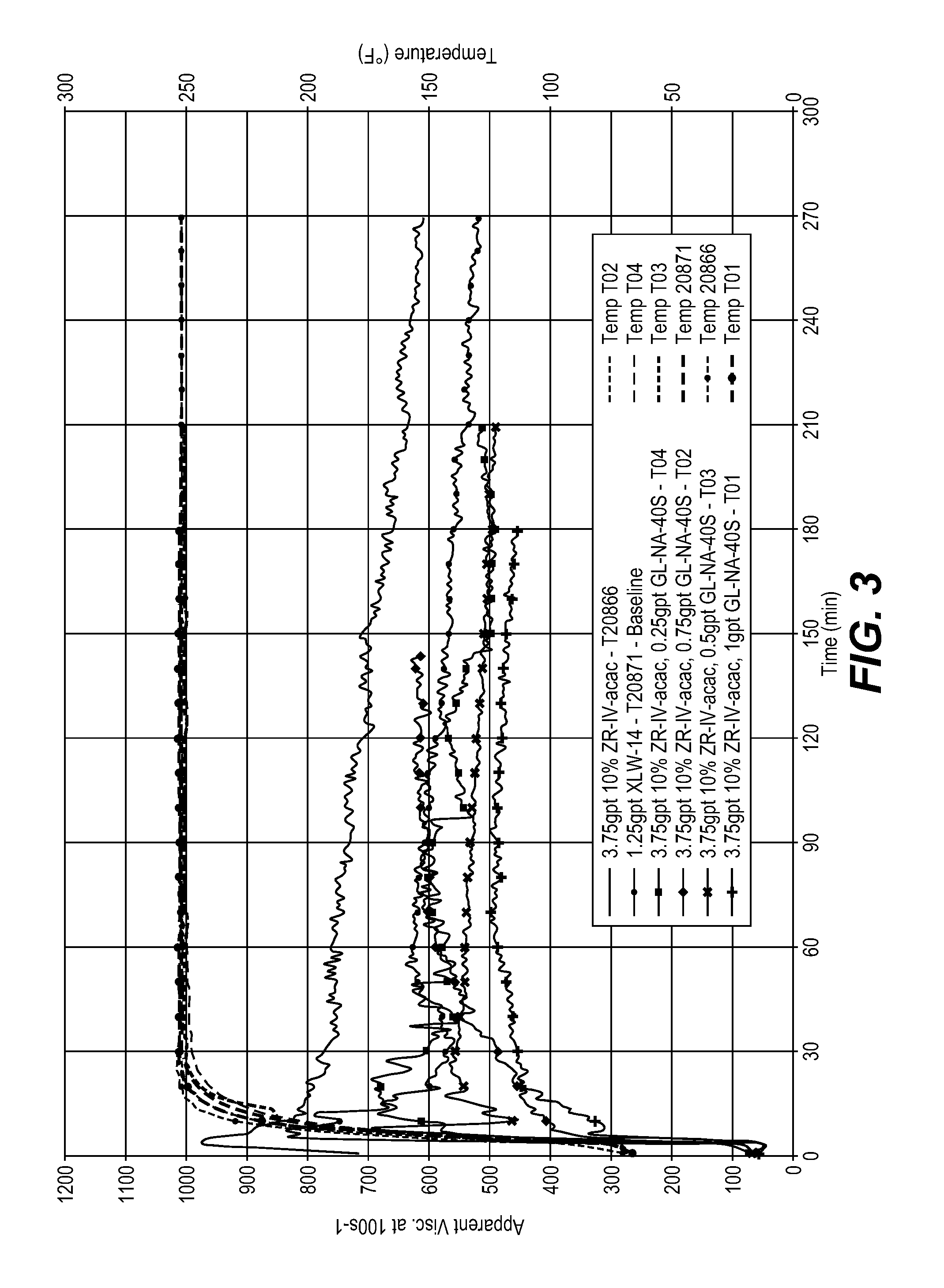

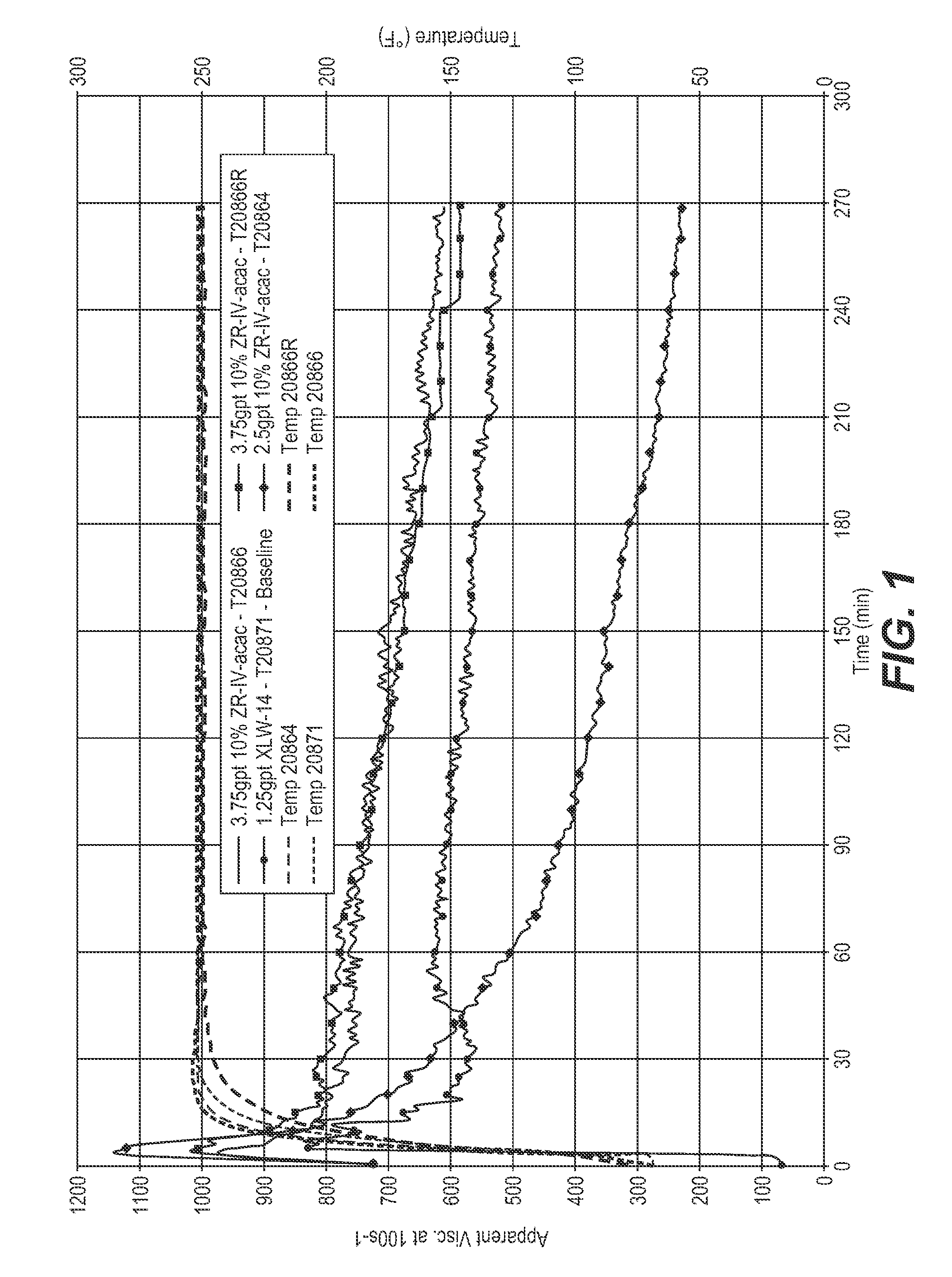

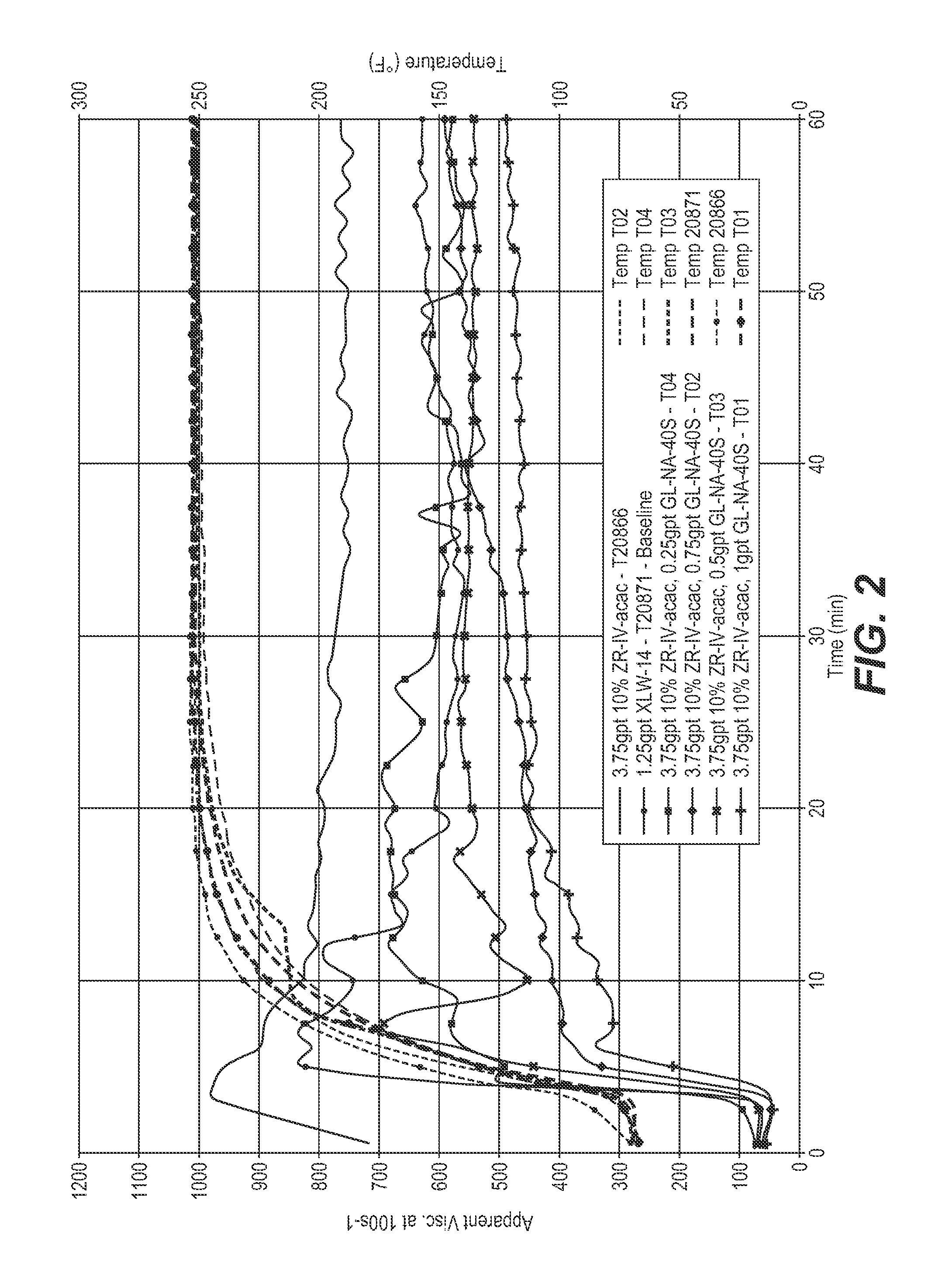

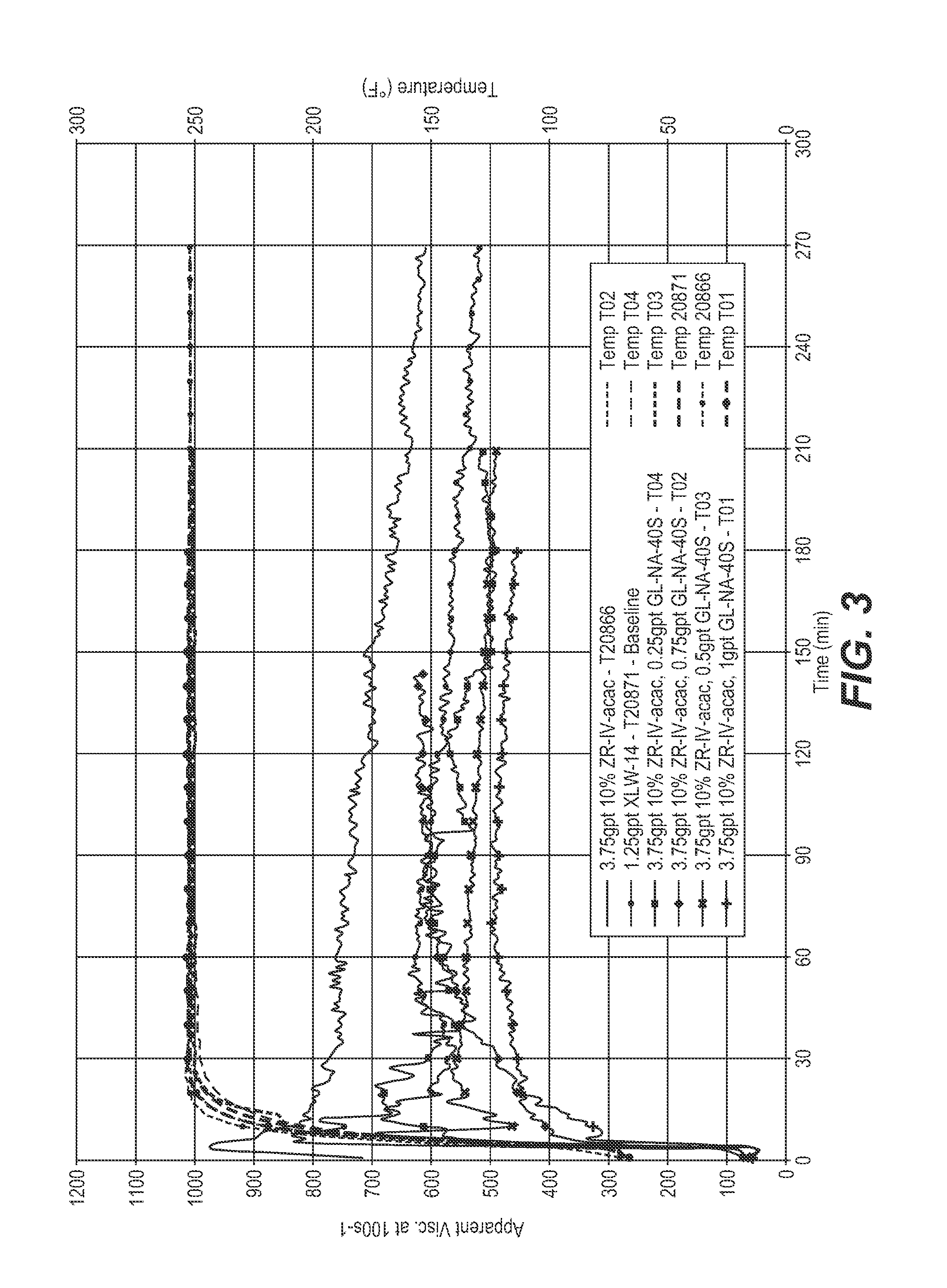

Method of delaying crosslinking in well treatment operation

Crosslinking of a crosslinkable viscosifying agent and a crosslinking agent may be delayed in a well treatment fluid by incorporated within the fluid a glutamic-N,N-diacetic acid salt, such as a glutamic-N,N-diacetic acid sodium salt like tetrasodium glutamate diacetate. The crosslinking agent may be a zirconium containing crosslinking agent like zirconium (IV) acetyl acetonate. The viscosifying agent may be guar or a guar derivative such as carboxyalkyl guars and hydroxyalkylated guars like carboxymethyl guar, hydroxypropyl guar, hydroxyethyl guar, hydroxybutyl guar and carboxymethylhydroxypropyl guar.

Owner:BAKER HUGHES INC

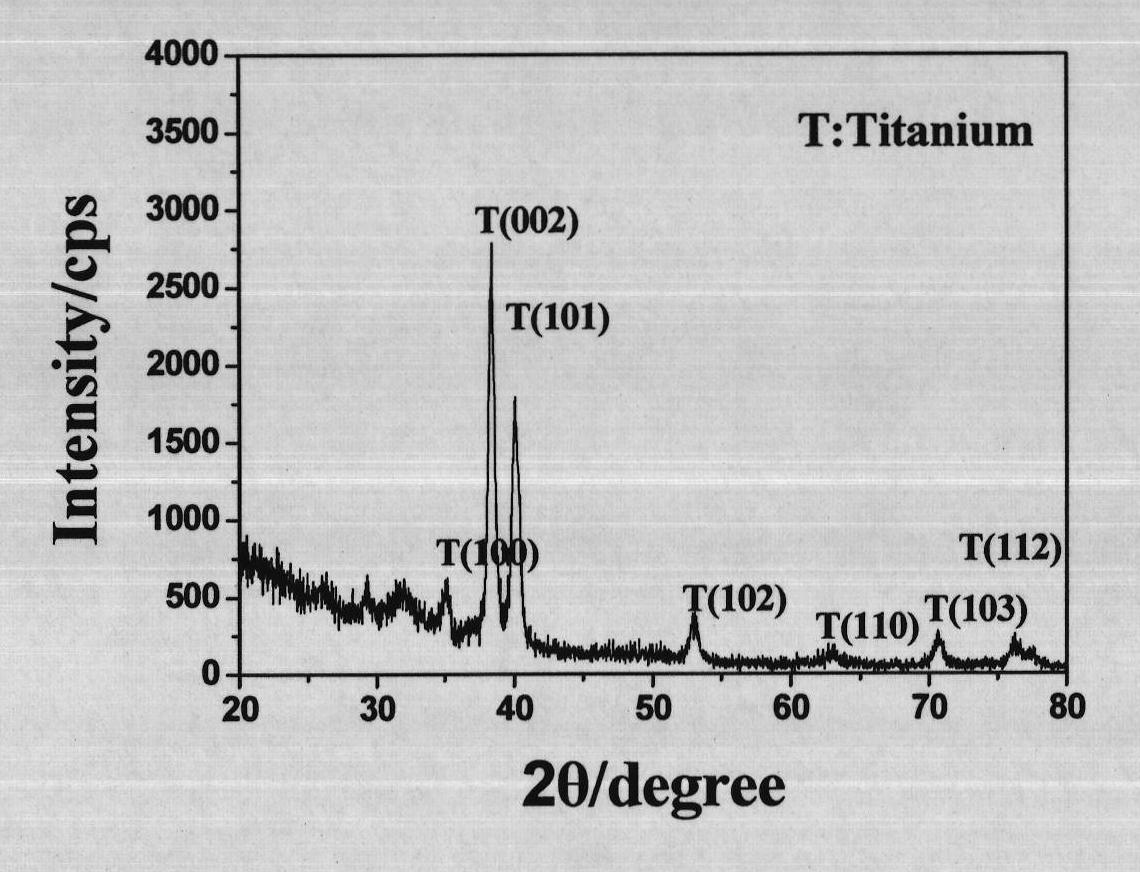

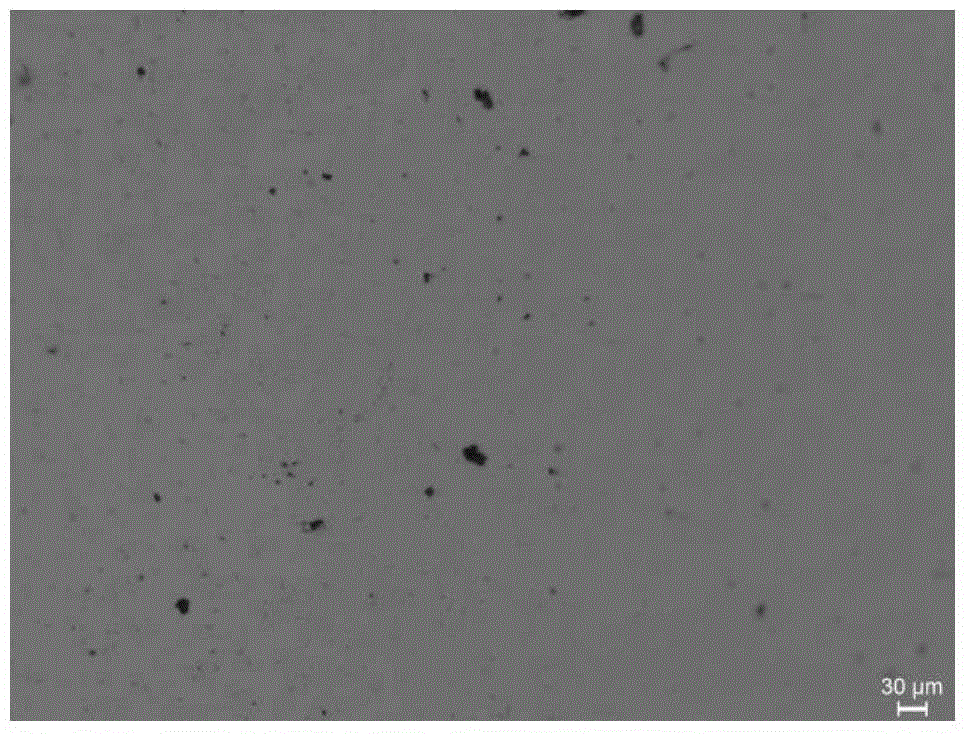

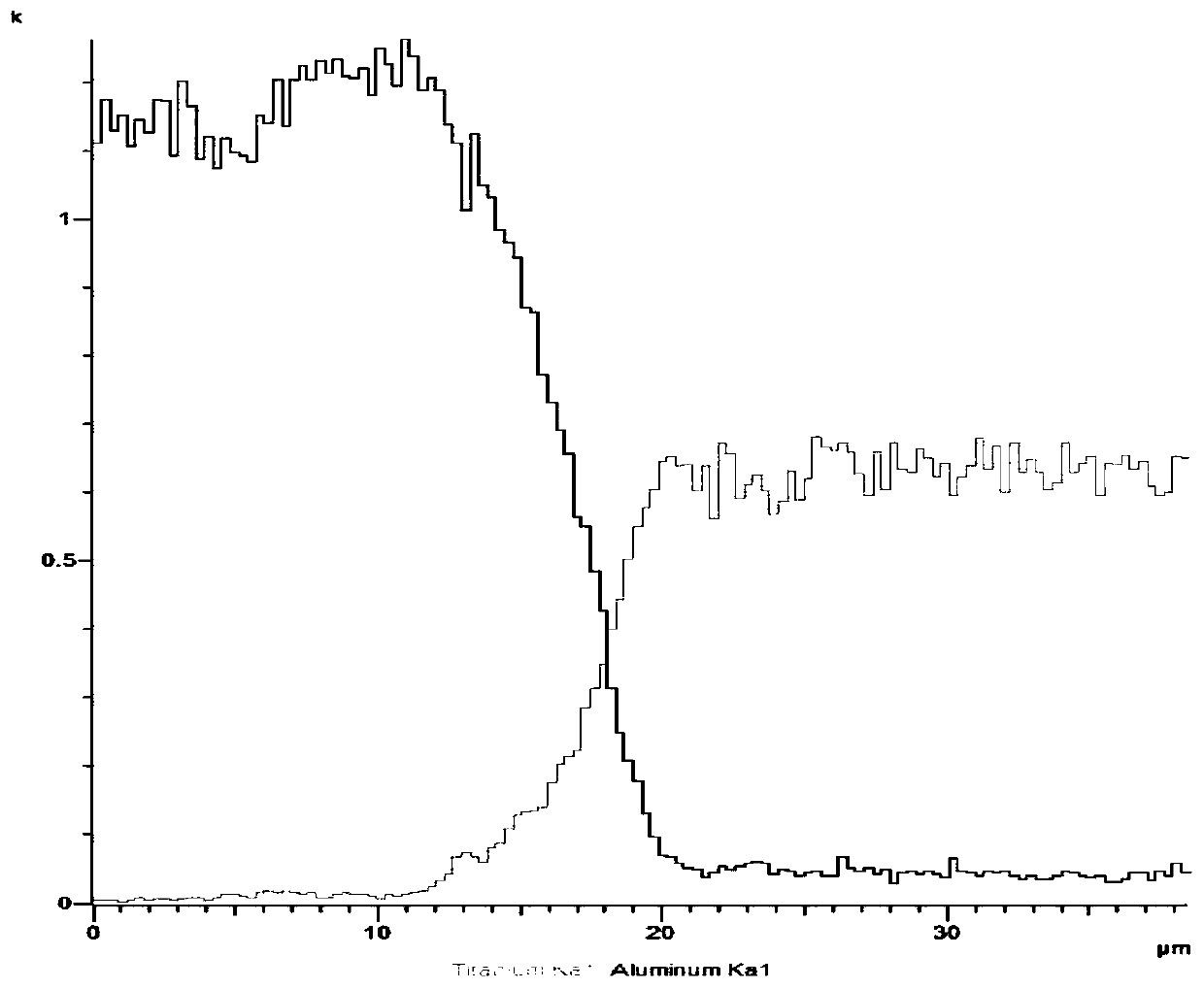

Method for preparing rutile-type TiO2 thin film at room temperature

InactiveCN101994094AImprove bindingImprove anticoagulant performancePharmaceutical containersVacuum evaporation coatingSurface engineeringBiological materials

The invention relates to a method for preparing rutile-type TiO2 thin film at room temperature, belonging to the field of surface engineering technique and biological materials. The single rutile-type TiO2 thin film is obtained on the surface of superfine crystal / nanometer crystal titanium at the room temperature by performing nanorization treatment on a titanium microstructure in advance and adopting a direct-current reaction magnetic control sputtering deposition technique. After nanorization of the titanium base material microstructure, the interface bonding force between the TiO2 thin film and the base material is improved remarkably, the technical problem of poor bonding condition between the TiO2 thin film with excellent anticoagulant property and a titanium vessel bracket is bettersolved and the bearing capacity of the interface is greatly improved. The invention better solves the problem that the single rutile-type TiO2 thin film is hard to prepare on the titanium surface at the room temperature, has simple process and is widely applied to the fields of vessel brackets, heart valves, and the like.

Owner:JIANGSU UNIV

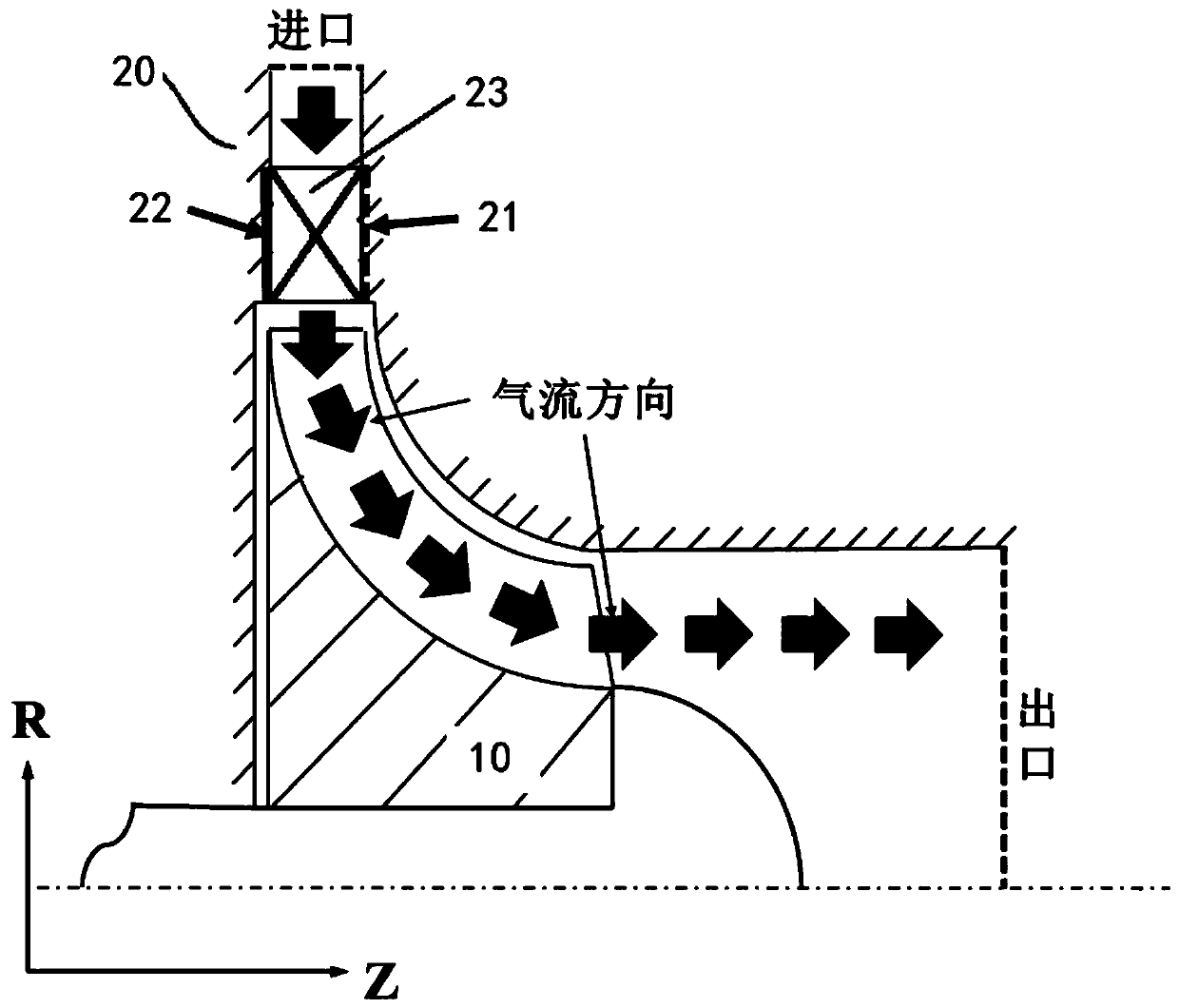

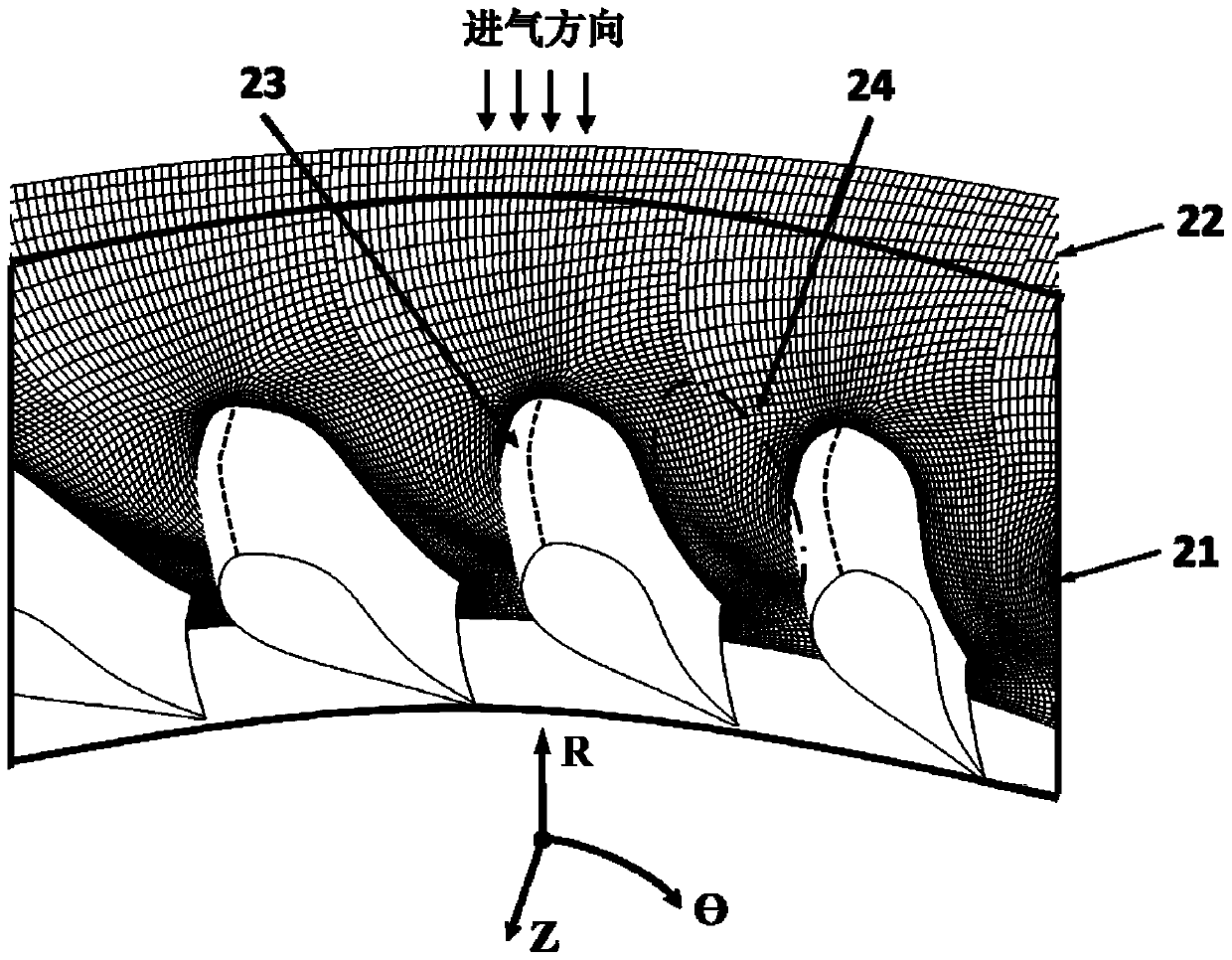

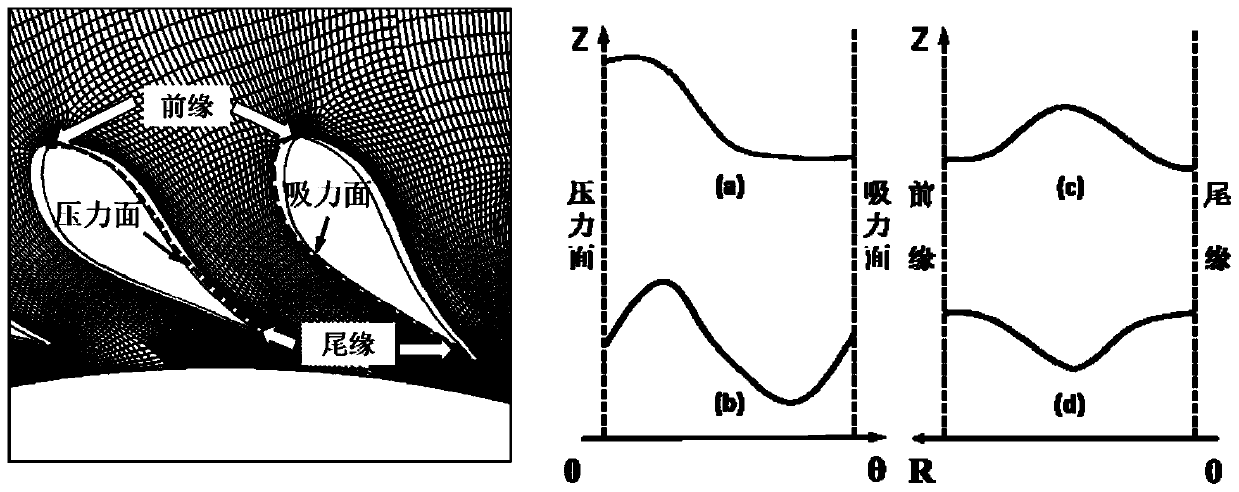

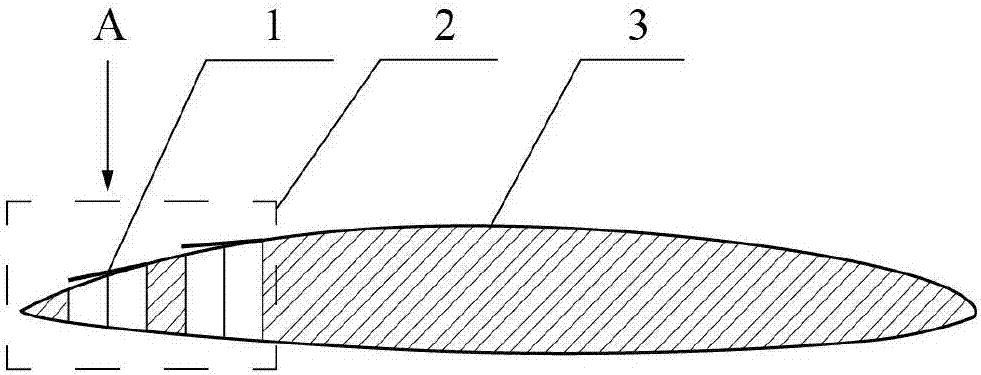

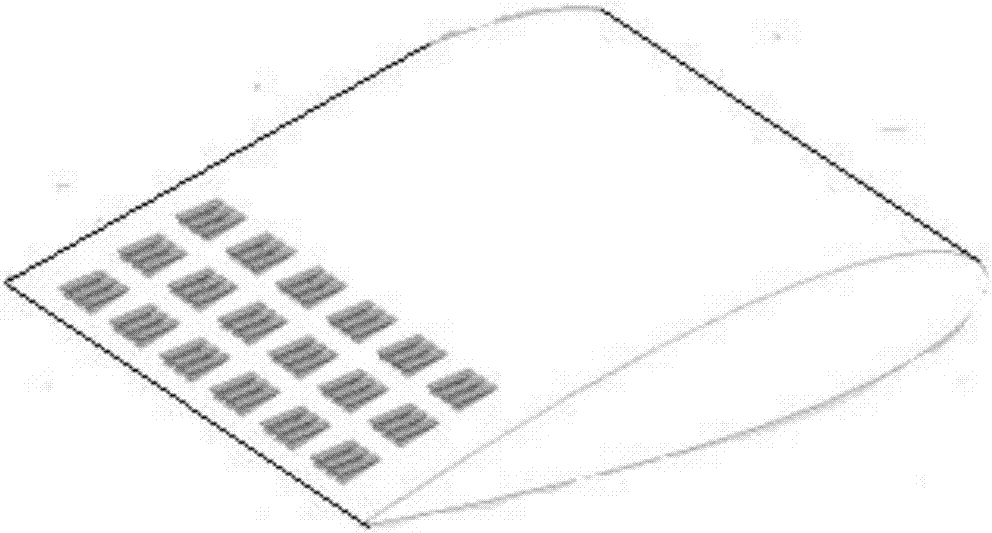

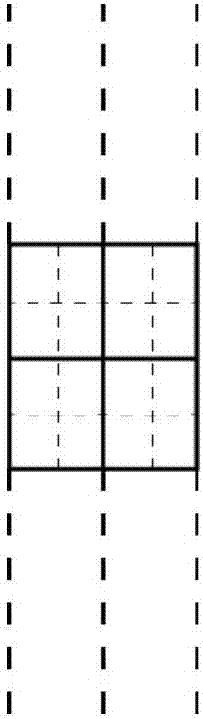

Radial flow turbine guide vane structure coupled with non-axisymmetric end walls

ActiveCN110608068ADelayed formationImproves airflow uniformityStatorsMachines/enginesEngineeringPressure difference

The invention relates to a radial flow turbine guide vane structure coupled with non-axisymmetric end walls. The radial flow turbine guide vane structure aims to solve the technical problems of remarkable secondary flow of low-span chord ratio runoff guide vane end walls, relatively large channel vortex size, poor outlet air flow uniformity and the like. A non-axisymmetric concave-convex end wallstructure is adopted at each of the front end walls and the rear end walls of radial flow turbine guide vanes and can be matched with the radial flow turbine guide vanes with the three-dimensional configuration to control the flow channel secondary flow loss more effectively. According to the radial flow turbine guide vane structure, a blade lattice is modified, and specifically, the inner surfaces of the front end walls and the rear end walls are correspondingly arranged as the non-axisymmetric concave-convex end wall structures, so that the flow area of each flow channel is changed, and theair flow pressure difference between the pressure surface on one side of each flow channel and the suction surface on the other side of each flow channel is reduced, so that the secondary flow velocity distribution is affected, the formation and development of the channel vortex are delayed, the channel vortex intensity is reduced, and the reduction of the secondary flow loss is finally realized.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

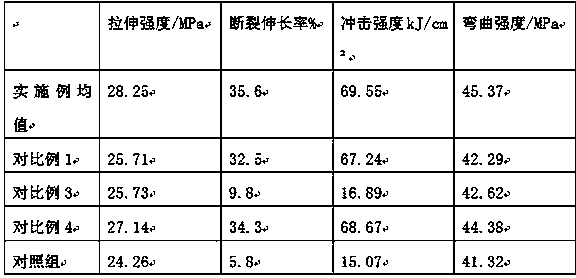

Preparation method of ultrahigh-toughness polystyrene resin

The invention relates to a preparation method of an ultrahigh-toughness polystyrene resin, which belongs to the field of chemical industry. The invention aims to provide the preparation method of the ultrahigh-toughness polystyrene resin, in which a graft polymerization technology is utilized to make a rubber particle surface graft with polystyrene material, and the binding force of the interface between the rubber particle and the polystyrene resin is enhanced so as to make the performance of a product stable and increase the toughness of the product. According to the invention, an emulsion graft polymerization technology is utilized to synthetize butadiene rubber particle grafted polystyrene powder; and in a double-screw extruder, shock resistant modifier powder, high-impact polystyrene and polystyrene are blended and modified to prepare high impact strength polystyrene resin in an extrusion mode. Through the blend modification technology, polybutadiene is grafted with a polystyrene shock resistant modifier to toughen the polystyrene. The high-impact polystyrene is added in order to utilize micron Salimi rubber particles and submicron rubber particles contained in the high-impact polystyrene to effect in a synergizing and toughening manners, the polystyrene is added in order to reinforce, and finally an ultrahigh-toughness polystyrene resin product is obtained.

Owner:CHANGCHUN UNIV OF TECH

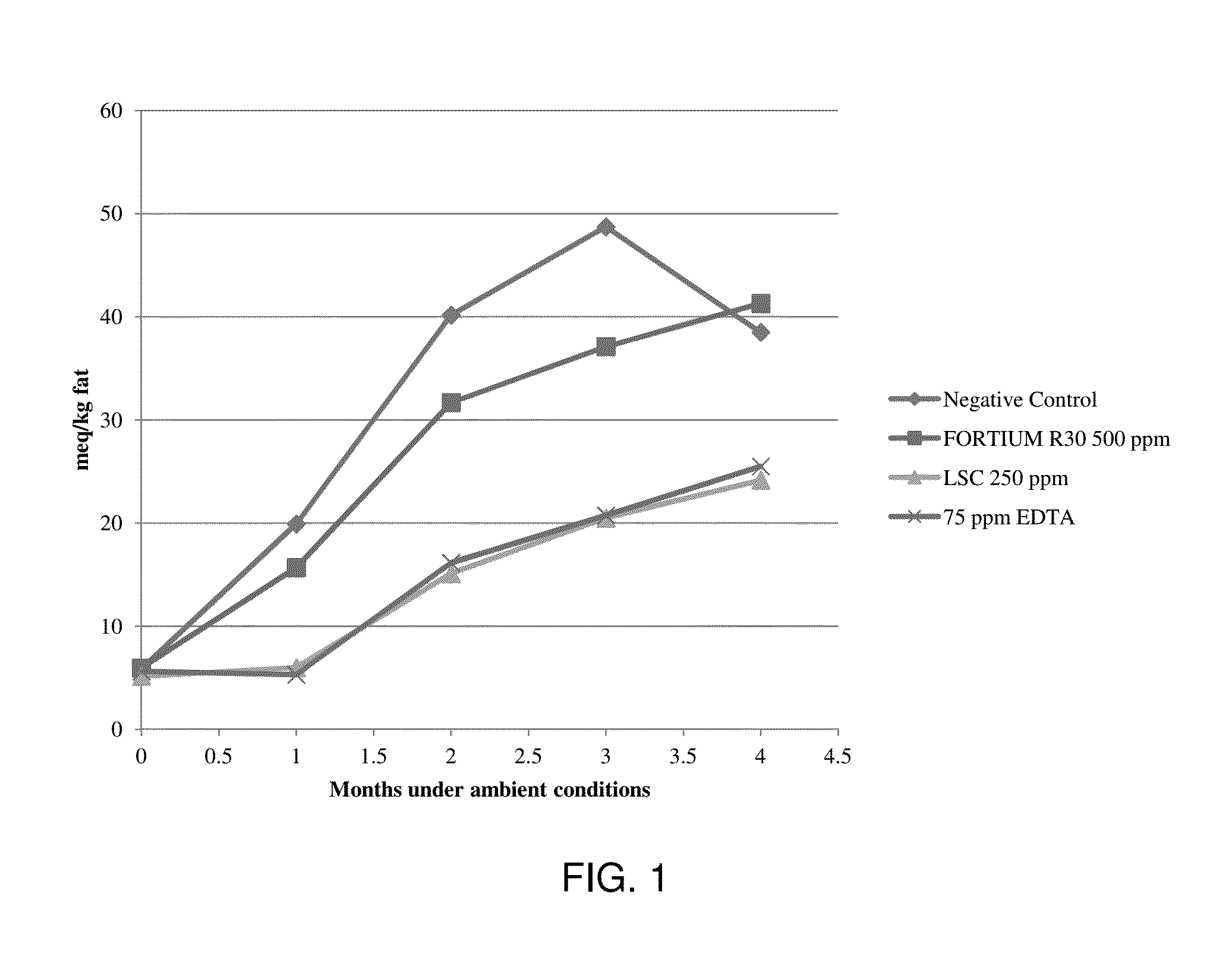

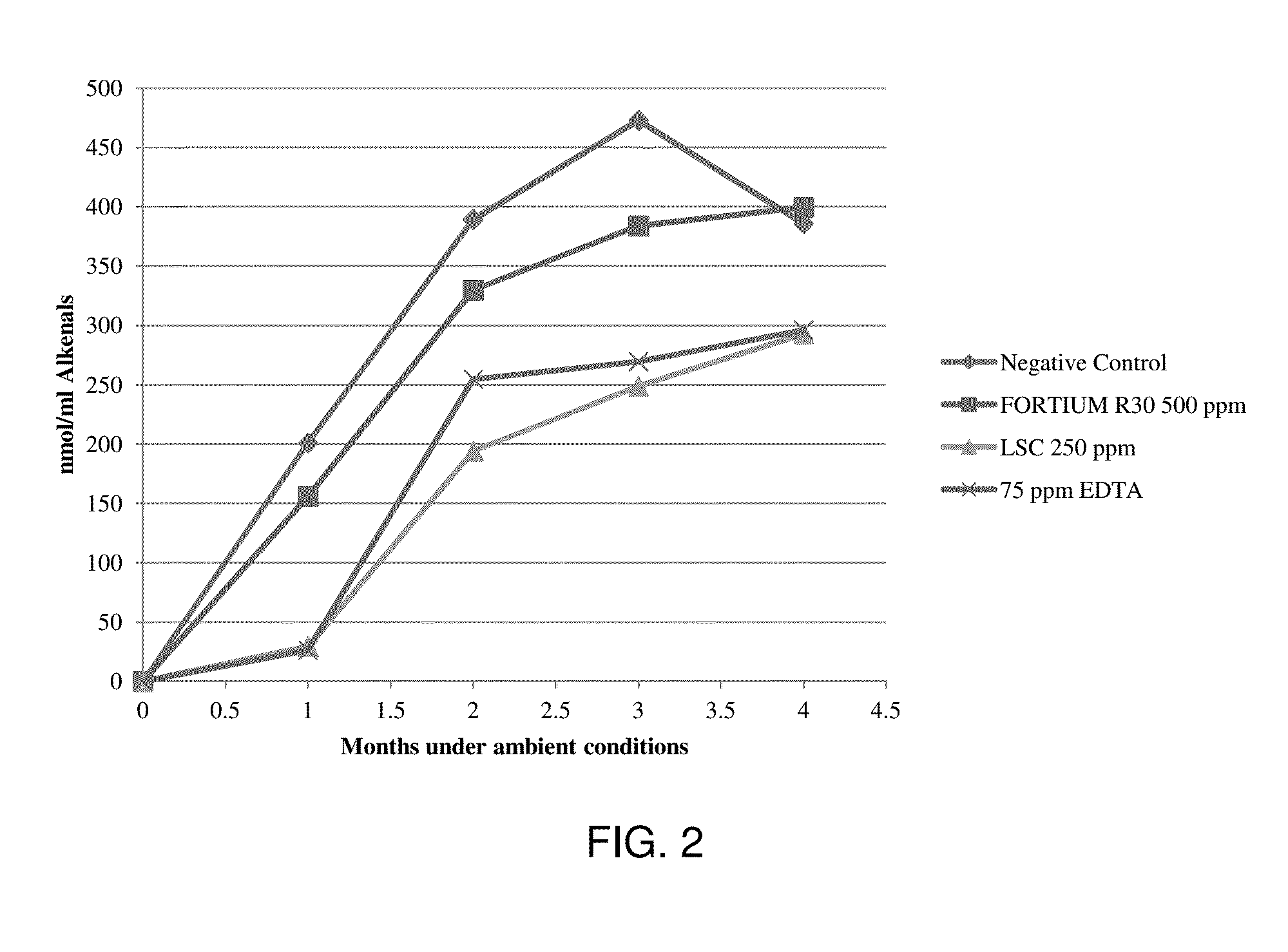

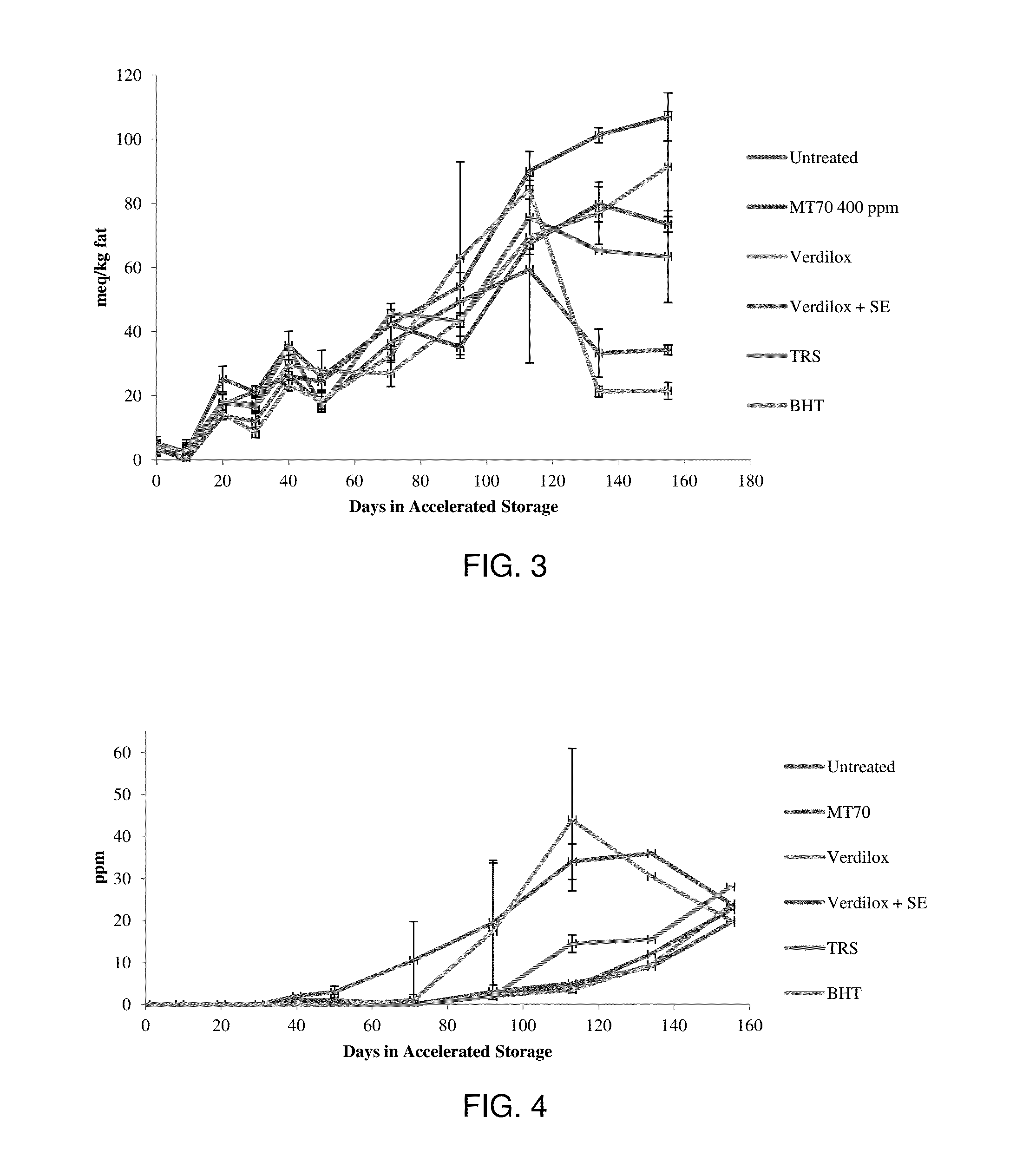

Delaying oxidation in food systems by use of lipid soluble tea catechins

InactiveUS20160058061A1Promote formationImprove stabilityFood ingredient as antioxidantFatty substance preservation using additivesEmulsionTea catechin

Lipid soluble tea catechins are found useful in delaying undesirable changes in the color and extending the oxidative stability of meat products, food emulsions and extruded foods. This composition has shown to be effective in maintaining the desirable red color of the meat products, as well as delaying the formation of oxidative byproducts, when compared to untreated meat products, maintaining the low oxidative products in food emulsions and maintaining the low secondary oxidative products and acceptable sensory profiles in extruded foods. This composition also has shown to be effective in delaying the formation of oxidation products in margarine and salad dressing.

Owner:KEMIN IND INC

Wind turbine blade capable of improving stalling characteristics based on fractal optimization

ActiveCN106949021AGuaranteed aerodynamic performanceIncrease stall angle of attackFinal product manufactureMachines/enginesTurbine bladeAerospace engineering

The invention discloses a wind turbine blade capable of improving stalling characteristics based on fractal optimization. The wind turbine blade comprises a blade body positioned at the front part corresponding to a flow incoming direction, and a blade tail edge positioned at the back part corresponding to the flow incoming direction; the blade tail edge is distributed with multiple elastic pieces and fractal holes with fractal structures; the elastic pieces are arranged on suction surface sizes of the fractal holes, and are suffered from a pressure difference effect of a blade pressure surface and a suction furnace to locate in a closing or opening state; and the fractal holes penetrate through the pressure surface and the suction furnace. When the blade incoming flow attack angle dose not reach stalling conditions, as the pressure difference between the blade pressure surface and the suction surface is smaller, and at this time, the elastic pieces are located in the closing state to stop passing of a fluid to stop small-scale turbulence so as to guarantee the blade pneumatic performances; when the blade incoming flow attack angle is increased to reach the stalling conditions, the elastic pieces are located in the opening state due to the effect of pressure difference, and the fluid can pass through the fractal holes to generate small-scale turbulence on the suction furnace to delay separation of a blade surface boundary layer, so that the formation of stalling clusters is delayed, and the purpose of improving the blade stalling characteristics is achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

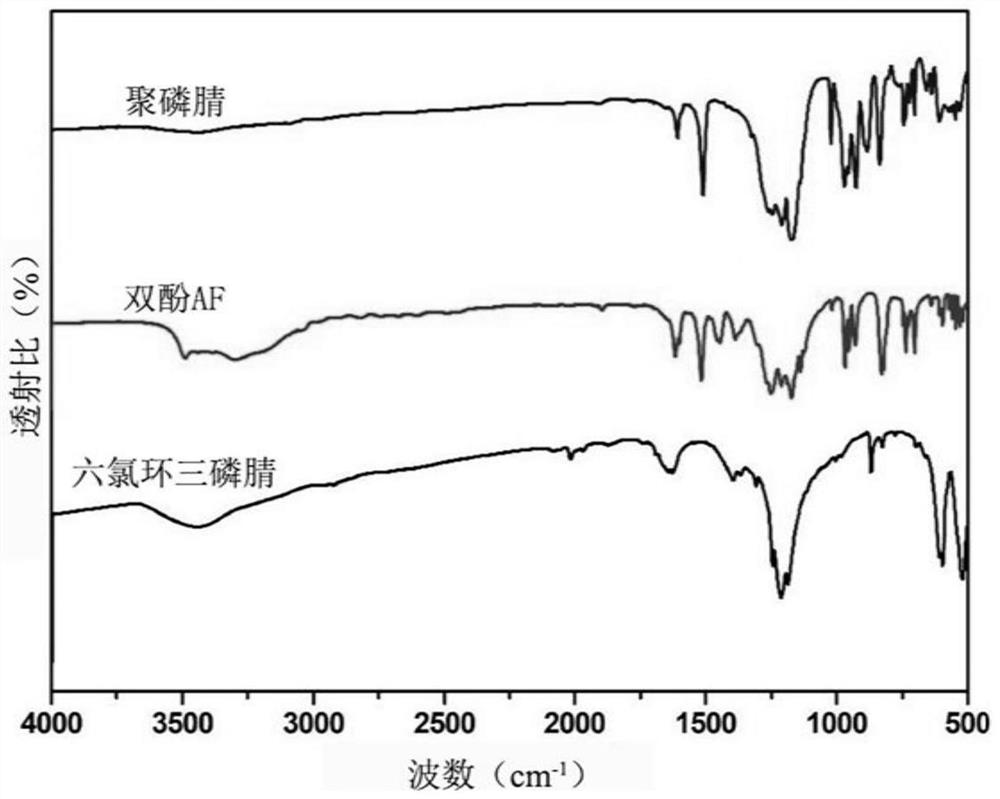

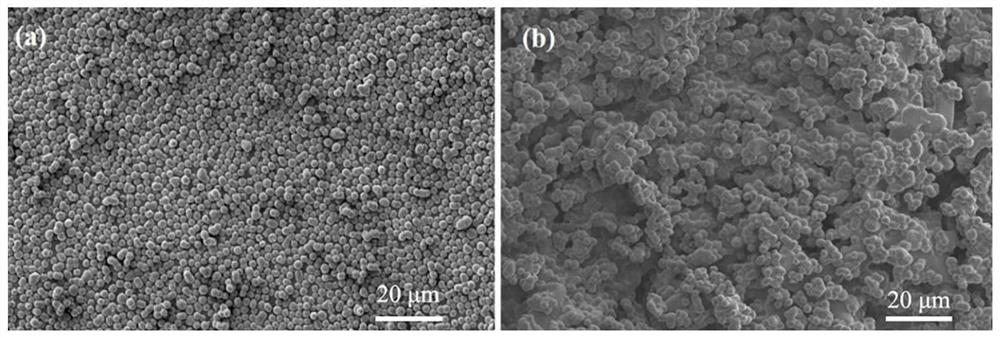

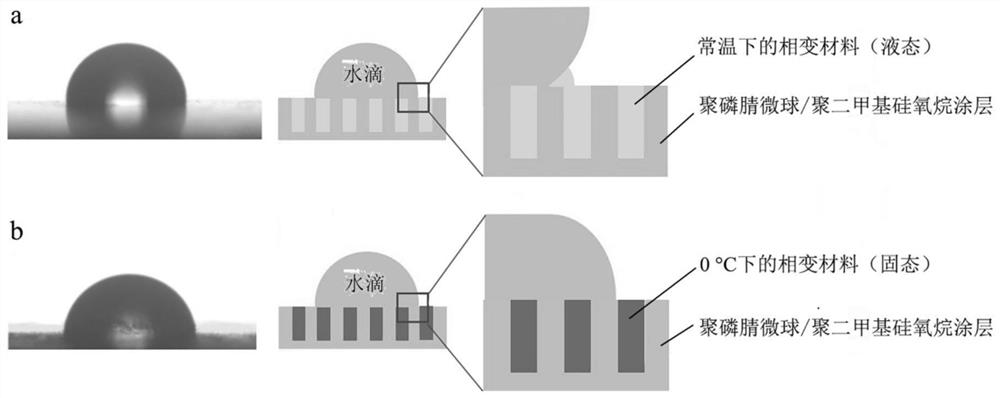

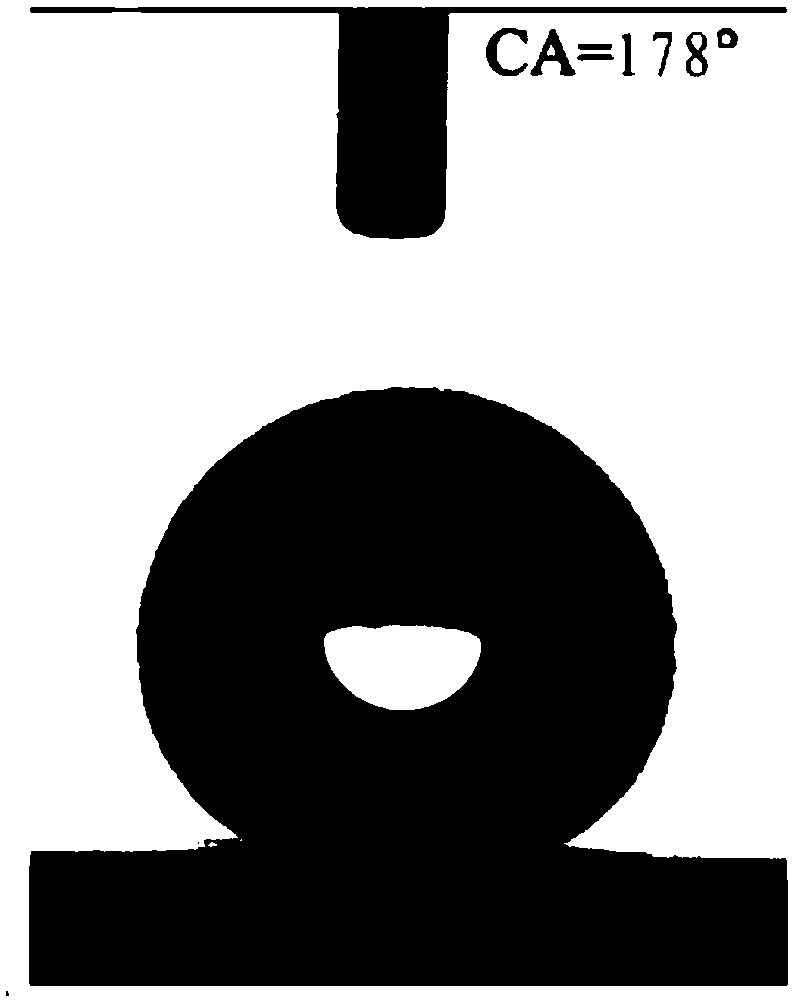

Phase-change material lubricated airplane anti-icing surface implementation method

PendingCN111842091ASolve the problem of easy freezingPromote endothermic meltingLiquid surface applicatorsOther chemical processesPorous substrateMicrosphere

The invention discloses a phase-change material lubricated airplane anti-icing surface implementation method. The method comprises the following steps of blending n-hexane, a polydimethylsiloxane prepolymer, a curing agent and polyphosphazene microspheres, coating a target surface with the mixture, drying and curing the target surface to obtain a polyphosphazene / polydimethylsiloxane porous substrate, injecting a phase-change material into the porous substrate until the adsorption is saturated, and preparing the phase-change material lubricated airplane anti-icing surface. According to the method, the polydimethylsiloxane and the polyphosphazene microspheres are simply blended to construct a porous structure with good elasticity, low surface energy and chemical stability, and then a properphase-change material is injected to obtain the phase-change material lubricated anti-icing surface with excellent anti-icing performance and durability. The method is simple, convenient, low in costand high in practicability, and has great application potential in the aspect of aircraft icing prevention.

Owner:SHANGHAI JIAO TONG UNIV

Medicinal cake and moxa cone for treating hyperlipemia, and moxibustion method through medicinal cake

InactiveCN103182057APromote intervention in endothelial cell inflammatory responseDelays the formation of atherosclerosisDevices for heating/cooling reflex pointsMetabolism disorderLeiomyocyteHuman health

The invention discloses a medicinal cake for treating hyperlipemia, and a moxibustion method through the medicinal cake. The medicinal cake can significantly lower lipid, treat and protect the injured vascular endothelial cells (intervention to inflammation), promote the outflow of macrophage cholesterol and interfere endothelial inflammation through activating expression of peroxisome proliferator activated receptors in atherosclerotic aortic endothelial cells and smooth muscle cells, so as to delay the formation of atherosclerosis. Therefore, the moxibustion method through the medicinal cake provides important reference to clinical rational use of acupuncture to treat the disease, also improves the clinical efficacy of acupuncture, gives full play to the role and benefits of acupuncture, enables more people to interfere and prevent generation and development of the disease through acupuncture treatment to improve people's health and quality of life, protect human health as an important requirement, and has an important application prospect and scientific value.

Owner:HUNAN UNIV OF CHINESE MEDICINE

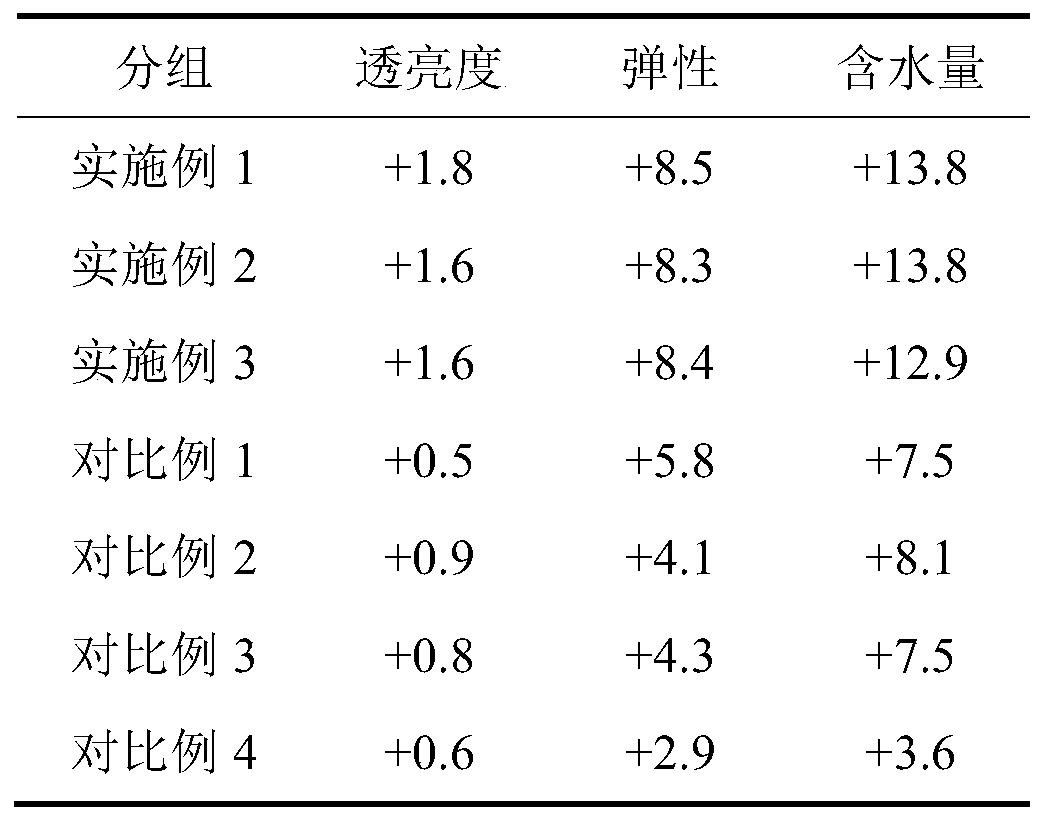

Moisturizing and repairing face cream and preparation method thereof

InactiveCN109820807AImprove anti-aging effectIncrease vitalityCosmetic preparationsToilet preparationsPropolisSkin tender

The invention discloses a moisturizing and repairing face cream. The moisturizing and repairing face cream is prepared from deionized water, chitosan, hyaluronic acid, lycium ruthenicum extract, astragalus root extract, sodium hyaluronate, okra extract, propolis, viola tricolor flower extract, butanediol, glycerin, xylitol, cocamidopropyl dimethylamine oxide, trehalose, sunflower seed oil, polydimethylsiloxane, PEG-20 methyl glucose sesquistearate, cetostearyl alcohol, biosaccharide gum-1 and catechin. The invention further discloses a preparation method of the moisturizing and repairing facecream. By adopting part of natural extract, the moisturizing and repairing face cream will not cause skin allergy or inflammation, and is safe and free of toxic or side effects; with the synergistic effect of the raw materials, the moisturizing and repairing face cream is high in oxidation resistance and good in absorption effect, has the effects of moisturizing the skin, repairing the skin barrier and enhancing the skin vitality, makes the skin tender, smooth, fine and glossy, promotes the regeneration of skin cells, repairs the skin, and effectively meets the demand of people for green, healthy and mild skin care.

Owner:易志

Method of delaying crosslinking in well treatment operation

InactiveUS20150101818A1Delayed formationFluid removalDrilling compositionAcetic acidCarboxymethyl guar gum

Crosslinking of a crosslinkable viscosifying agent and a crosslinking agent may be delayed in a well treatment fluid by incorporated within the fluid a glutamic-N,N-diacetic acid salt, such as a glutamic-N,N-diacetic acid sodium salt like tetrasodium glutamate diacetate. The crosslinking agent may be a zirconium containing crosslinking agent like zirconium (IV) acetyl acetonate. The viscosifying agent may be guar or a guar derivative such as carboxyalkyl guars and hydroxyalkylated guars like carboxymethyl guar, hydroxypropyl guar, hydroxyethyl guar, hydroxybutyl guar and carboxymethylhydroxypropyl guar.

Owner:BAKER HUGHES HLDG LLC

K4169 high-temperature alloy

The invention discloses a K4169 high-temperature alloy, which comprises the following components in percentage by mass: 0.056% of C, 52.54% of Ni, 19.15% of Cr, 3.11% of Mo, 0.61% of Al, 0.94% of Ti, 0.0048-0.0070% of B, 0.035-0.049% of Zr, 5.03% of Nb, 0.05% of Ta, 0.043% of Si, 0.0035% of Mn, 0.0018% of S, 0.0015% of P, not more than 0.01% of impurities, and the balance of Fe. The mobility of the K4169 high-temperature alloy can be improved by simultaneously changing the contents of boron and zirconium.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Ice coverage preventing electricity transmission cable and production method therefor

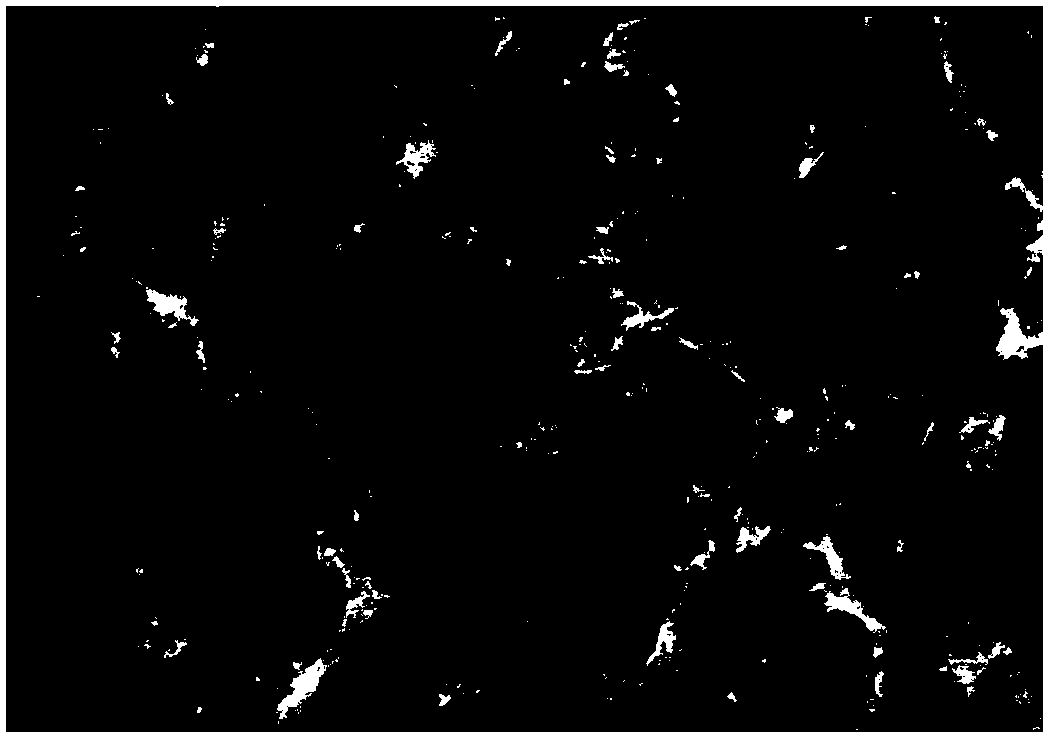

InactiveCN101425347AImprove toleranceAvoid icingVacuum evaporation coatingSputtering coatingAlkaneElectricity

The invention discloses an ice-coating resistant transmission cable and a manufacturing method thereof, and super-hydrophobic preparation technology is applied to a cable. The n-hexatriacontane of the adopted coating material is saturated alkanes, belongs to chemical inert material and has a good tolerance to the environment; in addition, the n-hexatriacontane is a hydrophobic material and has a low surface energy of only 20 mJ / m<2> . Because PVD technology is utilized to form a super-hydrophobic layer on the surface of a cable, the technology has no special requirement for the cable material components and thus wide applicability is available. After a super-hydrophobic layer is formed, rain water or wet snow is hard to adhere to the surface of a cable; therefore, the occurrence of an ice-coated grid is fundamentally inhibited; on the other hand, even if a small quantity of water droplets condenses on the surface of a cable, the formation of initial frost crystals is greatly delayed because the contact angle formed by water droplets is very large, which is conductive to avoid the occurrence of destructive frozen disasters; moreover, the formed frost crystals are loose in structure and easier to remove.

Owner:XIANGTAN UNIV

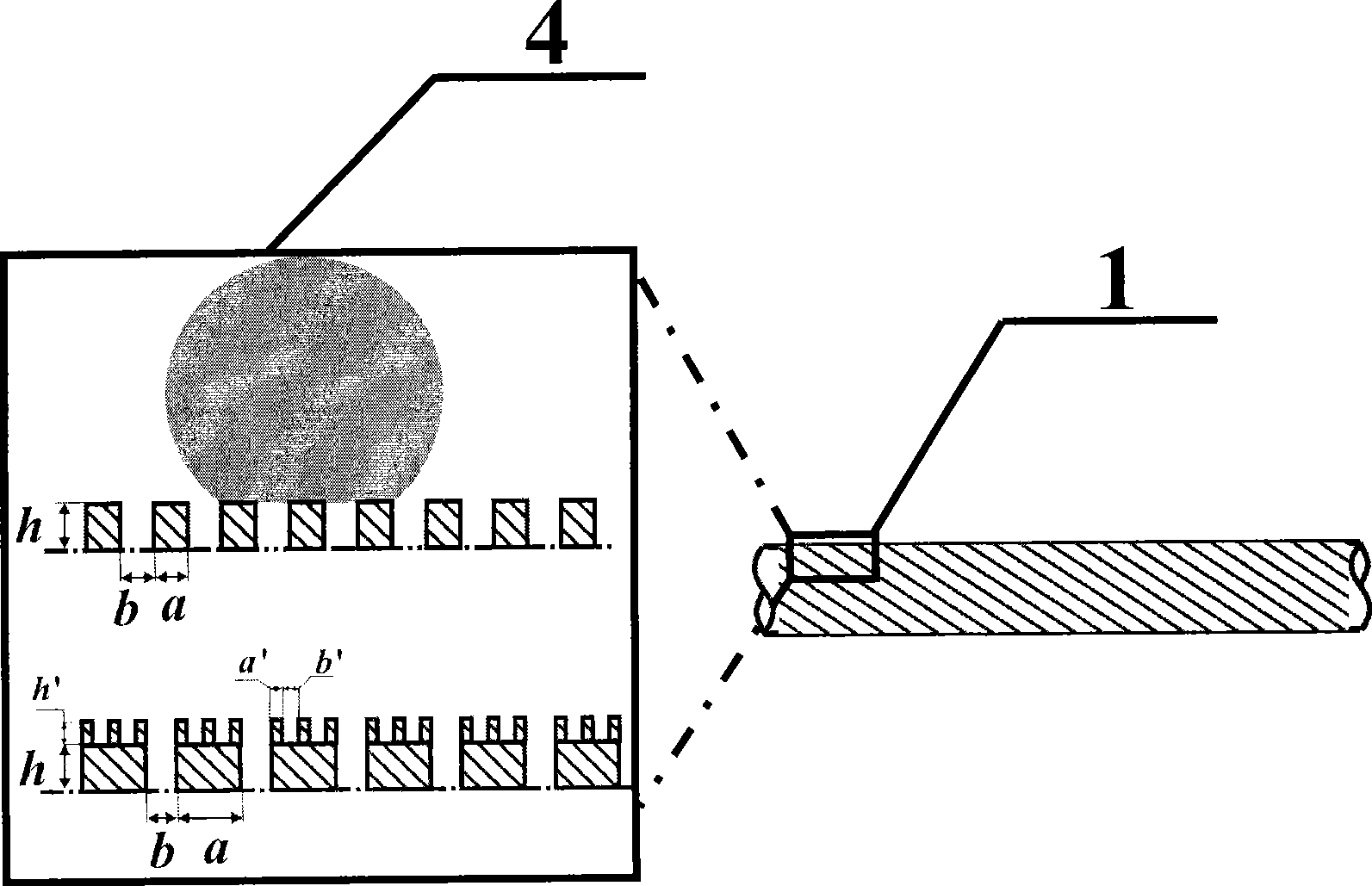

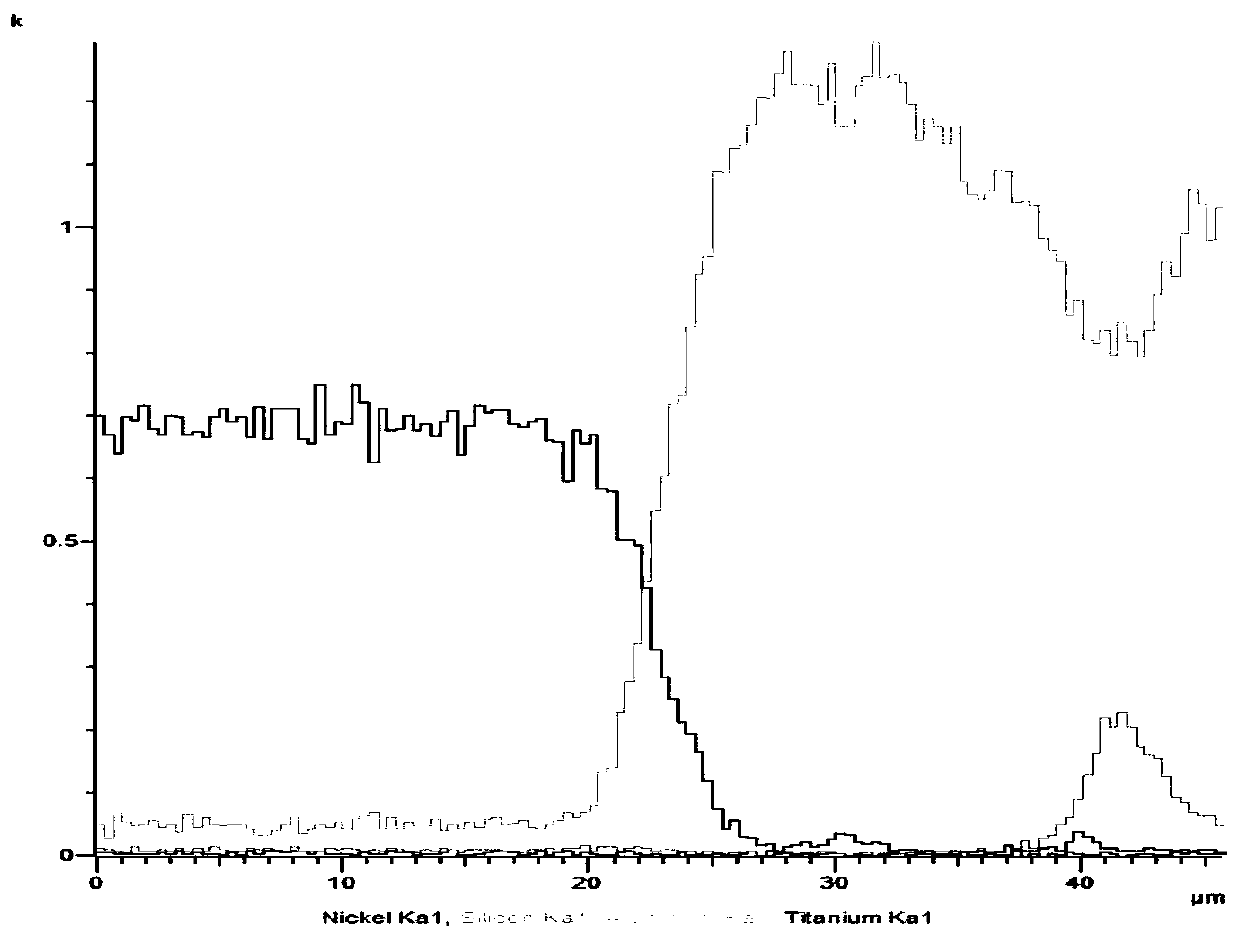

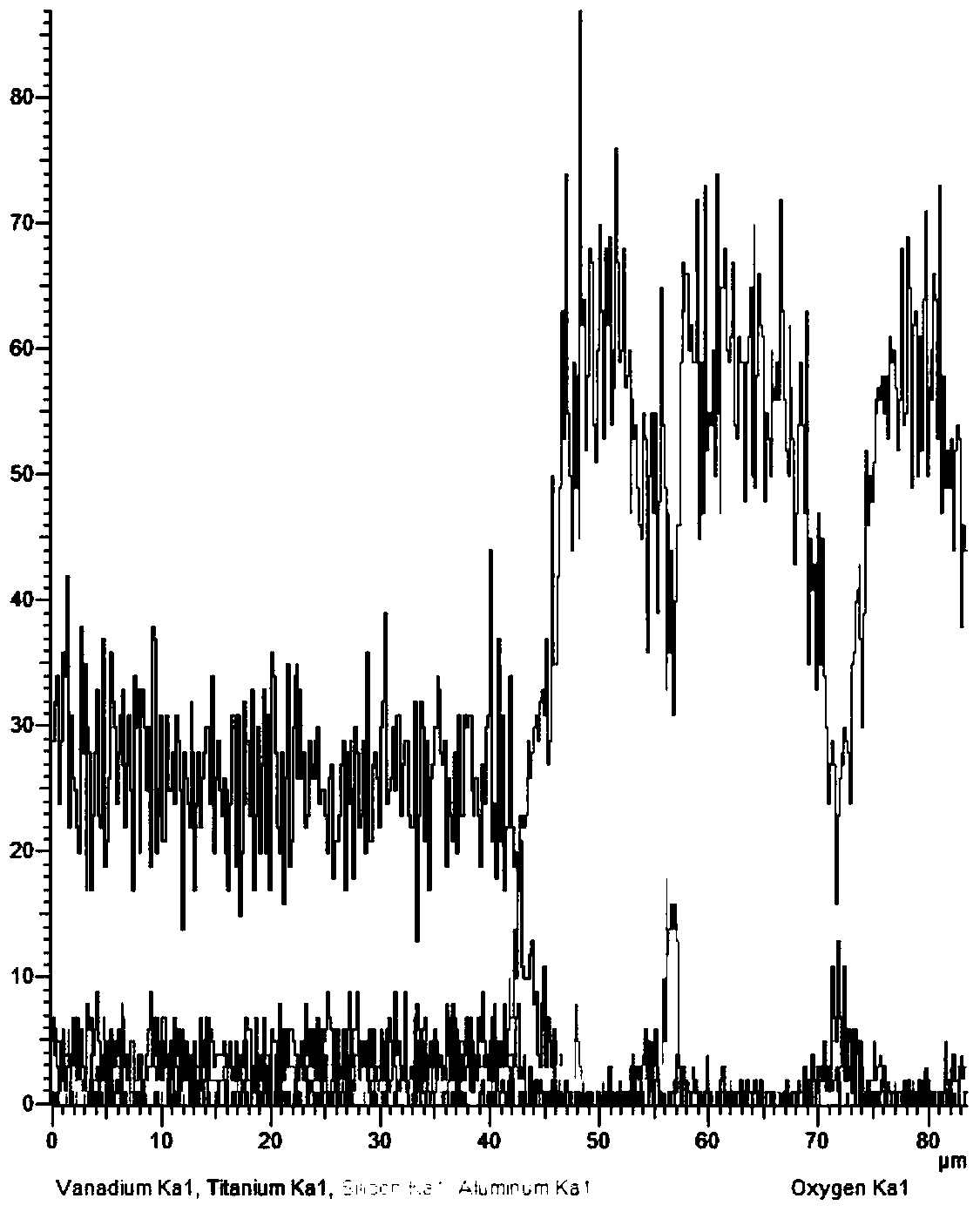

Metal filler for controlling brittle phases in titanium-aluminum dissimilar metal welded joints and application of metal filler

ActiveCN110541093AReduce brittle phaseImprove mechanical propertiesArc welding apparatusElectron beam welding apparatusTitaniumGrain boundary

The invention provides a metal filler for controlling brittle phases in titanium-aluminum dissimilar metal welded joints and its application and belongs to the technical field of welding fillers. Themetal filler comprises the following components in percentage by mass: 68%-78% of Al, 8%-15% of Si, 8%-18% of Ni and 6%-16% of Ag. Si in the metal filler plays a role in delaying formation of TiAl3 intermetallic compounds. Since the mutual diffusion coefficient of Ni and Ti is higher than that of Al and Ti, added Ni can preferentially diffuse and combine with Ti to interfere with generation of Ti-Al brittle phases; Ag can diffuse into the grain boundary of an Al matrix faster to interfere with and block generation of the Ti-Al brittle phases. The metal filler can adapt to various welding methods and can be applied flexibly. Data of the embodiment shows that the average tensile strength of the welded joints made of the metal filler is higher than 230 MPa.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

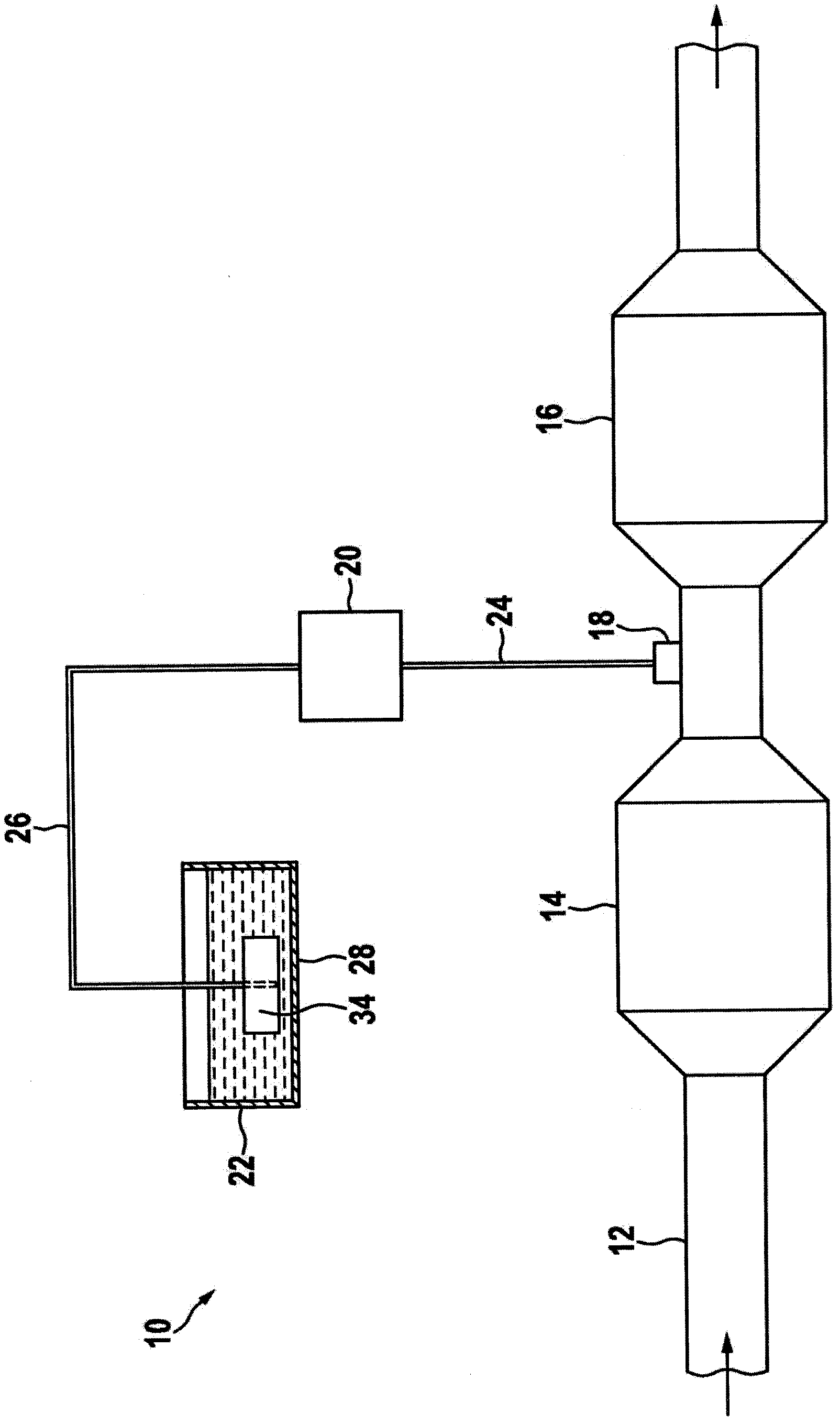

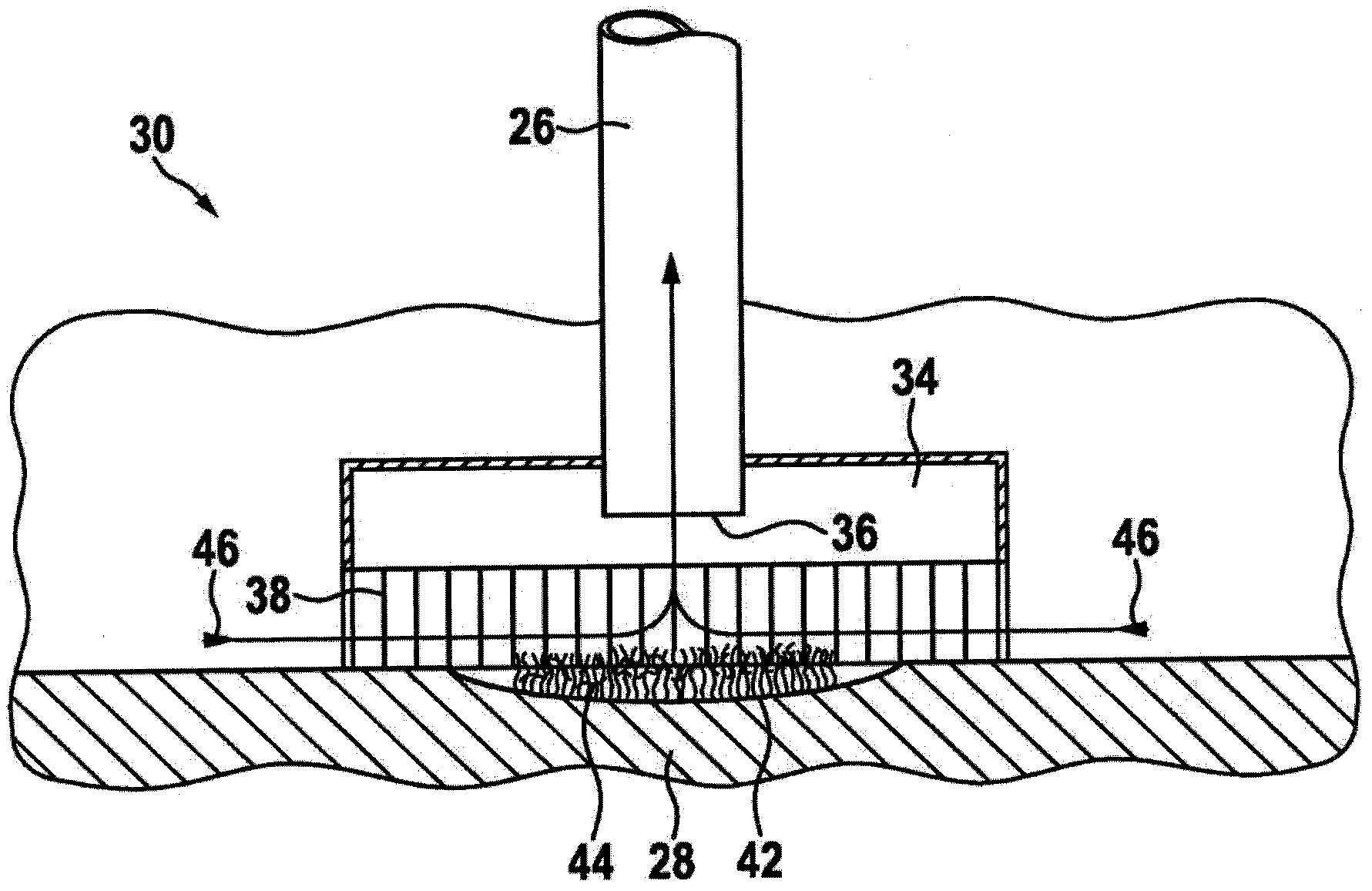

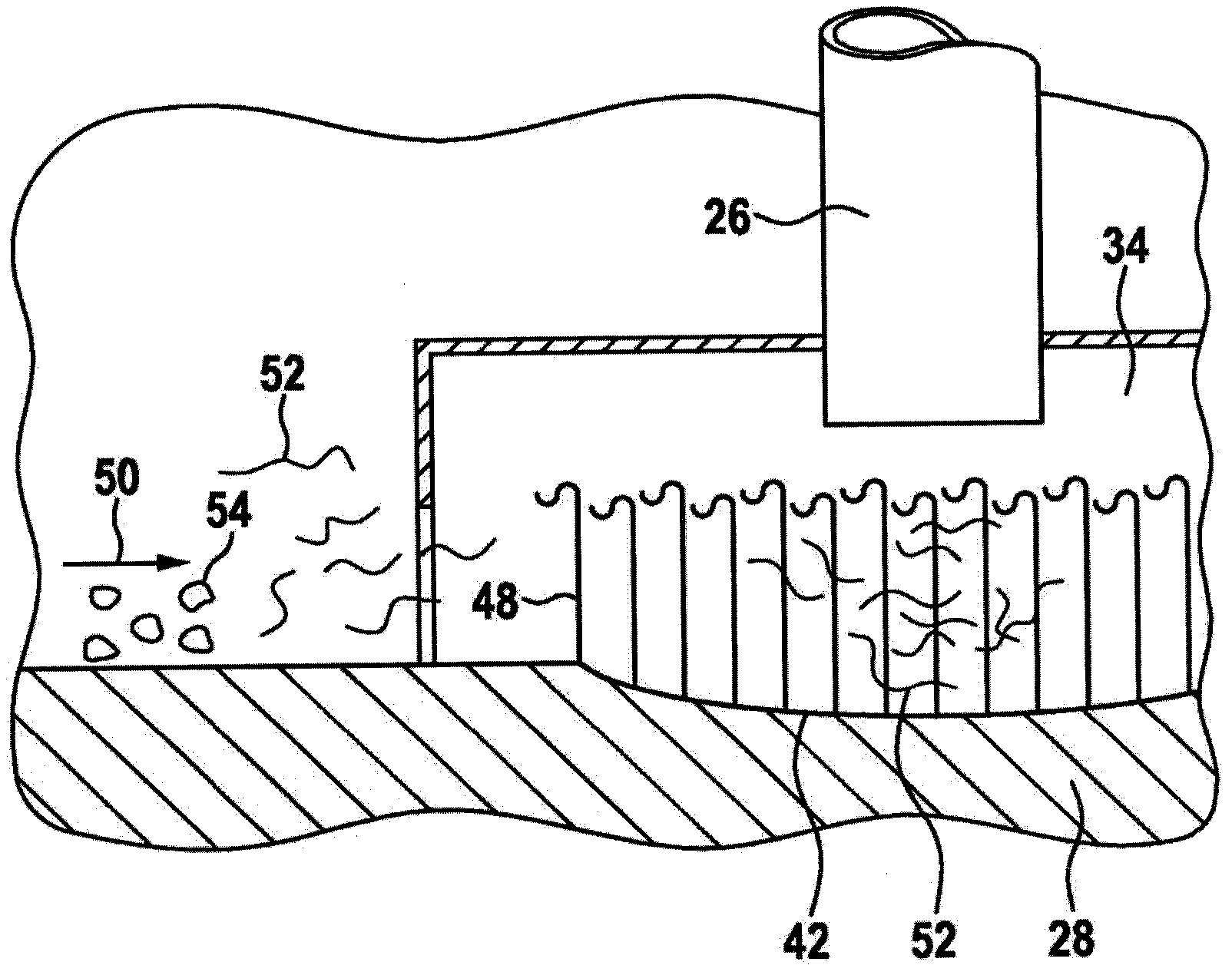

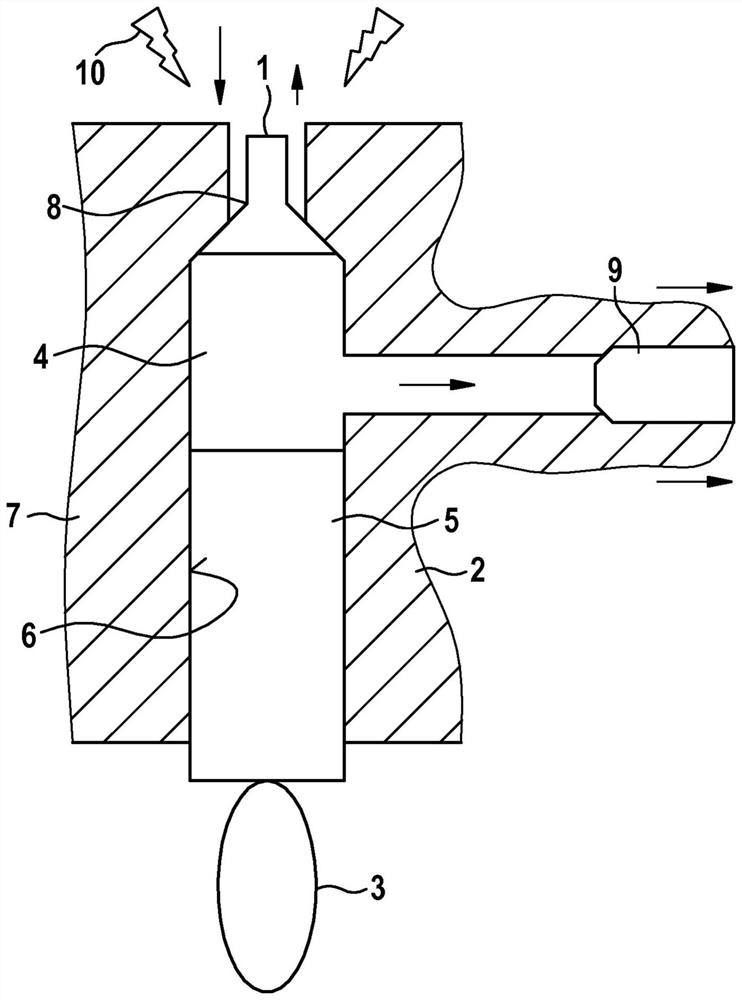

Reservoir for a liquid medium having a suction device and a filter unit

InactiveCN103221651AIncreased pressure lossDelayed formationInternal combustion piston enginesDispersed particle filtrationFiberLiquid medium

The invention relates to a reservoir (22) for a liquid medium, having a suction device (30) and a filter unit (34), wherein means for the sedimentation of particles and fibers are connected upstream of the filter unit (34).

Owner:ROBERT BOSCH GMBH

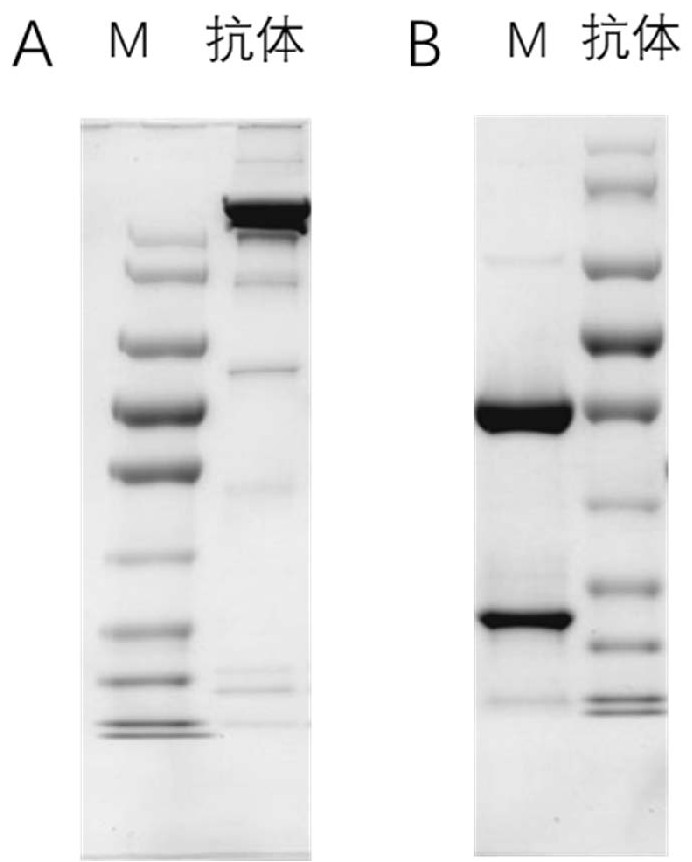

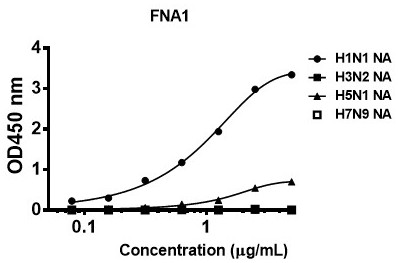

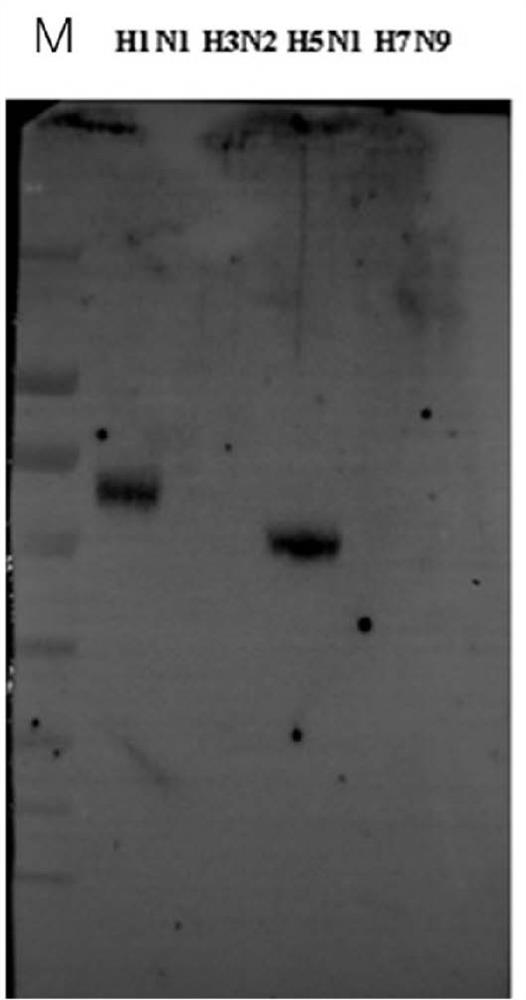

Antibody targeting influenza A virus N1 subtype NA protein

ActiveCN114106165AAvoid it happening againPrevent relapseImmunoglobulins against virusesAntiviralsAntigenAntibody targeting

The invention discloses an antibody targeting an influenza A virus N1 subtype NA protein. The invention also discloses a coding nucleic acid, a vector and a host cell of the anti-influenza A virus antibody. In addition, the invention also discloses an immunoconjugate and a detection kit for detecting the influenza A virus. The antibody provided by the invention can identify NA antigens of H5N1 and H1N1 N1 subtypes, and has the effect of inhibiting H5N1 pseudovirus release so as to limit intercellular propagation.

Owner:ACADEMY OF MILITARY MEDICAL SCI

Preparation method for polystyrene plastic with ultrahigh toughness

The invention discloses a preparation method of a polystyrene plastic with ultra high toughness, belonging to the technical field of novel materials. The preparation method comprises the following steps: (1) selection of raw materials; and (2) processing of the raw materials. According to the invention, a polystyrene solution has higher strength and can improve the processability of materials, sothe prepared polystyrene plastic has better processing performance and toughness.

Owner:马鞍山卓凡新材料科技有限公司

Surface treatment method for resisting frosting

ActiveCN108486627AExcellent anti-frost effectEasy accessSurface reaction electrolytic coatingMicro nanoMaterials science

The invention provides a surface treatment method for resisting frosting. The method comprises the following steps that (a) a water solution of oxalic acid serves as electrolyte, and a to-be-treated workpiece is subjected to anodic oxidation treatment at the current density of 0.1-0.4A / cm<2>; (b) the workpiece subjected to anodic oxidation treatment is subjected to surface modification treatment,and an anti-frosting workpiece is obtained; and a modifier adopted in the surface modification treatment process is one or more of lauric acid, fluorosilane, siloxane, a silane coupling agent and higher fatty acid. The method firstly conducts anodic oxidation treatment on the workpiece, so that a special micro-nano structure is formed on the surface of the workpiece, then conducts surface modification on the workpiece to further modify the micro-nano structure and adjust the free energy on the surface of the workpiece, therefore a special surface is formed on the surface of the workpiece, accordingly the workpiece has the excellent anti-frosting effect, and the anti-frosting property is long-lasting and effective.

Owner:GUANGDONG UNIV OF TECH

Regeneration method of deactivated hydrogenation catalyst

PendingCN111729689AReduce utilizationIncrease profitOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst regeneration/reactivationCarboxyl radicalPtru catalyst

The invention provides a regeneration method of an deactivated hydrogenation catalyst. The regeneration method comprises the following steps: carrying out charking treatment on the inactivated hydrogenation catalyst; dipping the charked deactivated hydrogenation catalyst in a solution containing a hydroxyl and / or carboxyl chelated ligand compound; and carrying out microwave vacuum drying on the catalyst subjected to dipping treatment so that the deactivated hydrogenation catalyst then recovers the activity. According to the technical scheme, microwave vacuum drying is adopted, due to the factthat operation is carried out under the condition of air isolation, oxygenolysis cannot occur in the drying process even if the decomposition temperature of an organic additive is high, and the utilization rate of the organic additive is remarkably increased.

Owner:湖北中超化工科技有限公司

Non-therapeutic use of a biodegradable hydrocarbon oil

ActiveUS20200093716A1Skin to slackenDelayed formationCosmetic preparationsHair cosmeticsAlkaneAnti ageing

A method for the anti-ageing cosmetic treatment of the skin or of the hair applying a hydrocarbon oil that has a content by weight of isoparaffins ranging from 90 to 100%, a content by weight of normal paraffins ranging from 0 to 10% and a content of carbon of biological origin greater than or equal to 90% relative to the total weight of the hydrocarbon oil.

Owner:TOTAL MARKETING SERVICES SA

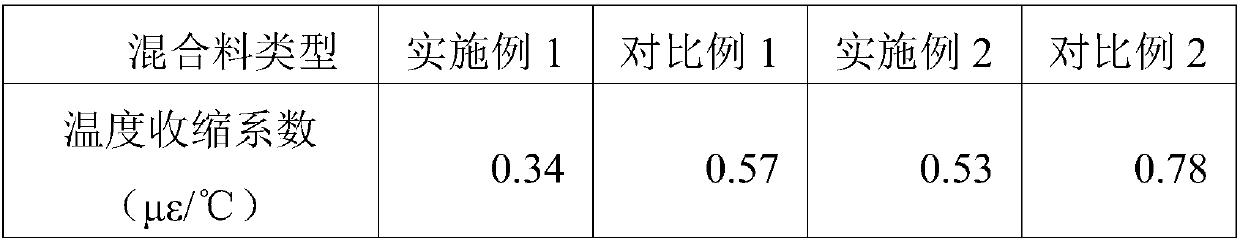

Temperature shrinkage active-control type cement stabilized macadam and preparation method thereof

ActiveCN109516736AImprove flexibilityImprove crack resistanceReflective crackButadiene-styrene rubber

Owner:CENT SOUTH UNIV +1

A kind of valacyclovir hydrochloride liposome tablet and preparation method thereof

ActiveCN112168791BHigh encapsulation efficiencyImprove stabilityAntiviralsPharmaceutical non-active ingredientsCholesterolPyrrolidinones

Owner:药大制药有限公司

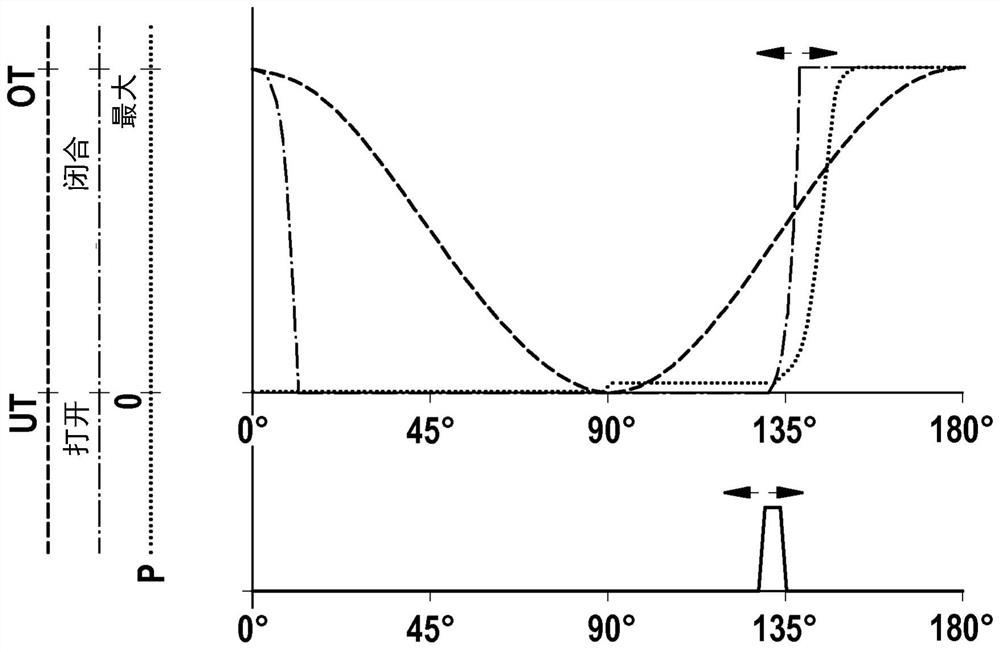

Method for operating an electrically operable suction valve

ActiveCN107148514BDelayed pressure buildupDelayed formationElectrical controlMachines/enginesCommon railInternal combustion engine

Owner:ROBERT BOSCH GMBH

Stabilized liquid and lyophilized formulations of adamts13

ActiveCN102573792BHigh specific activityDelayed formationPeptide/protein ingredientsInorganic non-active ingredientsDiseaseFunctional disturbance

The present invention relates to formulations of ADAMTS13 with improved or desirable properties. Accordingly, the present invention provides liquid and lyophilized formulations of ADAMTS13 suitable for pharmaceutical administration. Among other aspects, the present invention provides methods of treating various diseases and conditions associated with VWF and / or ADAMTS13 dysfunction in a subject. Also provided herein are kits comprising formulations of ADAMTS13 useful in the treatment of various diseases and conditions.

Owner:TAKEDA PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com