Wind turbine blade capable of improving stalling characteristics based on fractal optimization

A technology of wind turbine blades and stall characteristics, which is applied in wind turbines, climate sustainability, engines, etc., can solve the problems of high cost, control system and structure reducing the reliability of wind turbine blades, complex structure, etc., to ensure aerodynamic performance , Improve the stall characteristics, increase the effect of the stall angle of attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings, but this should not limit the scope of protection of this patent.

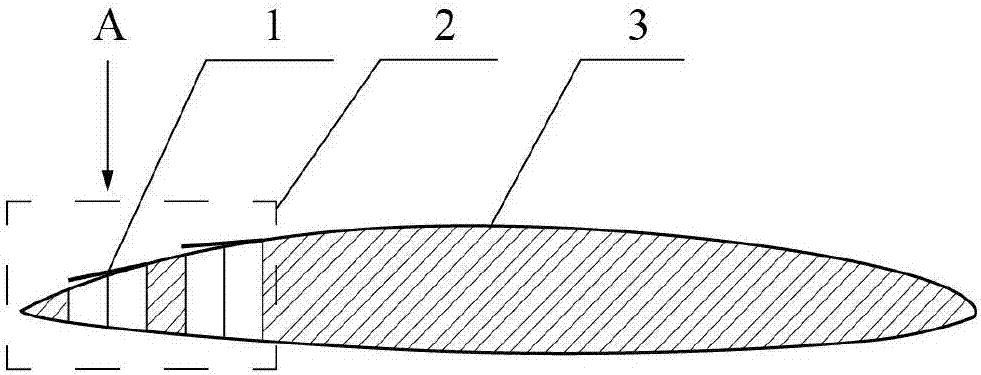

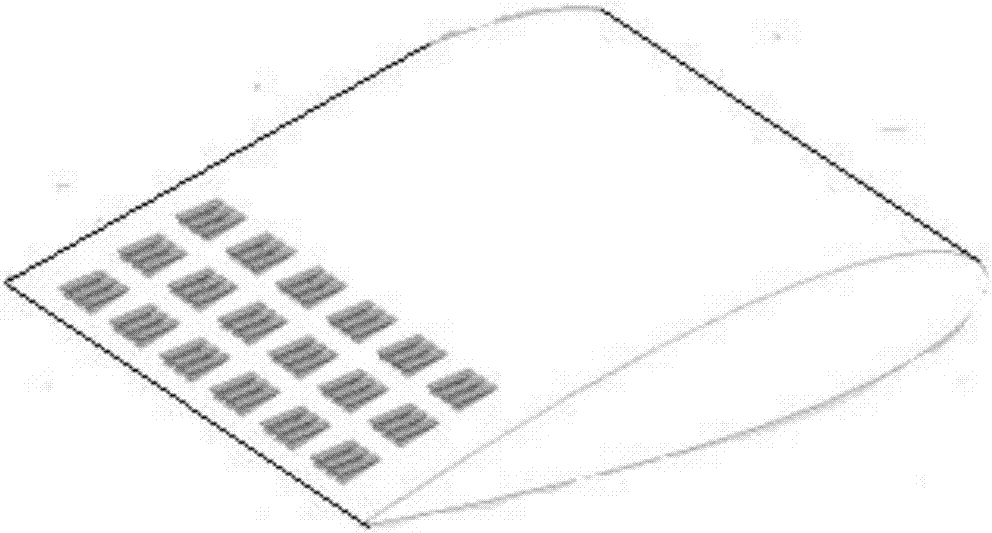

[0036] figure 1 and figure 2 A sectional view of a wind turbine blade airfoil that can improve stall characteristics based on fractal optimization according to the present invention is shown. In this example, the airfoil of the wind turbine blade adopts NACA0012, which is widely used in the wind power industry, but the airfoil structure of the present invention is not limited thereto.

[0037] Depend on figure 1 It can be seen that the wind turbine blade of the present invention mainly includes a blade main body 1 and a blade trailing edge 2 .

[0038] The main body 1 of the blade is made of fiberglass, and the trailing edge 2 of the blade can also be made of fiberglass, which is characterized by high strength, light weight and aging resistance.

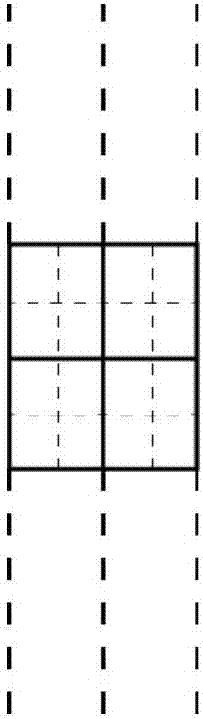

[0039] still refer to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com