Ice-melting heating structure of wind turbine blade and manufacturing method thereof

A technology for wind power generators and heating structures, which is applied to wind power generators, wind power generation, wind power generators in the same direction as the wind, etc. It can solve the problems of difficult laying process of hot air pipelines and large waste of heat, so as to avoid deformation, The effect of prolonging the service life and preventing the blades from freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] Example 1 Overall perfusion process

[0045] Including the following steps:

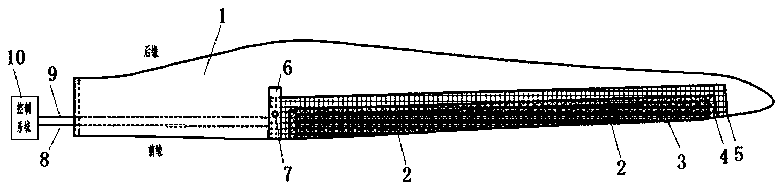

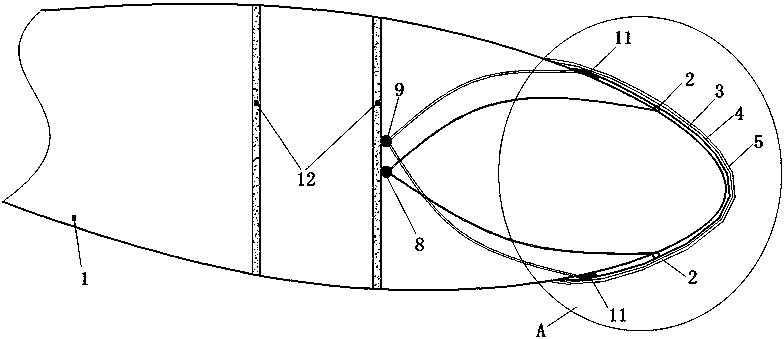

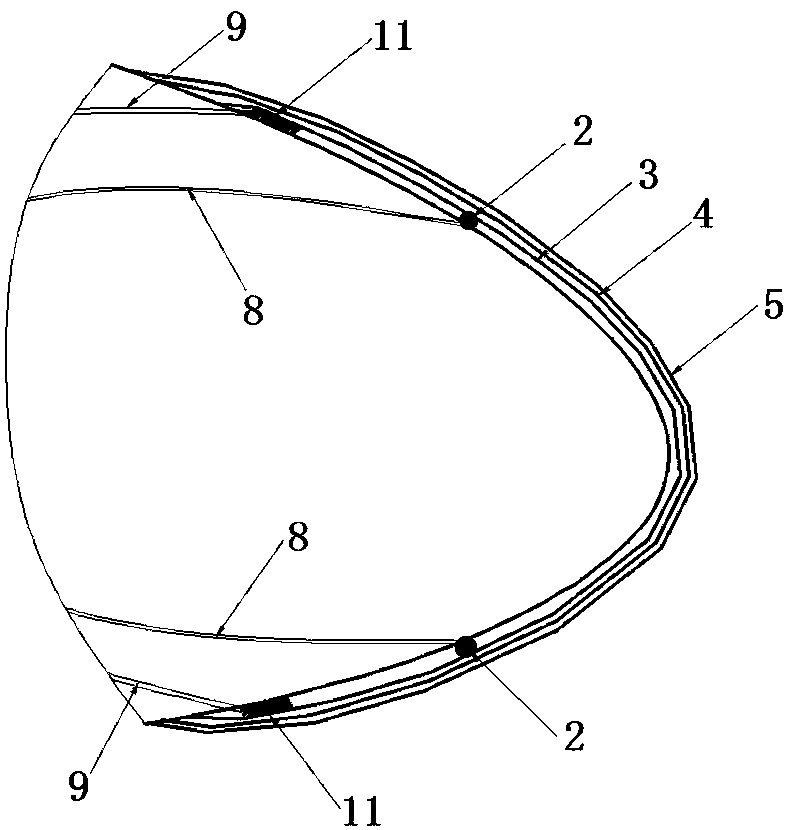

[0046] (1) Before pouring the shells of the upstream and downstream surfaces of the blades, lay low-density bidirectional glass fiber cloth, wire mesh 5, high-density bidirectional fiber cloth 4, and carbon crystal electric heating film 3 in the mold in sequence , corresponding to the ice-covered area, the temperature sensor 2 is arranged on the carbon crystal electrothermal film 3, and the lightning current lead 13 of the wire mesh 5, the power line 9 of the carbon crystal electrothermal film 3, and the signal line 8 of the temperature sensor 2 are all brazed Welded, wherein, the power line 9 of the carbon crystal electric heating film is welded with the electrode 11 of the carbon crystal electric heating film, and the lightning current lead 13 is directly welded with the copper foil shroud 6 of the wire mesh 5; Core;

[0047] (2) Vacuumize and infuse resin together to form, and wire mesh, ...

example 2

[0051] Example 2 Artificial hand lay-up process

[0052] Including the following steps:

[0053] (1) Use molds to infuse the shell on the upstream side, the shell on the downstream side, and the shear-resistant web of the blade respectively, then assemble and bond, close the mold for heat preservation, and maintain pressure until the adhesive is completely cured, then the mold is demoulded, and the blade is formed ;

[0054] (2.) Drill the holes of the carbon crystal electric heating film power line 9, the temperature sensor signal line 8, and the bolt 7 of the lightning protection device on the shell 1;

[0055] (3) Install the temperature sensor 2 in the ice-covered area of the leading edge of the blade shell 1 and braze the connection with the signal line 8;

[0056] (4) Apply an adhesive on the surface of the ice-coated area at the front edge of the blade shell 1, and then spread the carbon crystal electric heating film 3 with an area equivalent to the surface of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com