Automobile engine cooling fan

A technology for automobile engines and cooling fans, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc. It can solve the problems of reducing the service life of the fan, unbalanced force on the blades, and affecting the performance of the fan, so as to improve the air volume and air pressure. Improve the rigidity and strength, increase the effect of the effective work area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

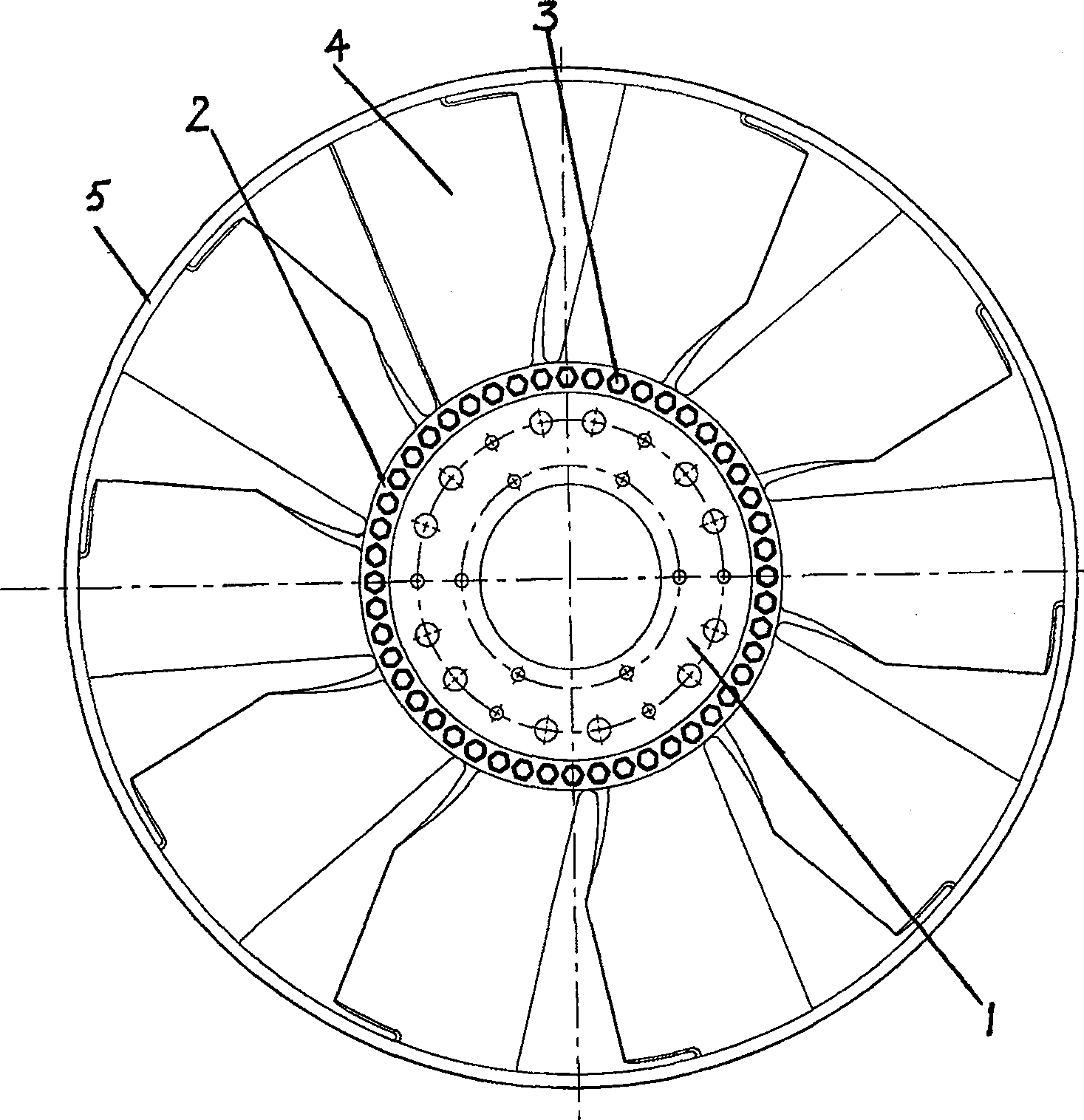

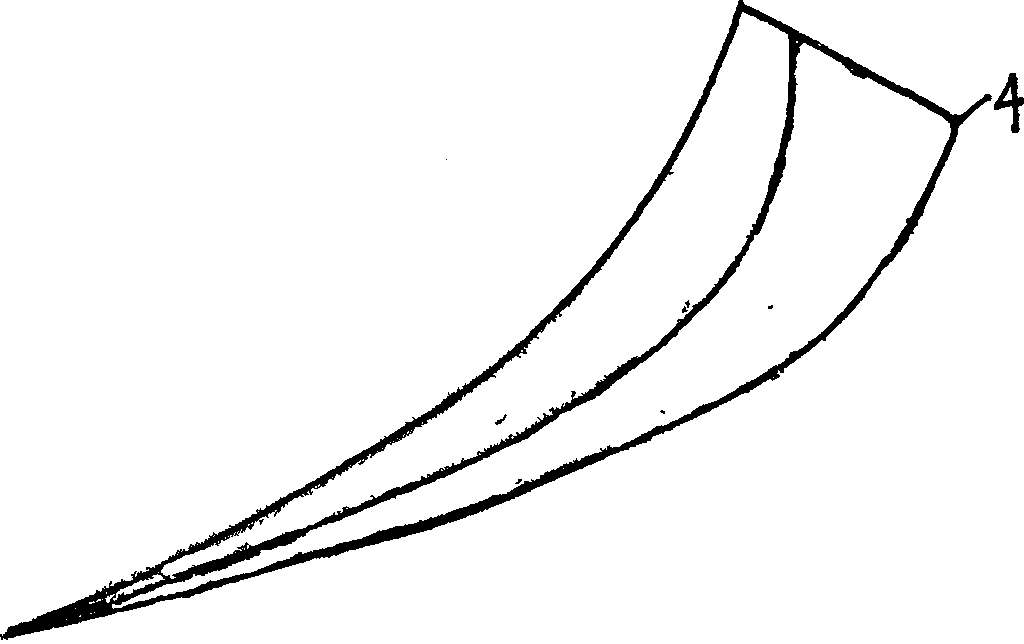

[0014] Embodiment one: see figure 1 and figure 2 , an automobile engine cooling fan, comprising a tray 1, a hub 2, ribs 3, and blades 4, the impeller is composed of the tray 1, the hub 2, and blades 4, the blades 4 are airfoil-shaped cross-section blades, and the blades 4 and the hub 2 are integrally formed , the ratio of the chord length between the inner and outer diameters of each blade 4 is 1:1.1, the angle between the line of the center of gravity of each section of the blade 4 and the radial straight line is 5°, and the projection distance of the line of the center of gravity of each section of the blade 4 on the rotation axis is controlled At 2% of the diameter of the impeller, it is in the shape of space distortion, the connection between the blade 4 and the hub 2 adopts a circular arc transition, and the reinforcing rib 3 is a honeycomb reinforcing rib, and the honeycomb reinforcing rib is a regular hexagon. The vane 4 is connected with the guide ring 5 together.

Embodiment 2

[0015] Embodiment two: see figure 1 and figure 2 , an automobile engine cooling fan, comprising a tray 1, a hub 2, ribs 3, and blades 4, the impeller is composed of the tray 1, the hub 2, and blades 4, the blades 4 are airfoil-shaped cross-section blades, and the blades 4 and the hub 2 are integrally formed The ratio of the chord length between the inner and outer diameters of each blade 4 is 1:1.5, the angle between the line of the center of gravity of each section of the blade 4 and the radial straight line is 25°, and the projection distance of the line of the center of gravity of each section of the blade 4 on the rotation axis is controlled At 8% of the diameter of the impeller, it is in the shape of space distortion, and the connection between the blade 4 and the hub 2 adopts a circular arc transition. Others are the same as embodiment one.

Embodiment 3

[0016] Embodiment three: see figure 1 and figure 2 , an automobile engine cooling fan, comprising a tray 1, a hub 2, ribs 3, and blades 4, the impeller is composed of the tray 1, the hub 2, and blades 4, the blades 4 are airfoil-shaped cross-section blades, and the blades 4 and the hub 2 are integrally formed , the ratio of the chord length between the inner and outer diameters of each blade 4 is 1:1.3, the angle between the line of the center of gravity of each section of the blade 4 and the radial straight line is 15°, and the projection distance of the line of the center of gravity of each section of the blade 4 on the rotation axis is controlled At 5% of the diameter of the impeller, it is in the shape of space distortion, and the connection between the blade 4 and the hub 2 adopts a circular arc transition. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com