Patents

Literature

131results about How to "Lift control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water purification device bringing convenience to water scale cleaning

InactiveCN107324424AEasy to cleanQuick clean upHollow article cleaningWater/sewage treatment by heatingDistillationEngineering

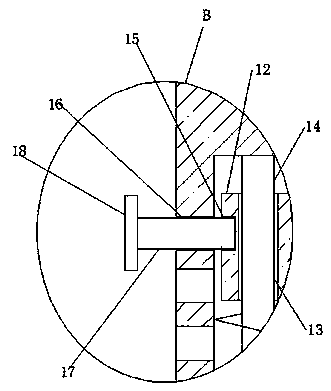

The invention discloses a water purification device capable of cleaning scale easily, comprising a distillation tank, the top of the distillation tank is an opening, a cover plate is arranged on the top of the distillation tank, a fixing rod is slidably installed in the cover plate, and the fixing rod Both ends extend to the outside of the cover plate, and the cover plate is provided with a lifting module that controls the lifting of the fixed rod. One end of the fixed rod located in the retort is provided with a cleaning module for cleaning the retort, and the lifting module can drive the cleaning module to rise and fall. The invention can conveniently and quickly control the lifting of the cleaning module through the lifting module, and can quickly clean the scale on the inner wall of the distillation tank through the cleaning module, thereby improving the quality of purified water and facilitating people's operation and use.

Owner:申翰昭

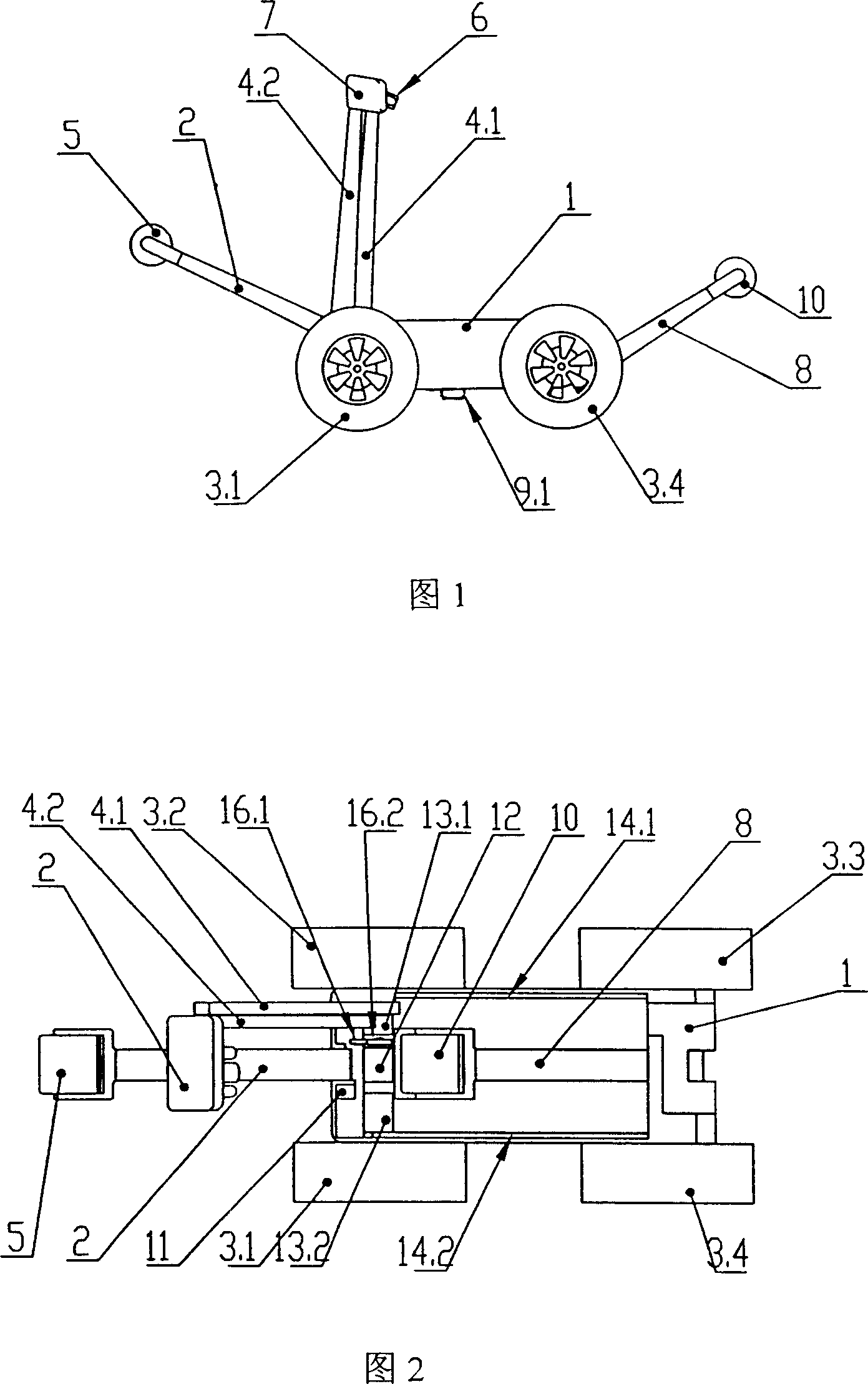

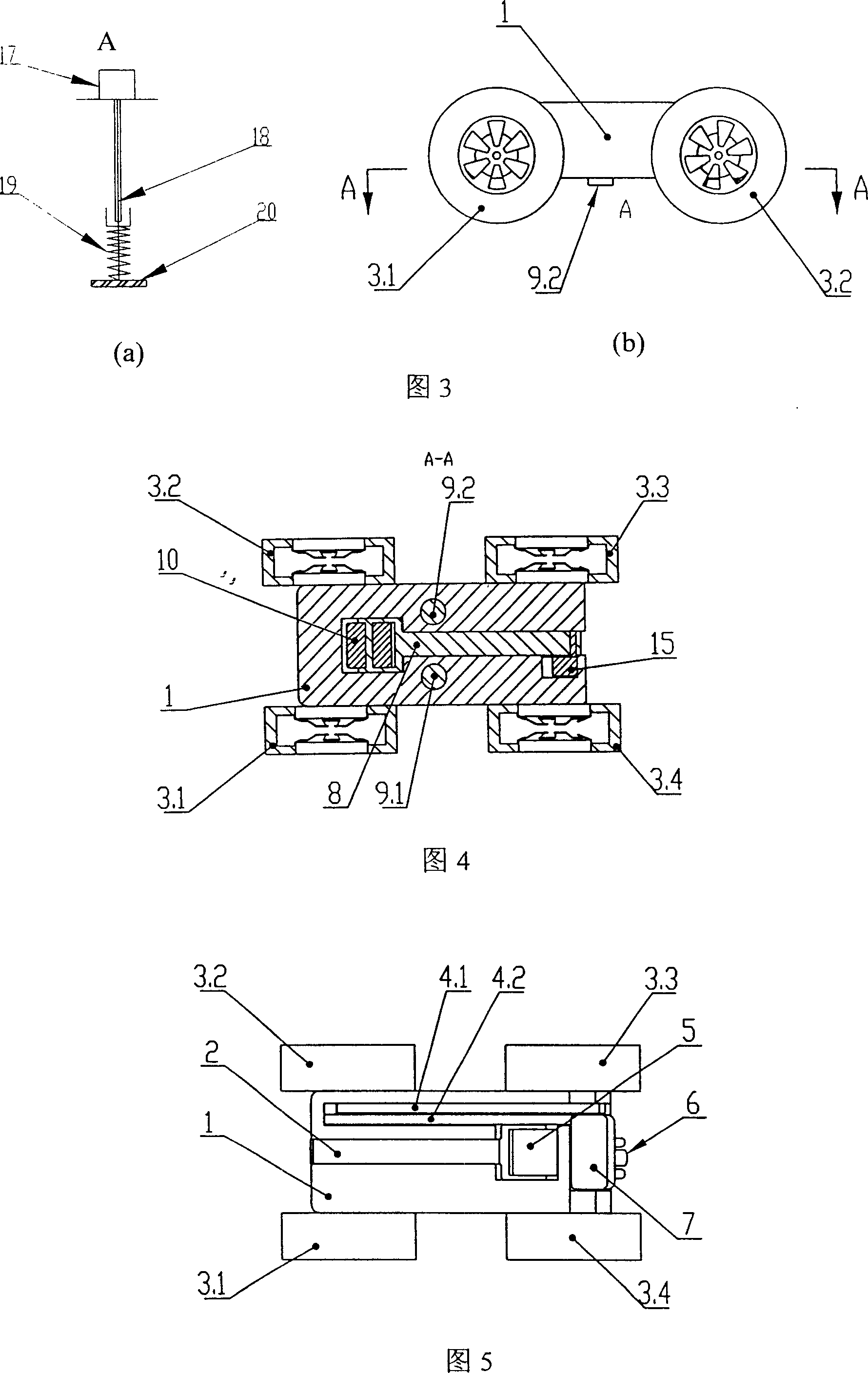

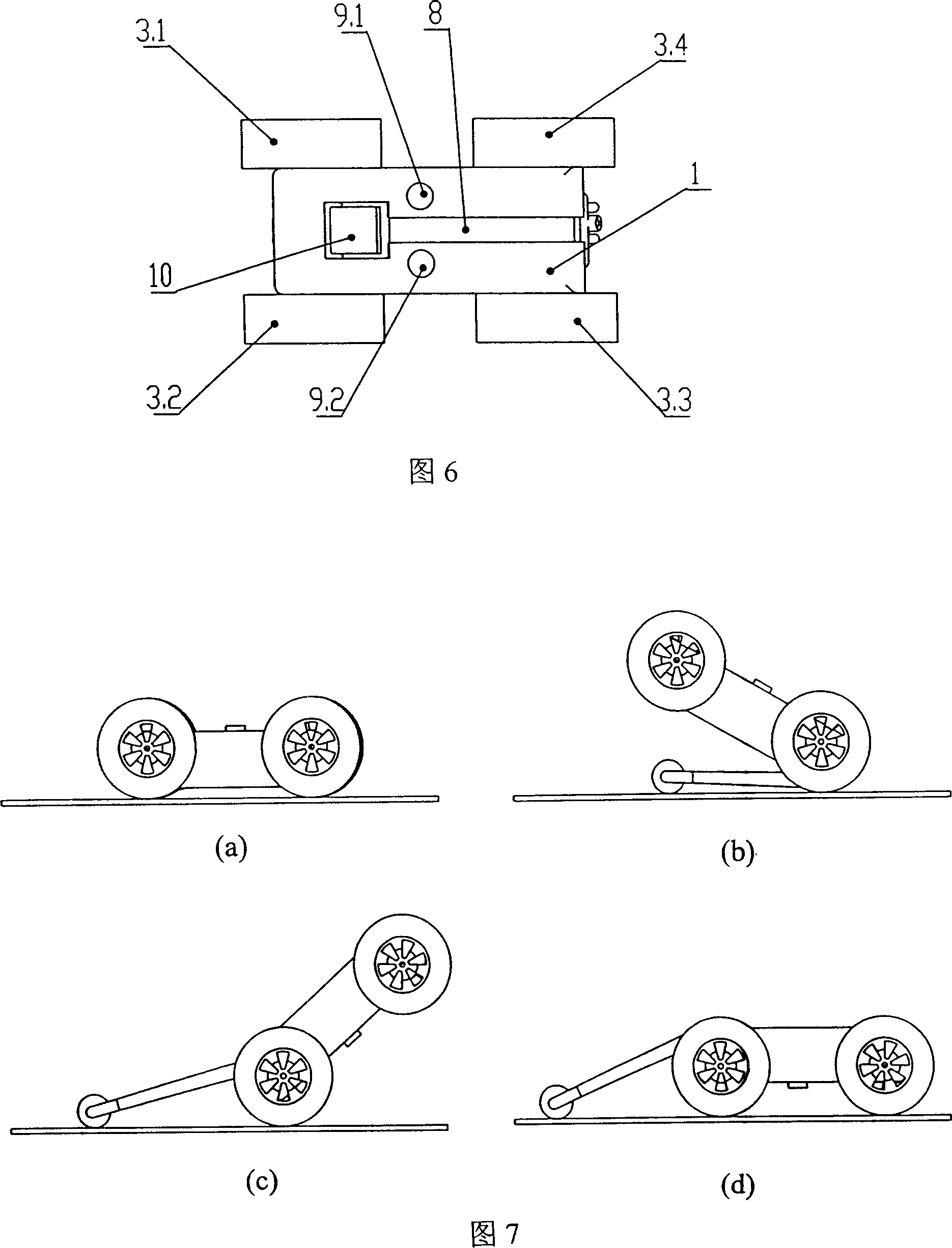

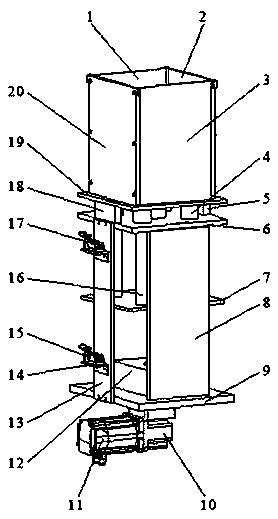

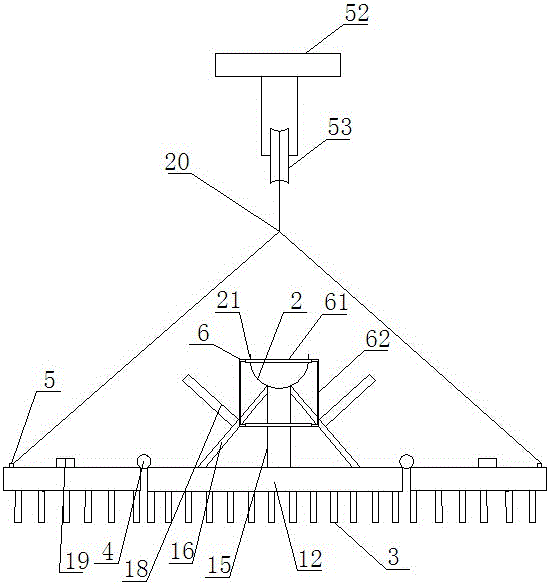

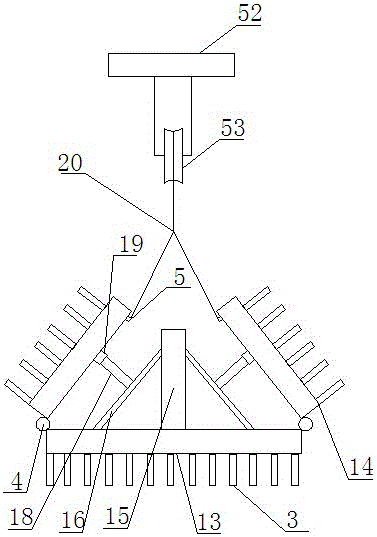

Wheel, leg, bounce mechanism combined mobile robot

InactiveCN1994804AImprove the ability to overcome obstaclesExpand field of viewSelf-moving toy figuresVehiclesCcd cameraMobile robot

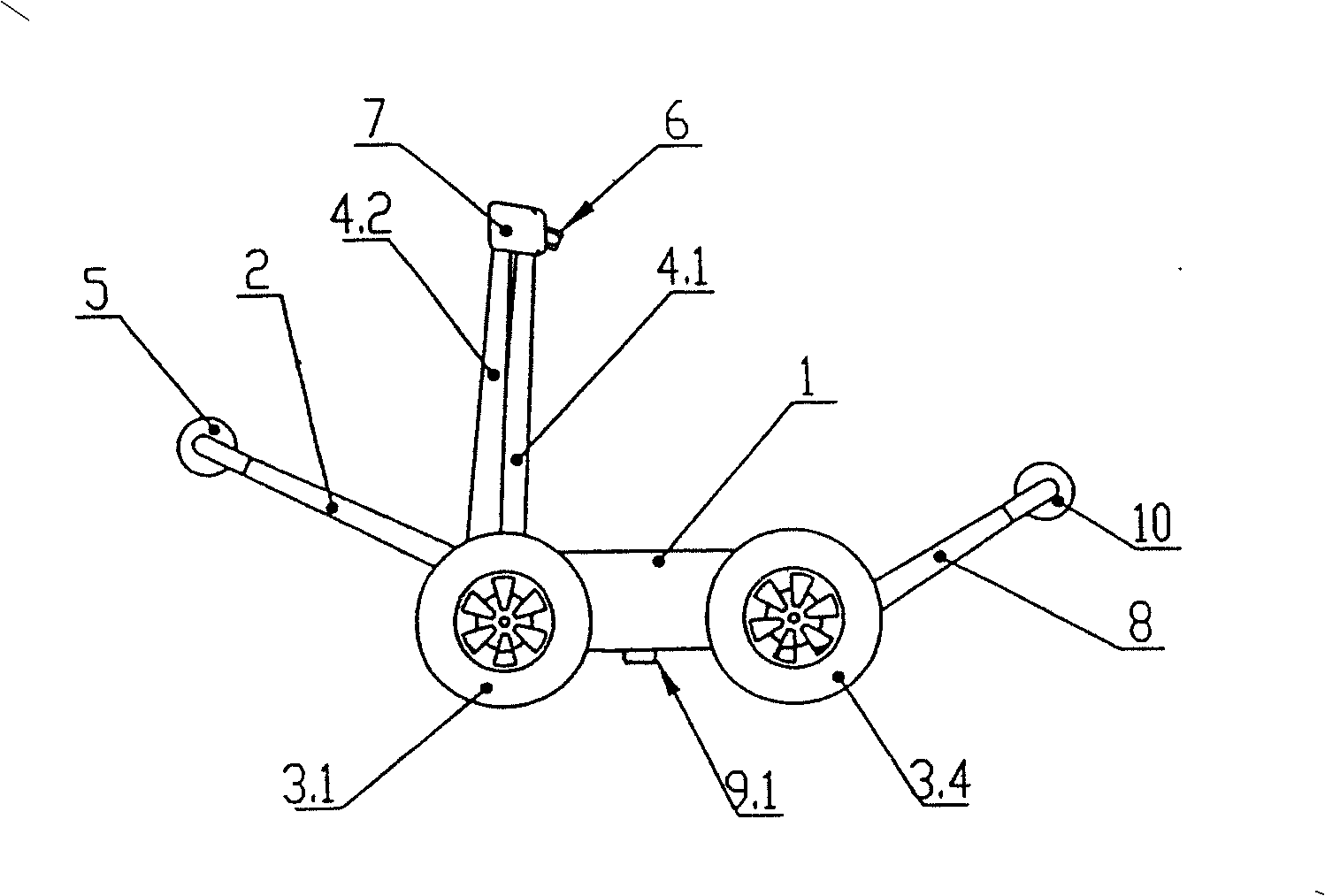

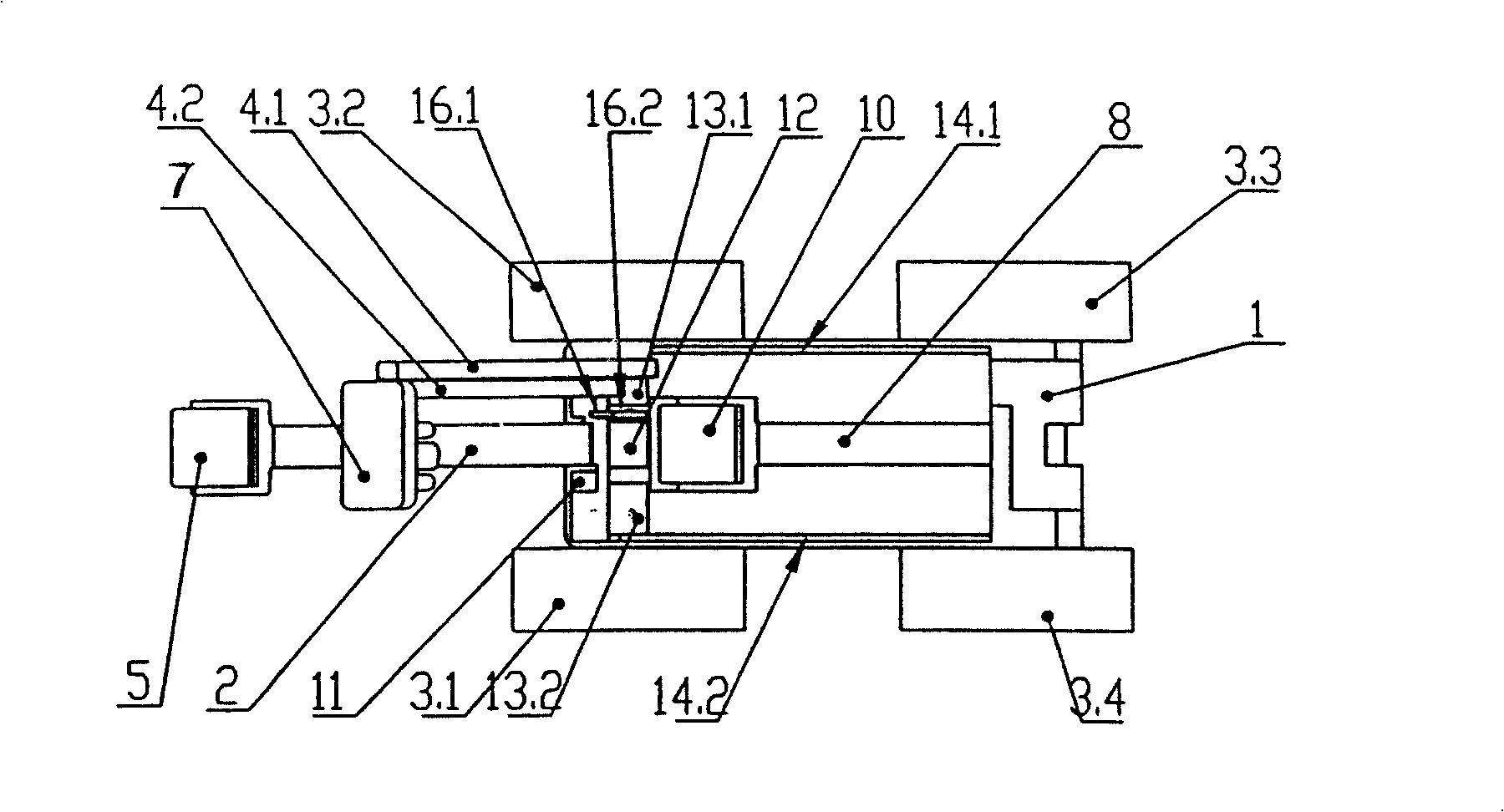

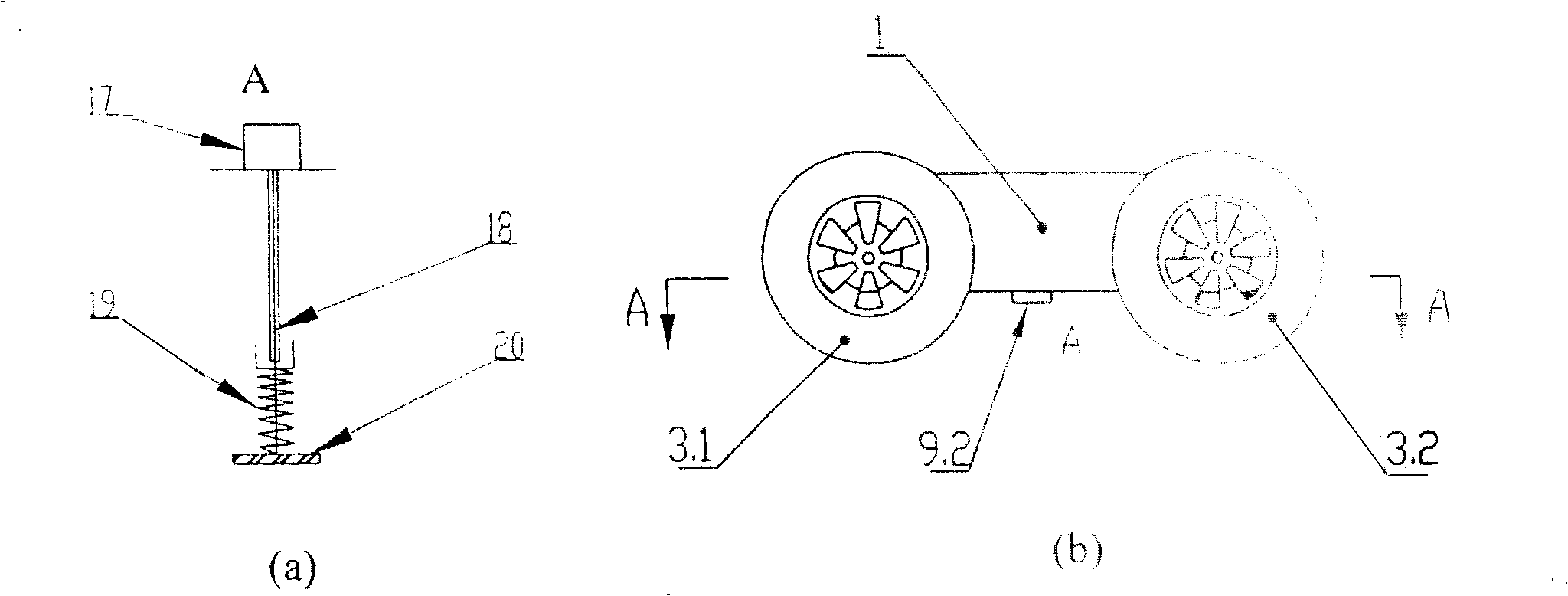

The invention relates to a wheel leg bounce movable robot, wherein it uses four-wheel body, with front and back swinging wheel legs and bounce structure. The invention combines wheel structure and leg structure, to change motion mode via different conditions. Via the back swinging wheel leg, when the robot is turnover, it can return by itself. The bottom bounce structure can fly over the obstacle; the table with CCD camera is mounted in the detecting table which can lift, to expand the view sight.

Owner:ZHEJIANG UNIV

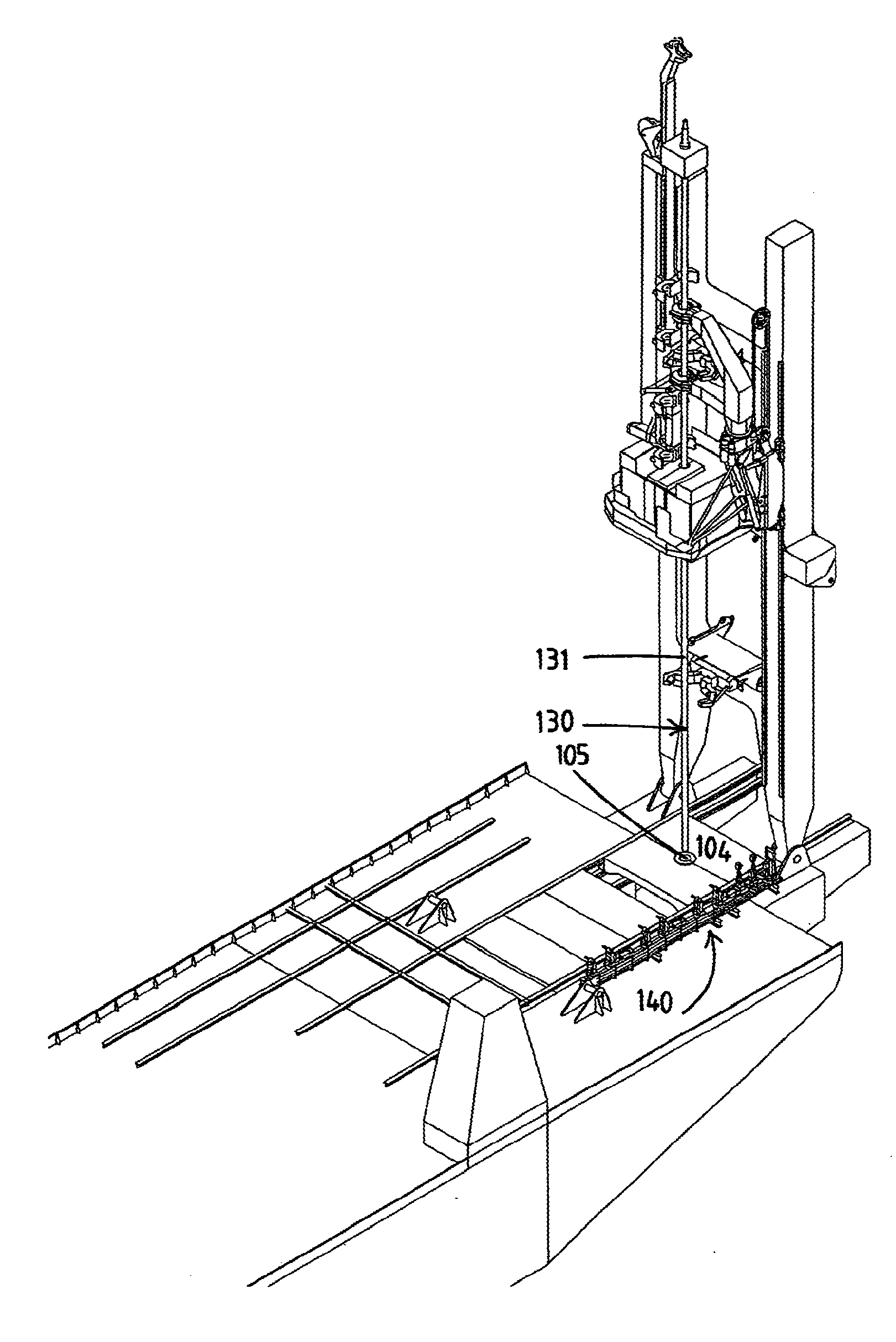

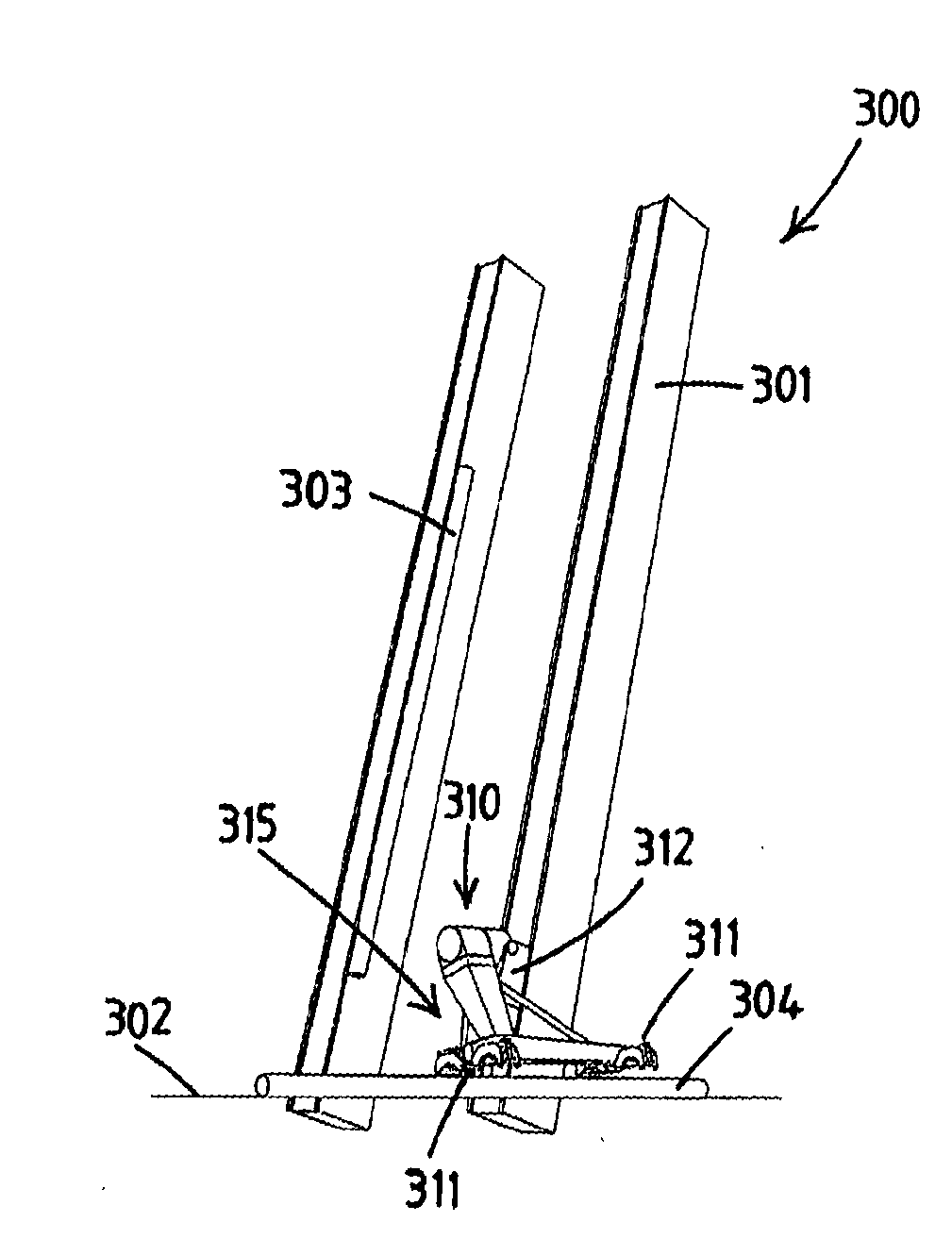

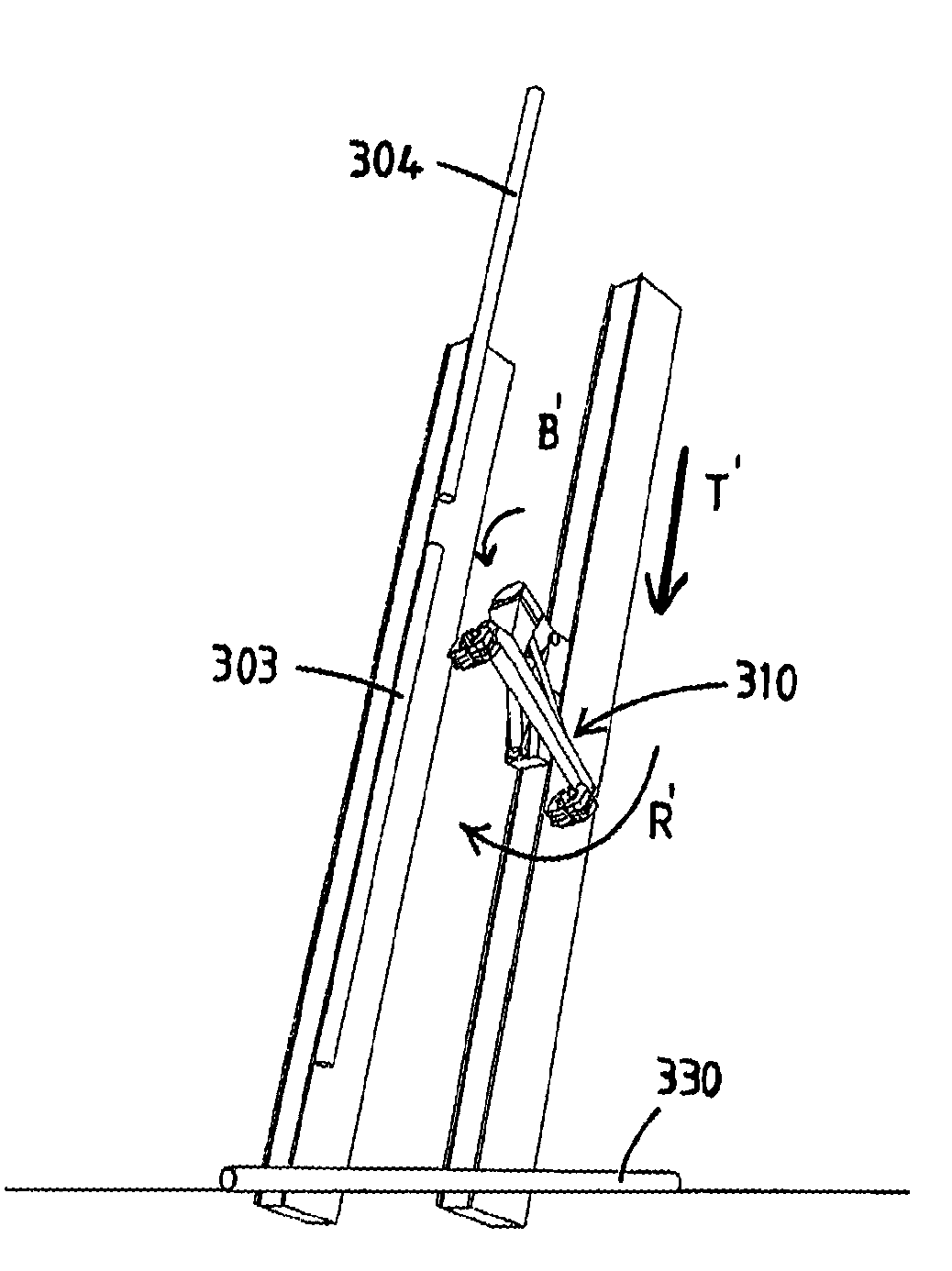

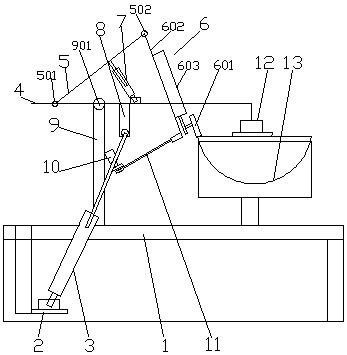

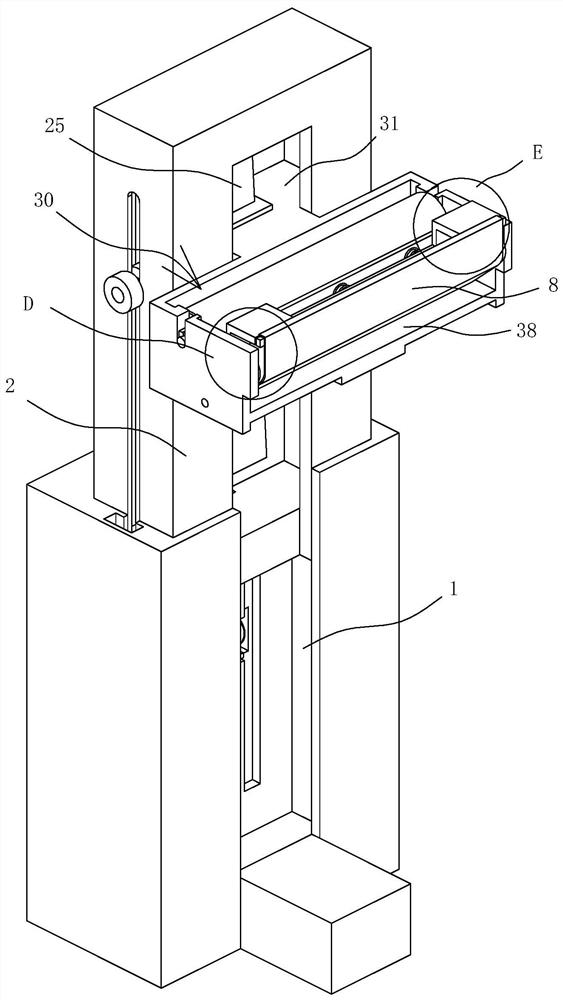

Tubular handling system and method for handling tubulars

ActiveCN102686925AEfficient methodImprove securityPipe laying and repairDrilling rodsHandling systemTower

The present invention relates to a tubular handling system (1) comprising: -a tower (10) comprising a tubular lift device for lowering and / or raising a tubular in an essentially vertical orientation, -a support (20) for supporting the tubular-laying tower -a tubulars supply system, preferably provided on the support, for supplying tubulars to an essentially horizontal supply position in the vicinity of the tower, -a tubular handling apparatus (2) for transporting a tubular between the essentially horizontal supply position and the tubular lift device in the tower, wherein the tubular handling apparatus comprises: a gripper (4a, 4b) adapted for gripping the tubular, a base (6), and a boom (5) to which the one or more grippers are attached, which boom is pivotable with respect to the base in a boom. According to the invention, the tubular handling apparatus further comprises a vertical extending frame (7), wherein said base is guided by said frame and movable in a vertical translational movement with respect to the frame.

Owner:ITREC BV

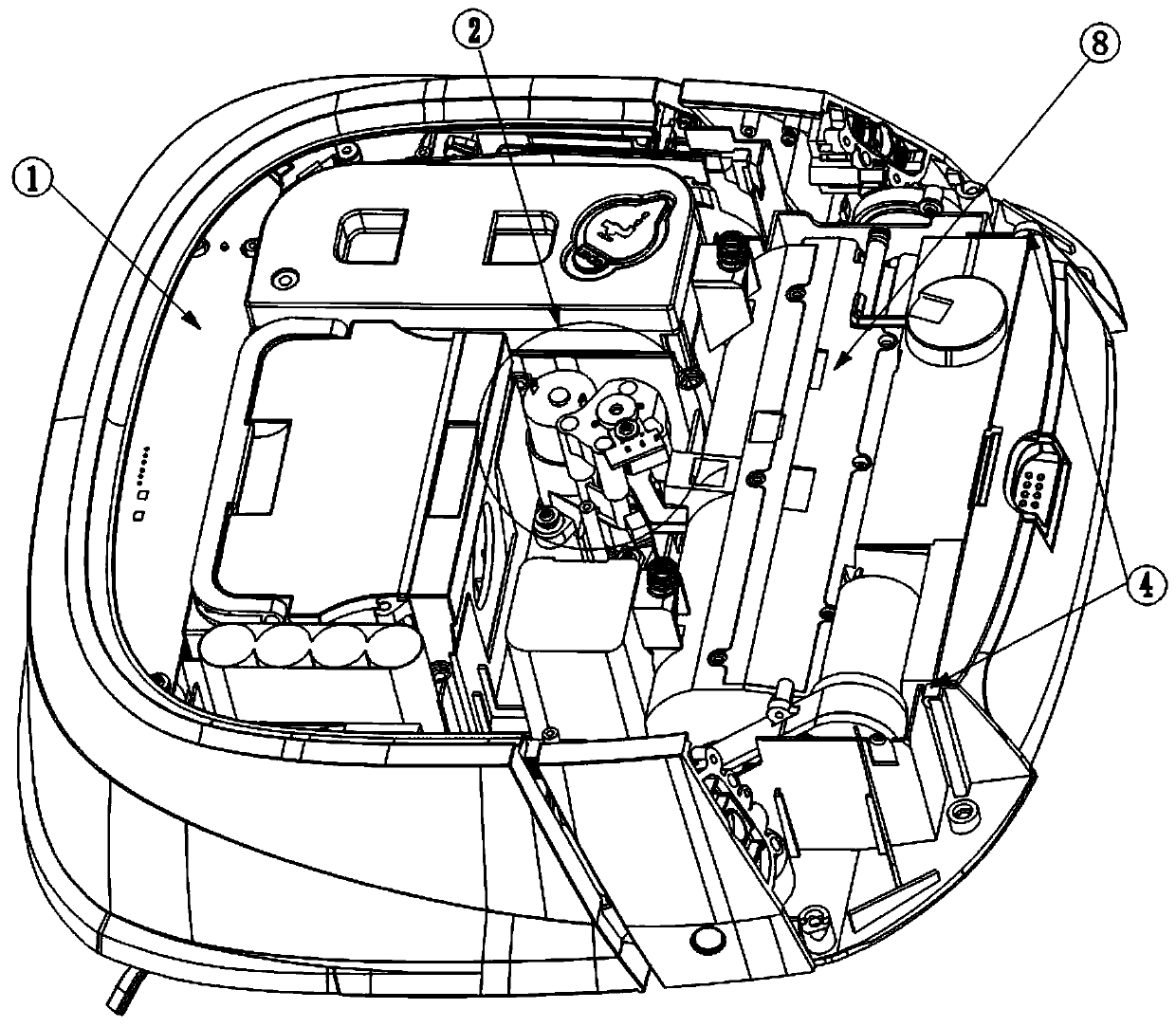

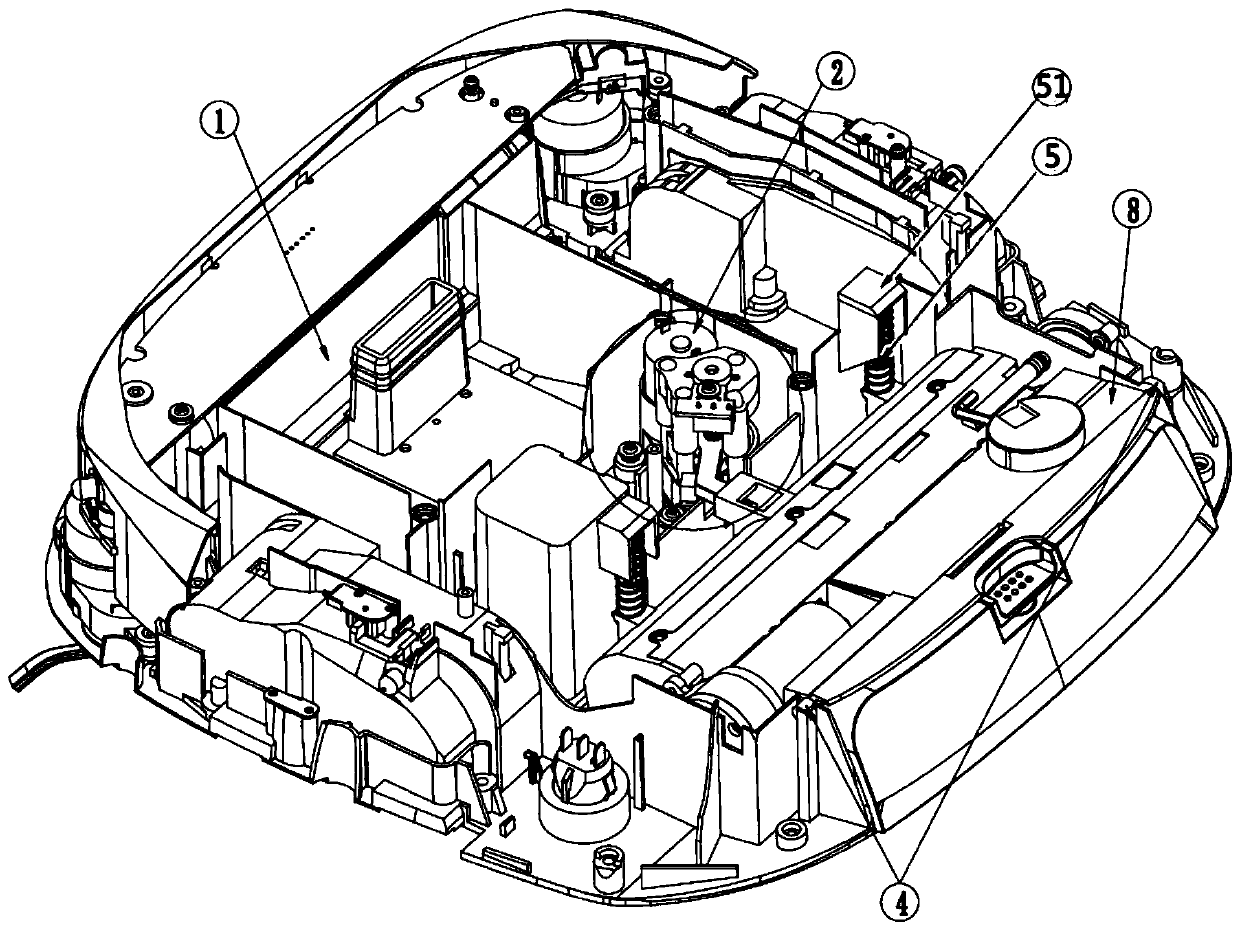

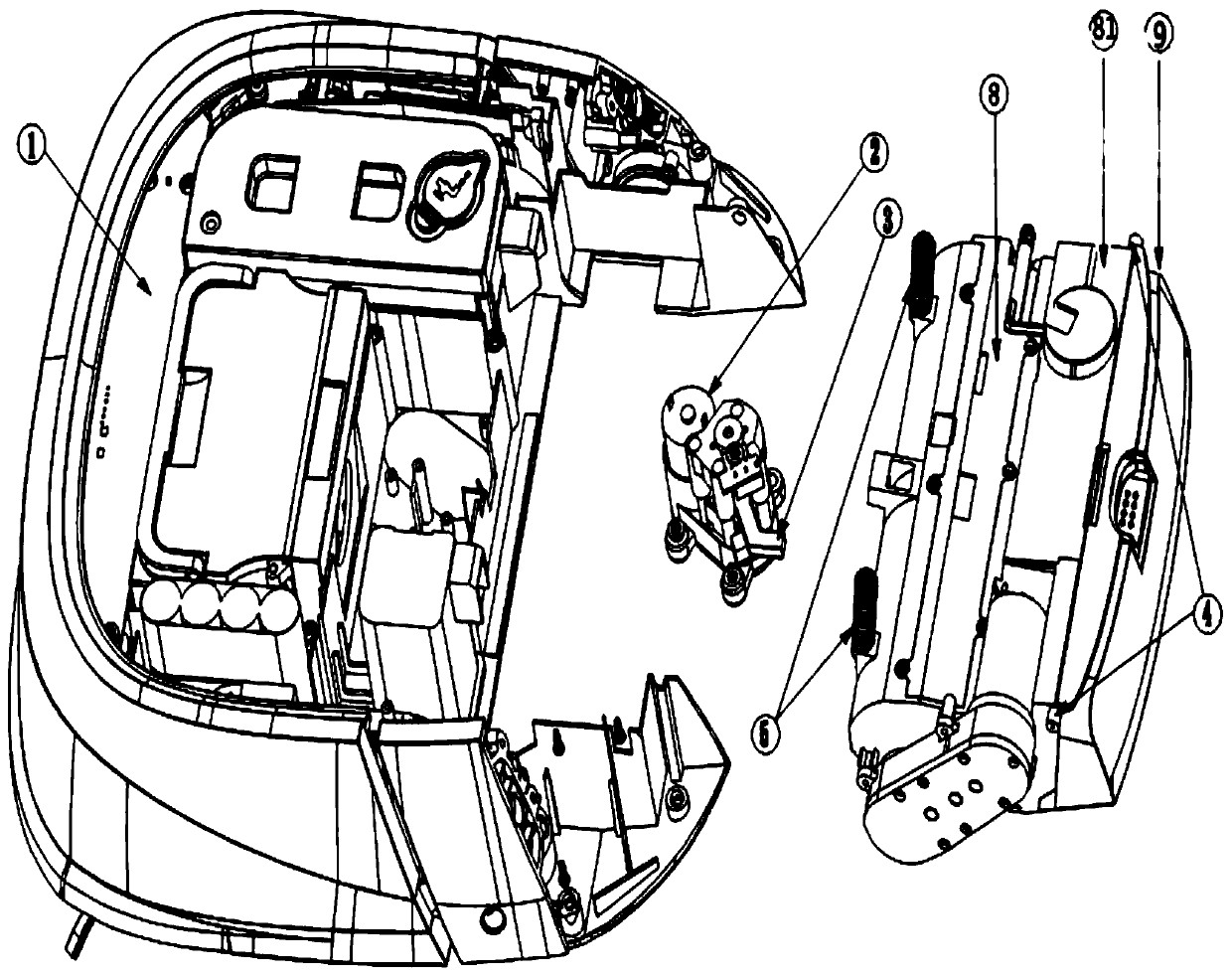

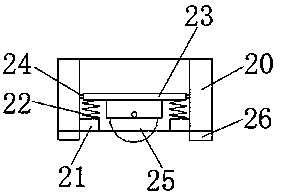

Lifting device for mopping roller of sweeping robot

PendingCN111568326AEffective beyondLightweight and fast operationCarpet cleanersCleaning action controlEngineeringMechanical engineering

The invention discloses a lifting device for a floor mopping roller of a sweeping robot, which comprises a body, a cleaning device is arranged on the body, the cleaning device comprises the floor mopping roller, floor mopping rag is arranged on the floor mopping roller, a lifting device is arranged in the body, the lifting device comprises a driving device, and the driving device is connected withthe cleaning device; a roller support is arranged on the body, and the cleaning device is arranged on the roller support. The lifting device for the mopping roller of the sweeping robot is simple instructure, flexible to use, accurate in lifting control and high in automation degree.

Owner:SHENZHEN TECBOT INTELLIGENT ROBOT CO LTD

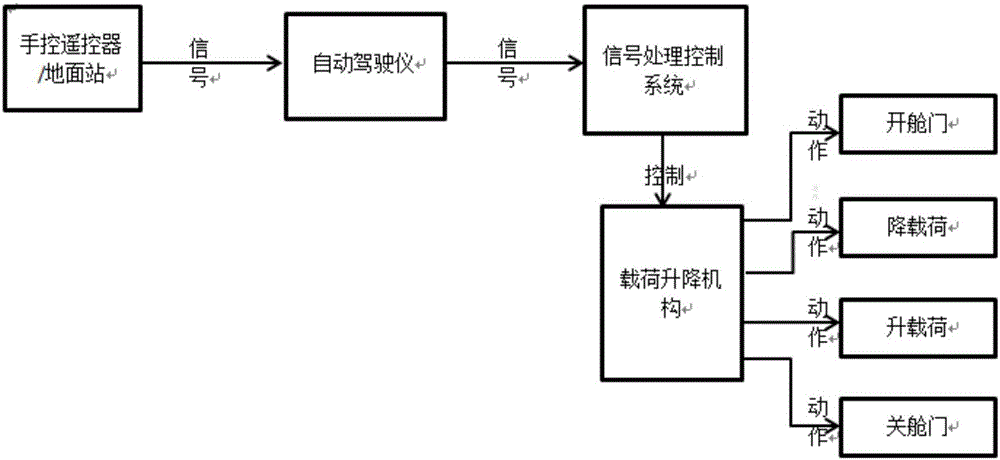

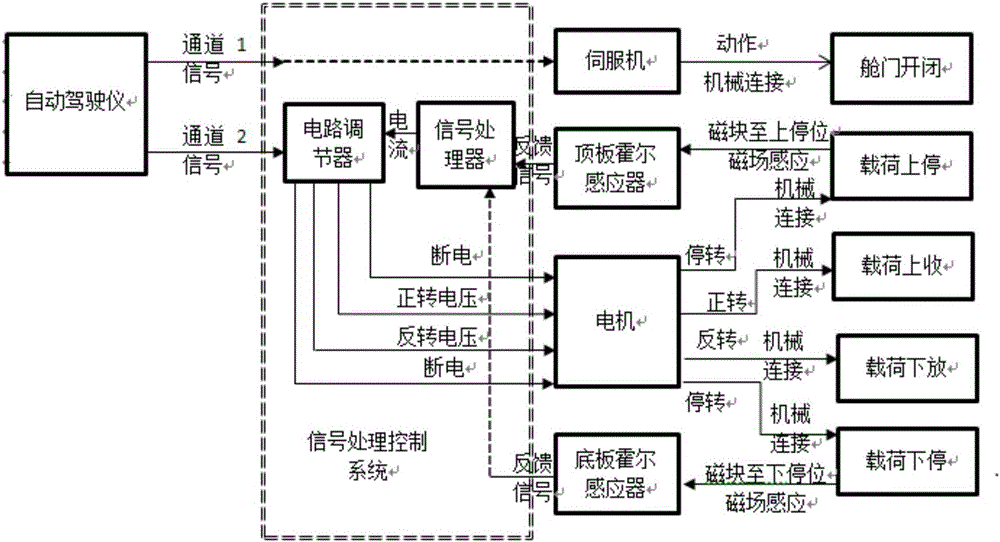

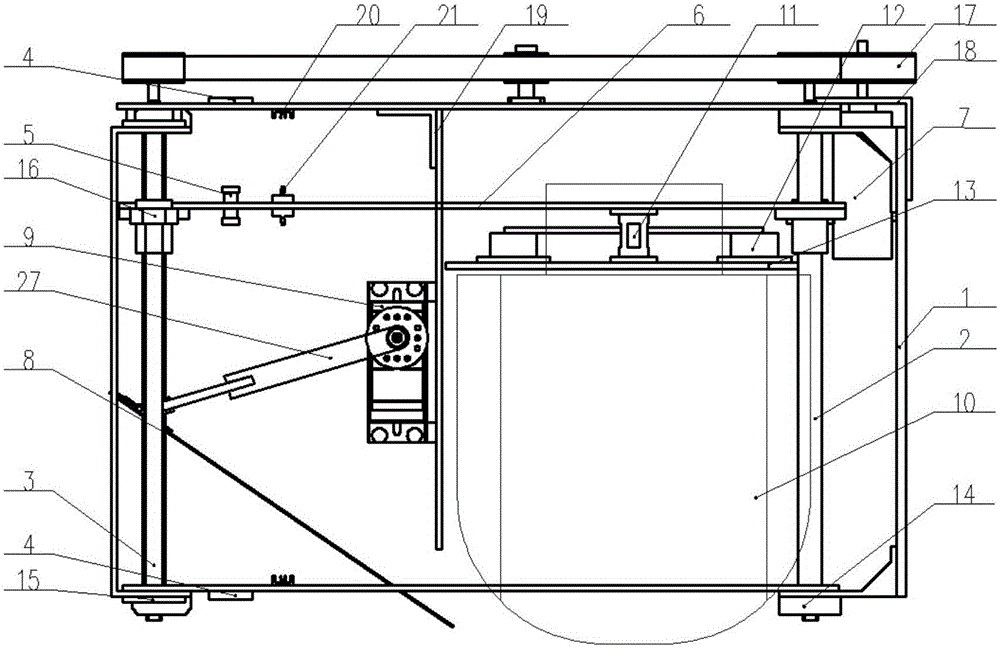

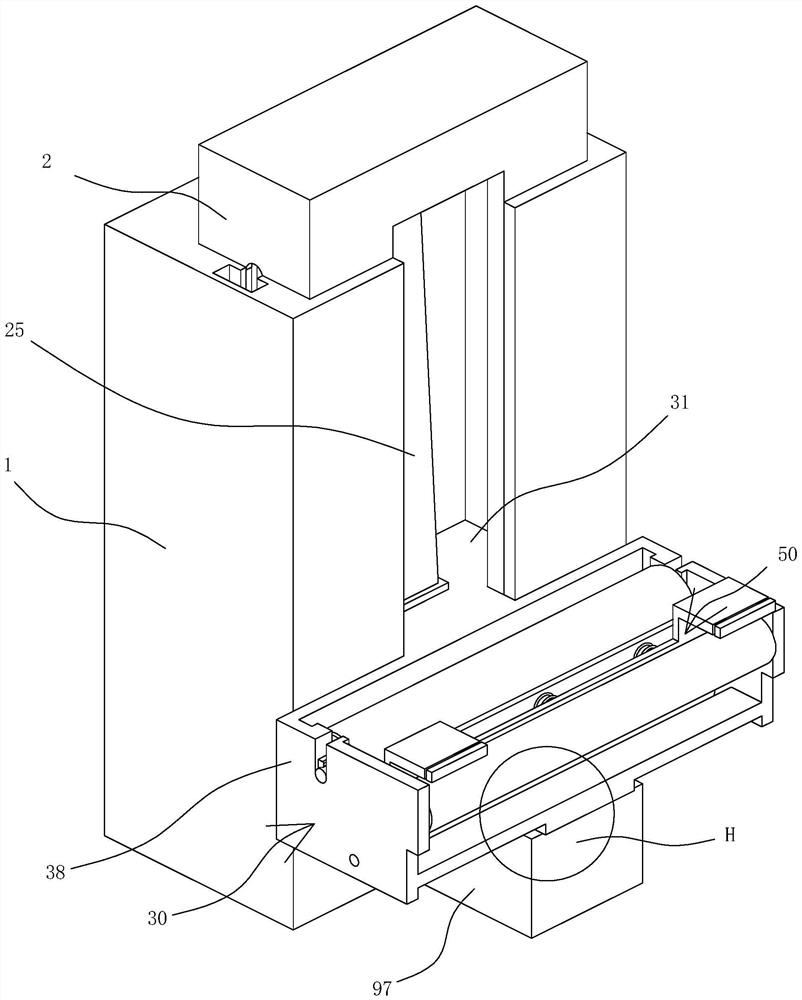

Small unmanned aerial vehicle openable-closeable cabin door load lifting mechanism

ActiveCN106005360AGuaranteed aerodynamic performanceImprove performancePower-operated mechanismFreight handlingMotor driveBall screw drive

The invention discloses an openable-closeable cabin door unmanned aerial vehicle load lifting mechanism. Ascending and descending of a platform and vertical limiting of a pod mounting plate are realized through two ball screws, vertical movement of the platform and horizontal limiting of the pod mounting plate are realized through two carbon tubes. A motor drives the ball screws to run, a synchronous wheel ensures the ball screws to move synchronously, the ball screws drive a middle mounting plate to lift and lower a task load, a servo motor controls opening and closing of a cabin door through a signal processing system, a Hall sensor and a magnetic block control a lifting mechanism to stop moving, and a lock fastener and a lock block ensure stability of the platform after working and being recycled. The task load is connected with the middle mounting plate and can be replaced at any time. By using the mechanism, closing load of the cabin door is unaffected in the process of launching and recycling an unmanned aerial vehicle, and pneumatic performance of the unmanned aerial vehicle can be ensured. The load can be replaced and mounted at any time before the unmanned aerial vehicle takes off, the mechanism is convenient, quick, small in occupied space, light in weight and economically feasible, and overall performance, safety and reliability of the unmanned aerial vehicle are improved greatly.

Owner:HIWING AVIATION GENERAL EQUIP

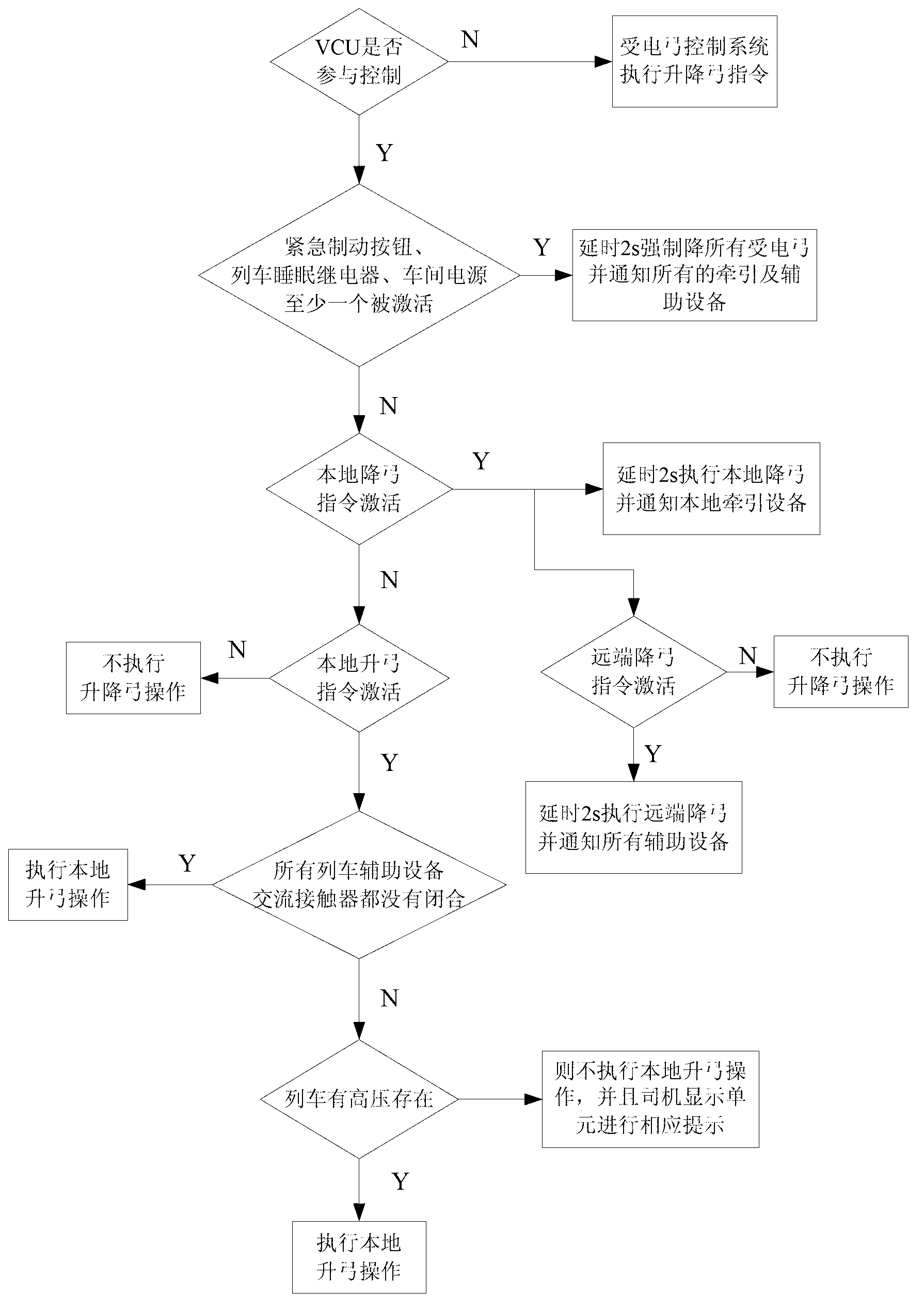

Subway train pantograph control method based on train network system

ActiveCN102910079AReduce manufacturing costReduce the hassle of wiringPower current collectorsElectricityControl system

The invention relates to a subway train pantograph control method based on a train network system. A pantograph hoisting instruction can be sent through a pantograph control switch on a driver display or a driver platform, the instruction is transmitted to a central control unit of the train network system through a driver display unit (when an operation is carried out on the driver display unit) or a remote input and output module (when the operation is carried out at the driver platform), the central control unit performs logic diagnosis by combining with states of relative system equipment and the like, and then sends a corresponding control instruction to a dragging assistant system and a pantograph control system, and then hoisting of the pantograph is controlled. By the subway train pantograph control method based on the train network system, a network system software is used for controlling the hoisting of the pantograph, manufacturing cost of a train is saved, and a trouble brought about by wiring is reduced. The subway train pantograph control method based on the train network system has the characteristics of high technical reliability, low equipment cost and simpleness in implementation and the like.

Owner:CRRC NANJING PUZHEN CO LTD

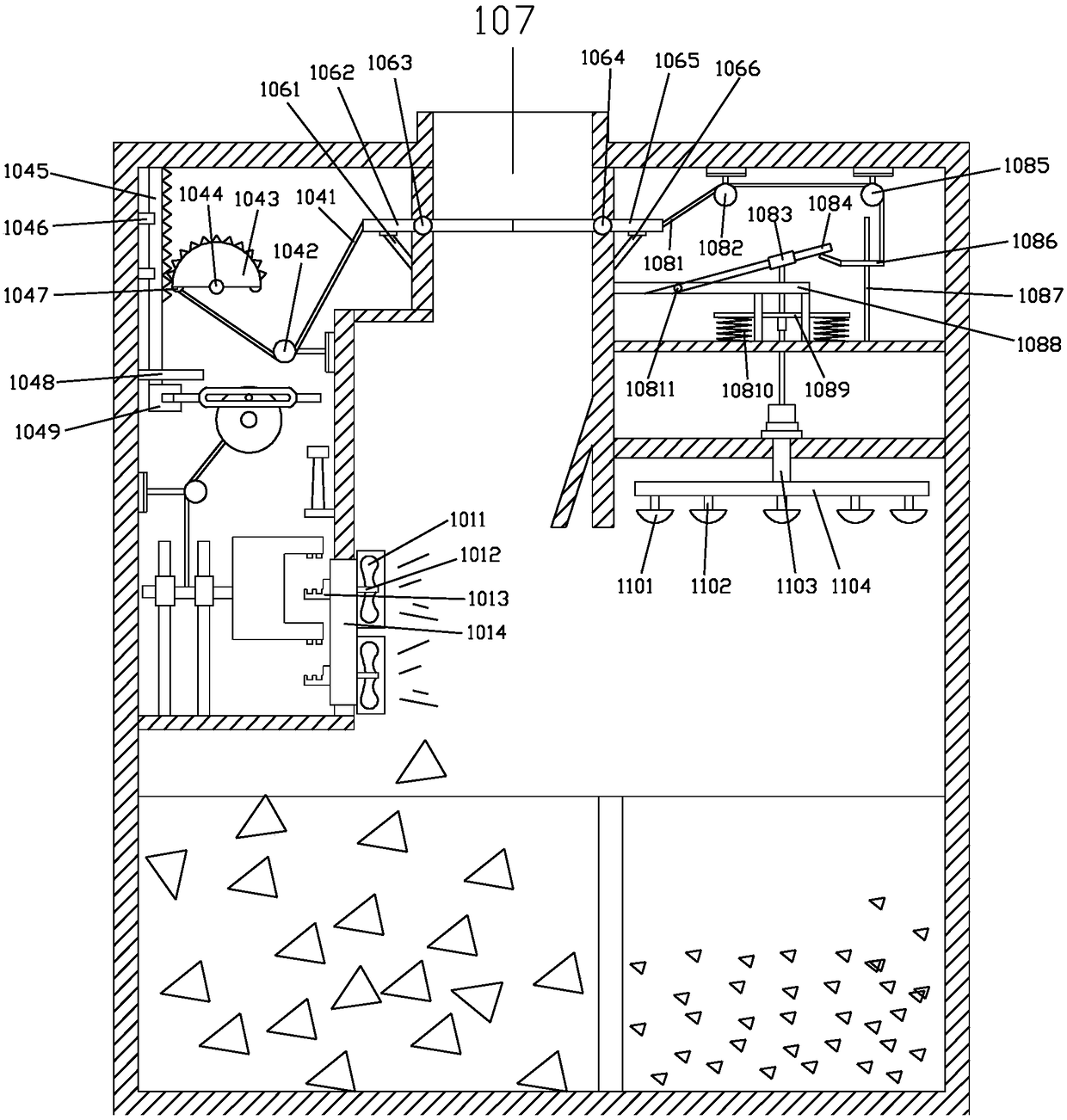

Dustbin buried underground

The invention discloses a dustbin buried underground. The dustbin comprises an outer box which is buried underground, a hydraulic pushing rod driven by a hydraulic pump is arranged in the outer box, an inner box is connected to the hydraulic pushing rod, a dustbin body is arranged in the inner box in a sliding connection mode, two dustbin bases which are movably connected are arranged at the bottom of the dustbin body, a cover plate is further connected to the inner box, the opening of the outer box can be covered with the cover plate in a sealed mode, a filter is further arranged on one side of the outer box, and a gas exhauster is arranged at the bottom of the outer box and connected with the filter through a gas exhausting pipe. The dustbin is simple in structure and convenient to use, the dustbin body can be sealed underground so that the phenomenon that harmful gas emitted by rubbish is spread into air can be reduced, the filter can be utilized for purifying and filtering the volatile harmful gas, and therefore harm of the harmful gas is further reduced.

Owner:HUNAN TANGQIAO TECH DEV

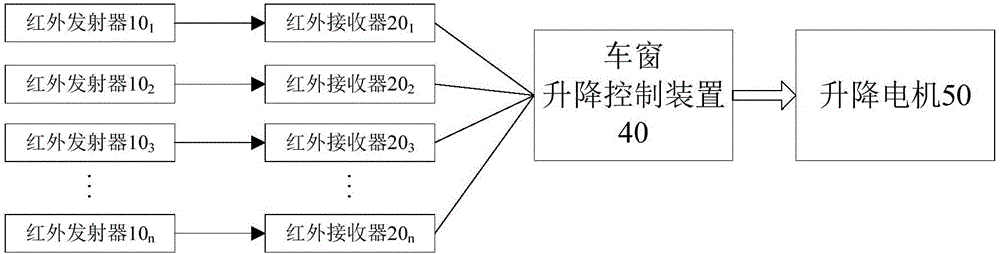

Vehicle window elevating control device, system and method

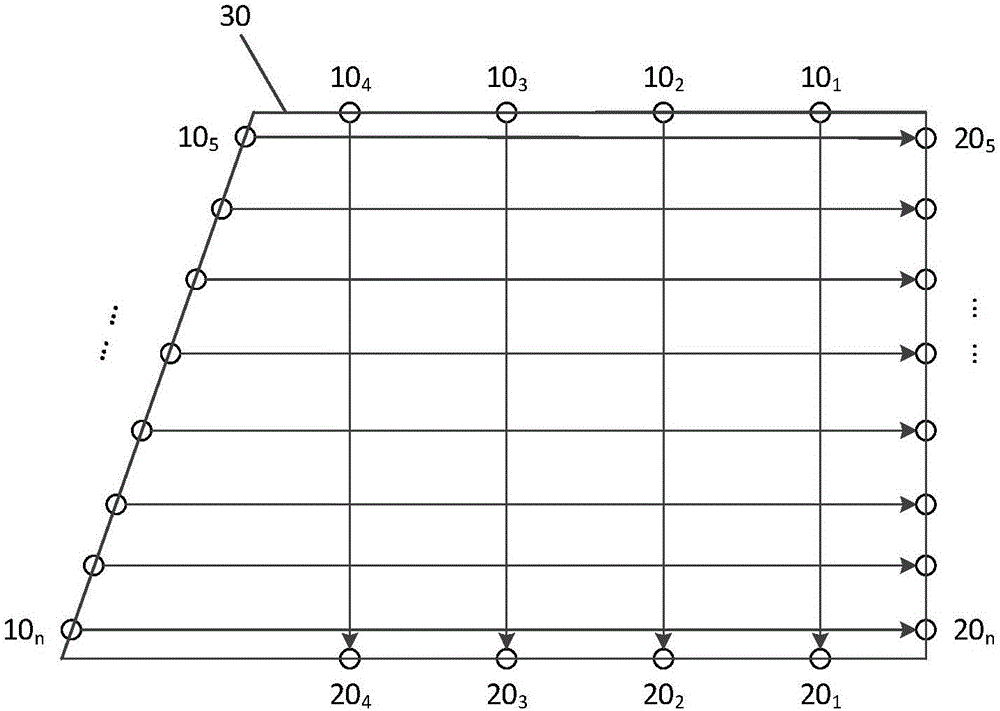

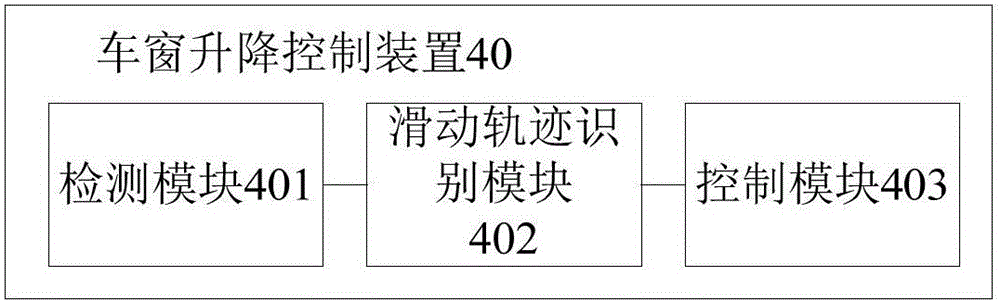

ActiveCN106382072ARealize lifting operationRealize touch operationPower-operated mechanismEngineeringInfrared emitter

The invention discloses a vehicle window elevating control device, system and method. the control device comprises a detection module configured to detect a plurality pairs of infrared emitters and each infrared receiving signal of each infrared receiver, a sliding track identification module configured to identify a sliding track of a sliding signal applied to a driver position window according to the infrared receiving signal, and a control module configured to determine a controlled vehicle window to elevate and a target position of the controlled vehicle window according to the sliding track, and to control work of an elevating motor of the controlled vehicle window according to the target position. The plurality of pairs of infrared emitters and the infrared receives are arranged on one side of the driver position facing a driving cap, and arranged along a glass door frame of the driving position vehicle window. Therefore, touch control operation of vehicle window elevating can be achieved.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Adjustable desk

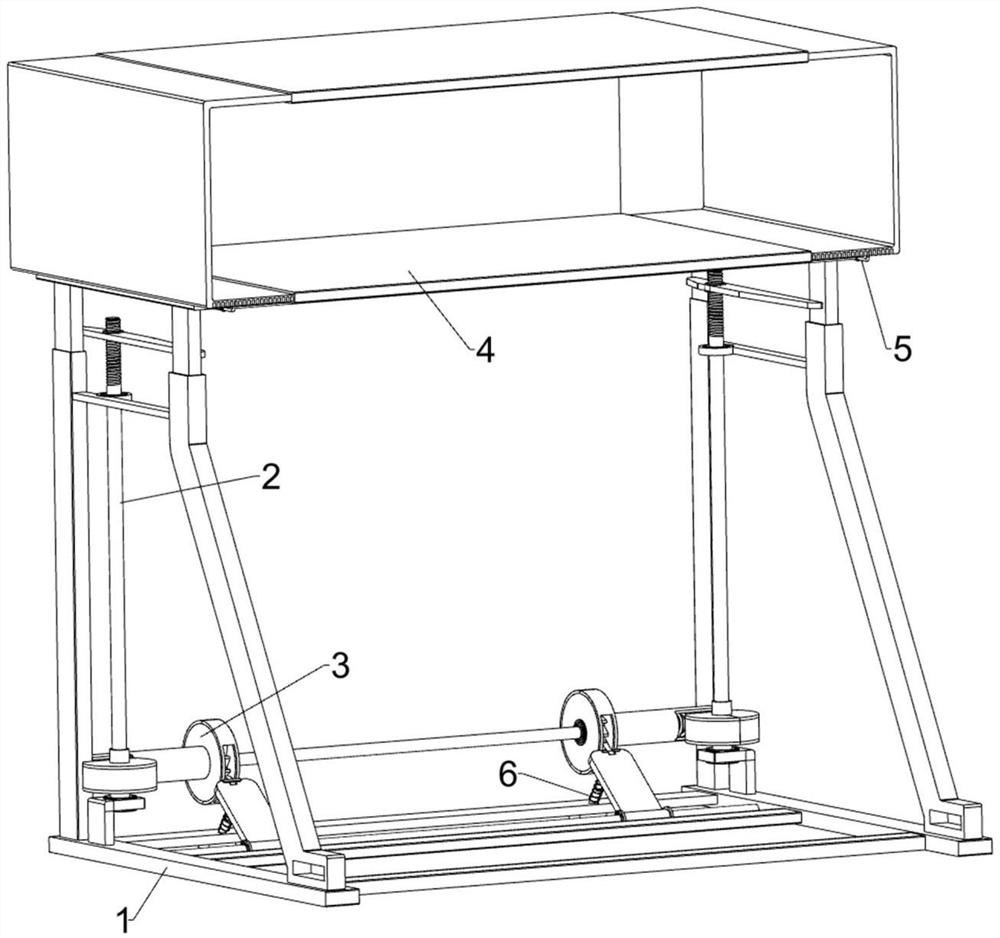

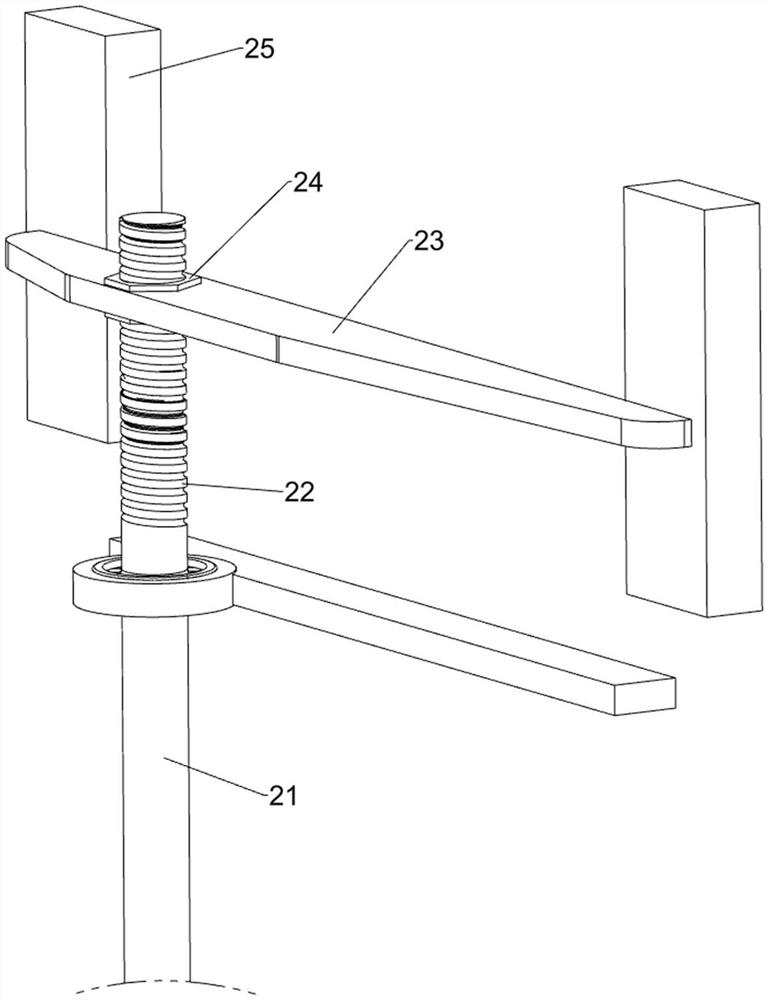

ActiveCN111789398ALift controlEasy to operateExtensible tablesSchool benchesElectrical and Electronics engineeringControl theory

The invention relates to a desk, in particular to an adjustable desk. According to the adjustable desk, the height can be adjusted, the operation is easy, and the space can be adjusted. The adjustabledesk comprises lifting components, power components and a space adjusting assembly, wherein the lifting components are installed at two sides of the supporting legs; the power components are installed on two sides of the supporting legs and are matched with the lifting components; and the space adjusting assembly is mounted on the supporting legs. The desk is provided with the lifting componentsso as to control lifting of the desk; the operation is easy, and only the rotating plates on the left side and the right side need to be stepped with feet; the desk is provided with the space adjusting assembly, so that the space in the desk can be controlled; the space in the desk can be increased when many books exist; and the space in the desk can be controlled to be decreased when too large desk space is not needed. The desk is provided with the stabilizing assembly, so that the desk is prevented from toppling over due to unstable supporting of the supporting legs caused by excessive stepping force.

Owner:北京日出天沐家具(深州)有限责任公司

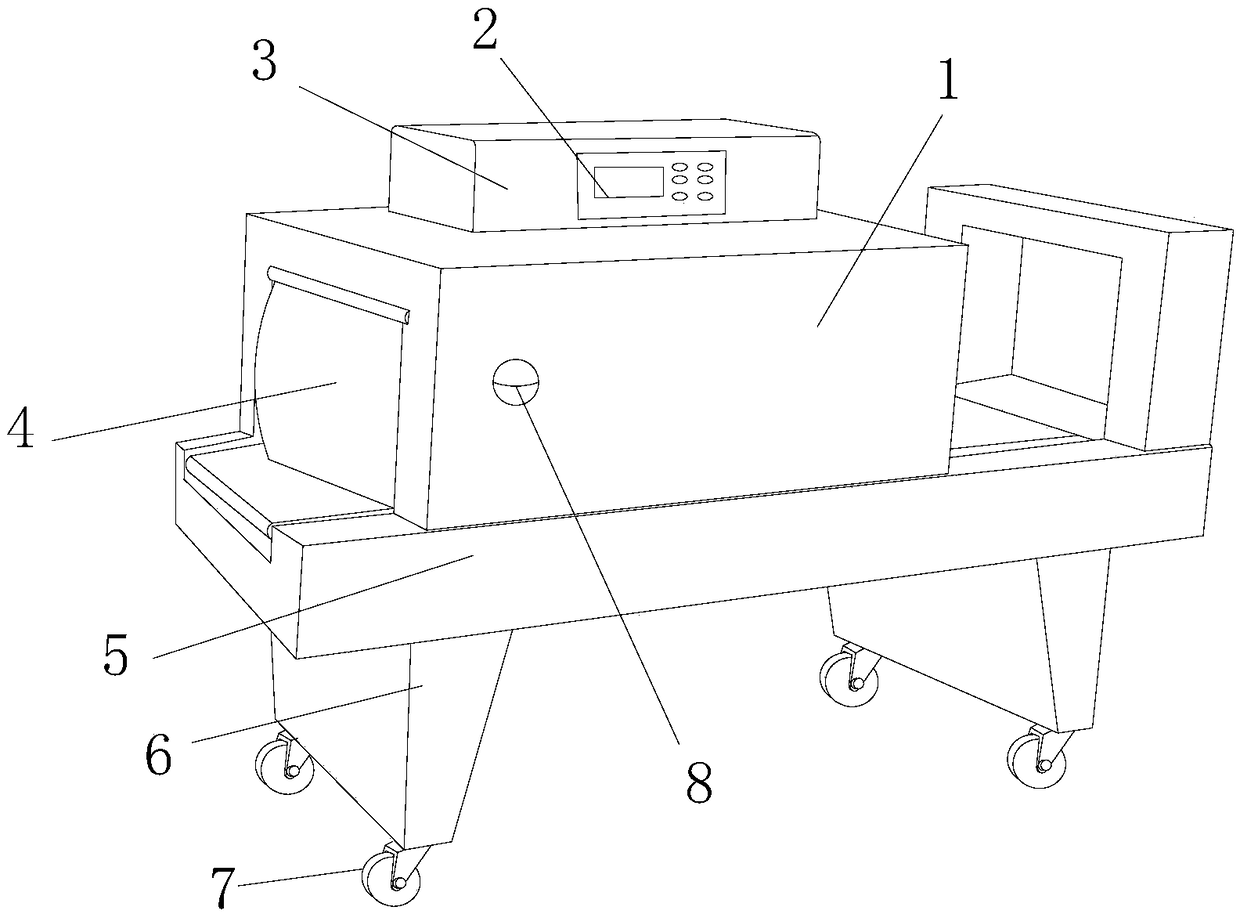

Automatic hair-mounting device for paint brush head

InactiveCN109171174AReduce work intensityImprove work efficiencyBrush bodiesBristleBristleEngineering

The invention discloses an automatic hair-mounting device for a paint brush head. The structure of the automatic hair-mounting device for a paint brush head comprises an integrated quick hair sortingdevice, a control panel, a control cabinet, a dust belt, a body, a support Frame, mobile wheels, a power indicator, wherein the integrated quick hair-splitting device is installed inside that body; the bottom of both ends of the body is fixedly connected with the top of the support frame; the movable wheels are sequentially connected into a rectangular structure and arranged at the bottom of the support frame; the back of the power indicator is fixedly connected with the front side of the left end of the body; the bottom of the control cabinet is vertically connected with the top of the body;the side of the control panel is embedded in the front side of the control cabinet; the left end of the machine body is provided with a dust belt; and when the automatic hair-mounting device for a paint brush head is used, the same thickness and shape of the wool installed on the paint brush head can be quickly sorted, so that not only the working intensity of the staff can be reduced, but also the working efficiency of the equipment can be improved, and the quality of the automatic bristle loading of the paint brush head can be improved.

Owner:刘培珠

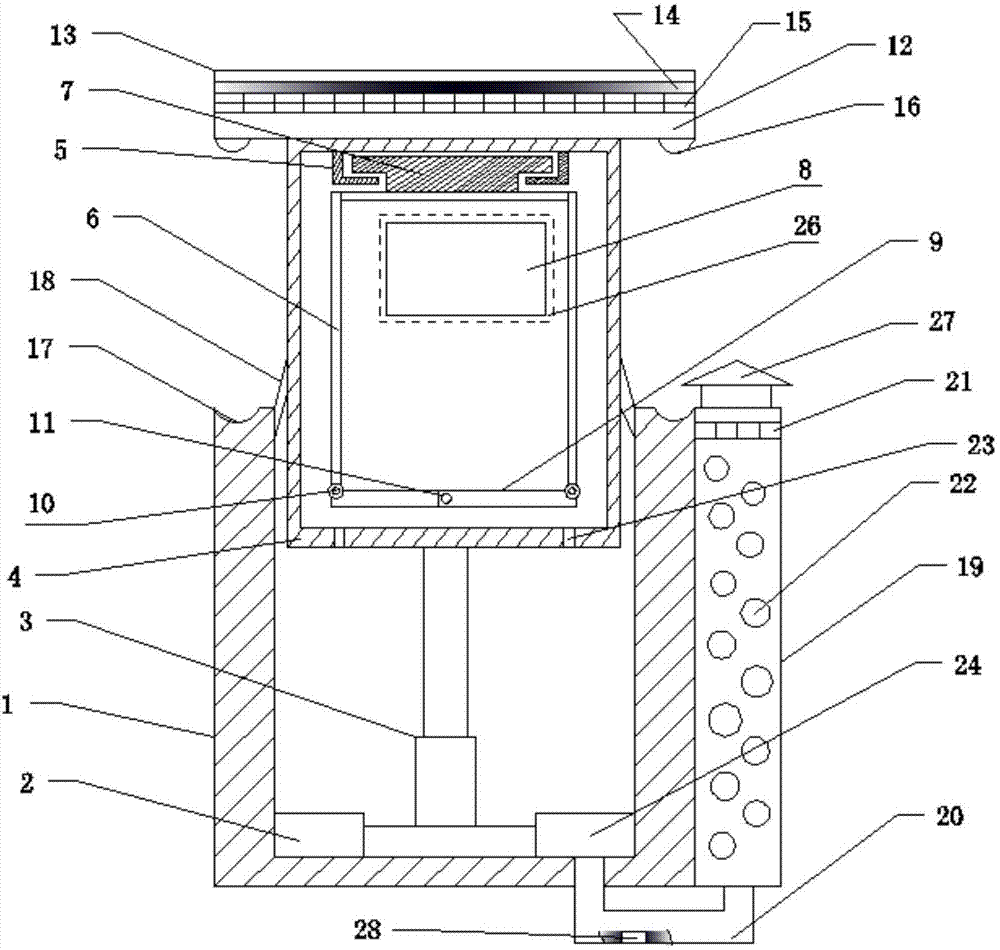

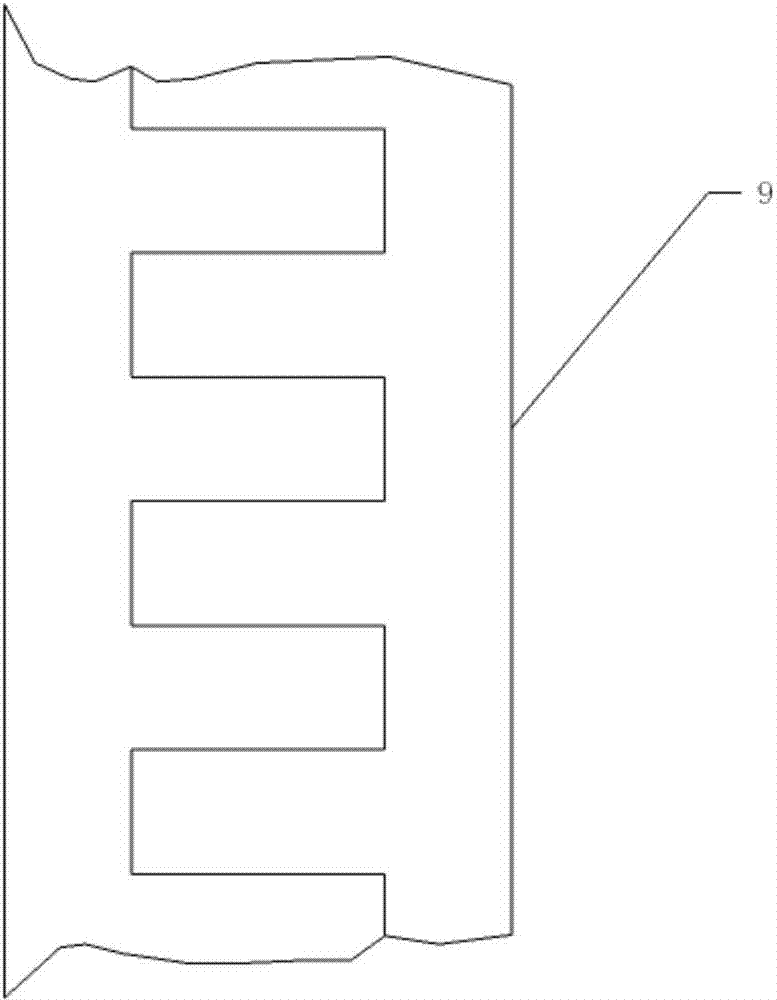

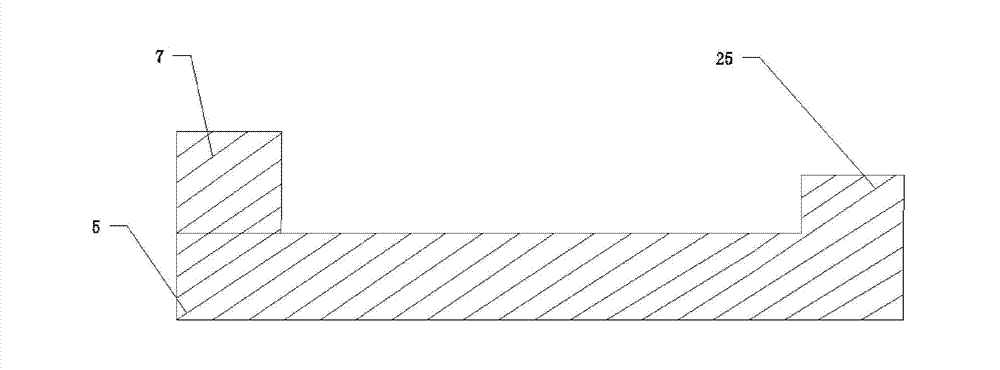

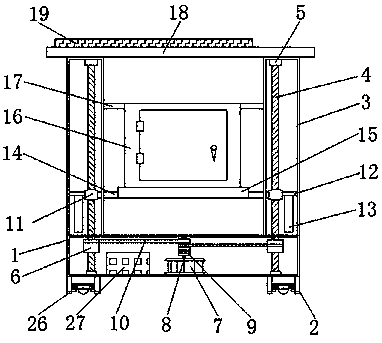

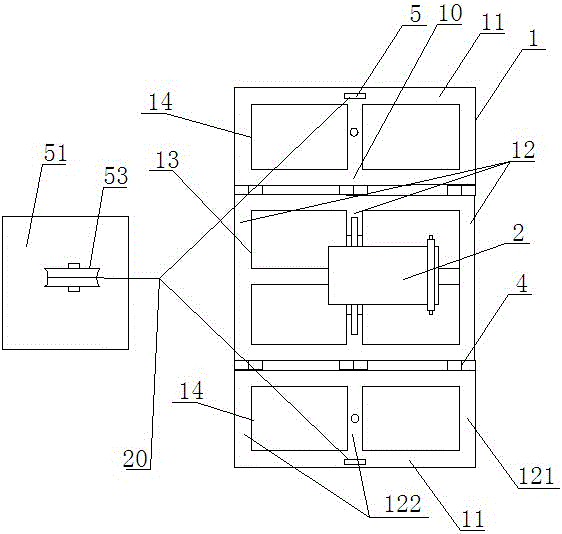

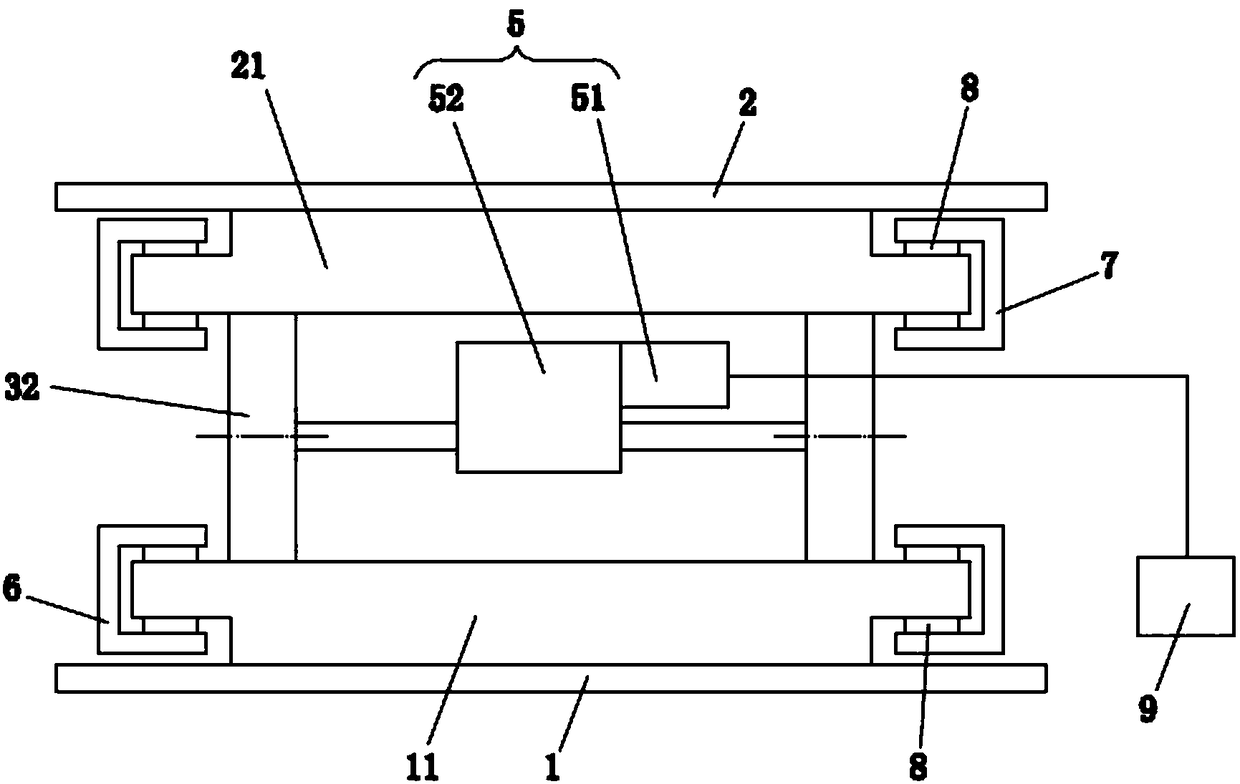

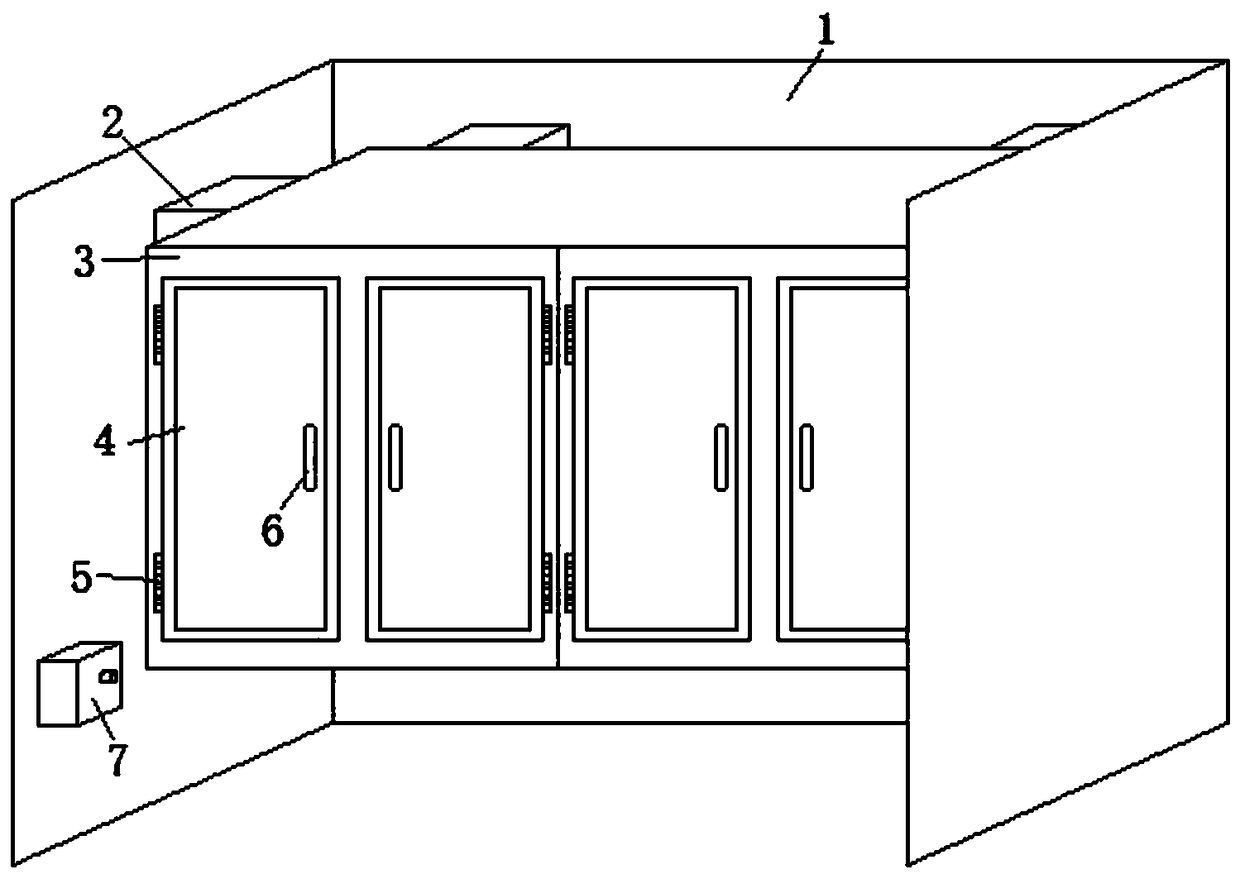

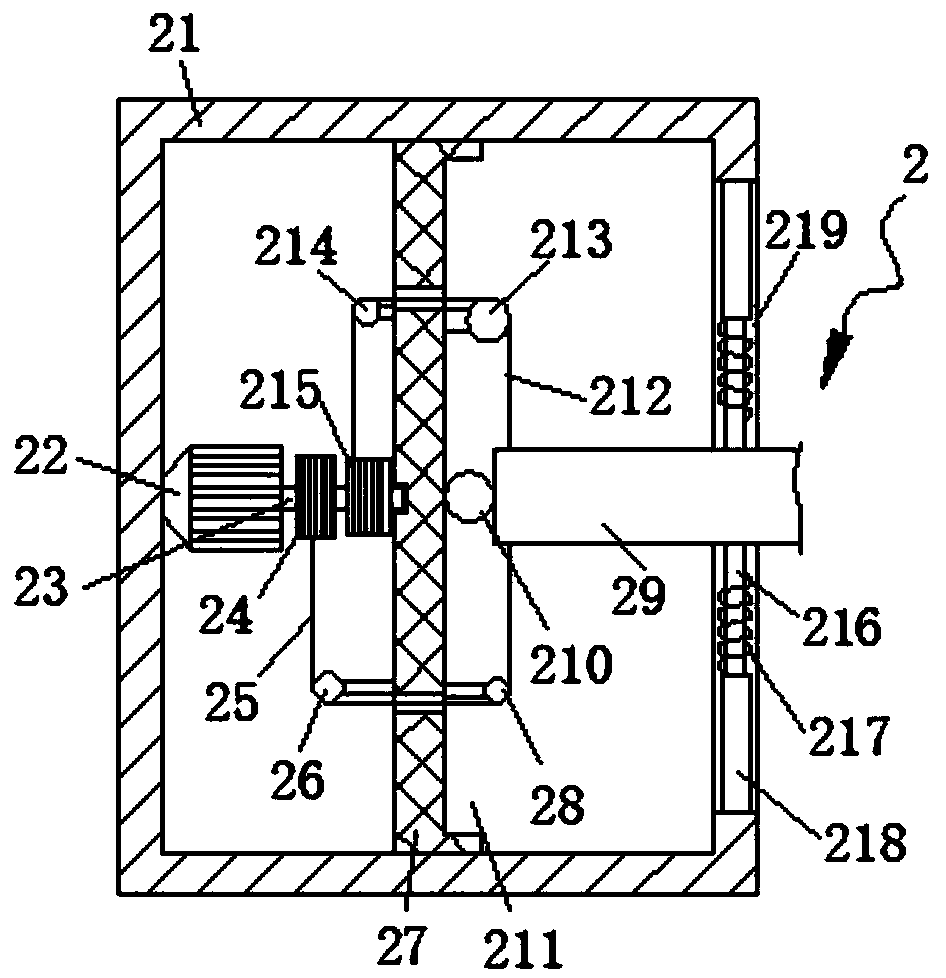

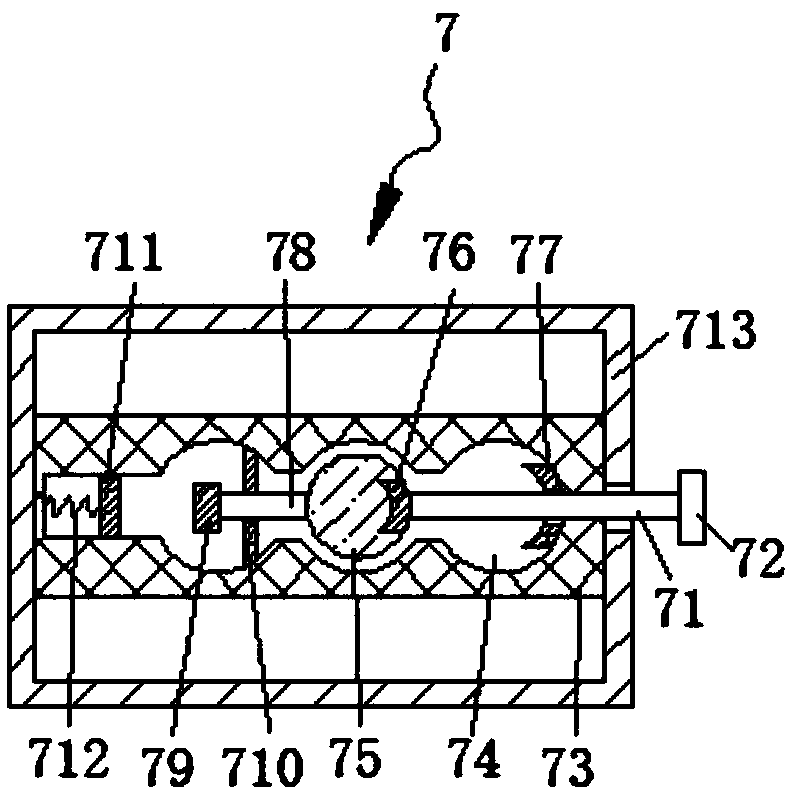

Outdoor lifting switch cabinet

InactiveCN109787107ALift controlWith mobile functionSubstation/switching arrangement casingsAnti-seismic devicesRubber ringDrive wheel

The invention provides an outdoor lifting switch cabinet, comprising a base, wherein a moving piece is fixedly arranged at the bottom of the base, a rubber ring is adhered to the bottom of the movingpiece, the top of the base is welded with the bottom of a side box, the top of the side box is welded with the bottom of a top plate, a photovoltaic panel is fixedly arranged at the top of the top plate, a motor and a storage battery are fixedly arranged at the top of the inner wall of the base, the storage battery is electrically connected with the motor and the photovoltaic panel, and the motoris electrically connected with an external control panel. According to the outdoor lifting switch cabinet, the motor drives a rotating rod to rotate, a driving wheel drives a transmission wheel to rotate through a belt, the rotation of a screw rod causes a turbine to move up and down on the outer surface of the screw rod, and a frame plate is driven to lift through a connecting rod to achieve thepurpose of controlling the lifting of the switch cabinet; and meanwhile, a compression rod is arranged, when the switch cabinet is lowered, the compression rod presses against the moving piece to press a universal wheel to contact with the ground, so that the switch cabinet has a movable function and is simple and convenient.

Owner:江苏盈裕工贸有限公司

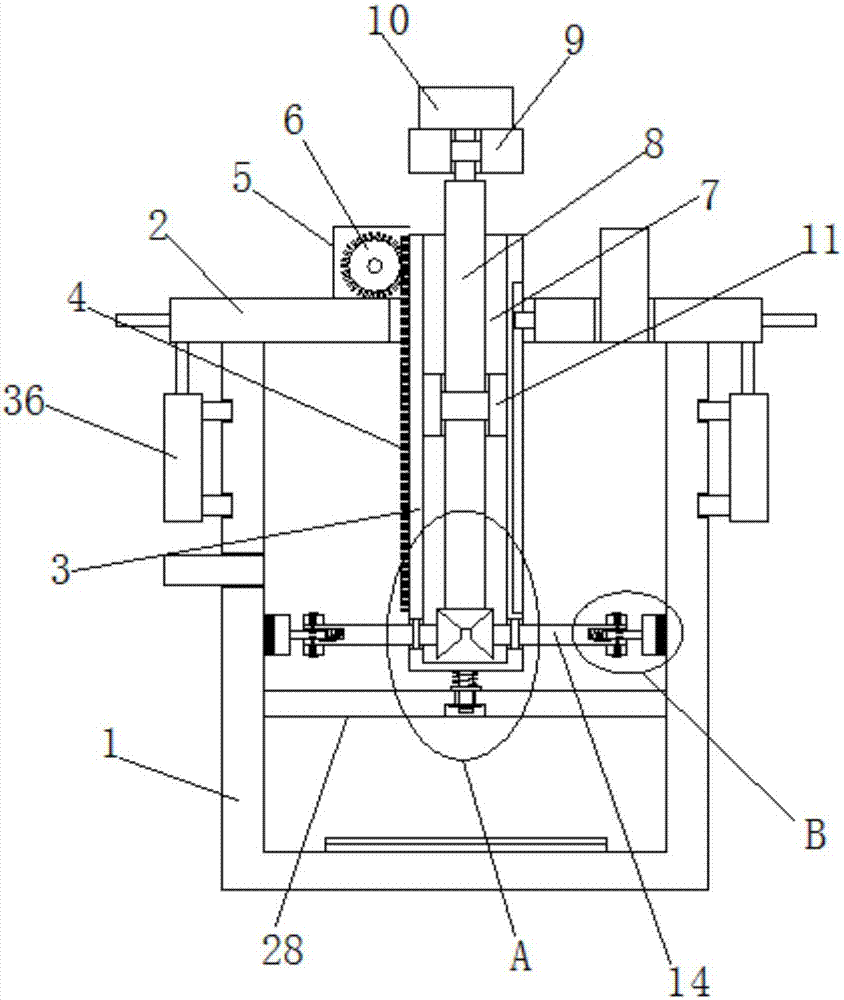

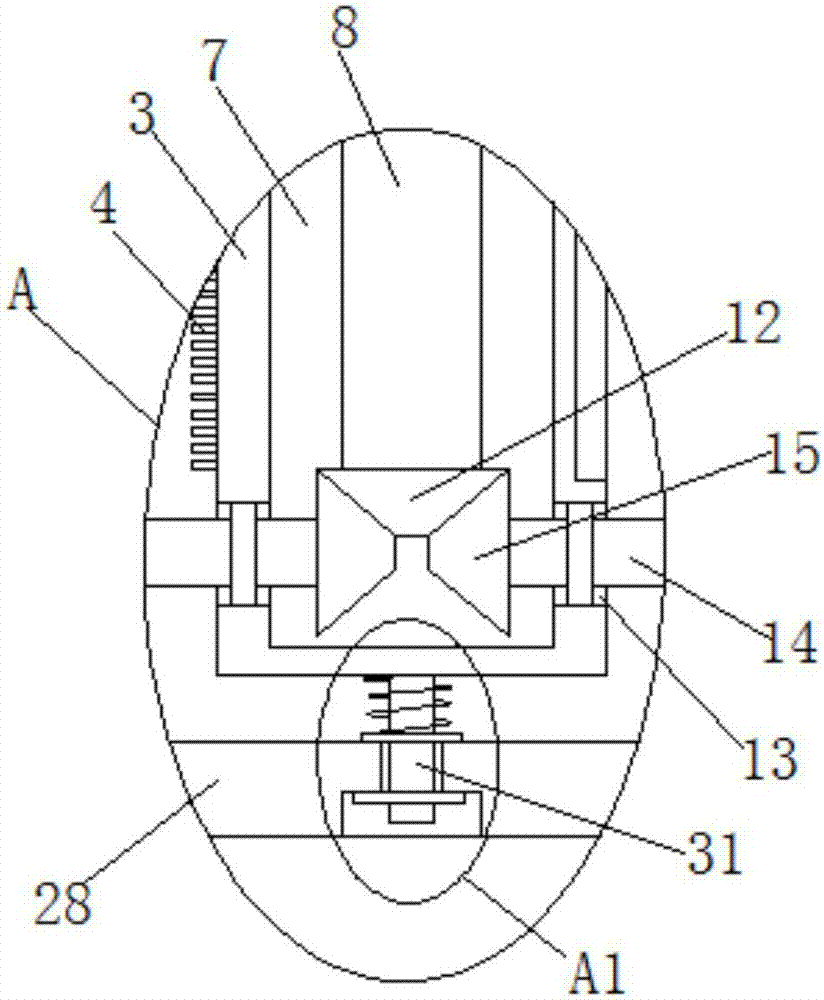

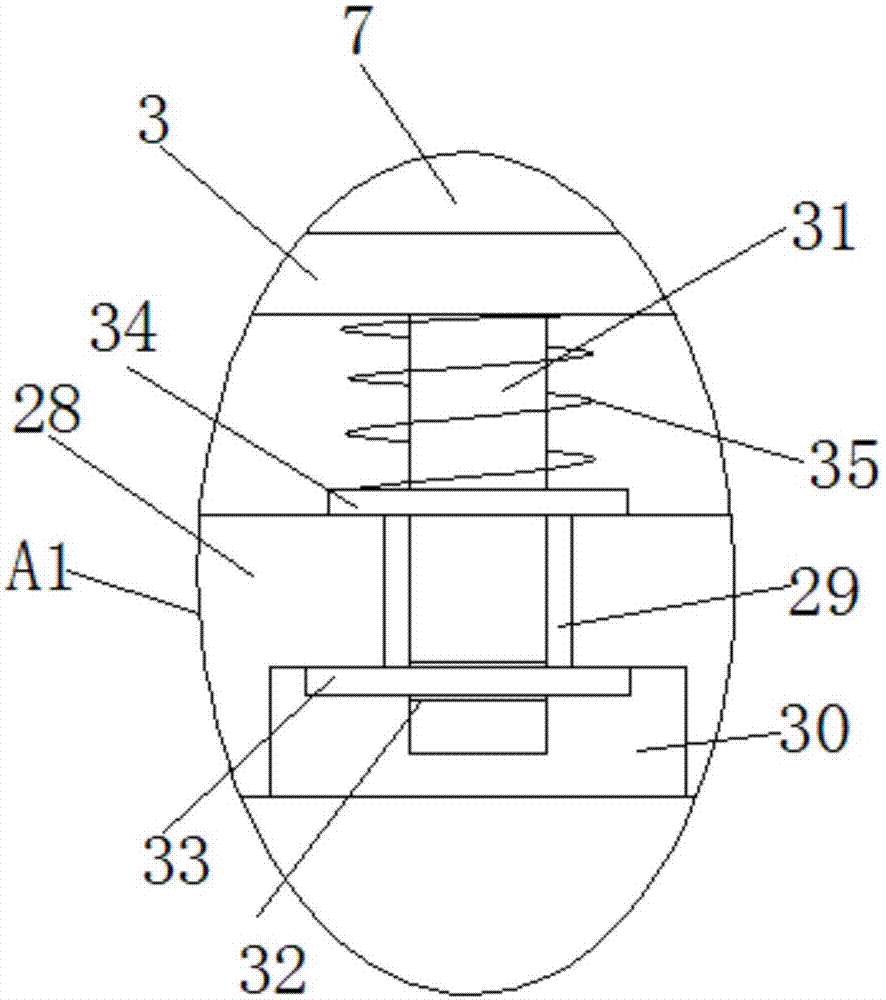

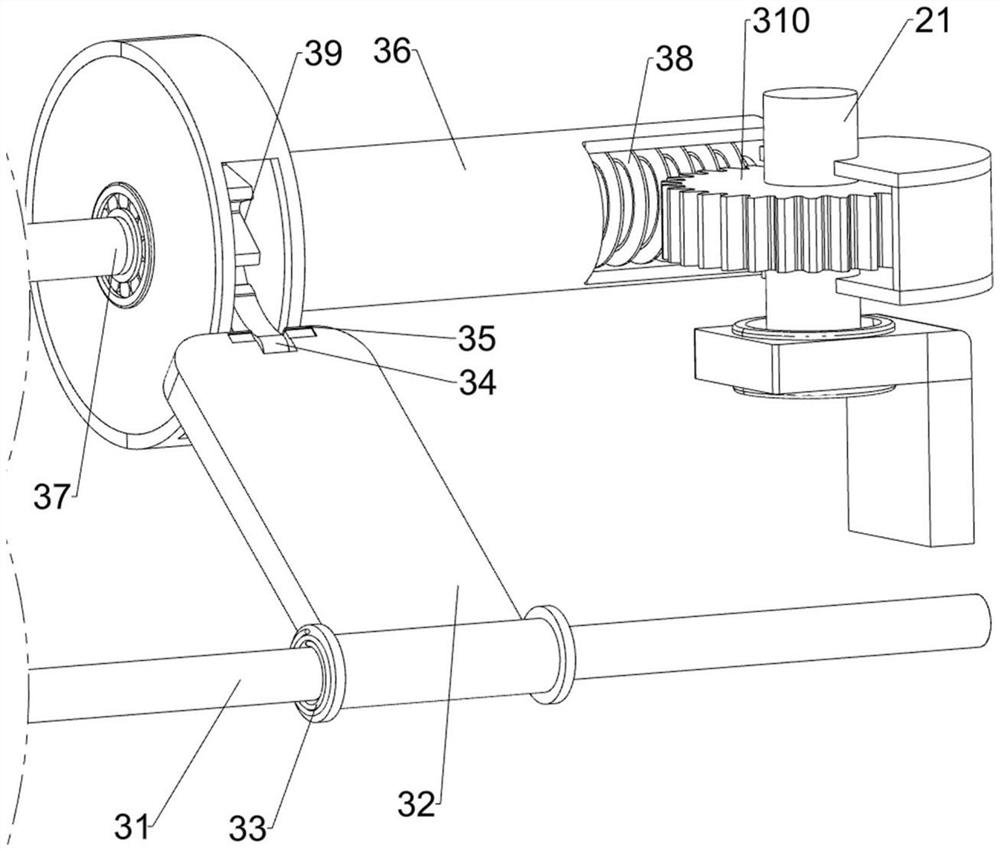

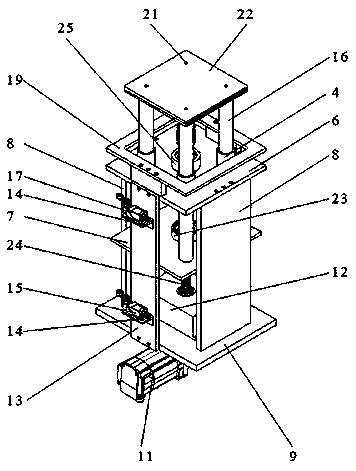

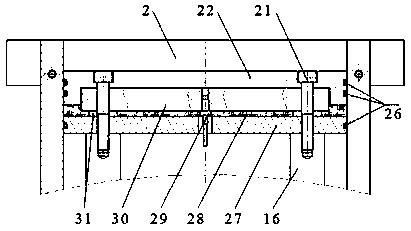

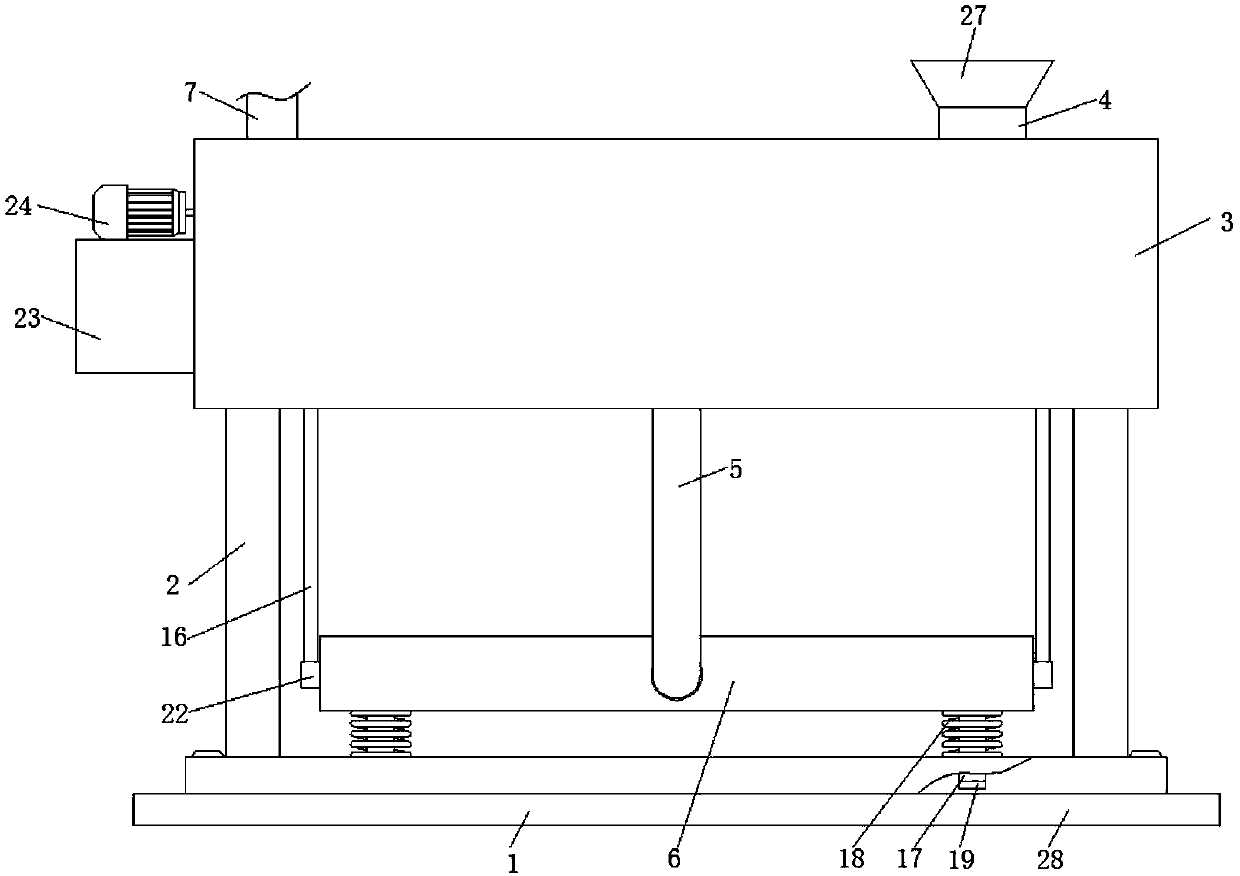

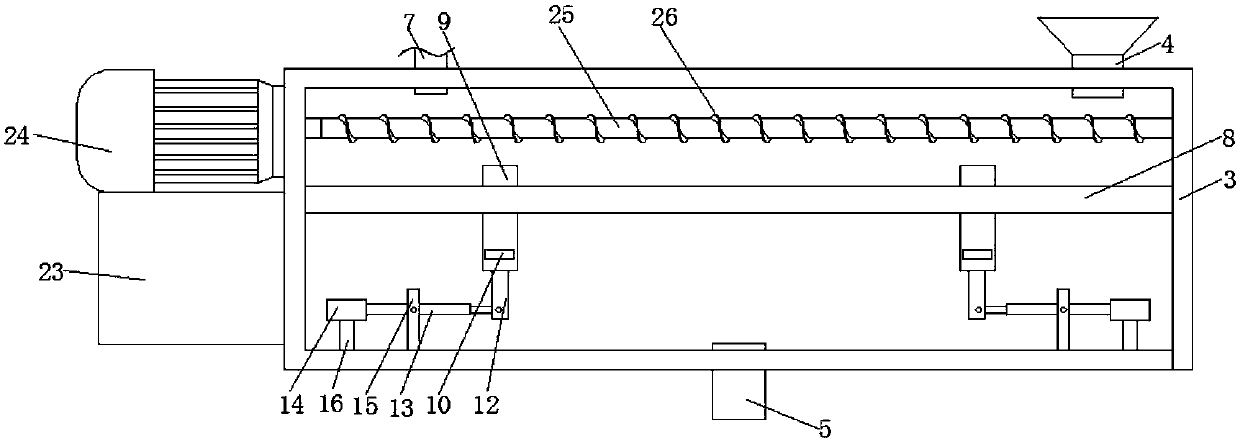

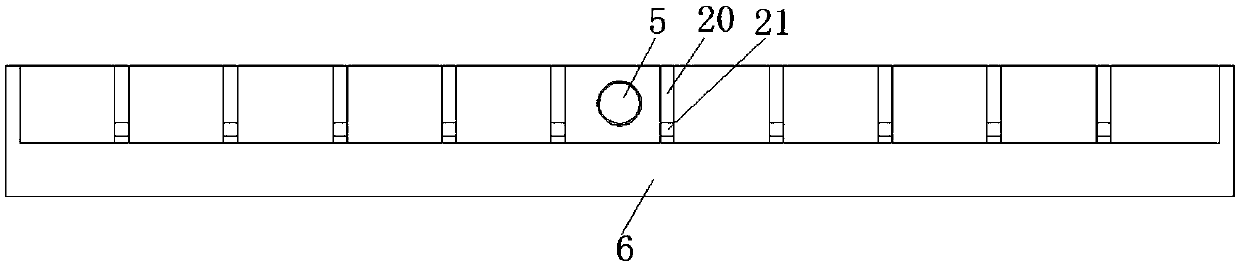

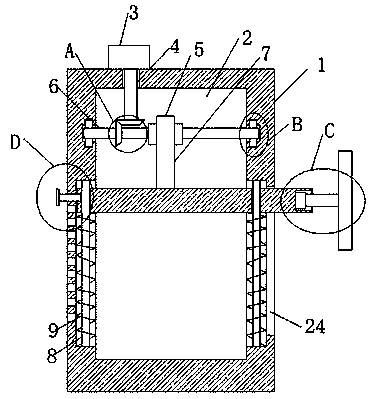

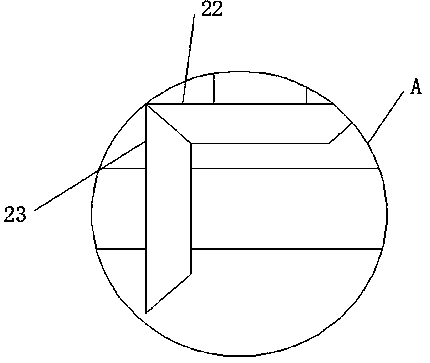

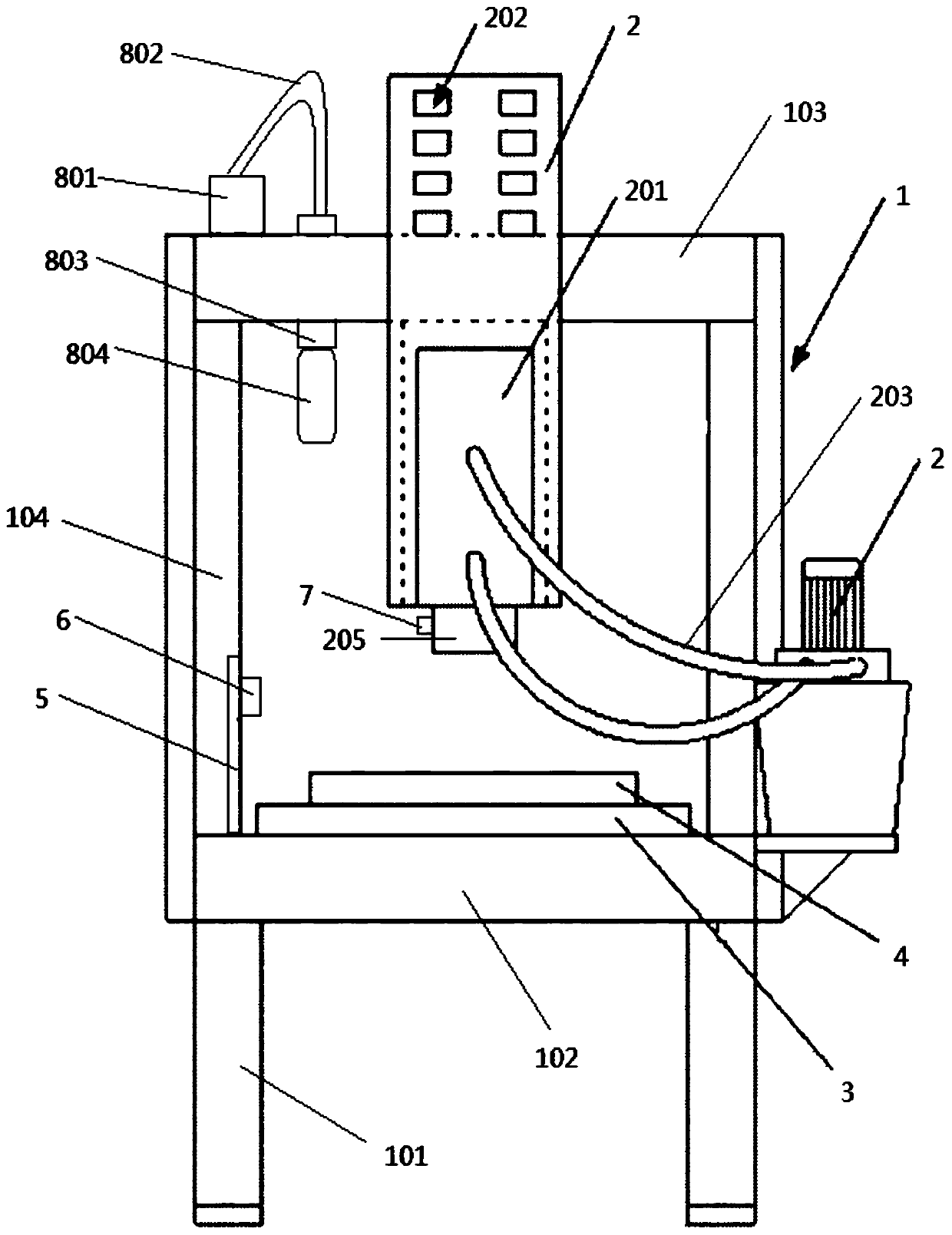

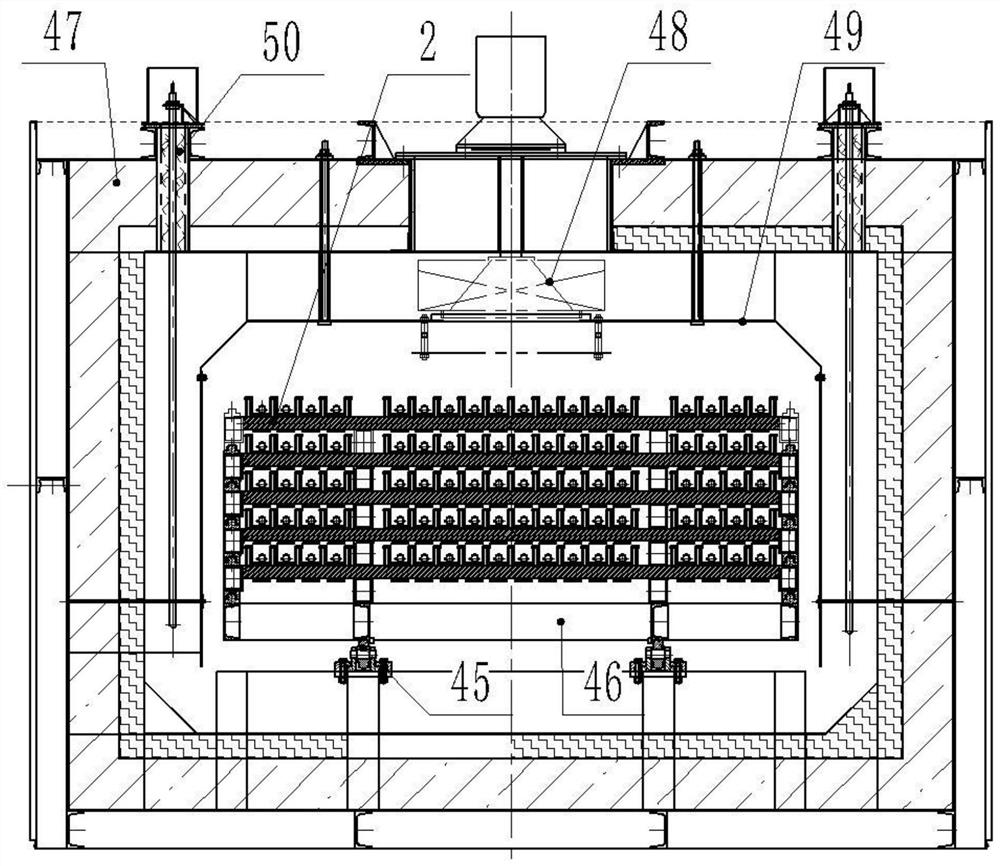

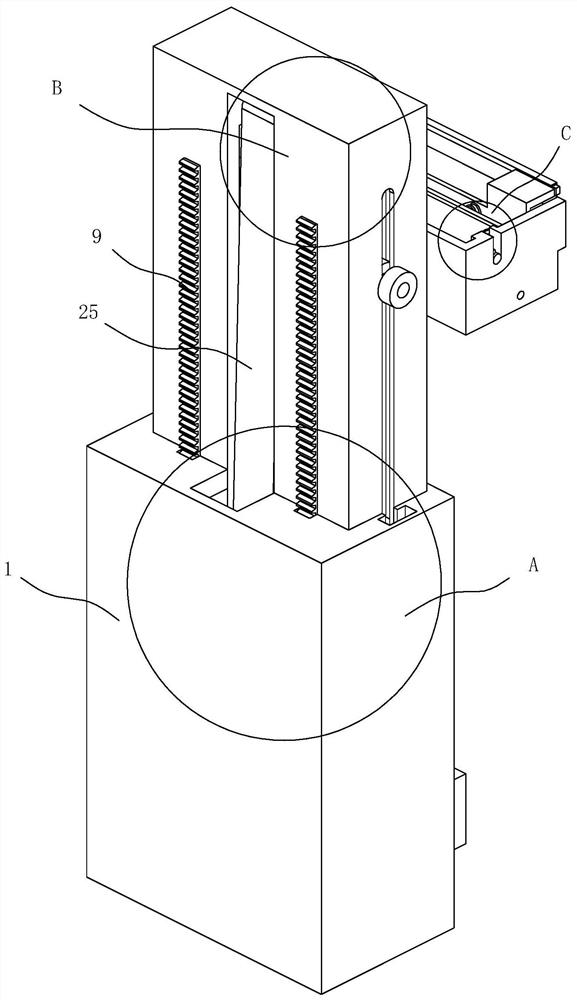

Forming cylinder system structure in SLM rapid forming equipment

InactiveCN111283198APrecise liftingEasy to controlAdditive manufacturing apparatusIncreasing energy efficiencyMachined surfaceBall screw

The invention discloses a forming cylinder system structure in SLM rapid forming equipment. According to the forming cylinder system structure in the SLM rapid forming equipment, a lifting mechanism is driven by the corresponding servo motor, a ball screw nut pair is driven by a right-angle speed reducer to move, then up-down movement of a preheating system structure is achieved, and the relevantthickness of the powder laying layer is controlled. The preheating system structure heats a base plate through a cast aluminum heating plate, a thermocouple is adopted as a temperature sensor, real-time control over the temperature is achieved, heat insulation silk floss and a heat insulation plate are additionally arranged below the heating plate for relevant heat insulation, and sealing rubber strips are installed on the side edges of the base plate and the heat insulation plate to prevent machined metal powder from falling along a forming cavity. According to the forming cylinder system structure in the SLM rapid forming equipment, the lifting mechanism is used for accurately controlling the thickness of the powder laying layer, the preheating system structure is used for accurately controlling the machining temperature of the metal part, the machining environment of the whole metal part is optimized, and the machining surface quality of the metal part is controlled and improved.

Owner:HANGZHOU DIANZI UNIV

Feeding device for animal husbandry

PendingCN107711549AImprove feeding efficiencyPromote absorptionAnimal feeding devicesAvicultureAnimal scienceAgricultural science

The invention discloses a feeding device for animal husbandry and relates to the field of animal husbandry. The feeding device comprises a base, wherein the top of the base is fixedly connected with the bottom end of a supporting column, a fodder storage box is fixedly installed at the top end of the supporting column, a feeding pipe is arranged at the top of the fodder storage box in a penetrating mode, a fodder discharging pipe is arranged at the central position of the bottom of the fodder storage box in a penetrating mode, a feeding trough is movably installed at the top of the base and fixed under the fodder storage box, one end of the fodder discharging pipe penetrates through the feeding groove and extends into the feeding trough, and a water inlet pipe is arranged on one side of the top of the fodder storage box in a penetrating mode. A fodder poured into the fodder storage box by a user can enter a feeding trough through matching of the fodder storage box and the feeding trough which are arranged, livestock is accordingly fed, the problems of complicated operation and time and labor waste of manual feeding are solved, accordingly the feeding efficiency is improved, and meanwhile the economic benefits of farmers are increased.

Owner:绍兴柯桥韩玉电子科技有限公司

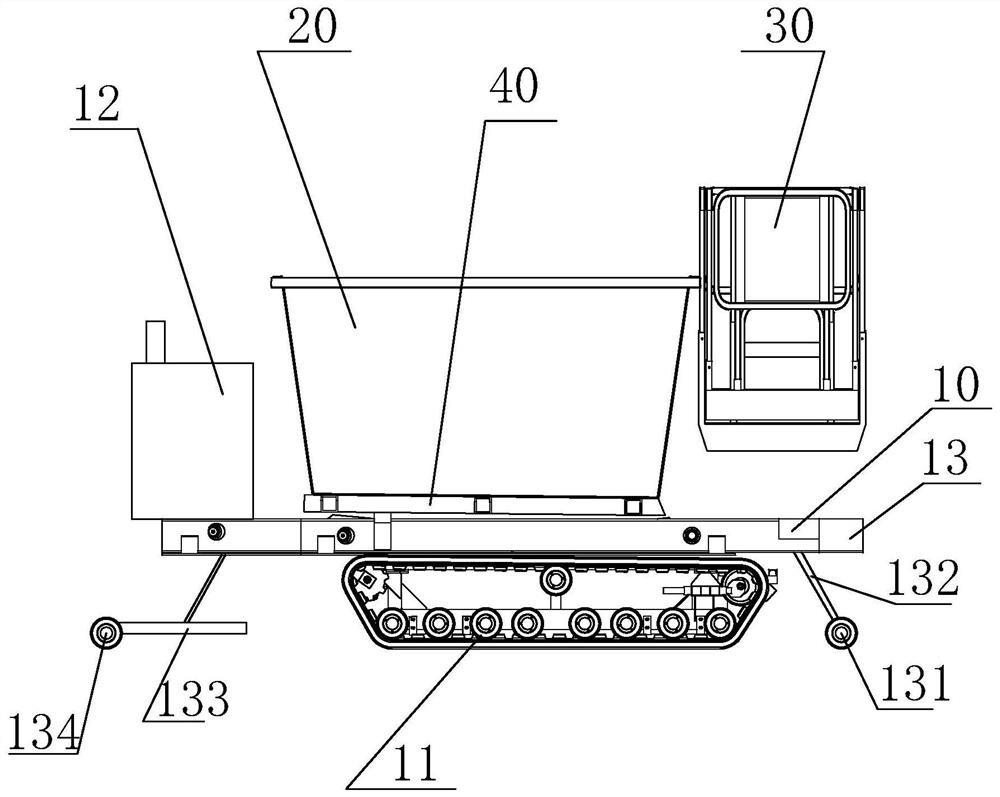

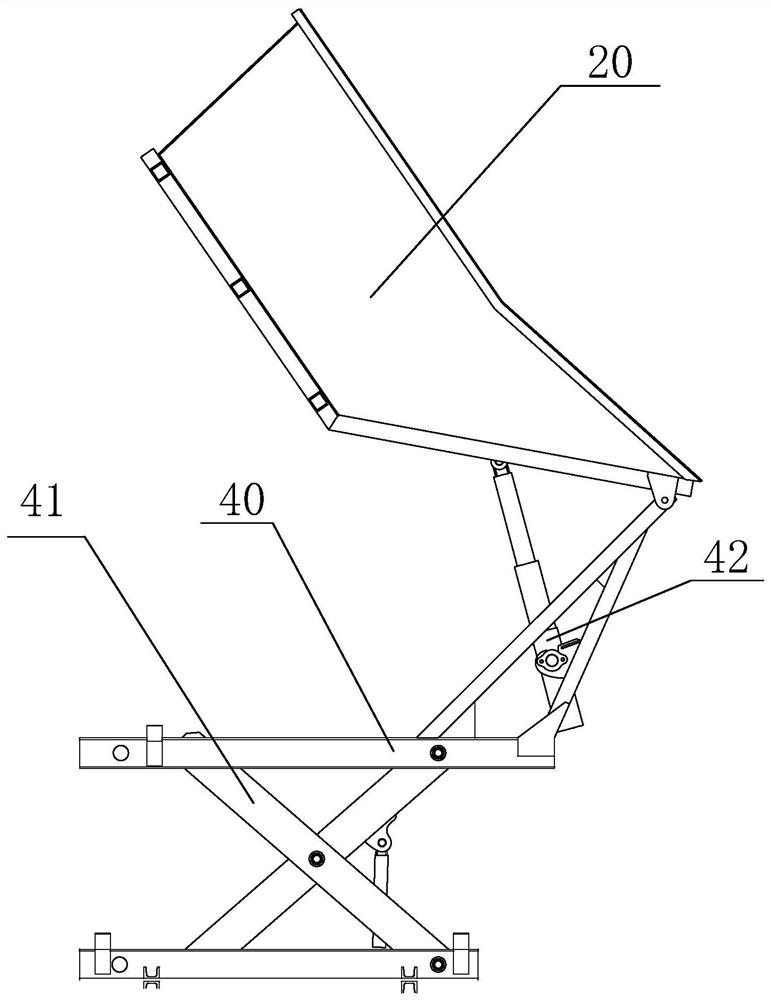

Multifunctional tracked machine for orchard

InactiveCN111713253AControl movementControl steeringMowersPlant waste comminutingAgricultural engineeringOrchard

The present invention discloses a multifunctional tracked machine for an orchard. The multifunctional tracked machine includes a vehicle travelling mechanism, a storage hoper disposed on the vehicle travelling mechanism and a manual desk; the vehicle travelling mechanism includes a track, a driving apparatus and a bottom board, the bottom board is disposed on the track, and the driving apparatus is fixedly disposed on the bottom board to drive the track to move; the storage hopper is disposed on the bottom board; a lifting mechanism is disposed between the storage hopper and the bottom board and is used for lifting and overturning the storage hopper for unloading materials; the manual desk is suspended in the side of the storage hopper, but does not overturn with the storage hopper; the overall storage hopper is supported by the bottom board, so that the stability of the storage hopper is enhanced; and due to the suspended arrangement of the manual desk, the design width of the bottomboard is reduced, and thus, a fruit picker may be set to be smaller and more flexible. The manual desk is provided with a manual operating desk for controlling the driving apparatus to drive the trackto move and steer and controlling the lifting mechanism to lift and overturn the storage hopper, and the bottom of the bottom board is provided with a universal wheel I and a mower, so that safe support is provided for the fruit picker, and meanwhile, weeding is realized during advancing.

Owner:湖南梅花机电科技有限公司

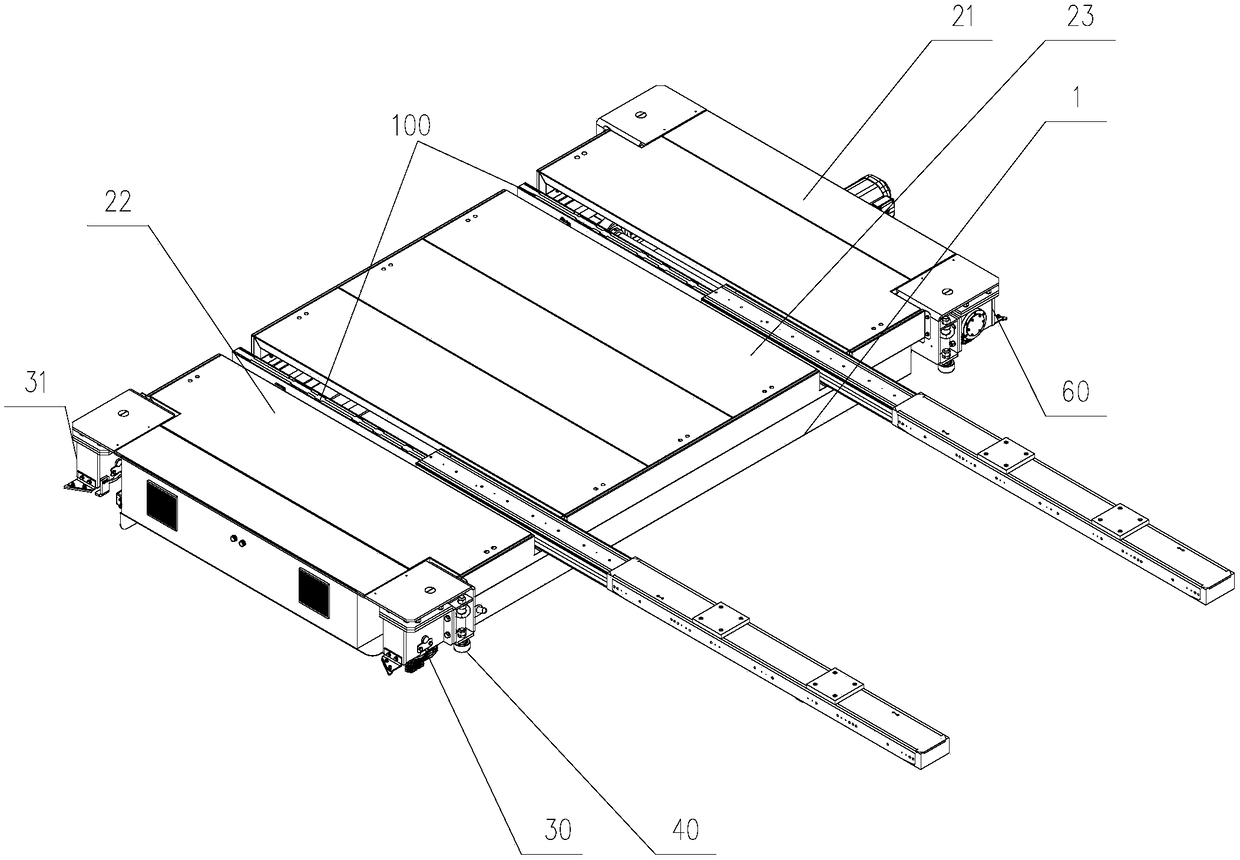

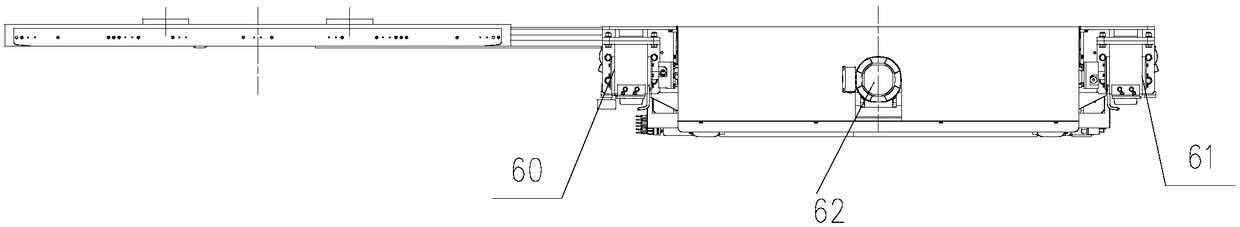

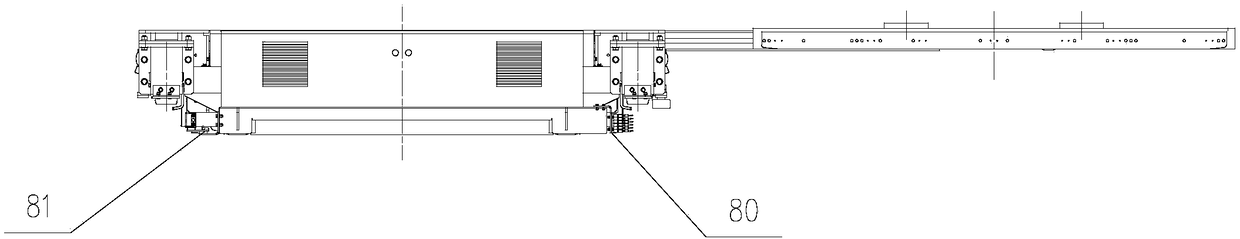

Shuttle vehicle with telescopic fork

Owner:SCIVIC ENGINNEERING +1

Conveniently used lifting device for garden clipping

The invention relates to the technical field of garden equipment, and discloses an easy-to-use lifting device for garden pruning, comprising a base, the upper surface of the base is fixedly connected with a U-shaped connecting plate, and the opposite surface of the U-shaped connecting plate is formed by the upper A card slot is opened at an equal distance from the bottom, and a storage slot is opened on the bottom wall of the slot. The bottom of the storage slot is fixed with a first telescopic rod, and an elevator is provided inside the U-shaped connecting plate. The easy-to-use lifting device for garden pruning can easily make the elevator slide inside the U-shaped connecting plate through the second telescopic rod to cooperate with the sleeve, the connecting block, the spring, the piston, the slot and the locking rod, and control the elevator. The position of the clamping rod can be clamped through the storage slot and the first telescopic rod and the clamping slot, so that the position of the lift is more stable and there will be no deviation, so that the workers have higher stability and safety during operation. And the lifting of the elevator is more convenient.

Owner:陈式好

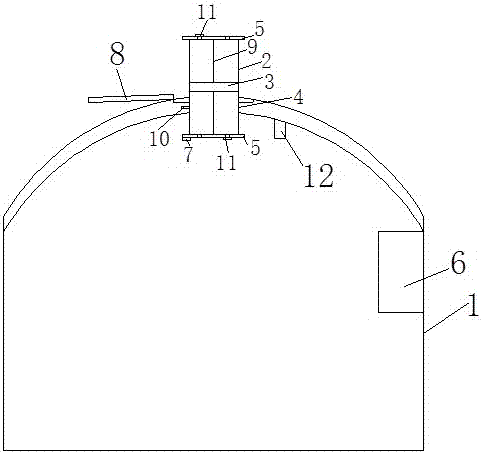

Automatic ventilation plant

InactiveCN107166617AEasy to useNot attackedSpace heating and ventilation safety systemsLighting and heating apparatusAutomatic controlControl engineering

The invention discloses an automatic ventilation plant. The automatic ventilation plant comprises a plant body. A plurality of ventilation devices capable of ascending and descending are arranged on a roof of the plant body. Each ventilation device comprises a ventilation pipe body, wherein a filtering and dust removing interlayer is arranged in the middle of the ventilation pipe body, the ventilation pipe body is arranged in a through hole of the roof, a step face is arranged above the through hole, annular bosses are arranged at the two ends of the ventilation pipe body, an air inlet / air outlet is formed in the upper end of the ventilation pipe body, and an air outlet / air inlet is formed in the lower end of the ventilation pipe body. A control device is arranged on the side wall of the plant body, the control device controls opening of the air inlets and the air outlets in the ventilation pipe bodies, and a pressure sensor is arranged below each ventilation pipe body. According to the automatic ventilation plant, the top of the plant body is provided with the multiple ventilation devices capable of ascending and descending for ventilation, the ventilation devices are automatically controlled according to the pressure, the temperature and the like in the plant, and the automatic ventilation plant is very convenient to use.

Owner:ZHENJIANG JUNENG ELECTRICAL

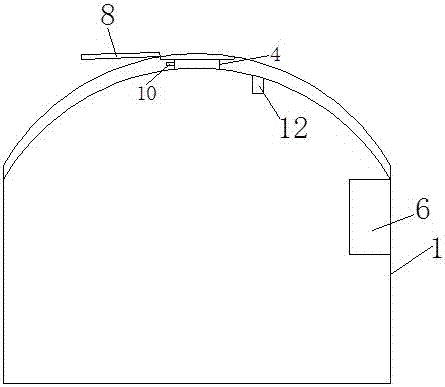

Table and chair board chamfering machining device

ActiveCN108202366APrevent flying outLift controlProfiling/shaping machinesBark-zones/chip/dust/waste removalWind drivenElectricity

The invention discloses a table and chair board chamfering machining device structurally comprising a waste collecting box, a cooling groove, a moving handle, adjusting valves, a protective cover, a machining box, a machining tabletop, a workpiece rotating disk, an operation panel and a machining main machine. The waste collecting box and the machining main machine are both of a rectangular structure and connected in a buckled manner. The lower end of the left side of the waste collecting box is provided with the cooling groove, and the cooling groove and the waste collecting box are of an integrated formation structure. The table and chair board chamfering machining device has the beneficial effects that a feeding mechanism arranged at a feeding opening arranged inside the arranged wastecollecting box raises a first seesaw and a second seesaw according to the weight of waste, a first transmission rope and a second transmission rope are driven to switch on an electrifying mechanism and a piston head in a water storage tank, an air blowing mechanism enables wood chips and wood blocks to be separately stored through wind drive, and a humidifying mechanism is started at the same timeto humidify the wood chips; and in this way, the differential storage function on the waste is effectively achieved, the humidified wood chips are not prone to generating the flying phenomenon, the cleaning efficiency is improved, and it is avoided that the hygienic environment is polluted.

Owner:FOSHAN KEZHIMEI FURNITURE

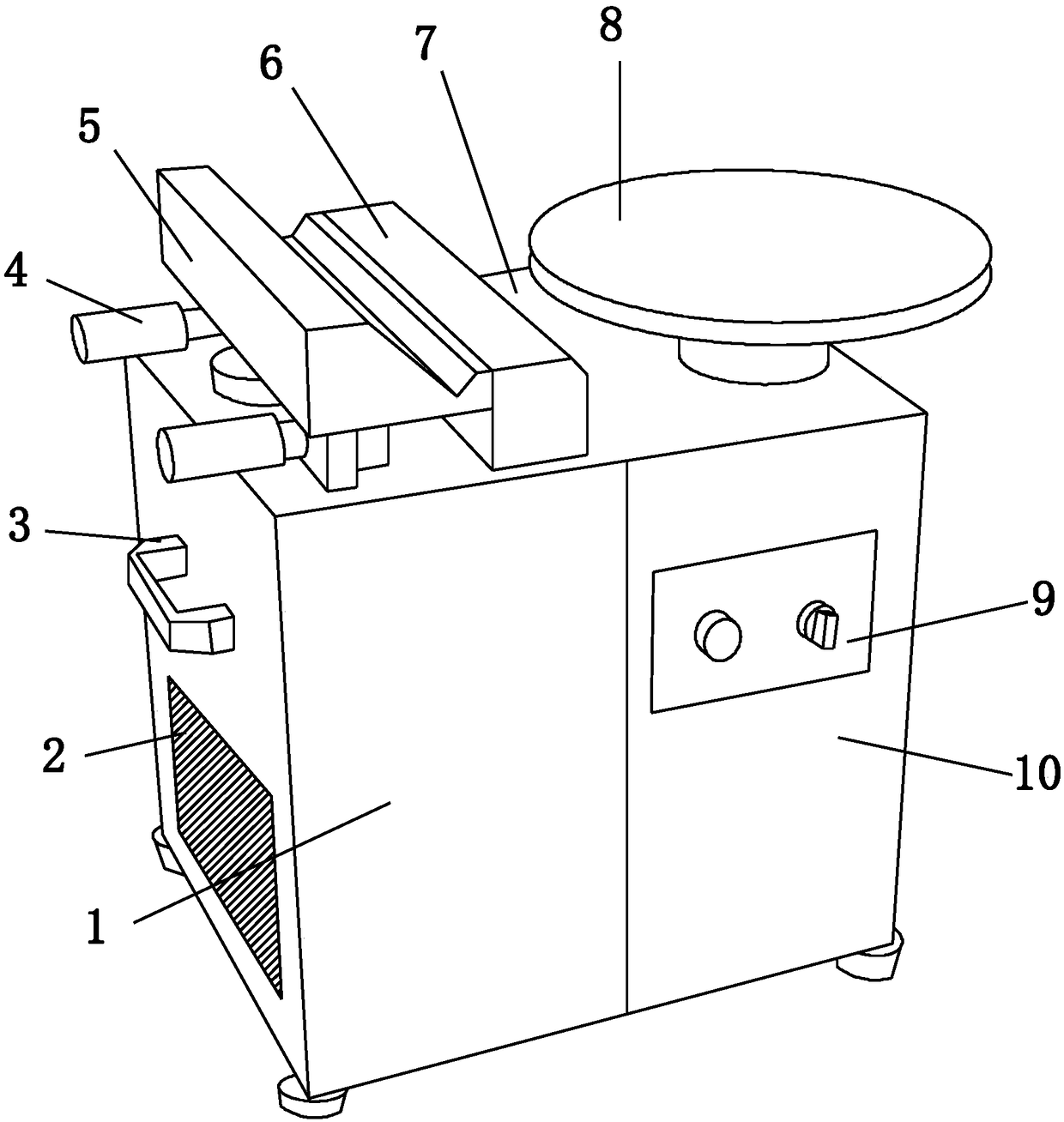

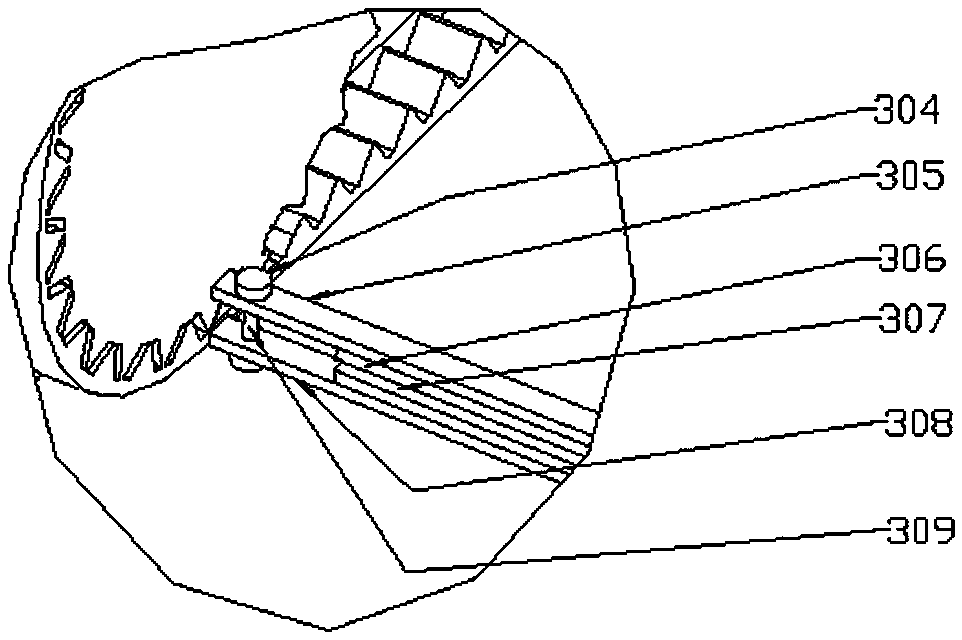

Automatic iron pan arc edge grinding device

PendingCN108356636AGuaranteed stabilityRealize automatic edgingEdge grinding machinesGrinding carriagesFixed frameEngineering

The invention relates to an automatic iron pan arc edge grinding device. The automatic iron pan arc edge grinding device comprises an underframe, a stable force rotary mechanism and a movable edge grinding mechanism. The movable edge grinding mechanism comprises an edge grinding abrasive wheel, an edge grinding abrasive wheel fixing frame and an edge grinding abrasive wheel driving motor. A stableforce rotary supported is arranged at the top end of a stable force rotary support bearing bracket. A stable force pressing plate assembly is arranged at the tail end of the stable force rotary support. A rotary pan mold is arranged below the stable force pressing plate assembly. The rotation direction of the edge grinding abrasive wheel is controlled by rotating a force applying rotary shaft frame and a swing motor connecting rod. The automatic iron pan arc edge grinding device is reasonable in structure and stable in operation and accurately achieves set arc edge grinding, no deviation is caused, the edge grinding radian is adjusted in time, the technical effects that in existing iron pan arc edge grinding processes, necessary stable force rotary mechanisms are not provided, operation is unstable, pan blank edges are ground unstably, deviations are liable to occur, and the edge grinding radian cannot be adjusted in time are solved, and the automatic iron pan arc edge grinding devicehas good market prospects and development spaces compared with the prior art.

Owner:HENAN MOXI MACHINE MFG

An omni-directional adjustable identification plate of a transmission pole and tower

The invention discloses an omni-directional adjustable identification plate of a transmission pole and tower, which includes a fixing block, a fixing cavity is arranged on the fixing block, a first servo motor is fixedly installed on the top of the fixing block, the top of the fixing block is provided with a rotating hole, the rotating hole communicates with the fixing cavity, the output shaft ofthe first servo motor extends through the rotating hole into the fixed cavity and is fixedly mounted with a rotating rod, the bottom end fixing sleeve of the rotary lever is provided with a first bevel gear, the inner walls of both sides of the fixing cavity are provided with rotating grooves, the two rotating grooves are rotatably provided with the same rotating column, the rotating column is fixedly sleeved with a winding wheel, one end of the winding wheel is wound with a thin rope, the inner walls of both sides of the fixing cavity are provided with fixing grooves, and the inner walls of both sides of the fixing groove are fixedly installed with the same fixing rod. The plate has the advantages of high practicability, simple structure and convenient operation, and is convenient for people to control the lifting and lowering of the identification card body and to fix the height of the identification card body.

Owner:YANTAI POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

Wheel, leg, bounce mechanism combined mobile robot

InactiveCN100429112CAchieve progressImplement backSelf-moving toy figuresVehiclesEngineeringCcd camera

The invention relates to a wheel leg bounce movable robot, wherein it uses four-wheel body, with front and back swinging wheel legs and bounce structure. The invention combines wheel structure and leg structure, to change motion mode via different conditions. Via the back swinging wheel leg, when the robot is turnover, it can return by itself. The bottom bounce structure can fly over the obstacle; the table with CCD camera is mounted in the detecting table which can lift, to expand the view sight.

Owner:ZHEJIANG UNIV

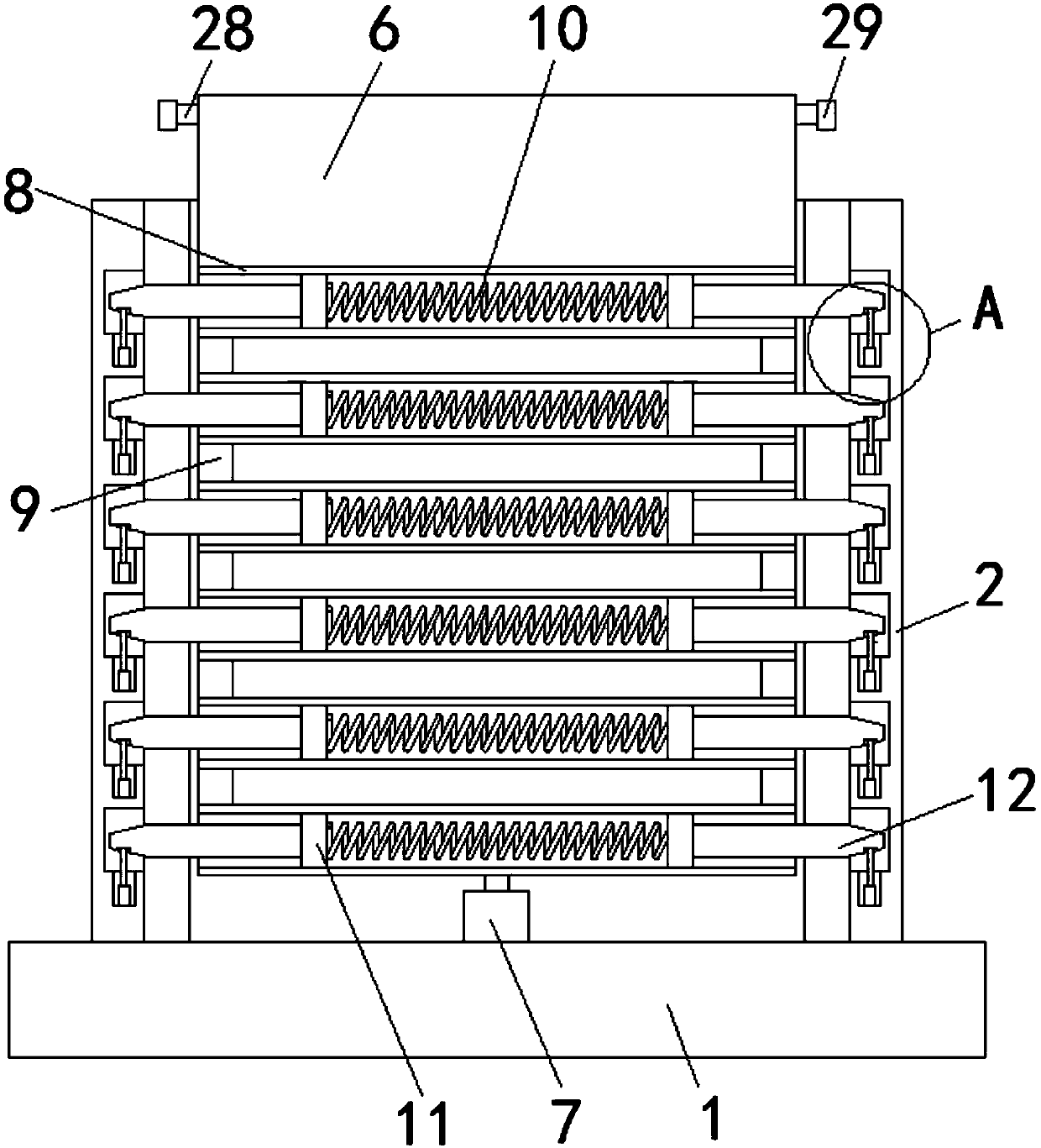

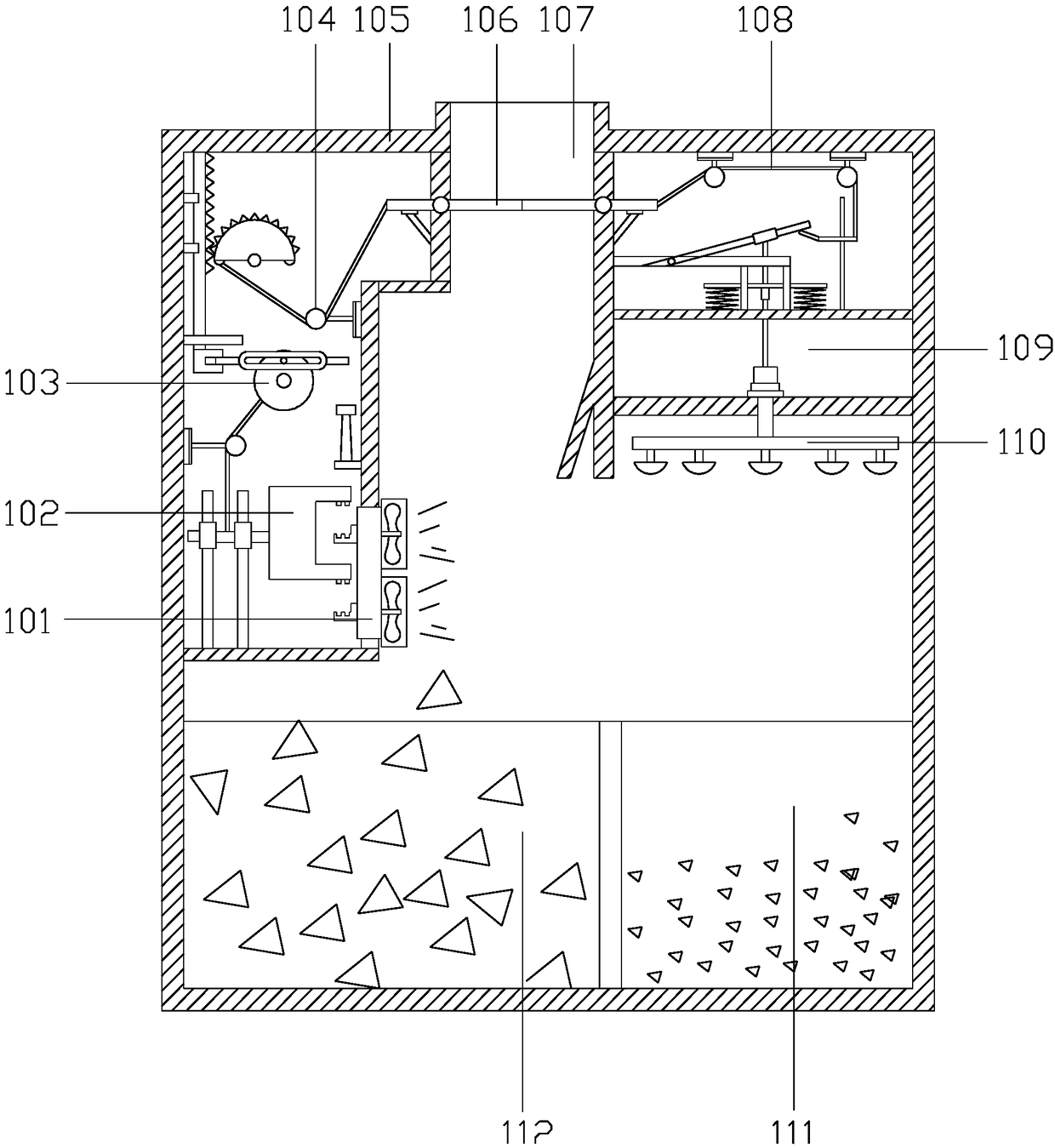

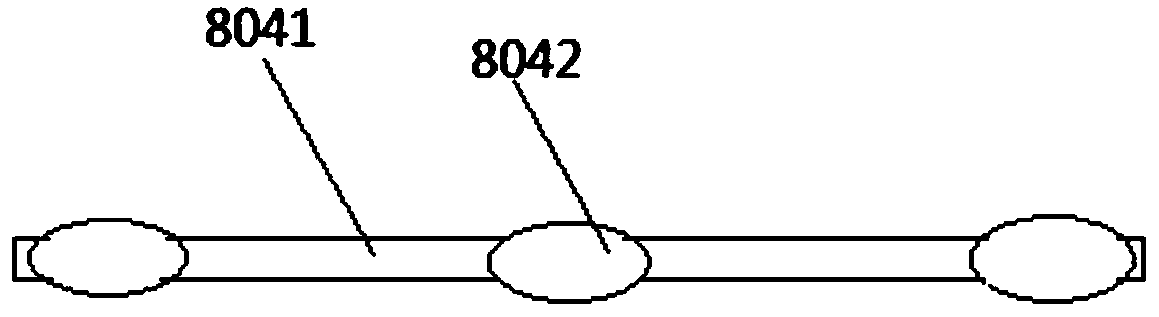

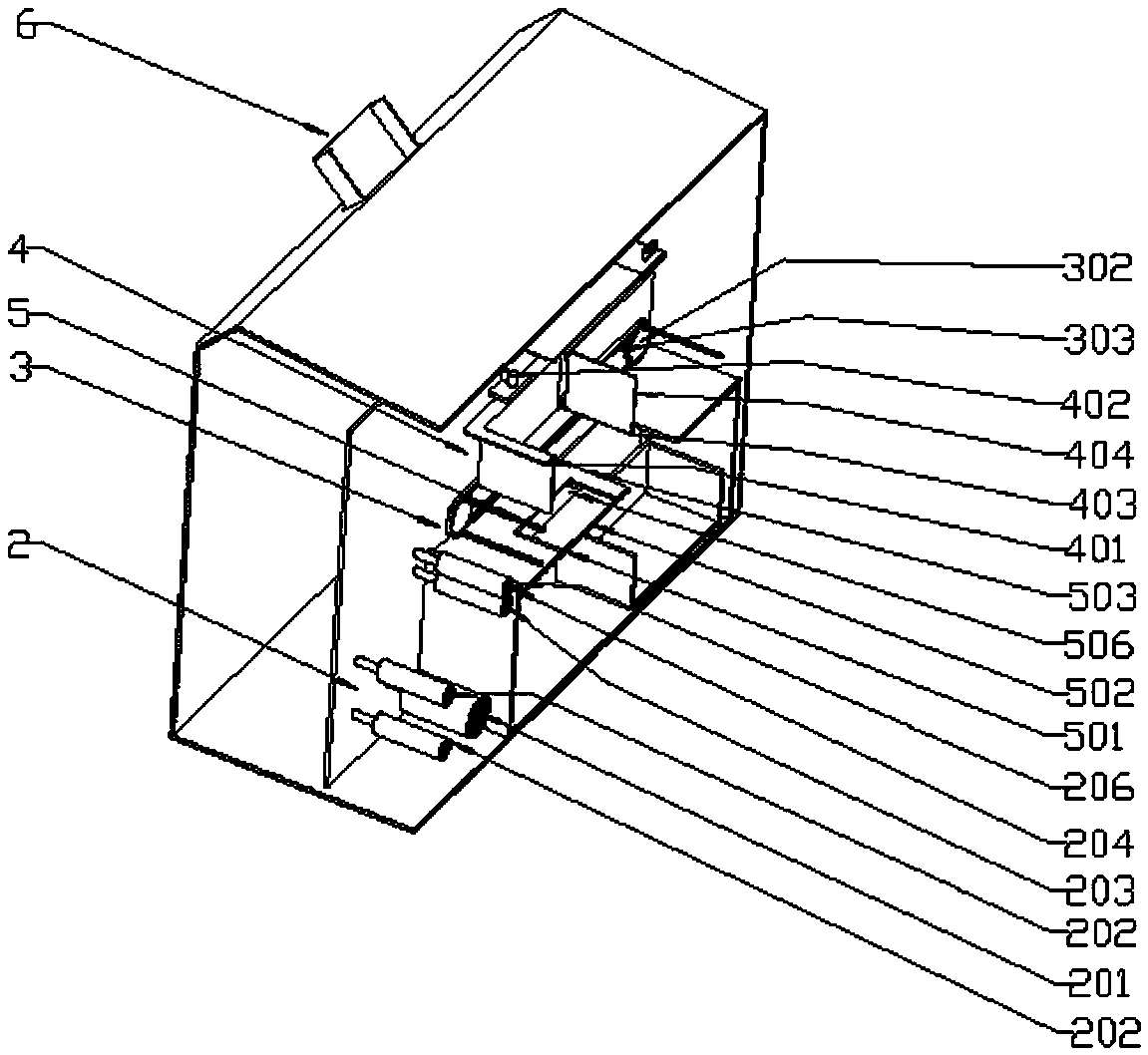

Stainless steel plate pressure finishing device capable of detecting finishing defects

PendingCN110076216ASolve the twistFix backbendShaping toolsShaping safety devicesArchitectural engineeringUltimate tensile strength

The invention discloses a stainless steel plate pressure finishing device capable of detecting finishing defects. The device comprises a frame (1); the bottom of the frame (1) is a support column (101); the upper end of the support column (101) is fixedly connected with an operation platform (102); a support frame (104) is fixedly arranged on the upper end surface edge of the operation platform (102); and the upper end of the support frame (104) is fixedly connected with a support beam (103). Cushion blocks with different specifications can be reasonably selected according to the thicknesses of stainless steel plates to meet the fixed sizes of the stainless steel plates; and a jack can straighten the strength needed by the stainless steel plates with higher strength, so that the defects oftwisting, back bending and overproof plane gaps of aluminum plates are solved, the pass percent of the aluminum plates is increased, and the production cost is reduced.

Owner:四川凡立美科技有限公司

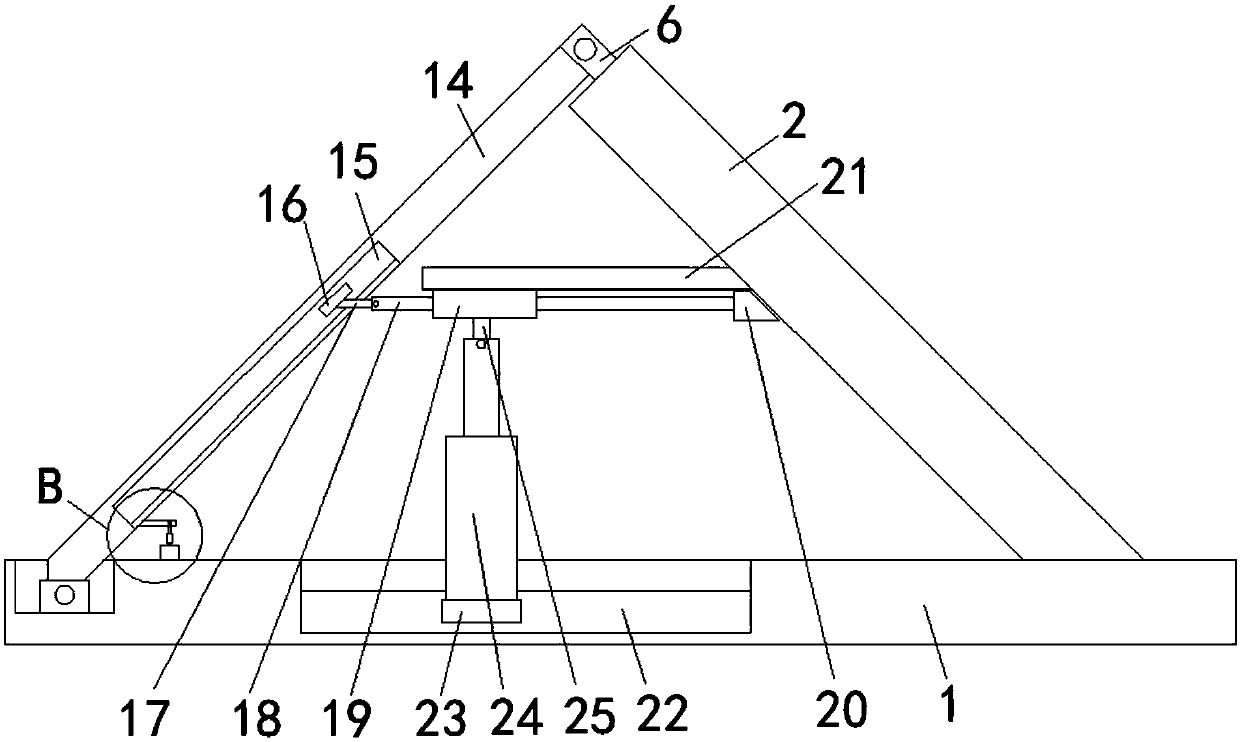

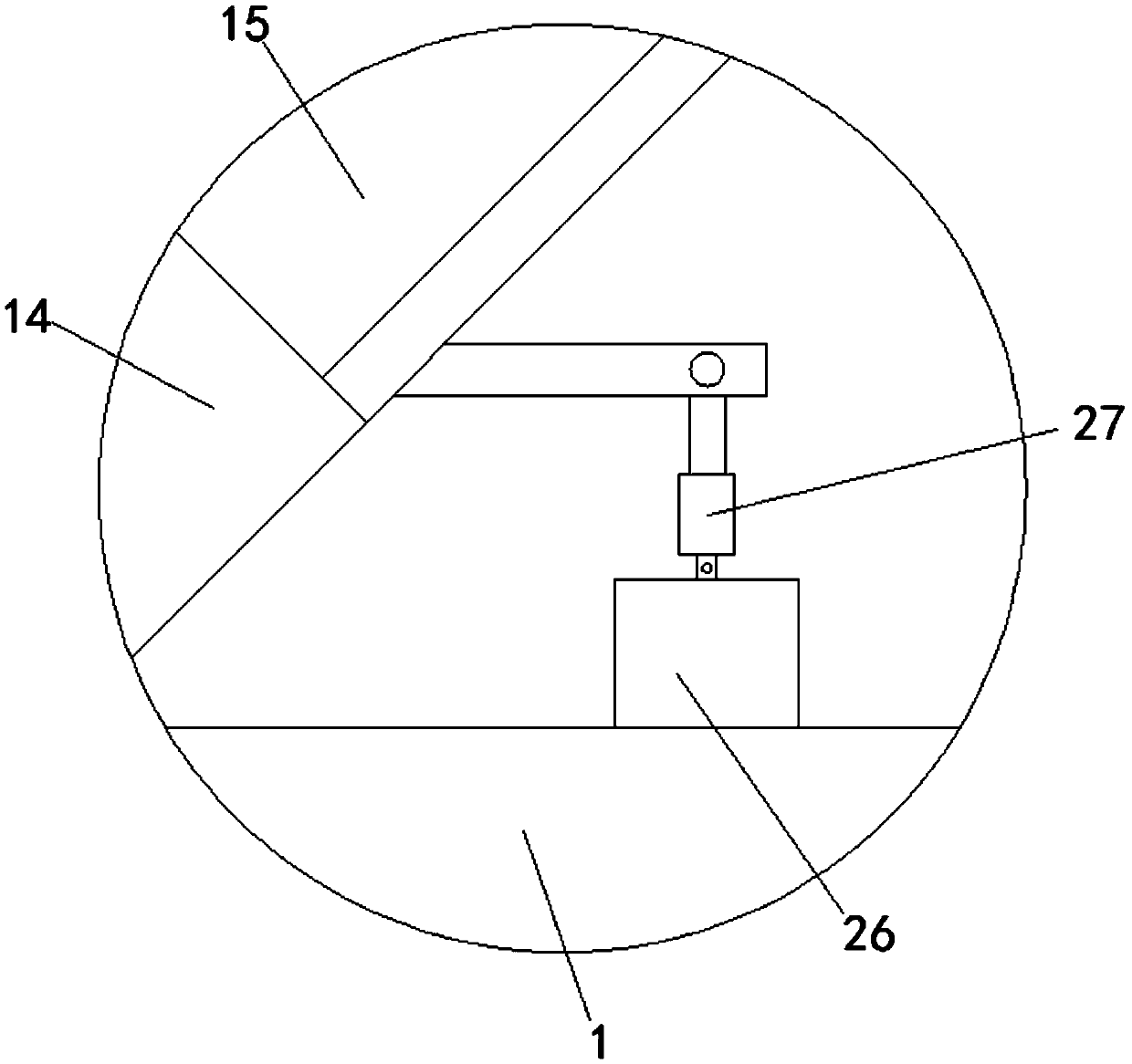

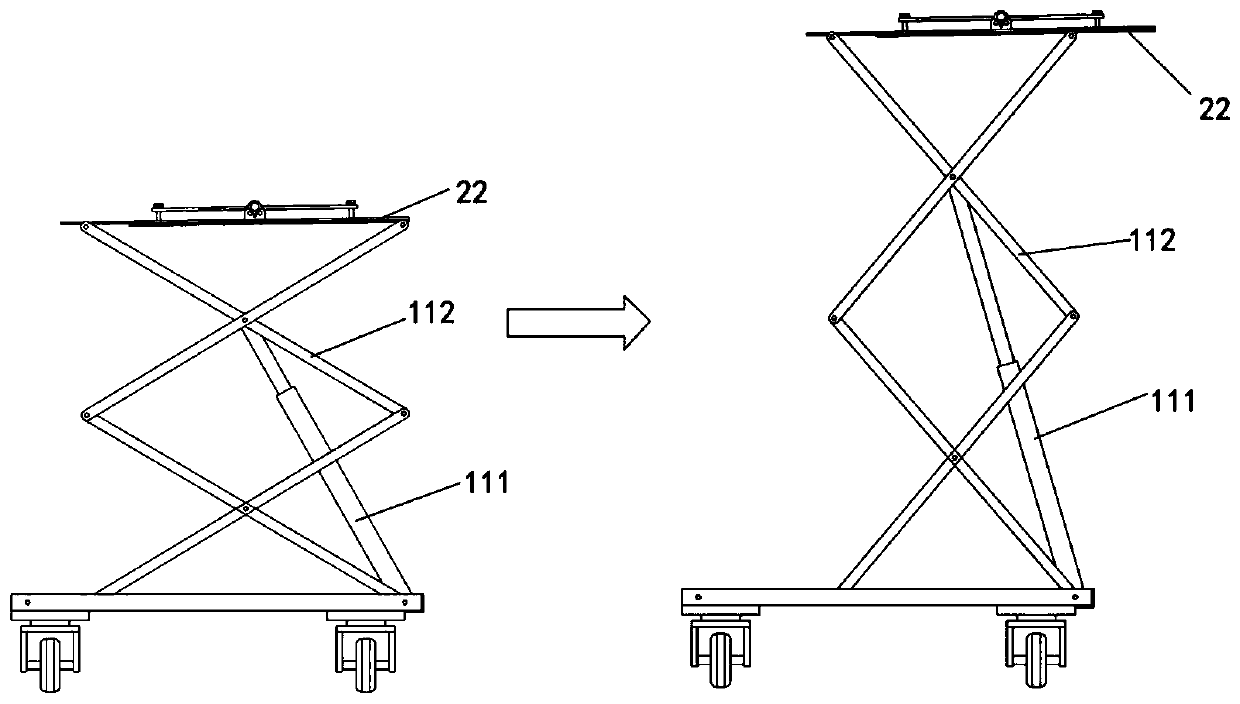

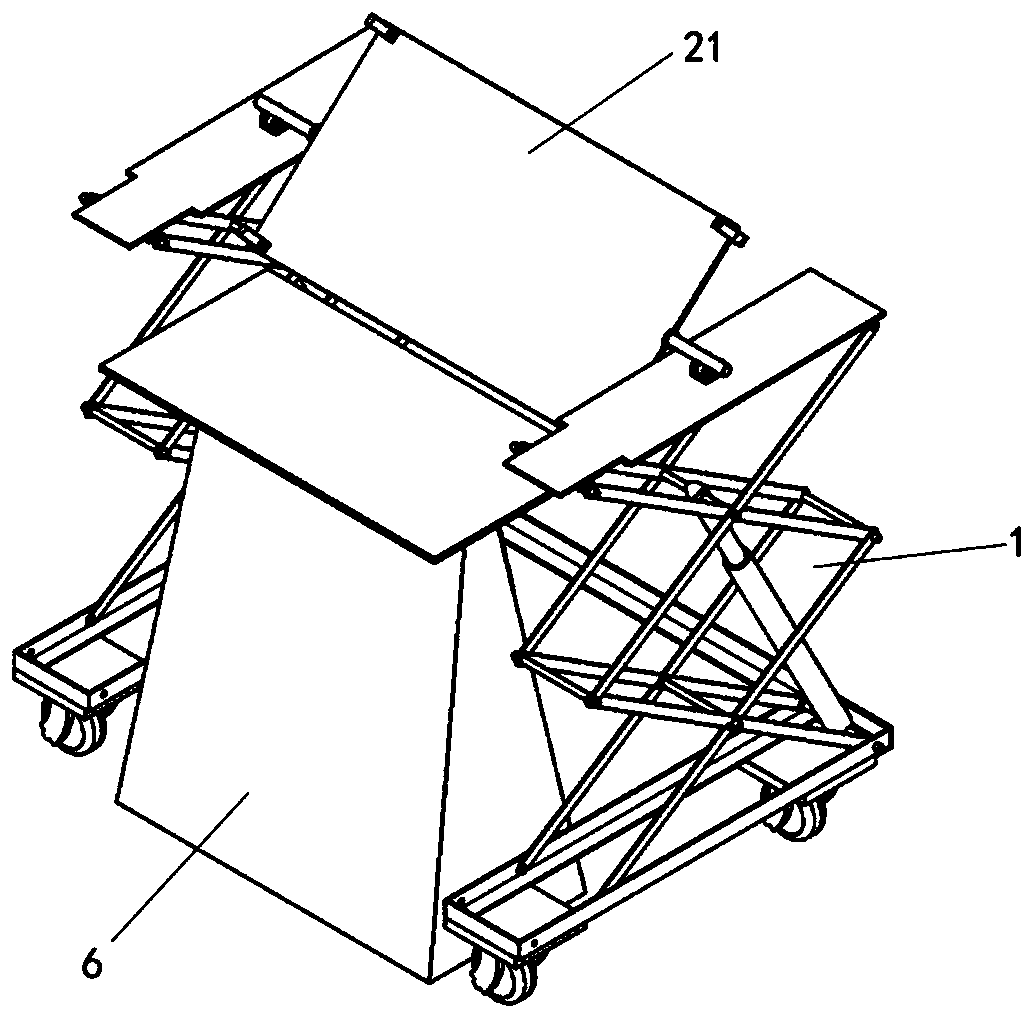

Cart bed for turning over before spinal operation

The invention relates to a cart bed for turning over before spinal operation. The cart bed comprises a lifting module and a turning over module, wherein the turning over module is mounted on the top of the lifting module and comprises a bed body, fixed brackets, rotating shafts and limiting mechanisms, the rotating shafts penetrate the bed body in the direction of the longitudinal centerline of the bed body, and two ends are connected with the fixed brackets, and the limiting mechanisms are arranged at four corners of the bed body, one end of each limiting mechanism is connected with the bed body, the other end is connected with the corresponding fixed bracket, and a human body fixing mechanism is arranged on the bed body. Compared with the prior art, the cart bed can prevent secondary injury of the spine of a patient when the bed is manually moved and turned over and can reduce manpower, and turning-over operation can be realized by only 1-2 medical workers.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

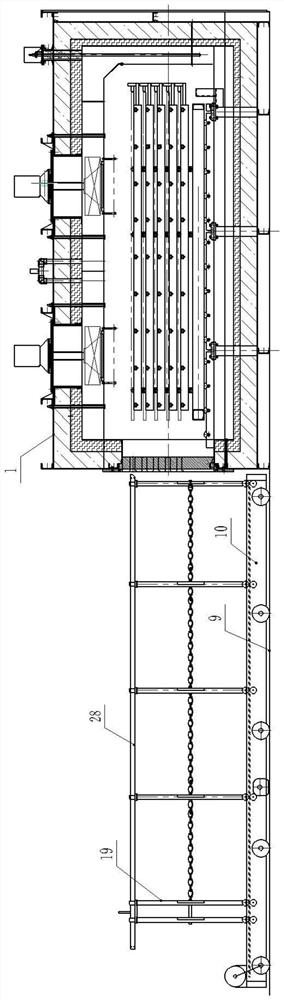

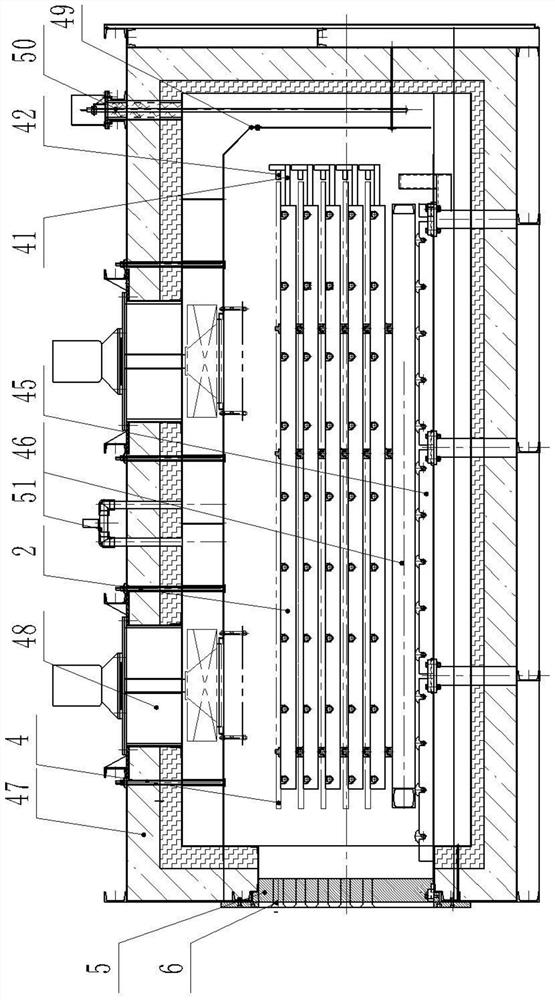

Method for taking out heat-treated bar for manufacturing copper-clad aluminum busbar cable

InactiveCN111705202AAvoid getting lostAvoid enteringFurnace typesHeat treatment furnacesBusbarElectric machinery

The invention discloses a method for taking out a heat-treated bar for manufacturing a copper-clad aluminum busbar cable. After the copper-clad aluminum bar placed on a copper-clad aluminum bar frameis subjected to heat treatment by a nitrogen protection heating box furnace, a trolley driving motor is controlled to drive an electric trolley to move to a lifting furnace door on a guide rail, a lead screw driving motor is controlled to drive a bidirectional lead screw to rotate to adjust the height of an electric material taking support frame, the height of a material taking pipe on the electric material taking support frame is made to be aligned with the height of a row of copper-clad aluminum bars needing to be taken out, nitrogen is introduced into the material taking pipe, a sealing plug is opened, a traction support frame is controlled to drive the material taking pipe to be inserted into a bar taking-out port, the material taking pipe continues to be inserted, the copper-clad aluminum bars are guided into the material taking pipe, the material taking pipe is pulled out by the traction support frame, and the copper-clad aluminum bars are cooled under nitrogen protection.

Owner:ZHENG WEI TECH SHEN ZHEN LTD

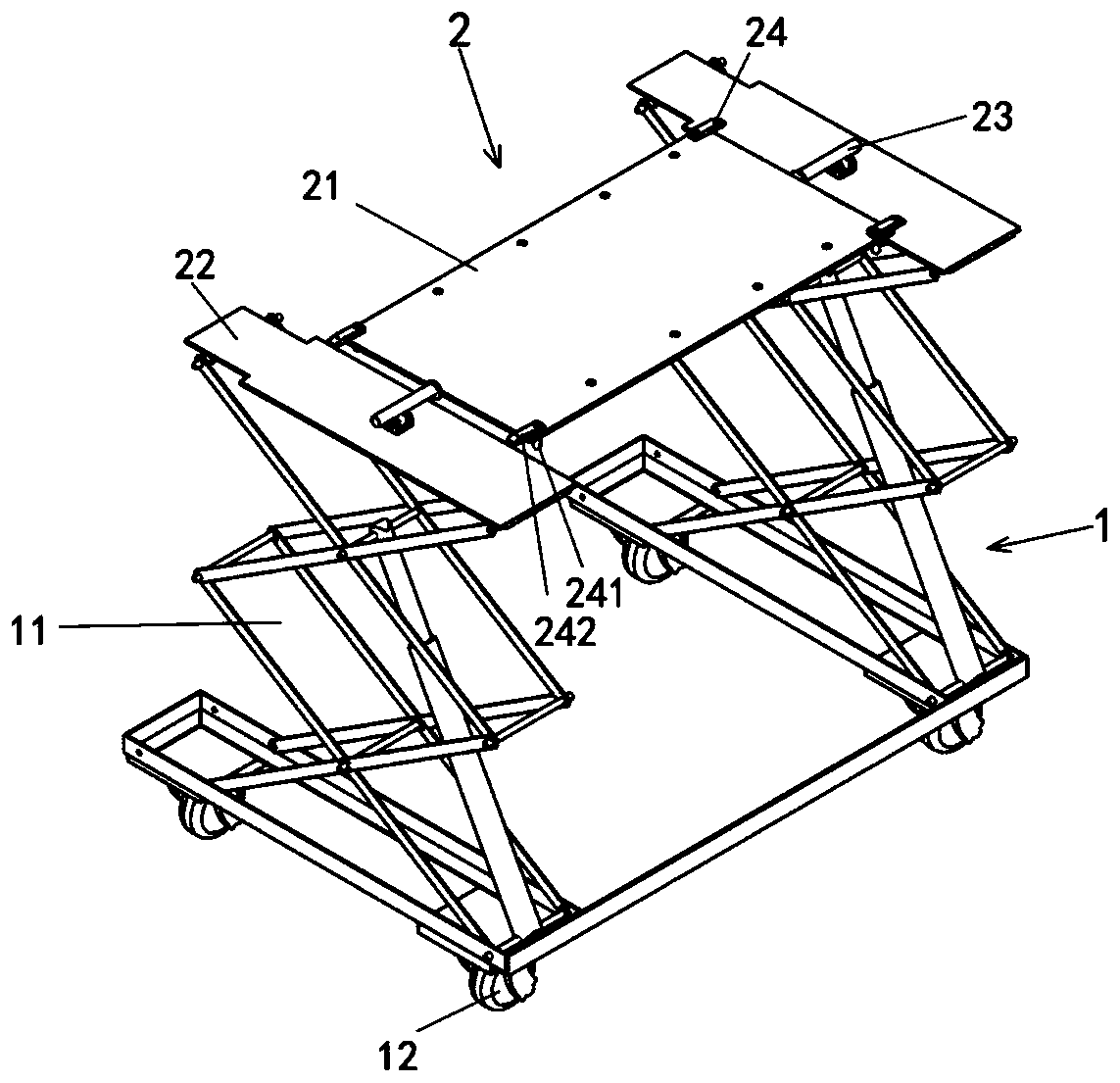

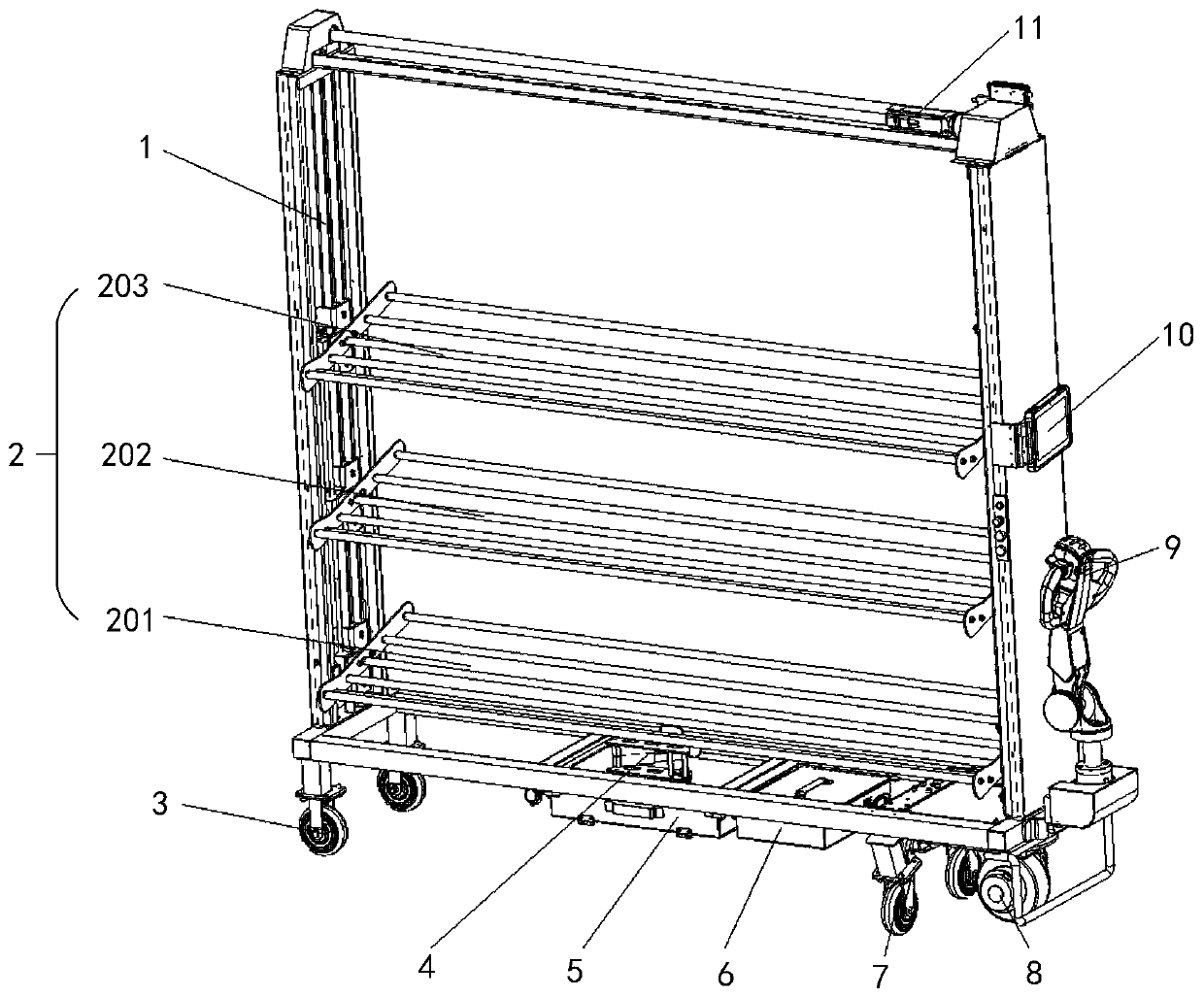

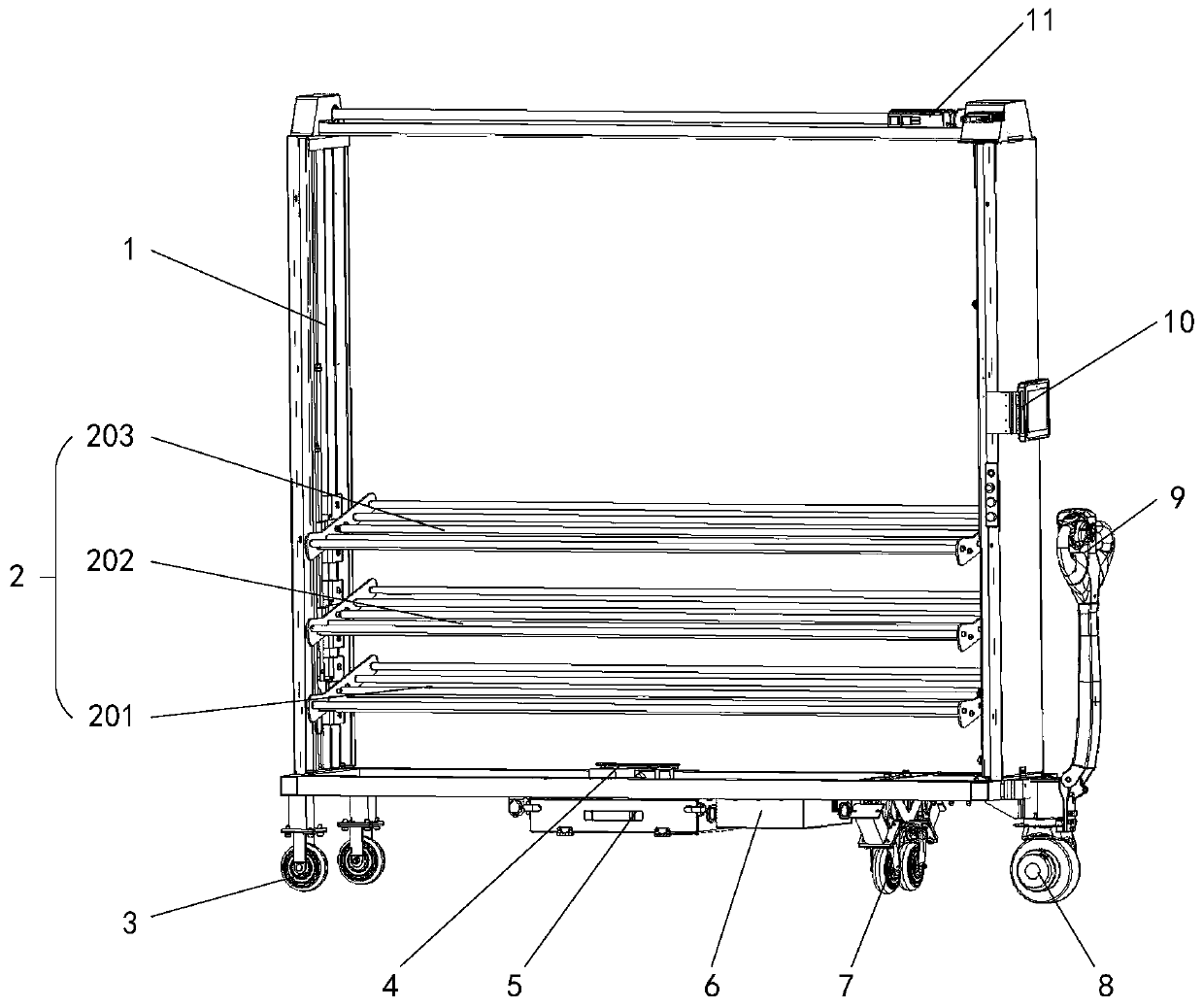

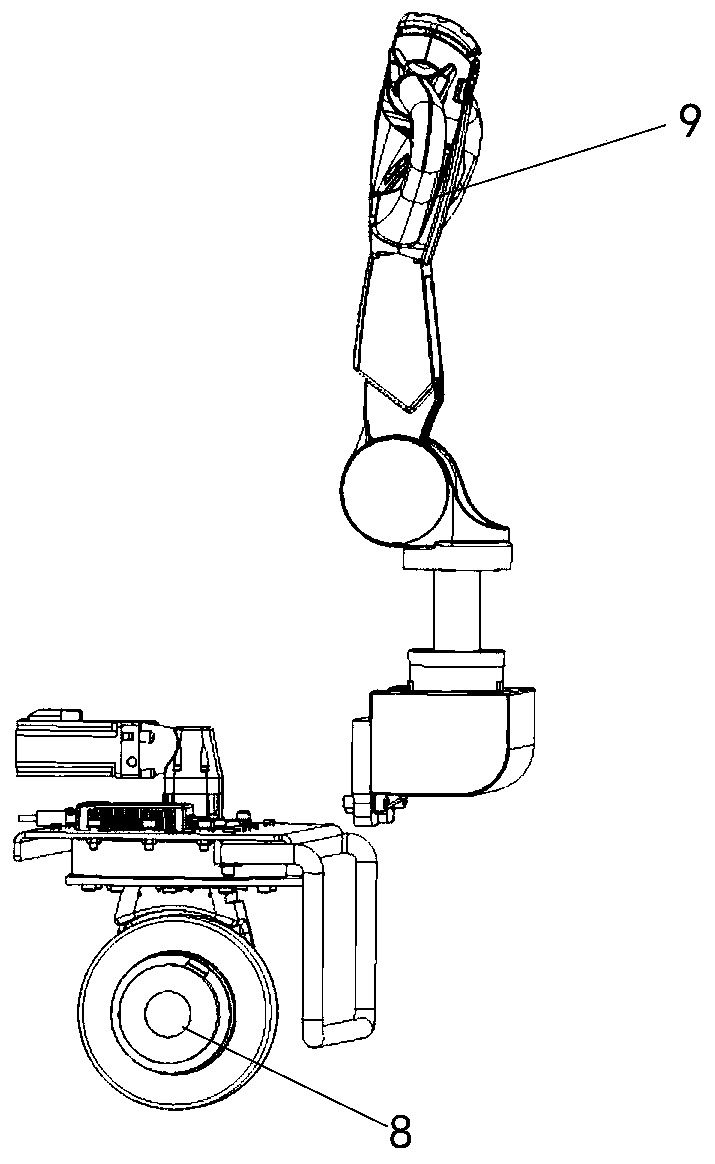

Logistics power-assisted vehicle

PendingCN109987124AEasy to transportReduce labor intensityHand carts with multiple axesVehicle frameLogistics management

Owner:ZHEJIANG GUOZI ROBOT TECH

Leveling machine with hydraulic lifting device

InactiveCN106258031AImprove gripNot easy to slipSpadesAgricultural machinesEngineeringHydraulic pressure

The invention relates to a leveling machine with a hydraulic lifting device. The temper mill comprises a vehicle body, wheels, a soil-loosening plate, the hydraulic lifting device and a traction device. The soil-loosening plate comprises a frame and a ditching groove. The frame includes a first frame and a second frame. A straight support rack, an oblique support rack and a support plate are arranged on the first frame. One end of the ditching groove is arranged at the top end of the straight support rack, and the other end thereof is connected with the support plate. Each wheel comprises a steel ring, a plurality of protrusions of the same shape are arranged on the outer wall of the steel ring, a plurality of expansion pieces are arranged on the steel ring, and the width of the expansion pieces is larger than the width of the steel ring. The leveling machine has the advantages that the leveling machine is reasonable in structural design, the first vertical plate of the soil-loosening plate loosens soil, and the second vertical plate of the soil-loosening plate levels the loosened farmland; ditching can be performed during soil loosening, and work efficiency is increased; the frame is foldable, the horizontal area of the whole frame is reduced, and traveling on a small road can be achieved; the leveling machine is stable during moving and good in grip effect, and the wheels do not sink into the land too deeply.

Owner:TONGXIANG LONGXIANG FARM MACHINERY & GRAIN OIL PROFESSIONAL COOP

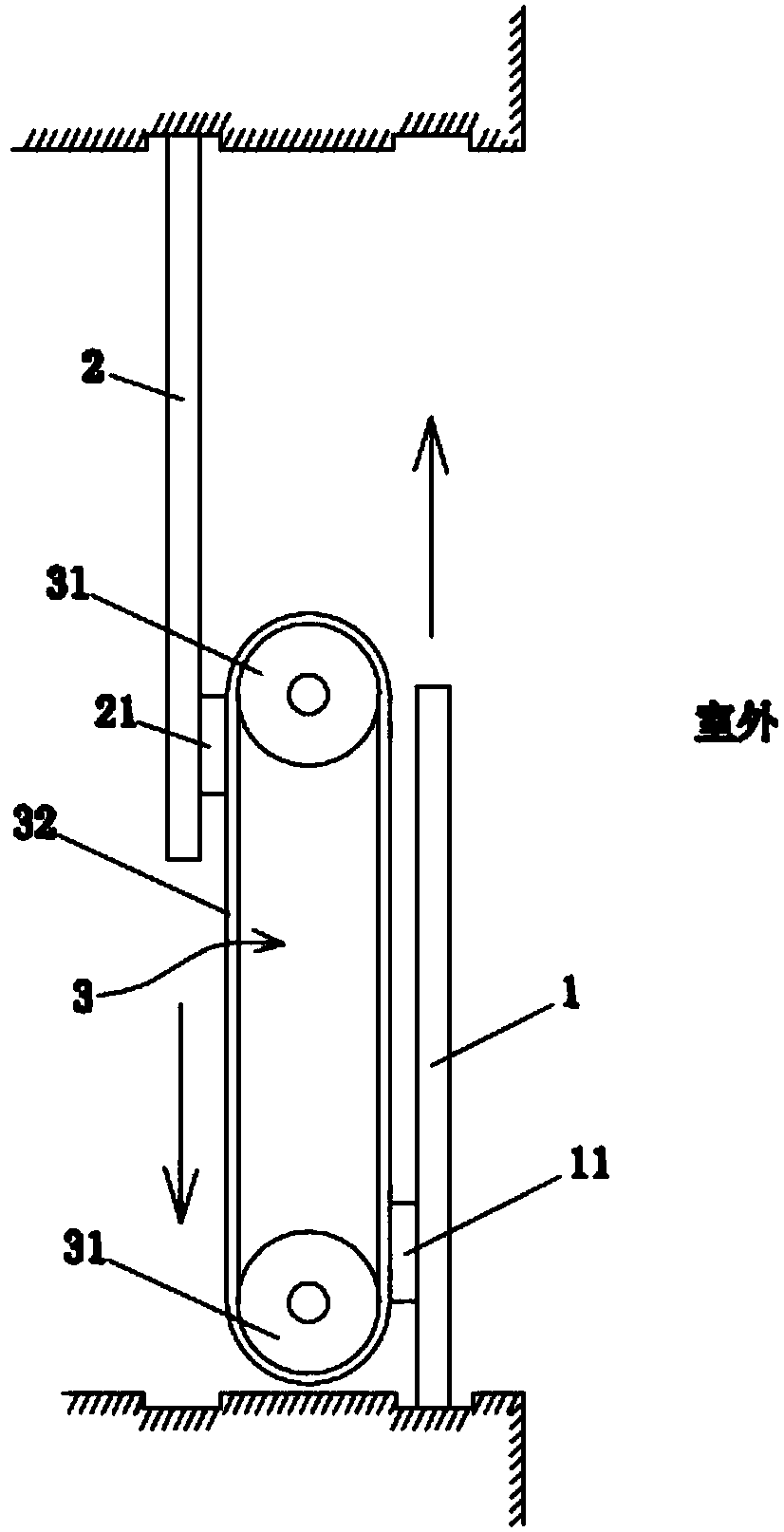

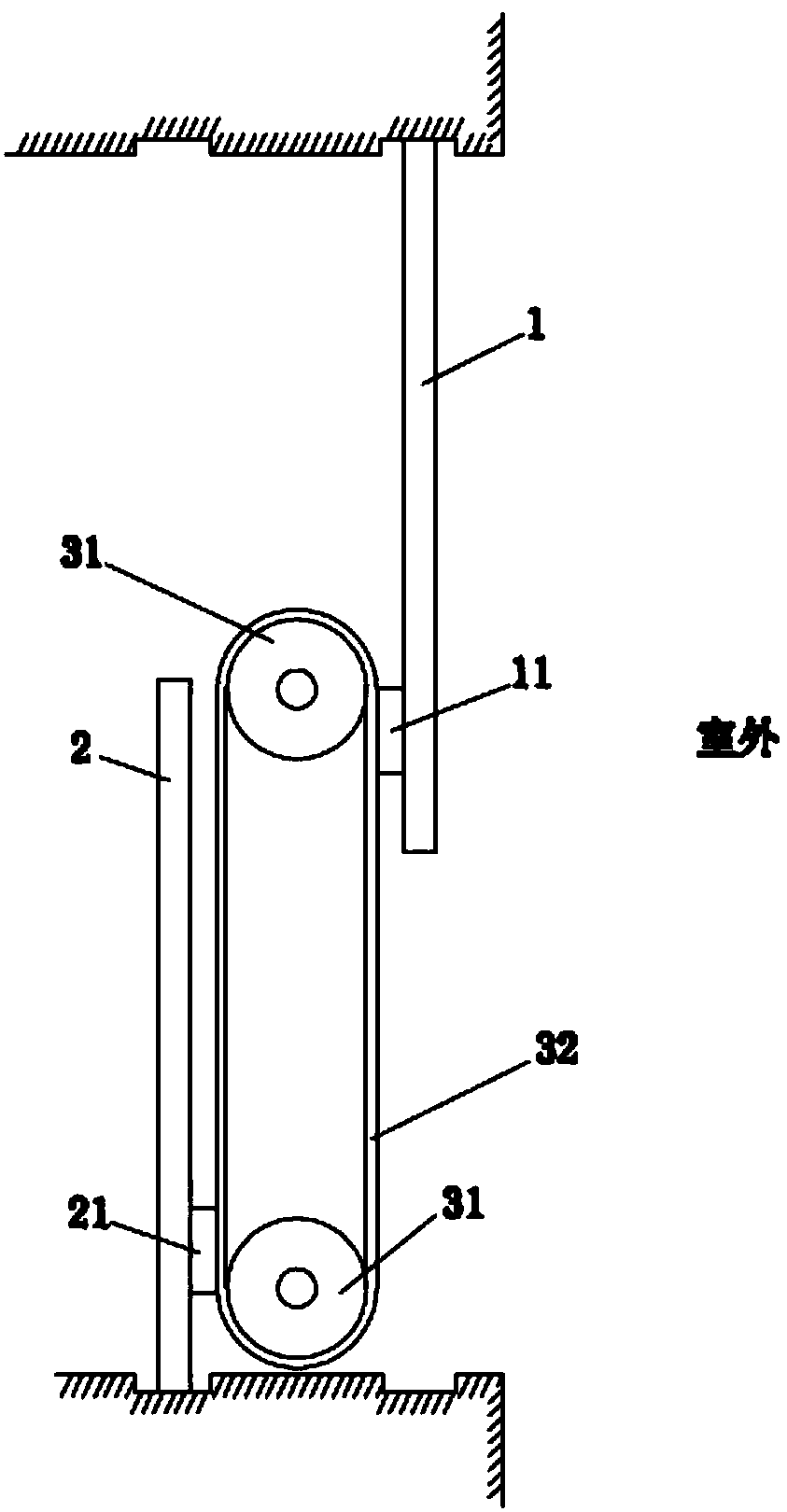

Automatic safe panoramic balcony window

InactiveCN108412362AAvoid climbing and fallingTo achieve the effect of guardrailPower-operated mechanismWing arrangementsEngineeringGlass window

The invention discloses an automatic safe panoramic balcony window, which comprises a glass window and a protective window, wherein the glass window and the protective window are parallel to each other; a lifting mechanism capable of enabling one of the glass window and the protective window to rise up and enabling the other one to go down at the same time is connected between the glass window andthe protective window; an overlapped region for seamlessly connecting the glass window with the protective window is arranged between the glass window and the protective window; the lifting mechanismis connected with a driving mechanism; and the driving mechanism is in circuit connection with a controller. According to the automatic safe panoramic balcony window provided by the invention, indoorpersonnel can be effectively prevented from falling down from a balcony on the premise of no fences, so that a thief cannot enter the novel safe balcony window from the balcony; and the product design is high in safety and wider in view.

Owner:文清波

Wallpapering equipment having automatic gluing function

The invention discloses wallpapering equipment having an automatic gluing function. The wallpapering equipment comprises a base; a lifting frame is arranged at the upper end of the base; a lifting mechanism is arranged between the rear end of the lifting frame and the base; a moving mechanism for wallpapering is arranged inside the lifting frame; a power mechanism for driving the moving mechanismto move is arranged at the rear end of the base; a gluing mechanism for gluing wallpaper is arranged inside the moving mechanism; and the wallpapering equipment disclosed by the invention implements gluing of the inner side of the wallpaper during wallpapering, so that the operation steps of a user are simplified, and the work efficiency is improved.

Owner:聊城绿天使科技发展有限公司

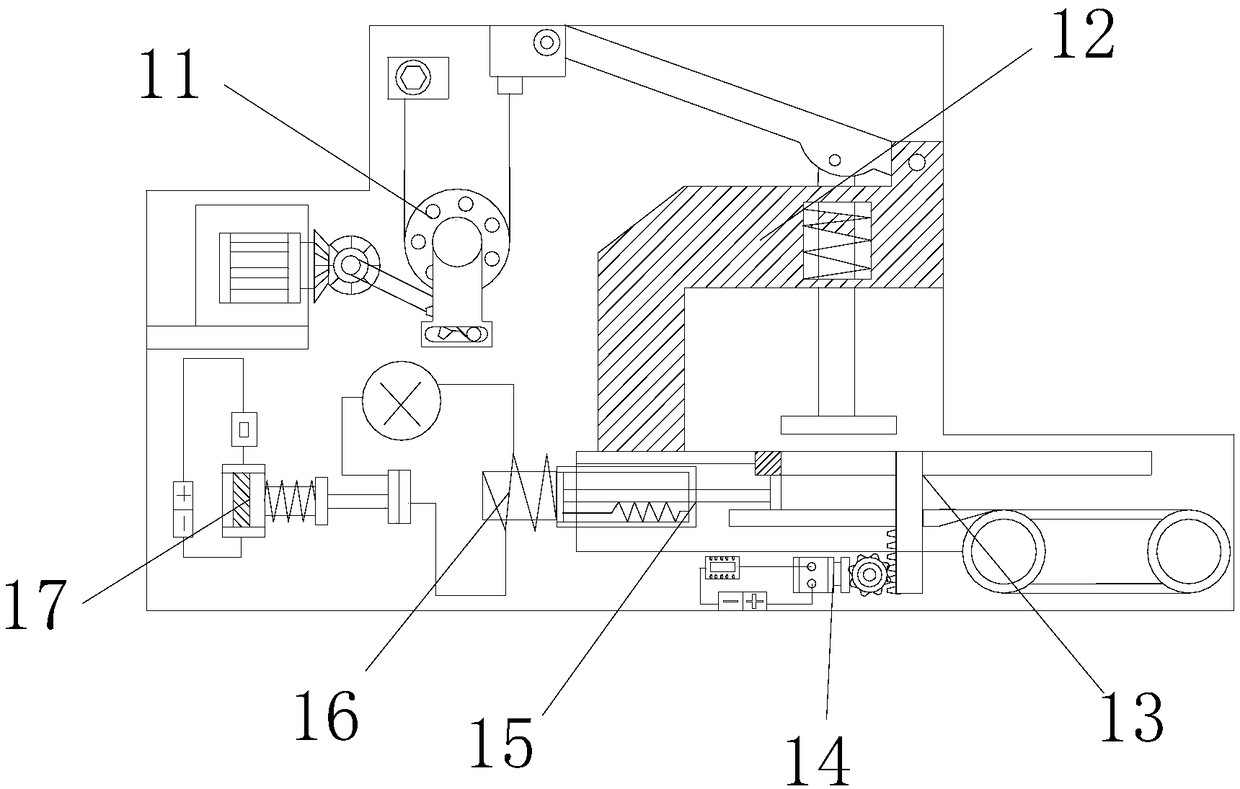

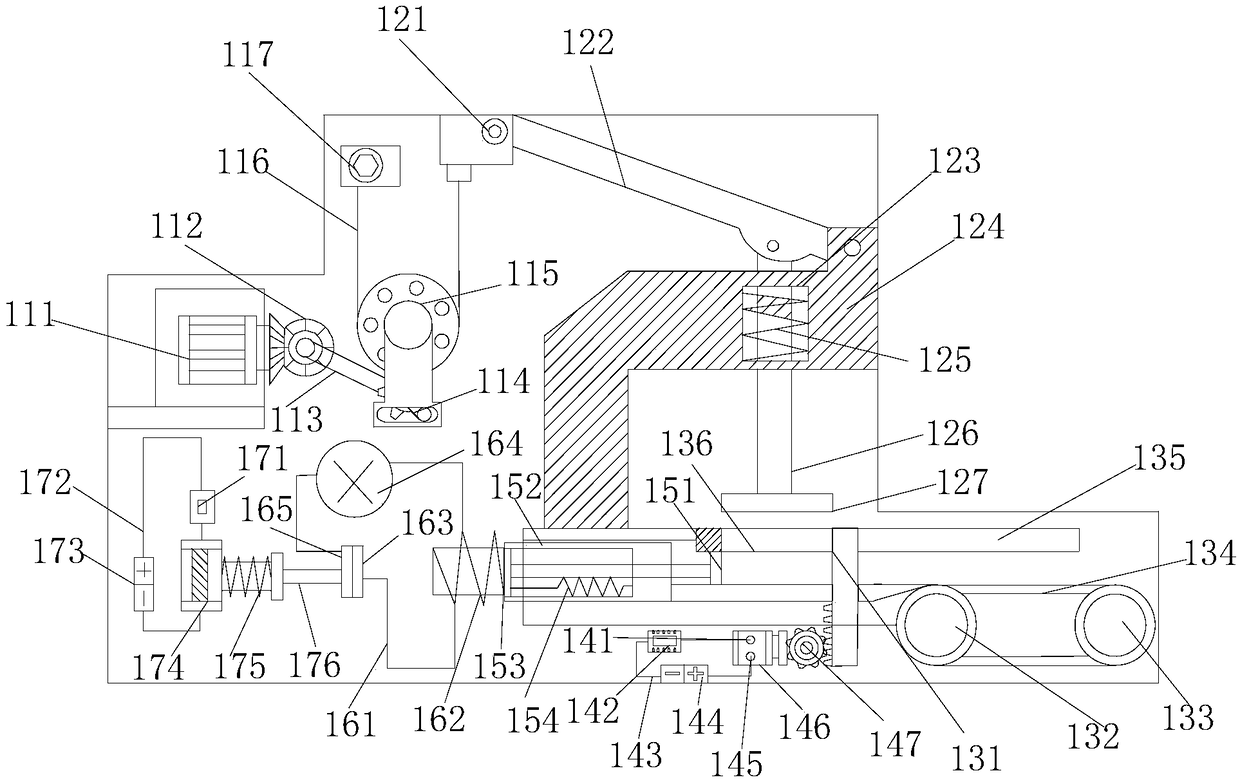

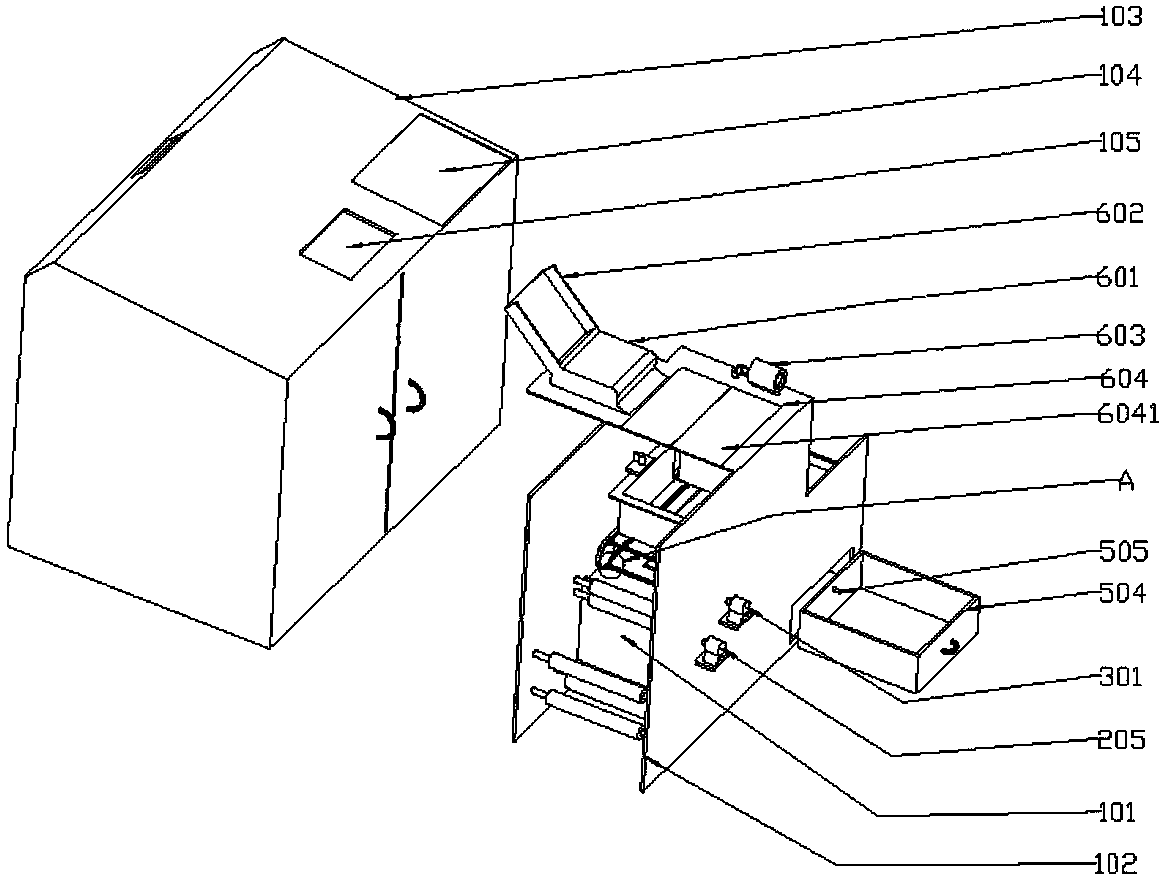

File automatic packaging-storing terminal

InactiveCN111301766ARealize integrationEasy clampingWrapping material feeding apparatusComputer hardwareAutomatic control

The invention provides a file automatic packaging-storing terminal. The file automatic packaging-storing terminal comprises a scanning module, a user interaction module, a workbench, an automatic control system, a bracket, a conveying module, a feeding module, a packaging module and an unloading module, wherein the packaging module comprises a lifting device and an edge sealing device; the liftingdevice is connected with the edge sealing device; a file limiting area is formed on the edge sealing device; the workbench is provided with a file unloading module; and the packaged files are unloaded from the unloading module. Through the adoption of the file packaging-storing terminal disclosed by the invention, the integration of file scanning and packaging is realized; the packaging need canbe met by setting a roll of packaging material for feeding; and file wrapping is realized through the arrangement of a chain wheel, a chain and a clamping device. Through the design of the packaging module, edge sealing and limiting functions are achieved, and the packaged files are convenient to store.

Owner:厦门商集网络科技有限责任公司

Height adjustable device for cabinet

InactiveCN108937221ALift controlAchieve liftingKitchen cabinetsMovable shelf cabinetPush and pullCoupling

The invention discloses a height adjustable device for a cabinet. A lifting device comprises a lifting frame, the inner side wall of the lifting frame is fixedly connected with a motor, the motor is fixedly connected with a connecting rod through a coupling, the other end of the connecting rod is rotatably connected to the side wall of a fixing plate, and the fixing plate is fixedly connected tothe inner side wall of the lifting frame. The device is provided with the lifting device and a control device, the lifting and lowering of the cabinet can be achieved by the cooperation of the liftingdevice and the control device, in the lifting device, the motor is a positive and negative rotation motor, the positive and negative rotation of the motor is achieved by the control device, thereby achieving the effect of lifting and lowering the cabinet, in the control device, the contact of a first contact piece, a second contact piece, a third contact piece and a fourth contact piece can be achieved by pushing and pulling a pressing plate, and the positive and negative rotation of the motor is achieved by controlling the switching on and off of two series connection circuits, thereby controlling the lifting and lowering of the cabinet.

Owner:合肥久新不锈钢厨具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com