Automatic iron pan arc edge grinding device

An automatic and circular arc technology, applied in the direction of grinding drive device, grinding/polishing safety device, machine tool suitable for grinding the edge of workpiece, etc., can solve the problems of unstable operation, unreasonable structure, and affecting enterprise benefits, etc. To achieve the effect of easy to use and ensure normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

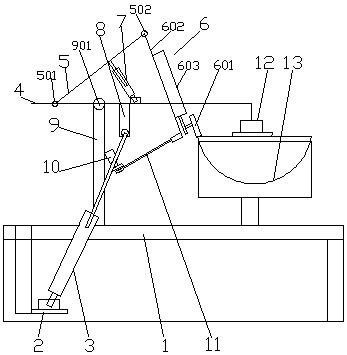

[0021] As shown in the figure, an automatic circular-arc edging device for an iron pan includes a base frame 1, a steady force rotating mechanism and a motion edging mechanism 6, the base frame 1 is a cuboid structure, and the steady force rotating mechanism includes an augmented rotating shaft frame 5 With the swing motor connecting rod 11, the head and tail ends of the motion edging mechanism 6 are fixedly connected by the added force rotating shaft bracket 5 and the swing motor connecting rod 11 respectively, and the motion edging mechanism 6 includes an edging emery wheel 601, an edging emery wheel fixed mount 602 And edging grinding wheel driving motor 603, described underframe 1 is provided with stable force rotating bracket supporting frame 9, and the top of stabilizing rotating bracket supporting frame 9 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com