Patents

Literature

55results about How to "Implement back" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

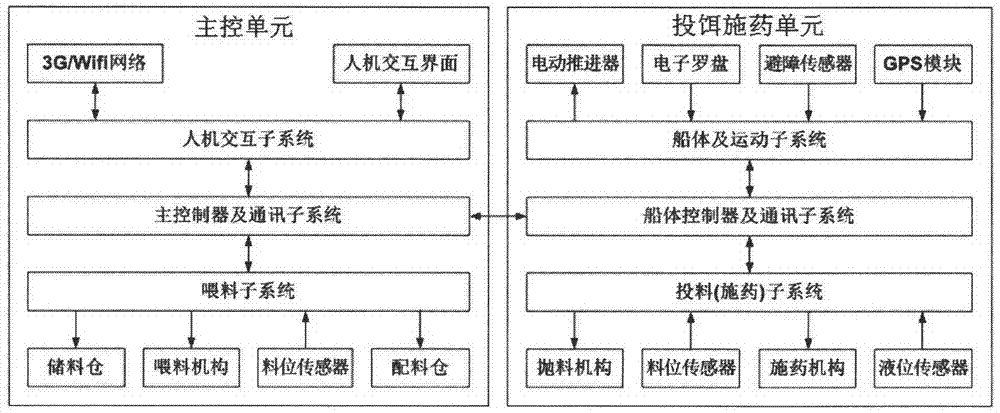

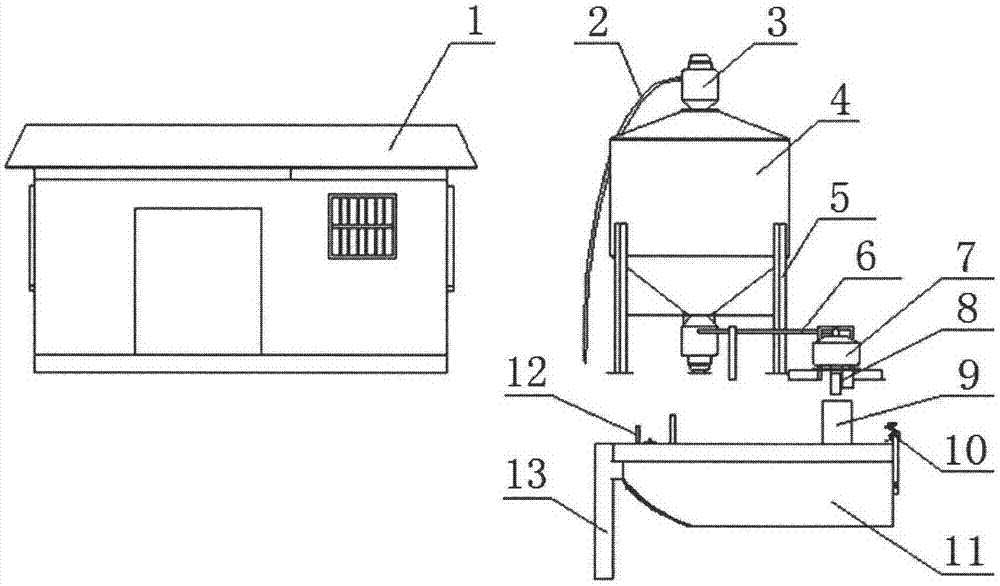

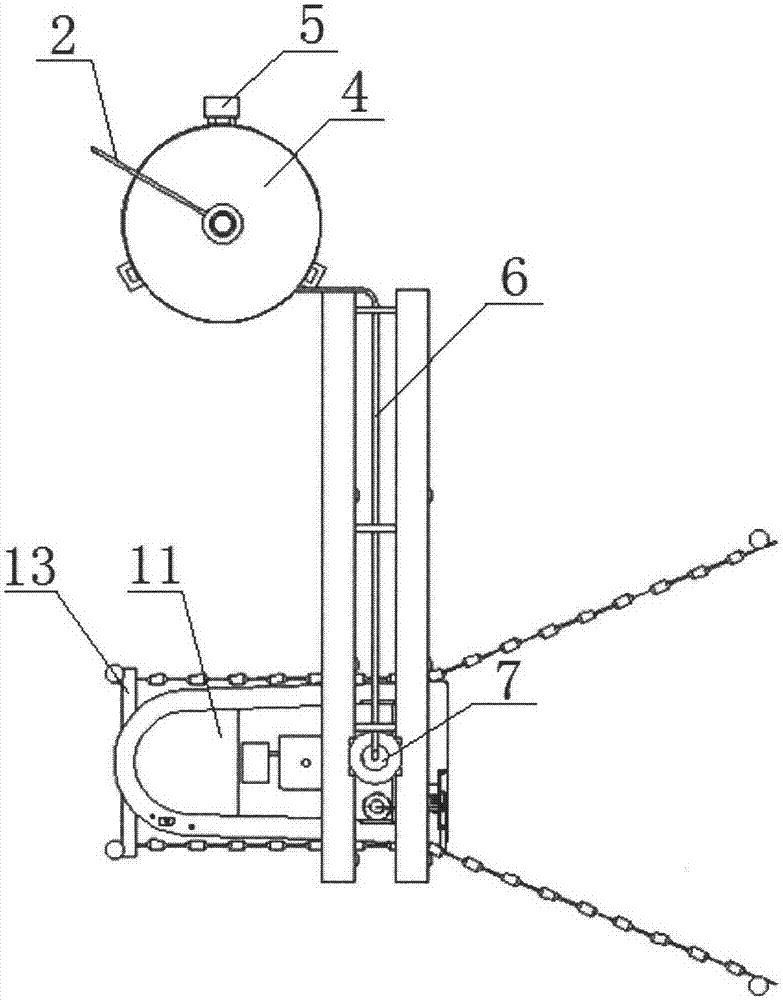

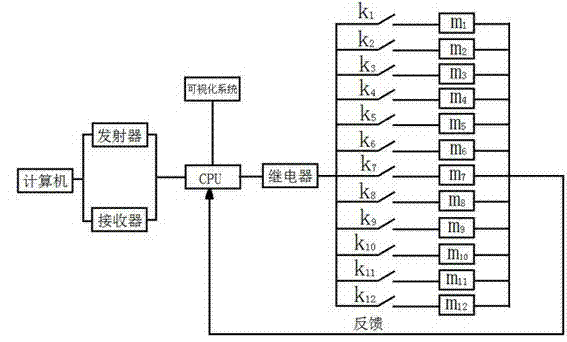

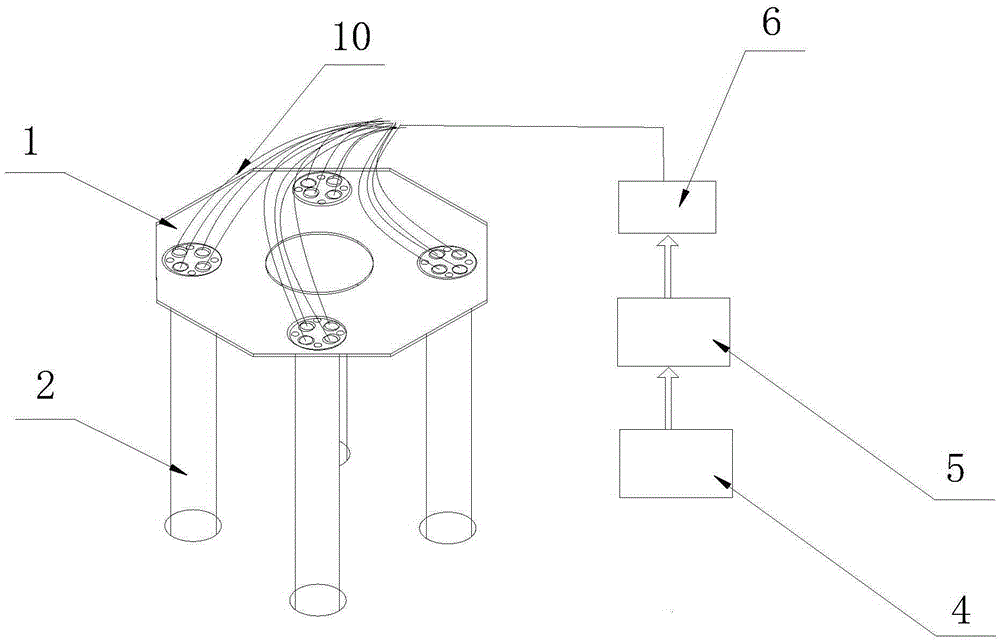

GPS (global positioning system) navigation based intelligent feeding and spraying system and device

InactiveCN103918596AReduce labor intensitySplash evenlyPisciculture and aquariaVeterinary instrumentsShrimpGps navigation

The invention discloses a GPS (global positioning system) navigation based intelligent feeding and spraying system and device, and belongs to the field of aquaculture equipment. A main controller receives a task and an instruction inputted by a man-machine interaction subsystem, and controls a feed subsystem to execute feed action; the feed subsystem feeds back feed information to the main controller, and the feed information is displayed to the man-machine interaction subsystem; a hull controller receives hull movement information inputted by a hull and a movement subsystem and controls the hull to move, and a feeding (spraying) subsystem executes feeding (spraying) action under an instruction of the hull controller; the feeding (spraying) subsystem feeds back feeding (spraying) information to the hall controller; the main controller and the hull controller are wirelessly connected through a communication subsystem. Labor intensity of aquaculture farmers is lowered greatly, accurate feeding of feed and uniform spraying of medicine are realized, use efficiency of the feed and medicine is improved, impact of aquaculture on the environment is reduced, and the system and device is particularly applicable aquaculture of shrimps and crabs.

Owner:常州智能农业装备研究院有限公司

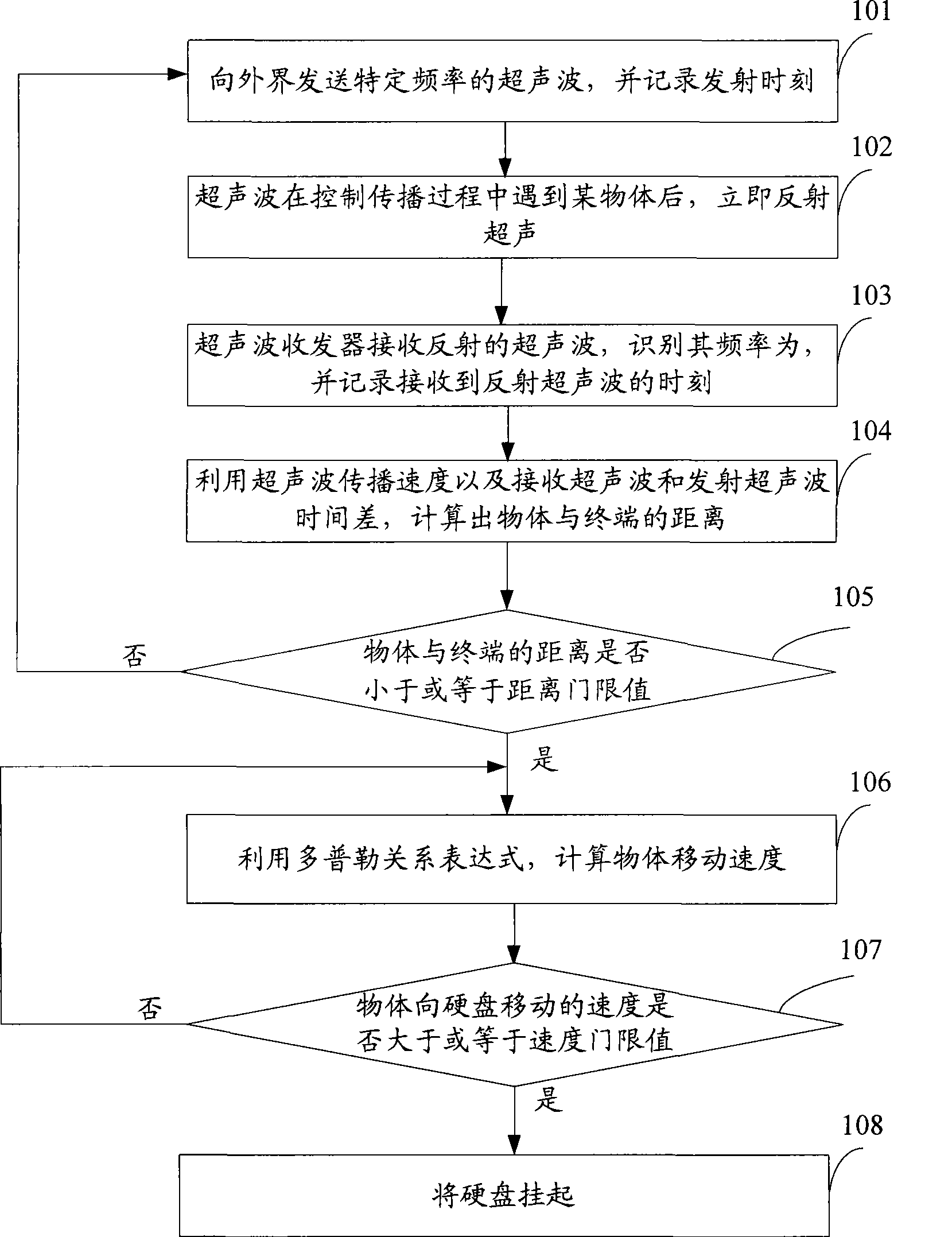

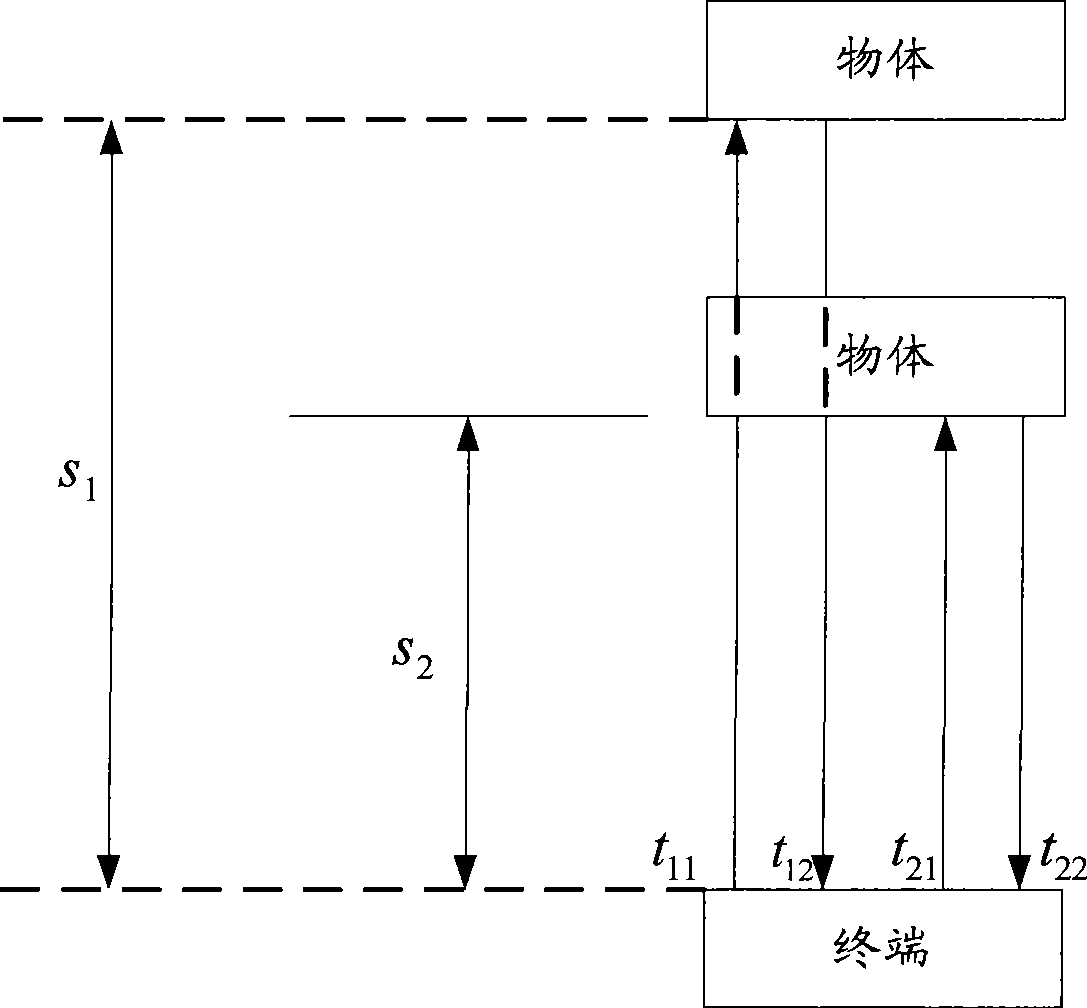

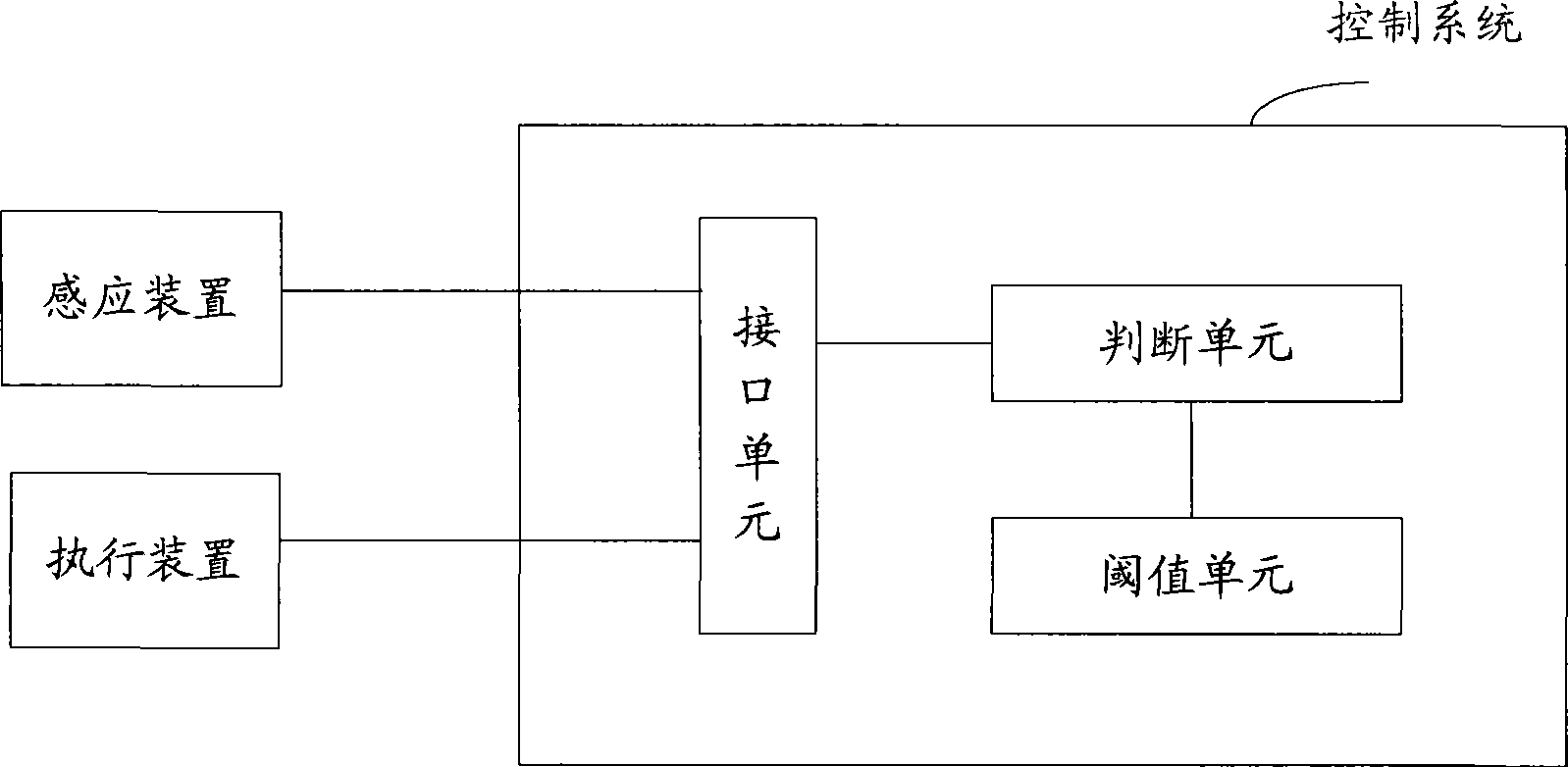

Method, system and terminal for automatic control terminal

ActiveCN101369248AProtection securityEnsure safetyInput/output for user-computer interactionHardware monitoringAutomatic controlControl system

The invention discloses a method for controlling terminal automatically, which includes the following steps: an induction device is installed in the terminal; the operation of the terminal parts is controlled automatically when the induction device detects special object within the range of prearrange distance. By using the method, the harddisk can be comprehensively protected and the power consumption of the peripherals such as keyboard or mouse can be saved, moreover, automatic startup or shutdown of the terminal, automatic forwarding and backwarding of the browser, and automatic turn-page of the application software can be realized. Corresponding to the method, the invention also includes a terminal control system and a terminal installed the control system.

Owner:LENOVO (BEIJING) CO LTD

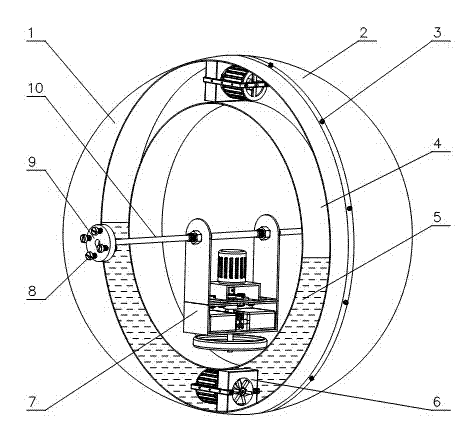

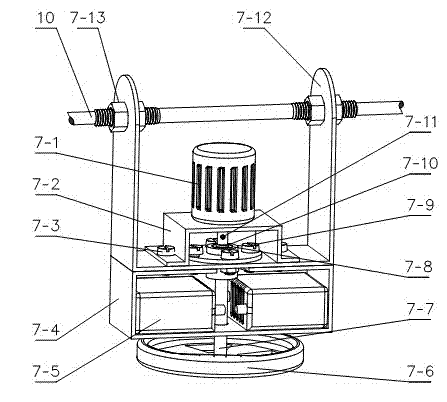

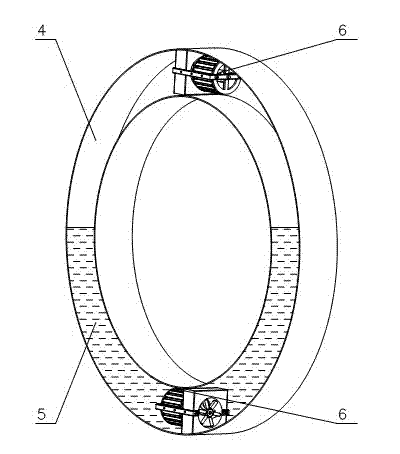

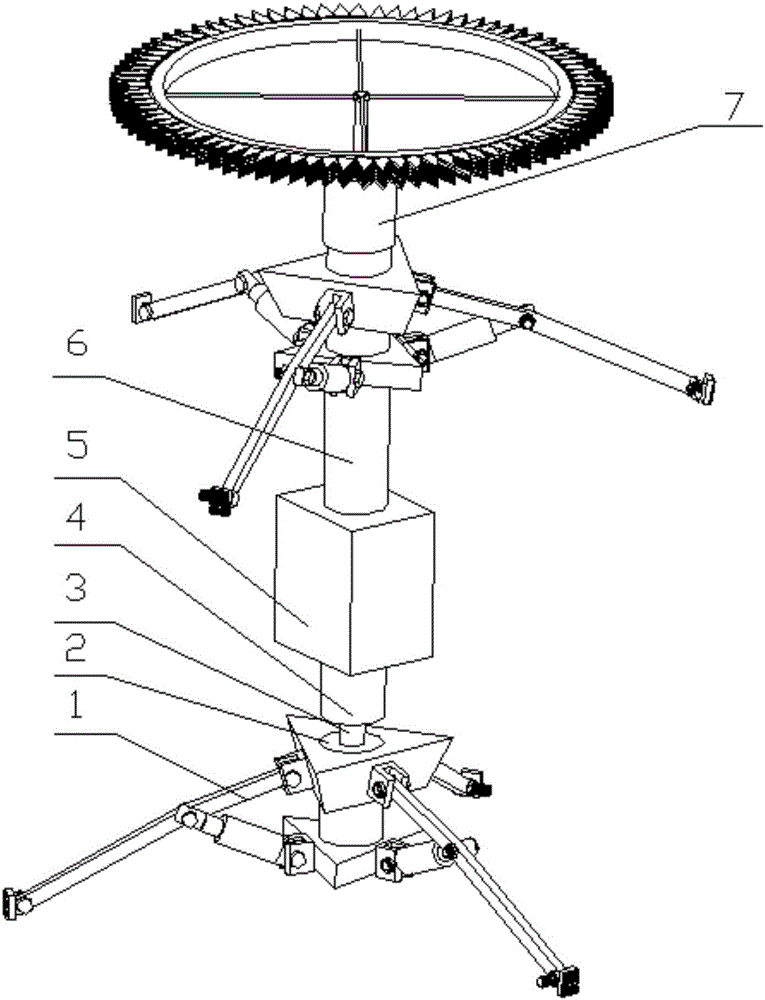

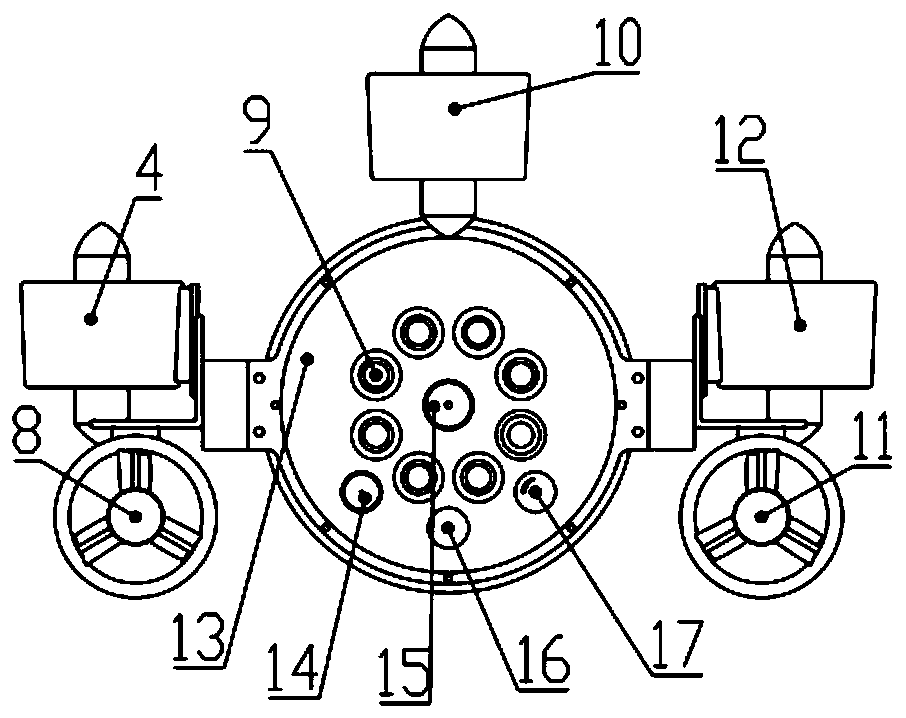

Fluid driving spherical robot

The invention belongs to the field of electromechanical technique, and relates to a spherical moving robot, and in particular relates to a fluid driving spherical robot which comprises a spherical shell, an annular seal container, axial flow devices, an inner driving rotating mechanism and a main shaft. The fluid driving spherical robot is characterized in that the spherical shell consists of two hemispherical shells including a left hemispherical shell and a right hemispherical shell; the annular seal container is positioned in the spherical surface; the outer annular surface of the container is concentric with the spherical surface of the spherical shell; the container is filled with fluid; the volume of the fluid is half of the volume of the container; two axial flow devices are symmetrically installed in the annular seal container; the axial flow devices drive a liquid to flow in the annular seal container, thus the mass center of the spherical robot is changed, thus the spherical robot can move forwards and backwards; the inner driving rotating mechanism positioned in the spherical shell mainly comprises an inner driving bracket, a motor, a motor support, a flywheel shaft, a flywheel, an electricity supply power supply and a controller; the main shaft is fixedly connected with the inner driving bracket through the motor support; the fly wheel is installed on the inner driving bracket through a bearing; the motor shaft is connected with the fly wheel through a coupling; and the motor drives the lower part of the motor to rotate together with the flywheel shaft vertical to the main shaft and the fly wheel, and the spherical robot takes a turn under the driving of the fluid on the basis of an angular momentum conservation principle.

Owner:TAISHAN UNIV

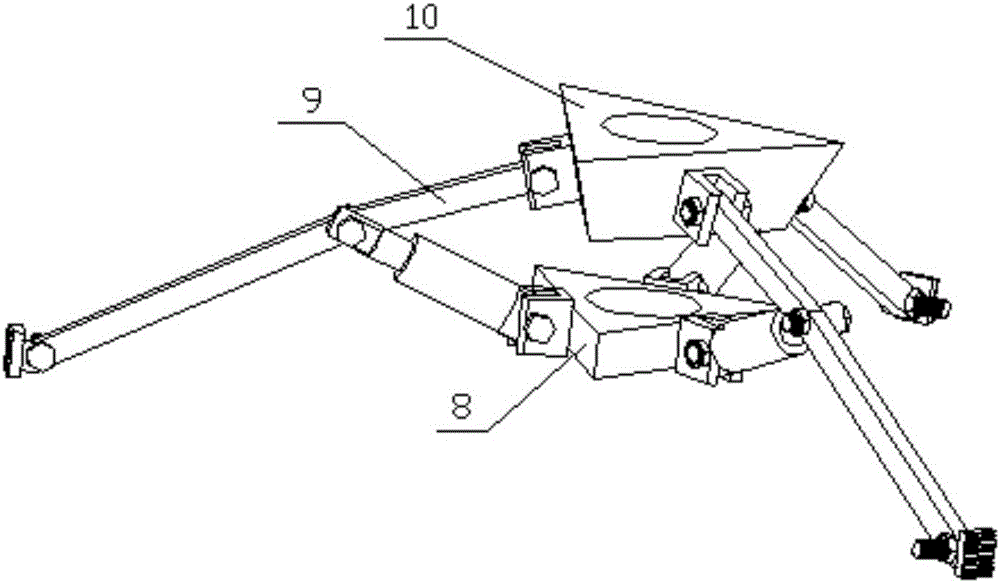

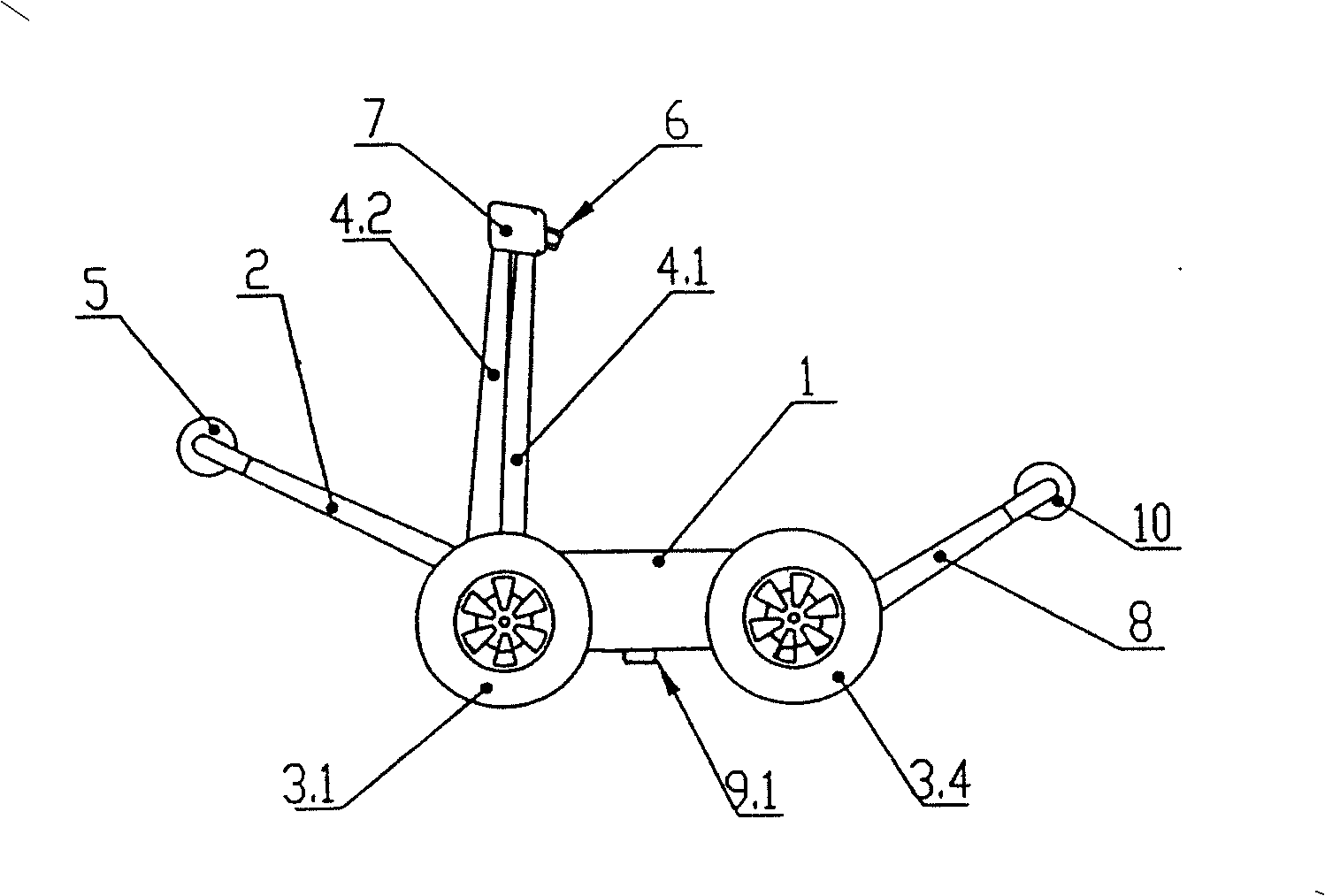

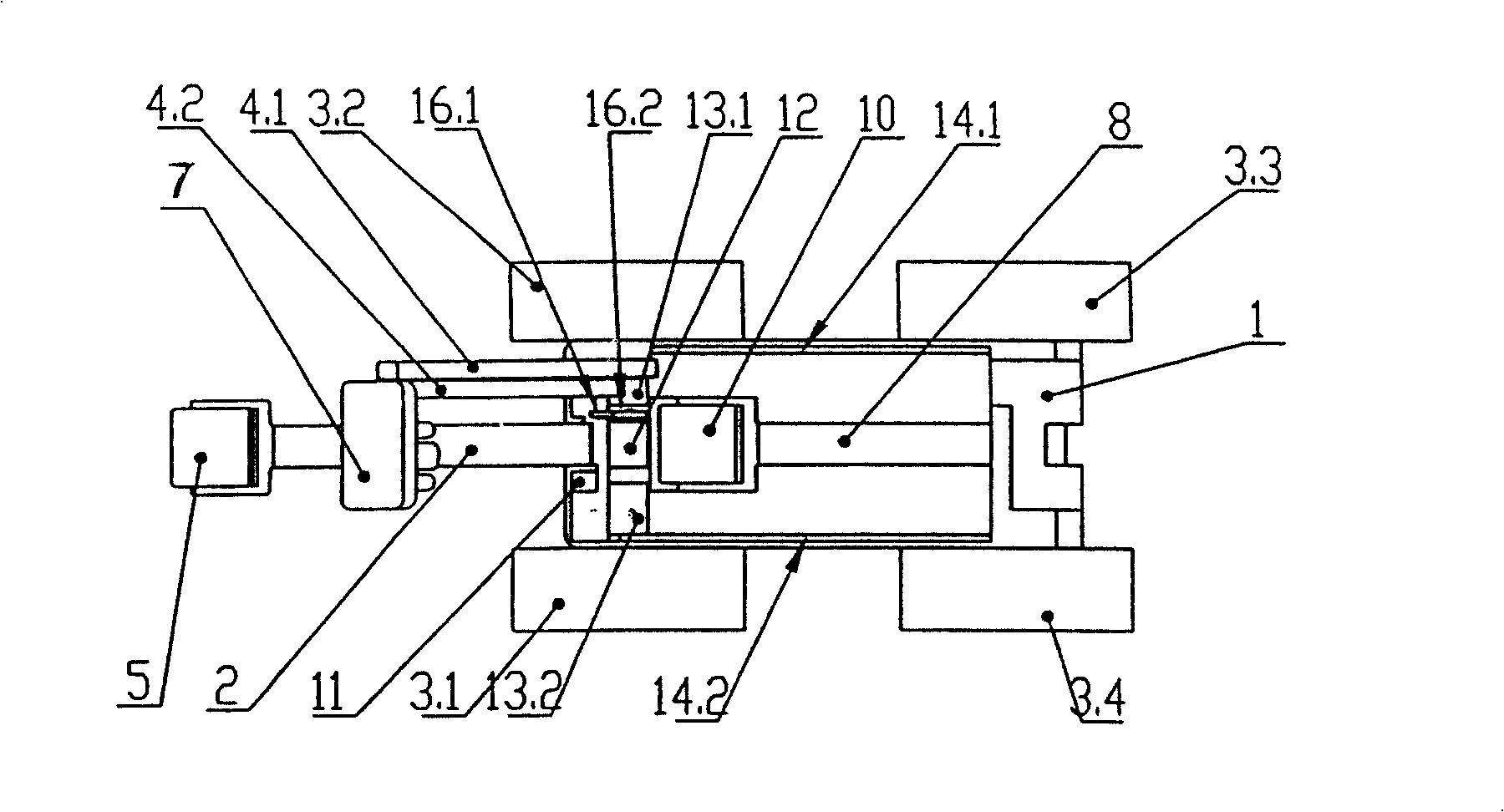

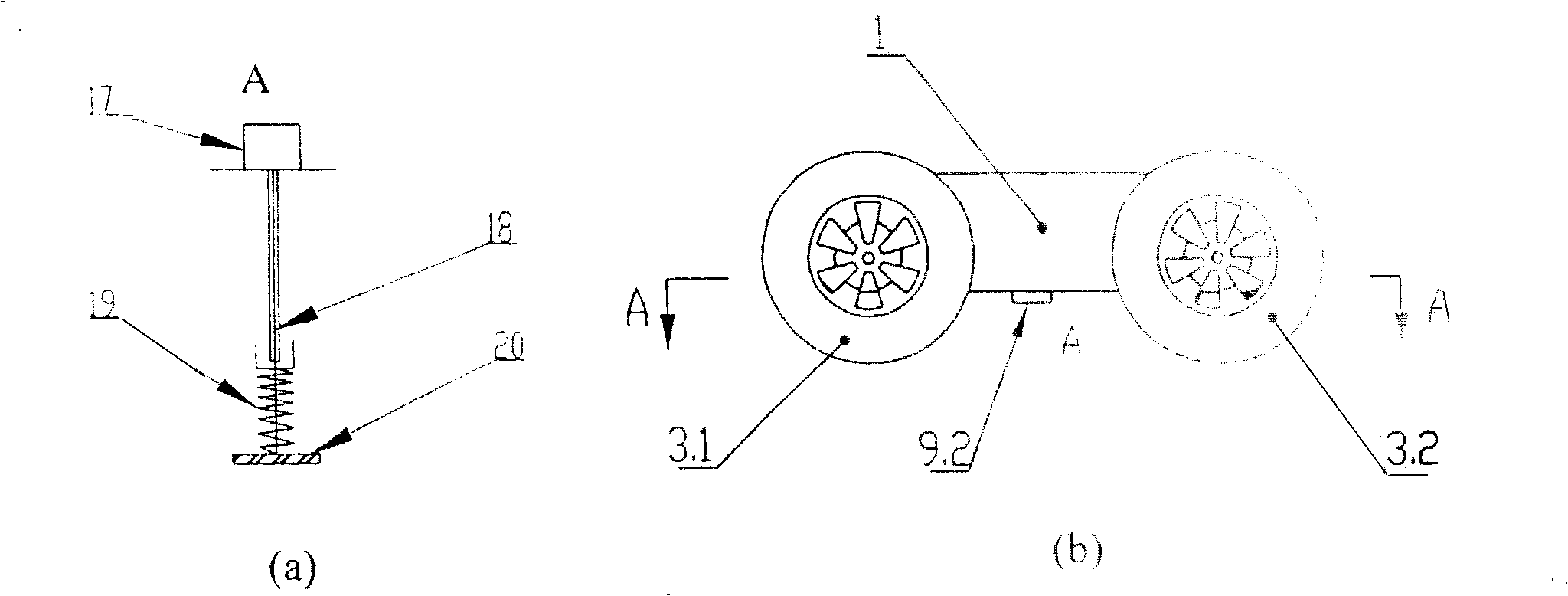

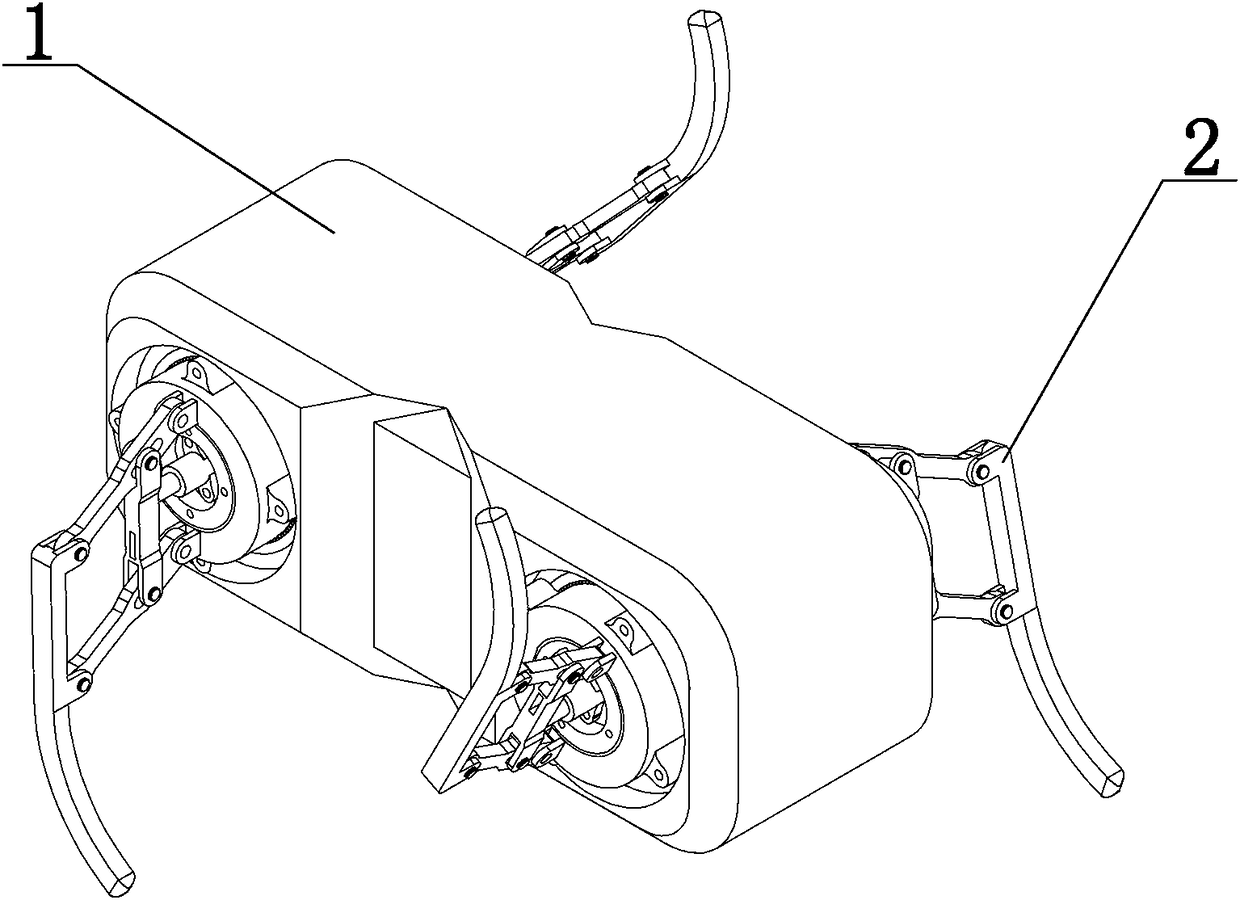

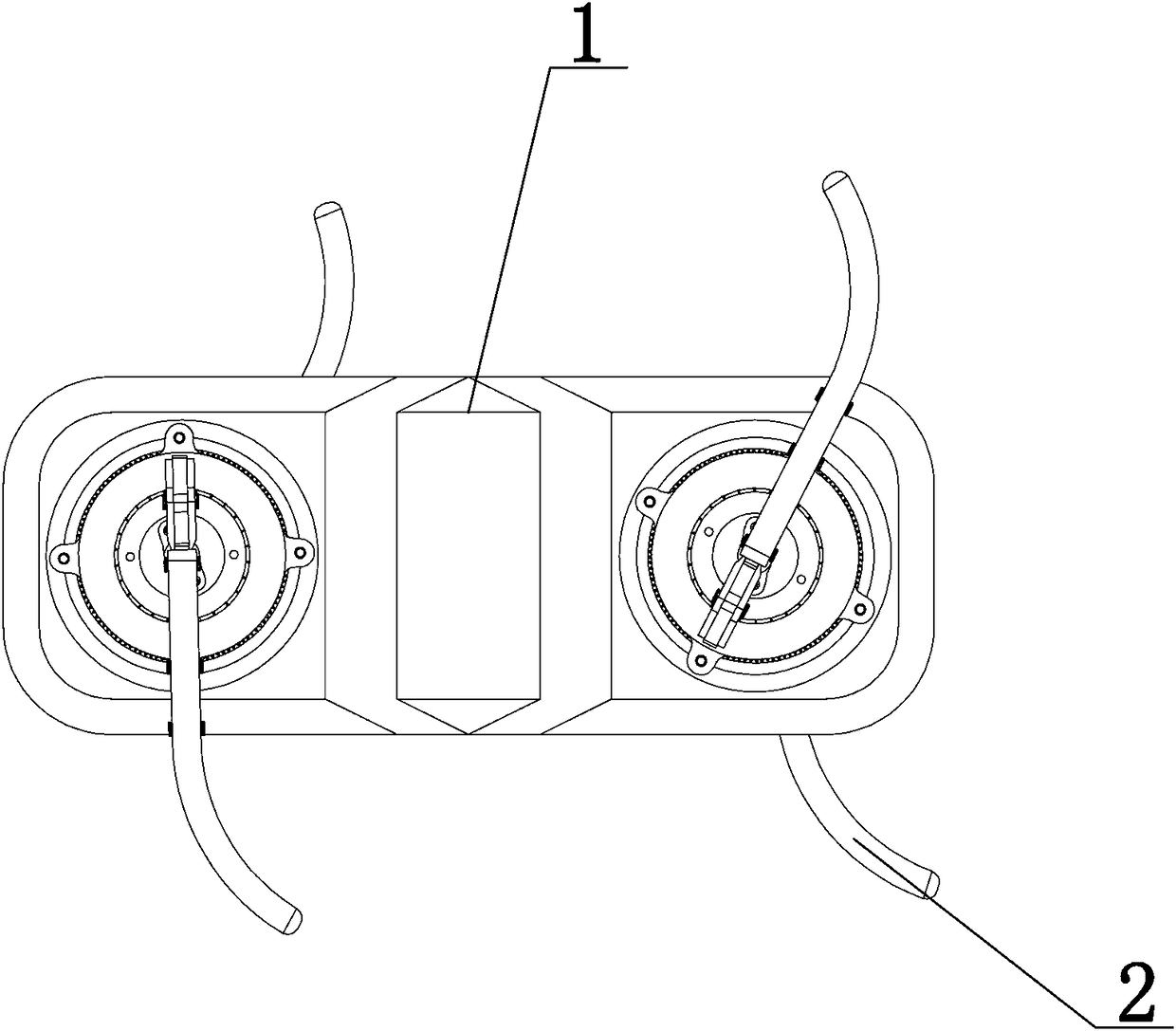

Wheel, leg, bounce mechanism combined mobile robot

InactiveCN1994804AImprove the ability to overcome obstaclesExpand field of viewSelf-moving toy figuresVehiclesCcd cameraMobile robot

The invention relates to a wheel leg bounce movable robot, wherein it uses four-wheel body, with front and back swinging wheel legs and bounce structure. The invention combines wheel structure and leg structure, to change motion mode via different conditions. Via the back swinging wheel leg, when the robot is turnover, it can return by itself. The bottom bounce structure can fly over the obstacle; the table with CCD camera is mounted in the detecting table which can lift, to expand the view sight.

Owner:ZHEJIANG UNIV

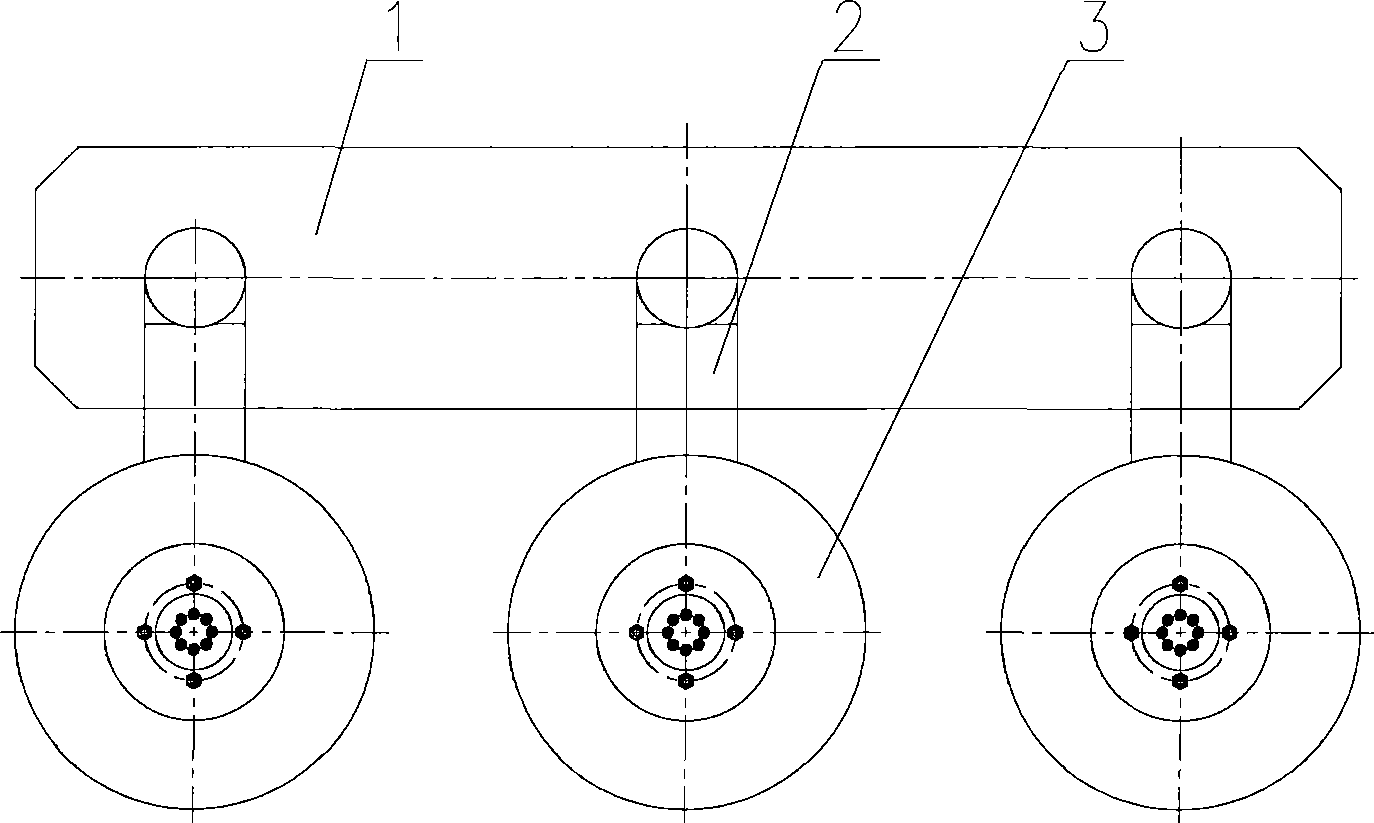

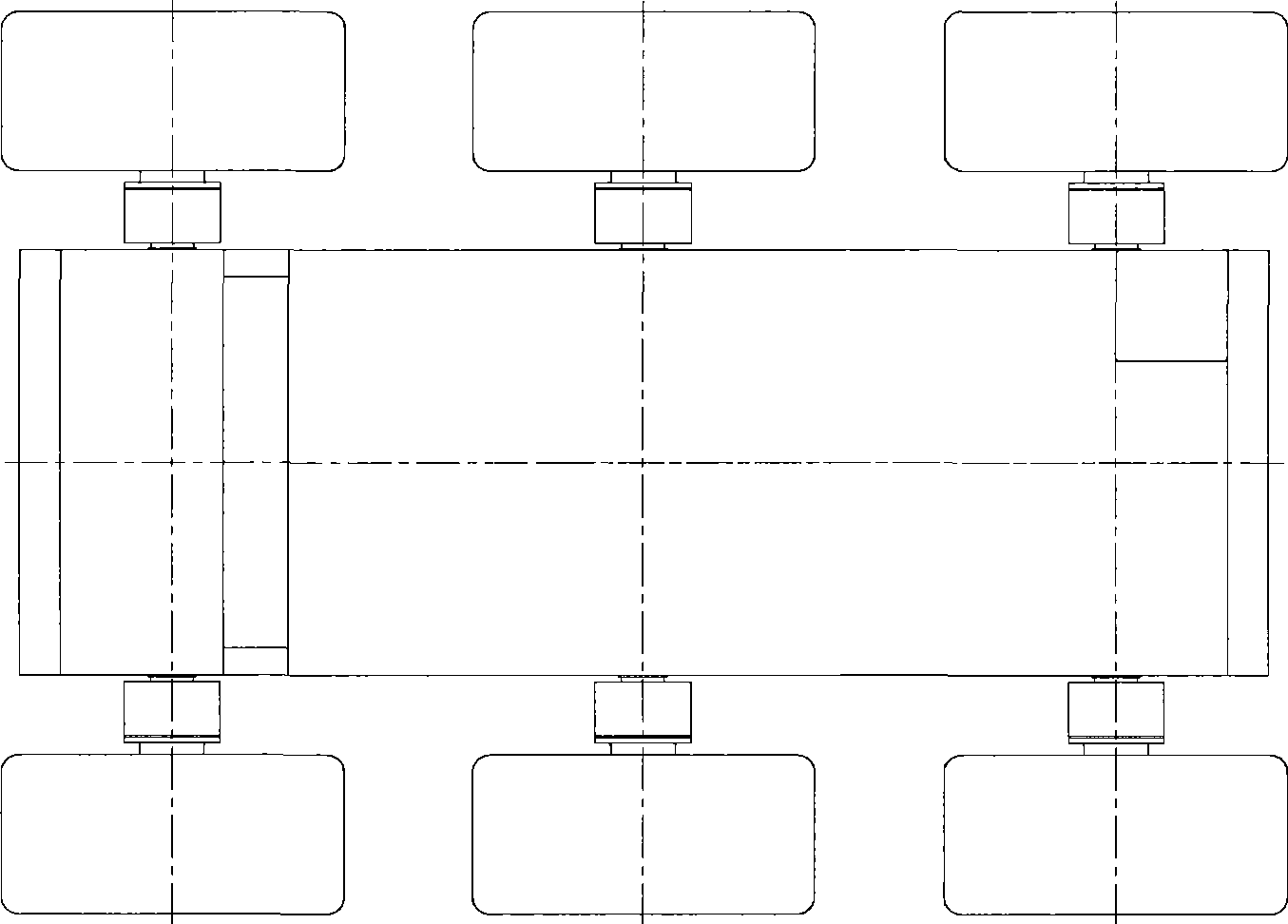

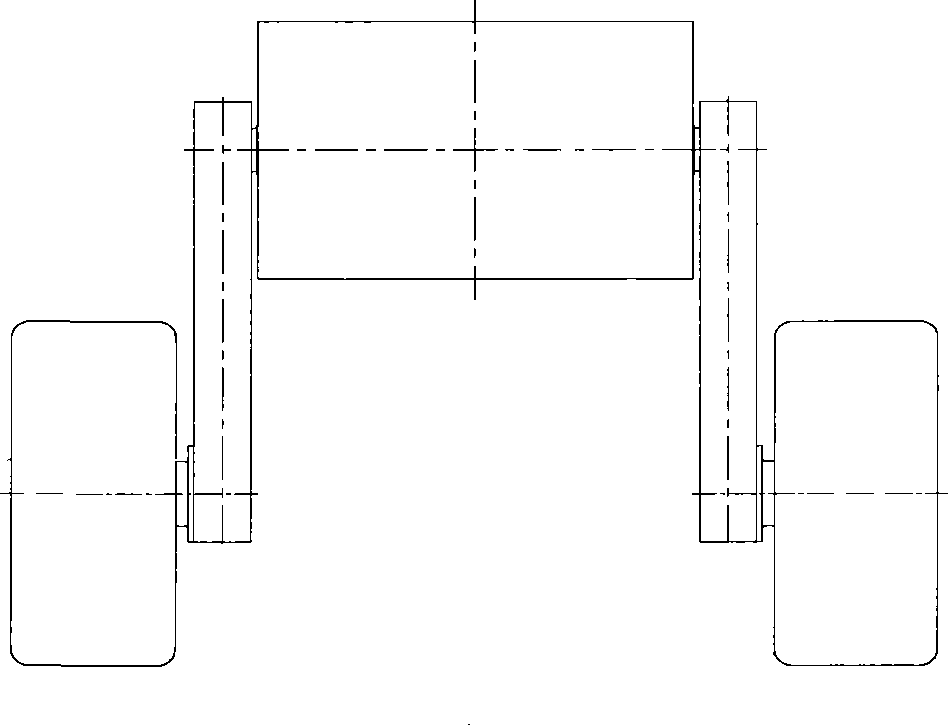

All-terrain moving robot

The invention belongs to the technical field of the advanced manufacture and automation, and particularly relates to an all-terrain mobile robot. The all-terrain mobile robot comprises a wagon box body, leg structures and driving wheels; the leg structures have six sets and are respectively arranged in front of the wagon box body, in the middle of the wagon box body and behind the wagon box body and are symmetrically arranged at the left side and the right side of the wagon box body; the driving wheels have six sets and are respectively arranged at the tail ends of the leg structures; the transition flanges of the leg structures are bolted with the output flanges of a worm and gear reduction box arranged in the wagon box body; the switching flanges arranged in the middle of the driving wheels are bolted with a transmission shaft arranged at the tail end of the leg structure. As the all-terrain mobile robot is provided with six wheel-legs and the mobile mechanism of the all-terrain mobile robot is in wheeled model and is provided with legs which can rotate 360 degrees, the all-terrain mobile robot can move in a high speed, pass the ditch independently, surpass the threshold, climb the grade and the like in subdued topography.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

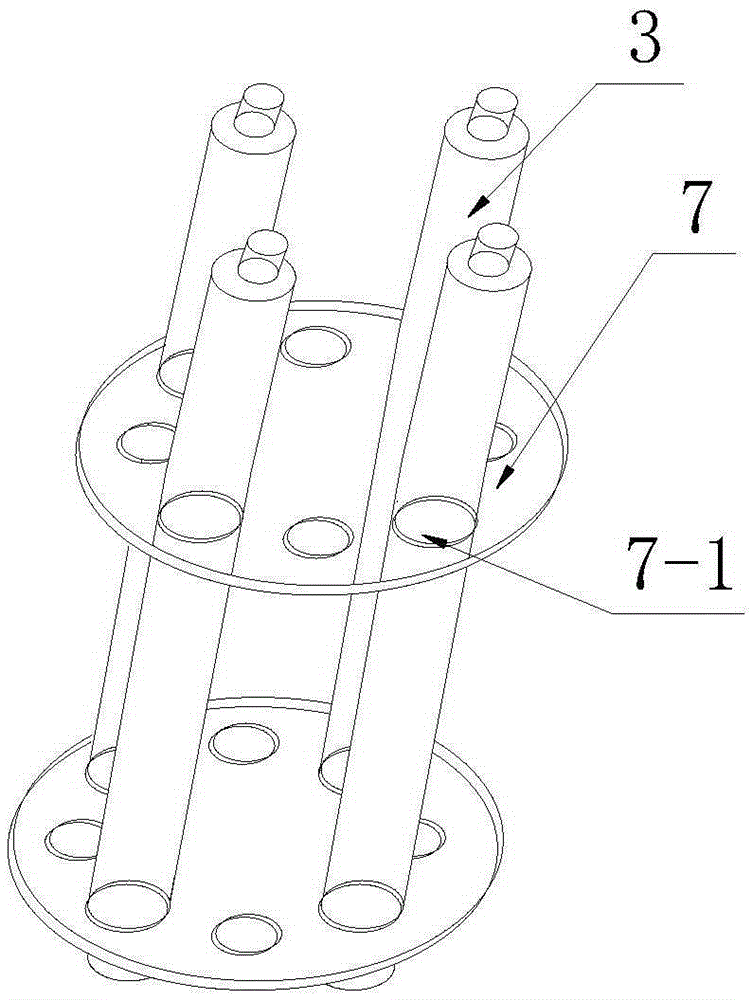

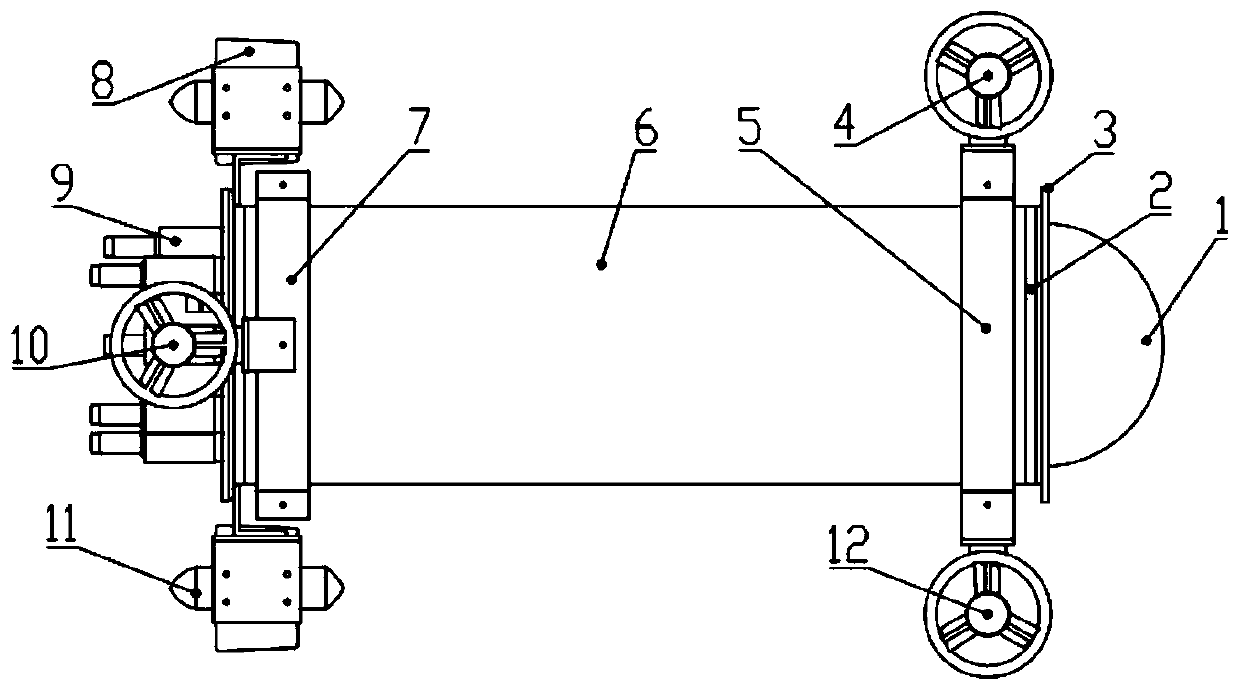

Suspension bridge steel wire rope damage patrolling robot

ActiveCN107175665AJudging the degree of damageEasy for daily maintenanceProgramme-controlled manipulatorMaterial magnetic variablesRemote controlEngineering

The invention discloses a suspension bridge steel wire rope damage patrolling robot. The suspension bridge steel wire rope damage patrolling robot comprises a base, a patrolling device arranged on the base and conducting patrolling on suspension bridge steel wire rope damage, and a control device controlling the patrolling device. The process for patrolling a steel wire rope includes the steps that firstly, the patrolling device is installed; secondly, the patrolling robot conducts patrolling on the suspension bridge steel wire rope; thirdly, after the robot finish patrolling, the robot returns to the initial end of the suspension bridge steel wire rope; fourthly, the first step, the second step and the third step are repeatedly conducted many times; and fifthly, damage state data are obtained. The suspension bridge steel wire rope damage patrolling robot is novel and reasonable in design, low in using cost, easy to operate, good in safety and capable of conveniently and rapidly finishing the suspension bridge steel wire rope damage patrolling operation; through the arrangement of the control device, a user remotely controls the patrolling robot to conduct high-altitude detection through a wireless remote control transmitter, and safety hidden danger of workers during high-altitude operation is avoided; and design is ingenious and reasonable, reliability and stability are achieved, the size is small, and practicability is high.

Owner:XIAN UNIV OF SCI & TECH

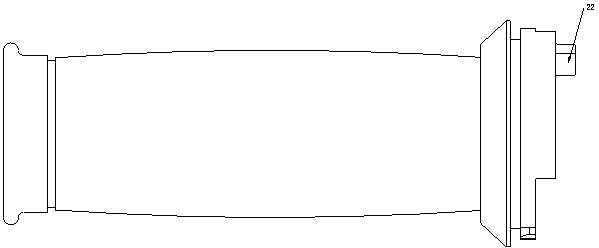

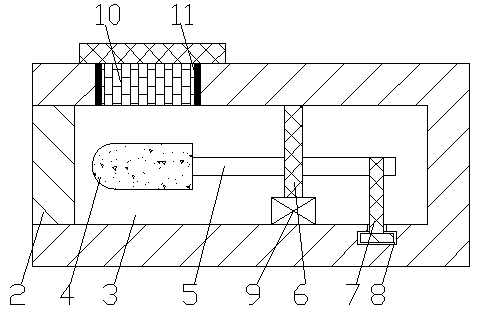

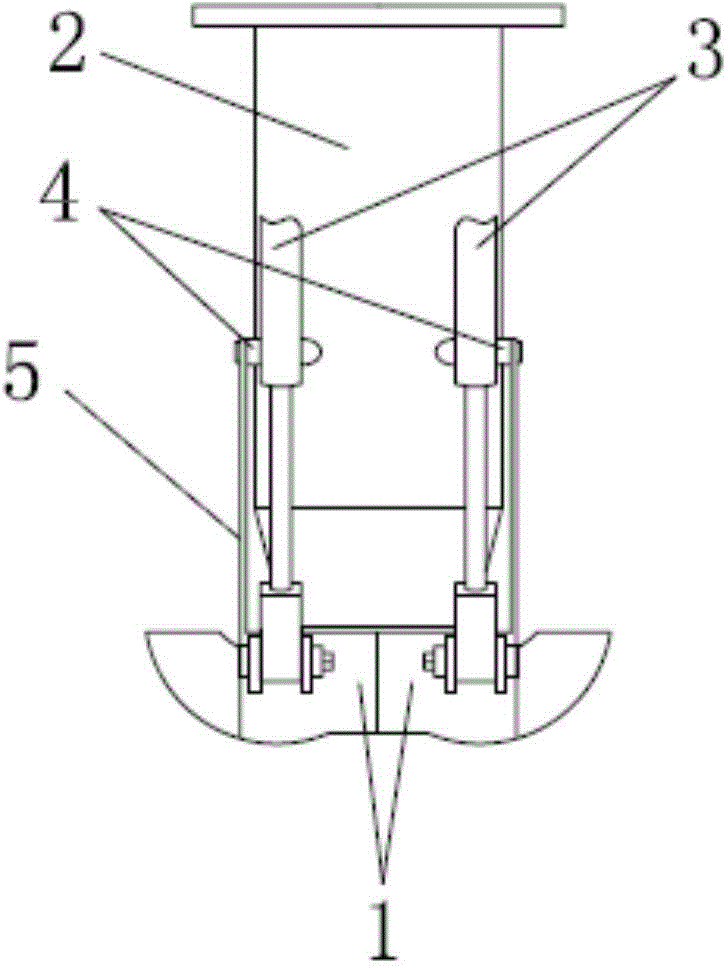

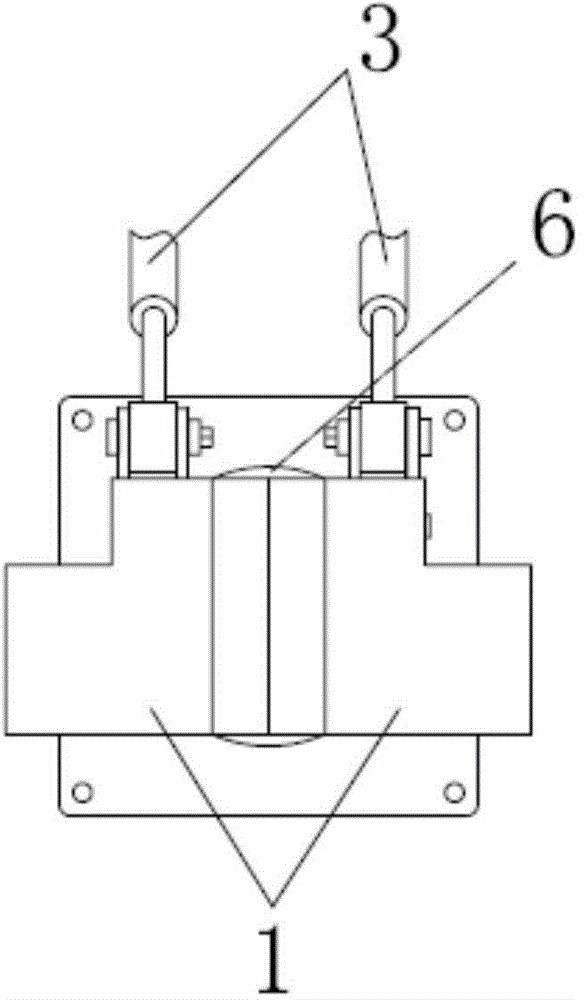

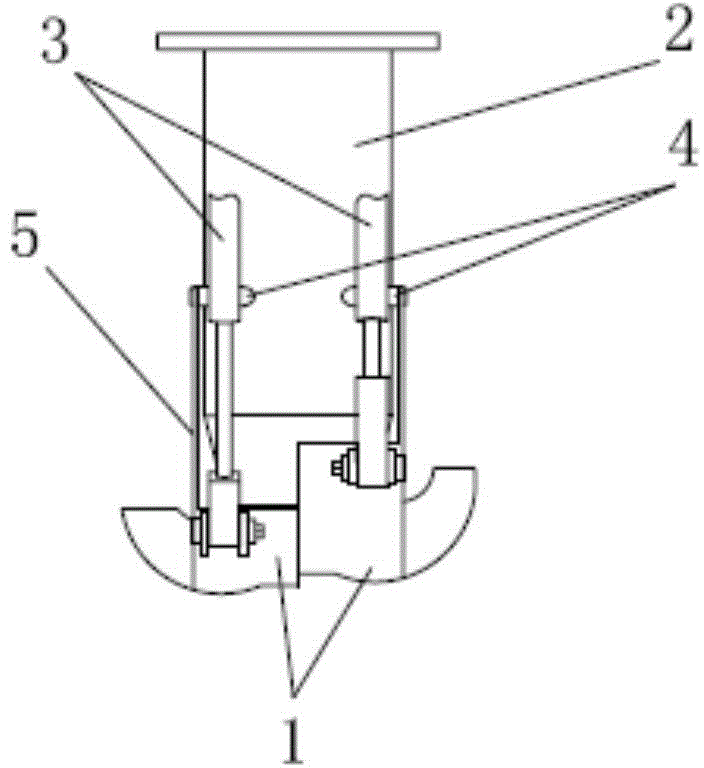

Pipe cleaning device

InactiveCN105945016AChieve progressImplement backHollow article cleaningHydraulic cylinderMotor drive

The invention discloses a pipe cleaning device. The pipe cleaning device comprises a climbing device, a sleeve, a hydraulic cylinder 1 piston rod, a moving pair 1, a controller , a hydraulic cylinder 1 cylinder body and a cleaner; the cleaner includes a connecting frame, a cleaning brush and a motor; and the cleaning brush is bonded on the outer side of the connecting frame through glue. The pipe cleaning device adopts hydraulic driving, can be fixed on the inner wall of a pipe through a support rod and an antiskid pad, can realize advancement and retreating in the pipe by using telescopic movement of the hydraulic cylinder piston rod corresponding to the hydraulic cylinder body, and drives the cleaning brush to clean the pipe through the motor driving the connecting frame to perform a rotating motion; and the pipe cleaning device is simple in structure, convenient for assembly, high in reliability, high in cleaning efficiency and convenient for control.

Owner:范志杰

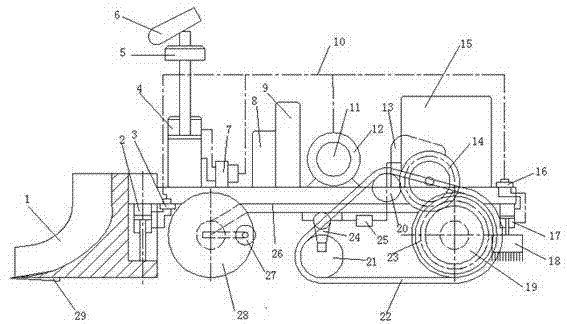

Full hydraulic automatic dung cleaning robot

InactiveCN102893875AChieve progressImplement backClimate change adaptationAnimal housingDiseaseElectronic speed control

The invention discloses a full hydraulic automatic dung cleaning robot, and belongs to the technical field of dung cleaning mechanical equipment. According to the full hydraulic automatic dung cleaning robot, a front wheel is provided with a steering gear; the back of a base plate is connected with a crawler-type back wheel; the crawler-type back wheel is connected to a driving system and is driven by the driving system; the front end of the base plate is provided with a concave dung scraper; the dung scraper is provided with a hydraulic control system for controlling vertical movement; the front end on the upper part of the base plate is provided with a visualization system; the steering gear, the driving system, the hydraulic control system and the visualization system are connected to an electronic control system; and the electronic control system is in wireless signal transmission connection with a computer to realize remote control and monitoring within 200 meters. The full hydraulic automatic dung cleaning robot can remotely control to clean dung and monitor livestock in 24 hours, working conditions of livestock breeding managers are improved, a good environment for the growth of the livestock is created, diseases are reduced, the meat quality of the livestock is improved and the like.

Owner:SICHUAN AGRI UNIV

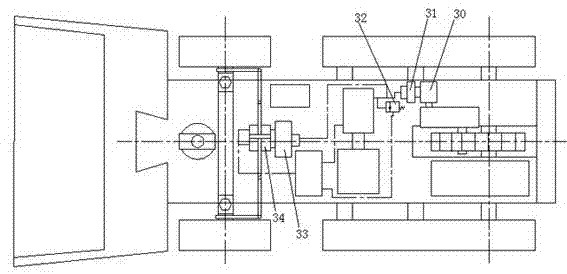

Single crawler type wall climbing robot based on electrostatic absorption principle

The invention discloses a single-crawler type wall climbing robot based on the electrostatic adherence theory, and relates to a wall climbing robot. The invention aims to provide a wall climbing robot which has the advantages of large range adapting to wall surface materials, low noise, smaller volume, small electrostatic adherence device self weight and high moving speed. Flexible aluminum plated film crawlers are adopted as a walking device and an adherence device of the robot. One end of a slide base plate is overlapped with one end of a slide guide plate, and the base plate is connected with an end part of the slide guide plate. One end of a spring is connected with a guiding and positioning rod piece, while the other end is connected with an end part of the slide guide plate. The other end of the slide base plate is perpendicularly connected with the middle part of a driving wheel supporting frame main body of a driving wheel supporting frame, and the other end of the slide guide plate is perpendicularly connected with the middle part of an inducement wheel supporting frame main body of an inducement wheel supporting frame. The wall climbing robot has the advantages of large range adapting to the wall surface materials, low noise, smaller volume, small electrostatic adherence device self weight and high moving speed, and has board application prospect in the aspects of anti-terrorism detection, high building detection and so on.

Owner:SHENZHEN LONGHAITE ROBOT TECH CO LTD

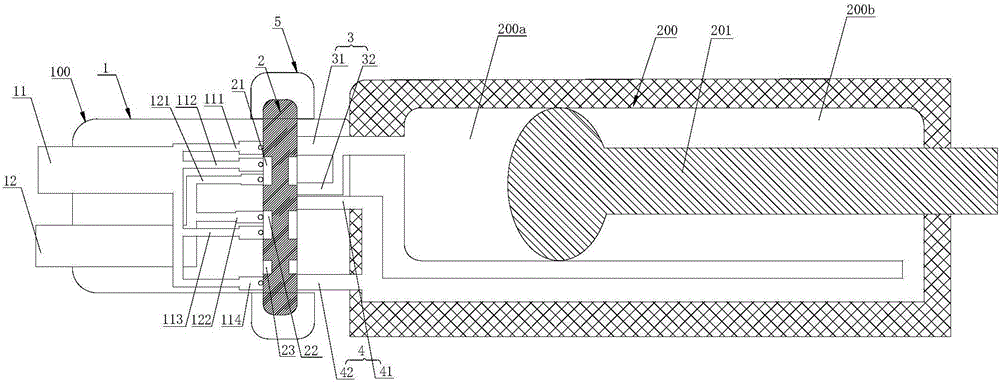

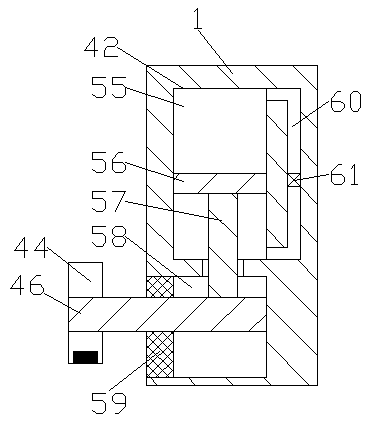

Conversion valve

ActiveCN106321544AChange auto forwardChange backServomotor componentsEngineeringElectrical and Electronics engineering

The invention provides a conversion valve which comprises a shell, a conversion control part, a first connection pipe and a second connection pipe, wherein a fluid inlet and a fluid outlet are formed in the shell; the conversion control part is arranged in the shell in the axial direction perpendicular to the shell; a plurality of through holes with the axial lines parallel to the direction of the fluid inlet are formed in the conversion control part; during conversion of the flowing direction, the conversion control part moves in the axial direction perpendicular to the shell; the first connection pipe and the second connection pipe are respectively connected to the conversion control part and an external closing device to form fluid circulation.

Owner:HANGZHOU OUDUN ELECTROMECHANICAL

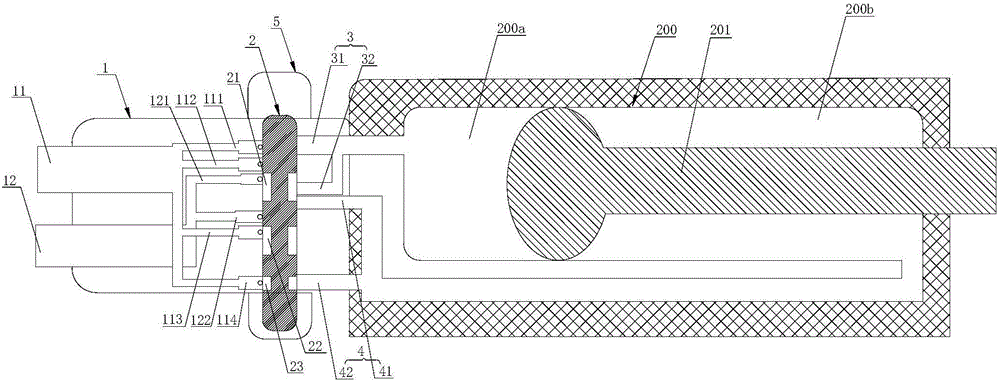

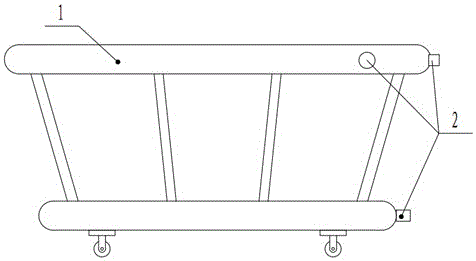

Baby walker with intelligent danger-avoiding function

InactiveCN105747688ARealize automatic parkingAchieve steeringChildren furnitureEngineeringBaby walker

The invention discloses a baby walker with an intelligent danger-avoiding function. The baby walker comprises a walker body, wherein a barrier-avoiding and danger-avoiding module is mounted on the walker body and connected to a control module; and a voice alarm module, a brake module, a speed detection module and a driver module are connected to the control module. According to the baby walker with the intelligent danger-avoiding function, the barrier-avoiding and danger-avoiding module, the voice alarm module, the brake module, the speed detection module and the driver module are mounted on the baby walker, so that automatic stopping, steering and backing of the baby walker are realized; when the baby walker encounters a step or other barriers, a guardian is reminded to preferentially handle a dangerous case through the voice alarm device, so that the baby walker is safer and does not need to be watched, the time and labor are better saved, and the problems that a baby walker is poor in safety and needs to be watched in real time in the prior art are effectively solved; and the baby walker has the characteristics of simple structure and convenience and quickness for control.

Owner:GUIZHOU UNIV

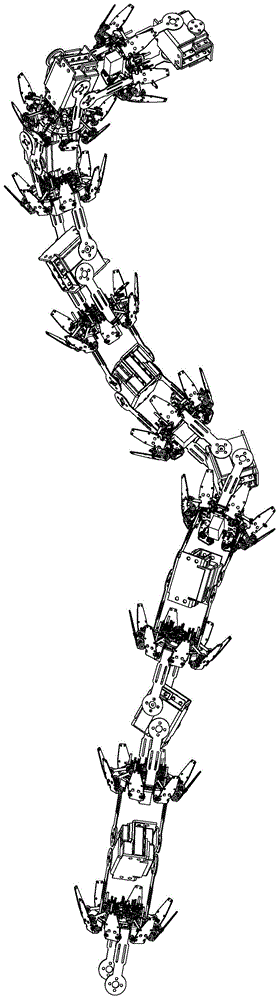

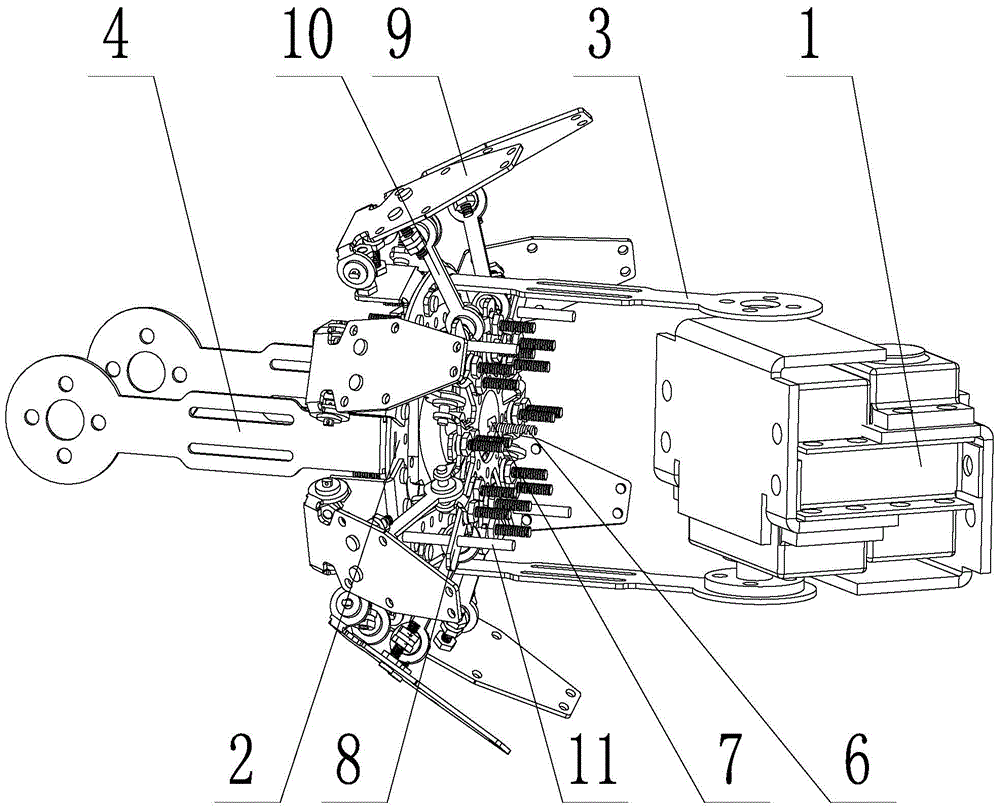

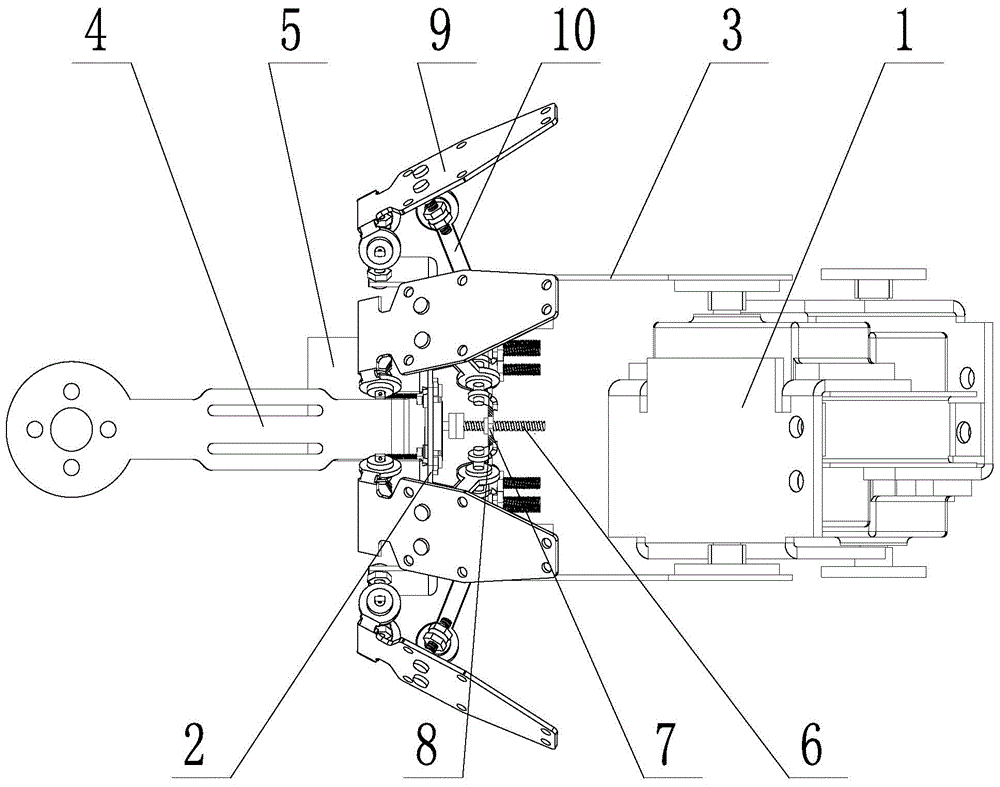

Scale-controllable type snakelike robot

InactiveCN104440897ARealize moving forwardImplement backProgramme-controlled manipulatorMotor driveControl theory

The invention discloses a scale-controllable type snakelike robot and belongs to the technical field of bio-robots. The snakelike robot is formed by connecting and combining a plurality of unit modules end to end. Each unit module comprises a dual motor drive steering engine, a module framework and a scale mechanism. The two motor shafts of each dual motor drive steering engine are arranged in parallel. The dual motor drive steering engines are connected with the module frameworks through steering engine connecting arms, scale opening and closing control motors of the scale mechanisms are installed on the module frameworks and drive guiding plates through screw rods and nuts, and the roots of scales are hinged to the module frameworks. The middles of the scales are connected with the guiding plates through connecting rods. According to the scale-controllable type snakelike robot, compared with the prior art, the scale mechanisms with the opening and closing function are introduce in for the first time, under the action of friction anisotropism of the scales, the scales can be in an opening state or a closing state, meanwhile, the adjacent unit modules are controlled to get close to each other or get away from each other through the dual motor drive steering engines, the snakelike robot can move forwards or backwards, and therefore the applicability of the snakelike robot is improved.

Owner:NORTHEASTERN UNIV

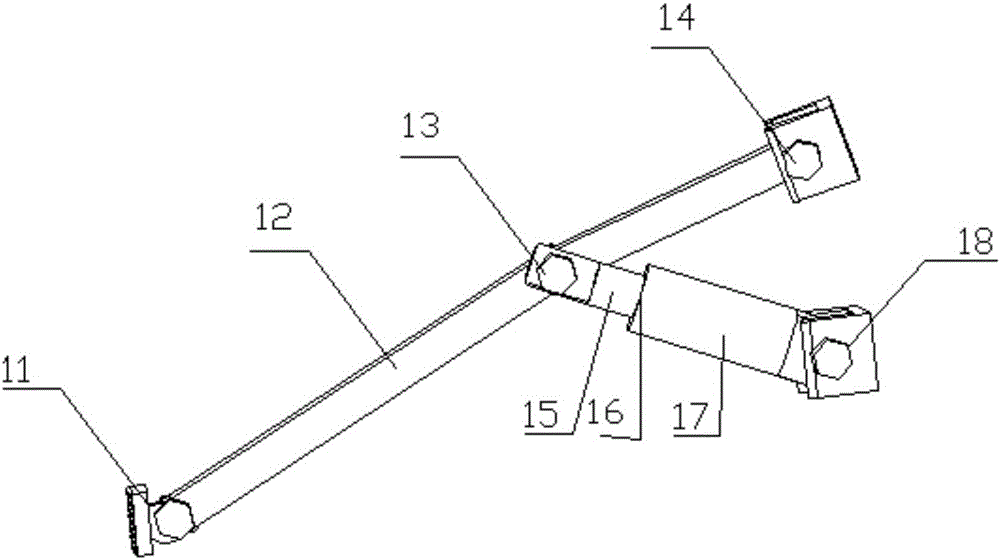

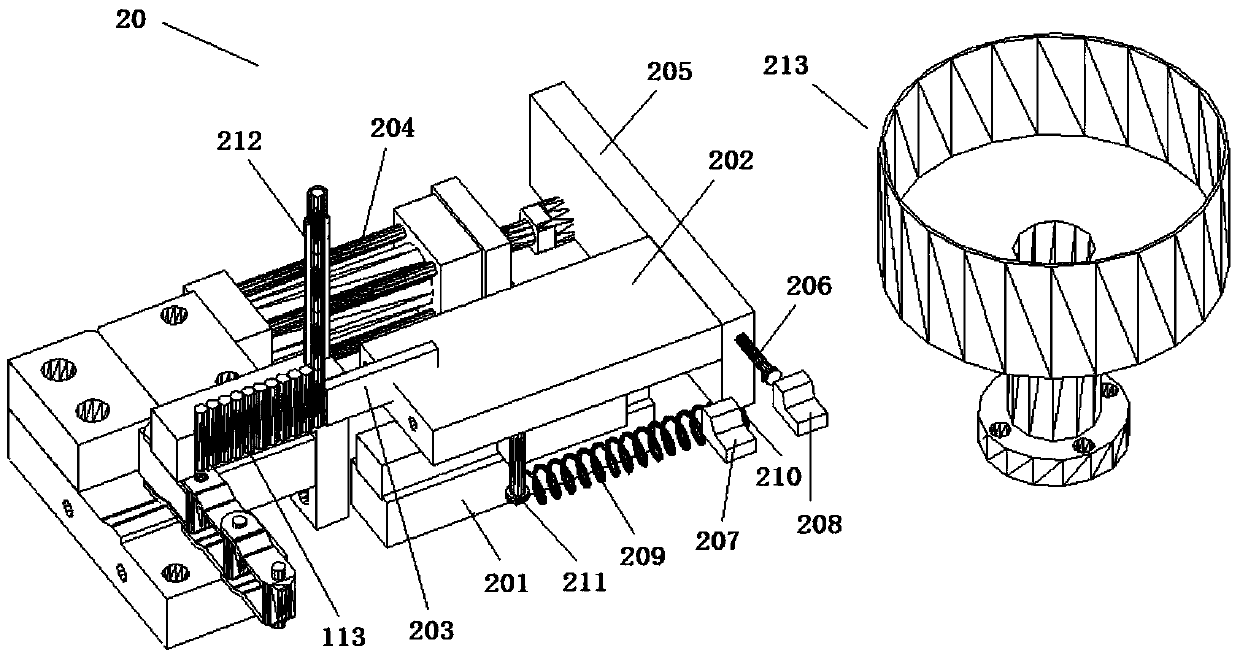

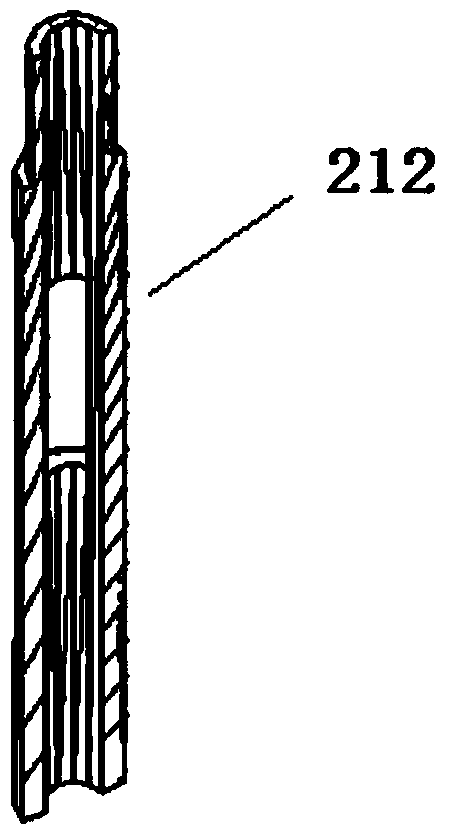

Hinge pin feeding device of chain assembly machine

The invention relates to a hinge pin feeding device of a chain assembly machine. The hinge pin feeding device comprises hinge pins, a hinge pin falling tube, a hinge pin push plate, a hinge pin push plate linear guide rail, a movement plate, a connecting plate, a stroke inductive head, a hinge pin push plate forward-pushing stroke inductor, a hinge pin push plate backward-movement stroke inductor, a hinge pin push plate returning tension spring, a driving mechanism and a hinge pin vibration feeding device body. The hinge pin feeding device of the chain assembly machine is ingenious in design and high in working efficiency; the movement plate forwards moves on the hinge pin push plate linear guide rail under driving of a thrust oil cylinder, and backwards moves on the hinge pin push plate linear guide rail under the effect of restoring force of the hinge pin push plate returning tension spring, and therefore the hinge pin push plate can move forwards or backwards; meanwhile, the stroke inductive head is further arranged on the connecting plate, and when moving forwards or backwards to be in place, the connecting plate can be detected through the hinge pin push plate forward-pushing stroke inductor and the hinge pin push plate backward-movement stroke inductor which are installed on a working table.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

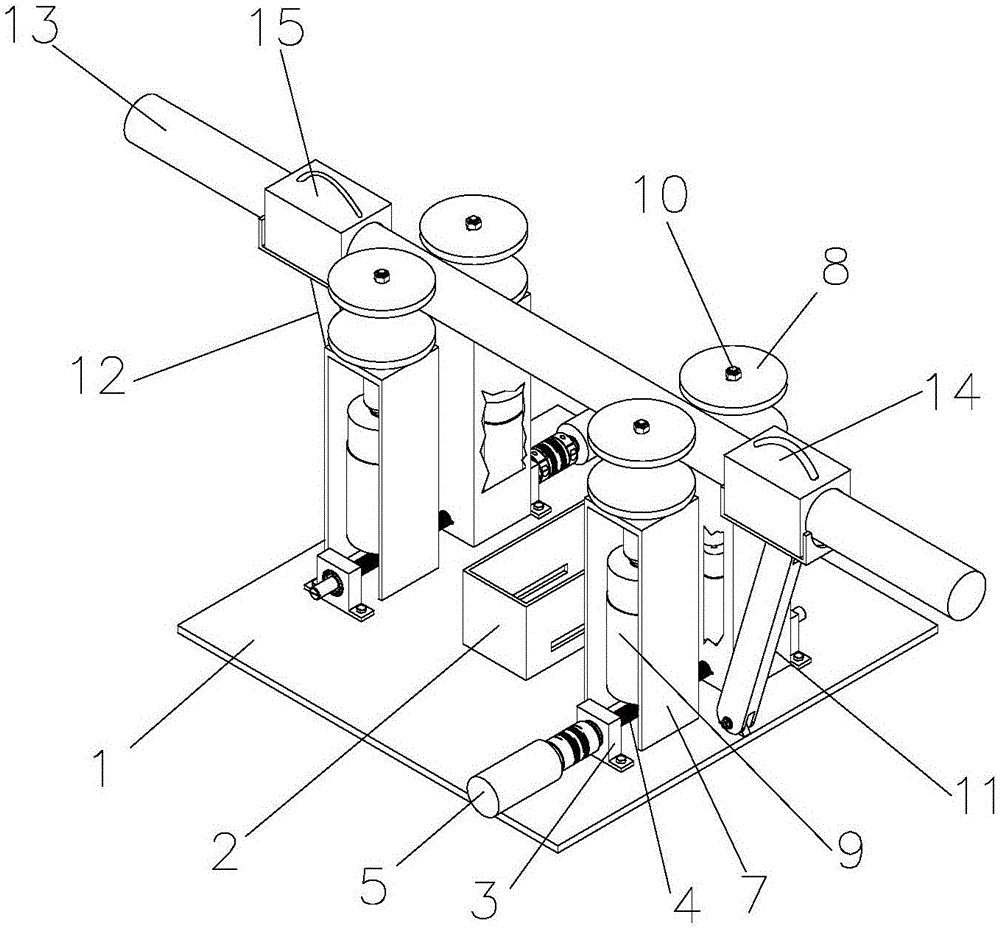

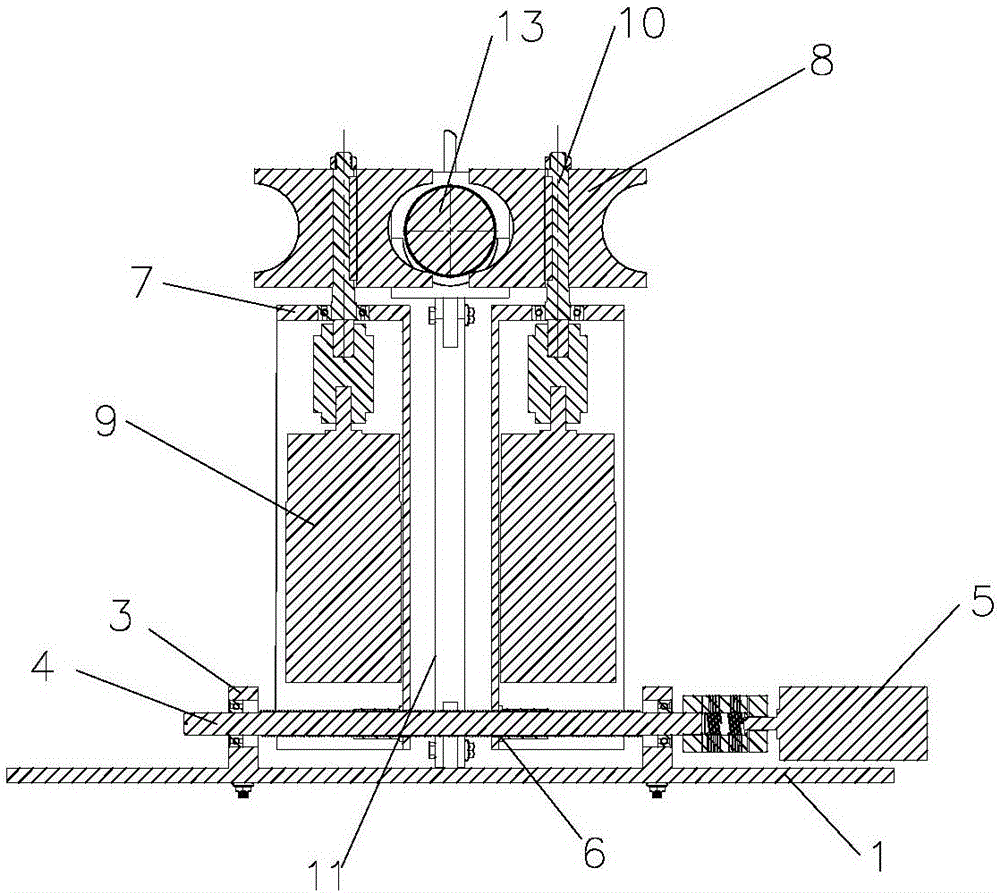

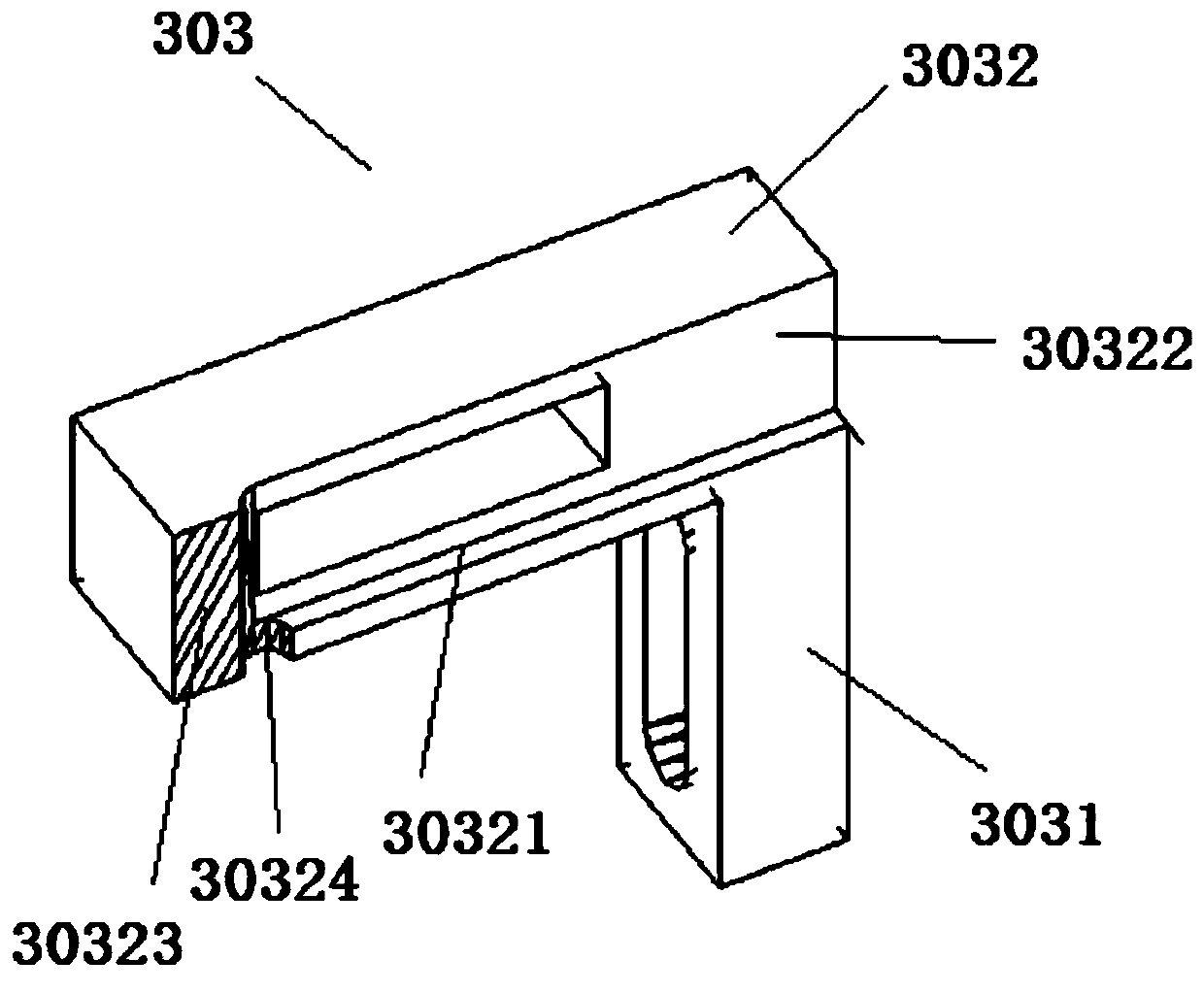

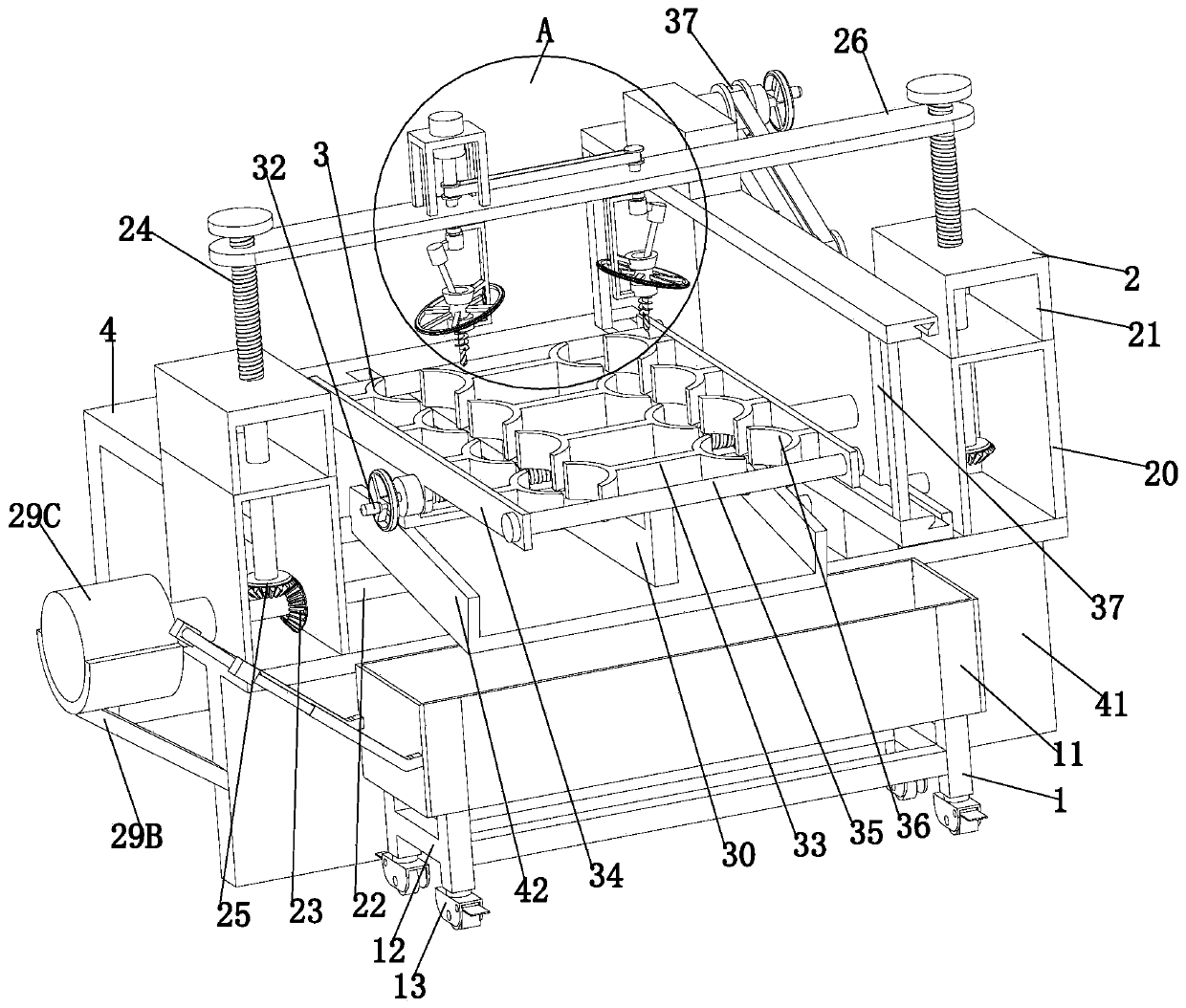

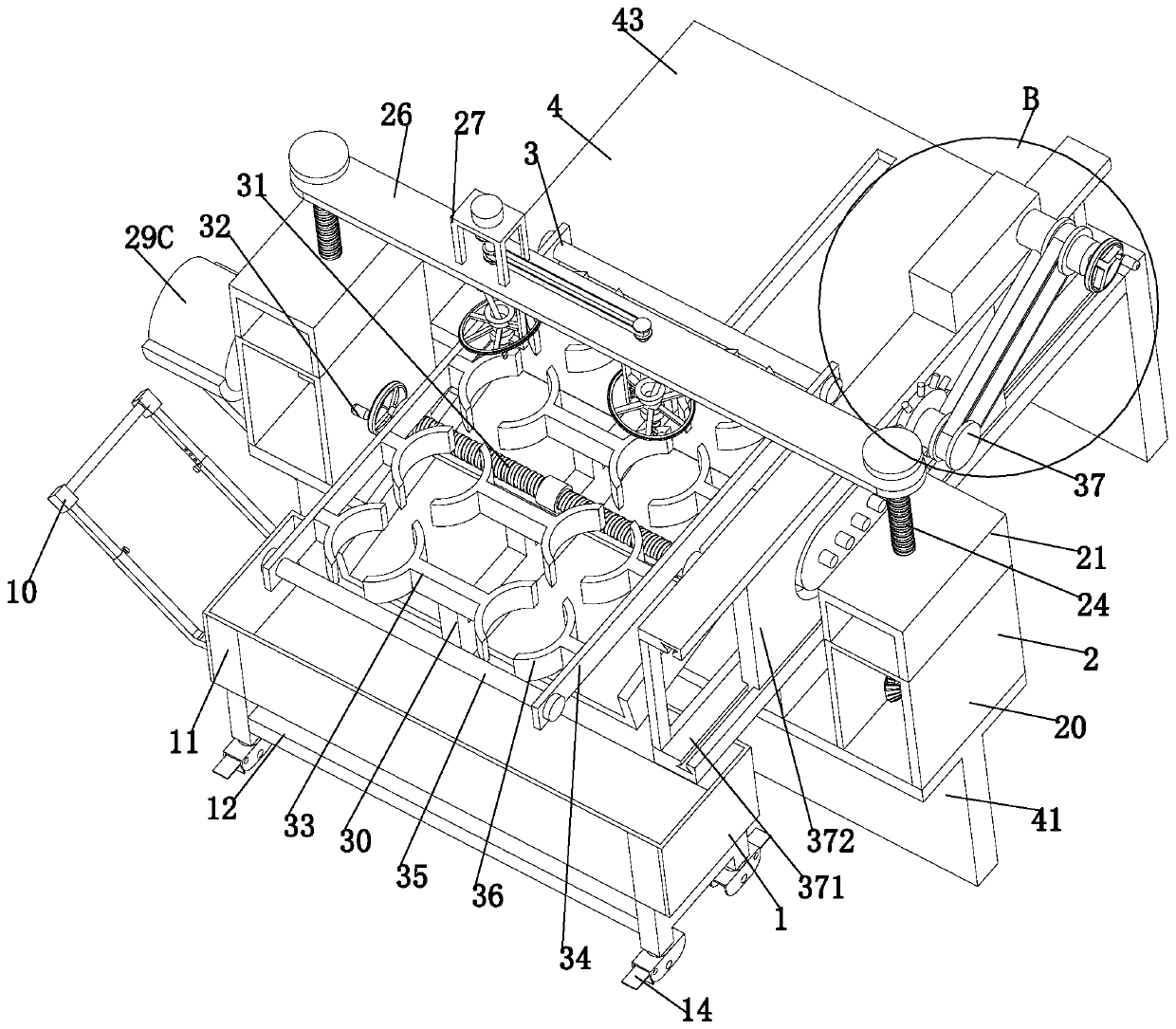

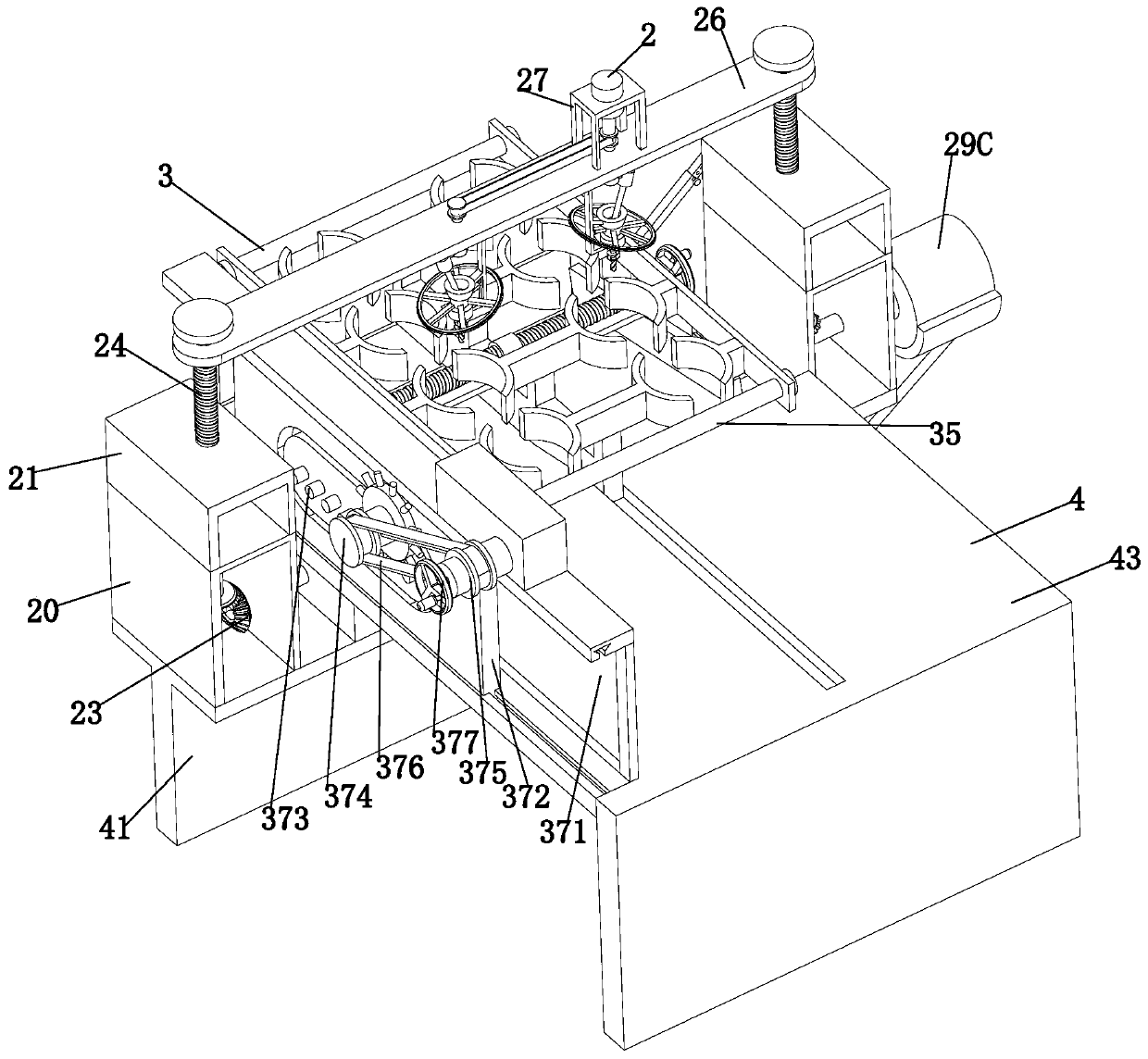

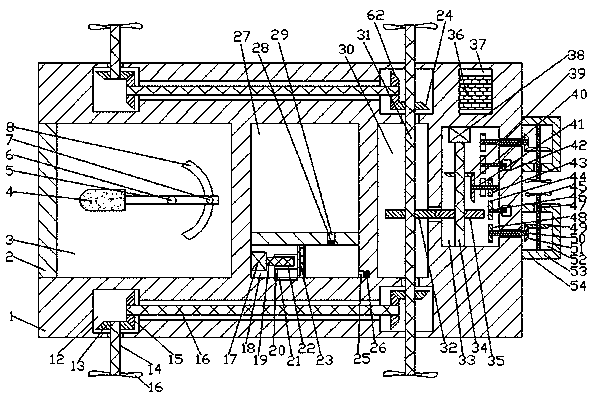

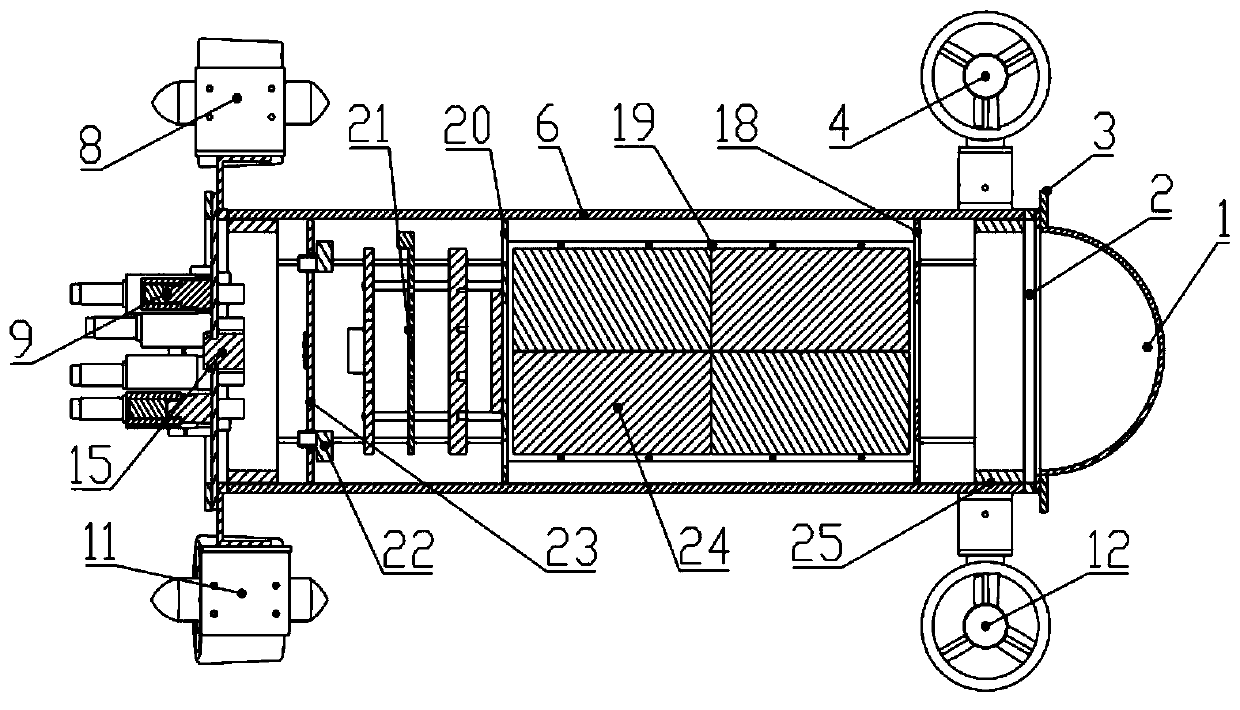

Quick sand shakeout processing equipment and quick sand shakeout processing process for cavity surface of casting piece

ActiveCN111203786AGuaranteed cleaning qualityImprove grinding efficiencyGrinding drivesGrinding machinesGrinding wheelMechanical engineering

The invention provides quick sand shakeout processing equipment and a quick sand shakeout processing process for a cavity surface of a casting piece. The quick sand shakeout processing equipment for the cavity surface of the casting piece comprises a collecting unit, an execution unit, a fixture unit and a supporting unit, wherein the execution unit is arranged above the supporting unit; the fixture unit is arranged in the middle of the execution unit and is arranged on the supporting unit; the collecting unit is arranged under the supporting unit; and the fixture unit is located above the collecting unit. The quick sand shakeout processing equipment and the quick sand shakeout processing process for the cavity surface of the casting piece provided by the invention can solve the problems that nowadays, after a sand core and the casting piece are mechanically separated, an inner cavity of a hollow casting piece still needs to be finished by manual operation, sand and burrs adhered on the surface of the inner wall of the casting piece are cleaned thoroughly through manually using a steel wire brush and a sand wheel, but the difficulty in cleaning the inner cavity of the hollow casting piece by manual operation is higher, time and effort are wasted for manual cleaning, the labor intensity is large, the production efficiency is low, the quality is hard to ensure due to manual cleaning, the construction period is extended, and the casting cost is increased.

Owner:新昌县越峰铸钢实业有限公司

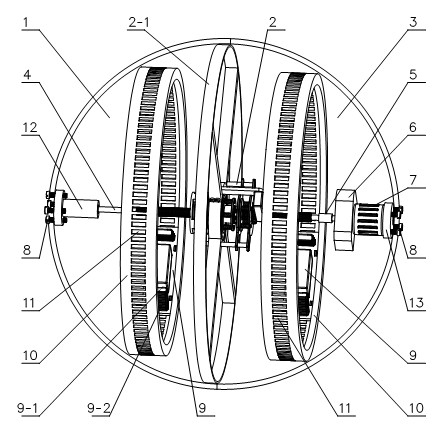

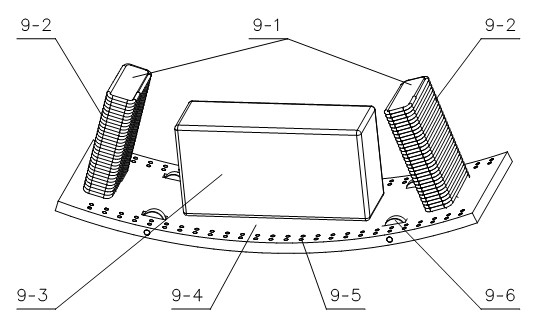

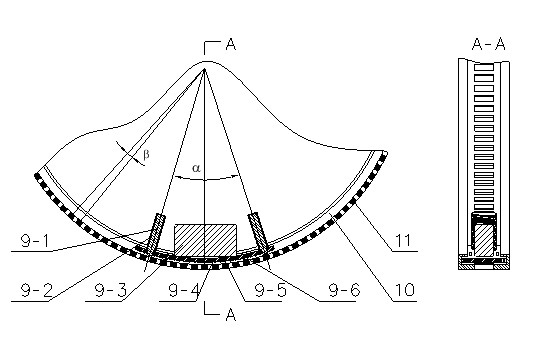

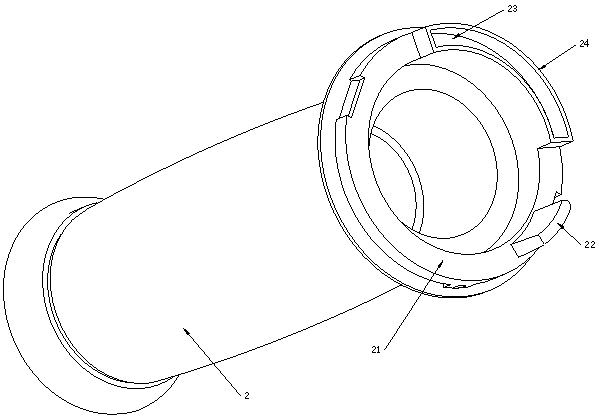

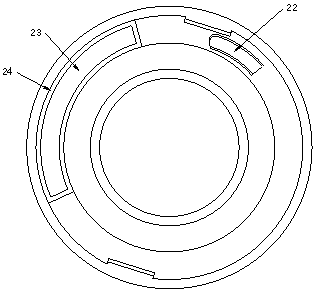

Double-ring clutch type electromagnetic-drive spherical robot

ActiveCN102602465AThe overall structure is simple and reliableFlexible and stable movementVehiclesElectric machineryEngineering

The invention relates to a double-ring clutch type electromagnetic-drive spherical robot, which comprises a left hemispherical shell, a hemispherical clutching mechanism, a right hemispherical shell, a lead screw shaft, a coupler, a speed reducer, a motor, bearing seat fixing screws, electromagnetic drive parts, magnetic steel rings, permanent magnetic steel pieces, a left bearing seat, a right bearing seat and rubber pads and the like. The left hemispherical shell and the right hemispherical shell form a spherical shell, one or more magnetic rings are arranged in each hemispherical shell, the magnetic steel rings and the spherical surface of the spherical shell are coaxial on the lead screw shaft, the permanent magnetic steel pieces are uniformly disposed on the magnetic steel rings, N-electrodes of two adjacent permanent magnetic steel pieces are opposite in direction, the electromagnetic drive parts mainly includes electromagnetic cores, electromagnetic coils, a control module, a power supply, a supporting plate, a plurality of infrared tubes and supporting wheels, the supporting plate is processed to be arc-shaped and concentric with the magnetic steel rings, and the infrared tubes are mounted on two sides of the supporting plate respectively. The spherical robot can progress and retreat according to the principle of electromagnetic stepping, is simple and reliable in structure, stable and flexible in motion and high in controllability when compared with conventional robots.

Owner:山东奥唯克智能科技有限公司

Soft-body crawling robot with four feet

The invention discloses a soft-body crawling robot with four feet. The robot comprises a robot body and a control system, wherein the robot body comprises a body bracket, and four legs mounted on the body bracket; each leg consists of four extended pneumatic muscles in parallel arrangement; the control system comprises a DSP control module and a driving amplifying module, wherein the input end of the driving amplifying module is connected with the DSP control module, and the output end of the driving amplifying module is connected with the extended pneumatic muscles through sixteen pneumatic valves; an air source is connected to the pneumatic valves. The soft-body crawling robot with four feet, disclosed by the invention, is simple in structure and small in size and can enter a small narrow space to complete tasks in complex environment; the extended pneumatic muscles are controlled to extend or return to the original positions, so that moving forwards or backwards of the robot with four feet can be realized. According to the soft-body robot disclosed by the invention, the DSP is adopted as a processor, and the extended pneumatic muscles are used as executing mechanisms, so that the movement of the soft-body robot with four feet is realized.

Owner:NINGBO HIGH NEW ZONE XINCHENG ELECTRONICS

Forward and reverse speed adjustable handle for electric vehicle and power control device for electric vehicle

ActiveCN104015855ADescribe wellRealize forward and reverse controlCycle control systemsEngineeringElectric vehicle

The technology provides a forward and reverse speed adjustable handle for an electric vehicle. The forward and reverse speed adjustable handle can be turned in both forward and reverse directions to control the forward or reverse turning of an electric vehicle. The forward and reverse speed adjustable handle has the advantages of simple structure, no back-up switch, convenience in operation and high reliability, and the cost is equivalent to that of an ordinary speed regulating handle. The forward and reverse speed adjustable handle comprises a fixed part consisting of a handle stem and a handle seat, and a turning handle, wherein a left turning spring and a right turning spring are arranged between the fixed part and the turning handle; the left turning spring enables the turning handle to counterclockwise turn relative to the handle stem, and the right turning spring enables the turning handle to clockwise turn relative to the handle stem; the turning handle is in a reset position under the combined action of the left turning spring and the right turning spring. When an external force is applied to the turning handle, the turning handle can clockwise or counterclockwise turn from the reset position; a Hall sensor and an arc-shaped permanent magnet are respectively arranged on the turning handle and the fixed part oppositely but without contact; when the turning handle is turned, the Hall sensor moves relative to the arc-shaped permanent magnet, senses different positions of the arc-shaped permanent magnet and outputs relevant different signals.

Owner:NANJING SANYE GOLDEN EAGLE MOTORCYCLE

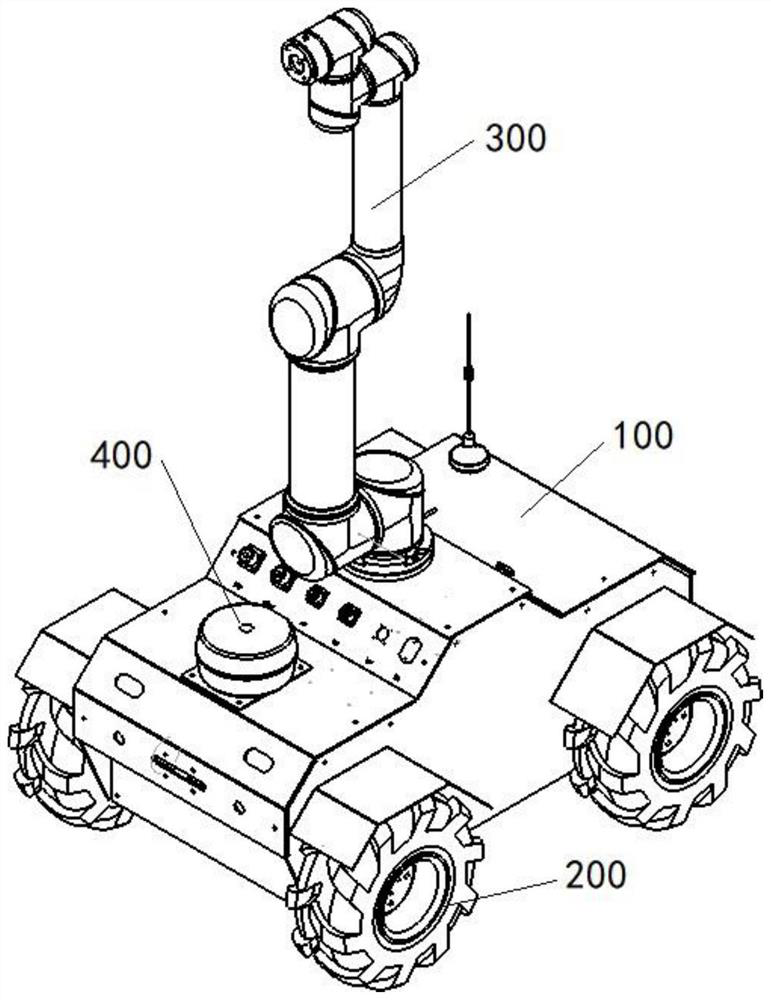

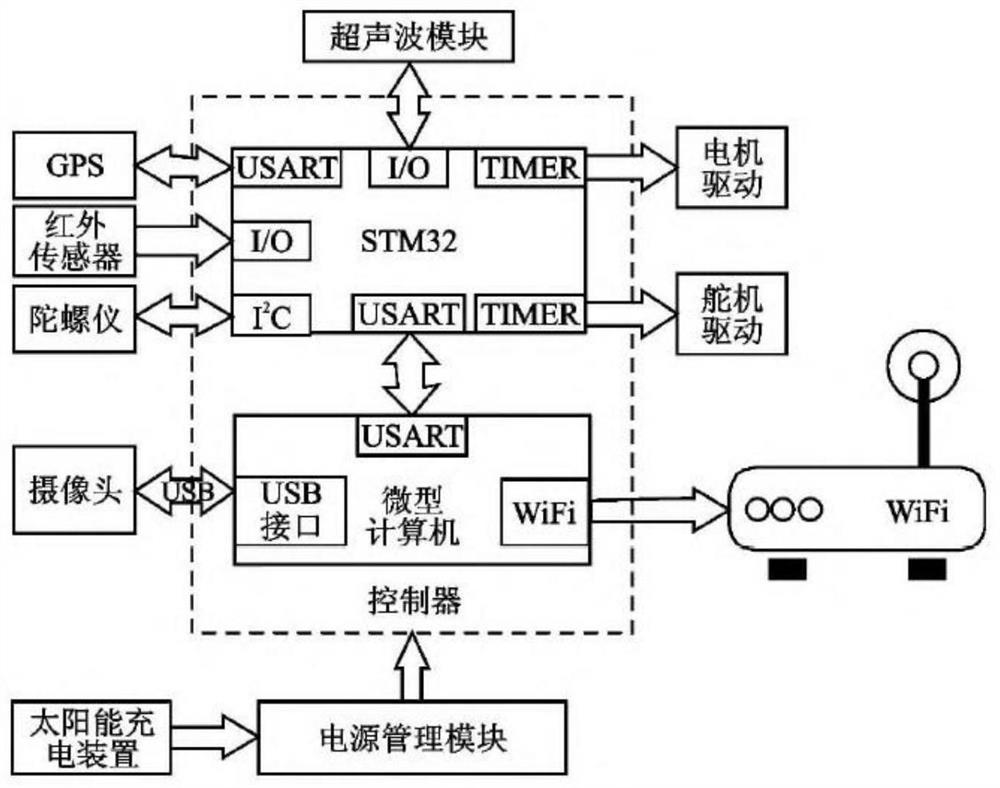

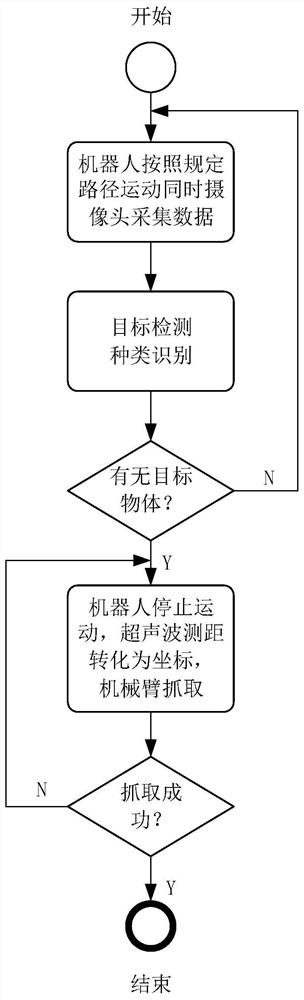

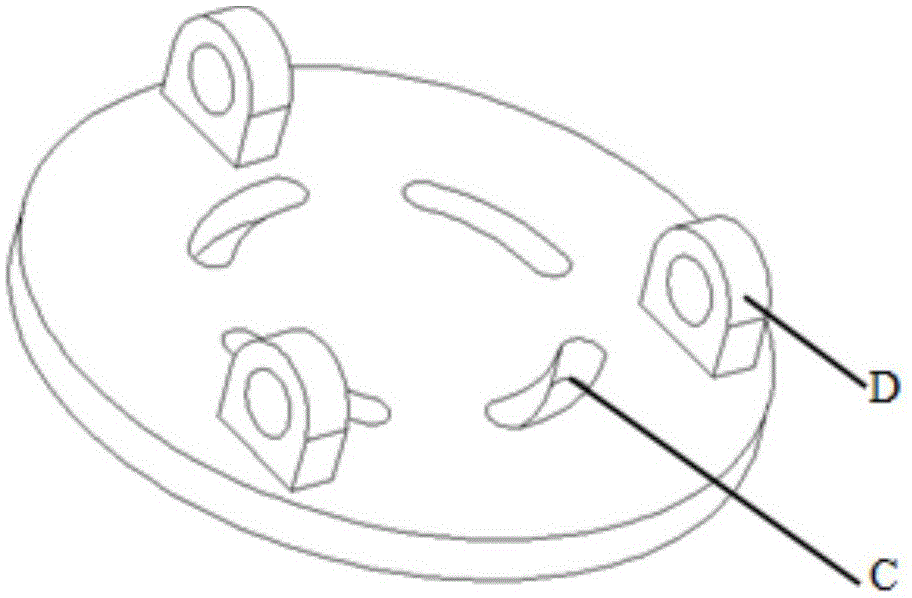

Vision based garbage sorting robot

PendingCN111844042AAchieve rotationAchieve progressProgramme-controlled manipulatorSortingComputer hardwareGyroscope

The invention relates to the field of garbage classification, and discloses a vision based garbage sorting robot. The vision based garbage sorting robot comprises a vehicle body and a control system.A set of drive device is arranged at the bottom of the vehicle body. A mechanical arm and an image collection device are arranged on the vehicle body. The control system comprises a sensor, a controller, a communication module and a power module. The drive device comprises two pairs of differential wheels arranged on the two sides of the vehicle body, and each pair of differential wheels is drivenby a direct current servo motor. A rotating shaft of each direct current servo motor is connected with a transmission shaft of one wheel through a coupling. The transmission shafts of the two wheelson the same side are connected with a synchronous belt through a synchronous belt wheel. The image collection device is a camera. The mechanical arm is a six-axis joint machine arm. The controller comprises an industrial personal computer and a motor driver. The sensor comprises a GPS module, an infrared sensor and a gyroscope. The communication module comprises a WIFI module and a router. The power module comprises a battery pack and a transformer.

Owner:KUNSHAN GUIBU ROBOT TECH CO LTD

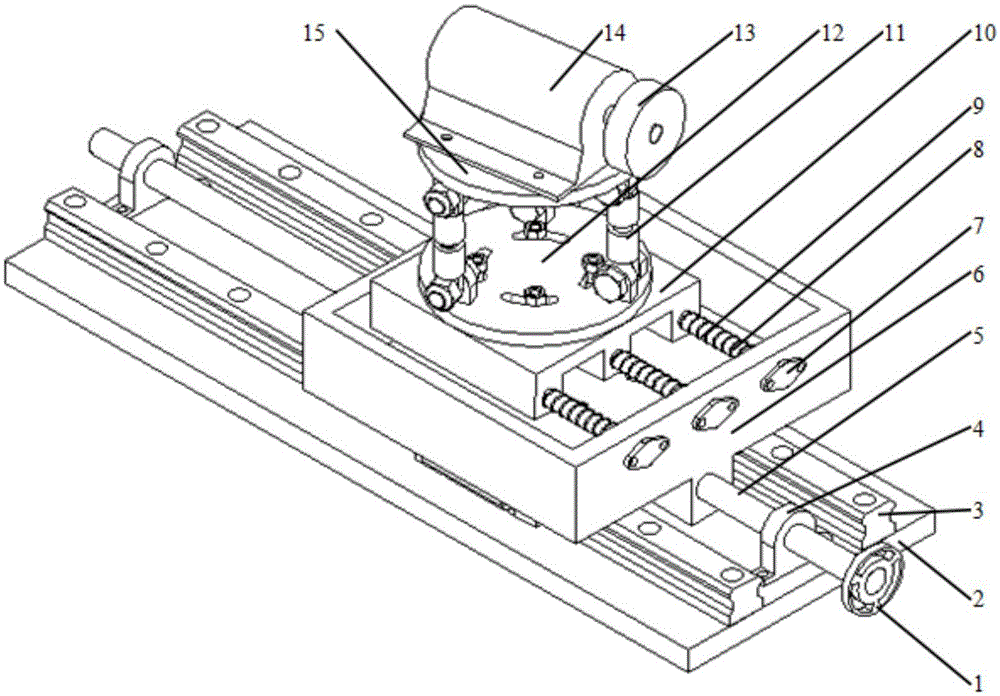

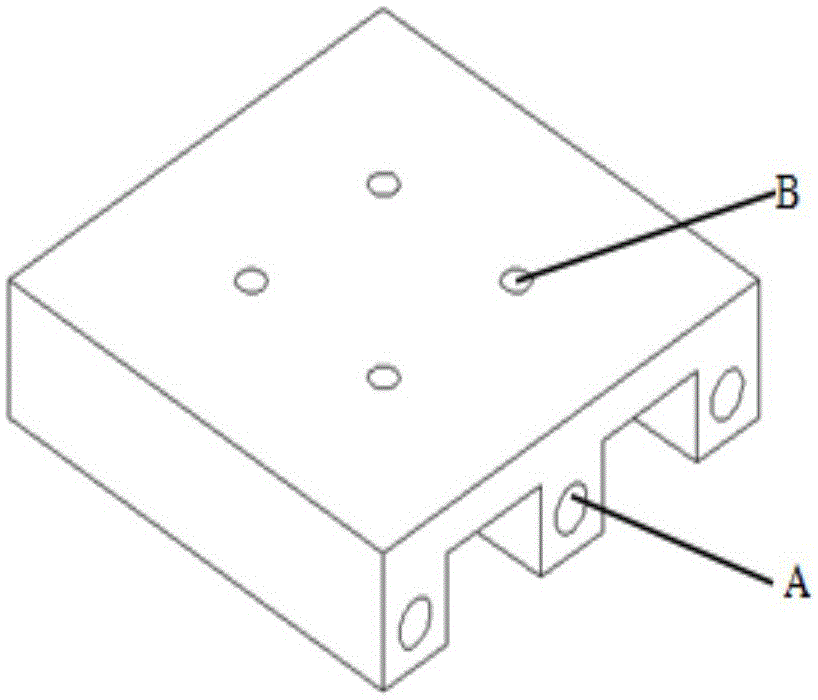

Strip steel burr polishing device applied to finishing unit, debugging method of strip steel burr polishing device

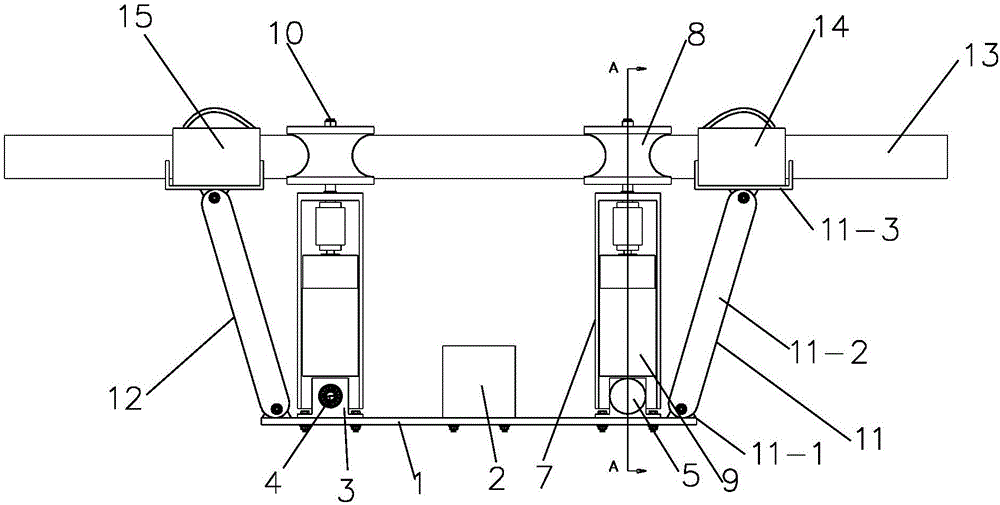

ActiveCN106392810AAvoid defectsQuality improvementEdge grinding machinesGrinding machine componentsLocking mechanismEngineering

The invention discloses a strip steel burr polishing device applied to a finishing unit. The strip steel burr polishing device comprises a horizontal feeding mechanism, a horizontal angle adjusting and locking mechanism and a vertical angle adjusting mechanism, wherein the horizontal feeding mechanism is used for allowing the strip steel burr polishing device to run along a track so as to adapt to changes of specification of strip steel; the horizontal angle adjusting and locking mechanism is arranged on the horizontal feeding mechanism and comprises a motor lower base (10) and a motor middle base (12), wherein the motor lower base (10) and the motor middle base (12) are connected by a bolt; the motor lower base (10) and the motor middle base (12) are provided with waist-shaped hole sliding chutes and a bolt structure, wherein the waist-shaped sliding chutes are used for relative horizontal rotation of the motor lower base (10) and the motor middle base (12), and the bolt structure is used for fixation, and thus adjustment of horizontal angle of the device is implemented; the vertical angle adjusting mechanism is arranged on the motor middle base (12) of the horizontal angle adjusting and locking mechanism and is used for adjusting the height and the vertical angle of the burr polishing device. The burr polishing device disclosed by the invention is ingeniously adjustable in feeding, adjustable in horizontal angle, adjustable in vertical angle, adjustable in height, adjustable in burr polishing pressure and capable of adapting to different burr polishing requirements of different specifications and different steel types.

Owner:BAOSHAN IRON & STEEL CO LTD

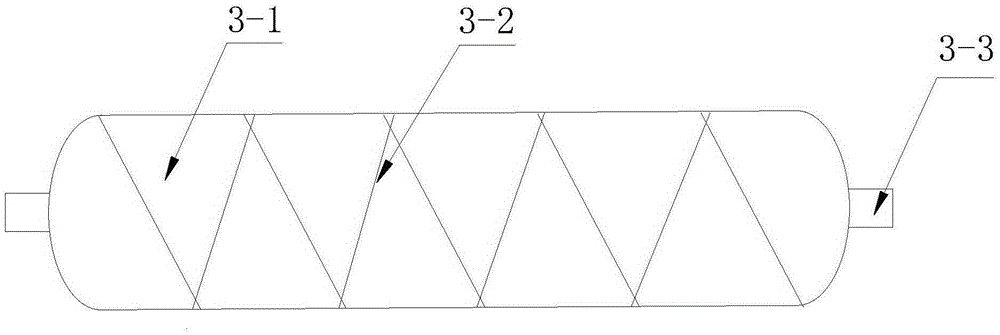

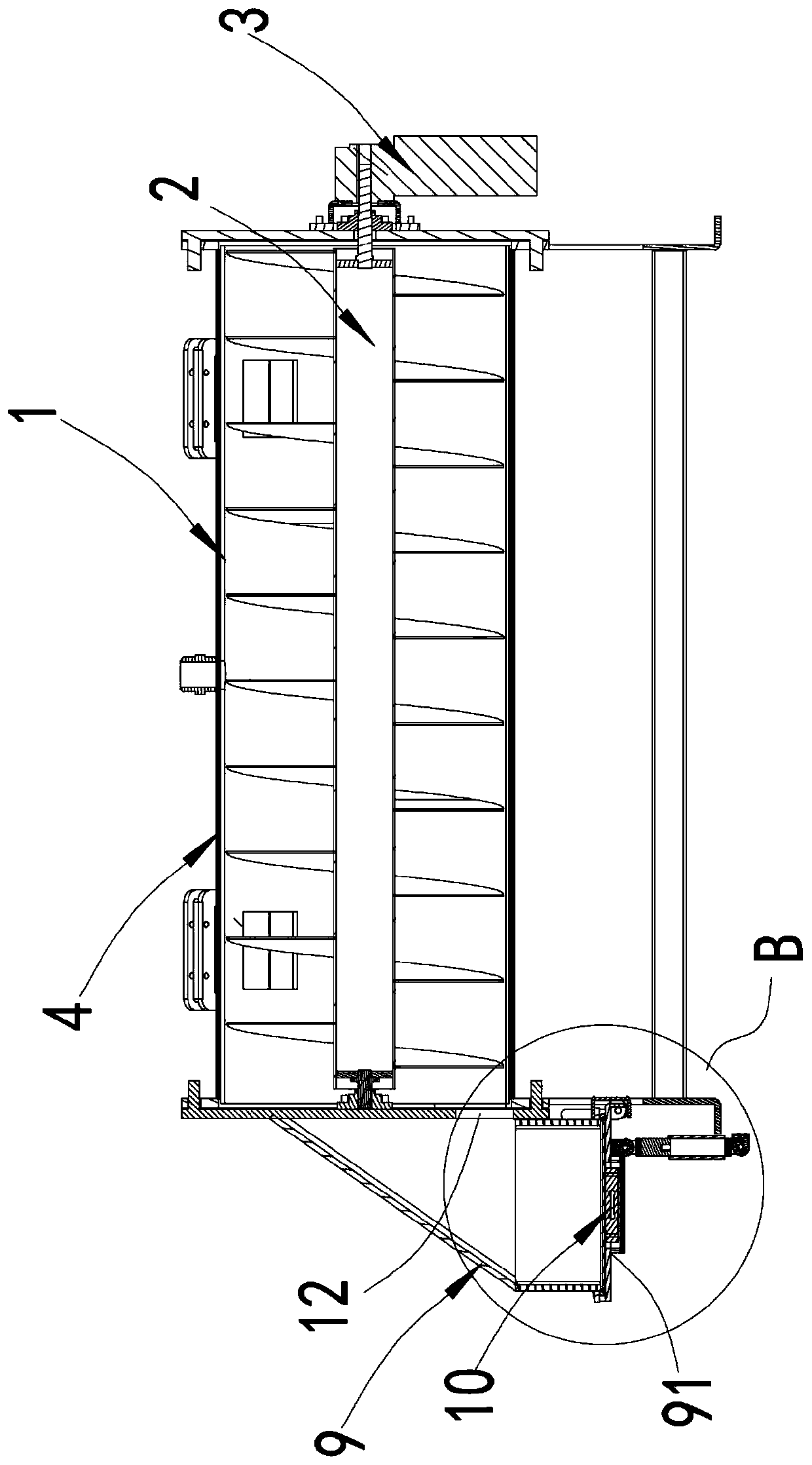

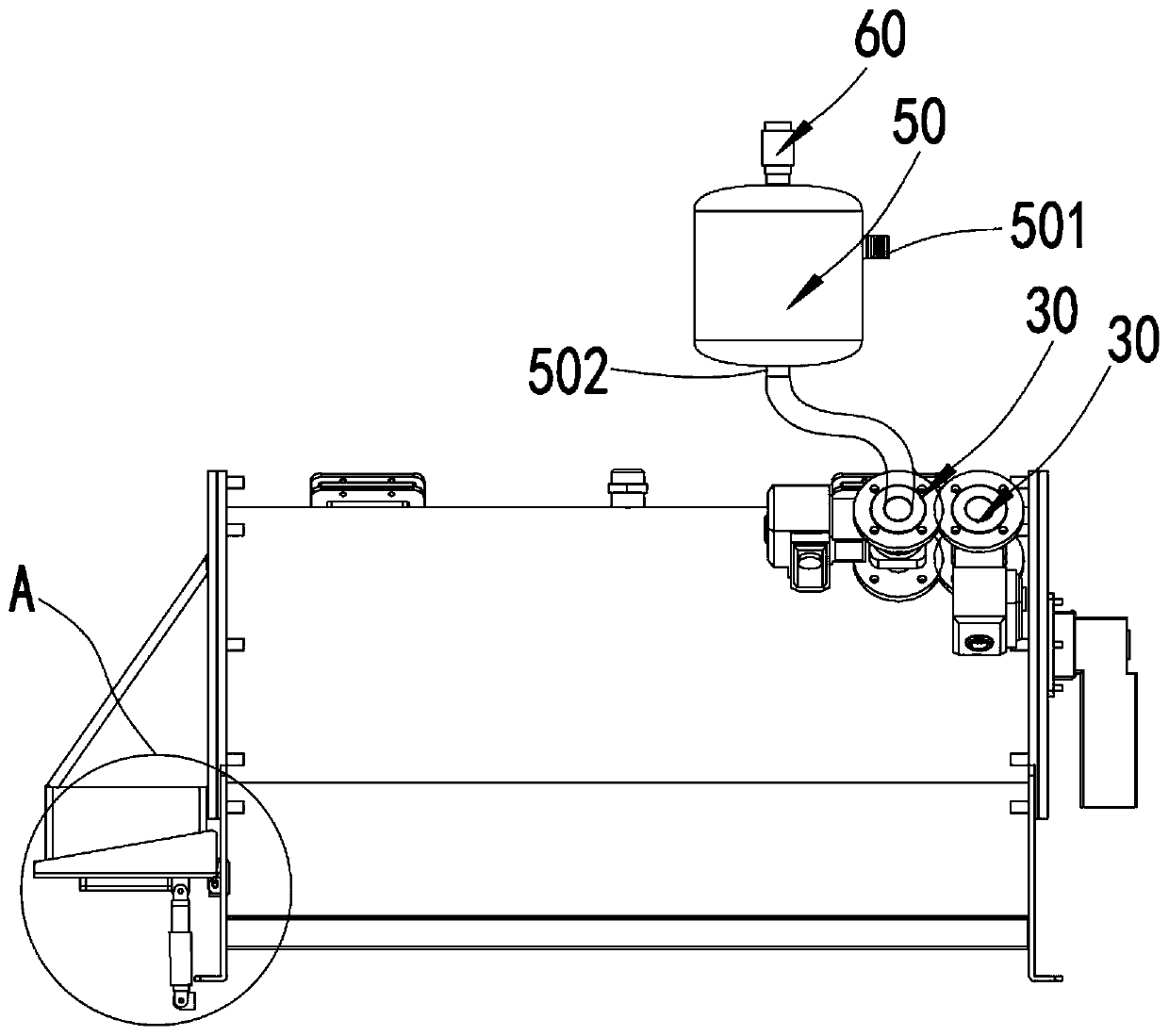

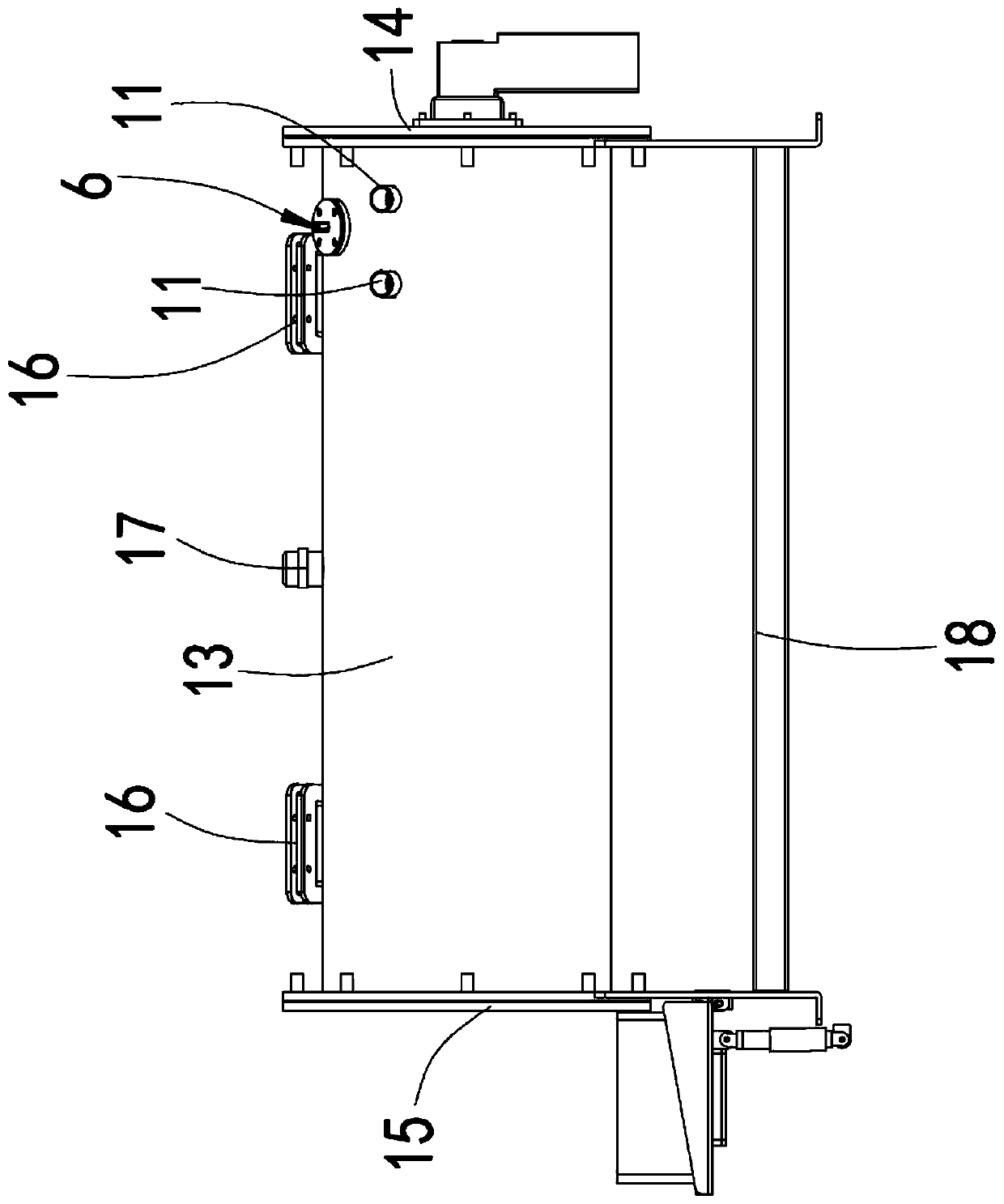

Quantitative discharging type fermentation equipment and fermentation method thereof

PendingCN111196741ARealize moving forwardImplement backDrying solid materials without heatClimate change adaptationProcess engineeringMechanical engineering

The invention discloses quantitative discharging type fermentation equipment and a fermentation method thereof. The quantitative discharging type fermentation equipment comprises a barrel, a spiral conveying shaft, a driving device, a heating device and a material receiving bin, wherein the barrel is provided with a feeding port and a discharging port which are located in the two ends; the spiralconveying shaft is arranged in the barrel body in the axis direction of the barrel body in a self-rotating mode; the driving device drives the spiral conveyor to rotate; the heating device is positioned on the barrel body; and the material receiving bin is arranged at the discharge port, a weighing sensor is integrated on a bottom plate of the material receiving bin, and the bottom plate of the material receiving bin can be opened and closed. According to the scheme, spiral horizontal conveying is adopted; forward movement and backward movement of materials can be realized; the standing time of the materials is controlled; the materials are turned over; the barrel body does not need an outlet capable of being automatically opened and closed, the internal structure is greatly simplified, the material receiving bin integrated with weighing equipment is arranged at the discharging port, a bottom plate of the material receiving bin can be opened, online quantitative discharging is effectively achieved, quantitative packaging is easy, and compared with the prior art, a feasible automatic weighing and discharging mode is provided.

Owner:SUZHOU HUANCHUAN ENERGY SAVING EQUIP CO LTD

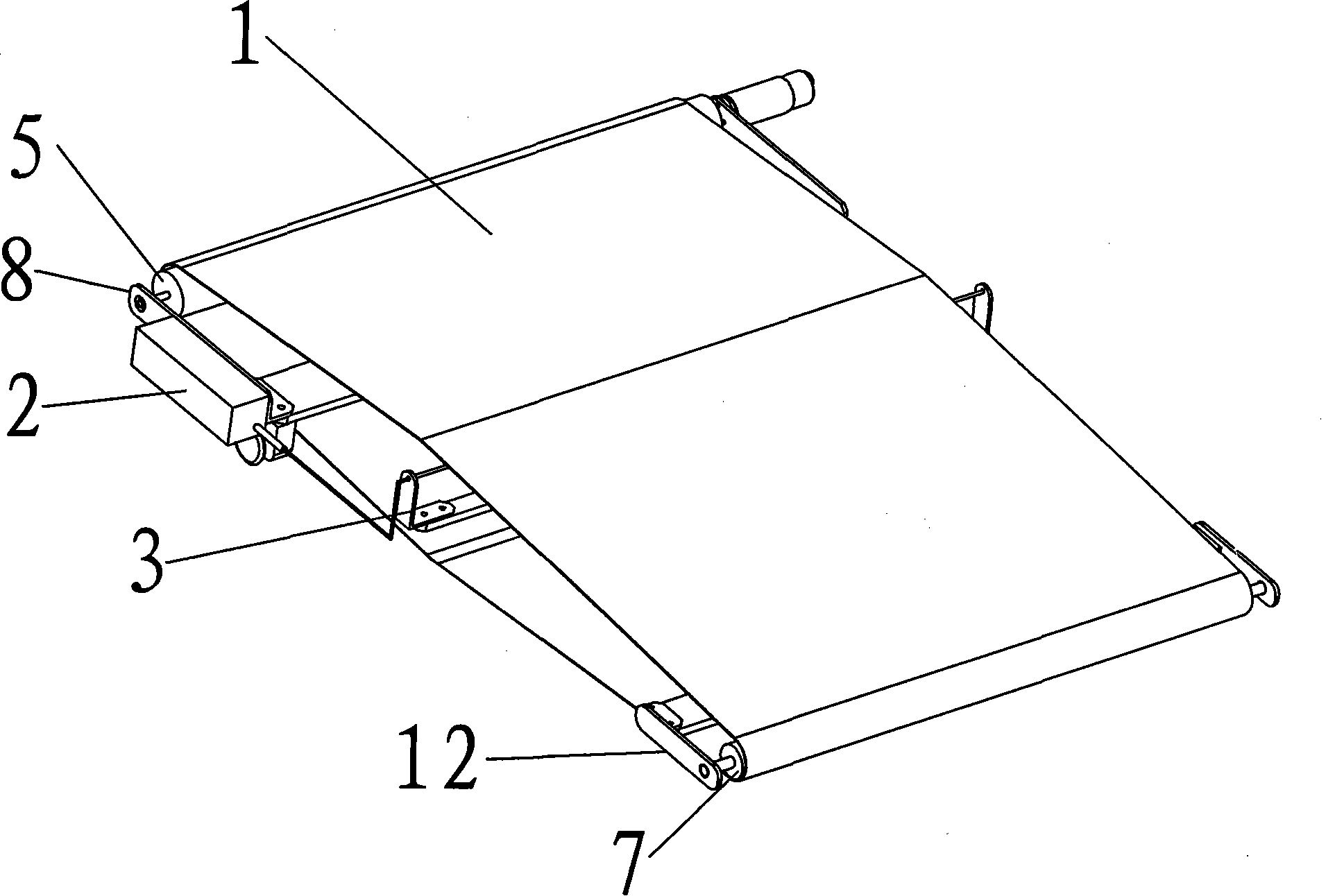

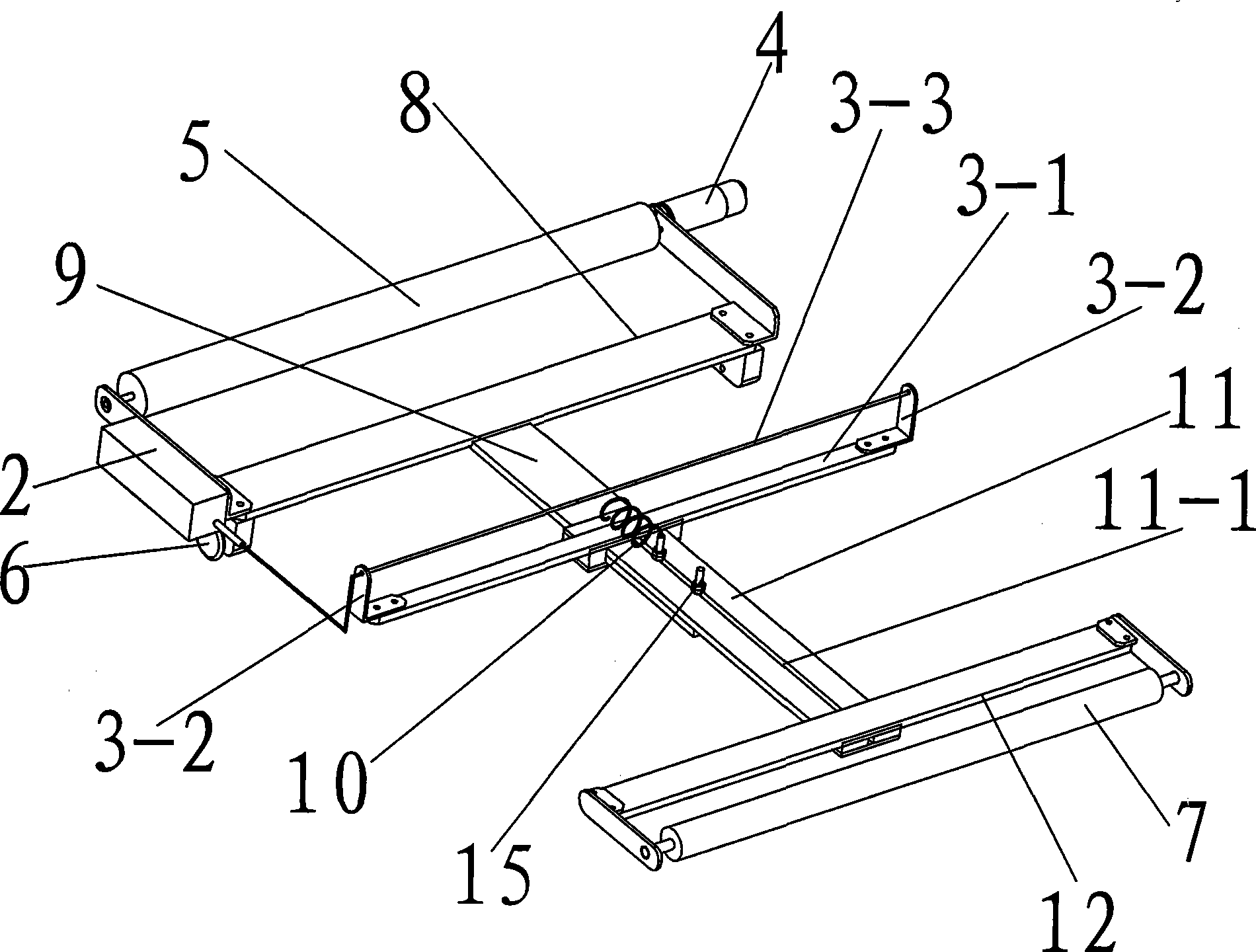

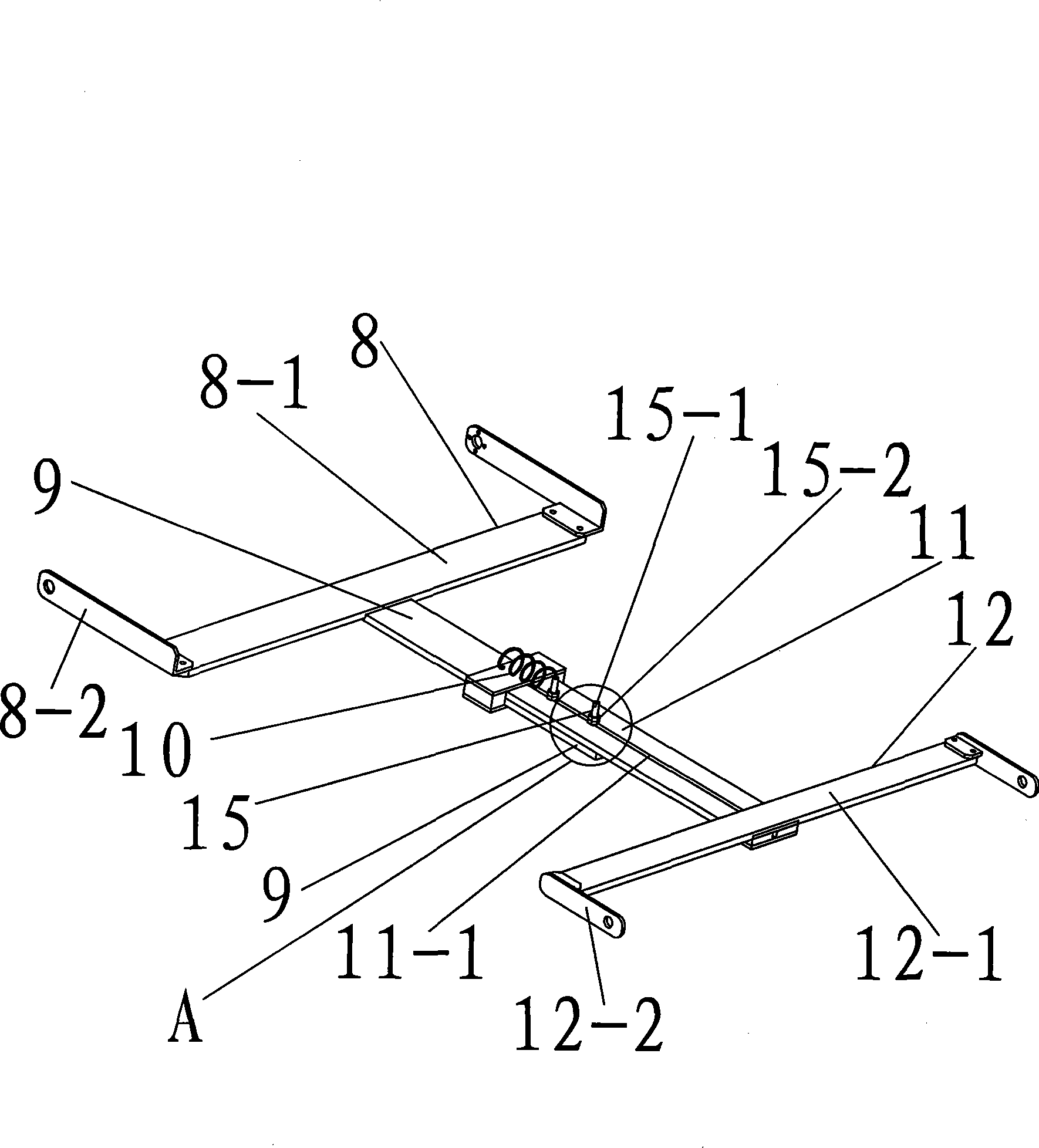

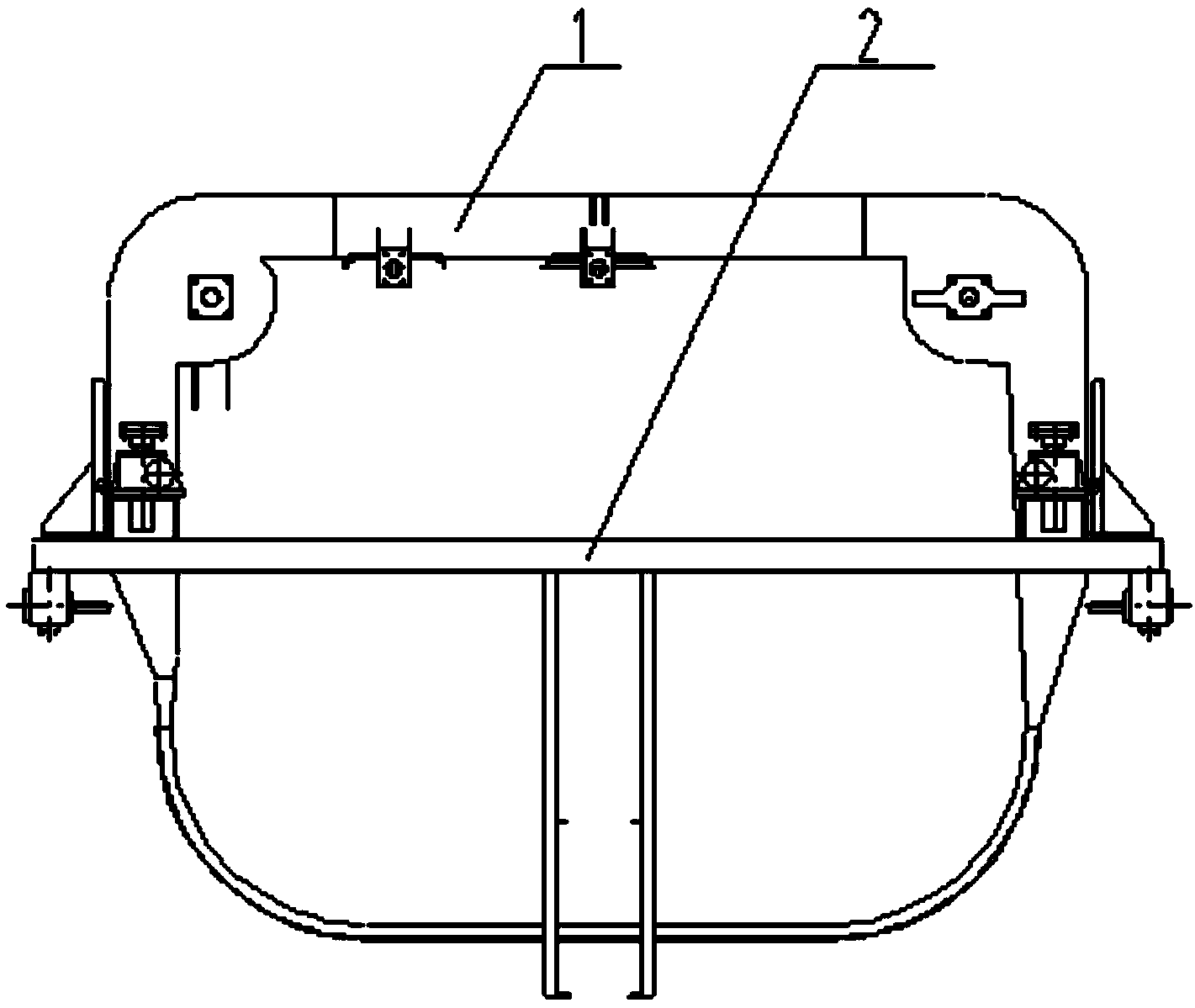

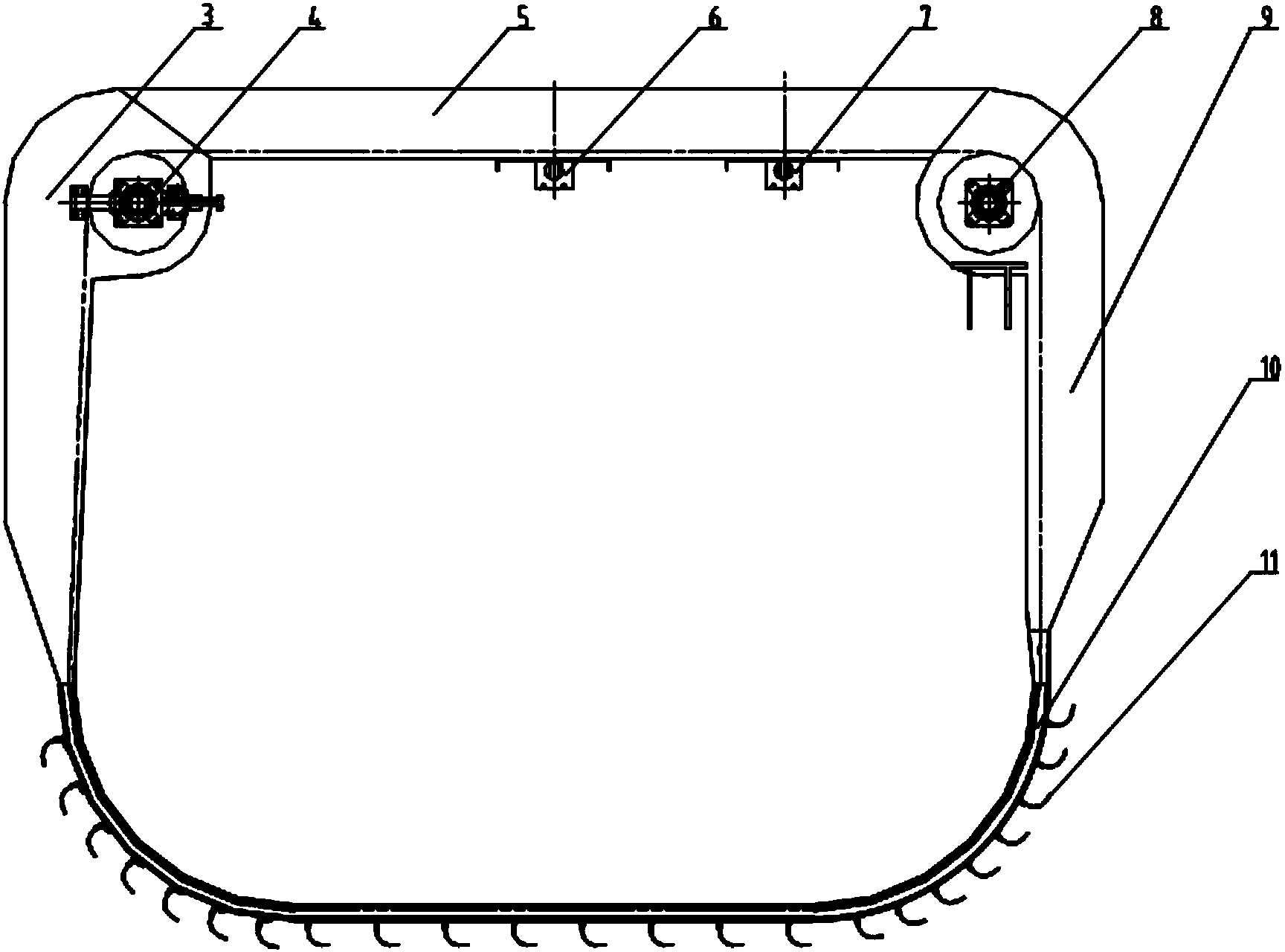

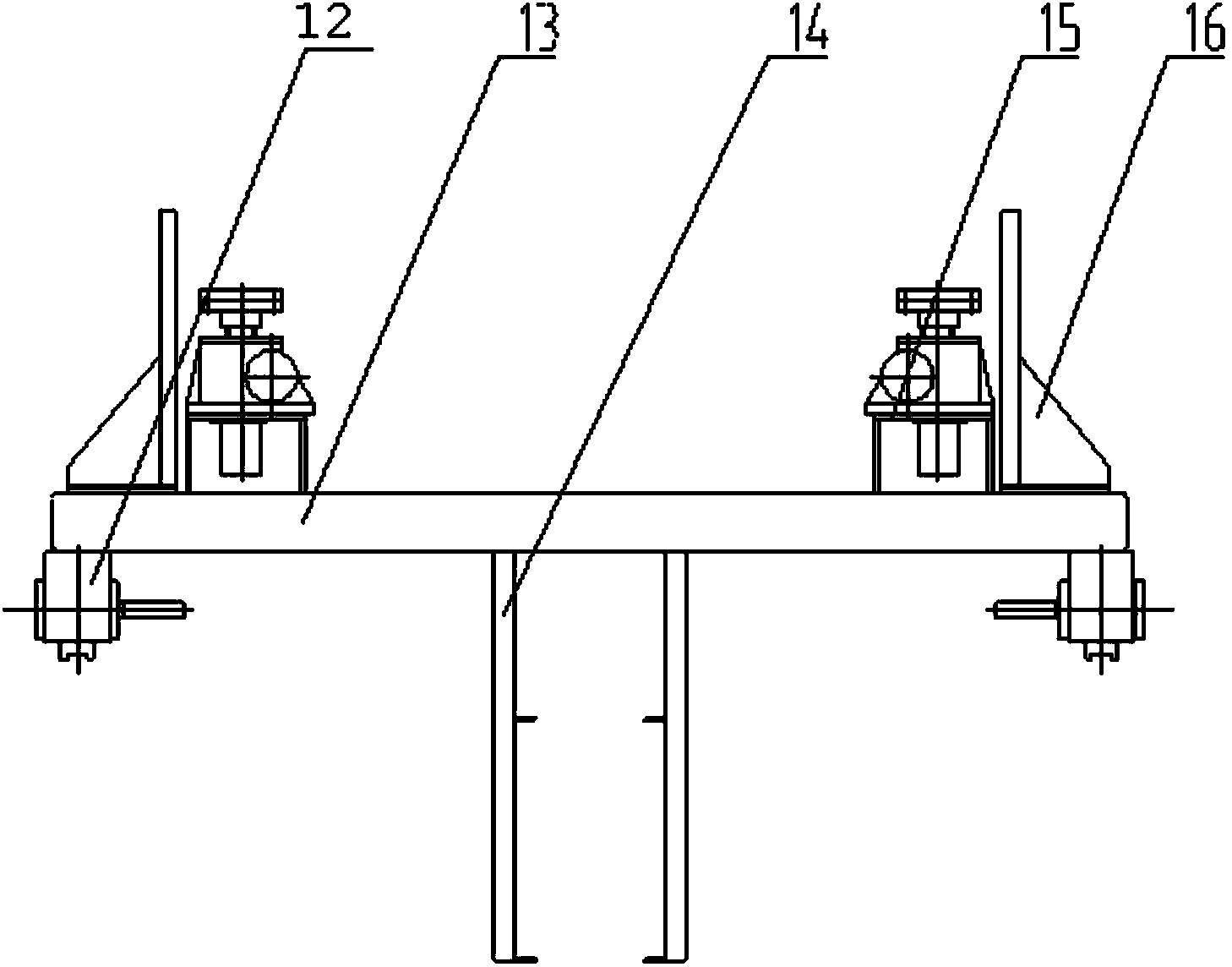

Annular conveyor and mobile vehicle associated with same

The invention relates to an annular conveyor and a mobile vehicle associated with the same. The annular conveyor and the mobile vehicle associated with the same can be mainly used for total cross-section material taking and conveying of various stacked materials and especially for vertical-surface annular conveying of sludge, the mixture of the sludge and other auxiliary materials, fermentation products and materials with the similar material property. The annular conveyor and the mobile vehicle are combined for achieving going forward and backward and ascending and descending of the annular conveyor. Feeding of the annular conveyor is achieved through an open arc-shaped bottom section. A vertical section and the bottom section are connected in a tapered big-end-up transition mode. The annular conveyor and the mobile vehicle can replace loading vehicles and transferring vehicles in actual projects, save a lot of manpower and material resources and lower the operating cost.

Owner:中科博联(遵化)环保装备有限公司

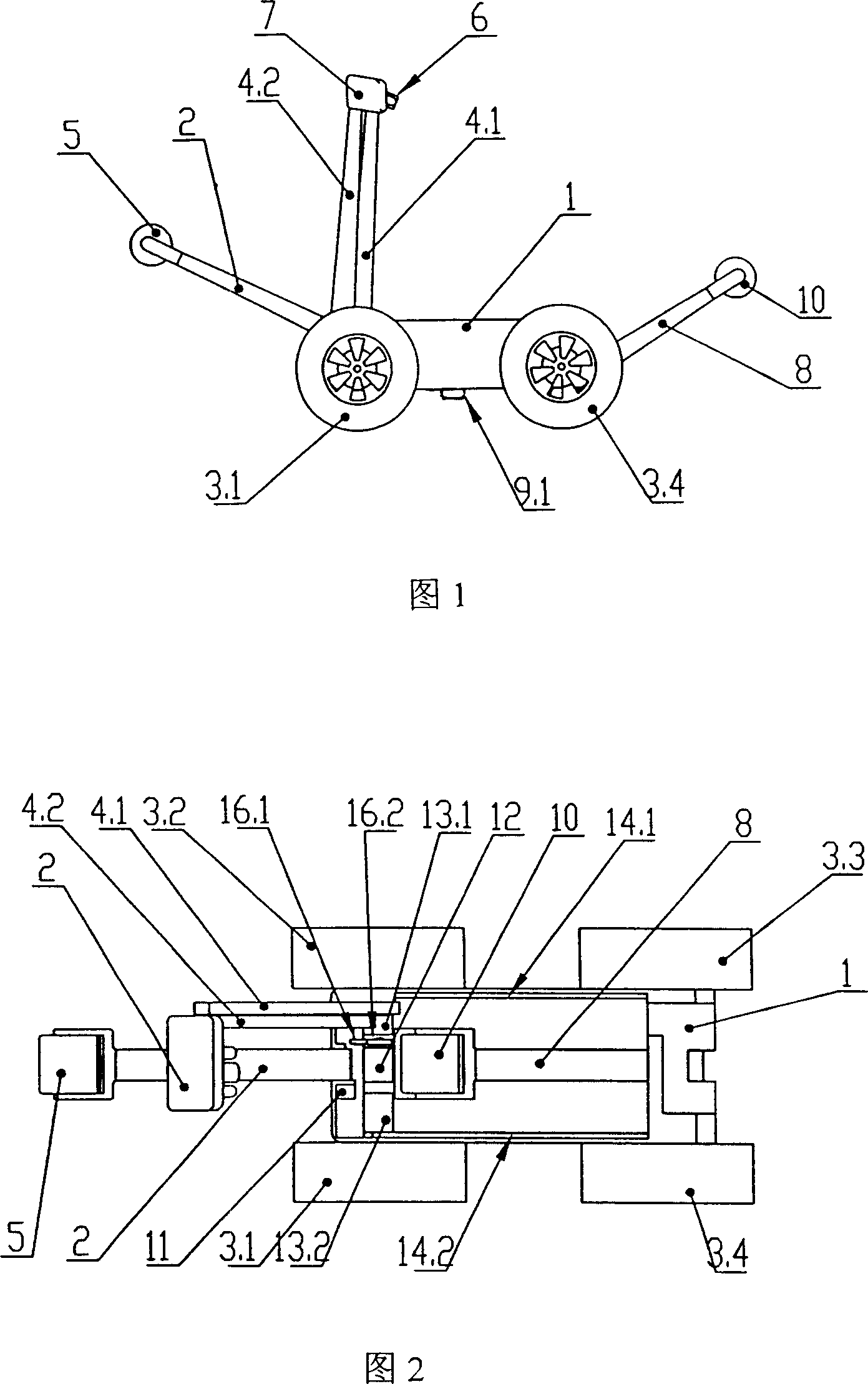

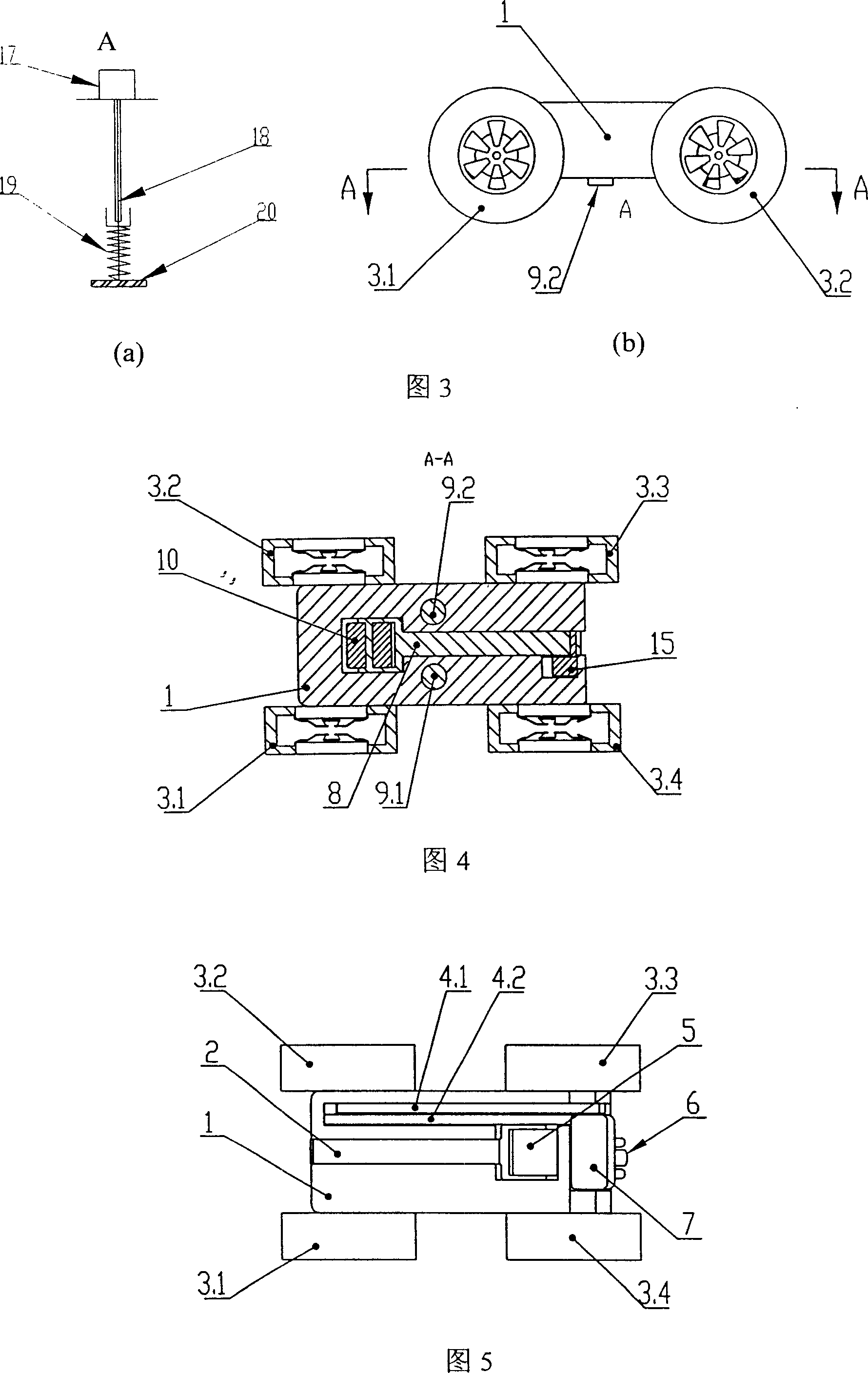

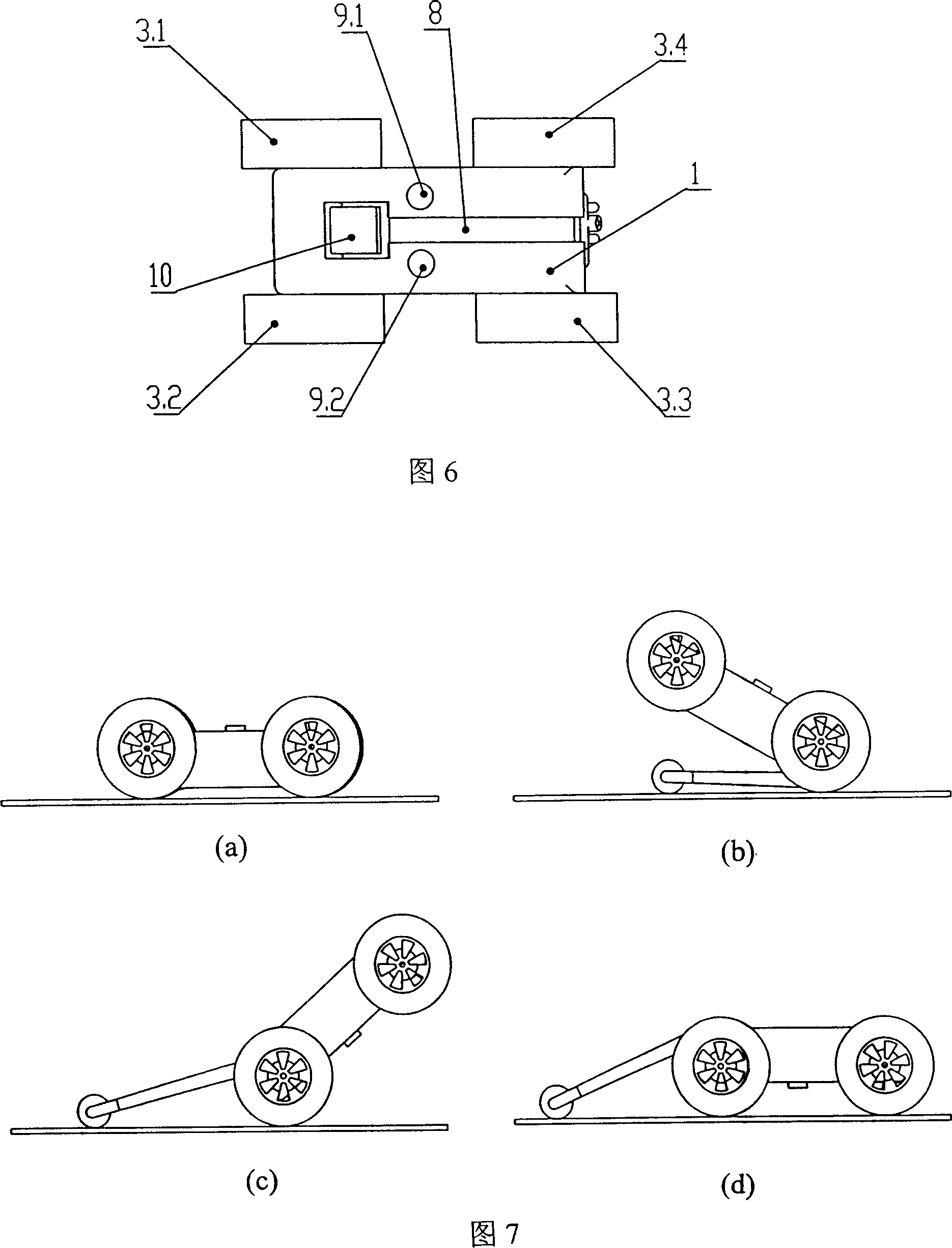

Wheel, leg, bounce mechanism combined mobile robot

InactiveCN100429112CAchieve progressImplement backSelf-moving toy figuresVehiclesEngineeringCcd camera

The invention relates to a wheel leg bounce movable robot, wherein it uses four-wheel body, with front and back swinging wheel legs and bounce structure. The invention combines wheel structure and leg structure, to change motion mode via different conditions. Via the back swinging wheel leg, when the robot is turnover, it can return by itself. The bottom bounce structure can fly over the obstacle; the table with CCD camera is mounted in the detecting table which can lift, to expand the view sight.

Owner:ZHEJIANG UNIV

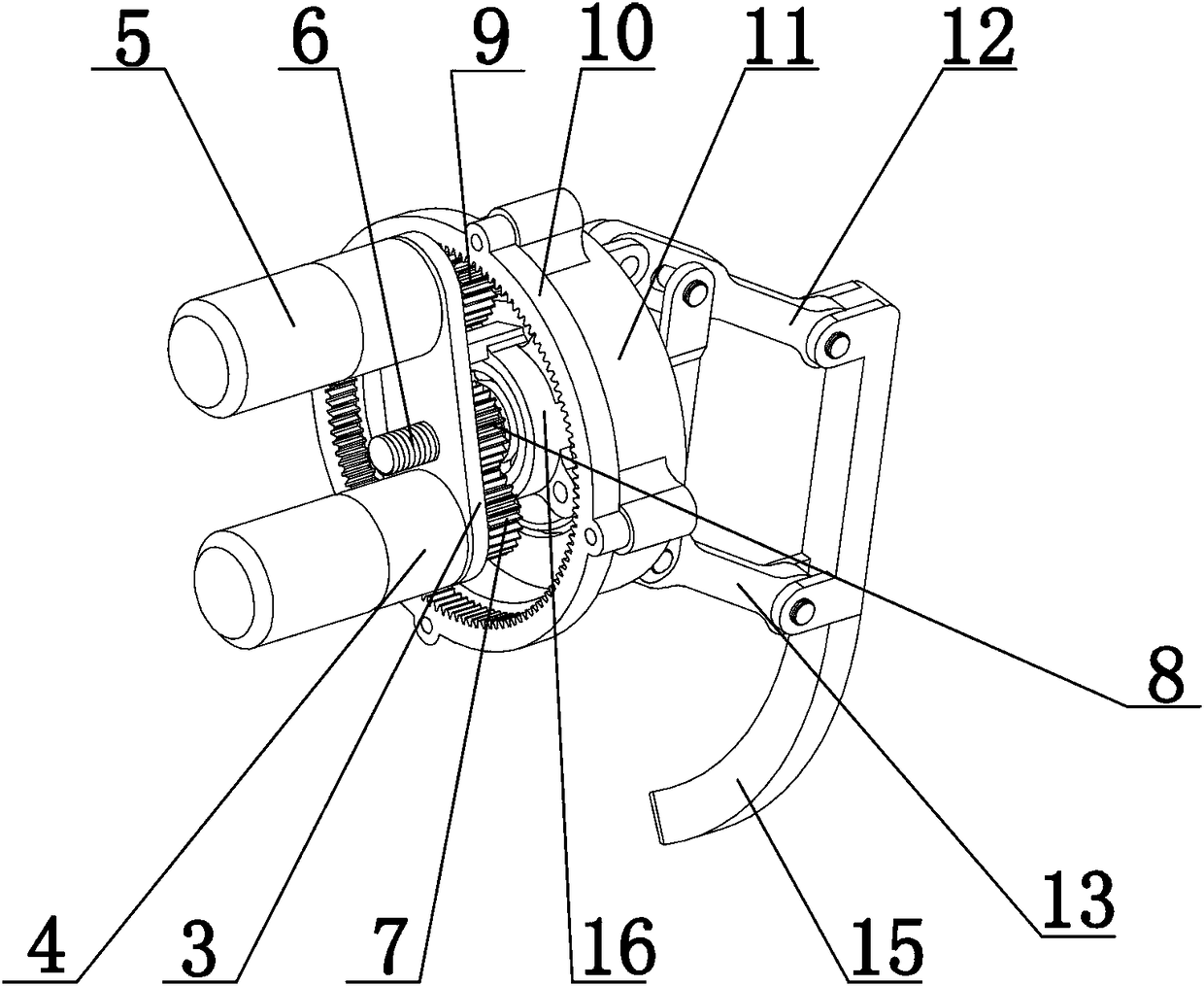

Multi-motion mode four-leg robot

The invention belongs to the technical field of robots and discloses a multi-motion mode four-leg robot. The robot includes an enclosure. The left and right sides of the enclosure are symmetrically fixedly provided with four identical leg motion components by four motor supports, i.e. left front leg motion component, right front leg motion component, left rear leg motion component and right rear leg motion component. The left side and the right side of the enclosure are provided with holes matched with the shape of the motor support. The motor support is fixed in the hole; the leg motion component includes a leg lifting system, a rotating system and a leg connecting rod component to realize the walking motion mode or the rotating motion mode of the four-leg robot. According to the invention, the leg lifting motor and the rotating motor are cooperatively used, so that the switching of two modes of motion of the robot is realized and more environment conditions can be accommodated; in addition, the robot has the advantages of simple structure, easy manufacture, low cost and very good application prospect.

Owner:XINYANG NORMAL UNIVERSITY

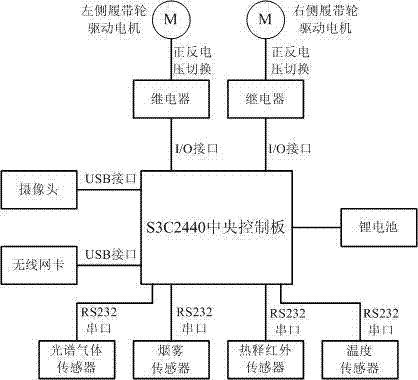

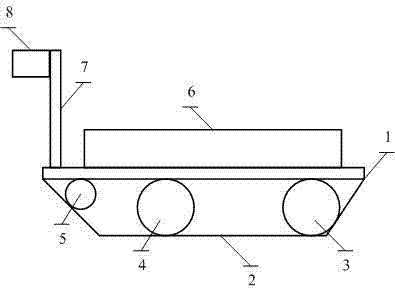

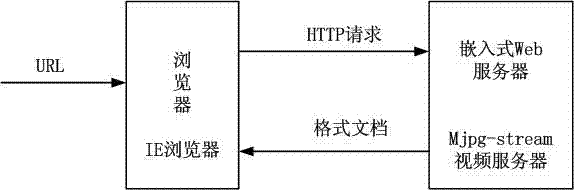

Webpage remotely-controlled patrol vehicle

InactiveCN104519311AVoluntary movement controlImplement backClosed circuit television systemsTransmissionSurveillance cameraWireless transmission

The invention discloses a webpage remotely-controlled patrol vehicle and relates to indoor mobile monitoring and patrolling equipment and techniques employing internet-based remote control. The vehicle can be controlled to move back and forth and turn by a user through a menu on a webpage in any internet terminal; images taken by a monitor camera on the vehicle are transmitted in real time to the webpage for displaying; data in a sensor on the vehicle is transmitted in real time to the webpage; smoke, gas, temperature and body thermal radiation status information can be acquired. An S3C2440 central control board is connected to the sensor, the monitor camera and a wireless local area network card to allow acquisition and wireless transmission of monitoring data; a two-key relay is controlled through an I / O port to switch so as to control travel positive and reverse rotation of a track wheel drive motor, thus moving or turning the vehicle.

Owner:WUHAN UNIV OF SCI & TECH

Lithium ion power battery

InactiveCN108657396AChieve progressImplement backUnderwater vesselsUnderwater equipmentPower batteryLithium-ion battery

The invention discloses a lithium ion power battery. The lithium ion power battery comprises a diving box. A camera shooting space is formed in the diving box. A gas storage space is formed in the right end wall of the camera shooting space. A sedimentation space is formed in the front end wall of the gas storage space. A transmission space is formed in the right end wall of the gas storage space.Two sets of driven spaces are symmetrically formed in the front end wall and the rear end wall of the transmission space. A drive space is formed in the right end wall of the transmission space. Thelower side at the front end of the right end face of the diving box and the upper side at the rear end of the right end face of the diving box are each fixedly connected with a drive mechanism. A tightening mechanism is arranged in the right end wall of the drive space. A power space is arranged in the rear end wall of the drive space. In the work process, a device is driven through the lithium ion battery, the cruising ability of the device is improved, the device is provided with few drive facilities, most components are connected through mechanical transmission, and power consumption is further reduced.

Owner:方小刚

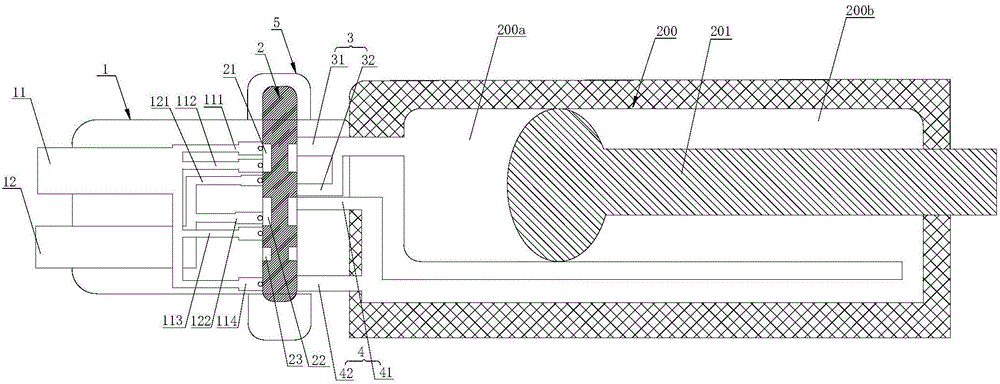

Micro-miniature underwater robot with power-off protection and power-off control method

ActiveCN110745220AExtended service lifeAchieving straight-line drivingProgramme control in sequence/logic controllersUnderwater vesselsMaster controllerMechanical engineering

The invention discloses a micro-miniature underwater robot with power-off protection and a power-off control method. The micro-miniature underwater robot with power-off protection comprises a sealingcabin, wherein the front end of the sealing cabin is detachably provided with a photography Pan&Tilt cover, vertical propellers are arranged in the front and rear of the sealing cabin, and the rear end of the sealing cabin is provided with a horizontal propeller; and an end cover of the sealing cabin is provided with a robot state detection sensor, wherein the vertical propellers, the horizontal propeller and the robot state detection sensor are all connected with a master controller through RS232 serial port lines, and each of the vertical propellers, the horizontal propeller and the master controller is provided with a power relay.

Owner:JIANGSU UNIV OF SCI & TECH

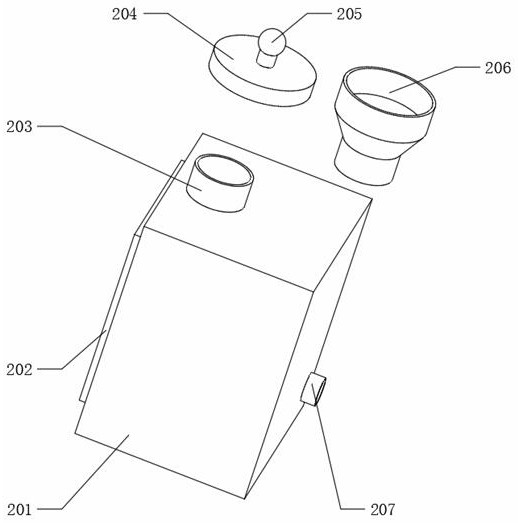

Irrigation device facilitating water quantity control for fruit tree planting and use method

InactiveCN112021157AEasy to controlSimple and fast operationWatering devicesCultivating equipmentsFruit treeWater storage

The invention discloses an irrigation device facilitating water quantity control for fruit tree planting and a use method, and relates to the technical field of fruit tree irrigation. The aim is to solve the problem of quantitative irrigation. The irrigation device comprises a bottom plate, a water storage assembly and a protection assembly, the outer wall of one side of the water storage assemblyis fixedly connected with a water supply assembly, the outer wall of one side of the water supply assembly is fixedly connected with a quantification assembly, the outer wall of one side of the quantification assembly is fixedly connected with an irrigation assembly, and the outer wall of the bottom of the bottom plate is fixedly connected with a moving assembly. The using method of the irrigation device comprises the following steps of device starting, water body filling, water body transporting, device moving, water quantifying, irrigation and repeated irrigation. According to the irrigation device and the using method, an air cylinder stretches and retracts to drive a plugging block to move, the plugging block enters and exits from a quantitative bin, and then the internal volume of the quantitative bin is adjusted; when irrigation is conducted, the quantitative bin needs to be filled with liquid, through volume adjustment and water body filling, quantitative control during irrigation can be met, operation is easy and convenient, and irrigation water body control can be more accurate.

Owner:衡东林馨农林科技开发有限责任公司

Novel static water surface atmospheric pollution gas sampling device

The invention provides a novel static water surface air pollution gas sampling device. The device comprises a floating box, a storage battery, moving wheels, a power device, a connecting thimble, a wind speed indicator, a marking post, a sampling storage box device, a barometer, a temperature and humidity meter, an anti-sundries cover, an air inlet funnel, a push-pull rack, a control winding diskstructure, an air pump and a counterweight bar. Accordingly, by means of the power motor, a connecting wheel and mooring plates, the gas sampling device can move forward or backward on the water surface conveniently, and the problem that a traditional gas sampling device cannot move on the water surface is solved; by means of an air outlet non-return pipe and an air inlet non-return pipe, samplinggas can be stored in the sampling box is facilitated, and the problem that the traditional gas sampling device is inconvenient for gas storage is solved; by means of a wire coil and a roller, windingof a control line is facilitated, and the problem that a control line of an ordinary gas sampling device is long, and inconvenience is brought to operation is solved.

Owner:湖南格致分析仪器有限公司

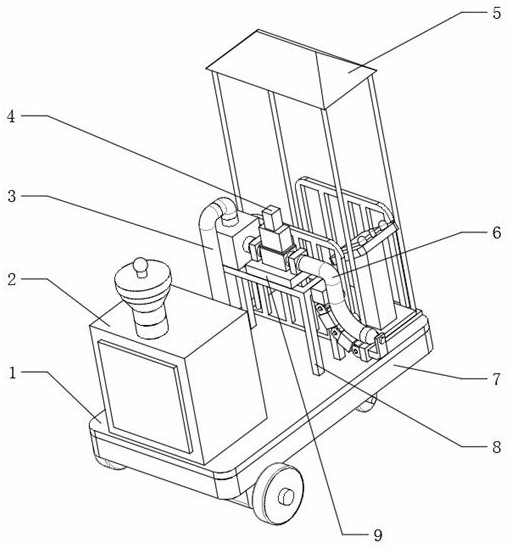

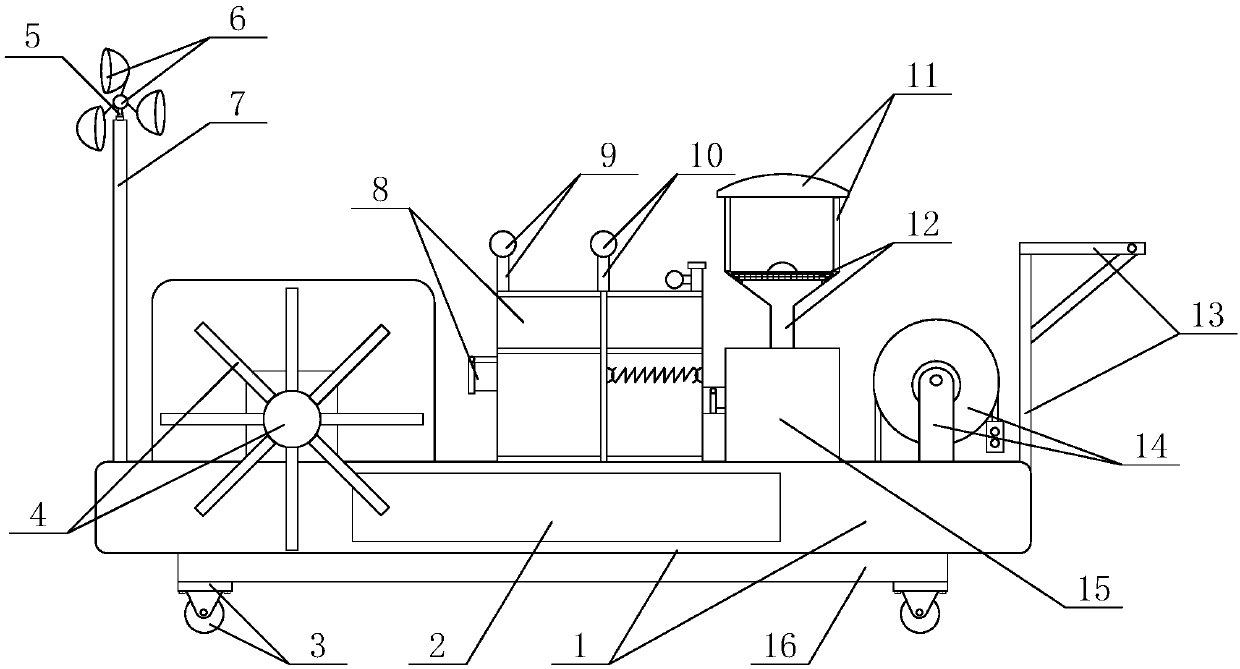

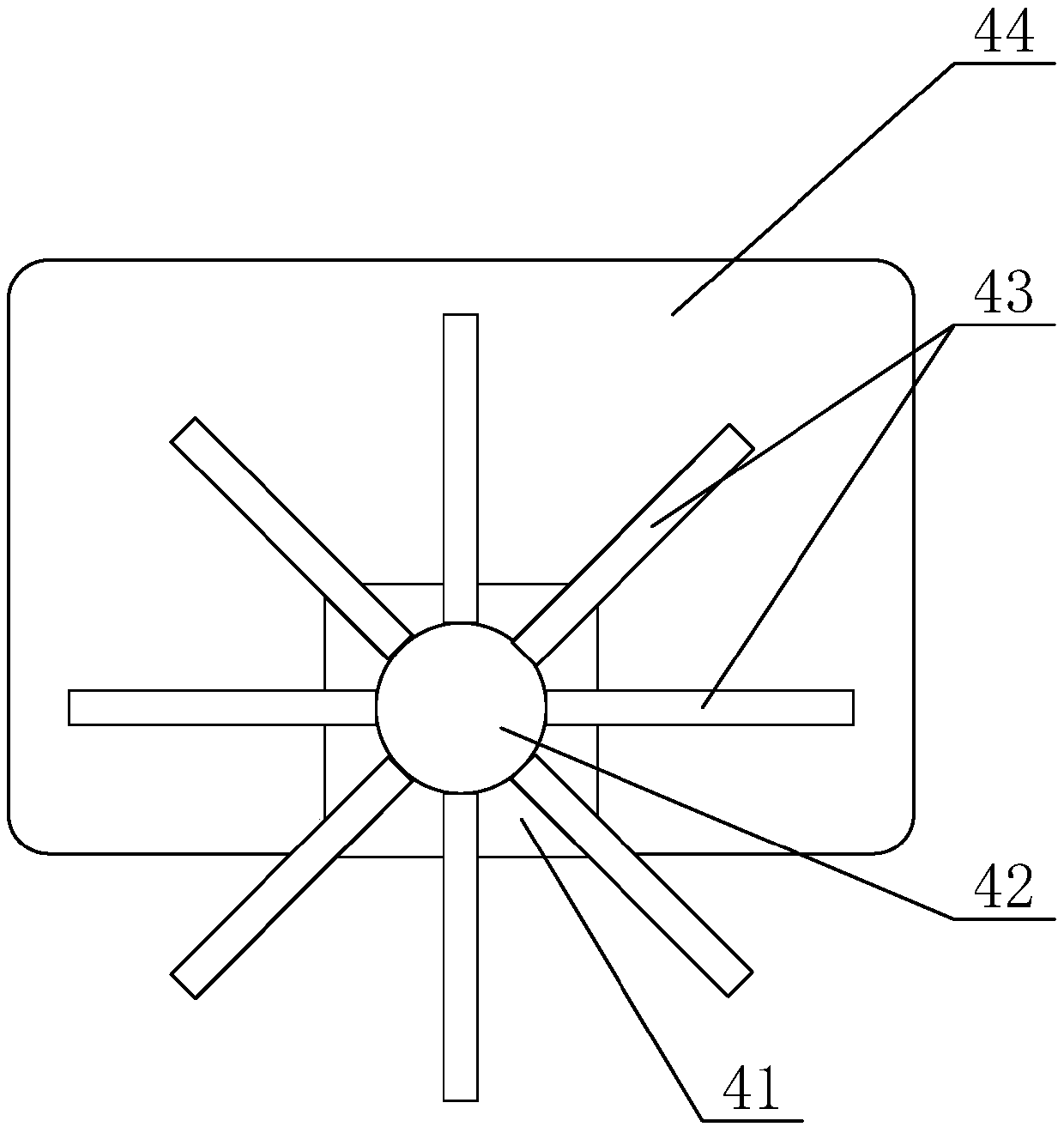

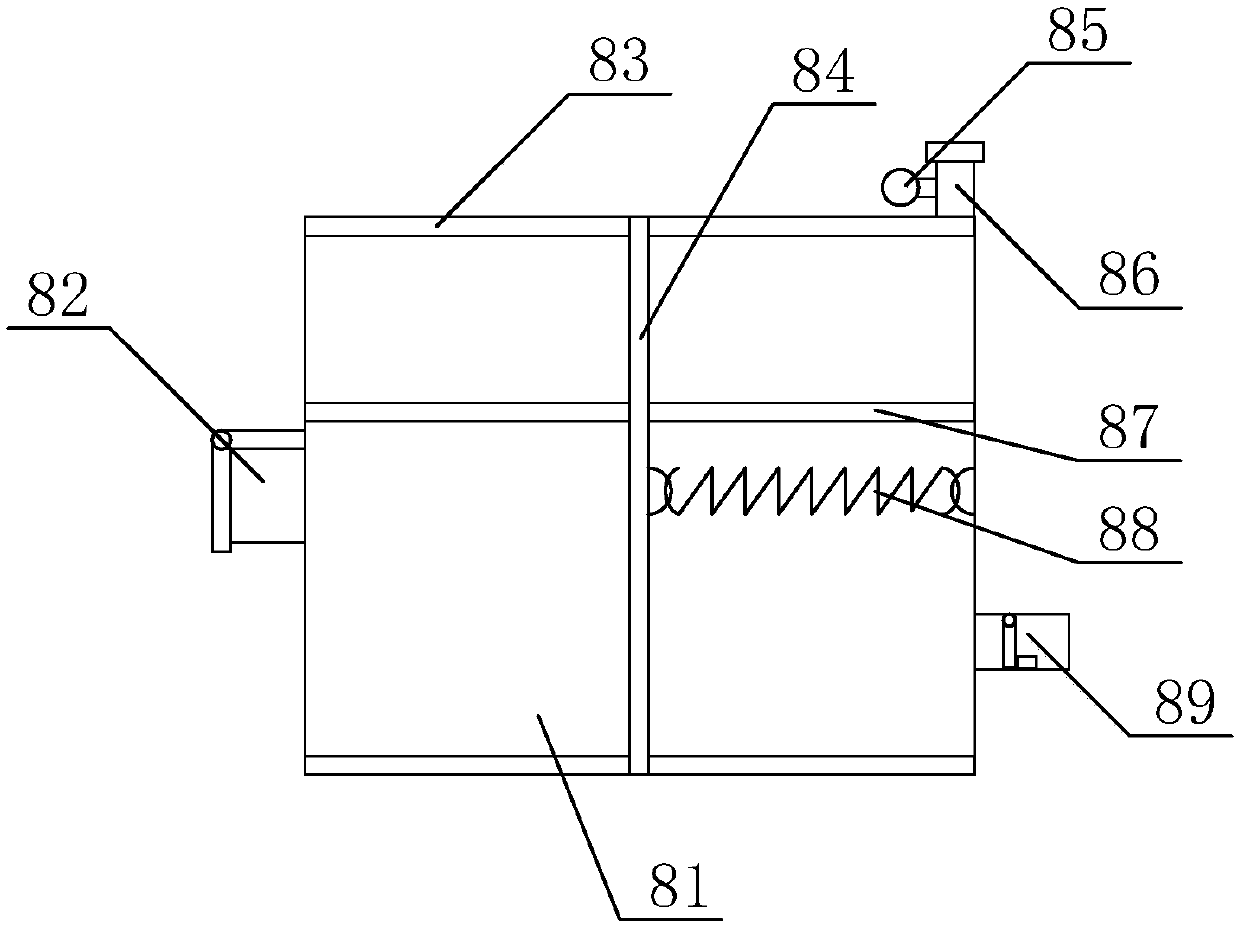

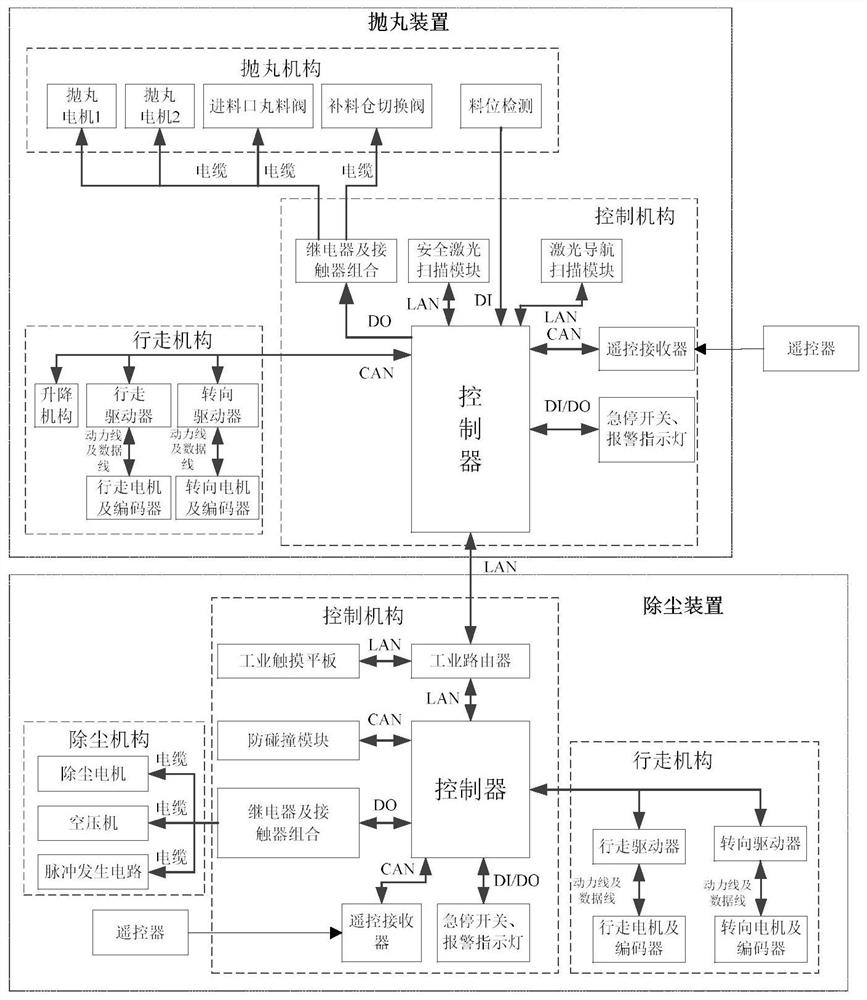

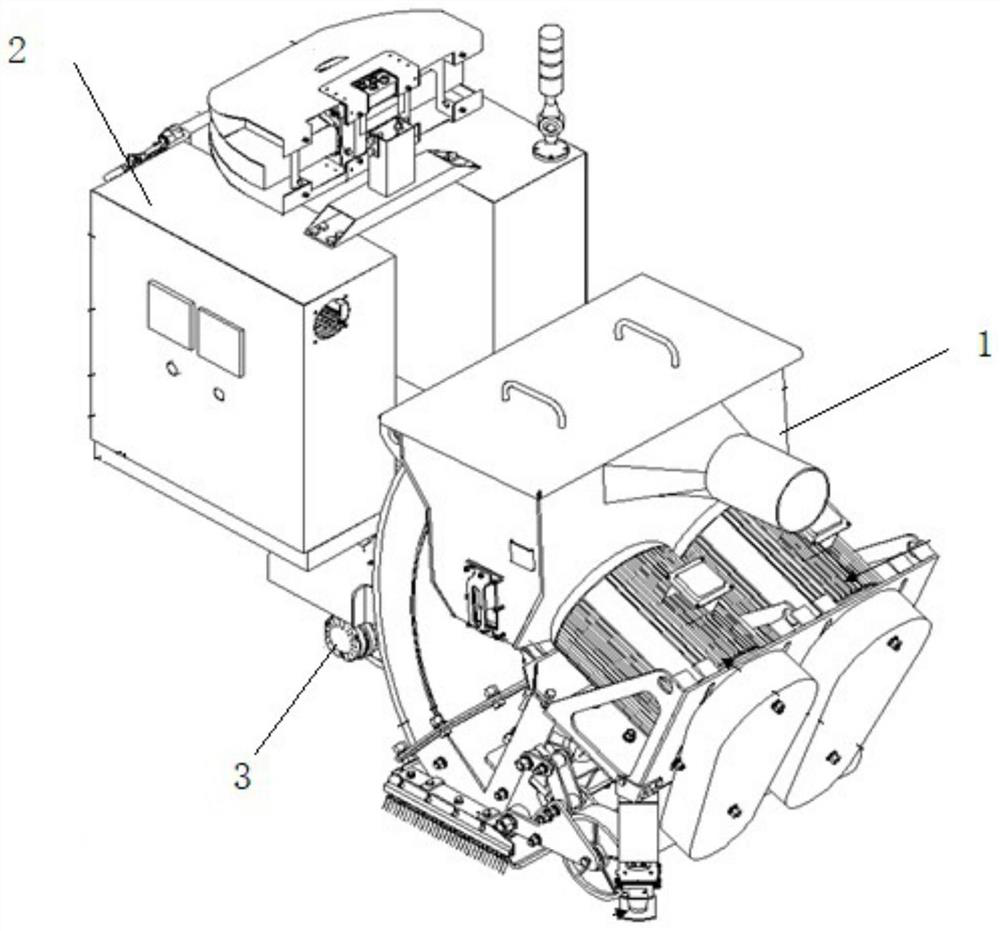

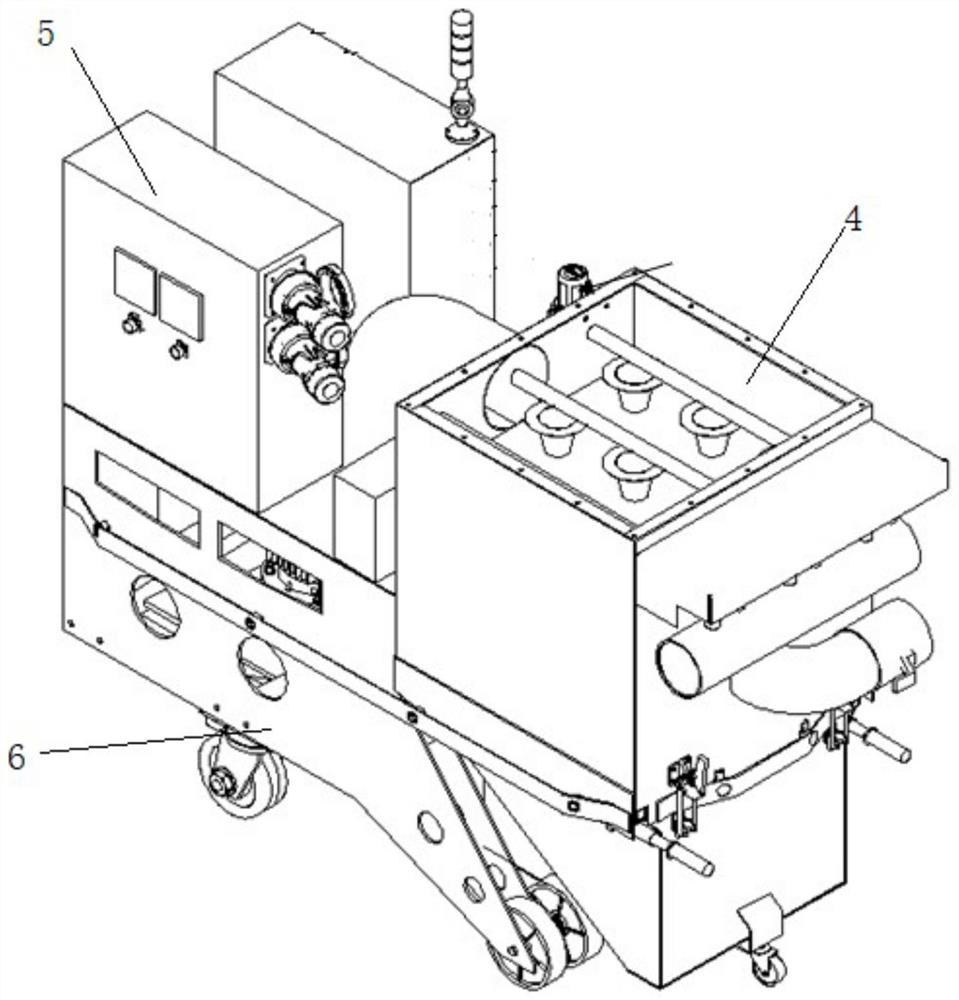

Shot blasting robot for ship deck and operation method

ActiveCN113134790AAchieve cleanupAchieve separationAbrasive machine appurtenancesManipulatorMarine engineeringRemote control

The invention discloses a shot blasting robot for a ship deck and an operation method. The shot blasting robot comprises a remote controller, a shot blasting device and a dust removal device; The shot blasting device is used for executing rust and paint removal operation on the ship deck, the dust removal device is used for recycling dust generated during cleaning of the shot blasting device, the shot blasting device and the dust removal device are connected through a hose, a cable and a network cable, and the remote controller is used for controlling the shot blasting device and the dust removal device to cooperate with each other to complete shot blasting operation; and the operation method comprises a remote control operation method and a guidance planning operation method. The problems of wide construction range, low efficiency, serious environmental pollution and the like in paint and rust removal operation are solved, obstacles can be detected and avoided, maintenance is convenient, and operation is easy.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +2

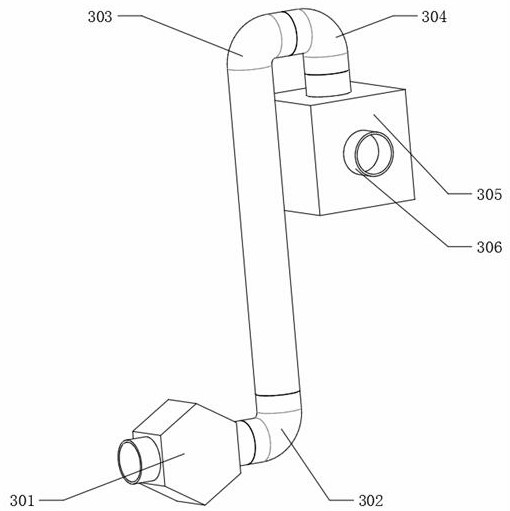

Backward steering device for propelling and direction control in water

InactiveCN104908918AReduce installationImplement backSteering by propulsive elementsPump-jetWater flow

The invention discloses a backward steering device for propelling and direction control in water. The backward steering device comprises a water spraying propeller, at least two rudders and shift devices, wherein the rudders are respectively arranged on the outer sides of a water spraying opening of the water spraying propeller and used for changing the flow direction of water sprayed by the water spraying propeller; the shift devices are respectively connected with the rudders and used for driving the rudders to deviate from and return to the outer sides of the water spraying opening of the water spraying propeller; one of the water spraying propellers is arranged, and correspondingly a pair of the rudders is arranged and relatively distributed on two sides of a vertical axle wire of the water spraying opening. According to the backward steering device for the propelling and the direction control in water, disclosed by the invention, during the rudders are reduced, a left turn function, a right turn function, a left turn in situ function, a right turn in situ function and a drawing back function can also be realized, so that parts and components are greatly reduced, besides the size is reduced, the weight is lightened, the speed is accelerated, the routine maintenance is convenient, and the related cost is relatively lower.

Owner:黄塬森

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com