Backward steering device for propelling and direction control in water

A steering device and direction control technology, which is applied to steering and other directions with propulsion components, can solve the problems of heavy weight, high cost, large volume, etc., and achieve the effect of reducing installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

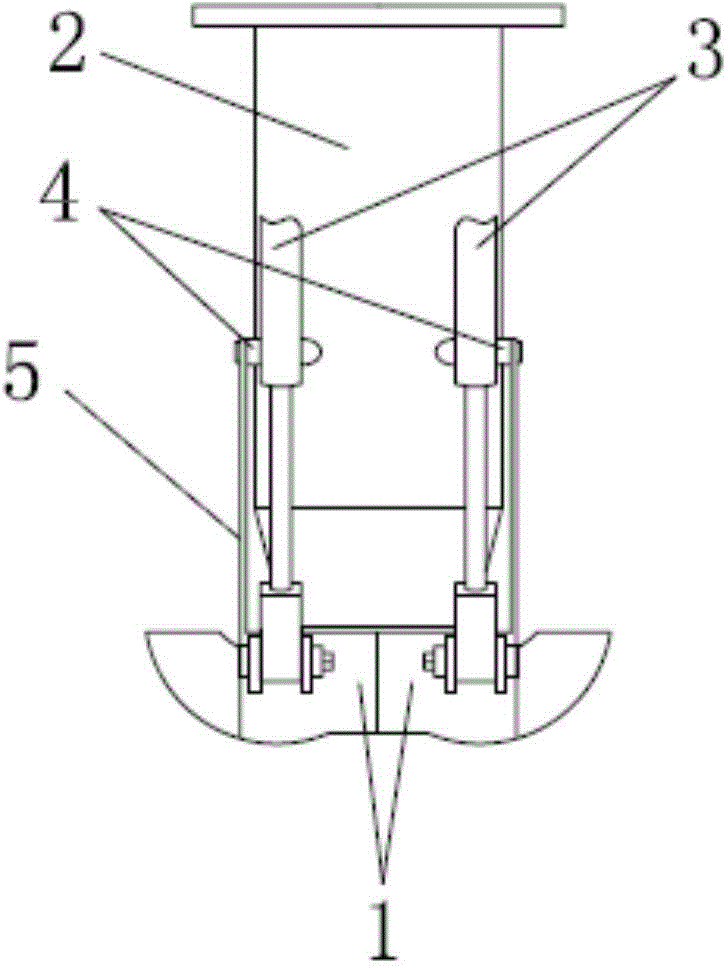

[0049] Such as figure 1 As shown, this embodiment discloses a reverse steering device for underwater propulsion and direction control, which includes a rudder 1 , a water jet 2 and a displacement device 3 .

[0050] Wherein, the number of the water jet propeller 2 is one. They are provided as a pair, and are symmetrically distributed on both sides of the vertical central axis of the water spout 6 . At the same time, each rudder 1 is connected to a shifting device 4, which is represented by a telescopic mechanism in this embodiment, and adopts hydraulic pressure, push-pull shaft or electric mode for telescopic operation, and is intended to drive the rudder 1 to deviate or Returns to the outside of the spout, but other mechanisms that serve the same purpose could be substituted.

[0051] Among them, the rudder is symmetrically distributed on the vertical central axis of the water nozzle, the purpose is to make the displacement device connected with it and give the push-pull fo...

Embodiment 2

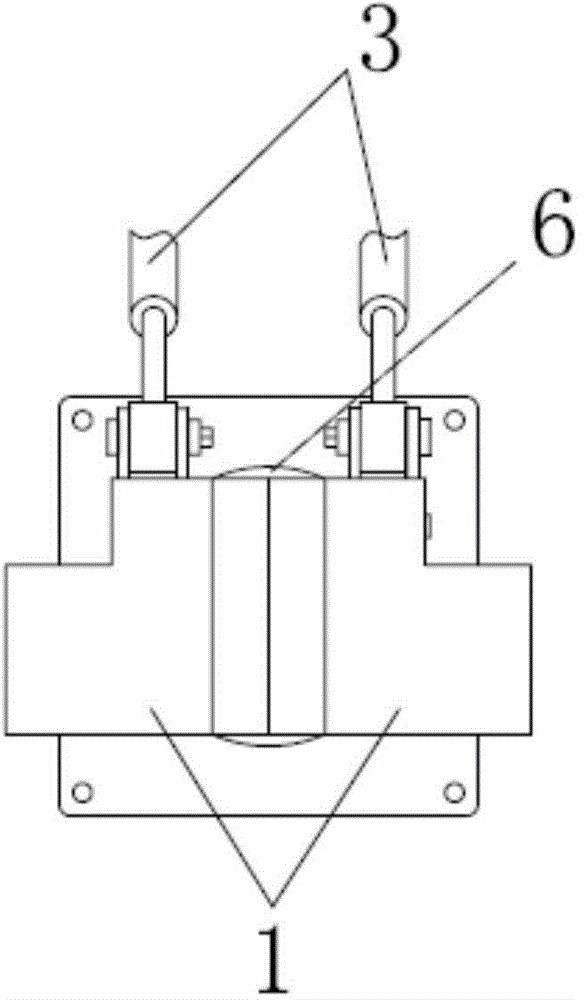

[0060] The difference between this embodiment and Embodiment 1 is that the rudder 1 is arranged laterally on both sides of the vertical central axis of the water jet 6 of the water jet propeller 2 through the connecting strut 5 . Since the reverse rudder 1 is arranged laterally, the hinge point 4 is located at the middle and lower part of the outer wall of the water jet propeller 2 .

[0061] The reason why the hinge point 4 is arranged on the middle and lower part of the water jet propeller 2 outer walls is that the reverse rudder 1 is arranged on the longitudinal plane of the water nozzle 6 in a horizontal manner, because the reverse rudder 1 is moving During the push-pull process of the positioning device 3, since its own length is relatively small in the horizontal dimension relative to the longitudinal dimension, when it is necessary to change the force of the sprayed water from the water spout 6 on the reverse rudder 1, the reverse rudder 1 is in the Deflection on the su...

Embodiment 3

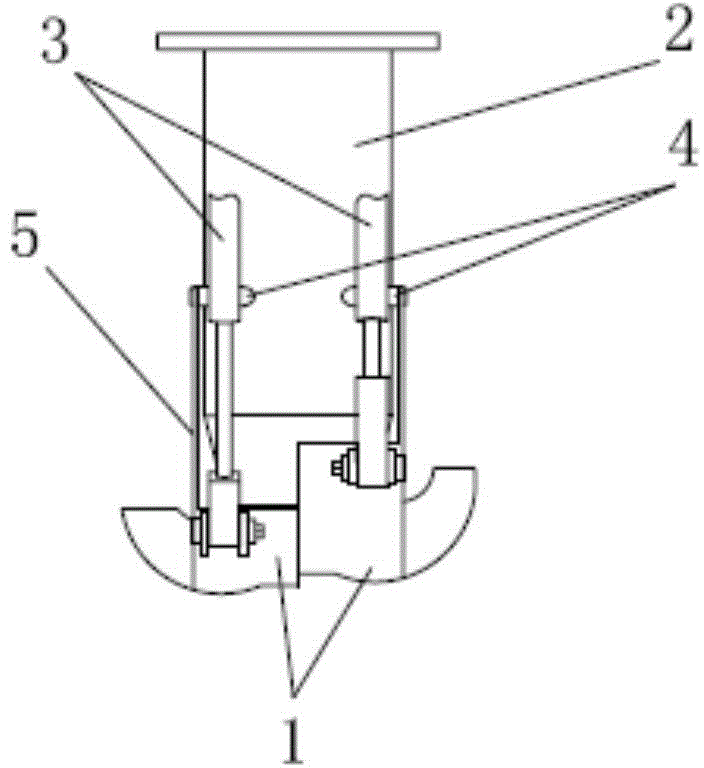

[0067] The only difference between this embodiment and Embodiment 1 is that the rudder 1 on the left side is arranged laterally, so the corresponding hinge point 4 is arranged in the middle and lower part of the water jet propeller 2, as Figure 9 As shown, the reverse rudders 1 connected to the two water jets 2 are connected in different ways, and the principle of setting the hinge point 4 there is the same as that of Embodiment 2, and will not be repeated here. . Of course, it is also possible that the rudder positioned on the left side is arranged longitudinally, and the rudder 1 positioned on the right side is arranged horizontally.

[0068] Depend on Figure 9It can be seen that it shows the state of turning counterclockwise in situ, the left rudder 1 does not deviate from the water nozzle 6, and the right rudder 1 completely deviates from the water nozzle 6, so the water flow on the left is moved forward by the rudder 1 The water flow on the right side is sprayed direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com