Patents

Literature

38results about How to "Realize forward and reverse control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Positive and reverse rotation control circuit of electric motor

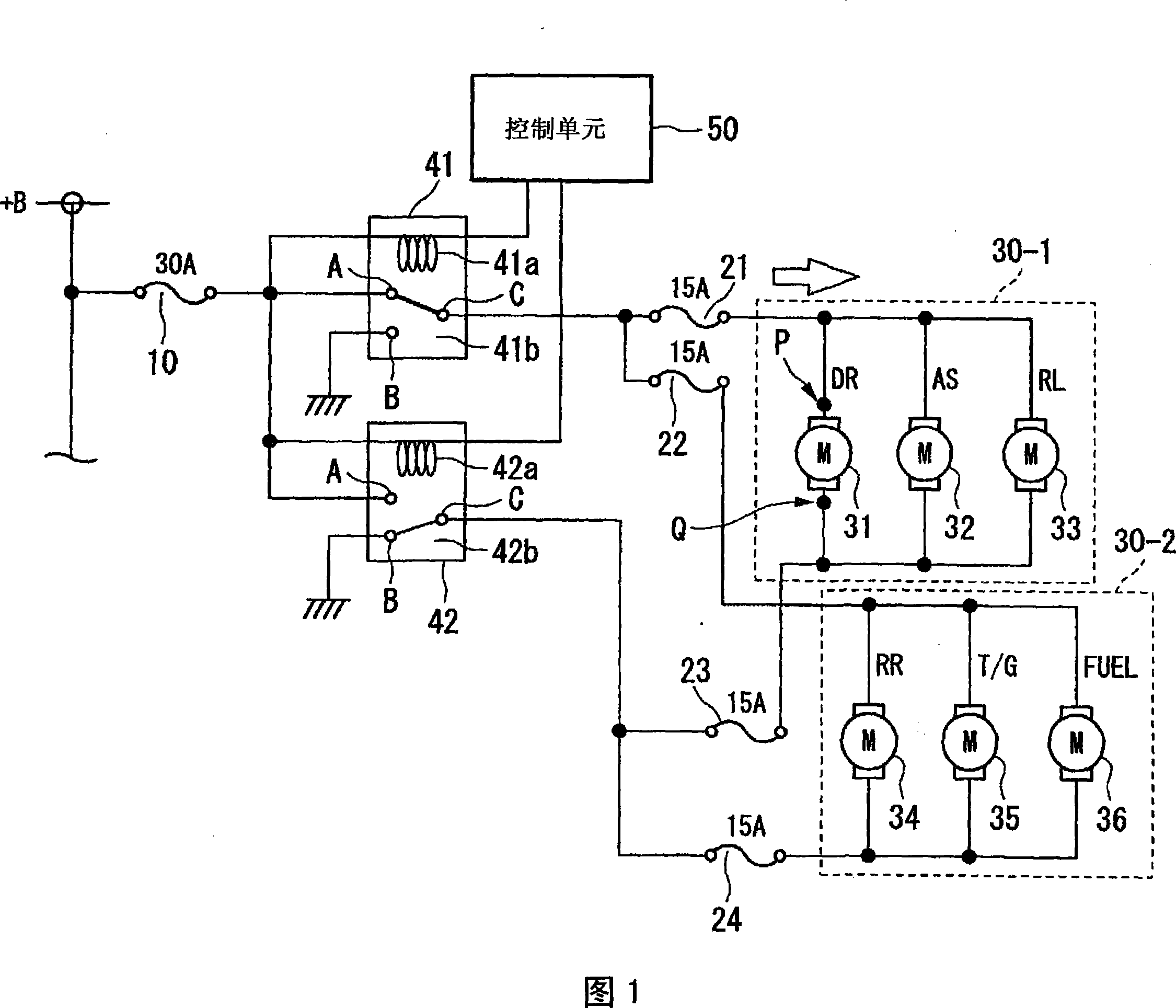

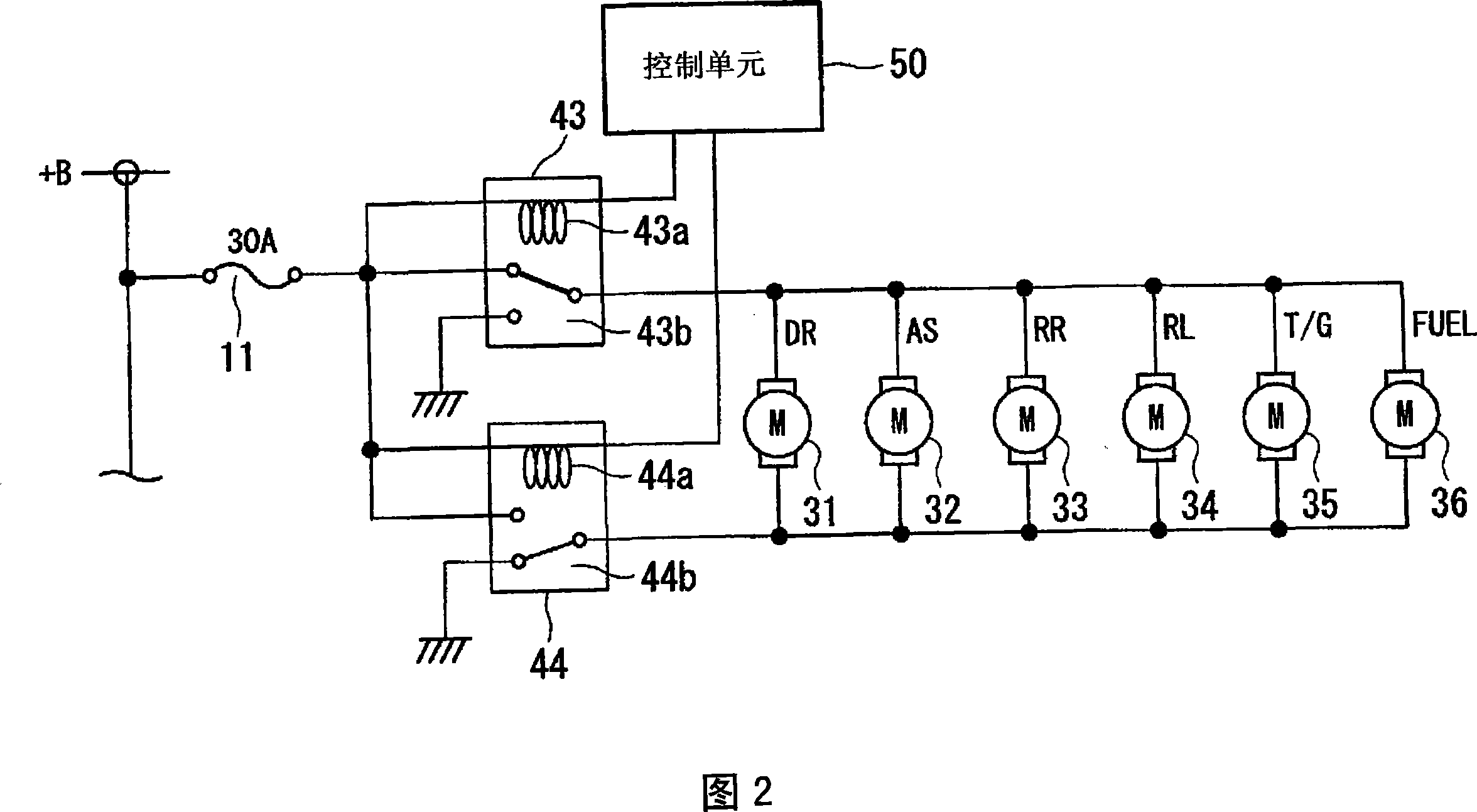

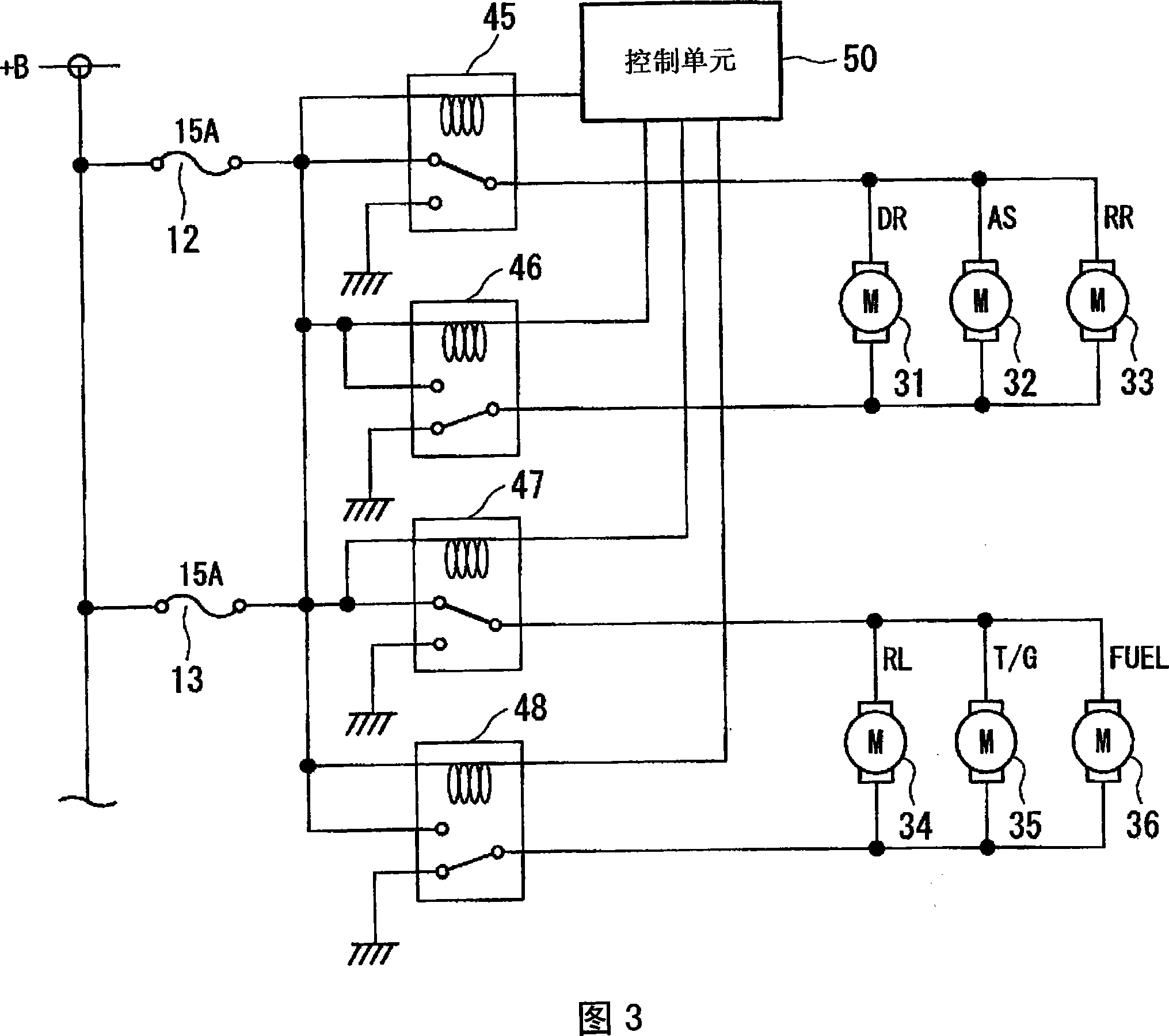

InactiveCN101222193AReduce the numberAvoid damageMultiple dynamo-motor startersRelaysCapacitanceEngineering

The present invention provides a forward and reverse control circuit of an electric motor, in which a plurality of motors (31-36) for opening and closing bodies are connected to a plurality of motor groups (the first motor group 30-1, the second motor group 30-2 ) are connected to the relay circuits (41) and (42) through the second fuses (21-24) with a current capacity value smaller than that of the first fuse (10), and the current capacity value is lower than that of the first fuse ( 10) Small wiring between the second fuses (21-24) connects each second fuse (21-24) and each switch body opening and closing motor (31-36). Therefore, it is possible to realize a forward and reverse control circuit of a motor that can be used in an electric door lock system of an automobile at low cost.

Owner:HONDA MOTOR CO LTD

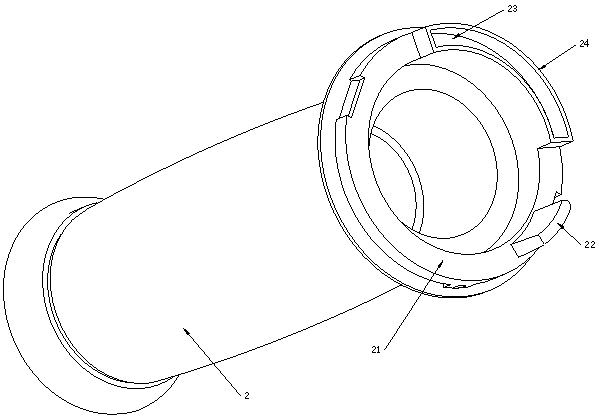

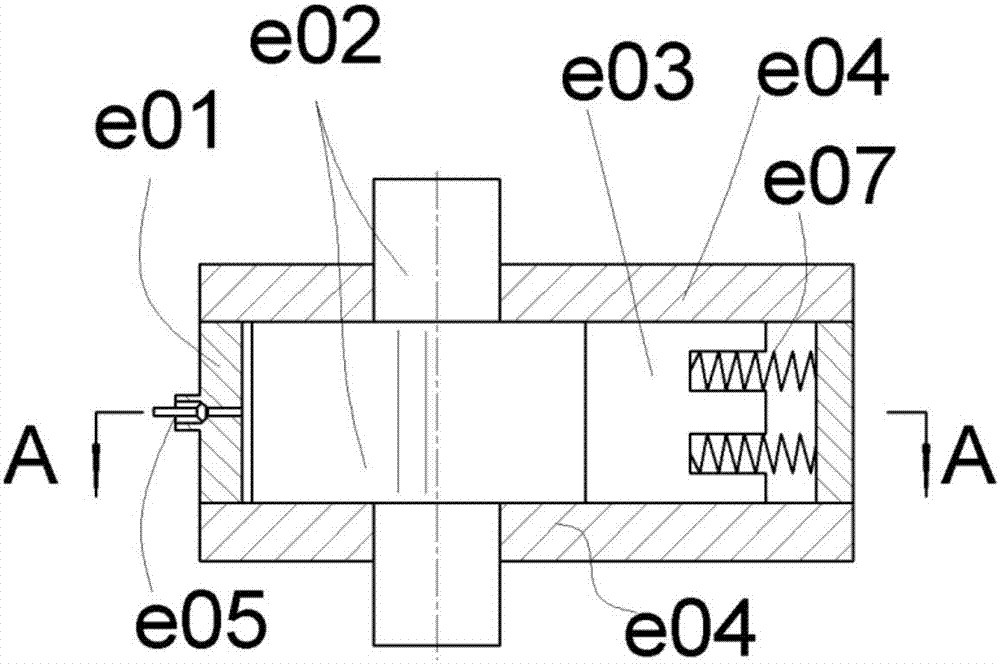

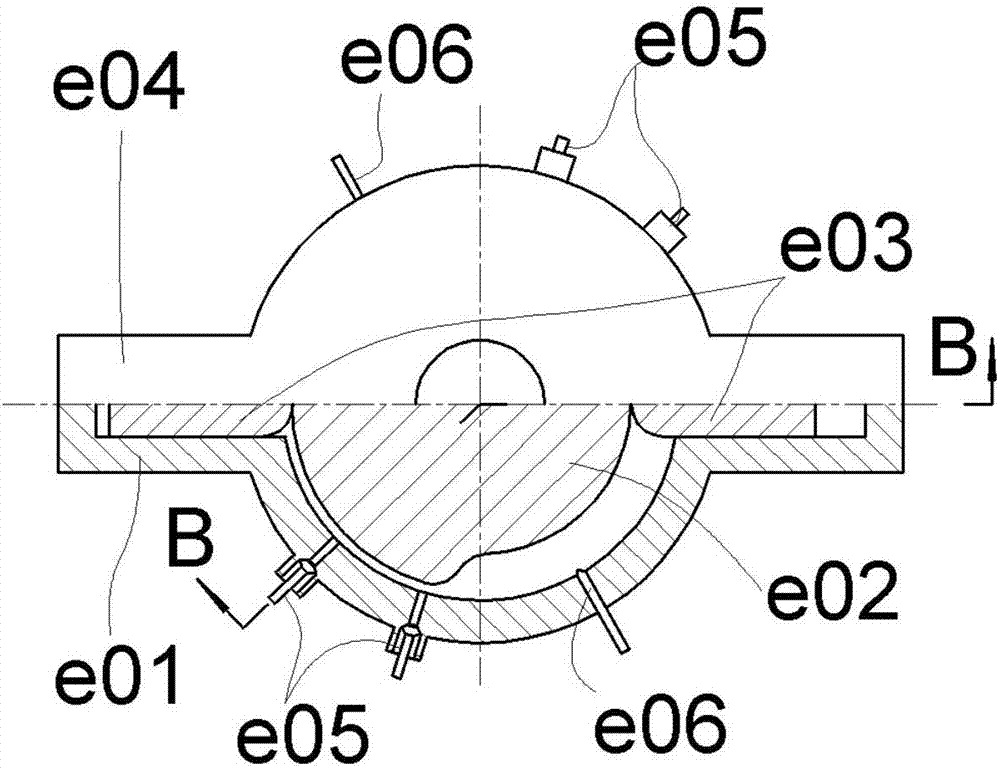

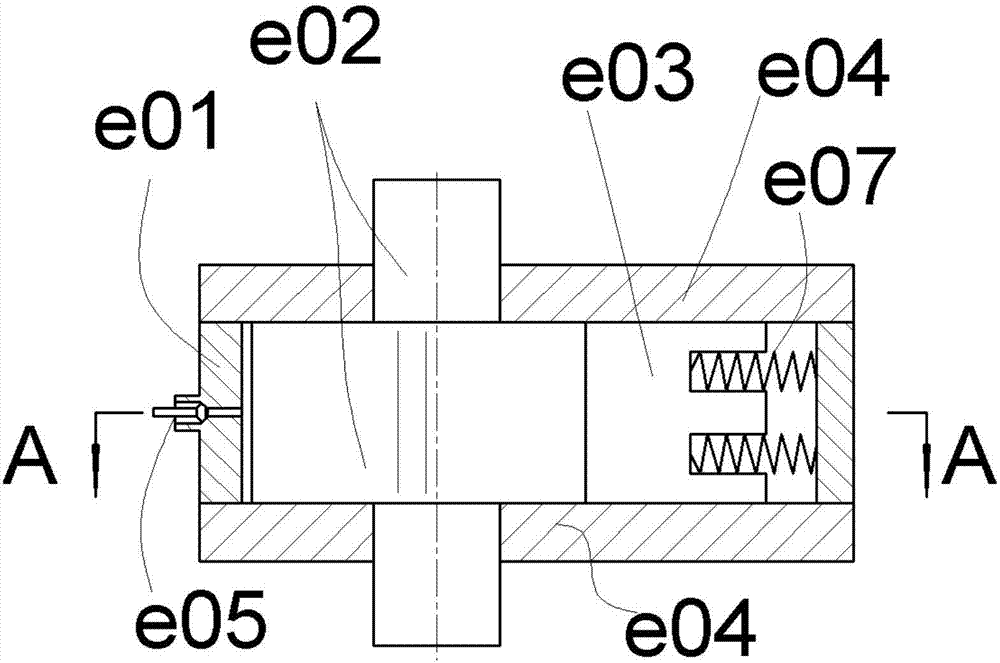

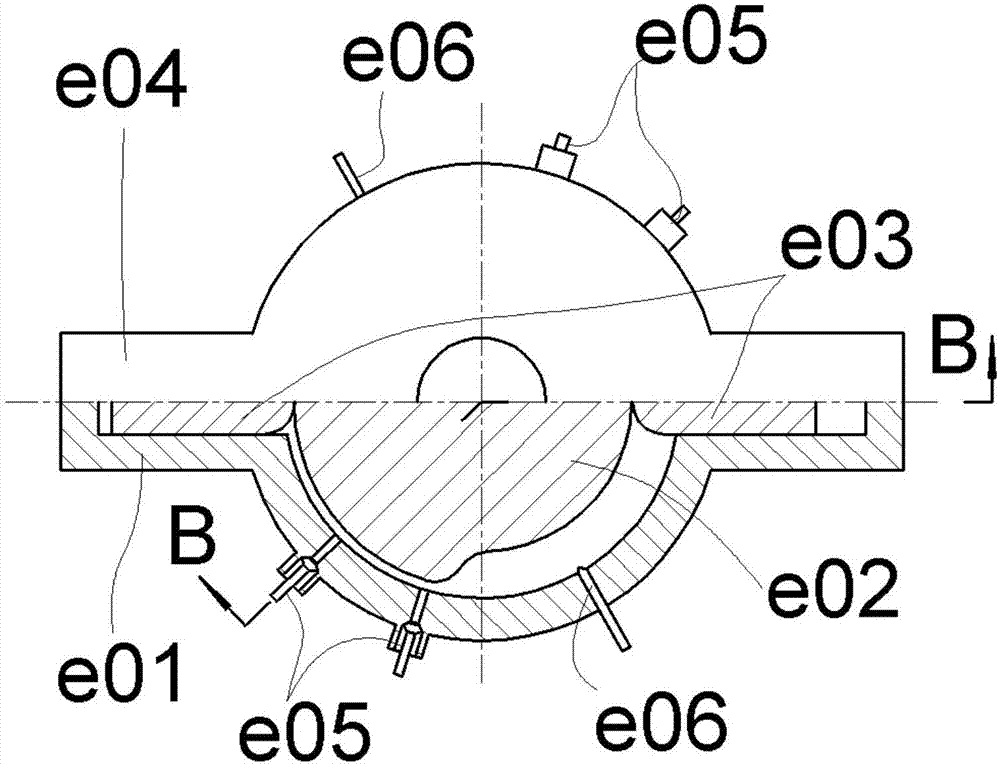

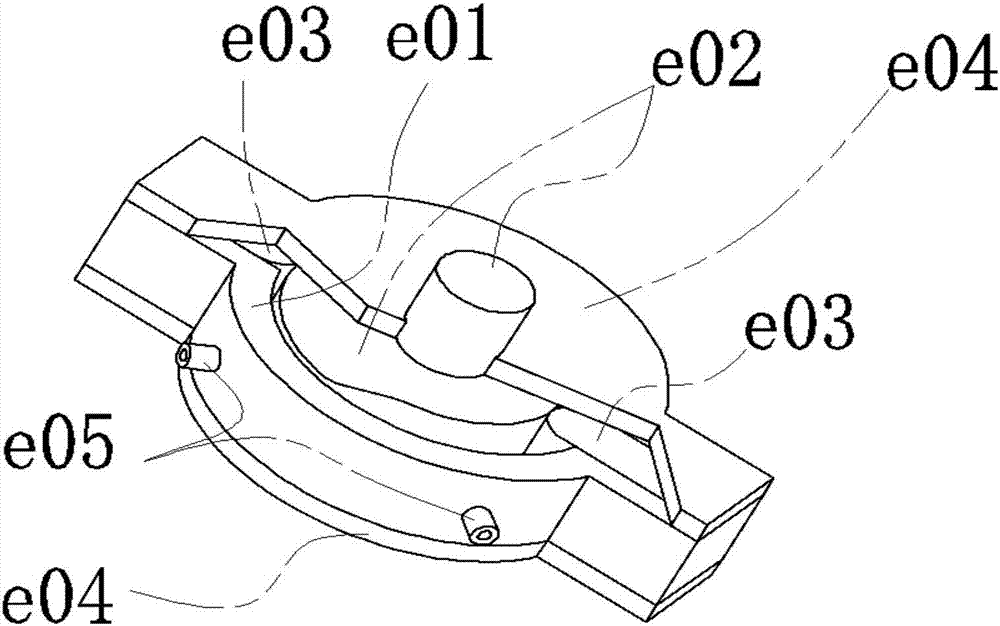

Forward and reverse speed adjustable handle for electric vehicle and power control device for electric vehicle

ActiveCN104015855ADescribe wellRealize forward and reverse controlCycle control systemsEngineeringElectric vehicle

The technology provides a forward and reverse speed adjustable handle for an electric vehicle. The forward and reverse speed adjustable handle can be turned in both forward and reverse directions to control the forward or reverse turning of an electric vehicle. The forward and reverse speed adjustable handle has the advantages of simple structure, no back-up switch, convenience in operation and high reliability, and the cost is equivalent to that of an ordinary speed regulating handle. The forward and reverse speed adjustable handle comprises a fixed part consisting of a handle stem and a handle seat, and a turning handle, wherein a left turning spring and a right turning spring are arranged between the fixed part and the turning handle; the left turning spring enables the turning handle to counterclockwise turn relative to the handle stem, and the right turning spring enables the turning handle to clockwise turn relative to the handle stem; the turning handle is in a reset position under the combined action of the left turning spring and the right turning spring. When an external force is applied to the turning handle, the turning handle can clockwise or counterclockwise turn from the reset position; a Hall sensor and an arc-shaped permanent magnet are respectively arranged on the turning handle and the fixed part oppositely but without contact; when the turning handle is turned, the Hall sensor moves relative to the arc-shaped permanent magnet, senses different positions of the arc-shaped permanent magnet and outputs relevant different signals.

Owner:NANJING SANYE GOLDEN EAGLE MOTORCYCLE

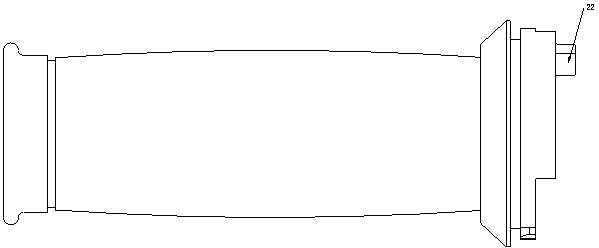

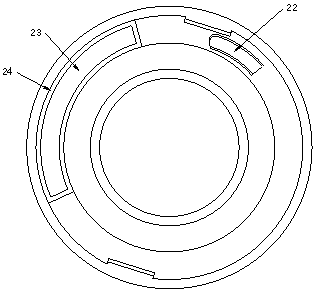

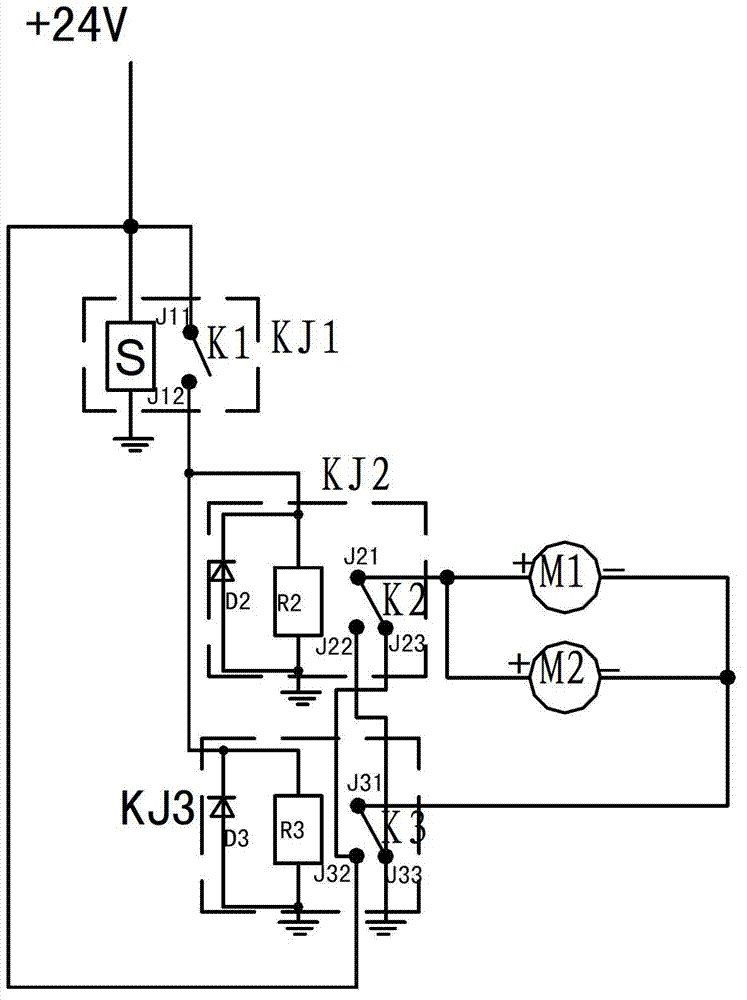

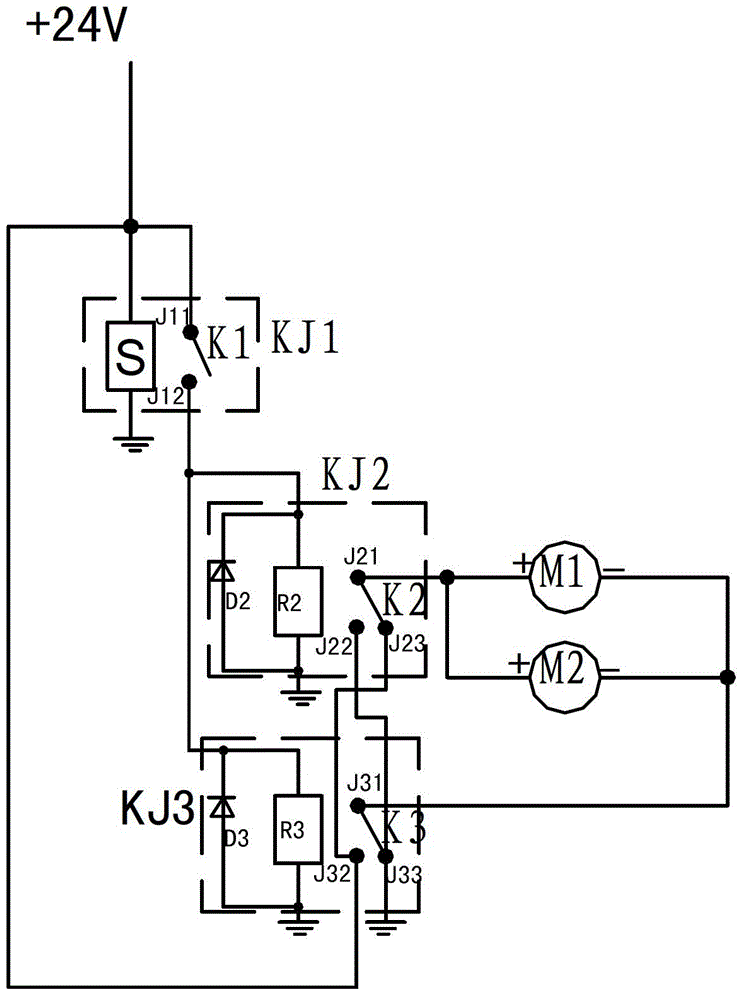

Forward and reverse rotation device of condensing fan

ActiveCN102788035ARealize forward and reverse controlImprove cooling effectPump controlNon-positive displacement fluid enginesControl circuitControl theory

The invention discloses an electromechanical device, and particularly relates to a device, used on a vehicle, of adjusting forward and reverse rotation of a condensing fan. The device comprises relays, a switch and a fan, wherein the relays comprise a time relay KJ1 and two relays KJ2 and JK3; a switch and the like are arranged in each relay; one of the two relays KJ2 and KJ3 is normally open and the other one of the two relays KJ2 and KJ3 is normally closed; and the forward and reverse rotation time is adjusted through time setting of the time relay JK1 to control the action of the fan. The device has the advantages of improving the radiating effect of a condenser and reducing the manual cleaning frequency. By using the condensing fan with excellent blowing and air suction effects and through control circuit design, forward and reverse rotation control of the condensing fan is realized to blow weeds and dust out. The device can be widely applied to mechanical vehicles operating outdoors.

Owner:杭州新都奥兰汽车空调有限公司

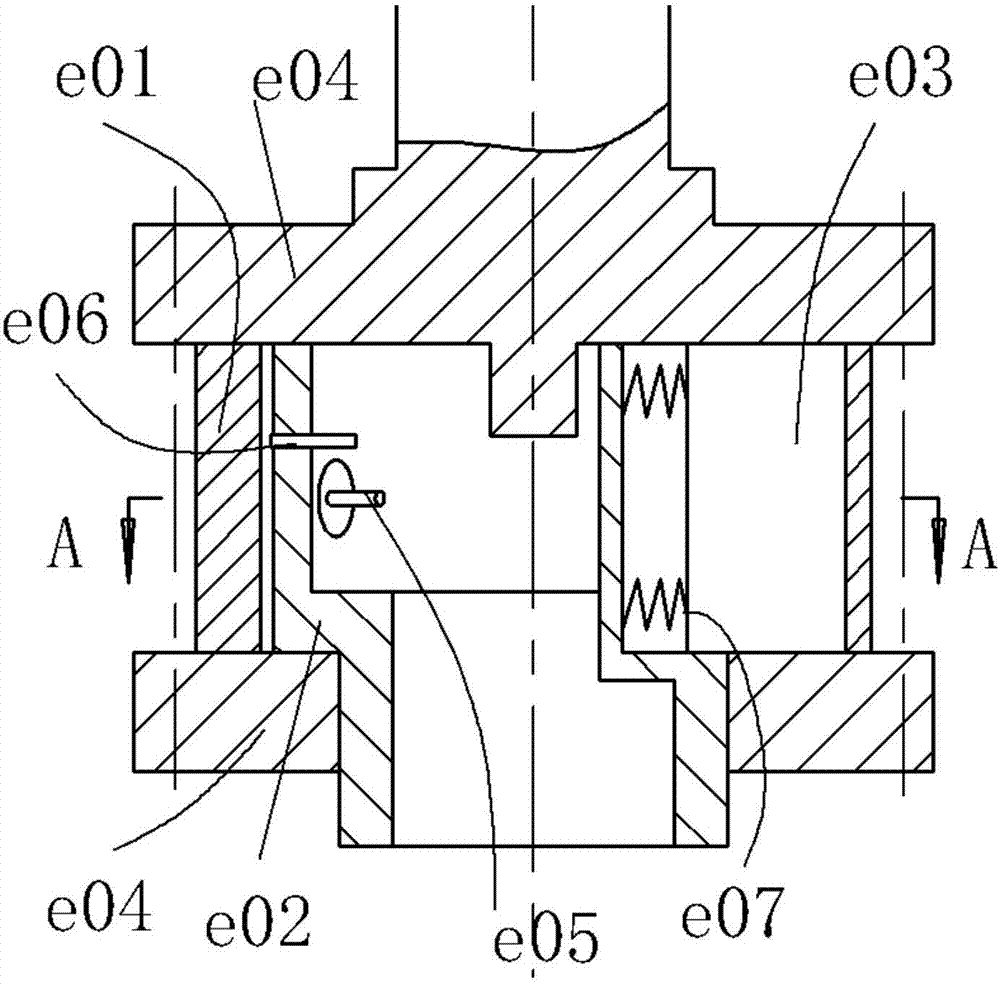

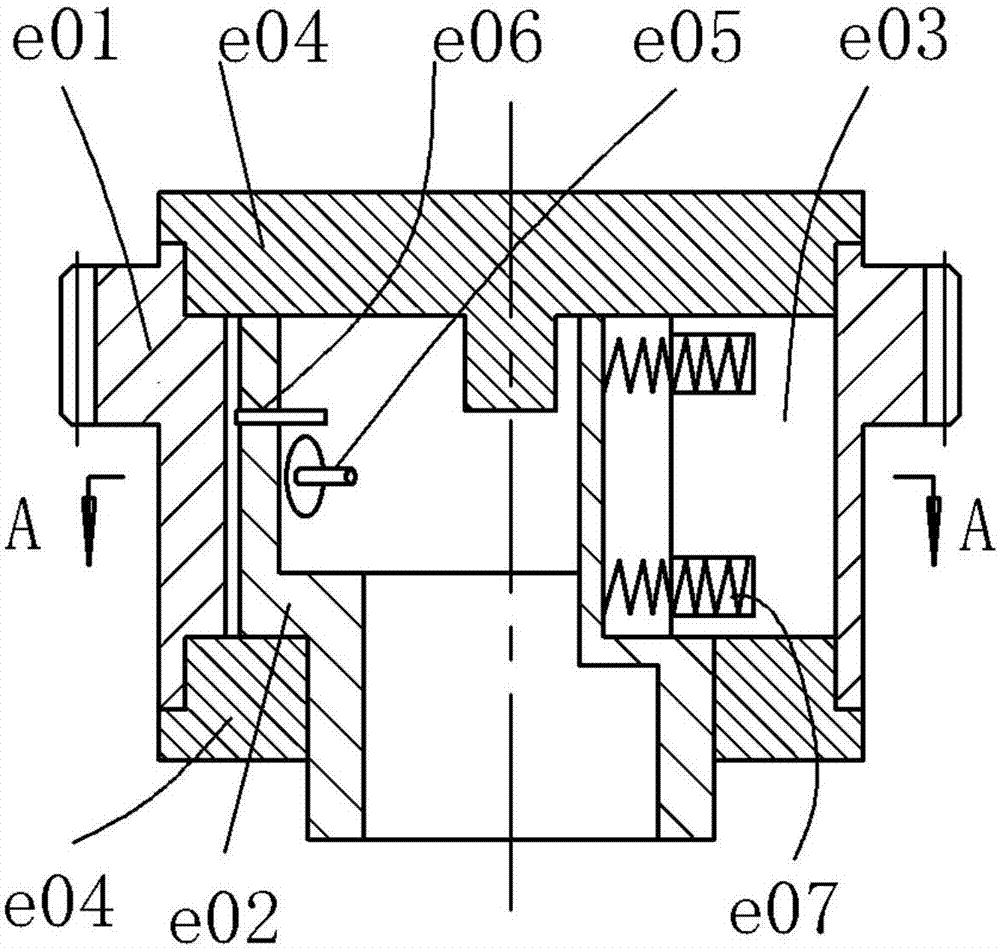

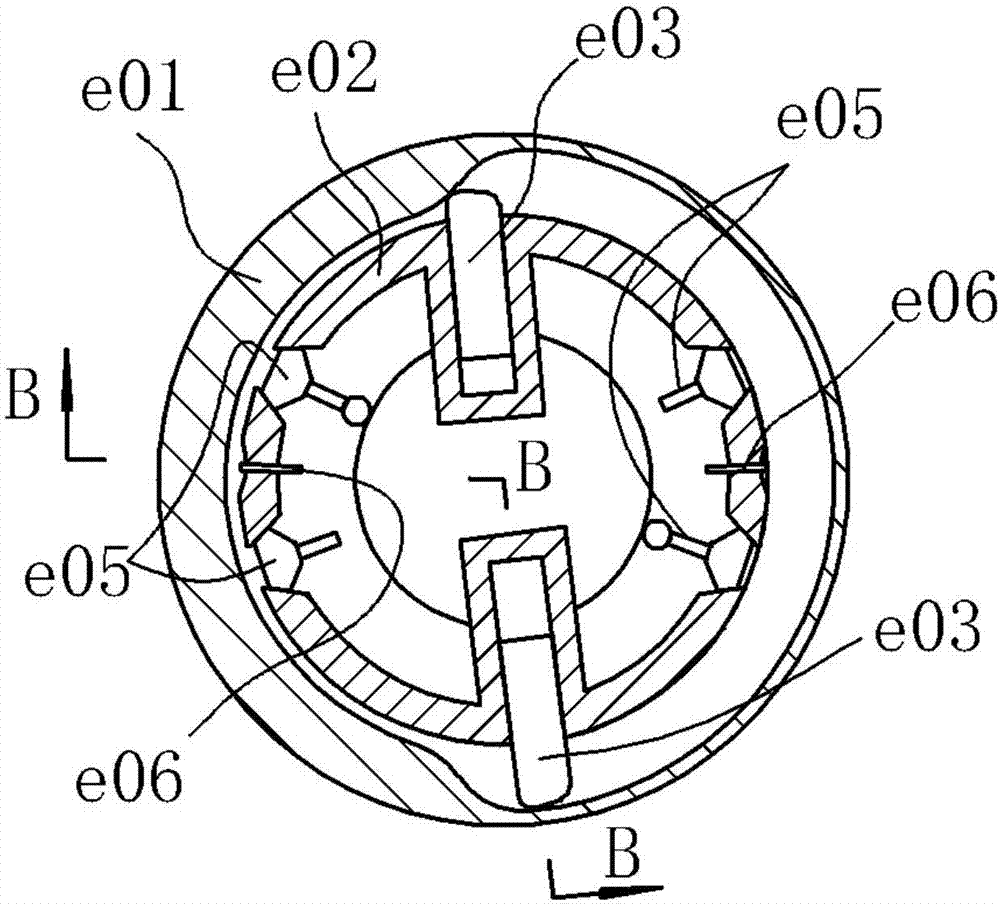

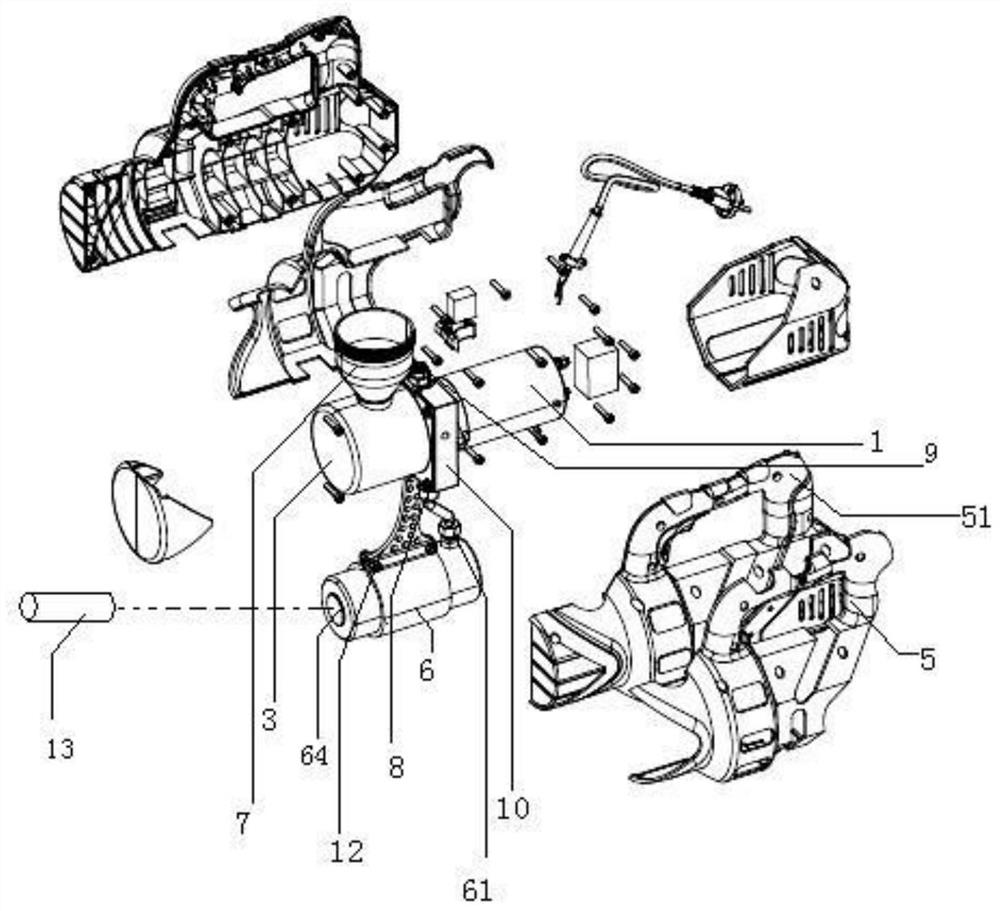

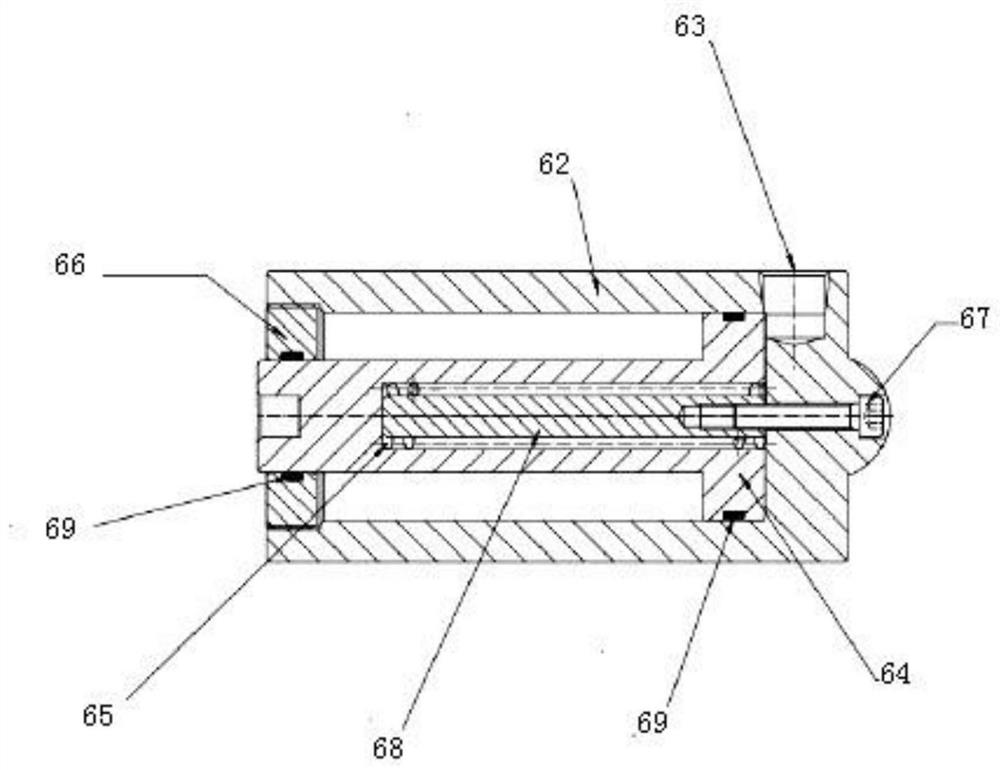

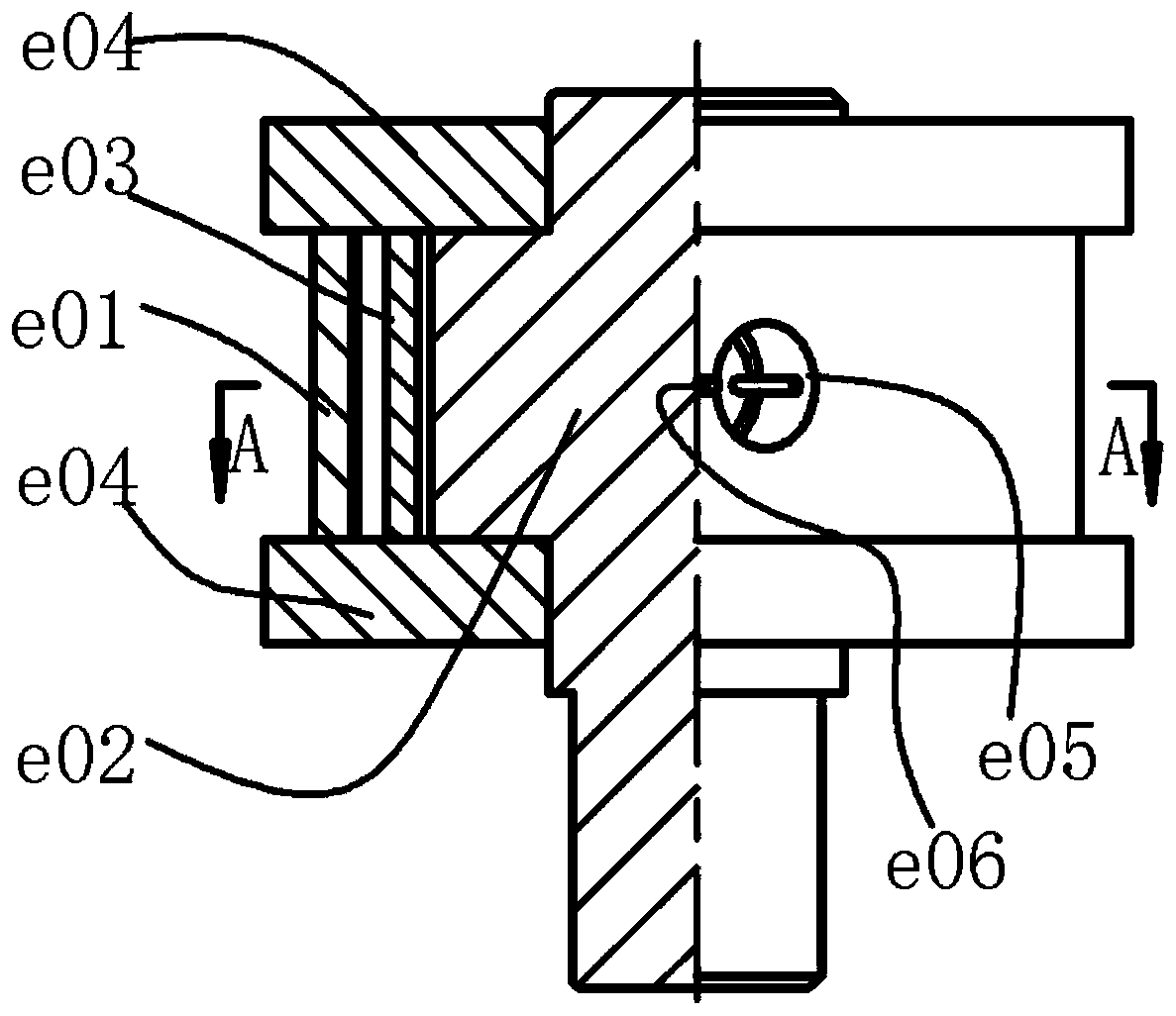

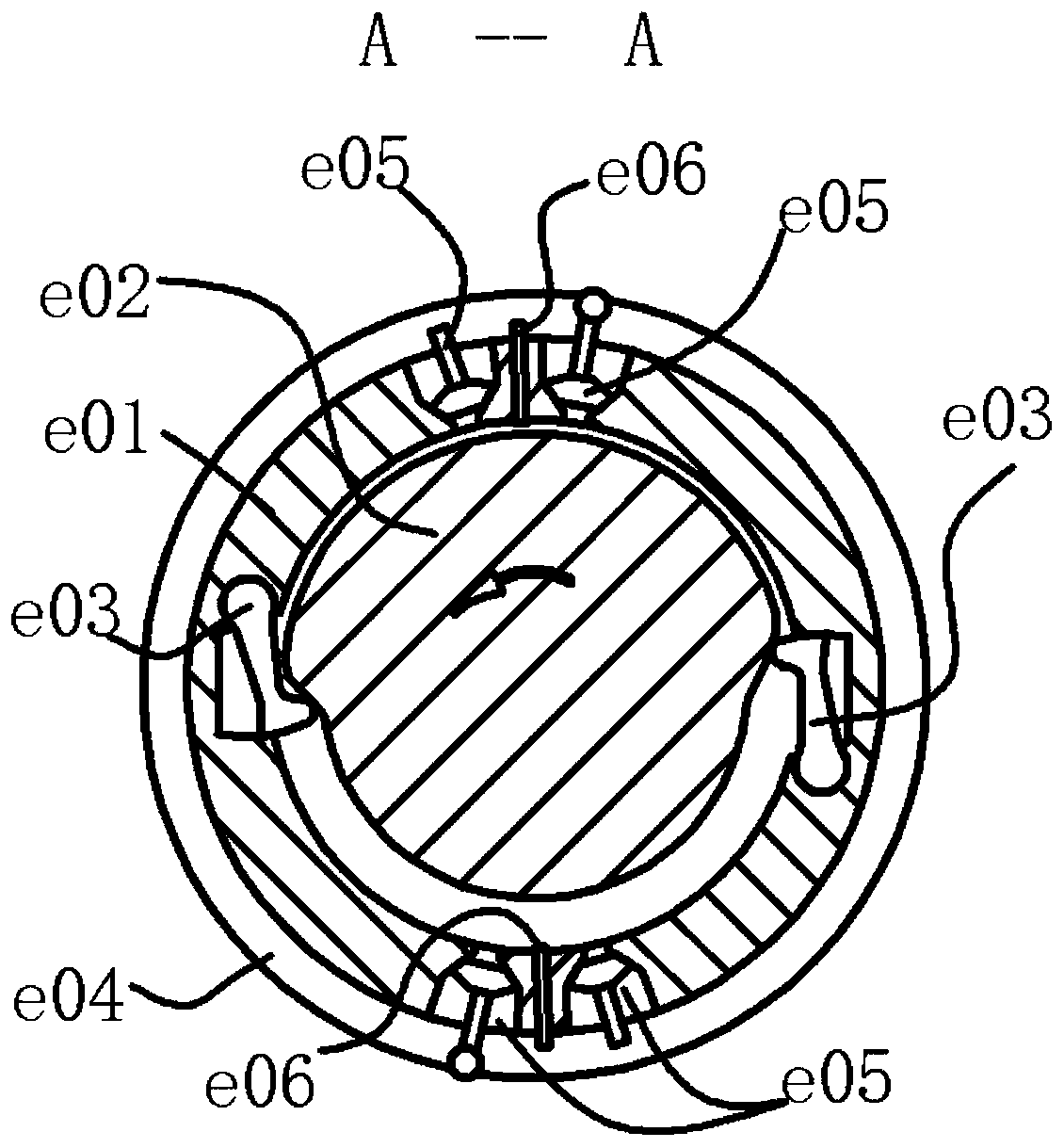

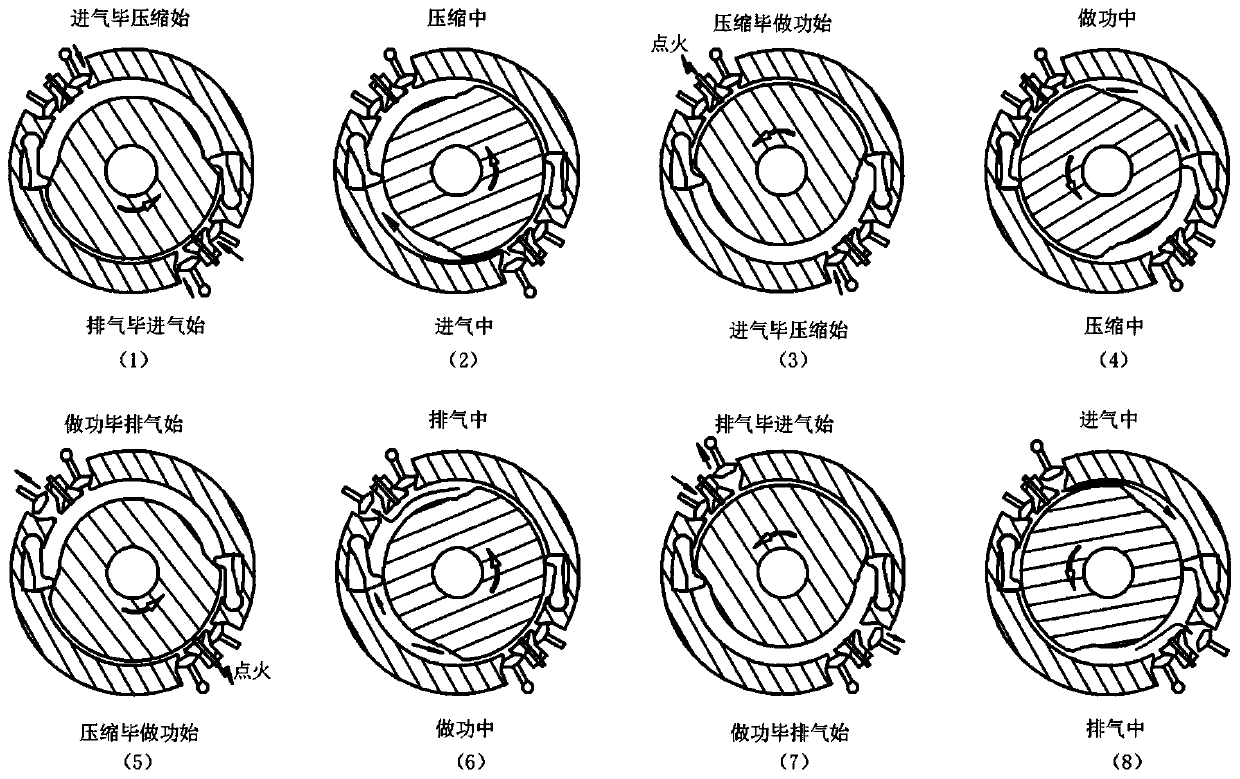

Cylindrical cam rotor internal combustion engine power system

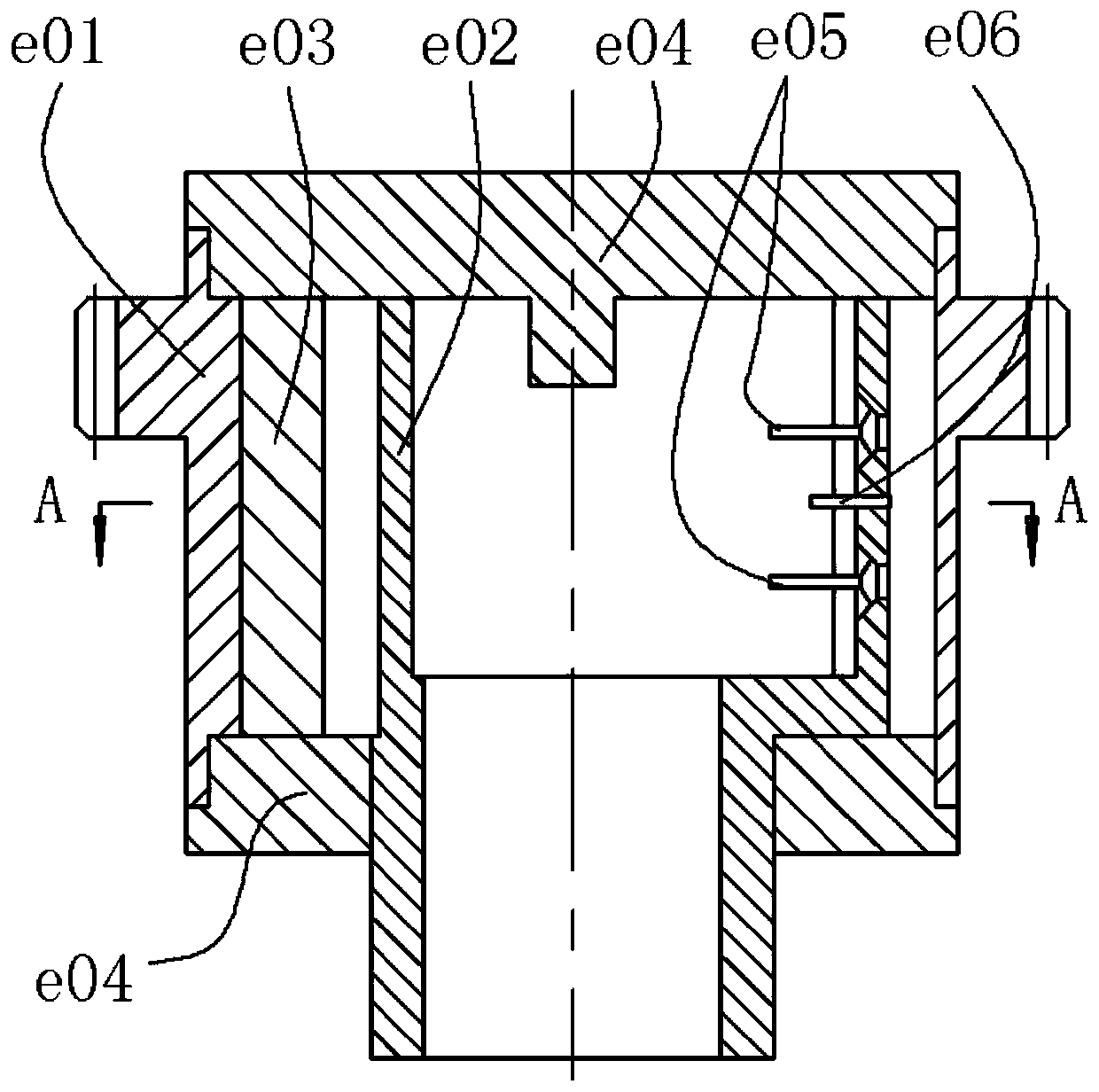

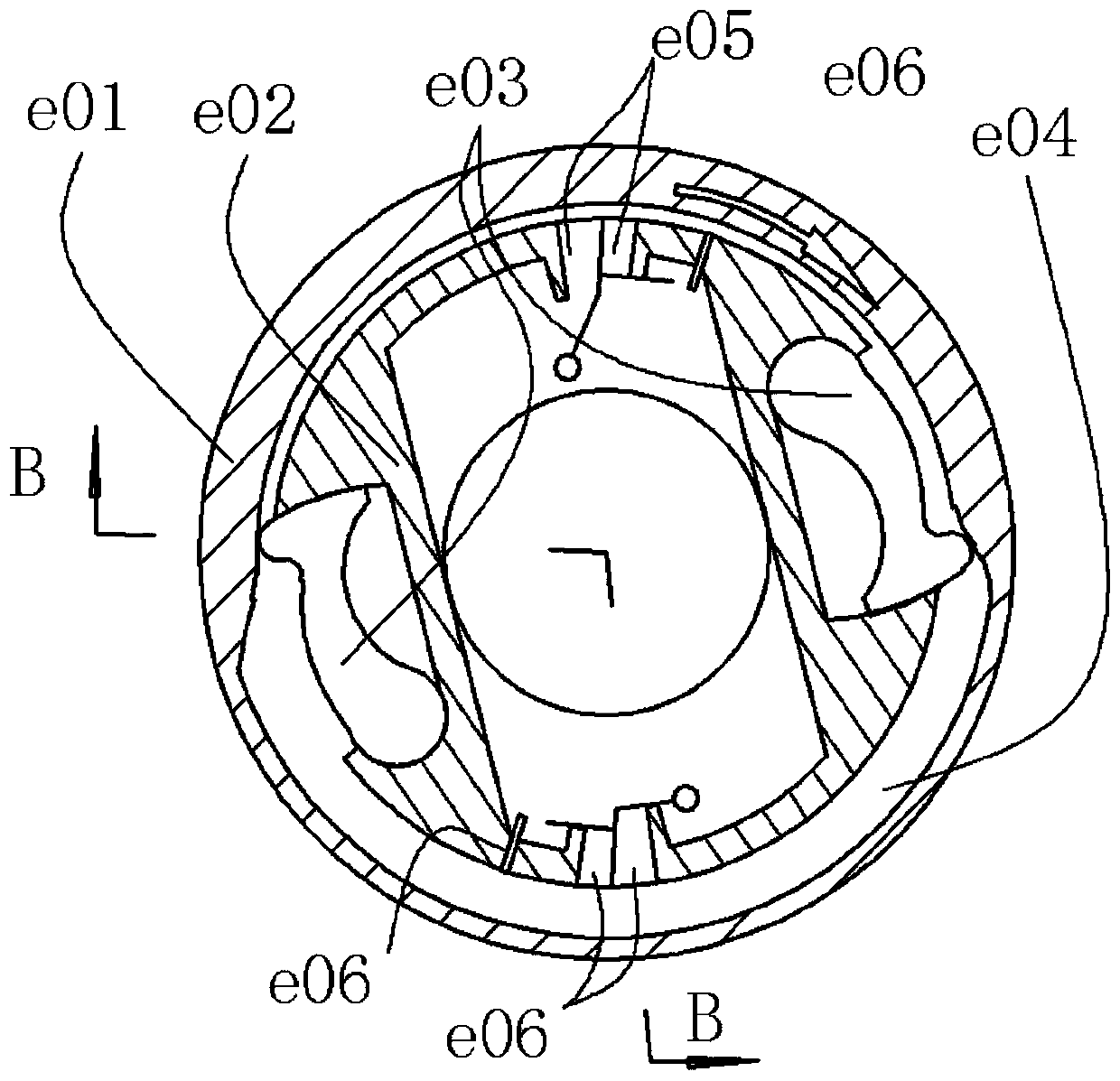

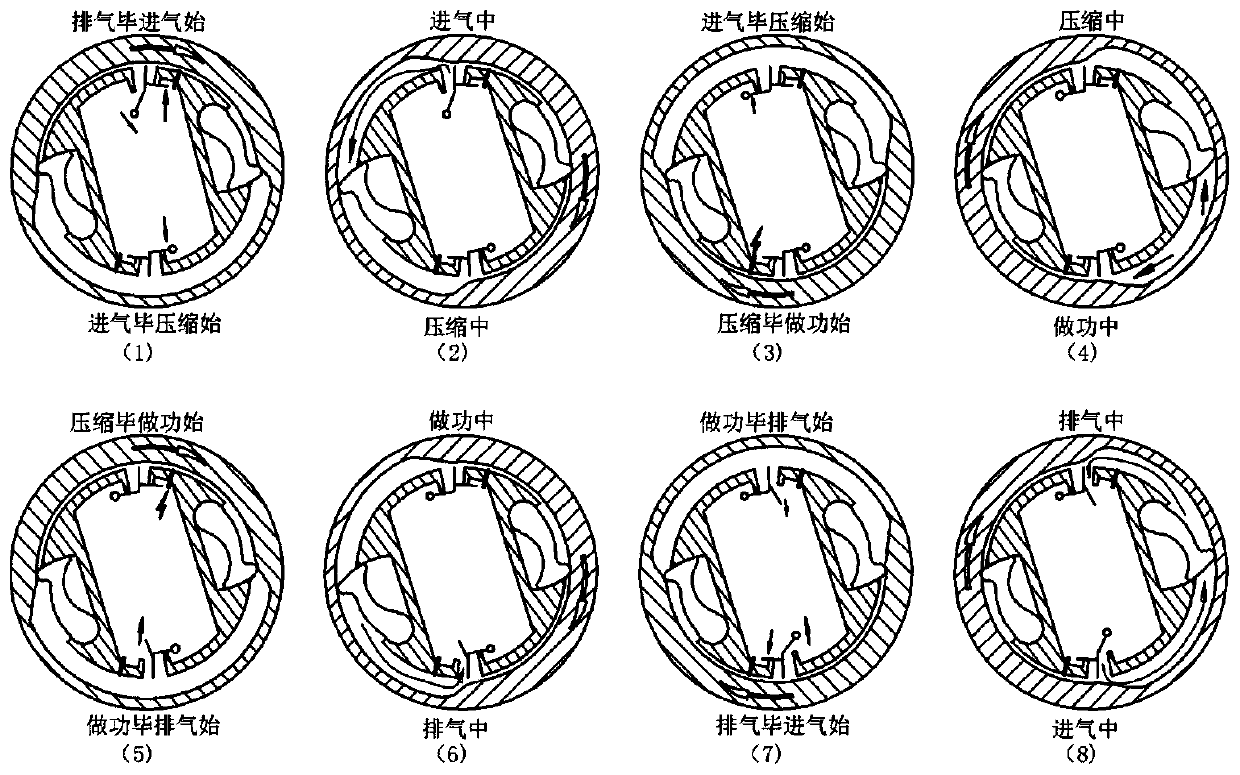

ActiveCN106948935AShort motion transfer linkImprove transmission efficiencyInternal combustion piston enginesExternal combustion engineOtto cycle

The invention relates to a cylindrical cam rotor internal combustion engine power system and belongs to the field of internal combustion engines. In the power system, a cylindrical cam and a plurality of sliding block driven parts are adopted to form a cam mechanism, and the cylindrical cam, the sliding block driven parts, a rotor chamber, a mandrel and end members form a plurality of circumferentially distributed sealed working chambers; the volumes of the sealed working chambers are changed along with relative movement of the sliding blocks and the cylindrical cam; the four processes of air inflowing, compression, acting and exhausting of an otto cycle are finished in the working chambers through cooperation with air valves; and the chemical energy generated by gas combustion is directly converted into fixed-shaft rotation type mechanical energy of the mandrel relative to the rotor chamber. According to the cylindrical cam rotor internal combustion engine power system, high-pressure gas directly acts on the cylindrical cam and the sliding blocks to generate output power, the structure is simple, and the parameter adjustable range is wide. Flexible control is easy to achieve under control of an added sliding block escapement device, even positive and negative rotation can be achieved, and compared with piston internal combustion engine and Wankel rotor internal combustion engine power systems, the cylindrical cam rotor internal combustion engine power system has much more outstanding advantages.

Owner:DALIAN UNIV OF TECH

Power system of cam rotor internal combustion engine

ActiveCN106968785AShort motion transfer linkImprove transmission efficiencyInternal combustion piston enginesValve drivesExternal combustion engineOtto cycle

The invention discloses a power system of a cam rotor internal combustion engine, belongs to the field of engines, and relates to a rotor internal combustion engine. The power system uses cams and multiple cam driven pieces to form a cam mechanism, and to form multiple sealed working cavities, peripherally distributed, with inner cavity components, outer rotating surface components and end components; the sealed working cavities change the volumes along with relative rotation of the cams and the cam driven pieces to match valves to finish four processes of intake, compression, acting and exhaust of the Otto cycle therein; and chemical energy generated by gas combustion is directly converted to mechanical energy in a rotor fixed-shaft rotating form. The power system discards a crankshaft of a piston engine; high-pressure gas directly pushes rotor fixed shafts to rotate and to output power; the structure is simple; and the parameter adjusting range is wide. The power system is liable to realize flexible control, or even can realize forward and reverse rotation under control of an additional cam driven piece encapement device; and compared with power systems of a piston internal combustion engine and a triangular rotor internal combustion engine, the power system of the cam rotor internal combustion engine has multiple prominent advantages.

Owner:DALIAN UNIV OF TECH

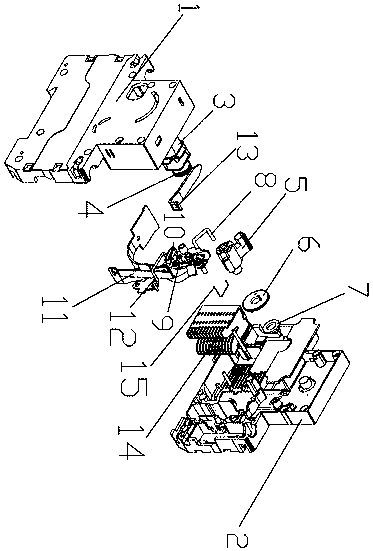

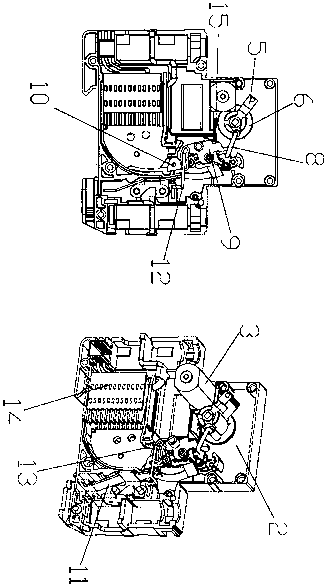

Prepaid circuit breaker reclosing device and implementation method

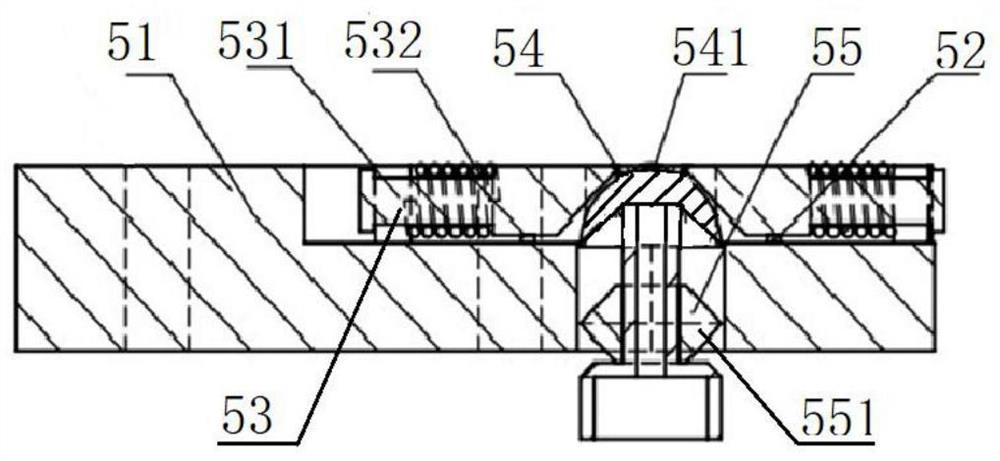

InactiveCN108198737AHigh sensitivityRealize forward and reverse controlProtective switch operating/release mechanismsCircuit-breaking switch contactsLinkage conceptControl circuit

The invention discloses a prepaid circuit breaker reclosing device and an implementation method. The device comprises a casing body and a cover body. A gear reduction motor, a guide wheel, a handle device, a control gear, a control circuit device, a pull rod, a tripper, a moving contact, a hot double gold metal piece, a static contact and an arc extinguishing device are arranged in the casing bodyand the cover body. The state detecting magnetic point of the control gear is used to detect opening, closing and tripping signals. A tripping function is realized through a tripping bump. Accordingto the invention, the poles (including the P pole and the N pole) of a circuit breaker are integrated with the tripping mechanisms of the poles; through the whole linkage of the handle device, the pull rod and the tripper, disconnection synchronization is realized; the moving contact and the static contact are matched in the manner of surface contact, which effectively reduces closing arcs; a control circuit board detects a magnetic point signal by receiving the state on the control gear; forward and reverse control of the gear is realized through program control; accurately transmitting toa small gap before a critical point is realized; and the opening and closing sensitivity of the circuit breaker is greatly improved.

Owner:林蔓琦

Power system of internal combustion engine with slide blocks combined with cam roller

ActiveCN106884710AShort motion transfer linkImprove transmission efficiencyInternal combustion piston enginesExternal combustion engineOtto cycle

The invention discloses a power system of an internal combustion engine with slide blocks combined with a cam roller, belongs to the field of internal combustion engines and relates to the power system of the internal combustion engine with slide blocks combined with the cam roller. In the power system, a cam mechanism is formed by means of the cam roller and a plurality of slide block driven members, and a plurality of peripherally distributed sealing work chambers are formed with a rotor cabin and an end portion member; these change in volume along with rotation of the cam roller and are matched with an air valve to finish four processes: air suction, compression, acting and exhausting of Otto cycle so as to directly convert chemical energy generated by gas combustion into mechanical energy of the roller in a form of rotation of a fixed shaft. High pressure gas directly pushes the fixed shaft of the rotor to rotate and outputs power, so that the power system is simple in structure and large in parameter adjustable range. Controlled by an additional slide block escaping, the rotor is easily flexibly controlled, and even can rotate forward and backward. Compared with a power system of a piston internal combustion engine and a power system of a triangular rotor internal combustion engine, the power system disclosed by the invention has many prominent advantages.

Owner:DALIAN UNIV OF TECH

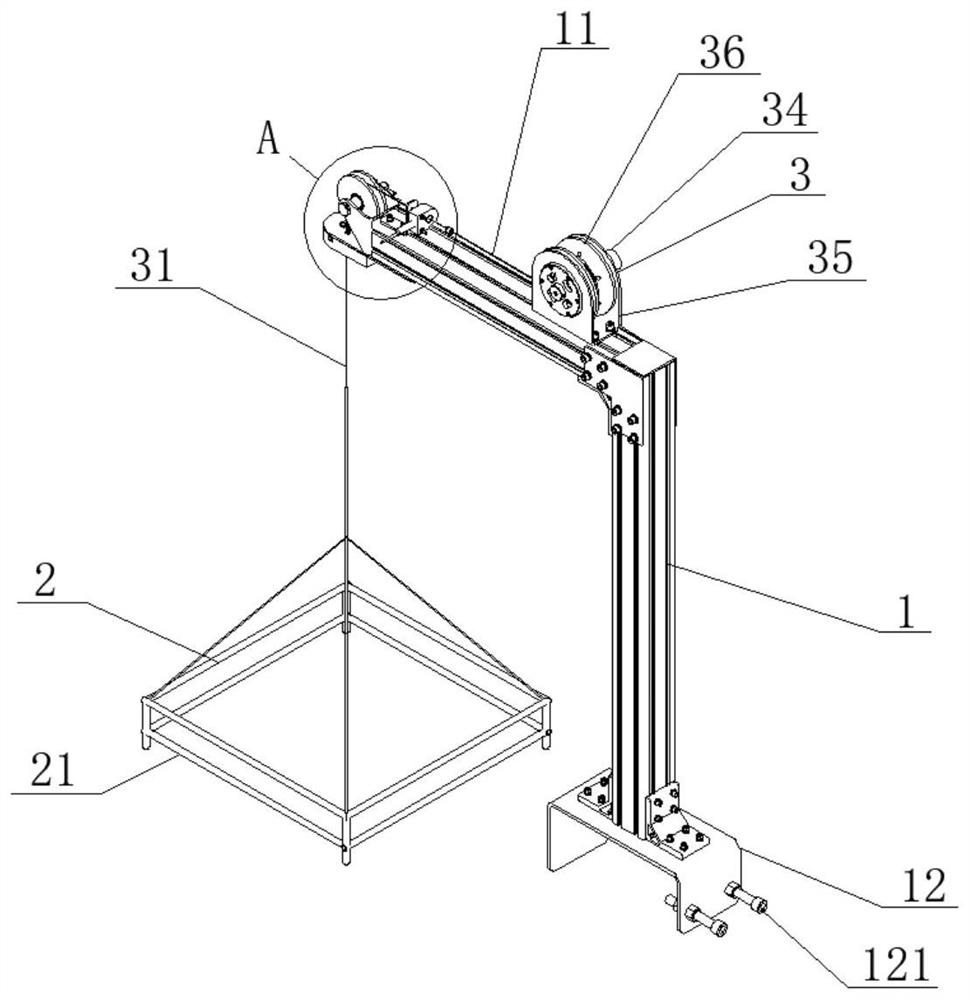

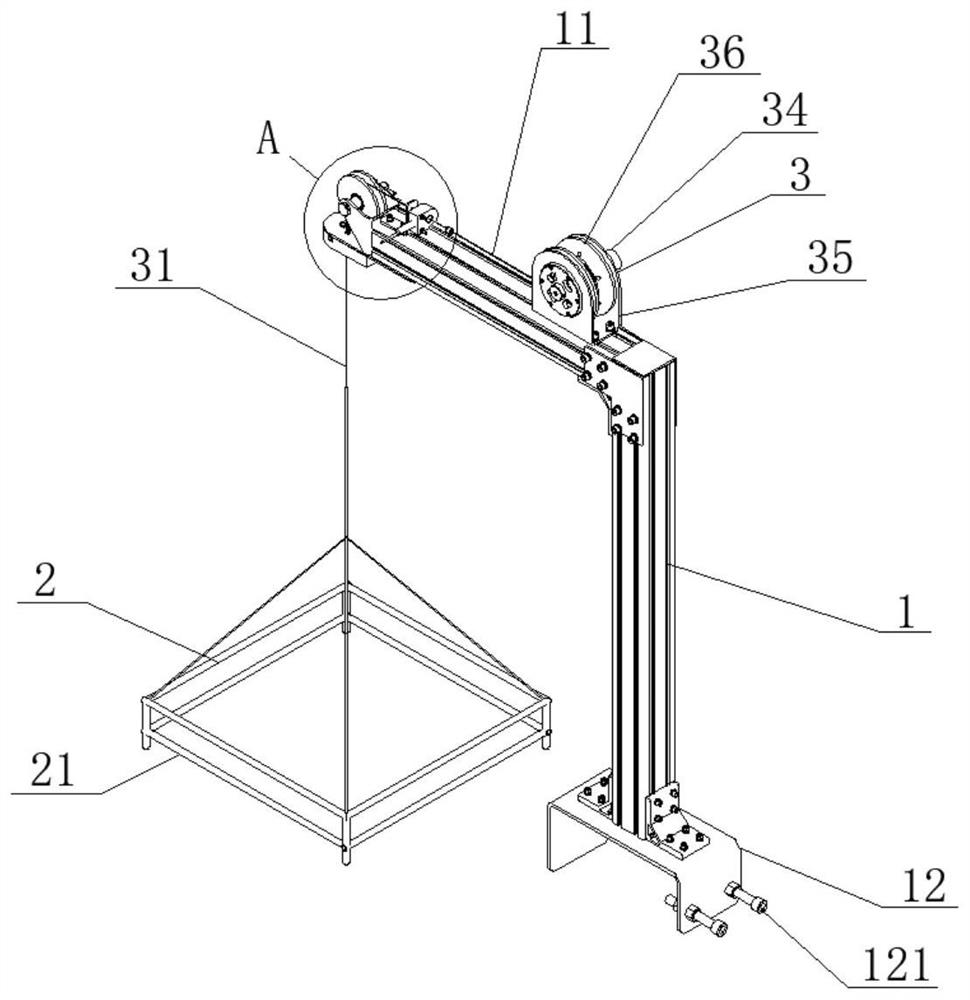

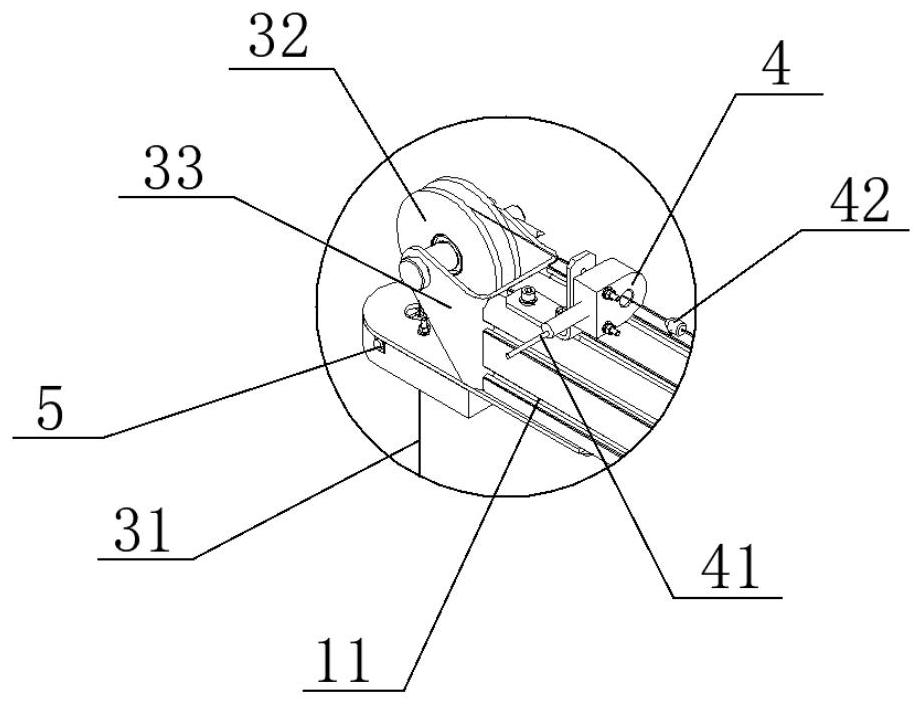

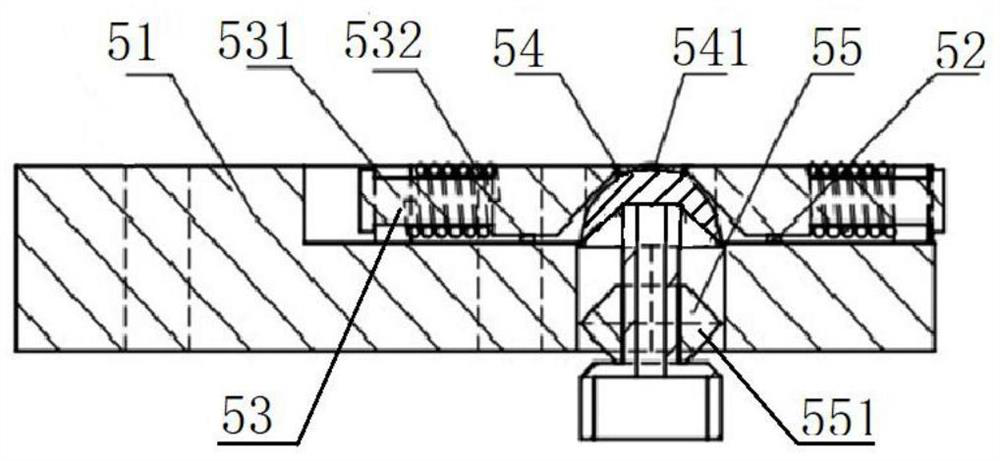

Intelligent observation device for pawn industrial aquaculture

ActiveCN111947753AFishing boostFast weighingClimate change adaptationPisciculture and aquariaCantilevered beamPrawn

The invention relates to the technical field of aquaculture equipment, in particular to an intelligent observation device for prawn industrial aquaculture. The device comprises a rack module, a prawnfishing module, a prawn lifting module, an infrared recognition positioning module and an automatic locking, unlocking and weighing module. The rack module is of an inverted L-shaped cantilever beam structure, the rack module comprises a cross beam with the upper portion extending outwards, the prawn lifting module is installed on the upper portion of a rack, an infrared recognition positioning module is arranged in the prawn lifting module, the automatic locking, unlocking and weighing module is fixedly installed at the tail end of the rack module, and a lifting cable is connected to the upper portion of the prawn fishing module. Through the prawn catching module, the prawn lifting device, the infrared recognition positioning device and the quick locking, unlocking and weighing device, quick catching, lifting and weighing of prawns can be achieved.

Owner:QINGDAO HAIYAN ELECTRONICS CO LTD

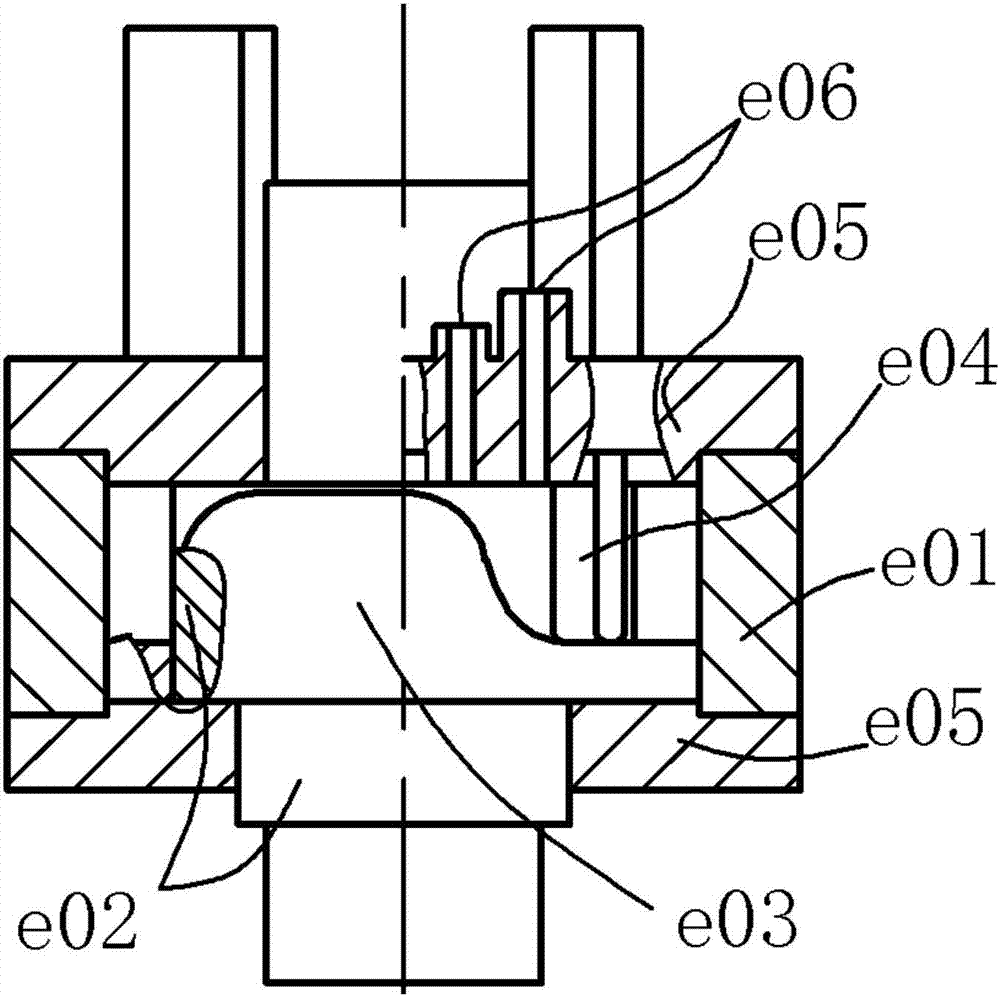

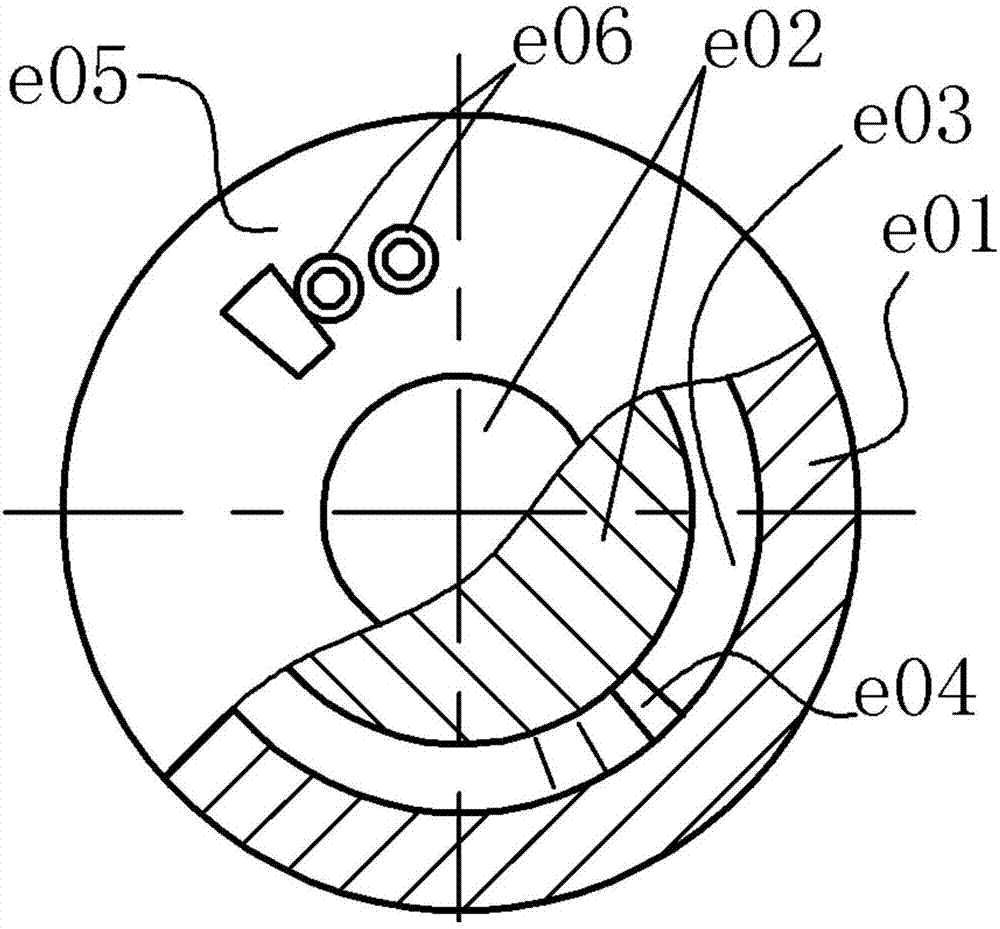

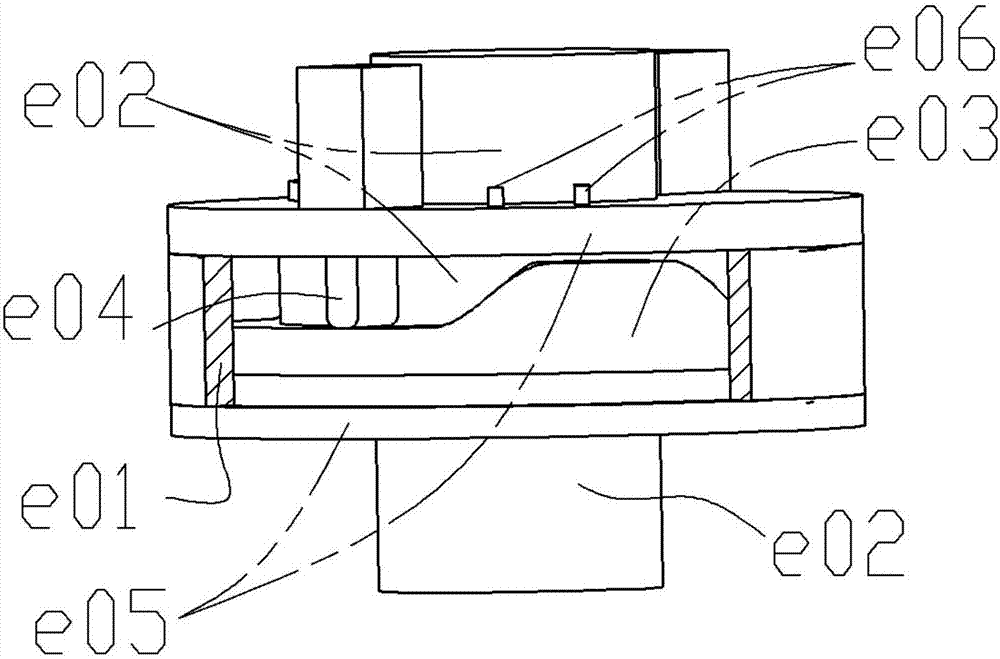

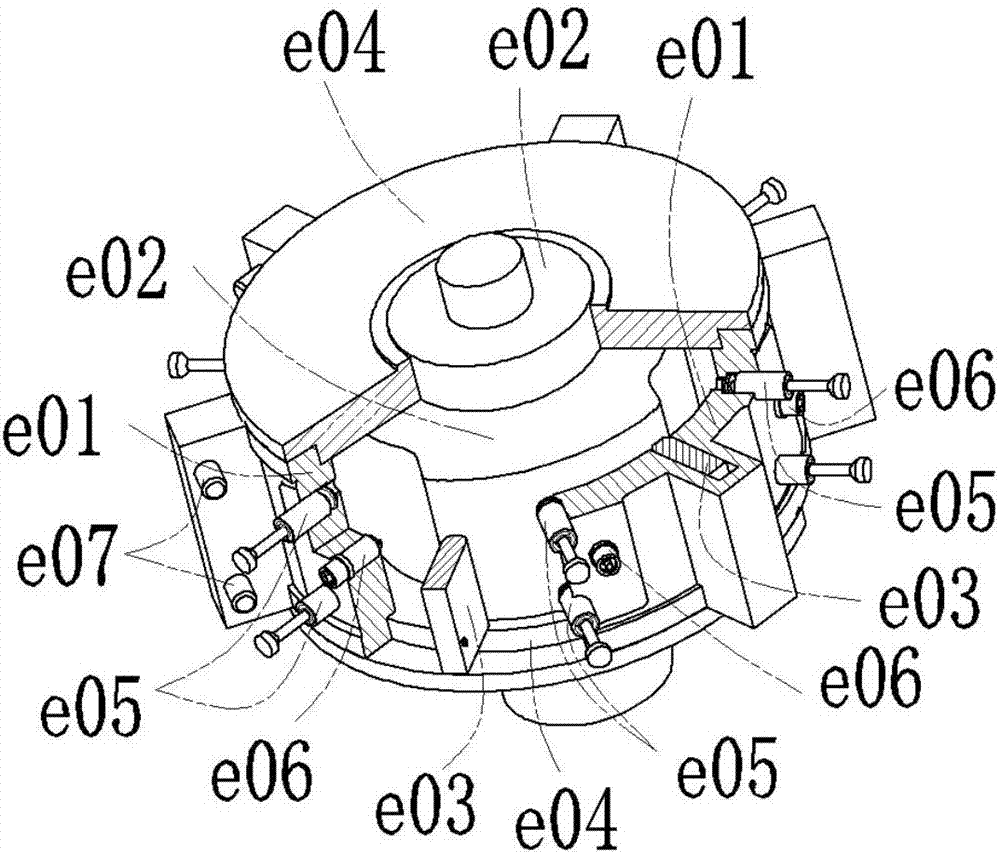

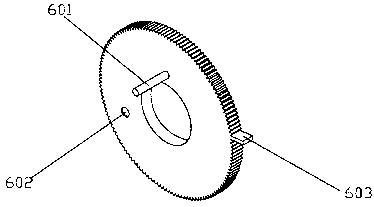

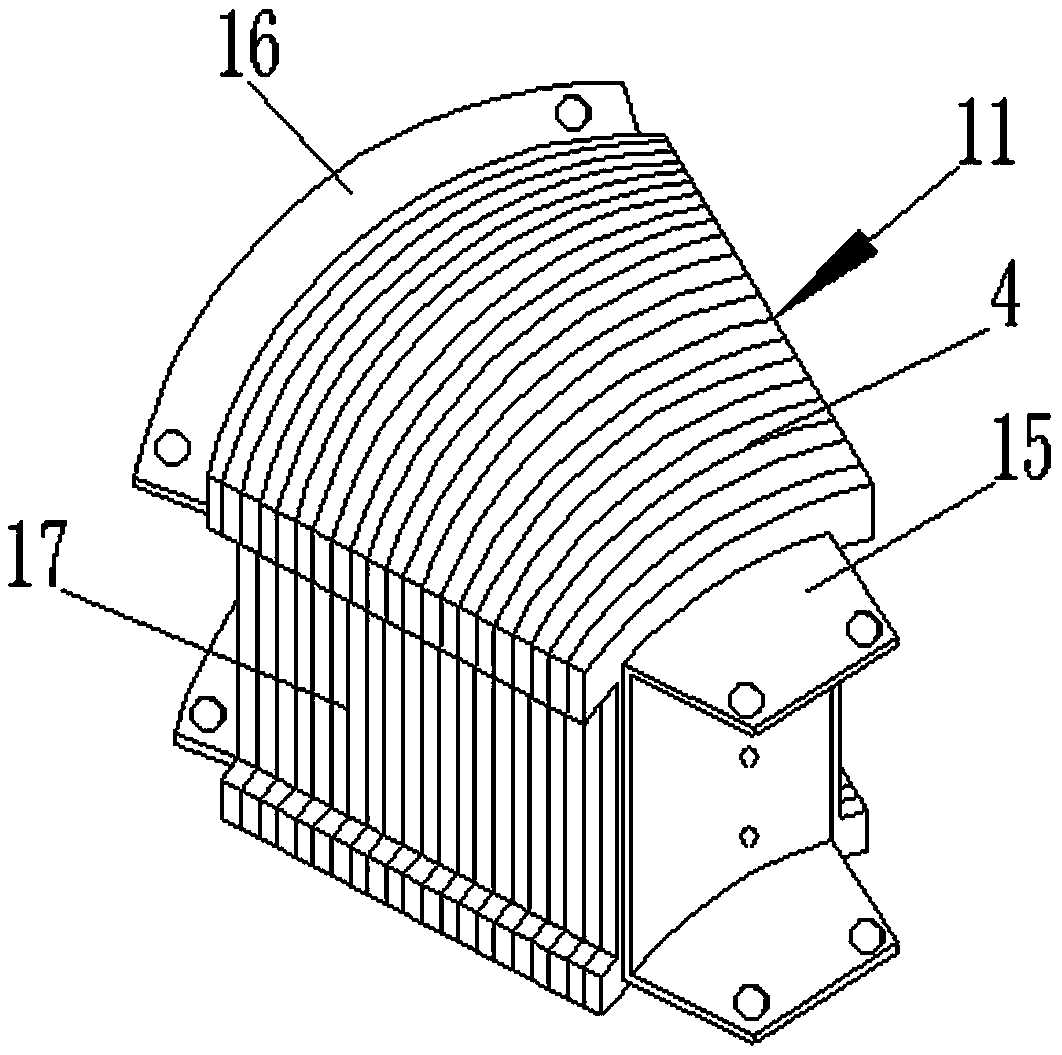

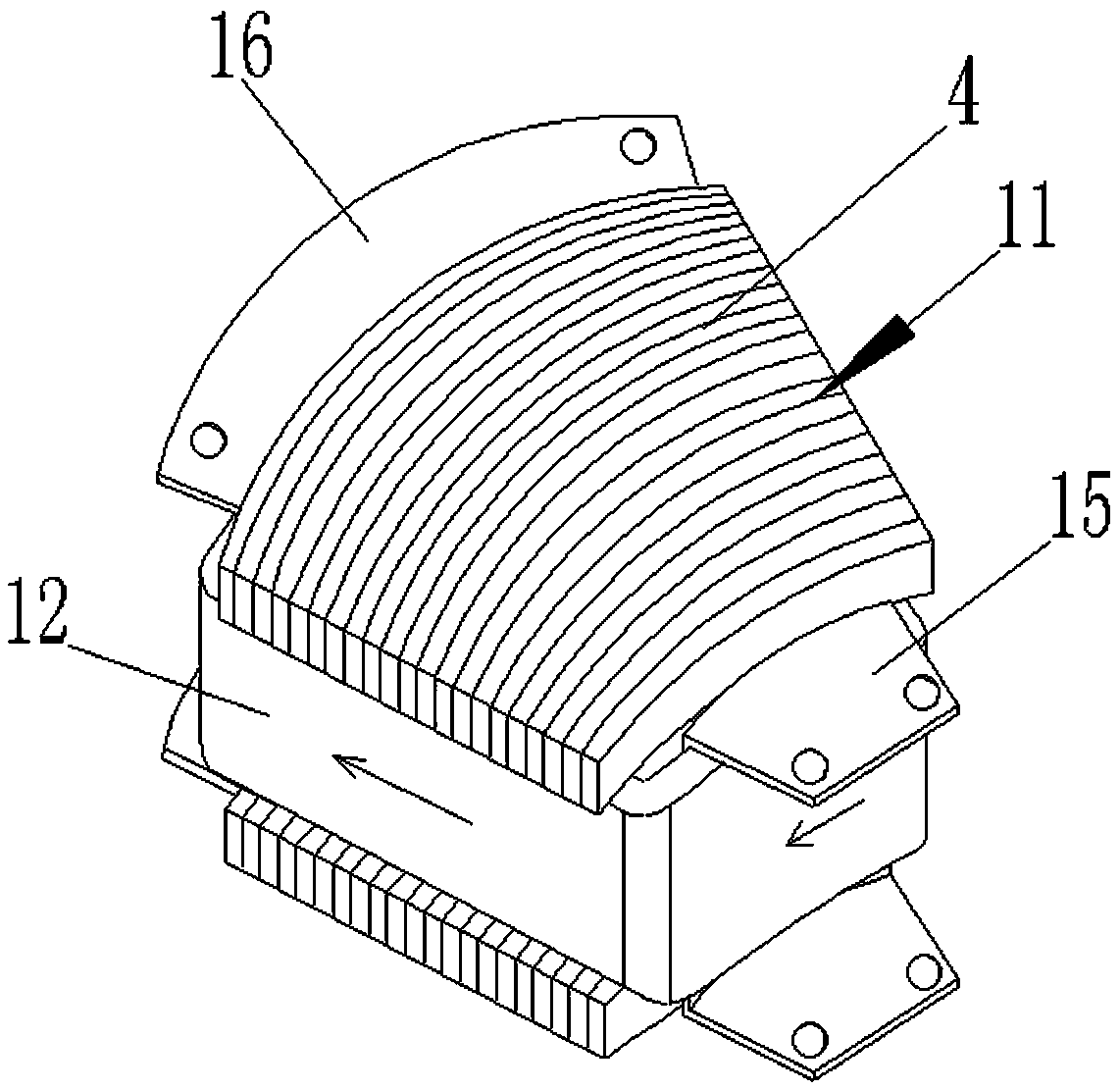

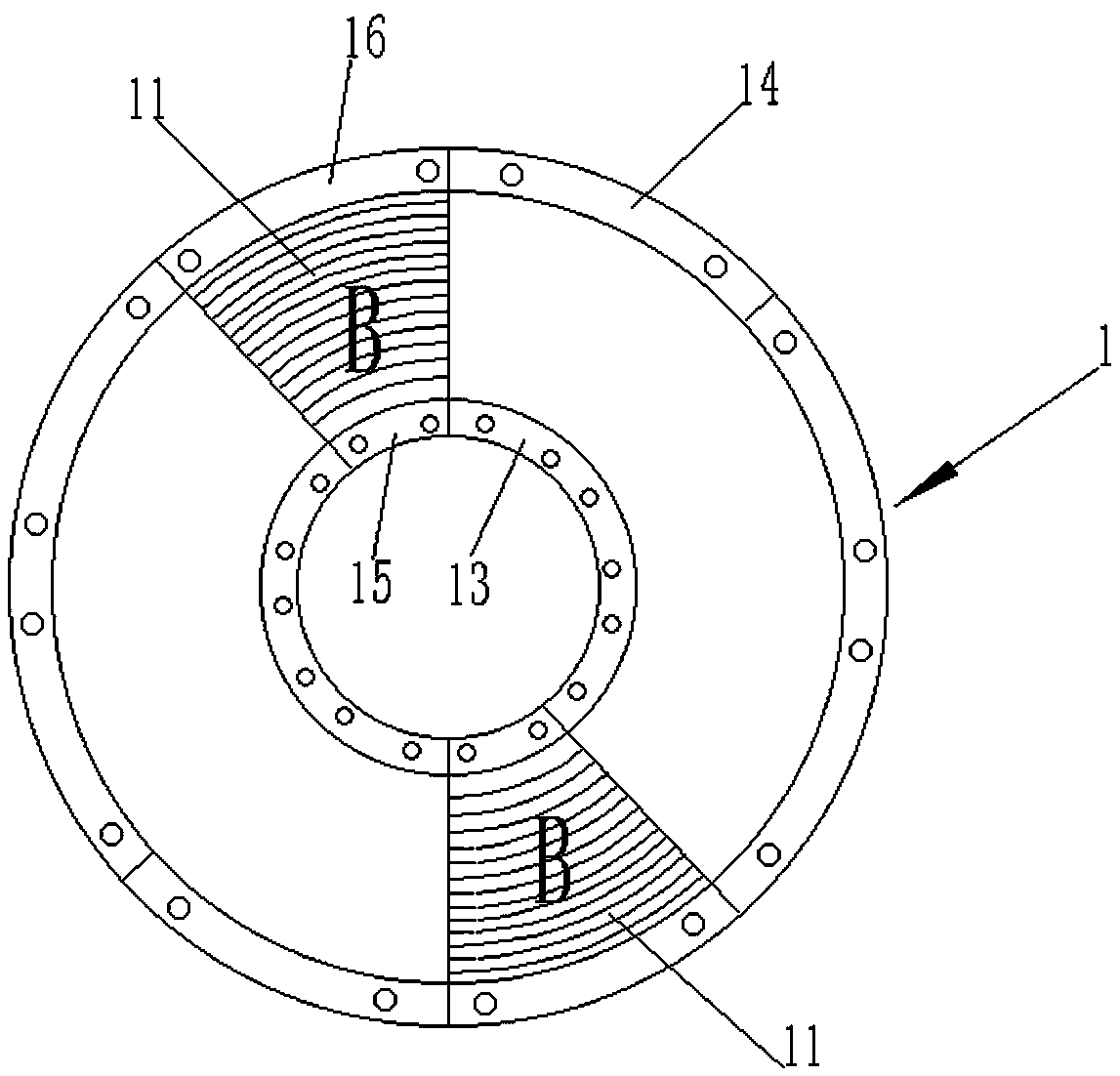

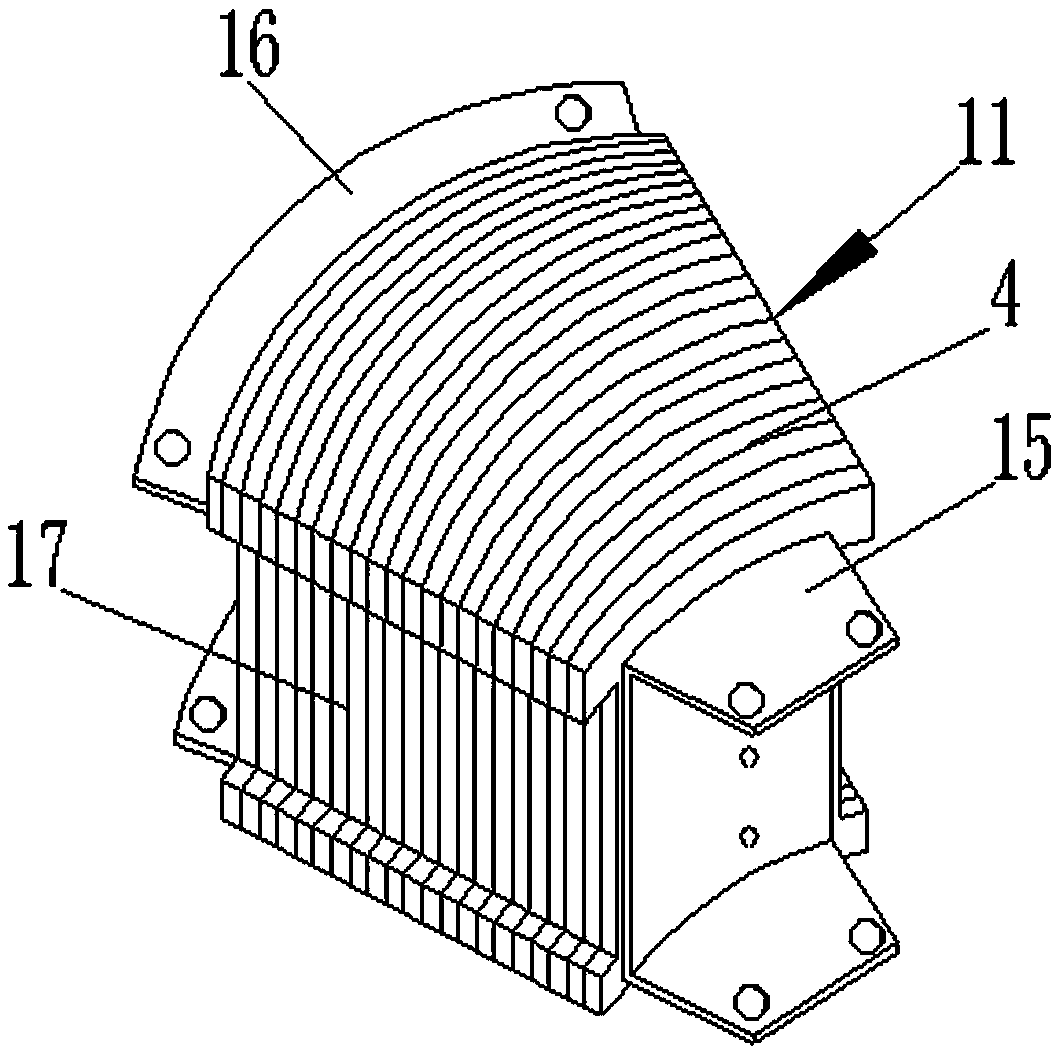

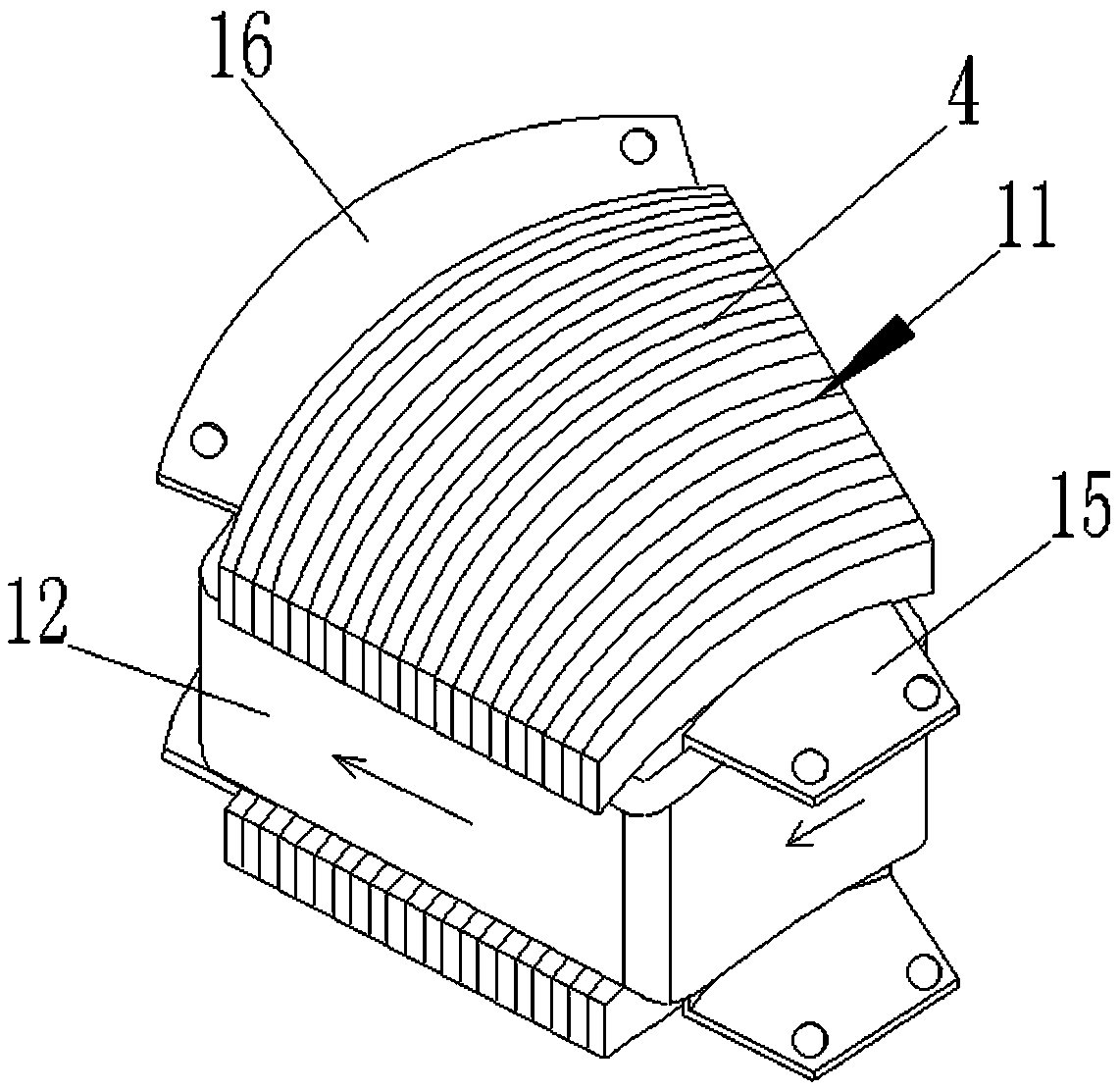

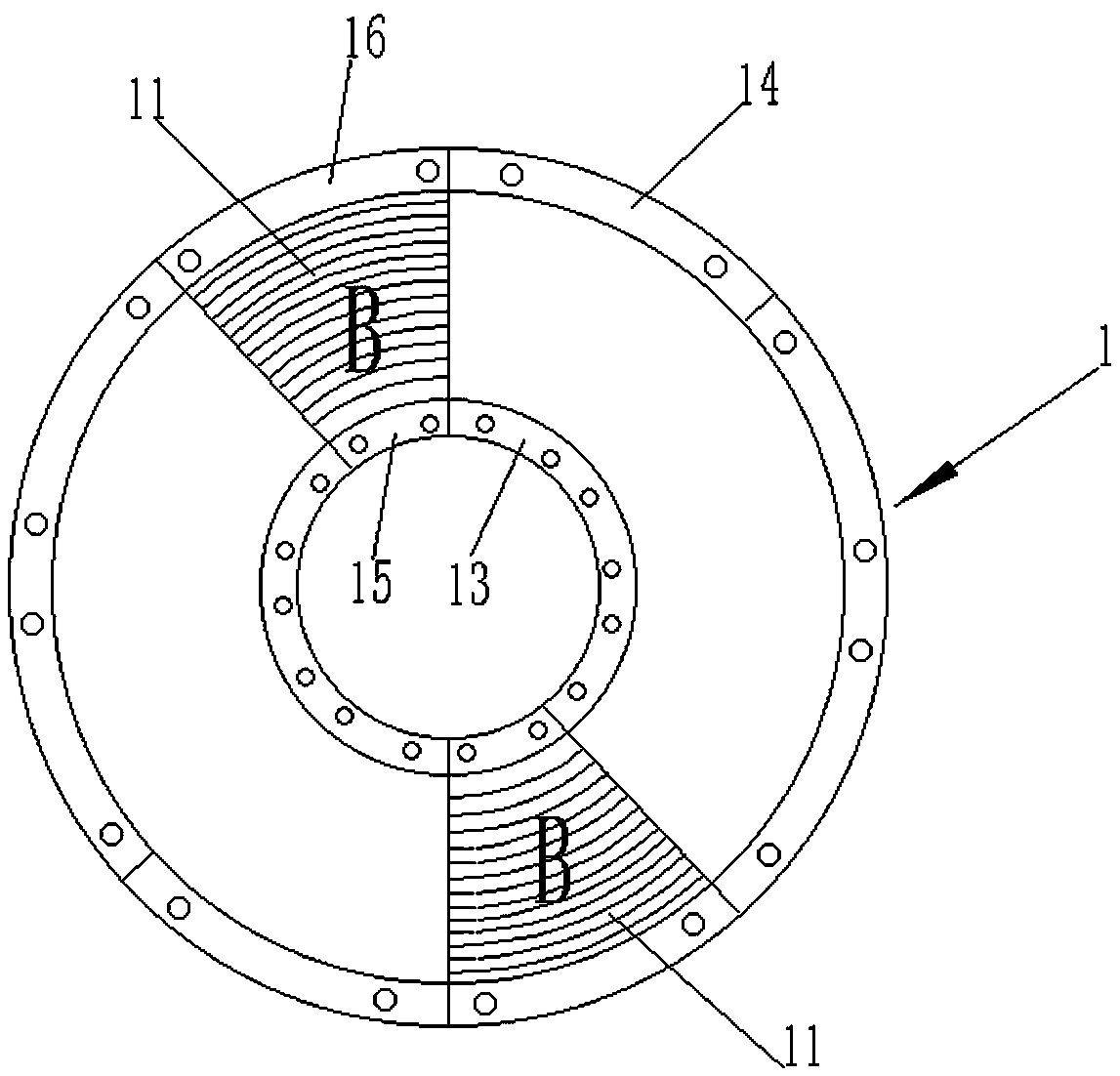

Building block type stator disc, permanent magnet motor and speed control method of permanent magnet motor

InactiveCN109802539ASimple structureEasy to controlMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesPermanent magnet motor

The invention relates to a building block type stator disc, a permanent magnet motor and a speed control method of the permanent magnet motor. The building block type stator disc comprises a pluralityof stator teeth. Windings which are parallel to the direction of the rotor disc are wound on each stator tooth. An inner fixing ring frame and an outer fixing ring frame are sleeved inside and outside the stator disc. The plurality of stator teeth are arranged between the inner fixing ring frame and the outer fixing ring frame to form an annular shape. One end of each stator tooth is fixedly connected to the inner fixing ring frame through a first connecting piece, and the other end of each stator tooth is fixedly connected to the outer fixing ring frame through a second connecting piece. Thepermanent magnet motor is simple in structure and convenient to control. The field of the permanent magnet motor does not need to be converted into a rotating magnetic field. Different from the control mode of a traditional permanent magnet motor, a motor can be driven to rotate through continuously changing a coil on different magnetic poles. Therefore, the cost is low and the maintenance is convenient.

Owner:高宪立

Inner cavity cam rotor internal combustion engine power system

ActiveCN106870123AShort motion transfer linkImprove transmission efficiencyInternal combustion piston enginesExternal combustion engineMechanical energy

The invention belongs to the field of internal combustion engines, and relates to an inner cavity cam rotor internal combustion engine power system. In the system, a cam mechanism is composed of inner cavity cams and a plurality of sliding block followers installed on central members in a cam cavity in the system, and a plurality of sealed working cavities distributed circumferentially are composed of the inner cavity cams and end members; the cam mechanism and the sealed working cavities change in volumes with the relative rotation of the inner cavity cams and the central members, and are fit to valves to finish four procedures, namely air intake, compression, acting and exhaust of Otto cycle therein; chemical energy generated from gas combustion is directly converted into mechanical energy output in the fixed-axis rotation form of the inner cavity cams or the central members. In the invention, a rotor fixed axis is driven to rotate and output power by high-pressure gas directly; the structure is simple, and the parameter adjustable range is wide. The flexible control is easy to achieve under the control of an additional sliding block escapement device, so that the positive and negative rotation is realized. Compared with piston internal combustion engine and triangular rotor internal combustion engine power systems, the inner cavity cam rotor internal combustion engine power system has many outstanding advantages.

Owner:DALIAN UNIV OF TECH

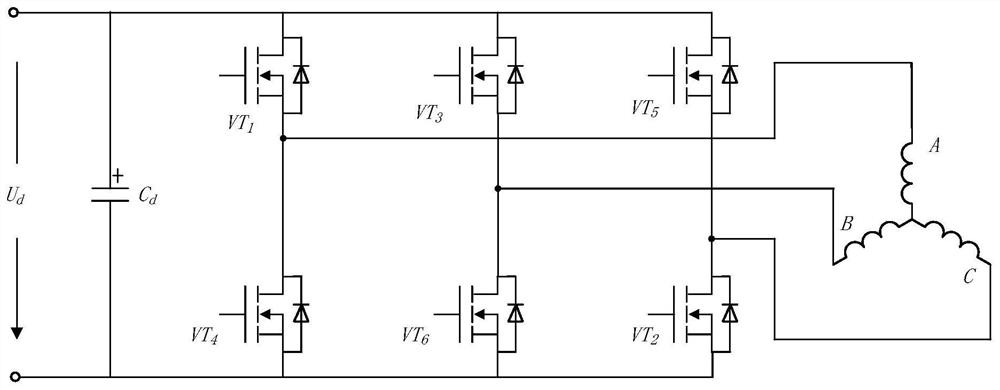

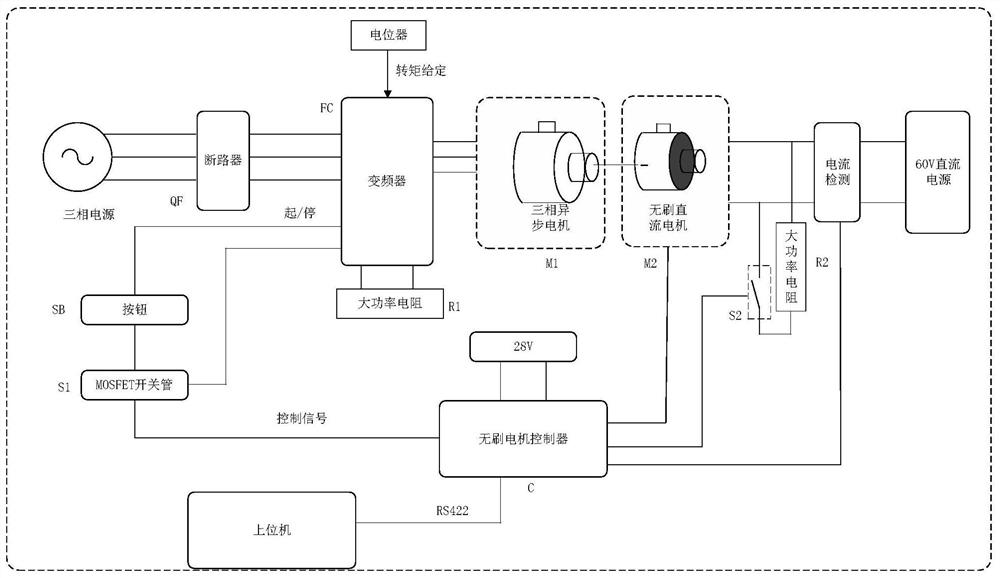

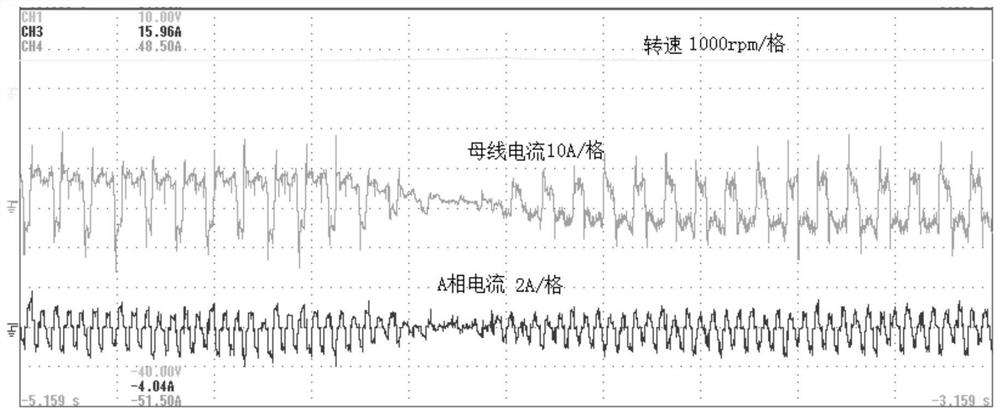

Unified control method for two operating states of brushless DC motor, motoring and generating

ActiveCN110417310BSpeed stabilization and controlAchieve unified controlSingle motor speed/torque controlField or armature current controlAddress busPwm signals

The invention relates to a unified control method for electric and power generation running states of a brushless DC motor. The unified control method can be realized in a brushless DC motor system controlled under a DSP+CPLD architecture. A CPLD serves as a peripheral and is connected with a DSP through a data bus address bus and a control bus which are parallel to each other. The DSP is responsible for changing the duty ratio in real time according to a control algorithm, forming complementary PWM signals and sending the signals to the CPLD. The CPLD performs the logical operation with the complementary PWM signals sent by the DSP according to the Hall position signal of the brushless DC motor to form a driving signal to control the main power circuit of the brushless DC motor, so that the stability and control of the rotating speed of the motor are realized. In the control system, a bipolar modulation method is adopted, driving signals with opposite phases and dead zones are appliedto an upper switching tube and a lower switching tube of the same bridge arm, and therefore, the unified commutation logic can be achieved. When the motor is switched between an electric state and apower generation state, the working state of the motor does not need to be judged, and the commutation logic does not need to be changed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Forward and reverse rotation device of condensing fan

ActiveCN102788035BRealize forward and reverse controlImprove cooling effectField or armature current controlControl circuitControl theory

The invention discloses an electromechanical device, and particularly relates to a device, used on a vehicle, of adjusting forward and reverse rotation of a condensing fan. The device comprises relays, a switch and a fan, wherein the relays comprise a time relay KJ1 and two relays KJ2 and JK3; a switch and the like are arranged in each relay; one of the two relays KJ2 and KJ3 is normally open and the other one of the two relays KJ2 and KJ3 is normally closed; and the forward and reverse rotation time is adjusted through time setting of the time relay JK1 to control the action of the fan. The device has the advantages of improving the radiating effect of a condenser and reducing the manual cleaning frequency. By using the condensing fan with excellent blowing and air suction effects and through control circuit design, forward and reverse rotation control of the condensing fan is realized to blow weeds and dust out. The device can be widely applied to mechanical vehicles operating outdoors.

Owner:杭州新都奥兰汽车空调有限公司

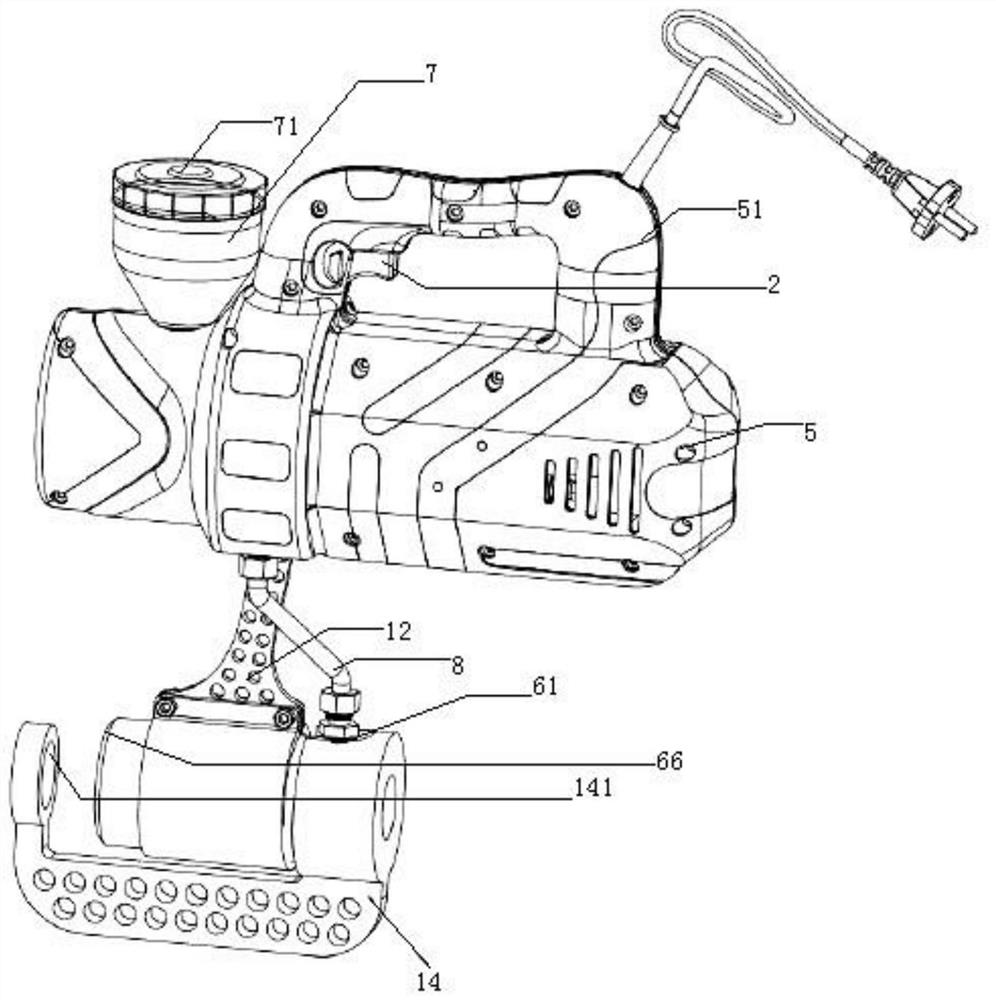

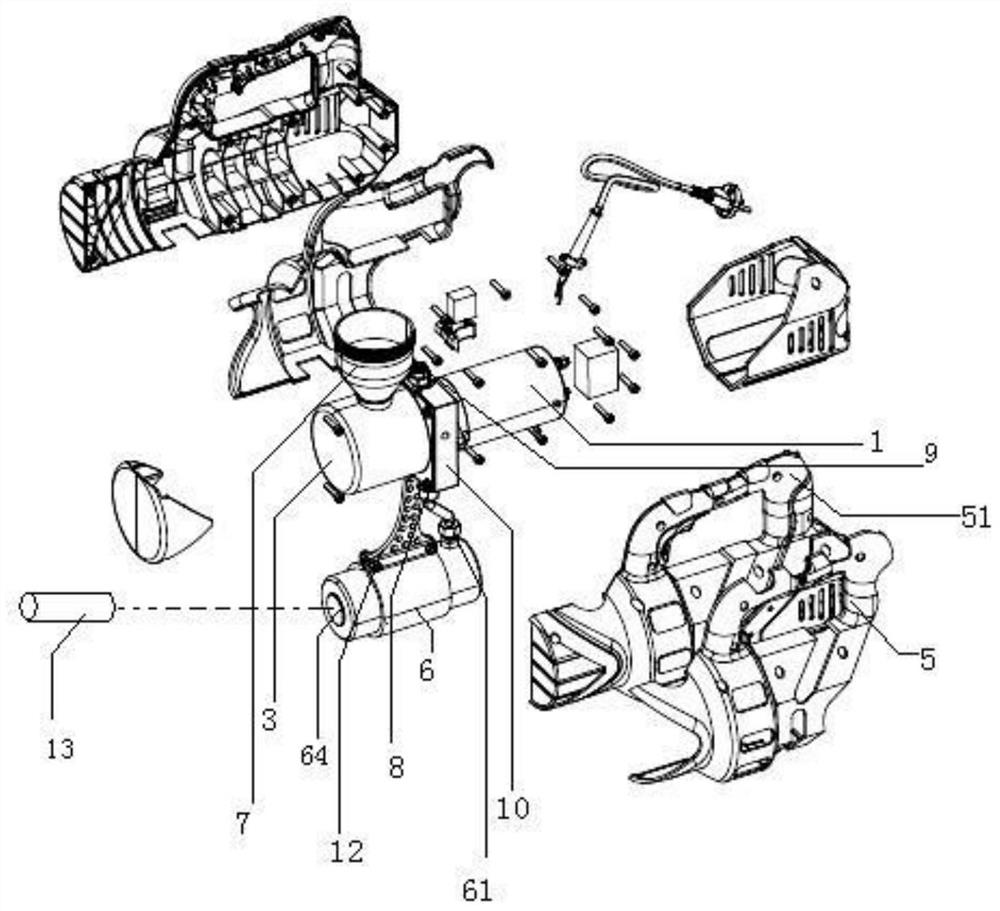

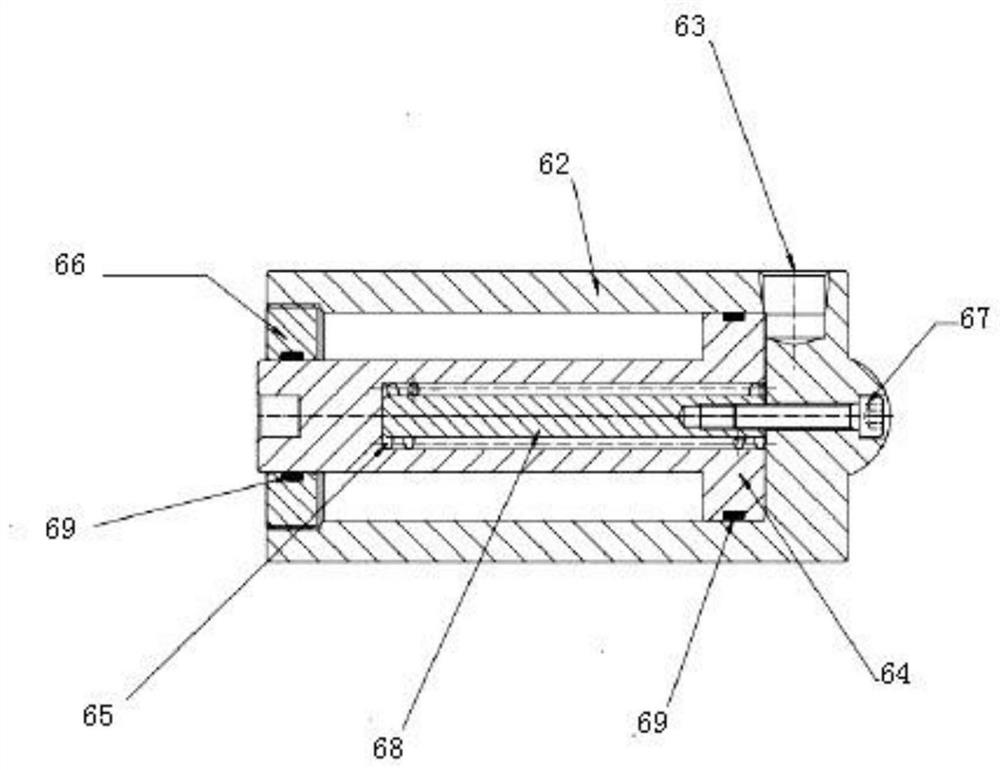

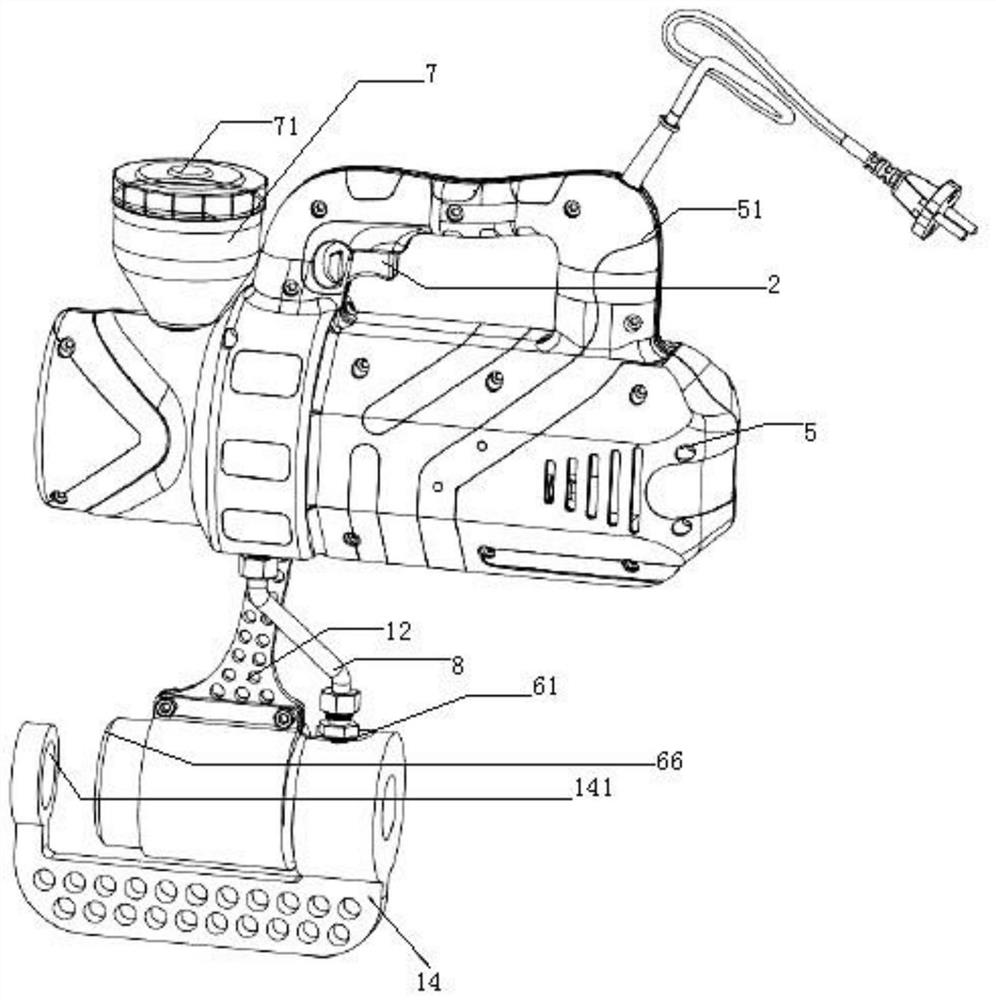

Hydraulic equipment for dismounting and mounting bucket tooth pin shaft

ActiveCN113293817ARealize forward and reverse controlCompact structureSoil-shifting machines/dredgersOil canGear pump

Hydraulic equipment for dismounting and mounting a bucket tooth pin shaft comprises a motor, a power switch, an oil drum, a bidirectional gear pump, a shell, an oil cylinder, an oil can, a high-pressure oil pipe, an overflow valve and an oil way integration distribution block. The oil can is mounted at the upper end of the oil drum; one side of the oil way integration distribution block is mounted on one side of the oil drum, and the motor is mounted on the other side of the oil way integration distribution block; the bidirectional gear pump is mounted on one side of the oil way integration distribution block, and a power input shaft of the bidirectional gear pump and a power output shaft of the motor are mounted together; the oil drum and the oil cylinder are mounted together; the overflow valve is mounted on the oil way integration distribution block; a lower oil pipe of the oil cylinder and a lower oil inlet and outlet pipe of the oil way integration distribution block are mounted together through an oil pipe; the shell is installed on the outer side of the motor, and the power switch is installed on the shell. The equipment is small and exquisite in structure and convenient to use, a piston of the oil cylinder can move forwards to eject out of or into the bucket tooth pin shaft and move backwards to return to the initial state only by controlling a power switch, so that the bucket tooth dismounting and mounting efficiency is improved.

Owner:漳州鑫山航机械有限公司

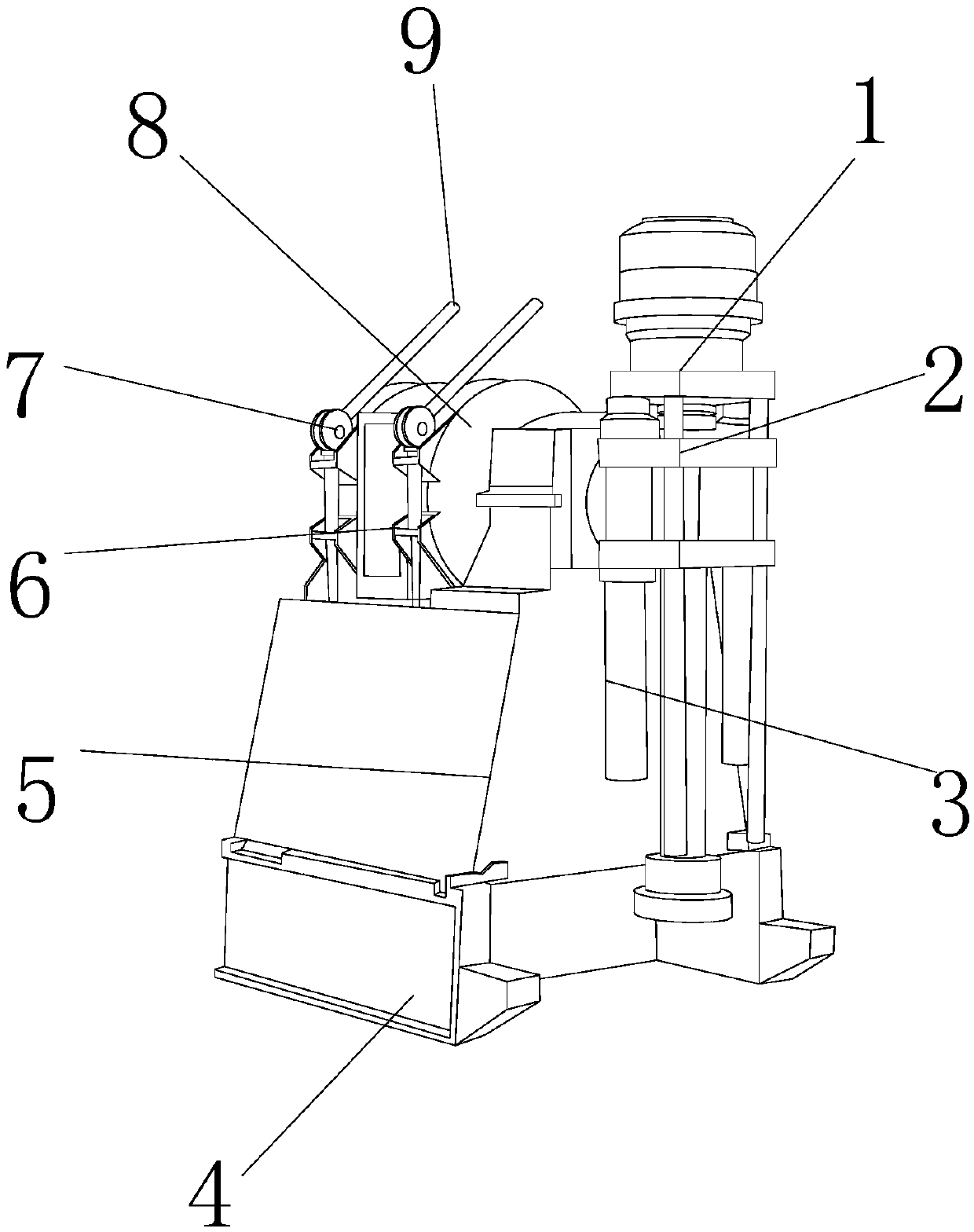

A drill pipe device for petroleum geological exploration

ActiveCN107605411BRealize forward and reverse controlReduce impactDrilling rodsBorehole drivesFixed frameCoupling

The invention discloses a petroleum geological prospecting drill pipe device. The petroleum geological prospecting drill pipe device structurally comprises a drill pipe device body, a prospecting head, an external reinforcing rod, a base, a geological prospecting machine body, connecting frames, fixing rods, an upper fixing frame and a rocking rod. The bottom of the geological prospecting machinebody is fixedly connected with the top of the base, the upper fixing frame is arranged at the top of the geological prospecting machine body, and the connecting frames are arranged to be in a rectangular shape and fixed to the front side of the fixing frame; and the fixing rods are parallel to each other, penetrate through the connecting frames and are connected to the interior of the top side ofthe geological prospecting machine body, and the right side of the upper fixing frame is in mechanical connection with the left side of the prospecting head. According to the petroleum geological prospecting drill pipe device, rapid rising and falling can be conducted through motor transmission, meanwhile stable output power is provided by a motor, the degree of outside interference can be reduced, the stability of equipment operation can be ensured, and meanwhile the impact force borne by the petroleum geological prospecting drill pipe device is reduced by a coupler.

Owner:浙江乔派电梯装饰有限公司

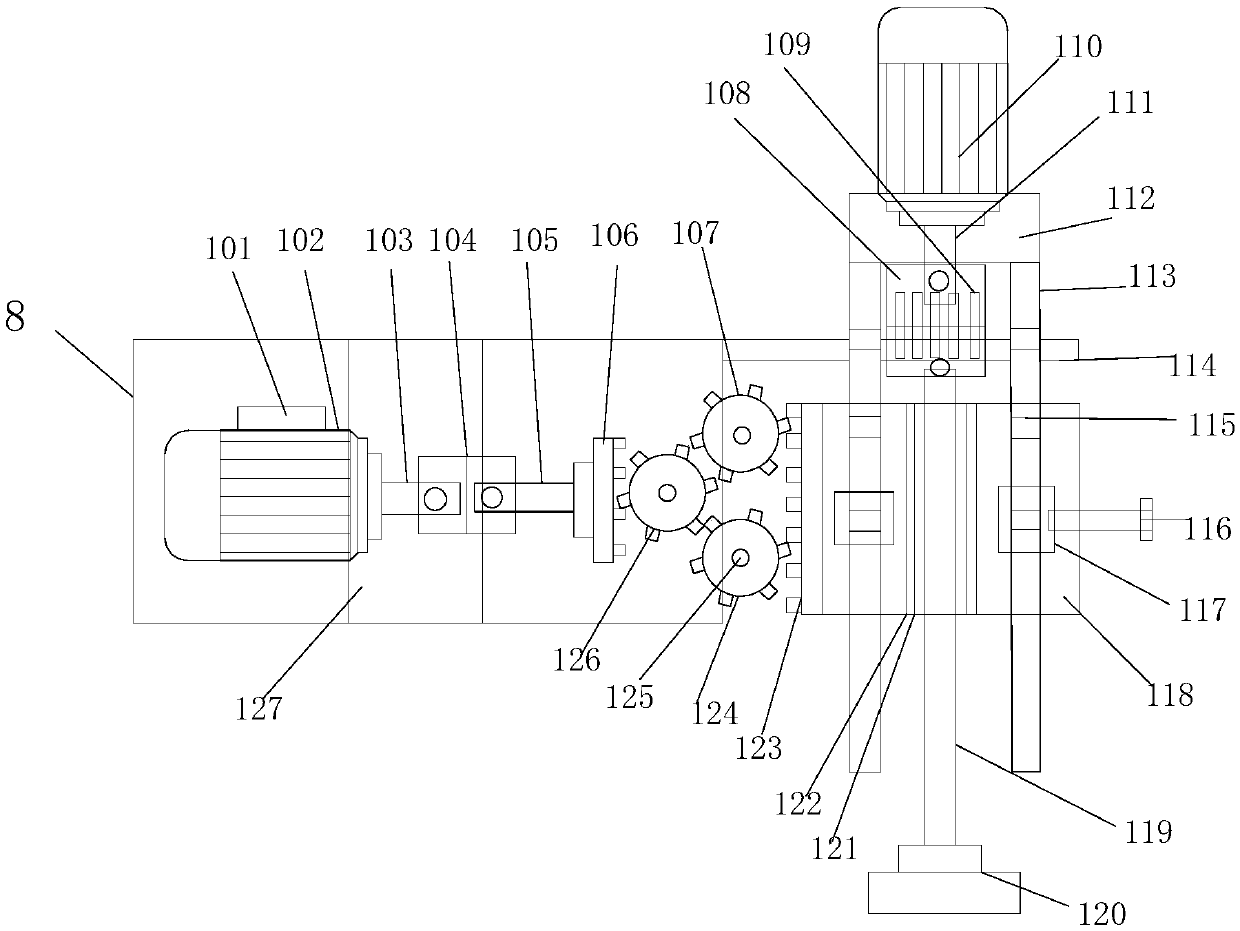

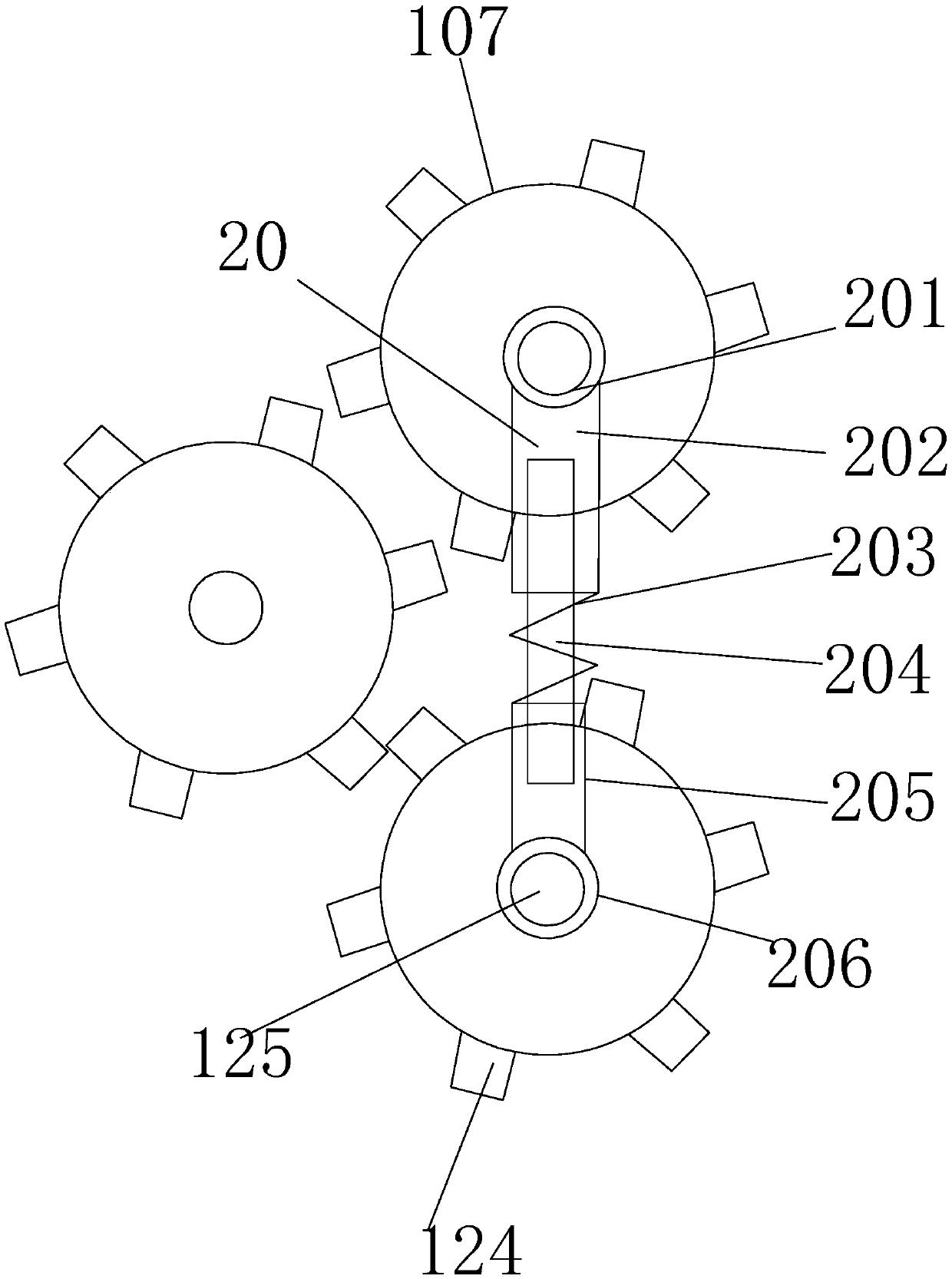

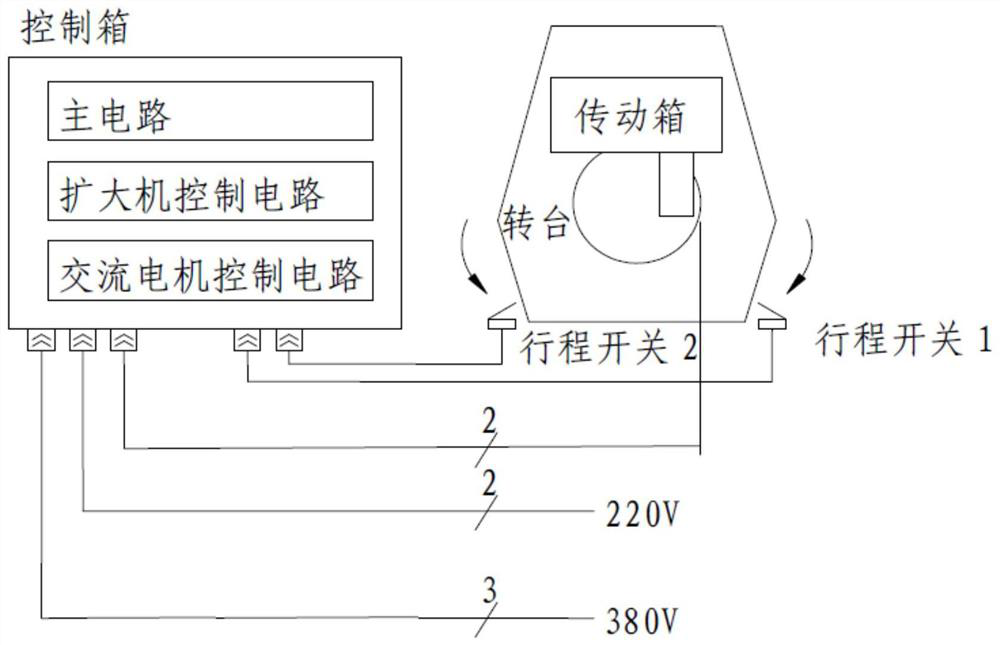

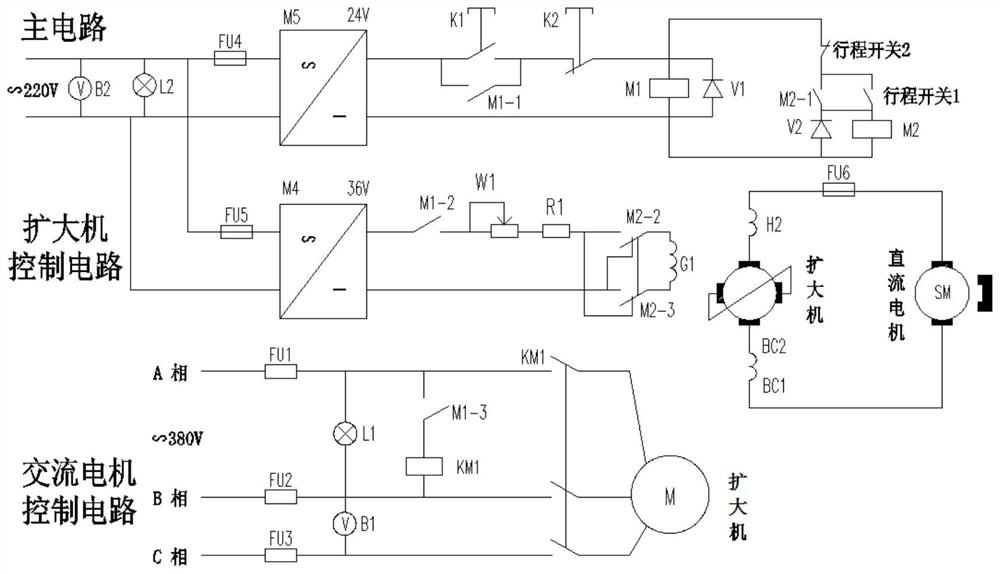

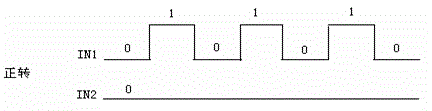

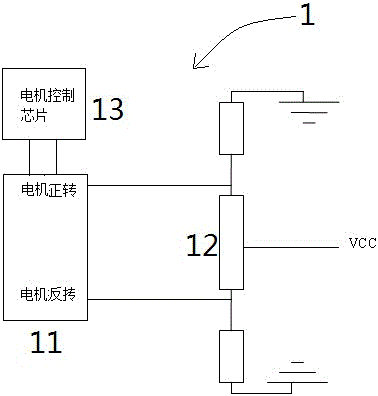

Direct-current motor forward and reverse rotation control system

PendingCN112039375AChange the direction of the currentRealize forward and reverse controlDC motor rotation controlDC - Direct currentControl system

The invention relates to a direct-current motor forward and reverse rotation control system, and belongs to the field of direct-current motor control. The direct-current motor forward and reverse rotation control system comprises a main circuit unit, an expander control circuit and an alternating-current motor control circuit unit. The main circuit unit comprises a 24V conversion power supply module and a commutation circuit module; the expander control circuit unit comprises a 36V conversion power supply module and an expander; and the alternating current motor control circuit unit comprisesan alternating current module. Control current direction conversion is completed through the commutation circuit module so as to drive the direct current motor to rotate forwardly and reversely. Debugging personnel do not need to manually control the direct current motor to steer according to actual operation conditions to complete running-in operation of the rotary table, and the working efficiency is improved.

Owner:西北机电工程研究所

A power system of an internal combustion engine with a pendulum block and an inner cavity cam rotor

ActiveCN106894890BShort motion transfer linkImprove transmission efficiencyInternal combustion piston enginesExternal combustion engineOtto cycle

Owner:DALIAN UNIV OF TECH

Hydraulic equipment for removing and installing bucket tooth pins

ActiveCN113293817BRealize forward and reverse controlCompact structureSoil-shifting machines/dredgersGear pumpPower switching

Hydraulic equipment for removing and installing bucket tooth pins, including motors, power switches, oil drums, bidirectional gear pumps, housings, oil cylinders, oiling pots, high-pressure oil pipes, overflow valves, and oil circuit integrated distribution blocks; the oiling pots are installed in the oil The upper end of the barrel; one side of the oil circuit integrated distribution block is installed on one side of the oil barrel, and the motor is installed on the other side of the oil circuit integrated distribution block; the bidirectional gear pump is installed on one side of the oil circuit integrated distribution block, and the power input of the bidirectional gear pump The shaft and the power output shaft of the motor are installed together; the oil drum and the oil cylinder are installed together; the relief valve is installed on the oil circuit integrated distribution block; the lower oil pipe of the oil cylinder and the lower inlet and outlet pipes of the oil circuit integrated distribution block are installed together through the oil pipe; The housing is mounted on the outside of the motor, and the power switch is mounted on the housing. The invention is compact in structure and convenient to use. Only by controlling the power switch, the piston of the oil cylinder can move forward to push out or push the bucket tooth pin shaft, and move backward to return to the initial state, thereby improving the efficiency of disassembling and installing bucket teeth.

Owner:漳州鑫山航机械有限公司

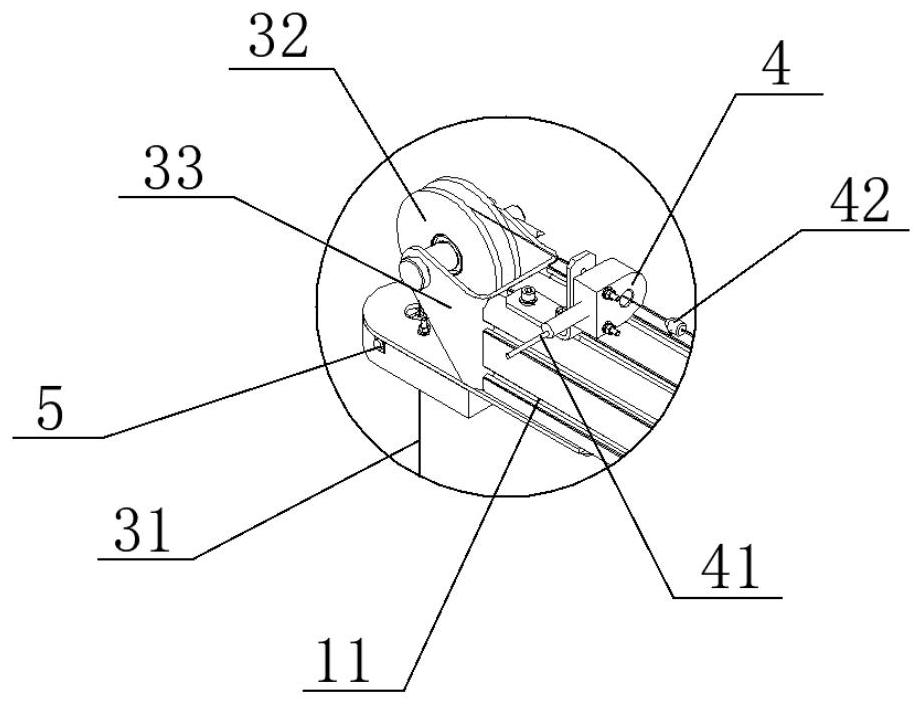

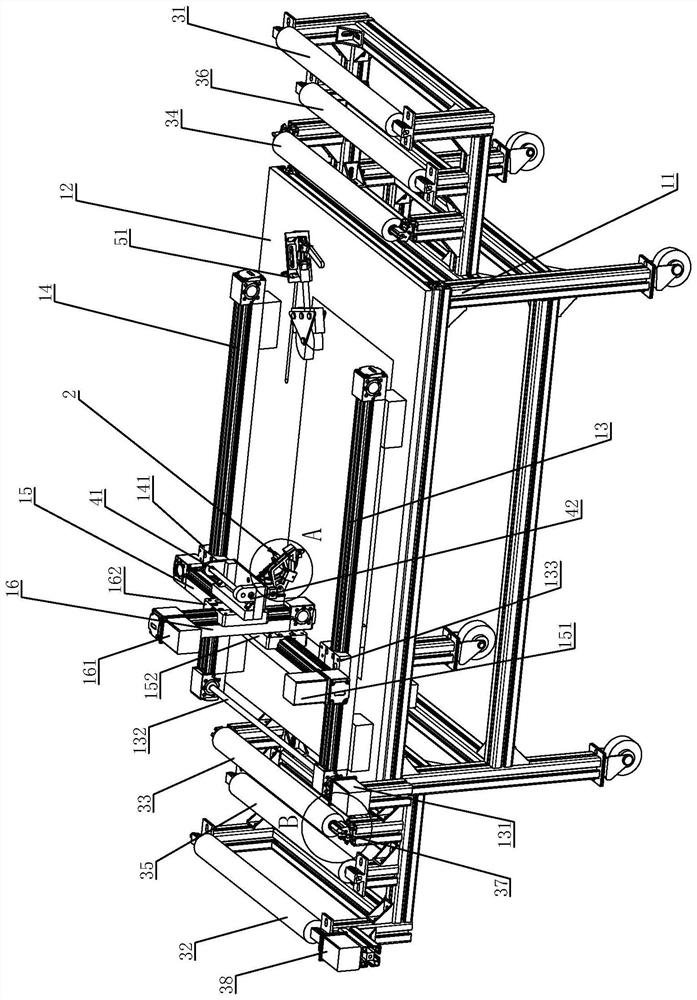

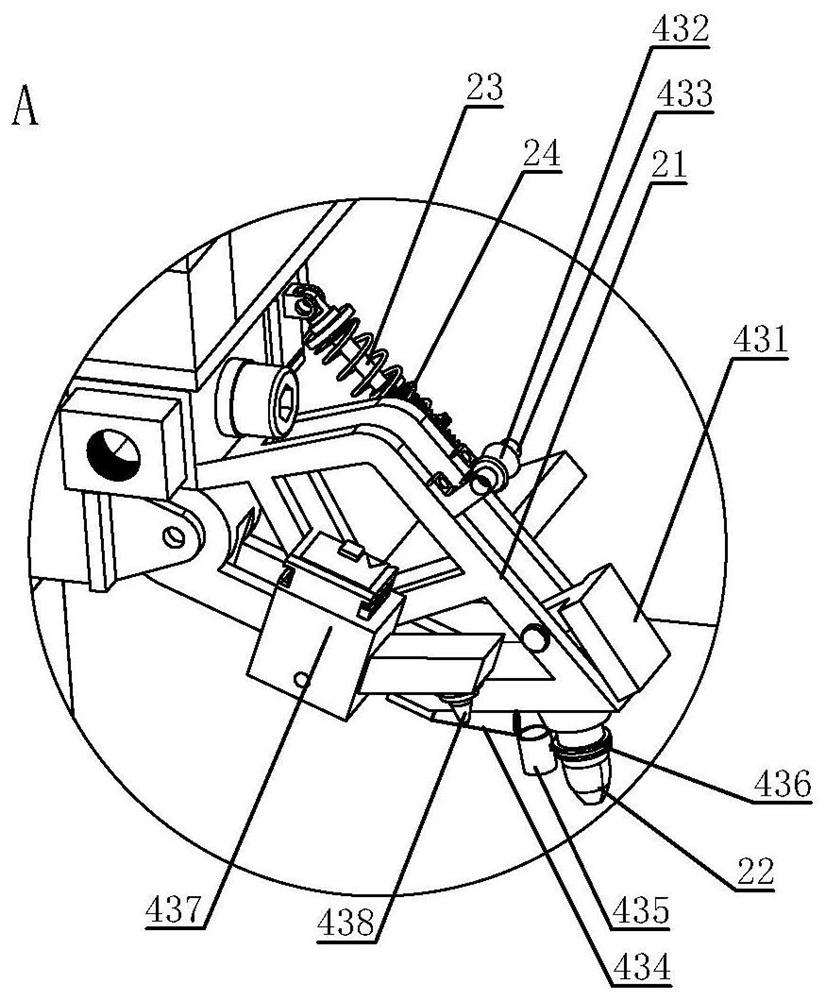

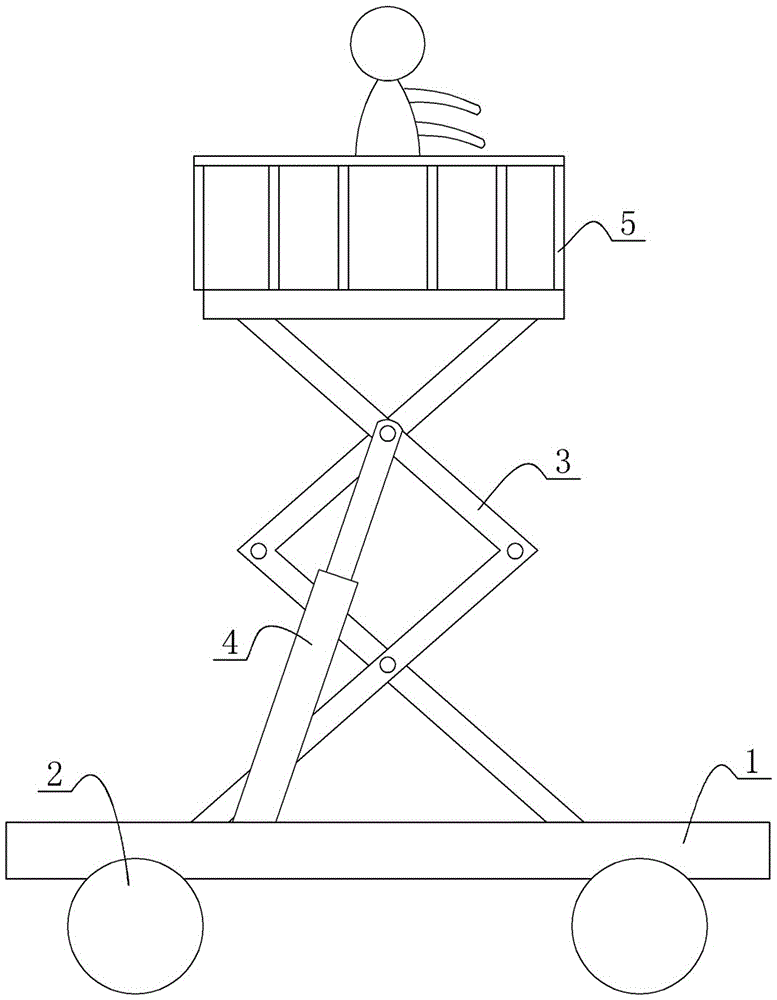

Automatic gauze element mounting equipment

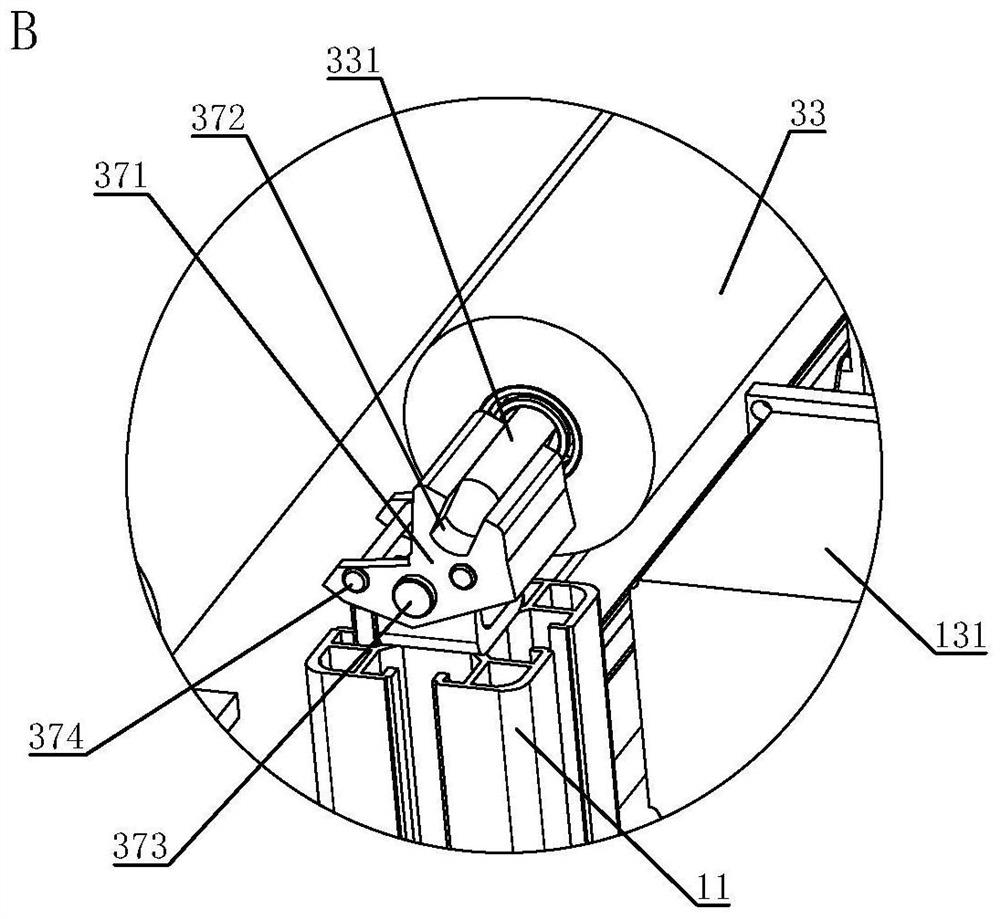

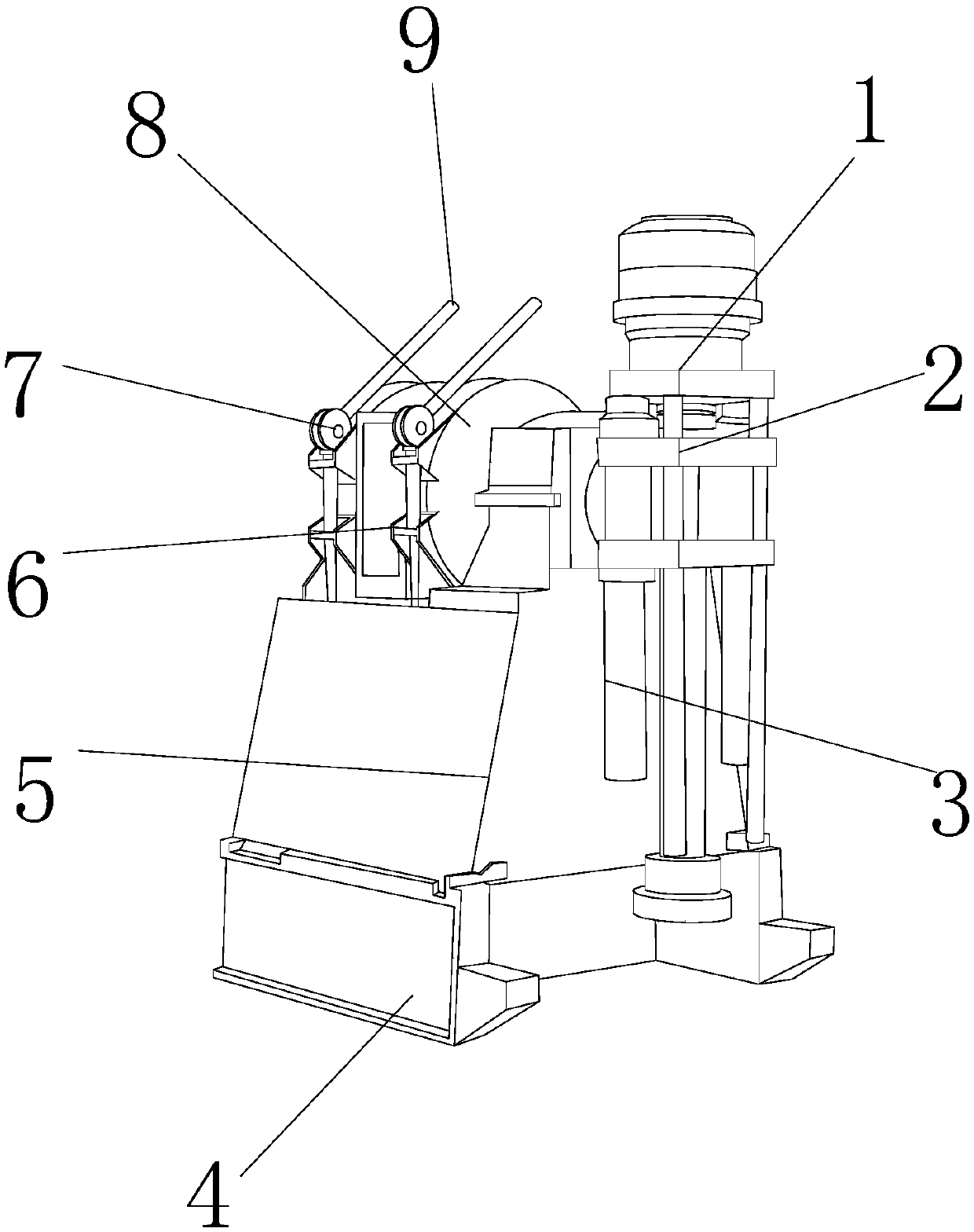

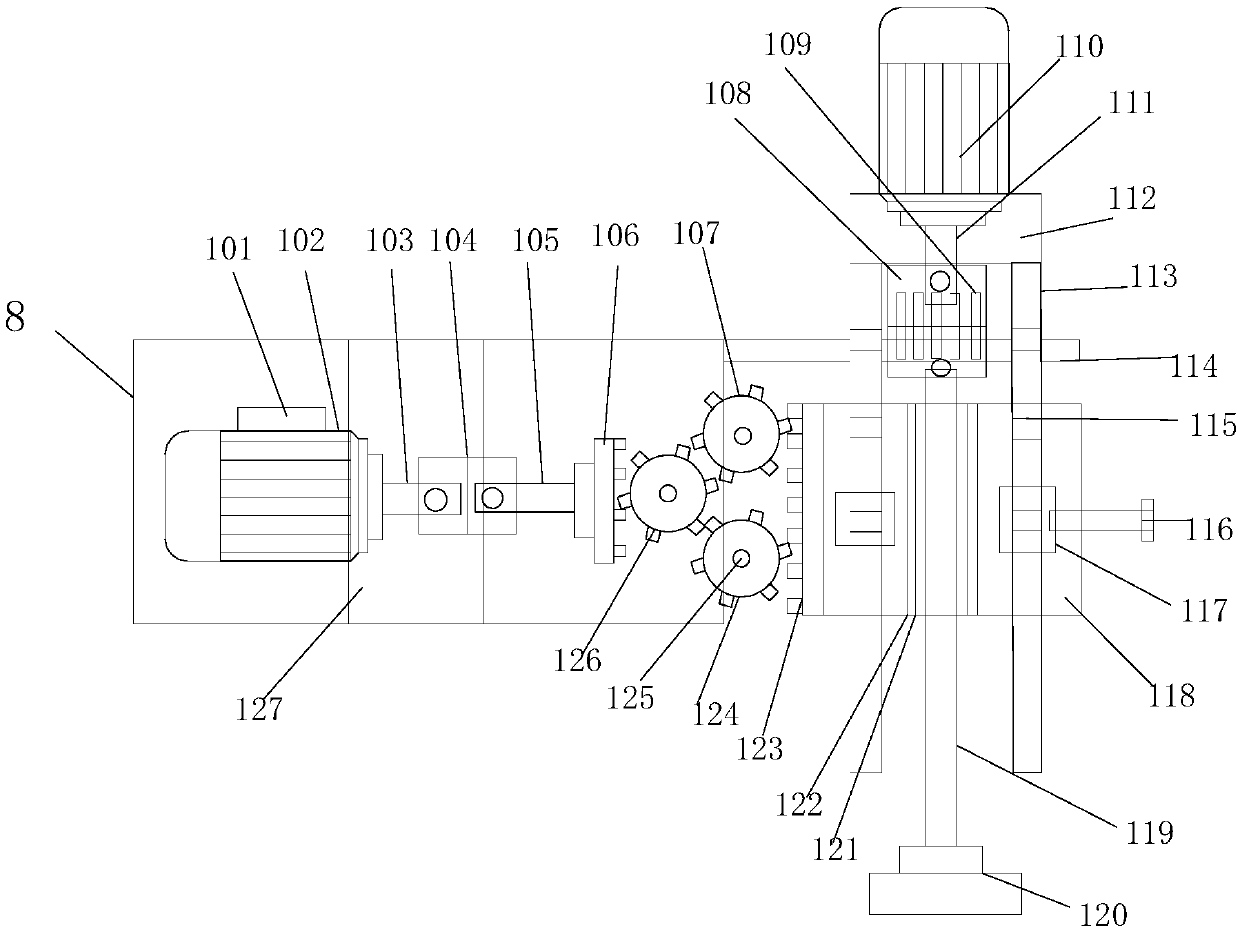

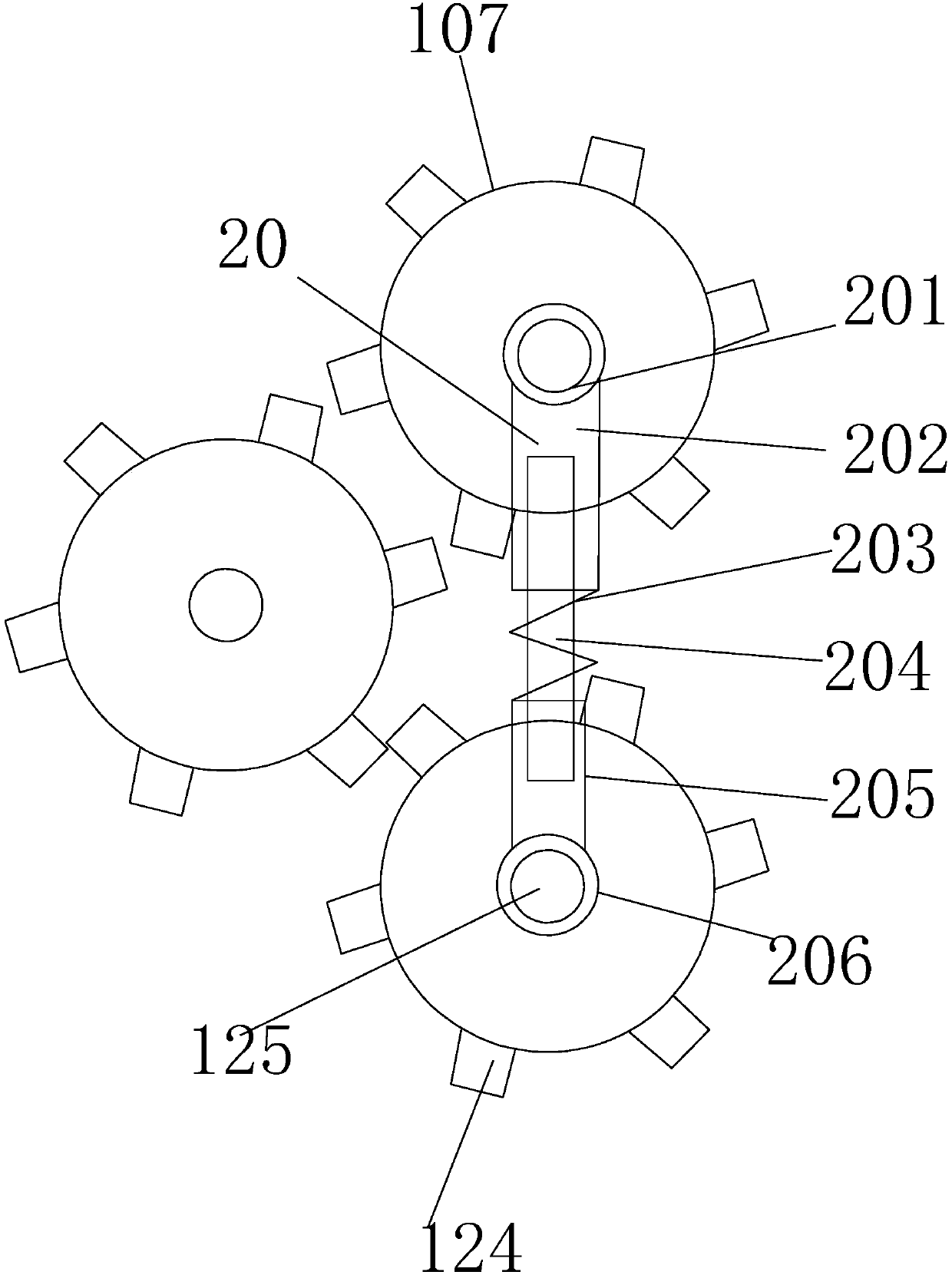

ActiveCN114211231AHigh degree of integrationIncrease flexibilityMetal working apparatusLaser beam welding apparatusEngineeringWorkbench

The invention discloses automatic gauze installation equipment which comprises a gantry type three-axis operation platform and a pressing strip pressing device, the gantry type three-axis operation platform comprises a support, a workbench and a three-axis gantry type combination module and is provided with an absolute coordinate system o-xyz, the workbench is fixed to the support, the three-axis gantry type combination module is installed on the workbench, and the pressing strip pressing device is arranged on the workbench. The three-axis gantry type combined module comprises an x-axis module, a y-axis module and a z-axis module; the pressing device comprises a pressing head frame rotationally connected to a z-axis module sliding block, a pressing head is arranged on the lower portion of the pressing head frame, a telescopic rod is hinged between one side of the pressing head frame and the z-axis module, and a compression spring is arranged between the outer end of an outer rod and the outer end of an inner rod of the telescopic rod. The equipment further comprises a gauze element conveying mechanism used for conveying the gauze element, a pressing strip conveying mechanism used for conveying pressing strips and a clamping mechanism used for clamping the outer frame of the screen window. According to the equipment, pressing strips are installed rapidly and reliably, the labor intensity is reduced, and the production efficiency of formed screen windows is improved.

Owner:SHANDONG LABOR VOCATIONAL & TECHN COLLEGE

Petroleum geological prospecting drill pipe device

ActiveCN107605411AStable output powerReduce distractionsDrilling rodsBorehole drivesCouplingFixed frame

The invention discloses a petroleum geological prospecting drill pipe device. The petroleum geological prospecting drill pipe device structurally comprises a drill pipe device body, a prospecting head, an external reinforcing rod, a base, a geological prospecting machine body, connecting frames, fixing rods, an upper fixing frame and a rocking rod. The bottom of the geological prospecting machinebody is fixedly connected with the top of the base, the upper fixing frame is arranged at the top of the geological prospecting machine body, and the connecting frames are arranged to be in a rectangular shape and fixed to the front side of the fixing frame; and the fixing rods are parallel to each other, penetrate through the connecting frames and are connected to the interior of the top side ofthe geological prospecting machine body, and the right side of the upper fixing frame is in mechanical connection with the left side of the prospecting head. According to the petroleum geological prospecting drill pipe device, rapid rising and falling can be conducted through motor transmission, meanwhile stable output power is provided by a motor, the degree of outside interference can be reduced, the stability of equipment operation can be ensured, and meanwhile the impact force borne by the petroleum geological prospecting drill pipe device is reduced by a coupler.

Owner:浙江乔派电梯装饰有限公司

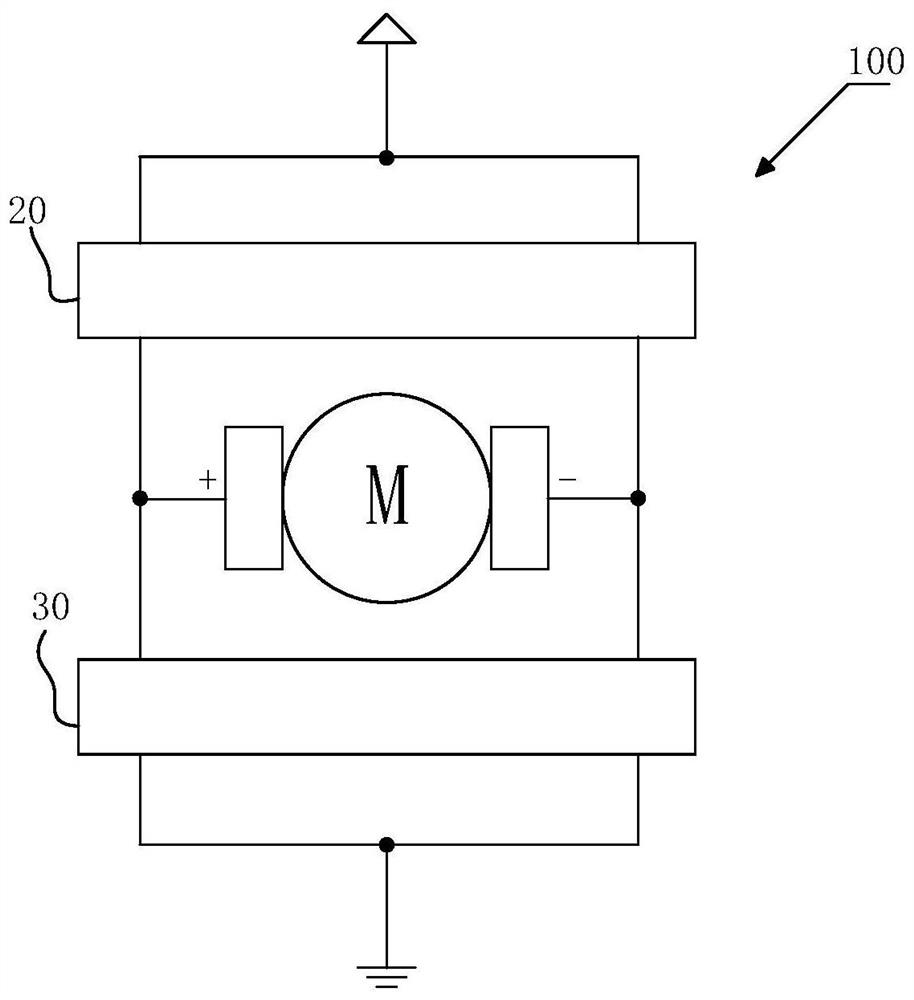

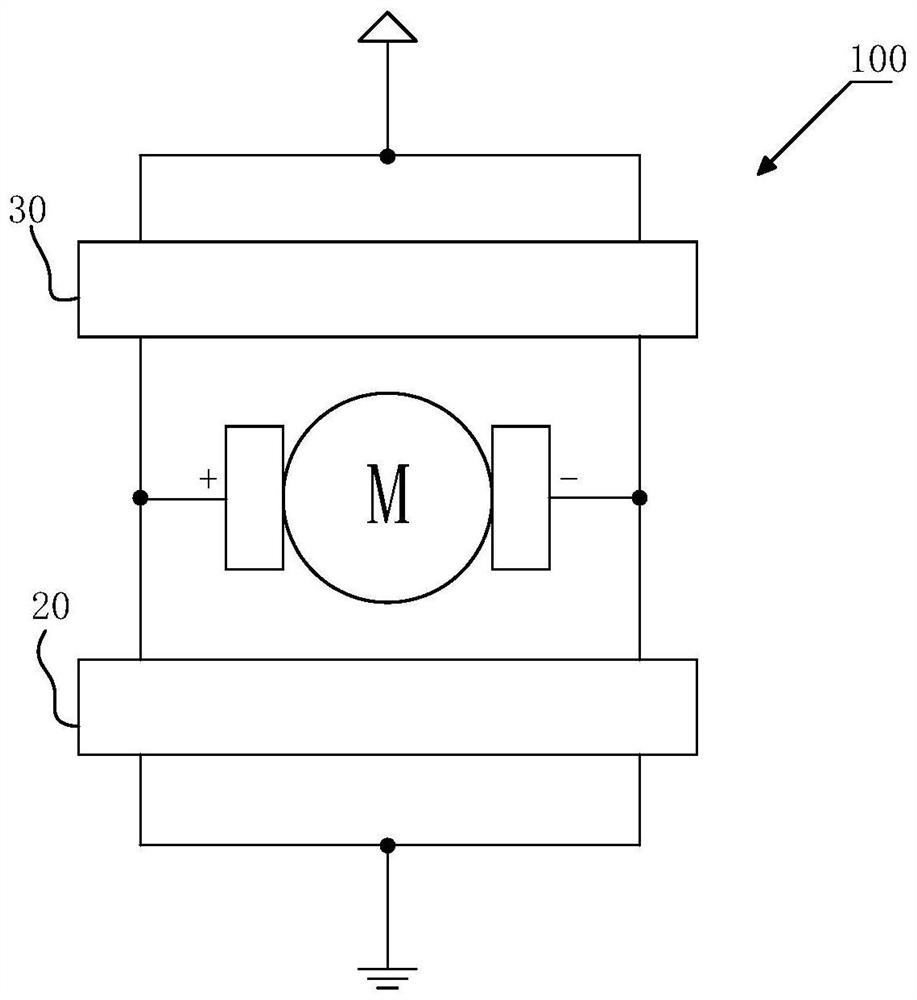

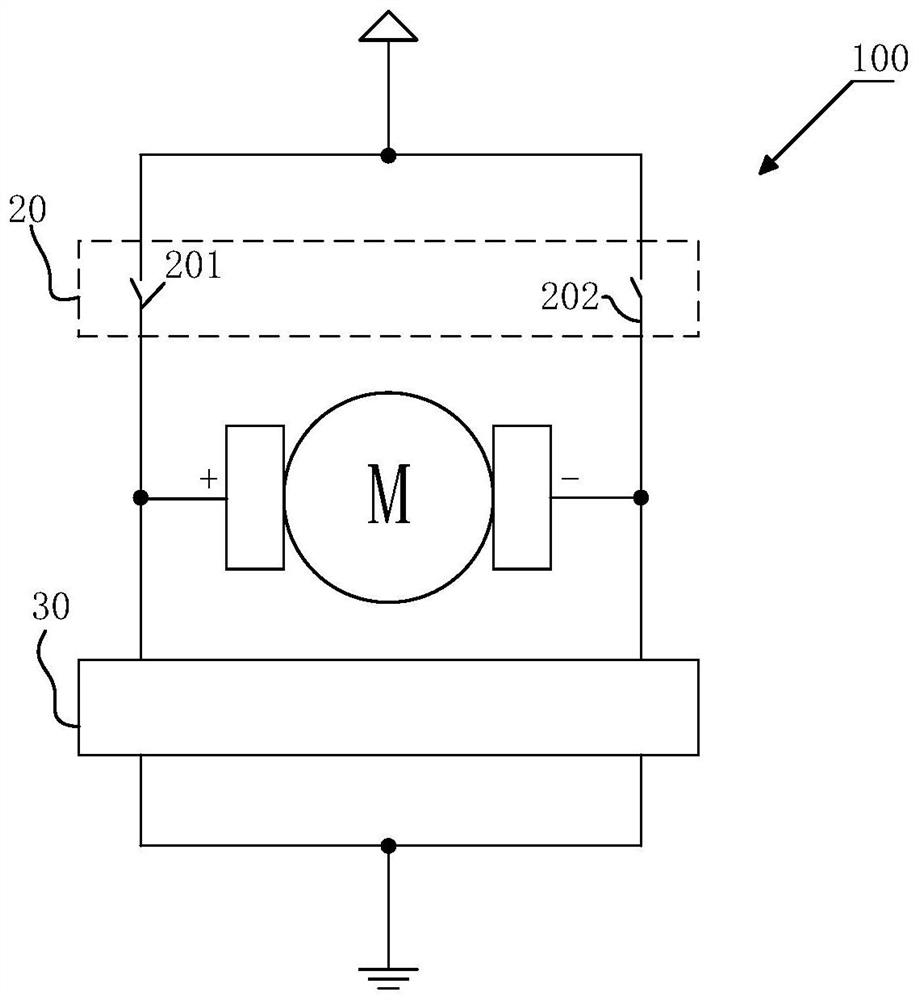

Motor control circuit, motor control system and motor driving device

InactiveCN113067507AThe control method is simple, convenient and practicalConducive to miniaturization designField or armature current controlDC motor rotation controlElectric machineControl system

The invention discloses a motor control circuit, a motor control system and a motor driving device. The motor control circuit comprises a first control unit and a second control unit, the first control unit and the second control unit are used for controlling a motor to rotate forwards or reversely, and the second control unit is further used for controlling the rotating speed of the motor. One end of the first control unit is connected with a power supply, the other end of the first control unit is connected with the motor, one end of the second control unit is connected with the motor, and the other end of the second control unit is grounded; or one end of the second control unit is connected with the power supply, the other end of the second control unit is connected with the motor, one end of the first control unit is connected with the motor, and the other end of the first control unit is grounded. The motor control circuit can realize positive and negative rotation control and rotating speed control of the motor, the control mode is simple, convenient and practical, and miniaturization design of products is facilitated.

Owner:QOROS

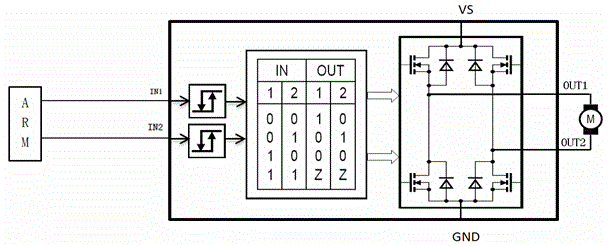

Control method and control mechanism for throttle motor of excavator

InactiveCN104832295ASignal has no effectRealize forward and reverse controlSoil-shifting machines/dredgersEngine controllersThrottle controlControl signal

The invention discloses a method for controlling a throttle motor of an excavator. A control mechanism mainly comprises a throttle control turn button detection circuit, an ARM controller, a throttle motor with position feedback and a throttle motor drive circuit, wherein the ARM controller controls the position of the turn button through a detection throttle, and two complementary PWM signal and turning control signals are generated therein to control the clockwise and counterclockwise turning and rotating speed of the throttle motor. Oil supply amount of an engine is controlled through a stay wire of the throttle motor to control the rotating speed of the engine. A triode circuit is added in the drive circuit of the throttle motor. The turning direction of the throttle motor can be immediately completed without time delay, and the control means is simple.

Owner:浙江联辉智能科技有限公司

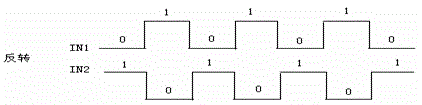

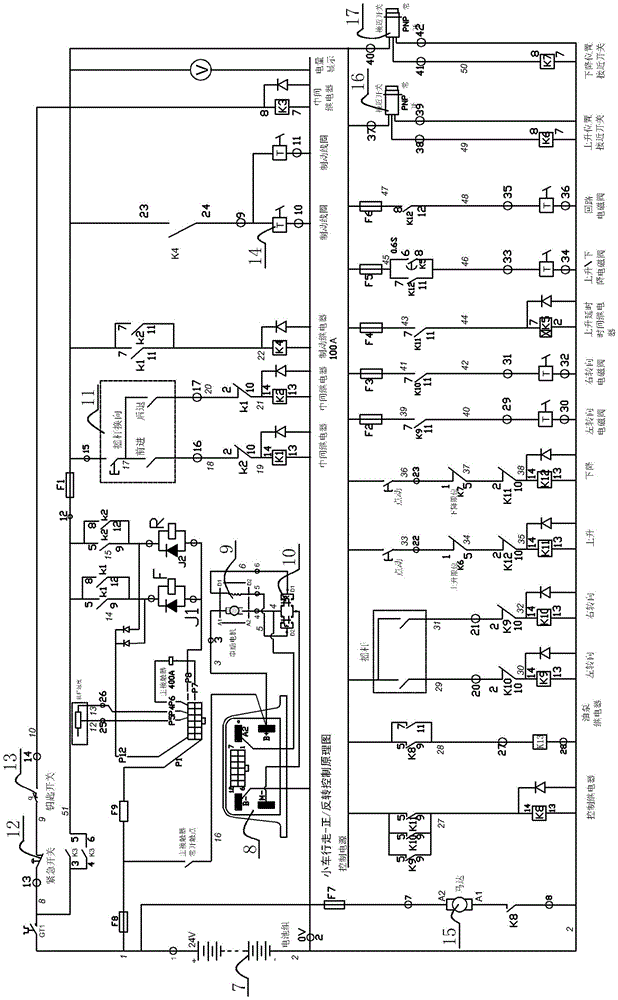

A control system for lift maintenance vehicle

ActiveCN104098056BStable resting stateRealize forward and reverse controlLifting devicesProgramme control in sequence/logic controllersControl systemSolenoid valve

The lift maintenance vehicle control system of the present invention is characterized in that: the forward gear is connected in series with the normally closed point of relay K2 and relay K1 and then connected to both ends of the power supply; The solenoid valve is connected in series with the normally open point of the relay K10 and connected to both ends of the control power supply; after the rising jog switch is connected in series with the normally closed point of the relay K12 and the relay K11, the descending jog switch is connected with the normally closed point of the relay K11 After being connected in series with the relay K12, both ends of the control power supply are connected. The lifting maintenance vehicle control system of the present invention realizes the forward and backward movement of the maintenance vehicle through forward and reverse control of the series excitation motor; the steering function can be realized under the control of the steering hydraulic cylinder by the left and right turning solenoid valves. By setting the relays K11 and K12 connected in series with the ascending jog switch and the descending jog switch, the ascending and descending operation of the console is realized.

Owner:JINAN KEYA ELECTRONICS SCI & TECH CO LTD

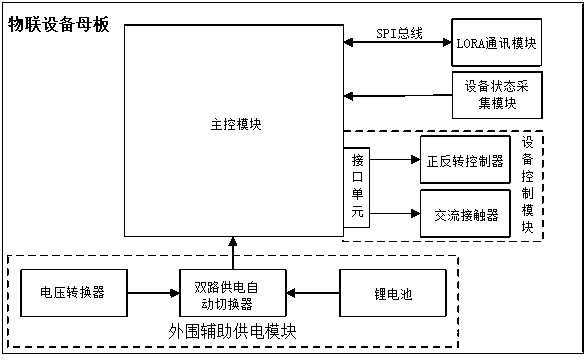

Underground engineering Internet of Things equipment based on LORA

PendingCN111463897ARealize forward and reverse controlEasy to connectMining devicesPower network operation systems integrationCurrent electricControl engineering

The invention relates to underground engineering Internet of Things equipment based on LORA. The equipment comprises a main control module, an LORA communication module, a peripheral auxiliary power supply module and a mother board, wherein the main control module is in interactive connection with the LORA communication module through the mother board, the peripheral auxiliary power supply moduleis also connected with the main control module through the mother board, the equipment further comprises an equipment control module and an equipment state acquisition module, the equipment control module is composed of an interface unit, a forward and reverse rotation controller and an alternating current contactor, the input end of the interface unit is connected with the main control module through the mother board, and the forward and reverse rotation controller and the alternating current contactor are respectively connected with the output end of the interface unit. According to the invention, various alternating-current electric devices can be controlled, connection with a controlled device is convenient, no additional component is needed, connection with a power supply terminal ofa controlled device can be directly realized, wireless Internet of Things establishment can be realized without laying cables, and the equipment has the characteristics of large signal coverage range,strong wall penetrating capability, low power consumption and the like when used in underground engineering.

Owner:中国人民解放军军事科学院国防工程研究院工程防护研究所

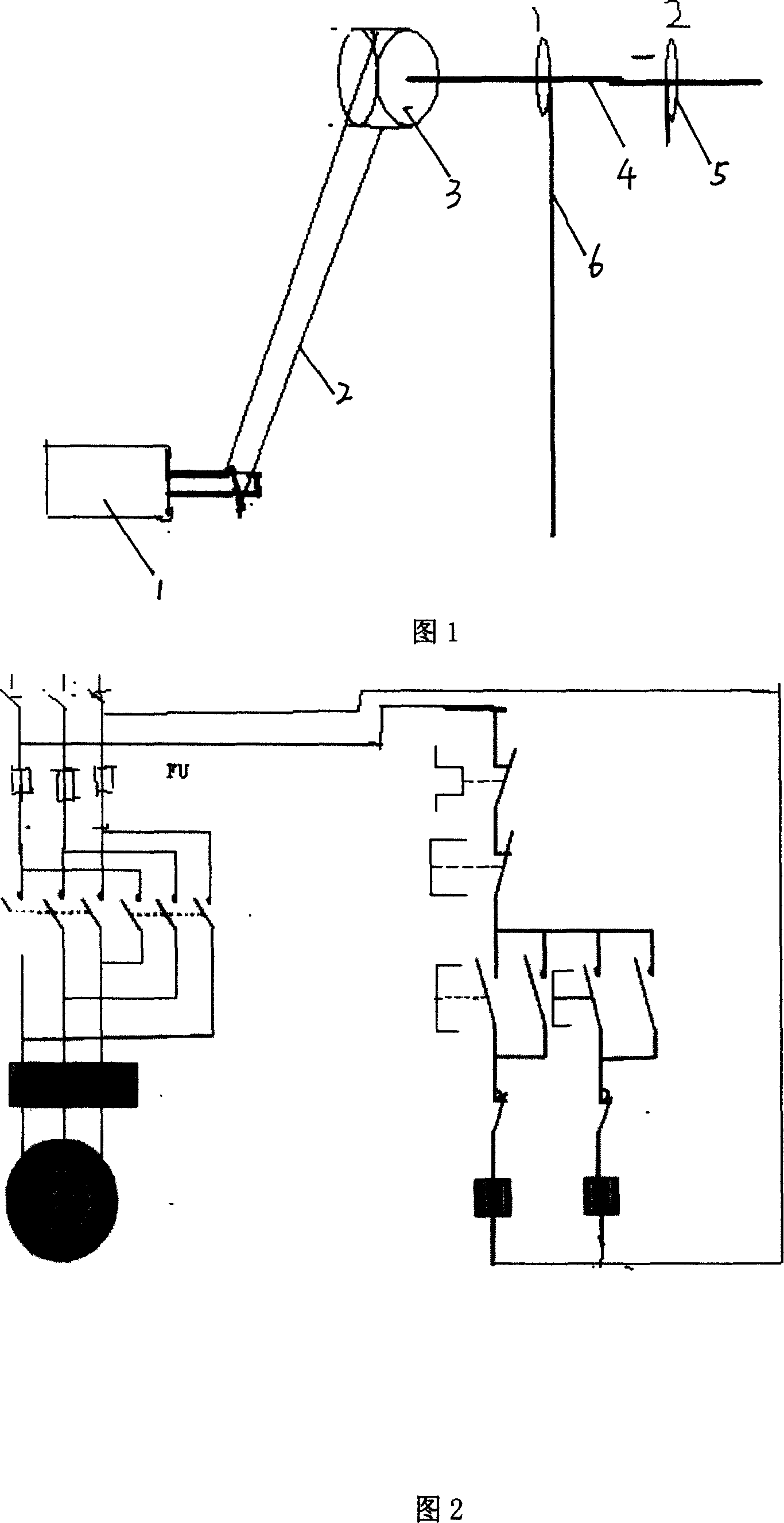

Corn conveying machine

InactiveCN101012050ARealize forward and reverse controlAchieve cycleLifting devicesHoisting equipmentsControl theoryControl circuit

The invention relates to a corn transmitter, which is simple in structure, convenient in use, saving labor and improved in labor efficiency, which comprises generator installed on the chassis, the said generator connected to the triangle belt with the pulley, shaft of the pulley connecting with a horizontal bar, a pair of iron ring with pulling ropes on the horizontal bar, pulling rope of an iron ring sticking out of the land, the other pulling rope sticking out of the iron ring and the generator connected with the control circuit.

Owner:邵传兵

Building block type stator disc, permanent magnet motor and speed control method thereof

ActiveCN110323907ASimple structureEasy to controlMagnetic circuit rotating partsMagnetic circuit stationary partsArchitectural engineeringMagnetic poles

The invention relates to a building block type stator disc, a permanent magnet motor and a speed control method thereof; the building block type stator disc comprises a plurality of stator teeth, a winding which is wound on each stator tooth in the direction parallel to the rotor disc direction, an inner fixed ring frame and an outer fixed ring frame, wherein the inner fixed ring frame and the outer fixed ring frame are arranged in a sleeved mode inside and outside; the plurality of stator teeth are arranged between the inner fixed ring frame and the outer fixed ring frame and are encircled toform an annular shape; and one end of the stator tooth is fixedly connected to the inner fixed ring frame through a first connecting piece, and the other end of the stator tooth is fixedly connectedto the outer fixed ring frame through a second connecting piece. The building block type stator disc is simple in structure and convenient to control, does not need to be converted into a rotary magnetic field, and is different from a traditional control mode of a permanent magnet motor, the motor can be rotated only by continuously changing the coils on different magnetic poles, the cost is low,and the maintenance is convenient.

Owner:高宪立

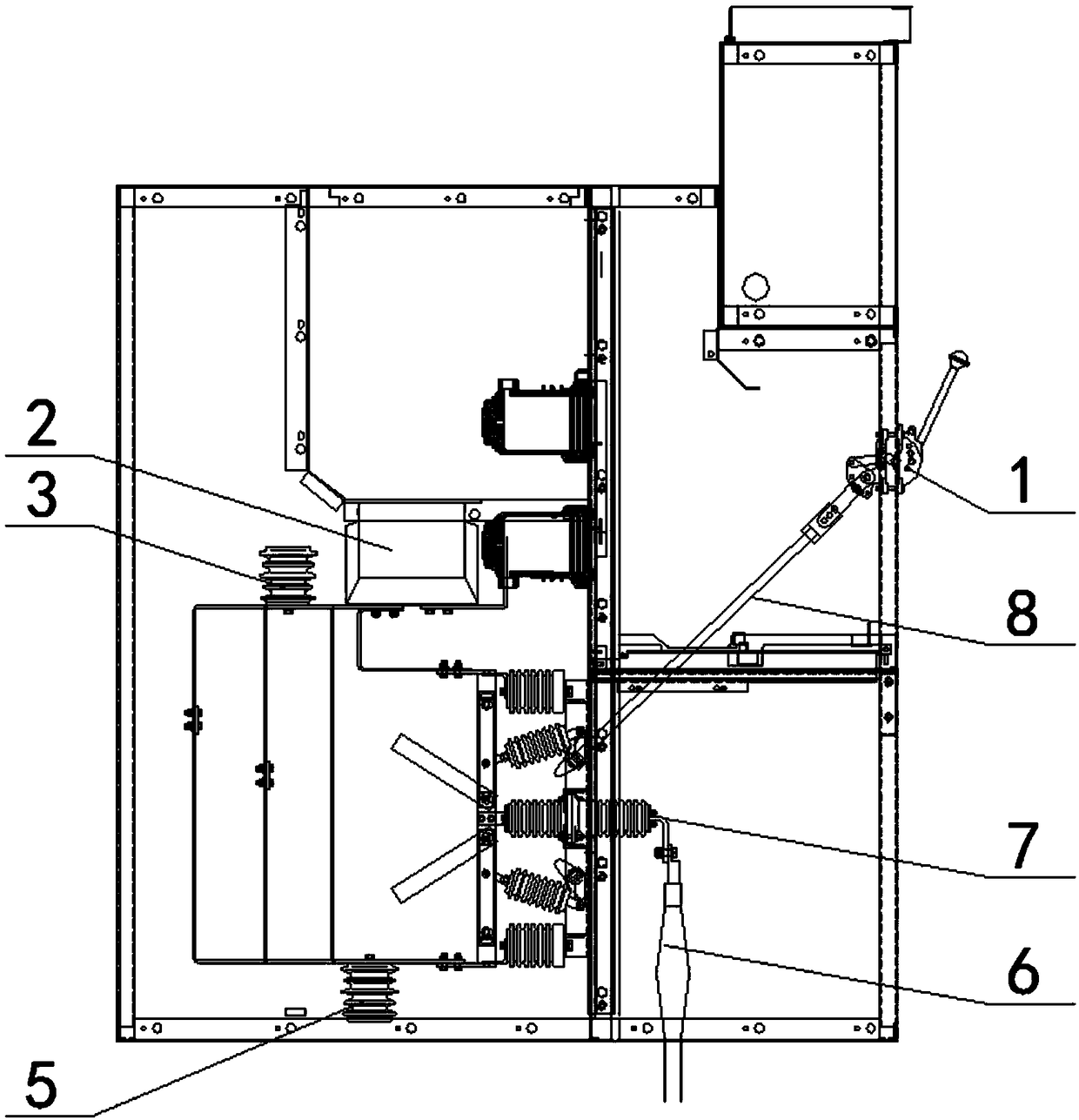

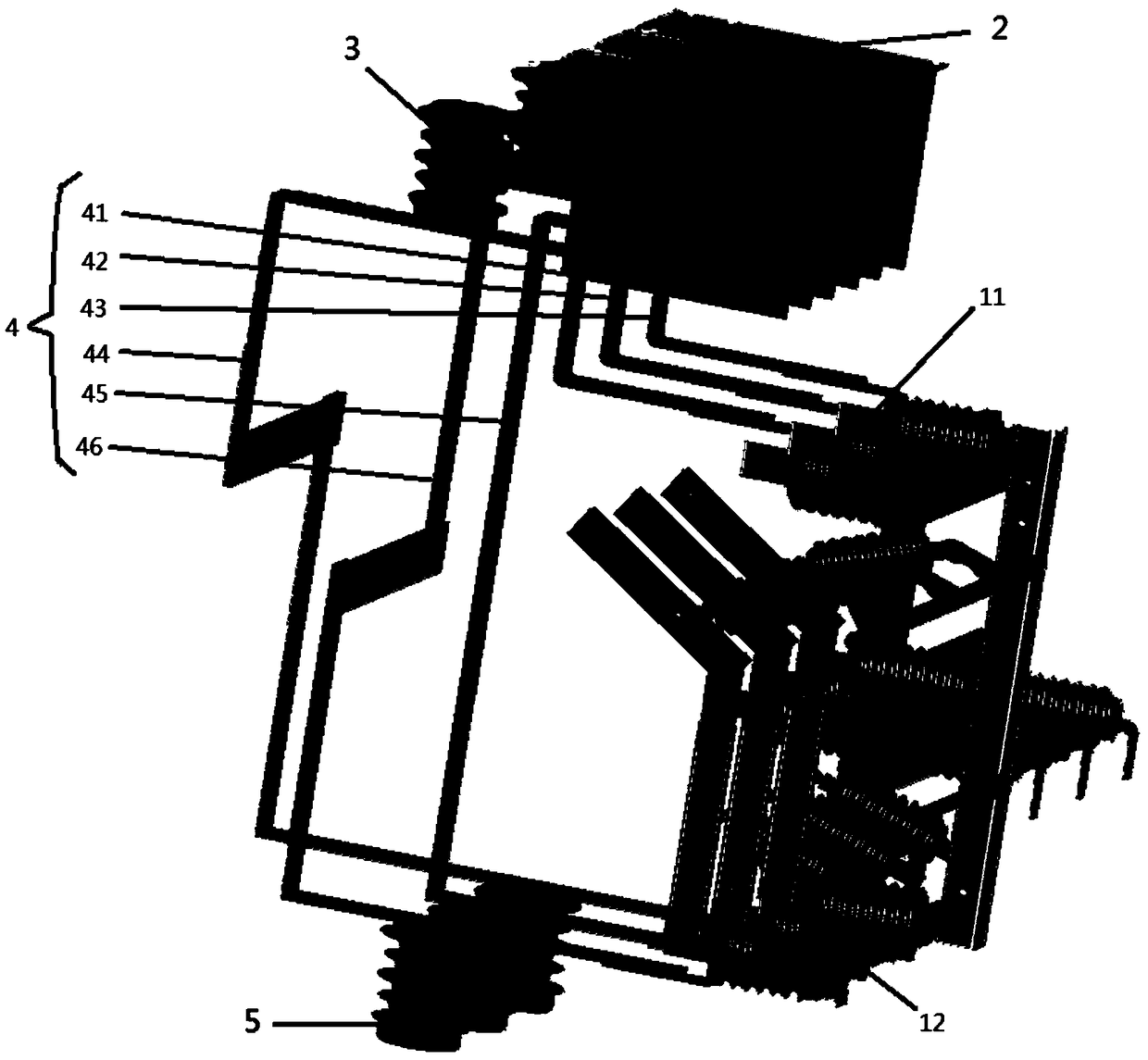

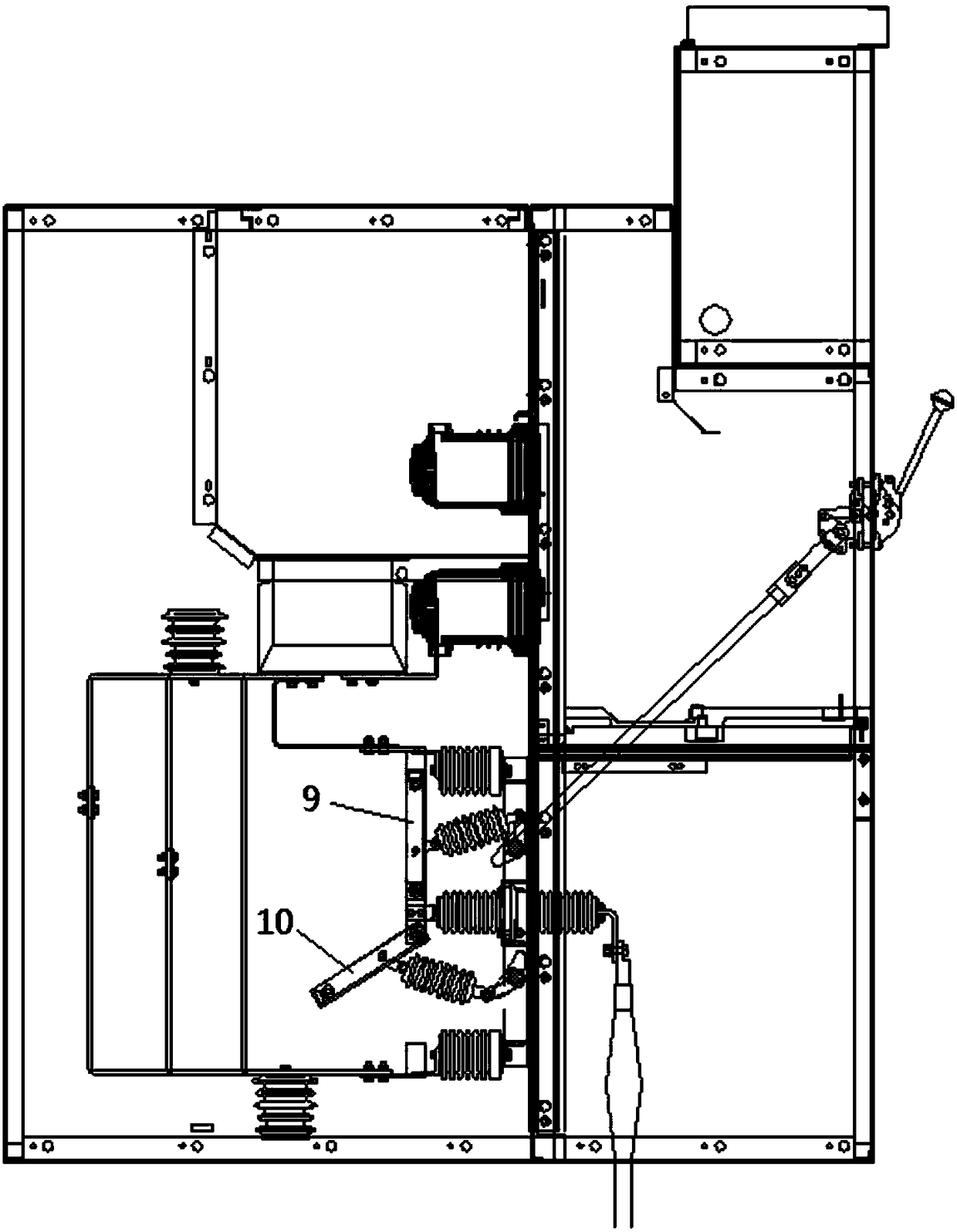

High-voltage switch cabinet

PendingCN108767683AForward realizationRealize forward and reverse controlSubstation/switching arrangement casingsAir-break switch detailsElectric machineThree-phase

The invention relates to the field of high voltage control, and specifically relates to a high-voltage switch cabinet. A three-phase disconnecting link comprising two three-phase moving contacts is arranged in a control cabinet; three phases of a three-phase input terminal are connected with the two moving contacts through different connection modes; and a motor is controlled to rotate forwardly when one three-phase moving contact is closed, and the motor is controlled to rotate reversely when the other three-phase moving contact is closed, so that the forward and reverse rotation of the motoris realized. The high-voltage switch cabinet provided by the invention is simple in structure and easy to operate, so that the motor can be smoothly switched between forward rotation and reverse rotation, and the forward and reverse rotation control of the motor is effectively realized.

Owner:HENAN SENYUAN ELECTRIC CO LTD

An Intelligent Observation Device for Prawn Factory Farming

ActiveCN111947753BFishing boostFast weighingClimate change adaptationPisciculture and aquariaCantilevered beamShrimp

The invention relates to the technical field of aquaculture equipment, in particular to an intelligent observation device for industrialized cultivation of prawns, including a frame module, a prawn fishing module, a prawn lifting module, an infrared identification and positioning module and an automatic locking and unlocking weighing module. The frame module is an inverted L-shaped cantilever beam structure, and the frame module includes an overhanging beam on the upper part. The prawn lifting module is installed on the upper part of the frame, and an infrared identification and positioning module is arranged inside the prawn lifting module. The automatic locking and unlocking weighing module is fixedly installed at the end of the frame module, and the upper part of the prawn fishing module is connected with a lifting cable. The present invention can realize rapid fishing, lifting and weighing of prawns through four major devices: a prawn fishing module, a prawn lifting device, an infrared identification and positioning device, and a fast locking and unlocking weighing device.

Owner:QINGDAO HAIYAN ELECTRONICS CO LTD

A Pendulum Block Matching Cam Rotor Internal Combustion Engine Power System

ActiveCN106948934BShort motion transfer linkImprove transmission efficiencyInternal combustion piston enginesOtto cycleMechanical energy

The invention relates to a swinging block and cam rotor cooperating internal combustion engine power system and belongs to the field of internal combustion engines. In the power system, cam rotors and a plurality of swinging driven parts are adopted to form a cam mechanism, the cam rotors, the swinging driven parts, rotor chambers and end members form a plurality of circumferentially distributed sealed working chambers; the volumes of the sealed working chambers are changed along with rotation of the cam rotors, and the four processes of air inflowing, compression, acting and exhausting of an otto cycle are finished in the working chambers through cooperation with air valves; and chemical energy generated by gas combustion is directly converted into fixed-shaft rotation type mechanical energy of the rotors. According to the swinging block and cam rotor cooperating internal combustion engine power system, planetary motion of Wankel rotors and an inner chamber in a specific shape are not needed, high-pressure gas directly pushes the rotors to perform fixed-shaft rotation and power is output, the structure is simple, and the parameter adjustable range is wide. Flexible control is easy to achieve under control of an added swinging block escapement device, and compared with piston internal combustion engine and Wankel rotor internal combustion engine power systems, the swinging block and cam rotor cooperating internal combustion engine power system has much more outstanding advantages.

Owner:DALIAN UNIV OF TECH

A peeping head control device

ActiveCN103048998BSmall sizeRealize forward and reverse controlPosition/direction controlElectrical resistance and conductanceElectric machine

The invention provides a probe control device which comprises two same control circuits and a rotation guide mechanism, wherein the rotation guide mechanism is used for adjusting the control circuits, each control circuit is composed of a motor, a potentiometer and a chip, both ends of the potentiometer are connected with pull-down resistors and connected with the ground, the center of the potentiometer is connected with a high level, and the both ends of the potentiometer are in input control connection with two direction levels of the motor controlled chip. According to the probe control device, through the two same unique control circuits and the rotation guide mechanism used for adjusting the control circuits, the size of the control device in the longitudinal space is reduced, the whole device is integrally thinner, the appearance is more attractive, the positive-negative rotation control over motors and the accurate control over a mechanical device by the control device are realized, and the device has the advantages of attractive appearance, convenience in operation and precision improvement.

Owner:徐州泰诺仕视觉科技有限公司

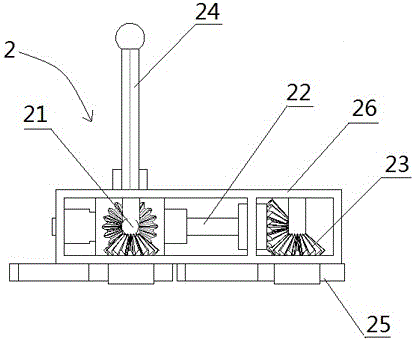

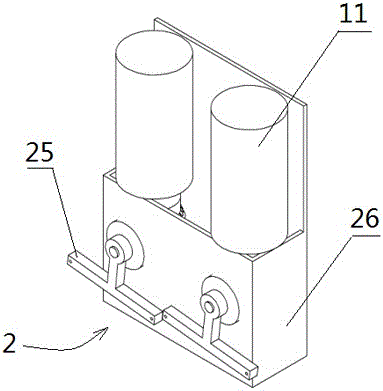

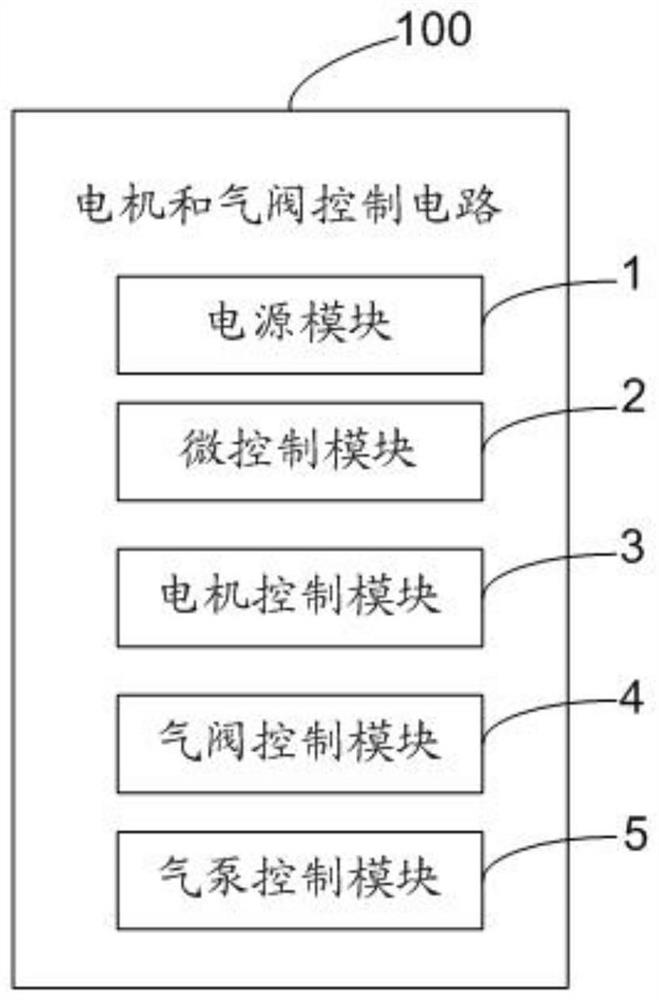

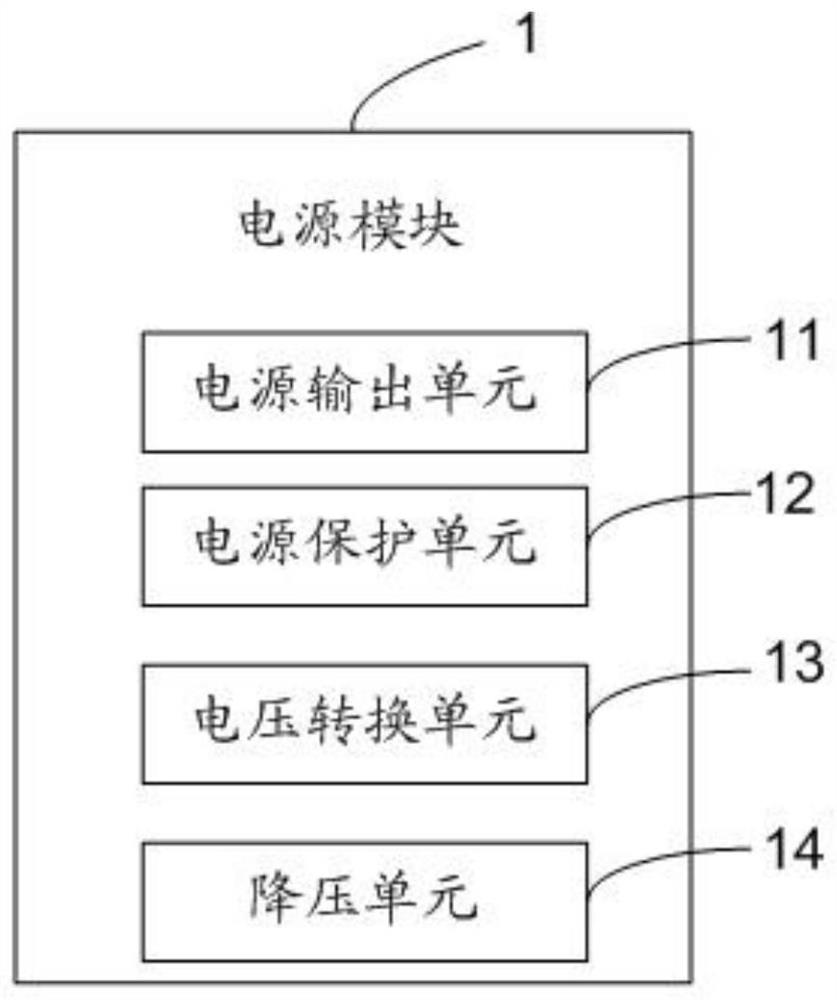

Motor and air valve control circuit

PendingCN114384844ARealize forward and reverse controlEasy to controlProgramme controlComputer controlAutomatic controlElectric machine

The invention provides a motor and air valve control circuit, which is used for a massage chair, and comprises a power supply module, a micro-control module, a motor control module, an air valve control module and an air pump control module, the power supply module is electrically connected with the micro-control module, the motor control module, the air valve control module and the air pump control module, and the air pump control module is electrically connected with the micro-control module. The micro-control module is electrically connected with the motor control module and used for controlling the motor control module to start, the air valve control circuit is used for controlling an air valve, and the air pump control module is used for controlling the air output of an air pump; when the micro-control module inputs a PWM signal, the positive and negative rotation control of the motor can be realized, the control of a backrest motor, a walking motor and a kneading motor of the massage chair is realized, and a series of massage manipulation control is realized through different program control. The system is good in automatic control effect, good in experience effect and wide in application range.

Owner:贵州凯晟电子技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com