Forward and reverse rotation device of condensing fan

A condensing fan, forward and reverse technology, applied in the direction of mechanical equipment, machine/engine, pump control, etc., can solve the problems of inconvenient removal of weeds, unfavorable efficiency, and affecting the heat dissipation of the condenser, so as to reduce the number of manual cleaning and improve The effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

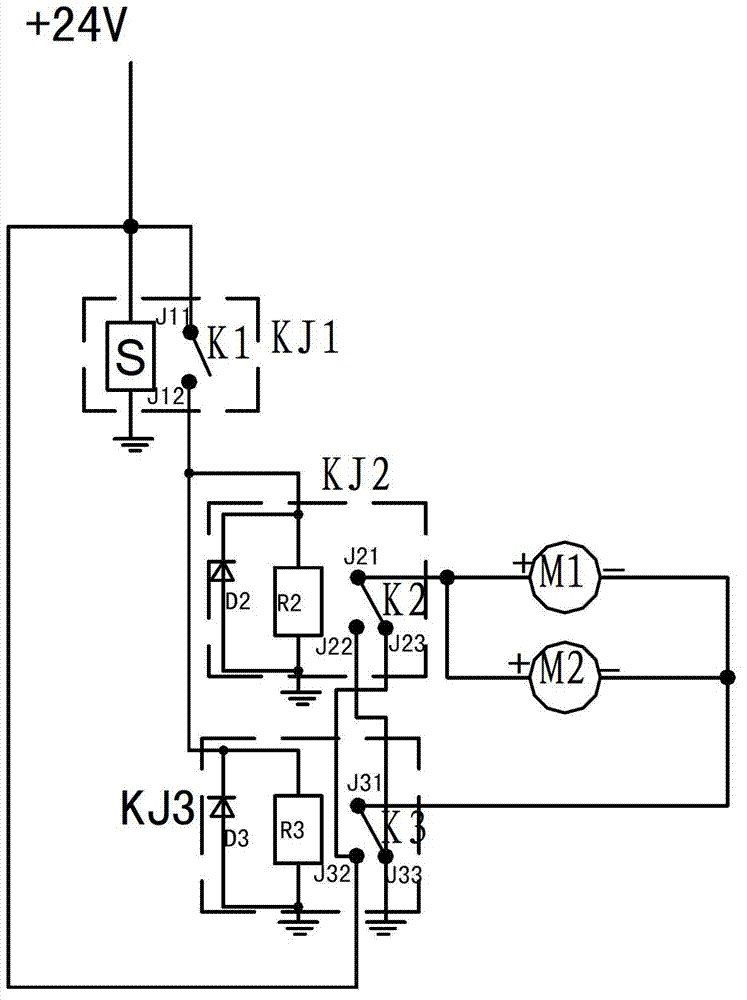

[0015] According to attached figure 1 The structure shown is to make a forward and reverse device for condensing fans, including relays, switches, and fans, one of which is a time relay KJ1, two relays KJ2 and KJ3; each relay has a switch inside, and the corresponding switches are K1, K2, and K3; one end J12 of the switch K1 in the time relay KJ1 is connected to one end of the resistance R2 inside the relay KJ2, and one end J12 of the switch K1 in the time relay KJ1 is also connected to one end of the resistance R3 inside the relay KJ3, and the resistance R2 and The other end of the resistor R3 is grounded;

[0016] The other end J11 of the switch K1 in the time relay KJ1 is connected to one end J32 of the switch K3 inside the relay KJ3, and one end J32 of the switch K3 is connected to one end J23 of the switch K2 inside the relay KJ2; one end J33 of the switch K3 is connected to the switch inside the relay KJ2 One end of K2 is connected to J22; one end J31 of the switch K3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com