Patents

Literature

163results about How to "Fast weighing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions and methods for supplementing the diet

InactiveUS20190313682A1Lower sugar contentIncrease in blood sugarAcidic food ingredientsFood ingredient as flavour affecting agentMedicineKetogenic diet

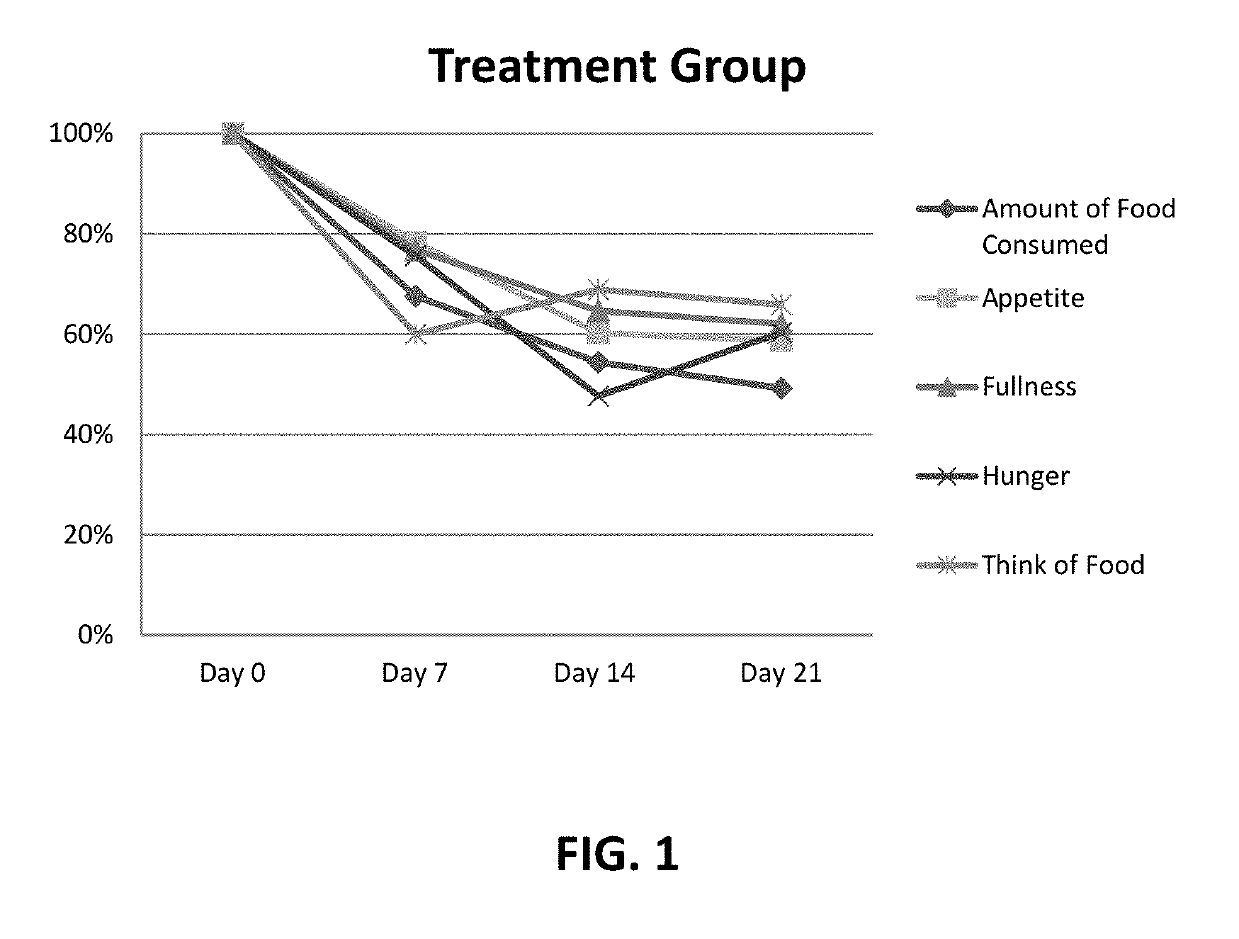

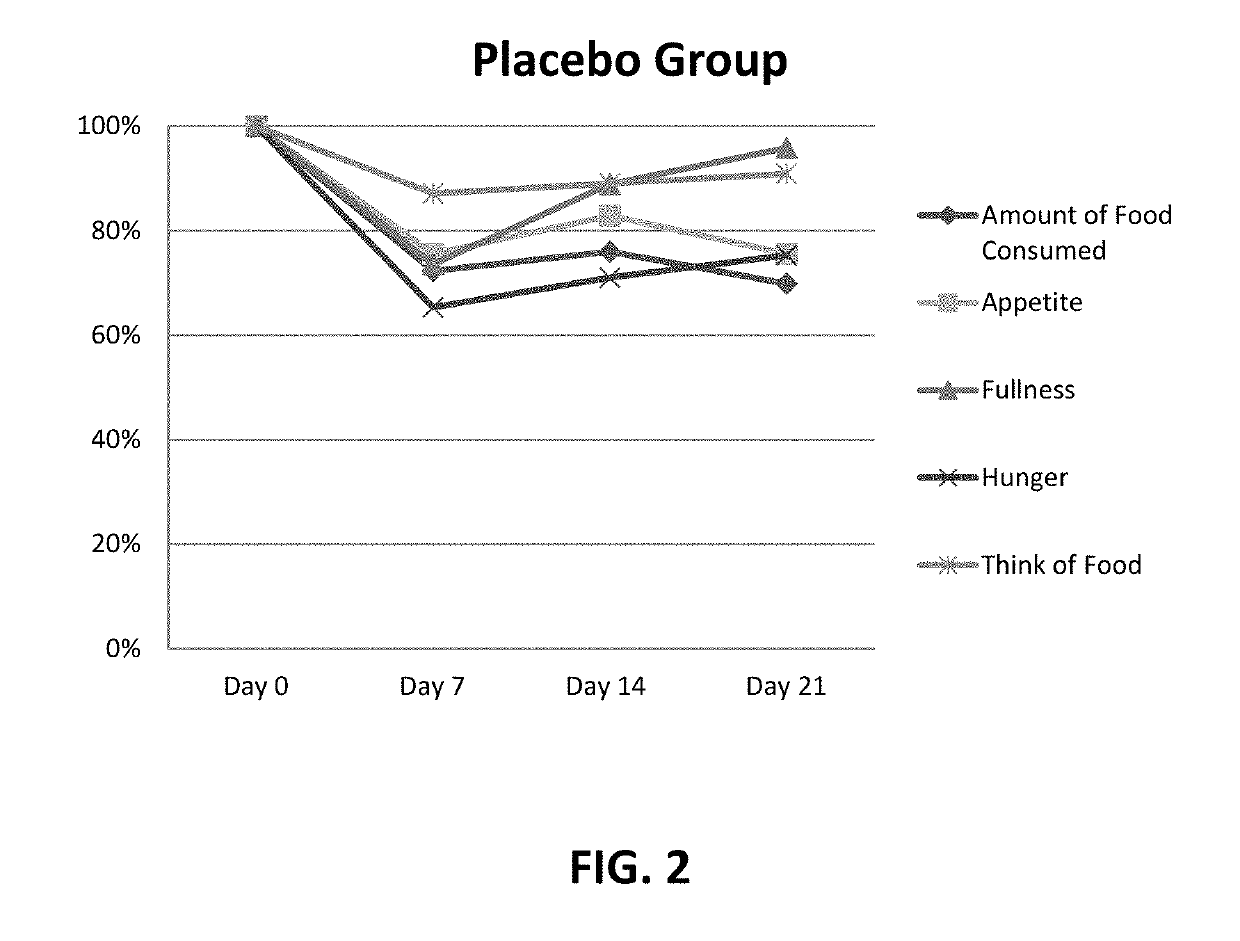

Various aspects and embodiments disclosed herein relate generally to compositions that can be used to increase physical and mental energy, reduce the sensation of hunger. At least some of the composition disclosed herein can be used to obviate or moderate some of the discomfort which may be associated with initiating or maintaining reduced calorie and / or ketogenic diets.

Owner:METABOLIC RECOVERY SYST LLC

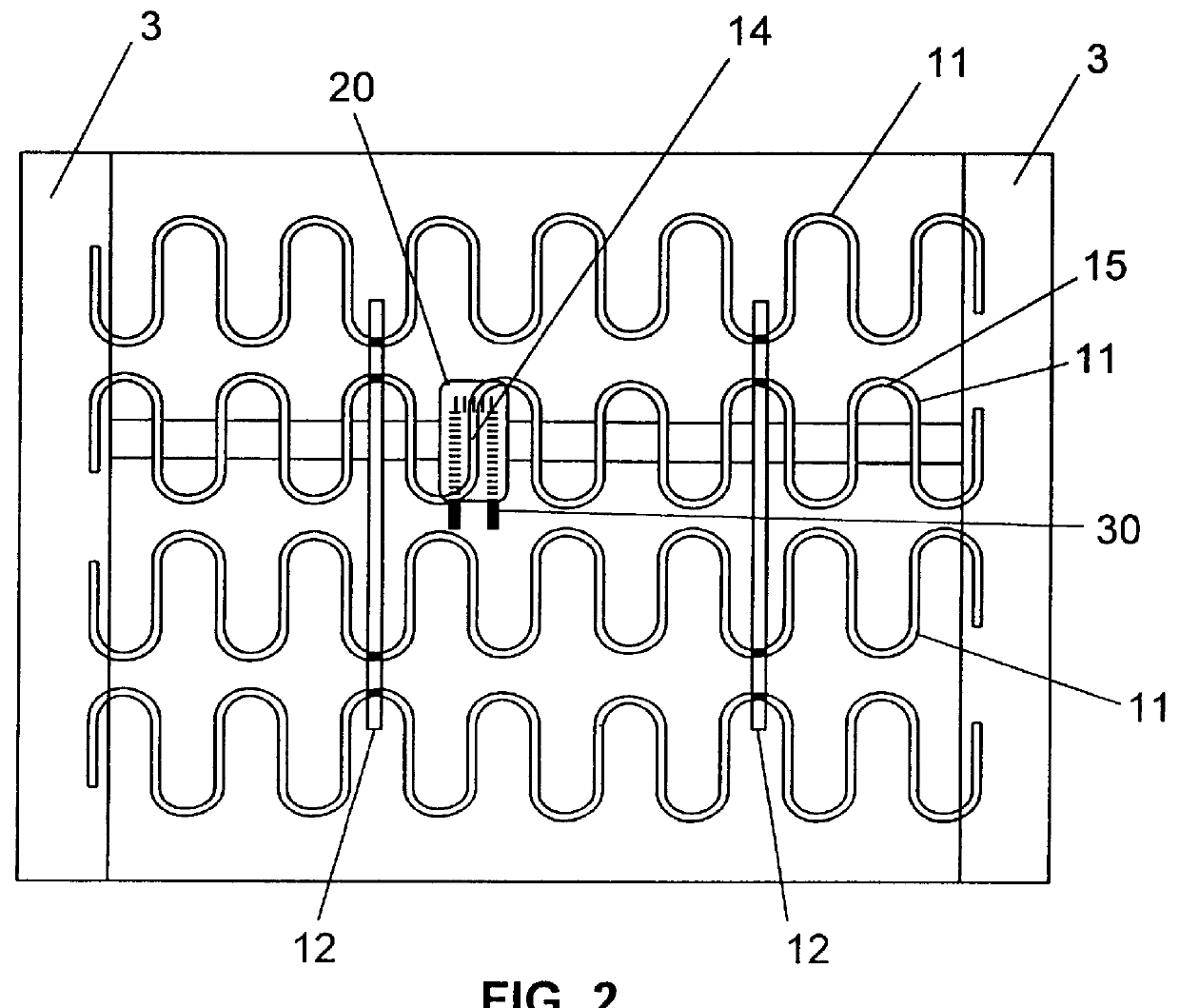

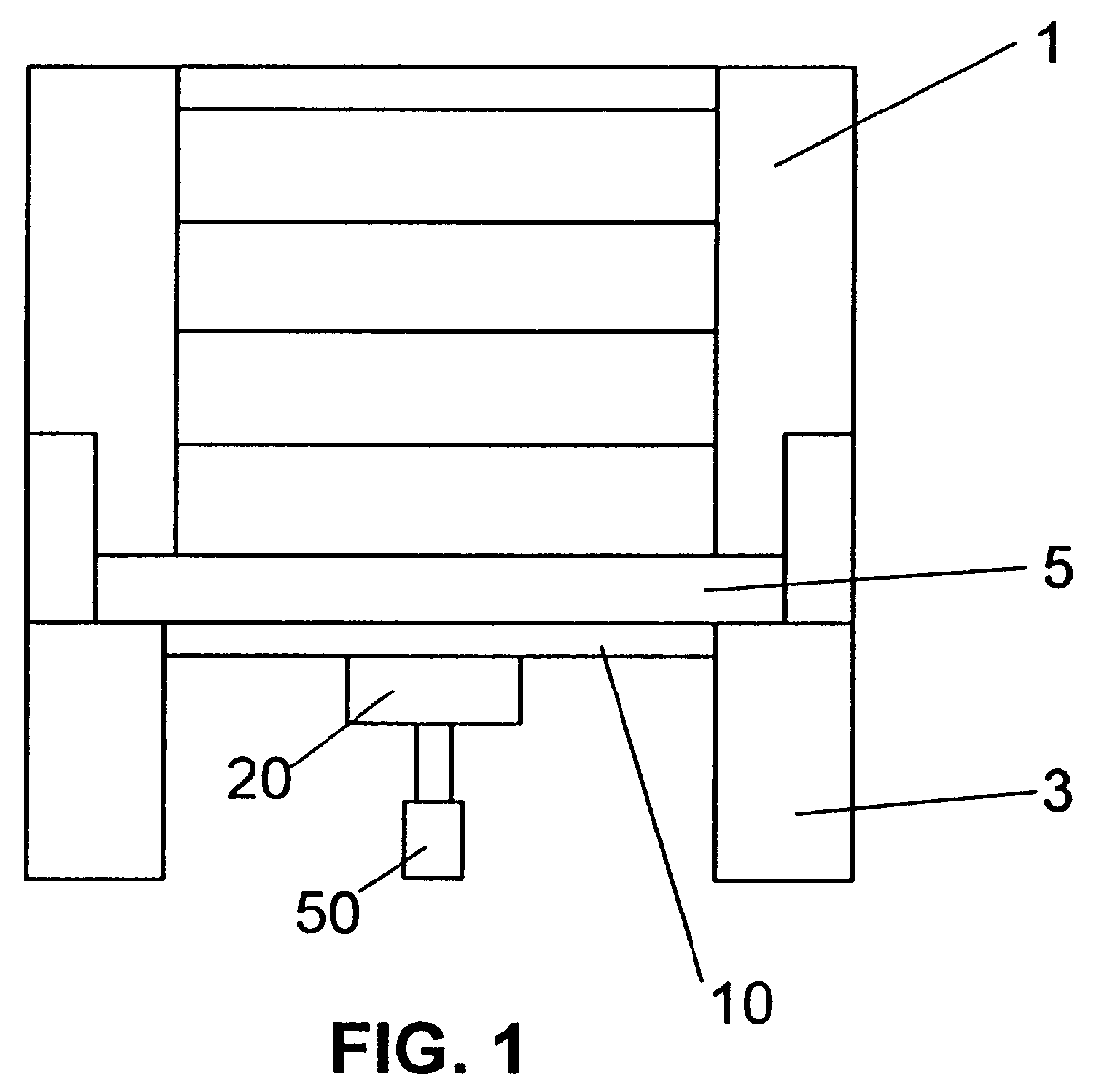

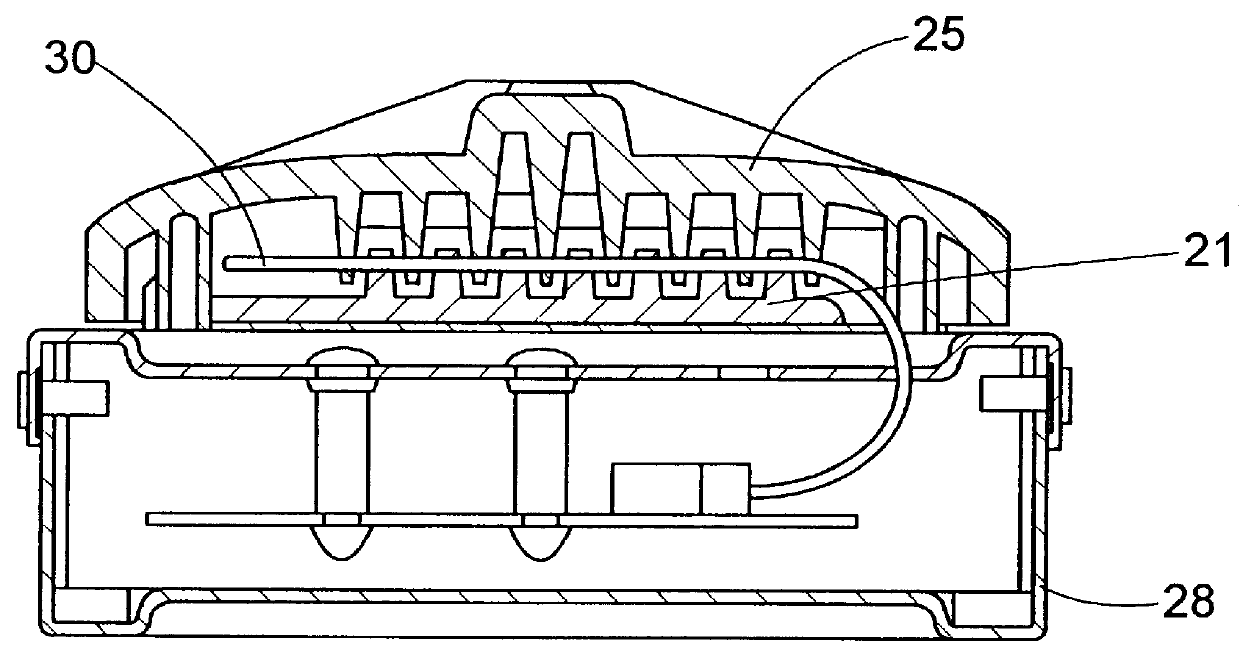

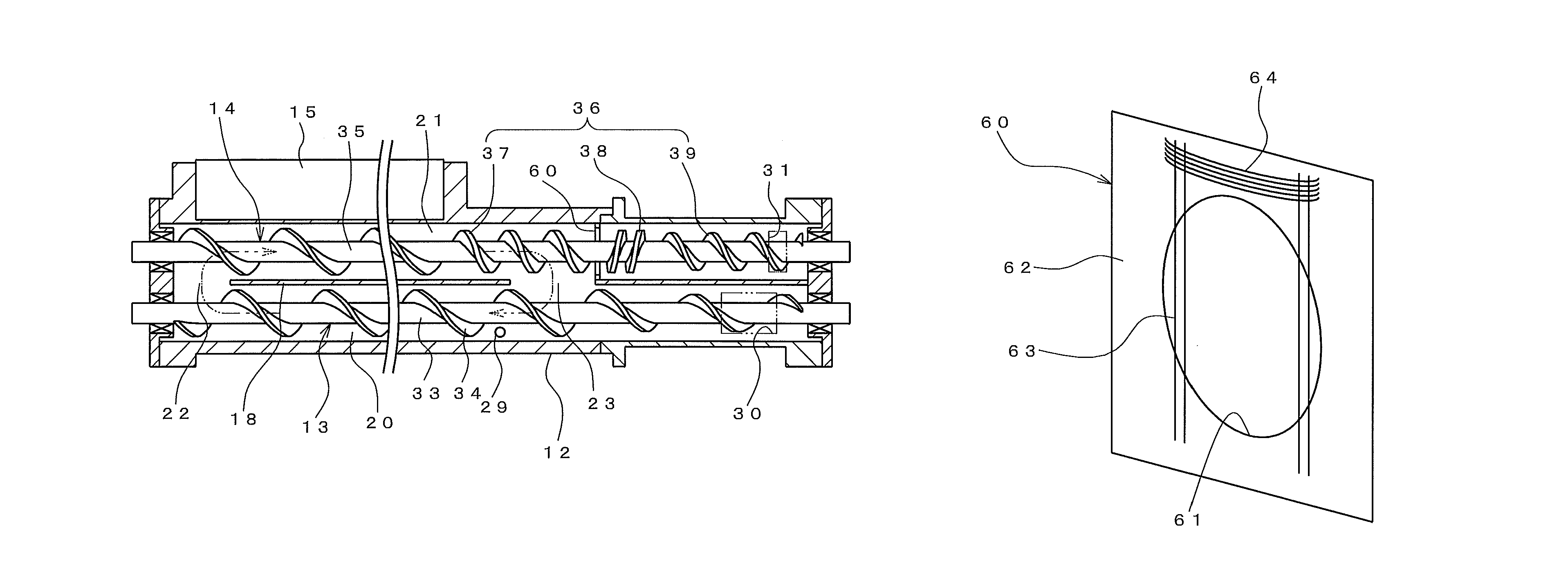

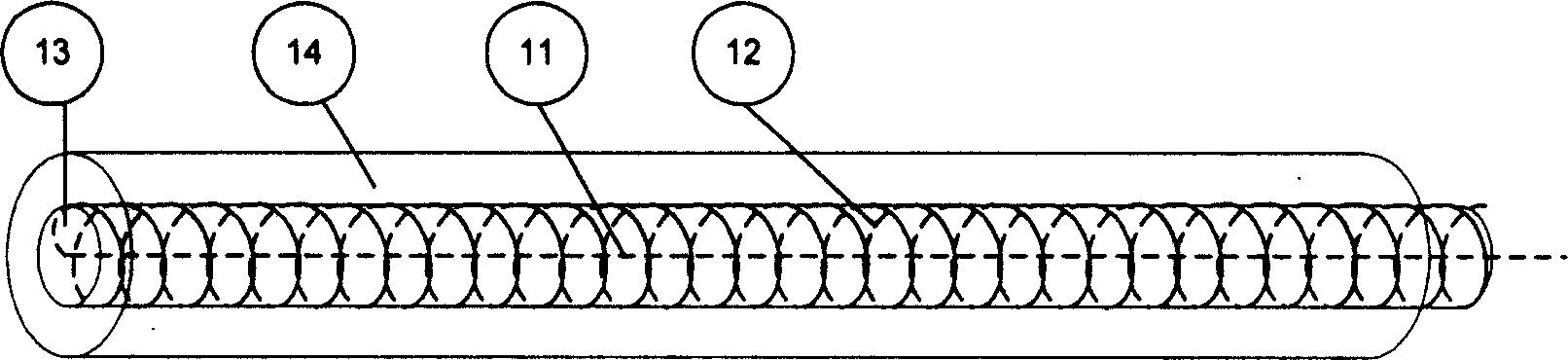

Biological-signal detecting device

InactiveUS6030347AImprove detection accuracyAvoid breakingStrain gaugePerson identificationBlood pressureEngineering

PCT No. PCT / JP97 / 00027 Sec. 371 Date Aug. 8, 1997 Sec. 102(e) Date Aug. 8, 1997 PCT Filed Jan. 9, 1997 PCT Pub. No. WO97 / 24976 PCT Pub. Date Jul. 17, 1997A biological-signal detecting device of a non-wrapper type for accurately detecting a biological signal of a user such as heartbeat number, respiration number or blood pressure, comprises a frame, a spring net fixed to the frame and having an elastic deformation capability to support a weight of the user, and a biological-signal detecting unit. The detecting unit is disposed on a second supporting surface of the spring net opposed to a first supporting surface of the spring net for receiving the weight of the user. The detecting unit determines the biological signal of the user according to a biological vibration which is a cyclic, minute load-variation of the user transmitted through the spring net when the weight of the user is supported by the spring net.

Owner:MATSUSHITA ELECTRIC WORKS LTD

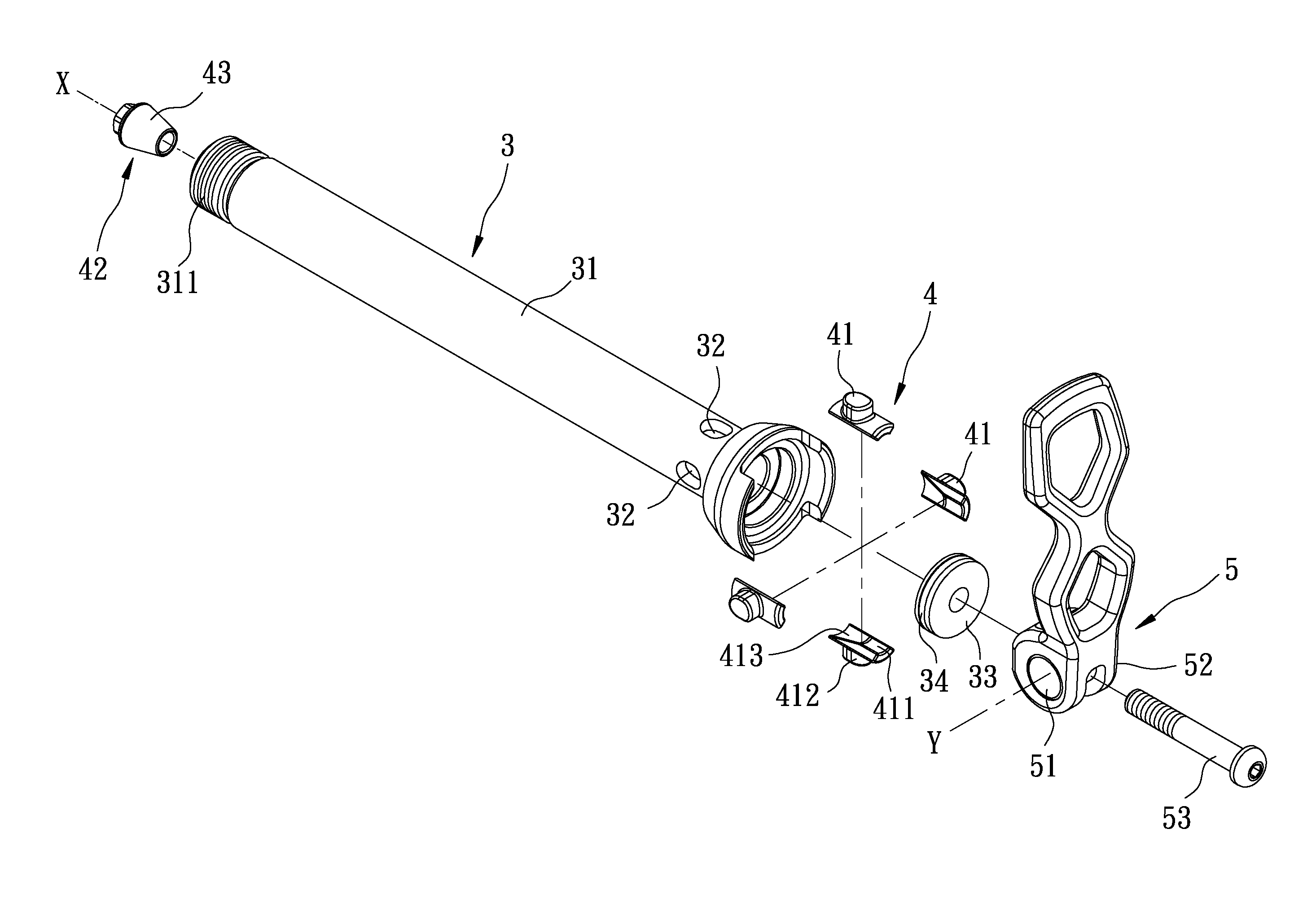

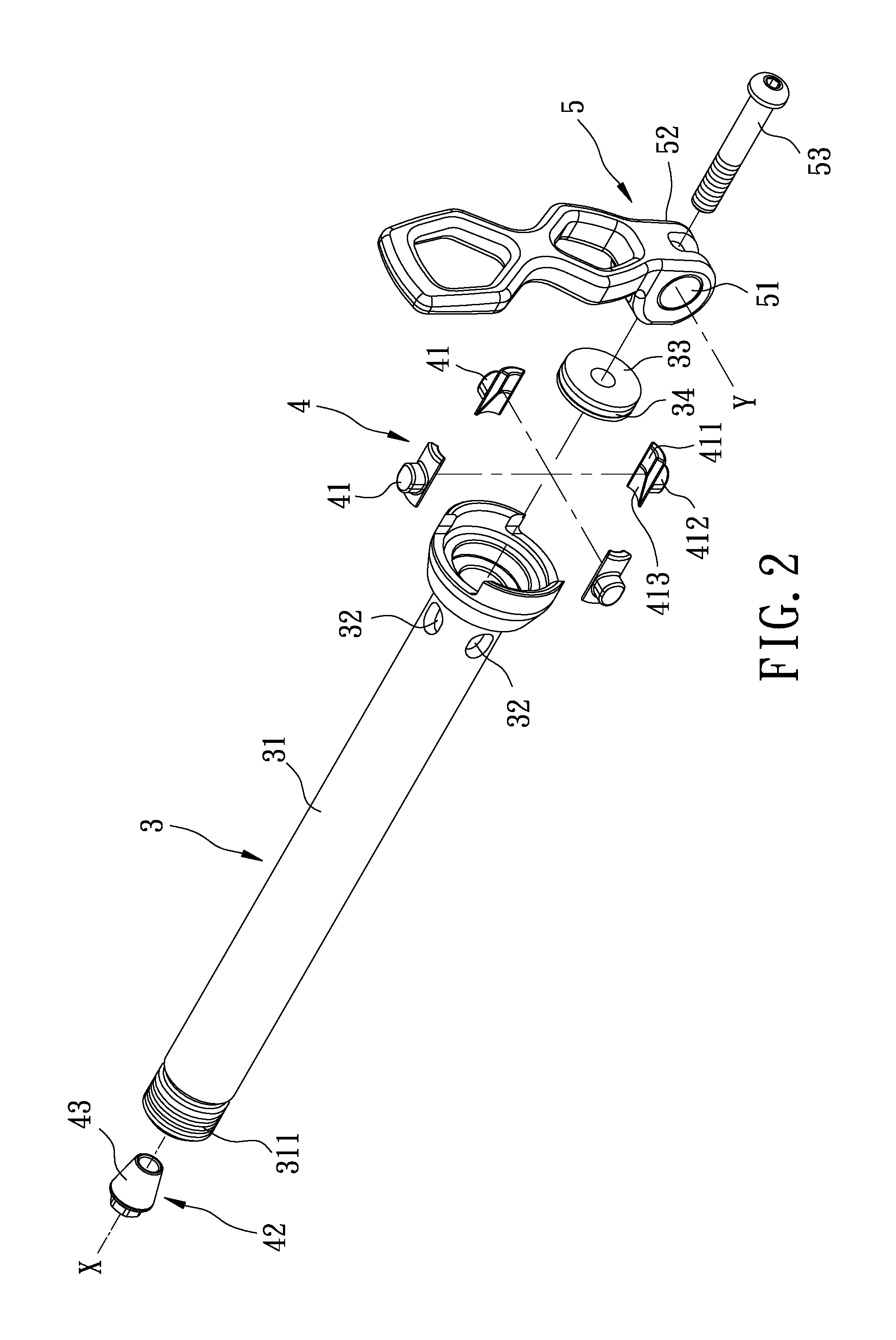

Quick release devices

Owner:APROTECH

Diet supplement for causing rapid weight loss, controlling appetite, managing stress, supporting relaxation, combating fatigue and supporting mental well-being

InactiveUS20060286183A1Rapid weight lossAppetite suppressantBiocidePeptide/protein ingredientsDietary supplementMental health

Compositions and methods for administering to the diet of humans a composition for inducing rapid weight loss, controlling appetite, managing stress and supporting mental well-being, supporting relaxation, and combating fatigue. A diet supplement comprising Calcium and Potassium double salt of Garcinia Cambogia Extract supplying 60% Hydroxycitric Acid, Gymnema Sylvestre Leaf Extract, Rhodiola Rosea Root Extract, Theanine, Astaxanthin Algae Extract, Chromium Polynicotinate, Hoodia Gordonii, N-olyl-phosphatidyl ethanolamine (NOPE) / EGCG blend, Vinpocetine, Russian Tarragon Extract, N-acetyl tyrosine, and Withania Somnifera Root Extract is provided. Said diet supplement is comprised of at least Hoodia Gordonii wherein the extract does not contain any extract from the root of the plant.

Owner:SMARTBURN FORMULATIONS LTD

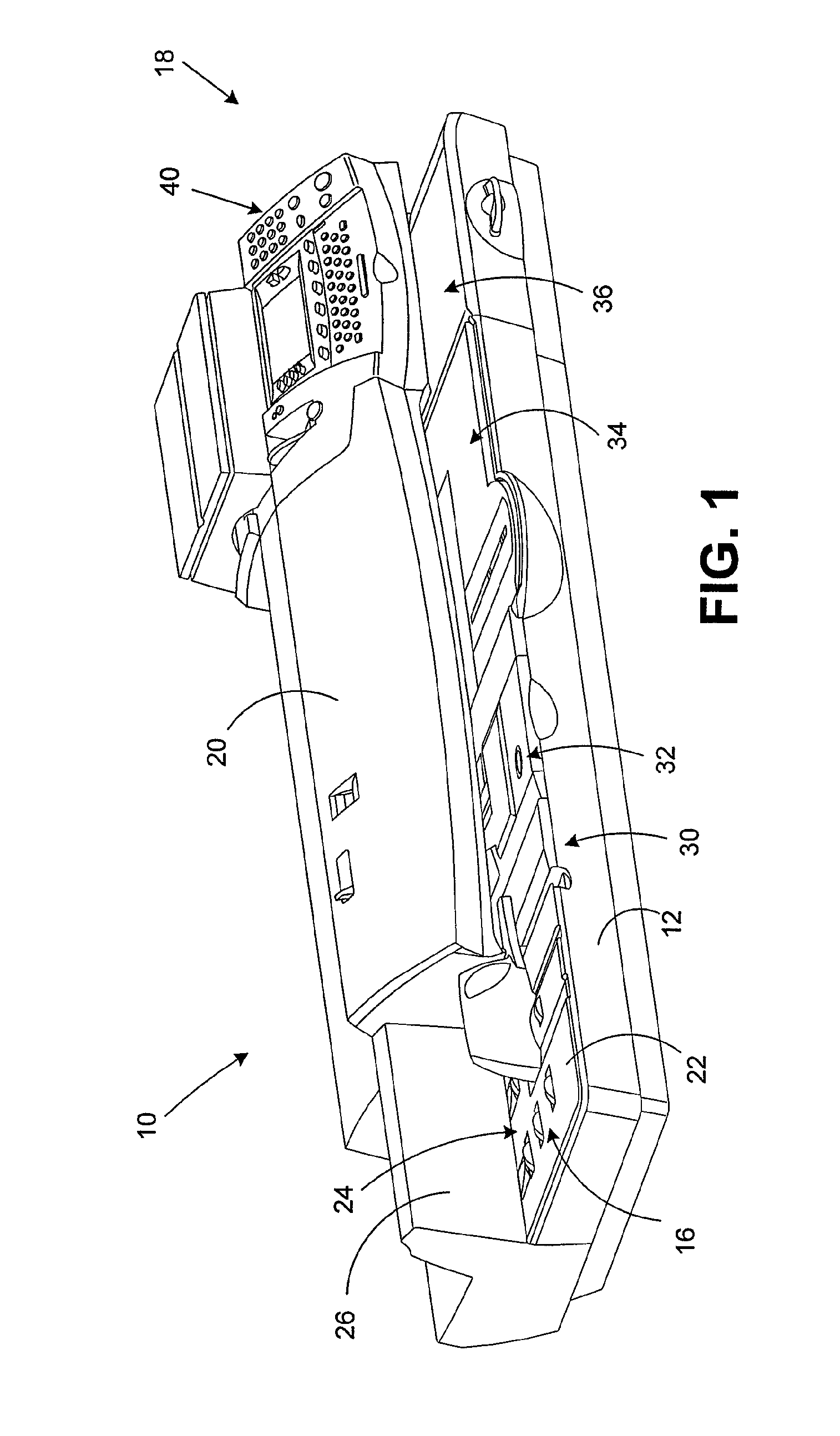

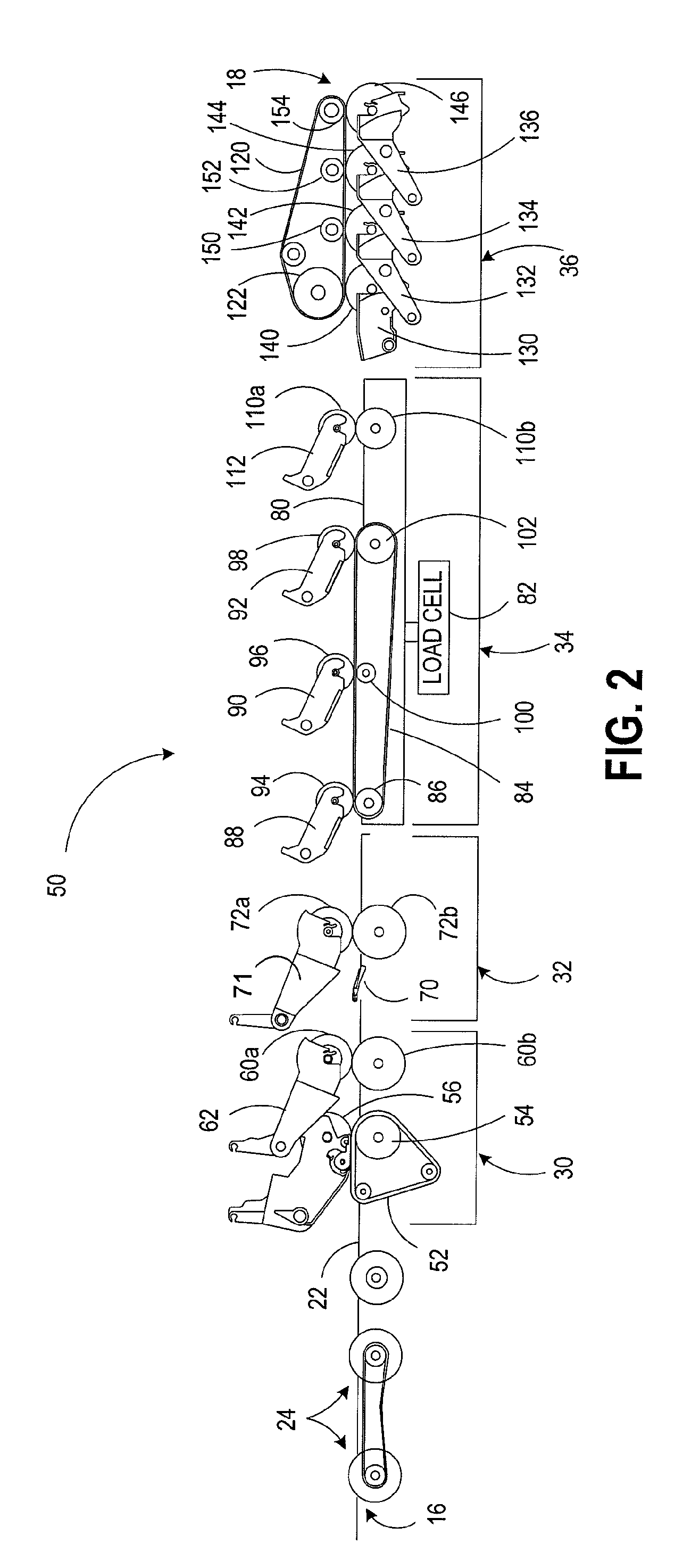

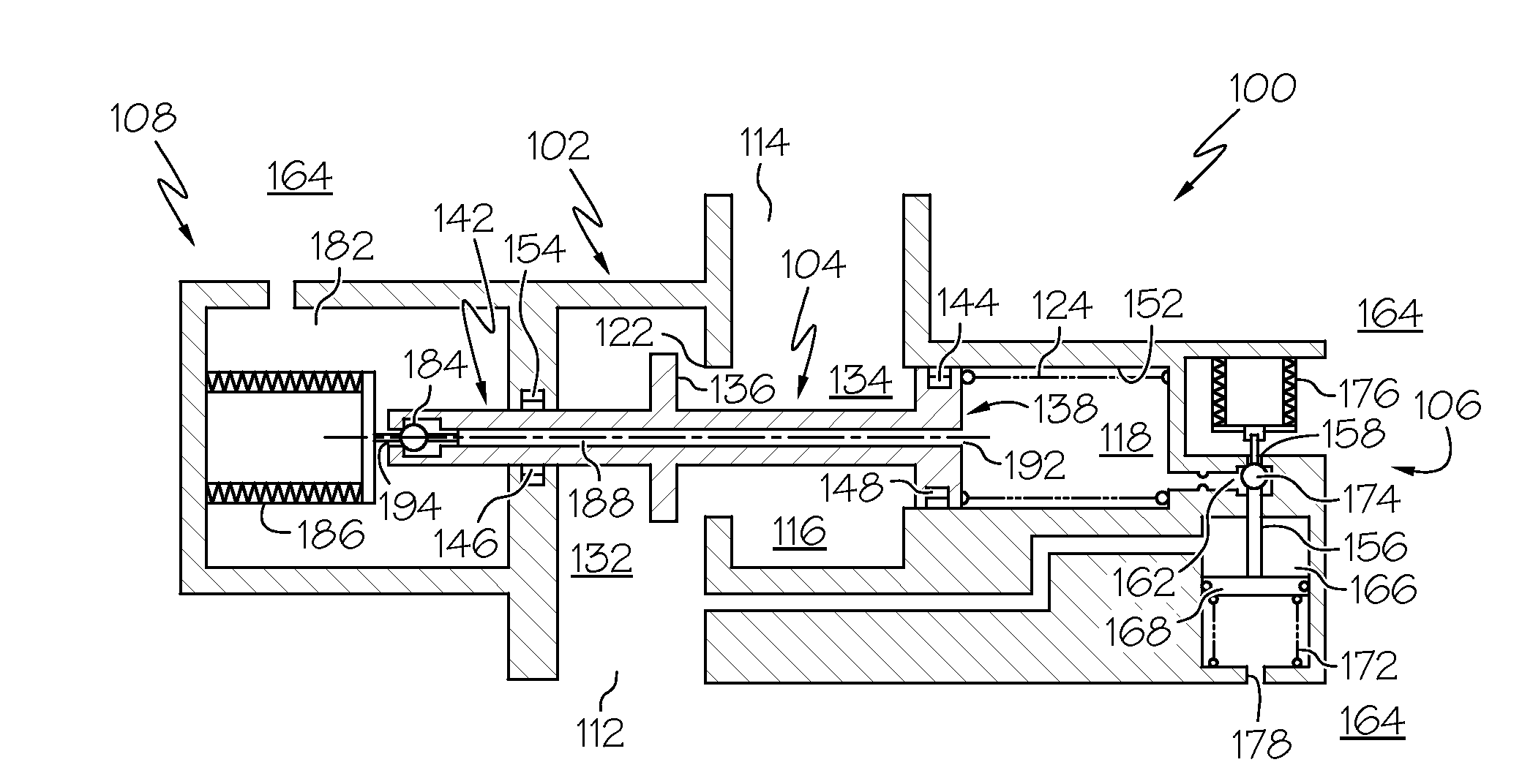

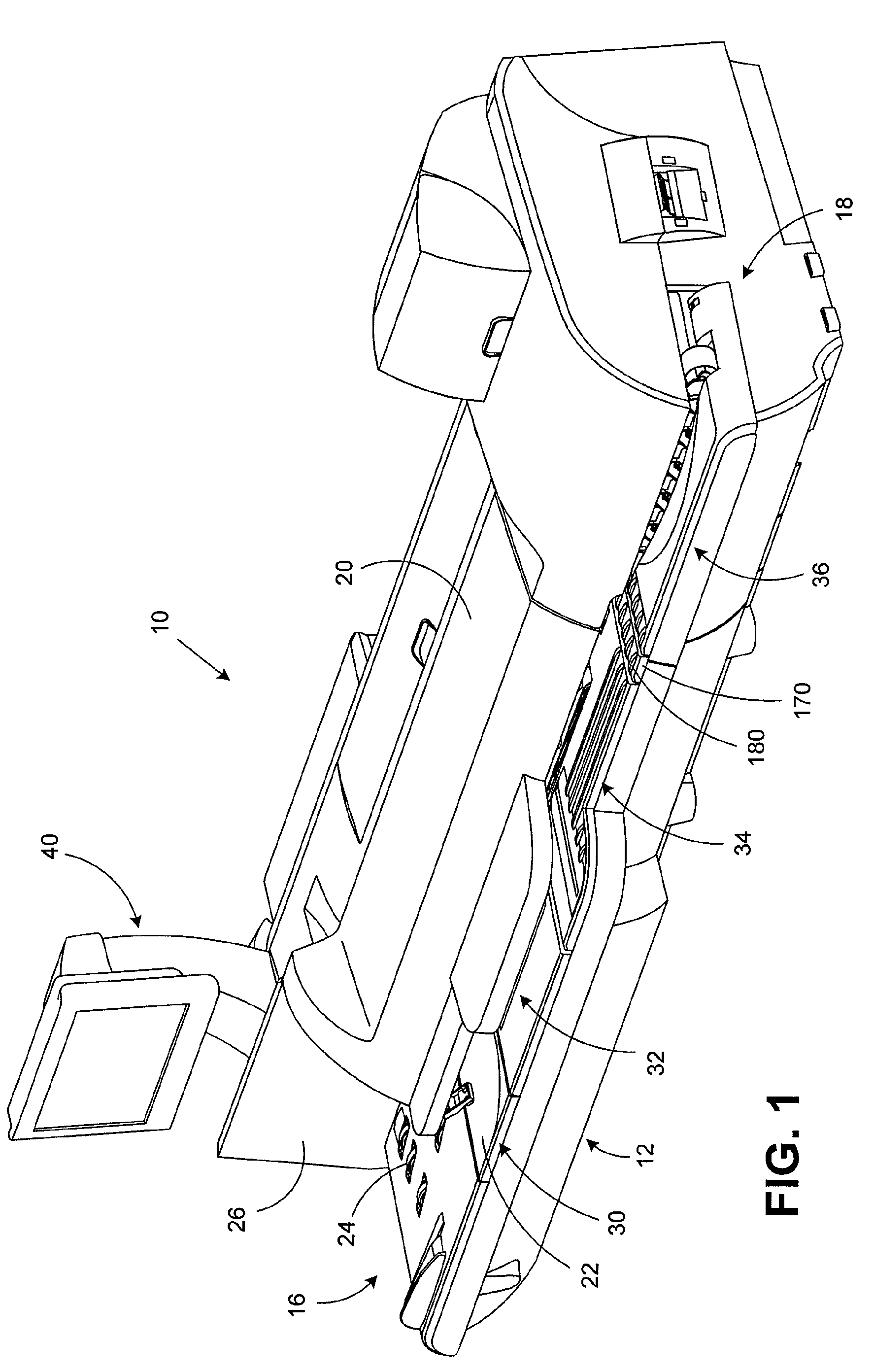

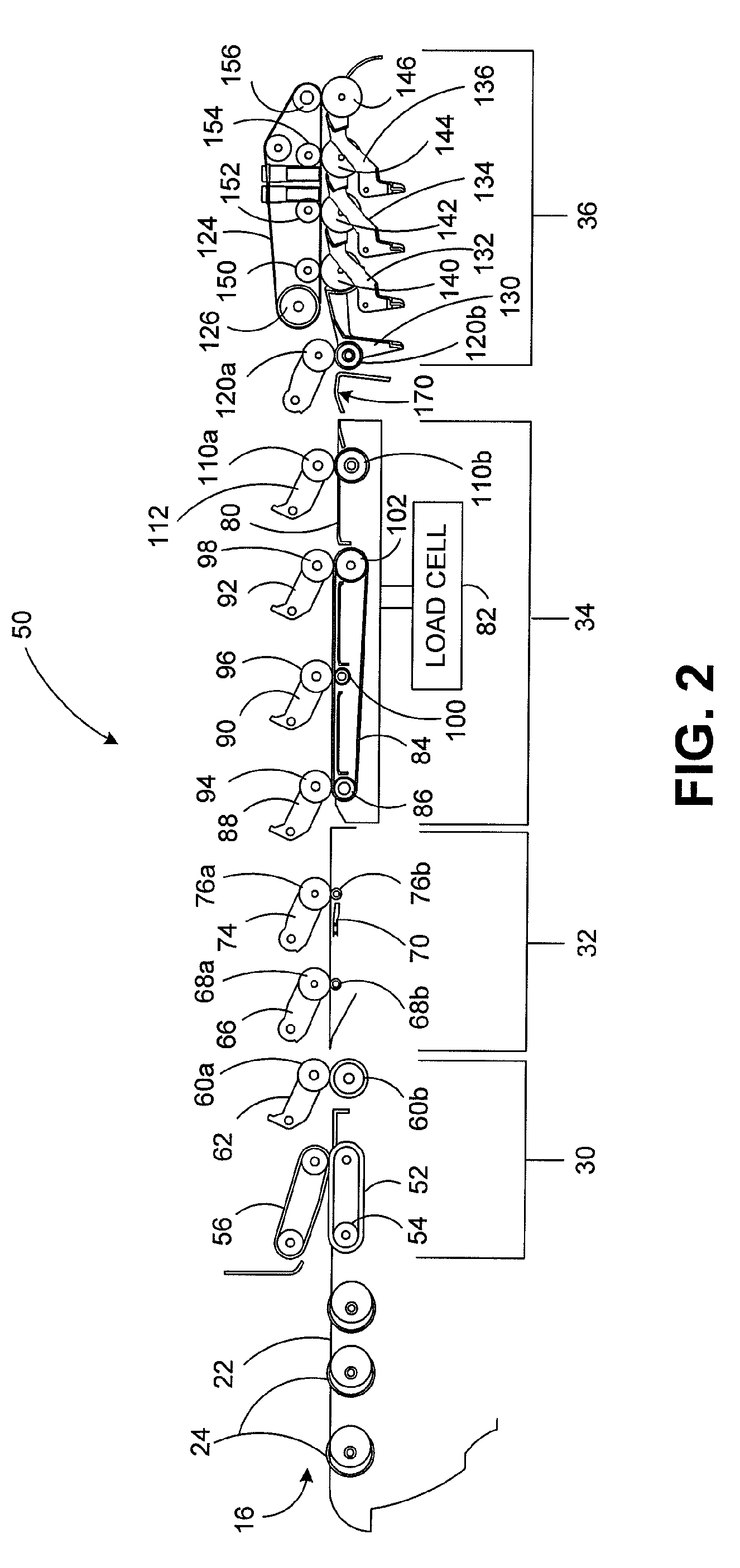

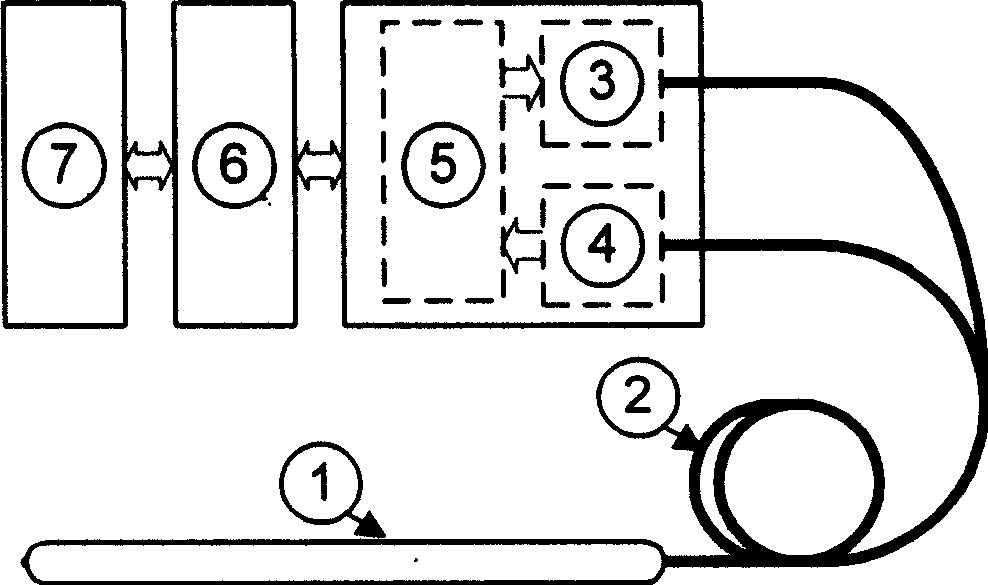

Mailing machine transport system with integral scale for weighing mail pieces where the contact force on the take away rollers is reduced to eliminate oscillations of the weighing platform

ActiveUS8148650B2Reduce oscillationFast weighingOscillations damping for weighingFranking apparatusTransport systemContact force

Owner:PITNEY BOWES INC

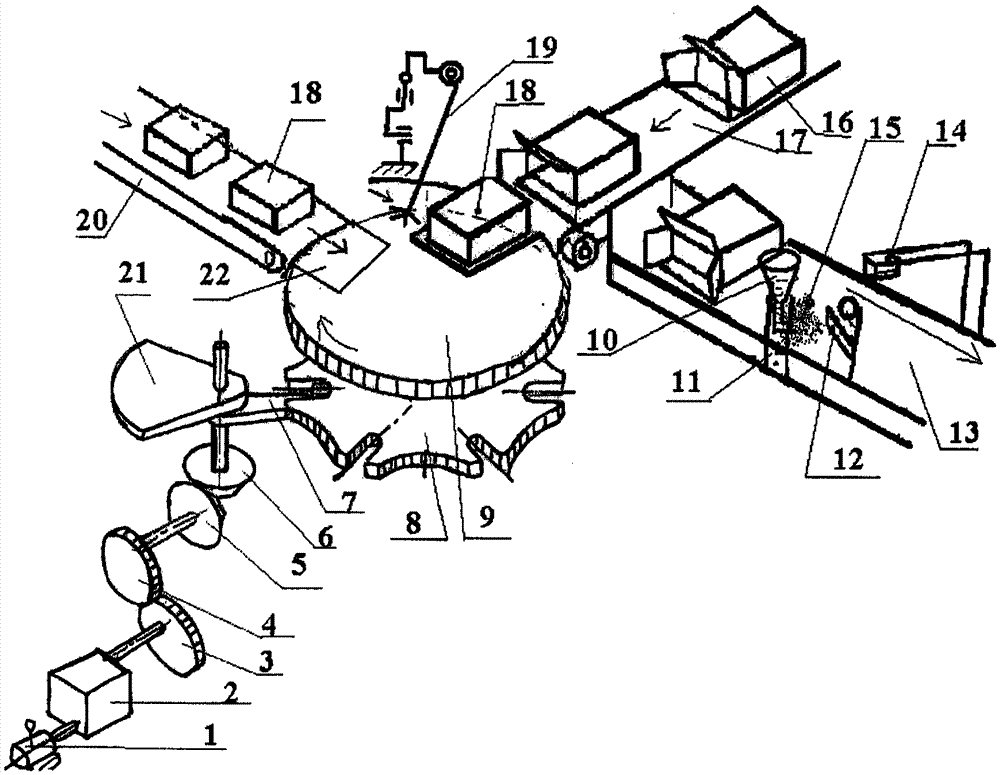

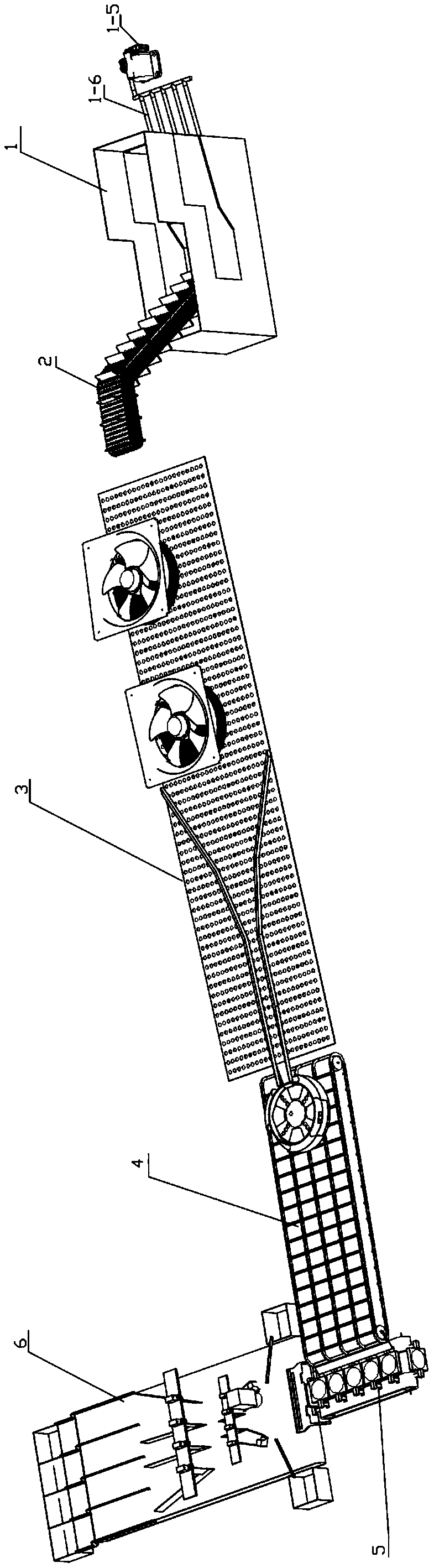

Automatic packaging equipment

InactiveCN105438534AFully automatedReduce labor intensityWrapper twisting/gatheringTransmission beltReduction drive

The invention relates to packaging automation flow-line equipment and particularly relates to automatic packaging equipment. The automatic packaging equipment comprises a goods transmission system, a cam indexing rotary plate transmission system, an empty box transmission system and a package seal printing system, and is characterized in that the goods transmission system comprises goods and a goods transmission belt; the cam indexing rotary plate transmission system is composed of a motor, a speed reducer, a small elliptical gear, a large elliptical gear, a small cone gear, a large cone gear, a connecting rod, a grooved wheel, a rotary plate, a driver plate and a groove; and the grooved wheel and the rotary plate are assembled on the same shaft through two common flat keys. Due to the adoption of the automatic packaging equipment provided by the invention, the labor intensity of tedious work such as manual package, production date printing and the like can be lowered greatly, detecting automation and serialization can be achieved, the sealing operation is convenient, the weighting speed is fast, and the practicability is strong.

Owner:徐怡恺

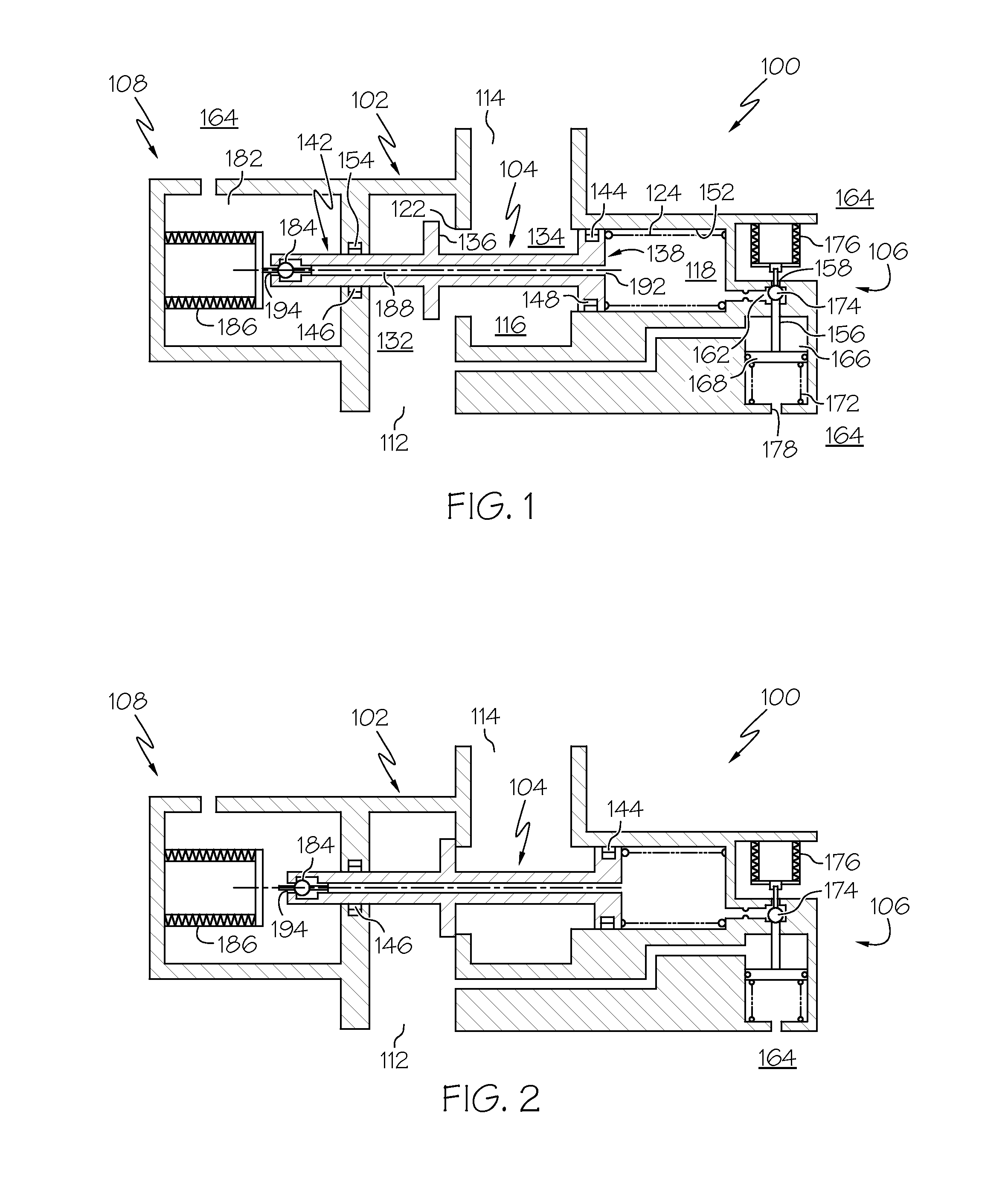

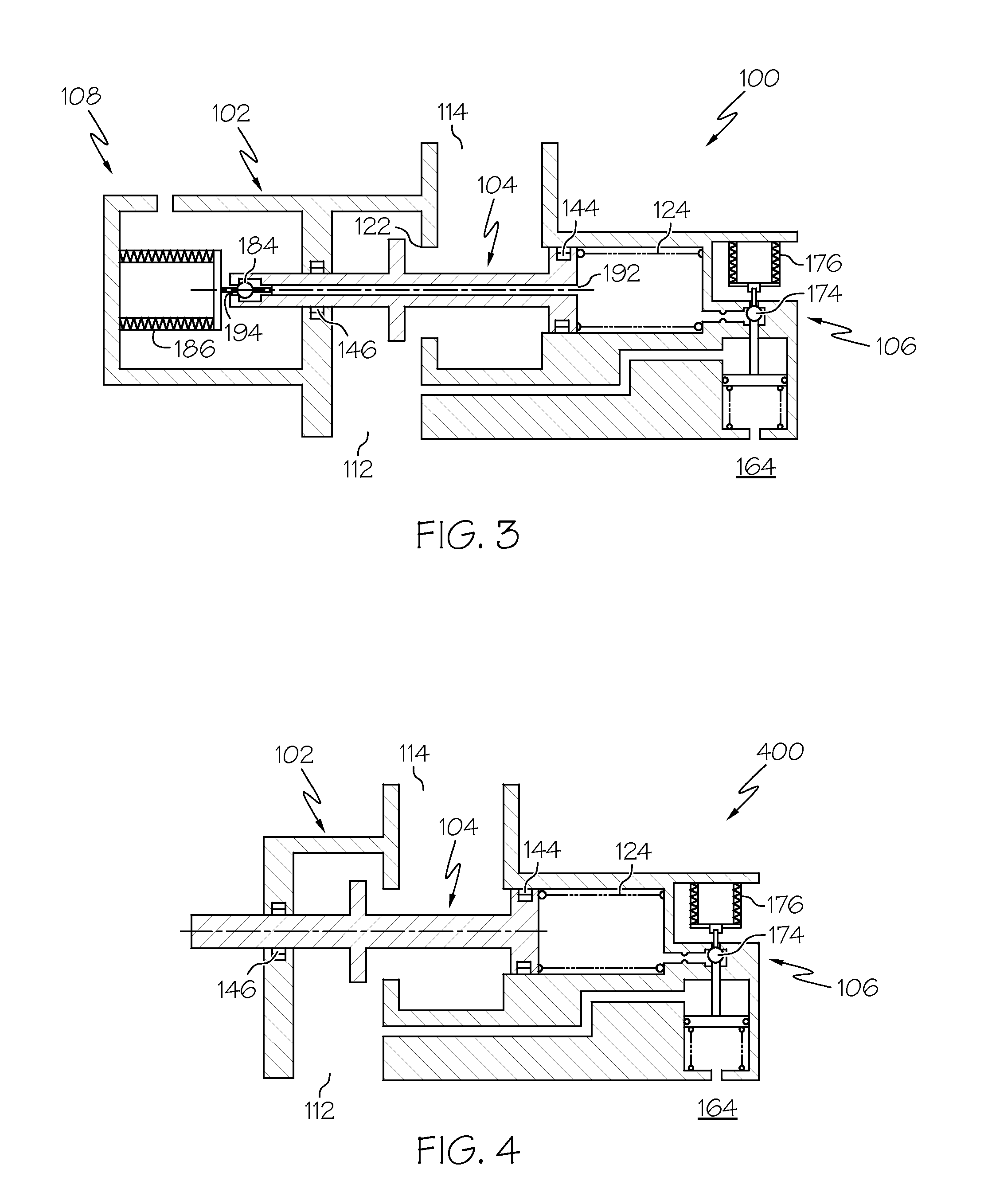

Pressure and flow altitude compensated shutoff valve

ActiveUS20130312843A1High altitudeQuickly in volumeOperating means/releasing devices for valvesEqualizing valvesEngineeringControl valves

A pressure and flow altitude compensated shut off valve includes a valve body, a valve element, and an altitude compensation pilot valve. The valve body has an inlet port, an outlet port, and a flow passage extending between the inlet port and the outlet port. The valve element is disposed within the flow passage and is responsive to fluid pressure at the inlet port to move between a closed position, in which fluid may not flow through the flow passage, and a plurality of open position between the closed position and a full-open position. The altitude compensation pilot valve is coupled to the valve body and is responsive to pressure variations at the second port to control the fluid pressure at which the valve element moves to the closed and open positions.

Owner:HONEYWELL INT INC

Concrete preparation method

InactiveCN108214863AWell mixedExpand the scope of workDischarging arrangementCeramic shaping plantsRaw materialCivil engineering

The invention relates to the technical field of concrete preparation, in particular to a concrete preparation system and method. The concrete preparation system comprises a raw material weighing device, a raw material mixing device, a pouring-into-mold device, a curing device, a demolding device and a mold cleaning device. Through reasonable arrangement of the above processes and coordination anddistribution of responsibilities, concrete is prepared, an automatic process of concrete preparation is realized, labor is saved, work efficiency is improved, and use is convenient.

Owner:湖南道同消防工程有限公司

Branched low profile additives and methods of production

Owner:ASHLAND LICENSING & INTPROP LLC

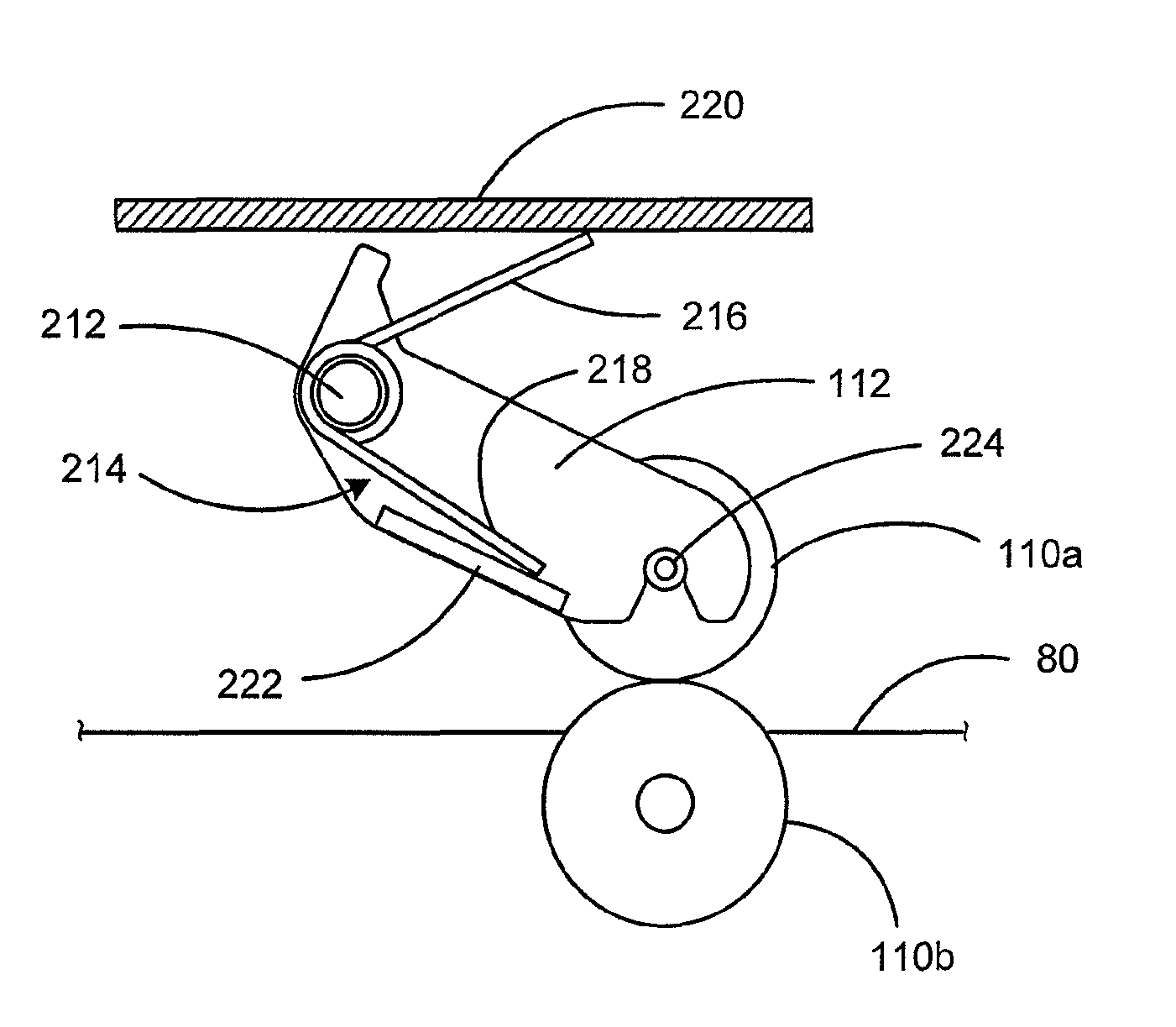

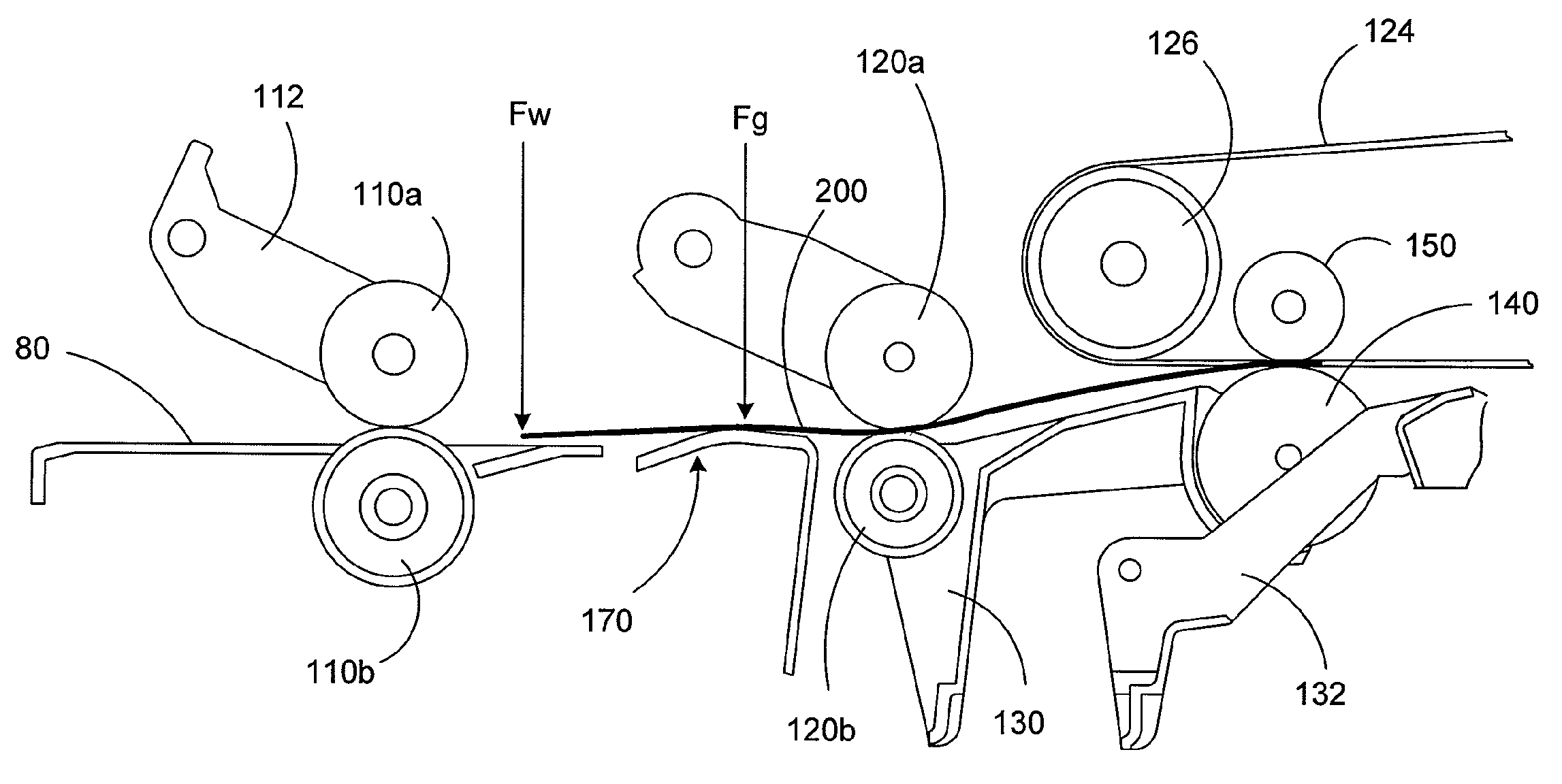

Mailing machine transport system including a guide to reduce the impact on the weighing device caused by the trailing edge of the mailpeice

ActiveUS8178796B2Reduce external forceFast weighingWeighing apparatus detailsFranking apparatusTransport systemTrailing edge

A mail processing system having a transport that reduces the amount of oscillation of the scale to allow for faster weighing of mail pieces is provided. A mailing machine includes a plurality of different modules through which mail pieces are fed by a transport system. A guide piece is provided in the transport path between the weighing module and the subsequent module, e.g., a printing module. The guide piece is structured such that forces imparted on the weighing platform of the weighing module by the trail edge of a mail piece being transported off of the weighing platform are reduced. Because of the reduction in this significant external force on the weighing platform, a faster weighing algorithm can be used on more mail pieces, thereby increasing the throughput of the mailing machine.

Owner:PITNEY BOWES INC

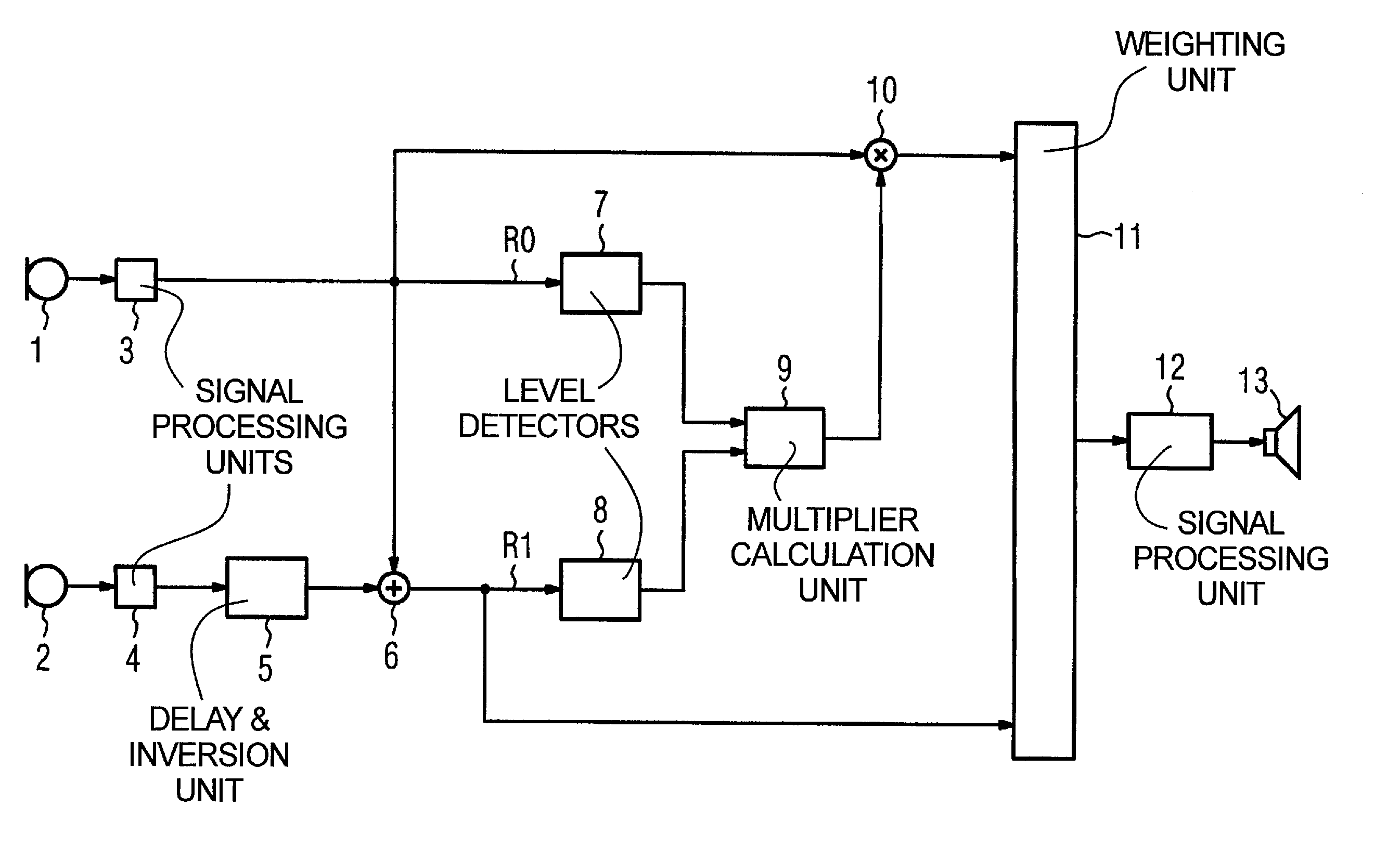

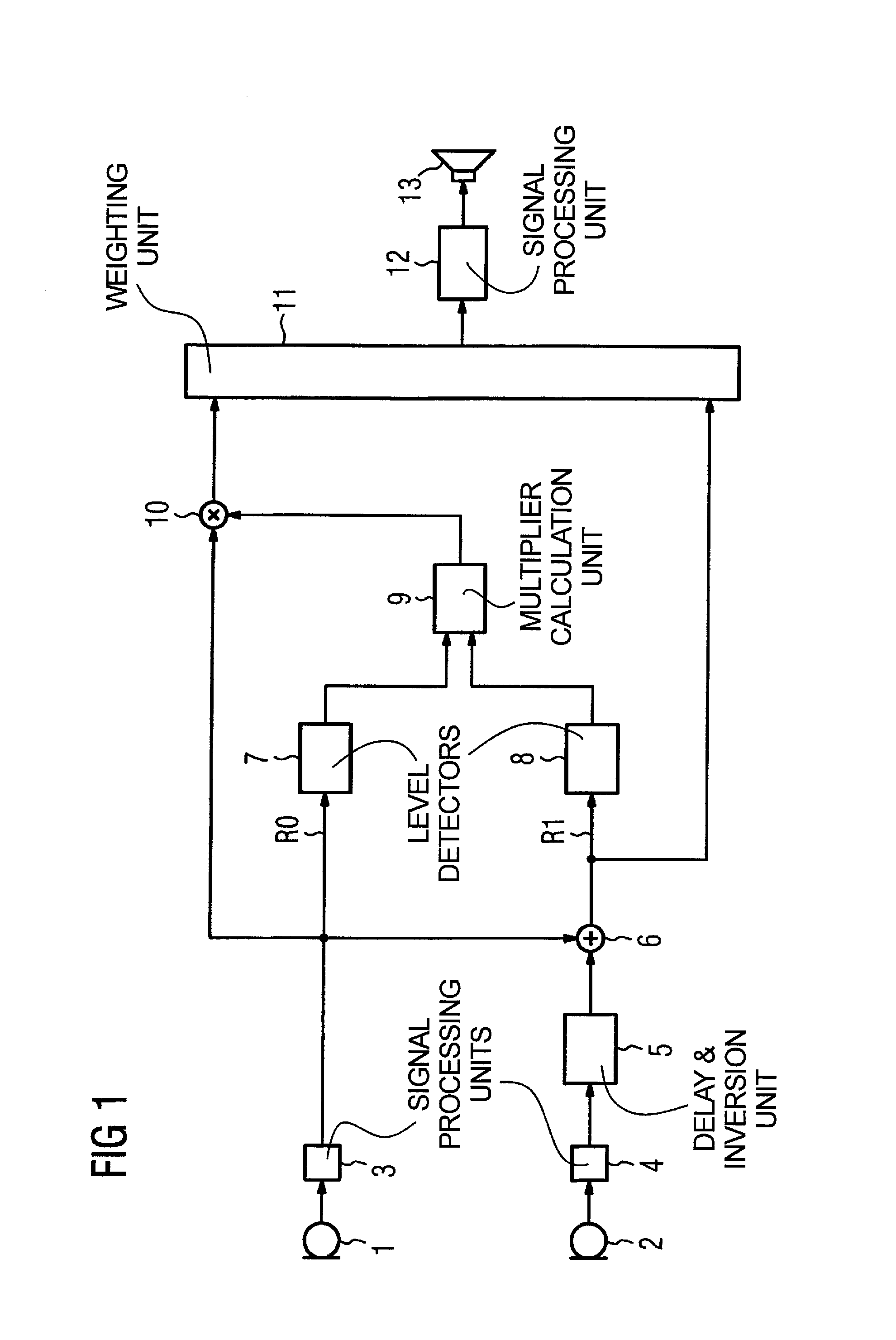

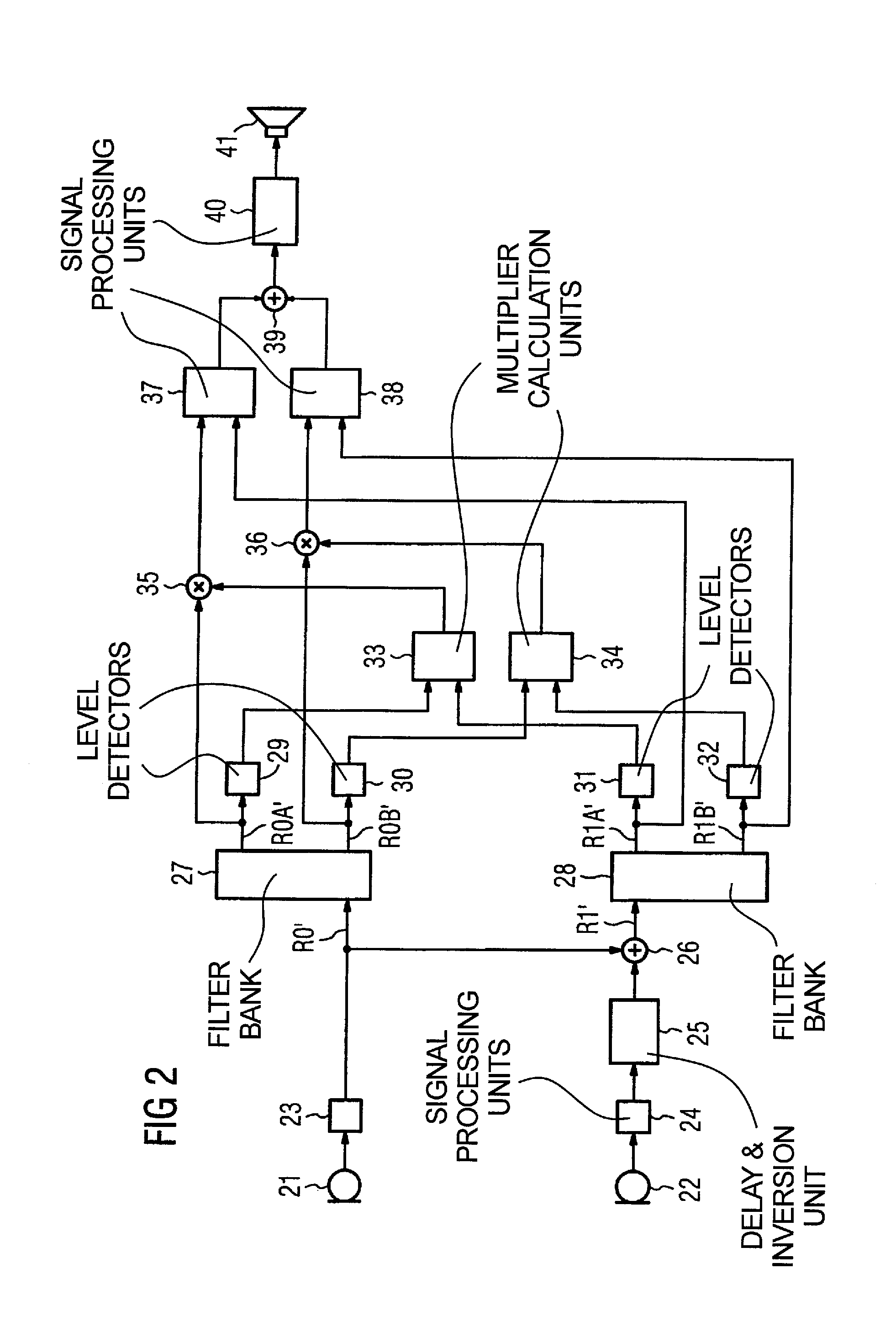

Hearing aid and operating method with switching among different directional characteristics

InactiveUS7340073B2Precise positioningFast weighingMicrophonesElectronic input selection/mixingSuperimpositionHearing aid

In a hearing aid having a microphone system composed of multiple microphone units, in order to avoid artefacts from being created when switching between different directional characteristics, the signal levels of microphone signals that respectively originate from different microphone units with different-order directional characteristics are matched with regard to a reference signal. The switching or superimposition is then always carried out between microphone signals with the same signal level, so that the switching or superimposition does not result in any sudden level changes.

Owner:SIVANTOS PTE LTD

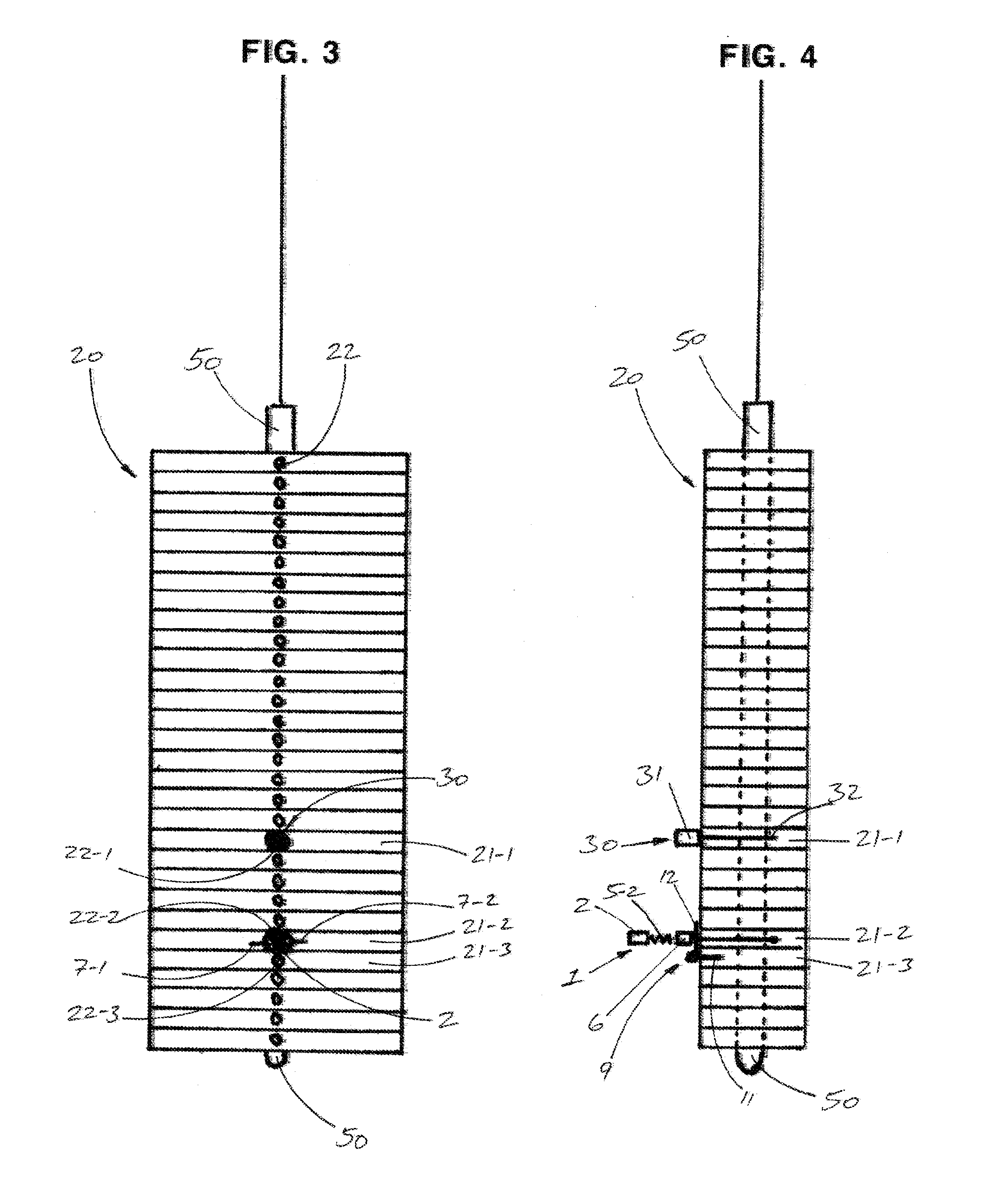

Drug weighing detection system

InactiveCN102954831ASimplify the weighing inspection processFast and efficient weighing detectionWeighing apparatus with automatic feed/dischargeControl systemInteraction interface

The invention relates to a drug weighing detection system, which comprises a control system, a drug tablet delivery system and a weighing sensor system. The drug tablet delivery system comprises a drug leaking mechanism, a drug shifting mechanism and a drug separating mechanism, and the weighing sensor system is arranged between the drug leaking mechanism and the drug shifting mechanism; wherein the drug leaking mechanism comprises a drug leaking motor connected with the control system, and the output of the drug leaking motor is connected with a pipeline for filling of drug tablets and a rotary block for controlling the drug tablets in the pipeline; the weighing sensor system comprises a weighing platform and a weighing sensor, and the weighing sensor is arranged at the lower end of the weighing platform and is connected with the control system; the drug shifting mechanism is arranged on the weighing platform and comprises a drug shifting motor with a drug shifting rod, and the drug shifting motor is connected with the control system; the drug separating mechanism comprises a drug separating motor with a drug separating frame, and the drug separating motor is connected with the control system; and the control system comprises a measurement and control system and a human-computer interaction interface. The drug weighing detection process can be simplified, and the weighing detection of drug units can be made rapider and more efficient.

Owner:BEIJING UNIV OF POSTS & TELECOMM

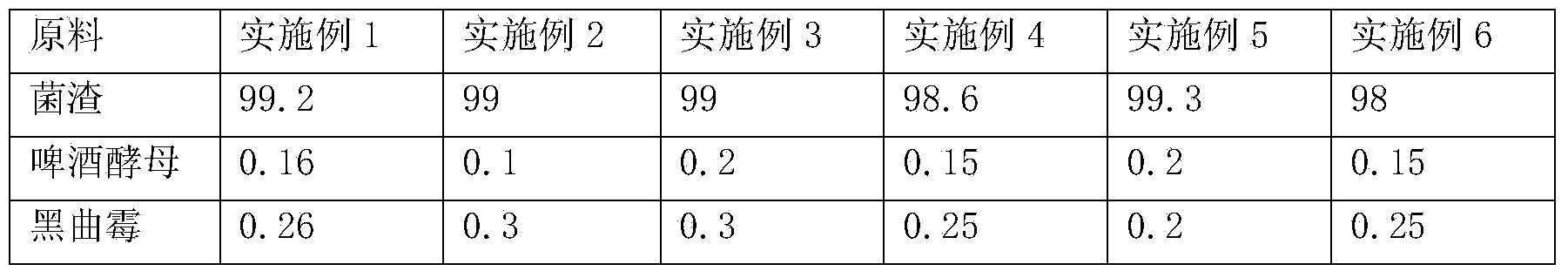

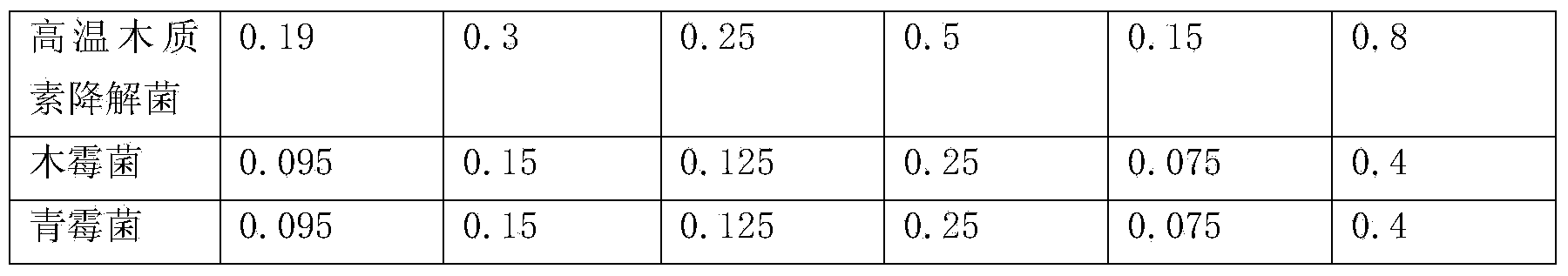

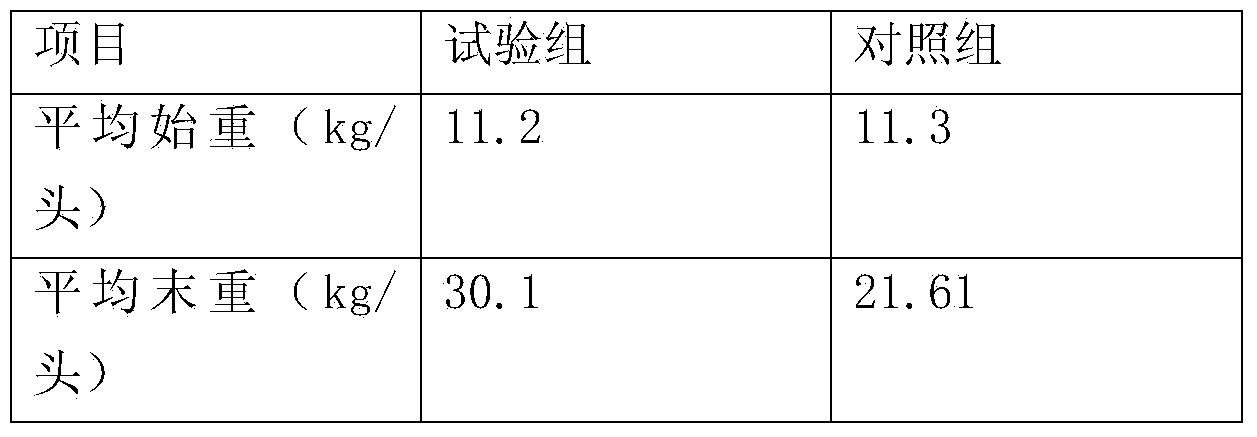

Mushroom dreg feed and preparation method thereof

The invention relates to a mushroom dreg feed. The mushroom dreg feed contains the following raw materials in parts by weight: 95-99.5 parts of mushroom dregs, 0.1-0.2 part of saccharomyces cerevisiae, 0.2-0.3 part of aspergillus niger and 0.3-0.4 part of compound strains. According to the mushroom dreg feed, a main raw material of the mushroom dregs is mulberry twig powder which is rich in microelements, such as amino acid, iron, calcium, zinc and magnesium, and a disease resisting system is formed by some metabolites, a trace amount of phenolic substances, creatine, polypeptides, sterol and the like, so that the disease resistance of cattle and sheep can be improved.

Owner:四川绿食佳农业有限公司

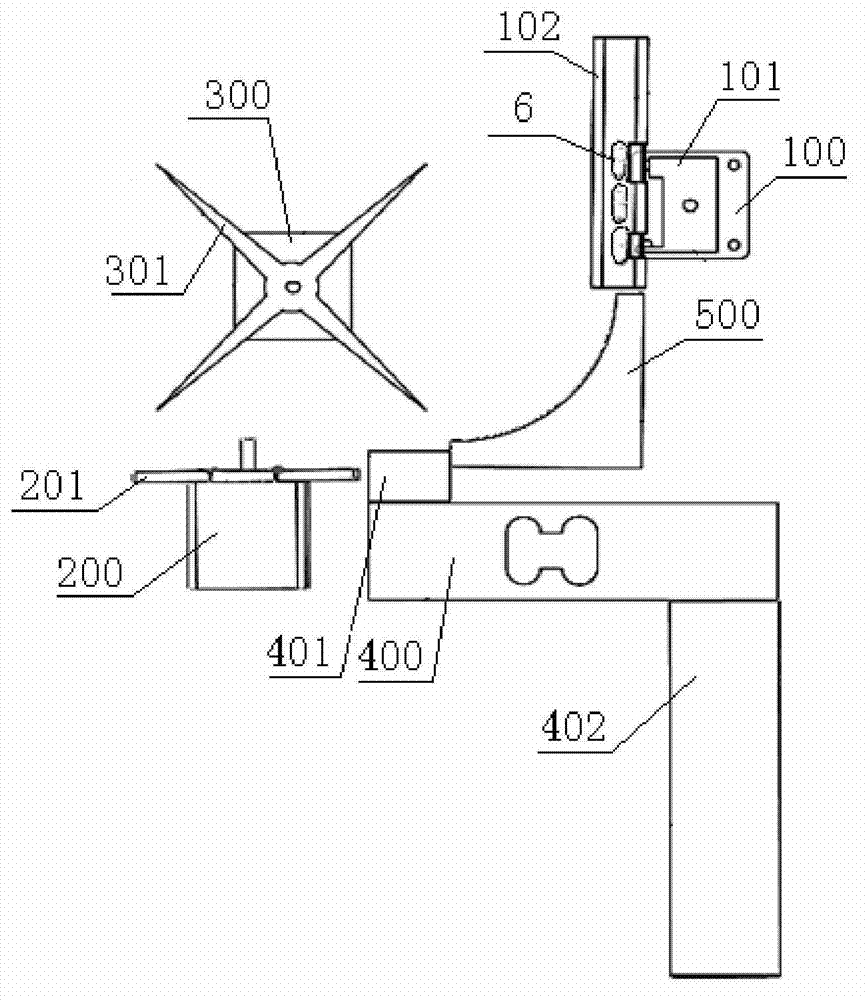

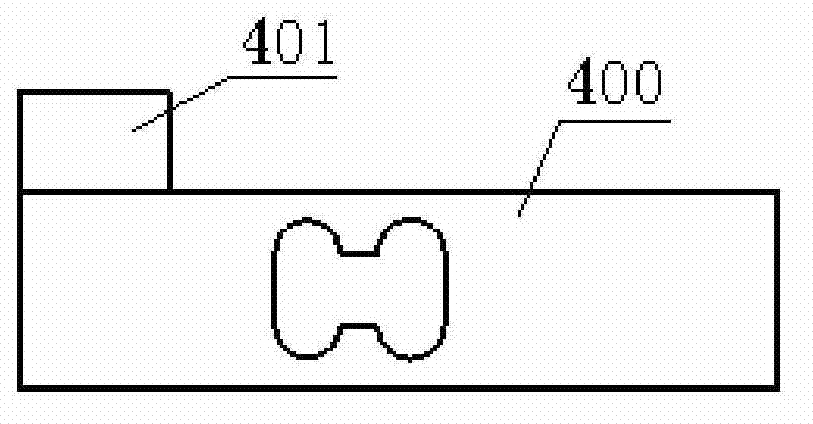

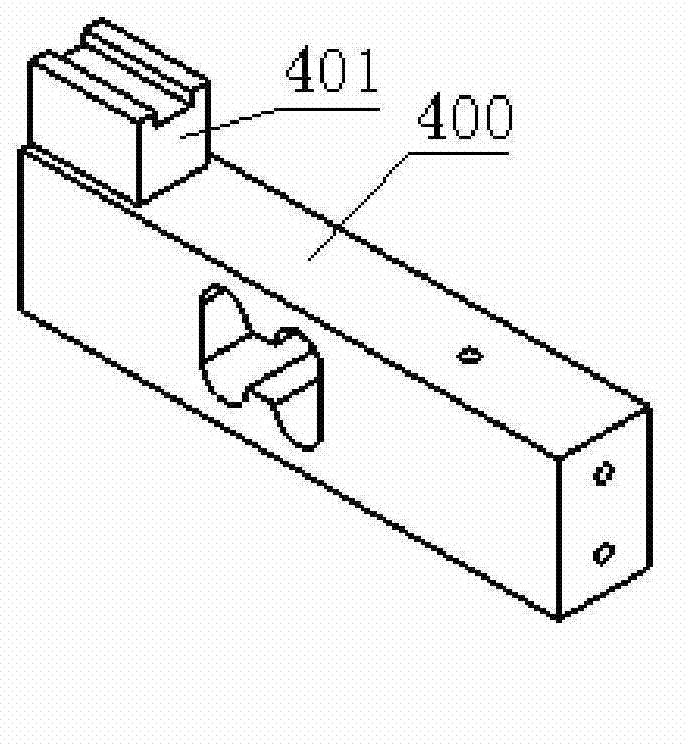

Cigarette weight sorting device

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Diet supplement for causing rapid weight loss, controlling appetite, managing stress, supporting relaxation, combating fatigue and supporting mental well-being.

InactiveUS20070237786A1Fast weighingAppetite suppressantBiocideMetabolism disorderDietary supplementMental health

Owner:SMARTBURN FORMULATIONS LTD

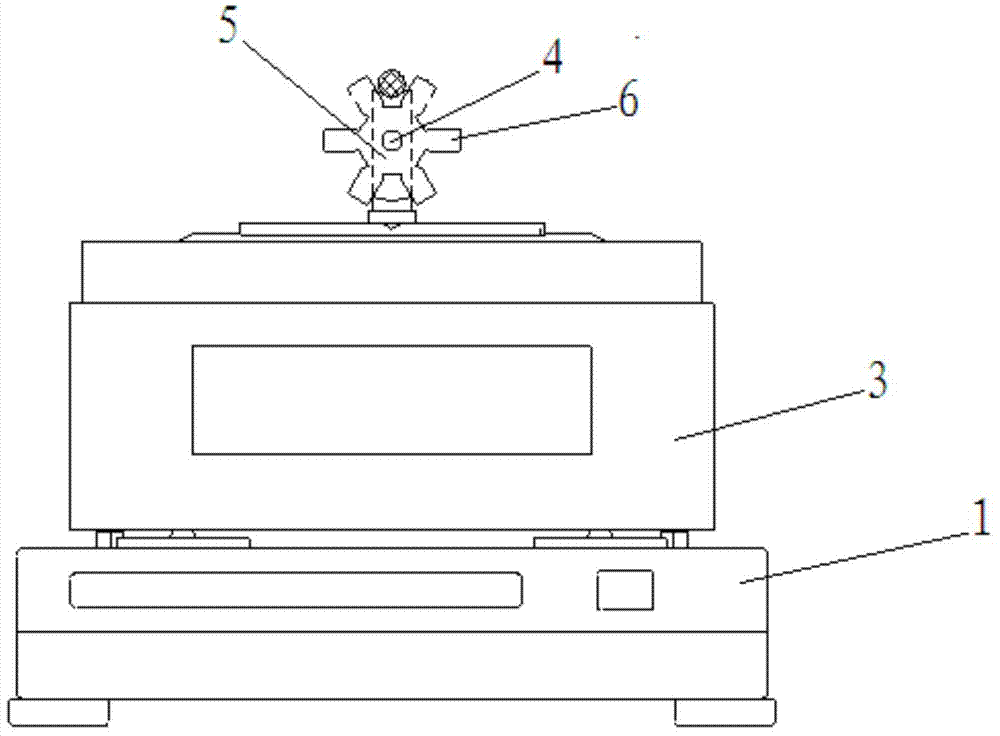

Weighting test instrument device and manufacturing method thereof

InactiveCN106493088AAccurate rotation positioningRealize automatic flipWeighing apparatus for materials with special property/formSortingTester deviceEngineering

The invention provides a weighing test instrument device and a manufacturing method thereof. The weighing test instrument device comprises a feeding unit, a weighing sorting unit, a discharging unit and a control unit. The control unit controls the feeding unit to deliver to-be-weighed materials to overturning balances of the weighing sorting unit separately; the overturning balances weigh the materials separately and feed weighing data back to the control unit; and the control unit controls a rotary table to rotate to the positions above target material receiving cases according to sorting standards, the overturning balances are overturned, and weighed and sorted materials are placed into the target material receiving cases separately. By adoption of the weighing test instrument device and the manufacturing method thereof, the technical problems that when an existing weighing test instrument device is used for weighting, testing and sorting batch materials, time and labor are wasted, and much manpower is needed for sorting out the materials are solved, and accordingly, the technical effects that the batch materials are automatically fed separately, rapidly weighed, precisely sorted and discharged in a batched mode in time through the weighing test instrument device are achieved.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

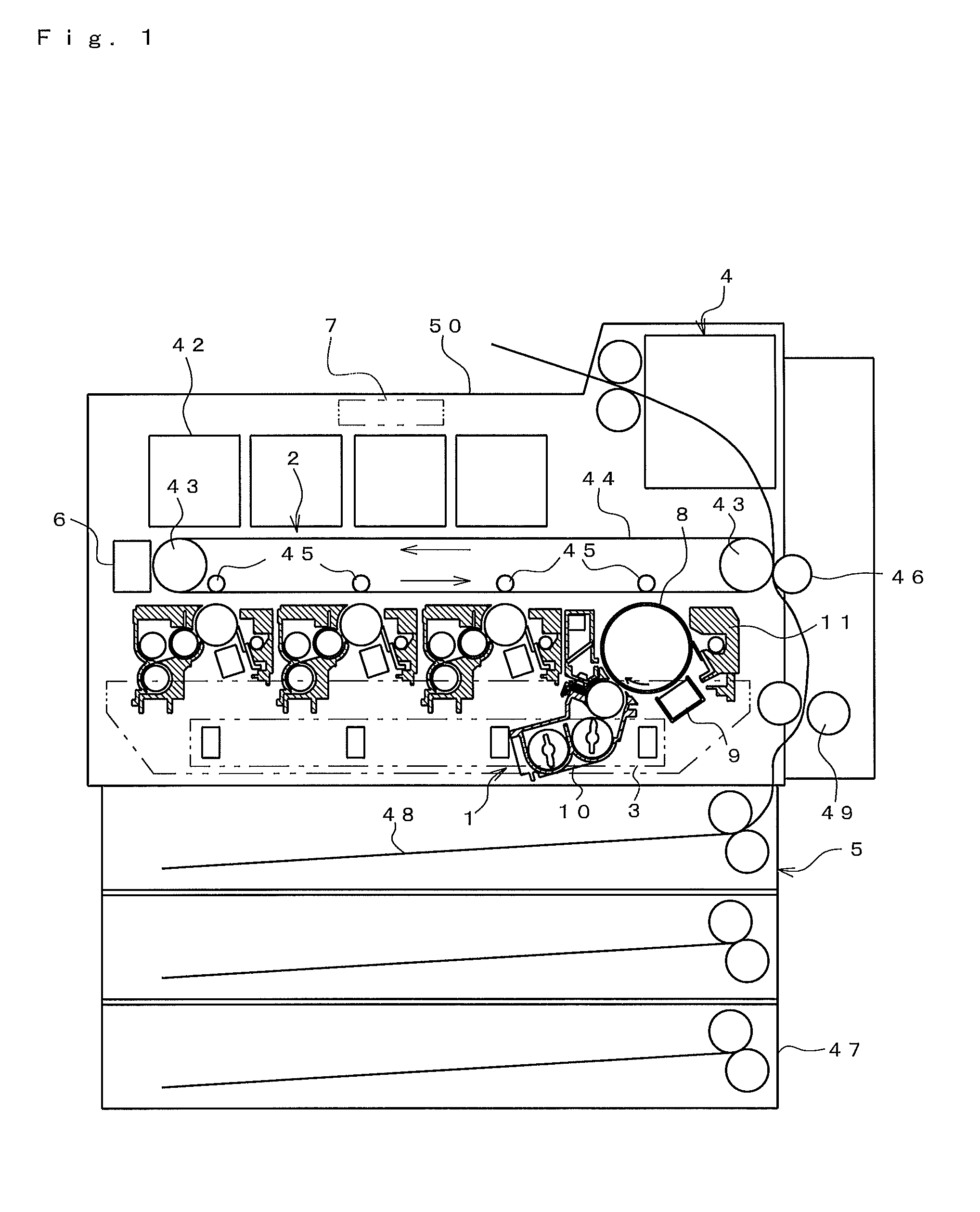

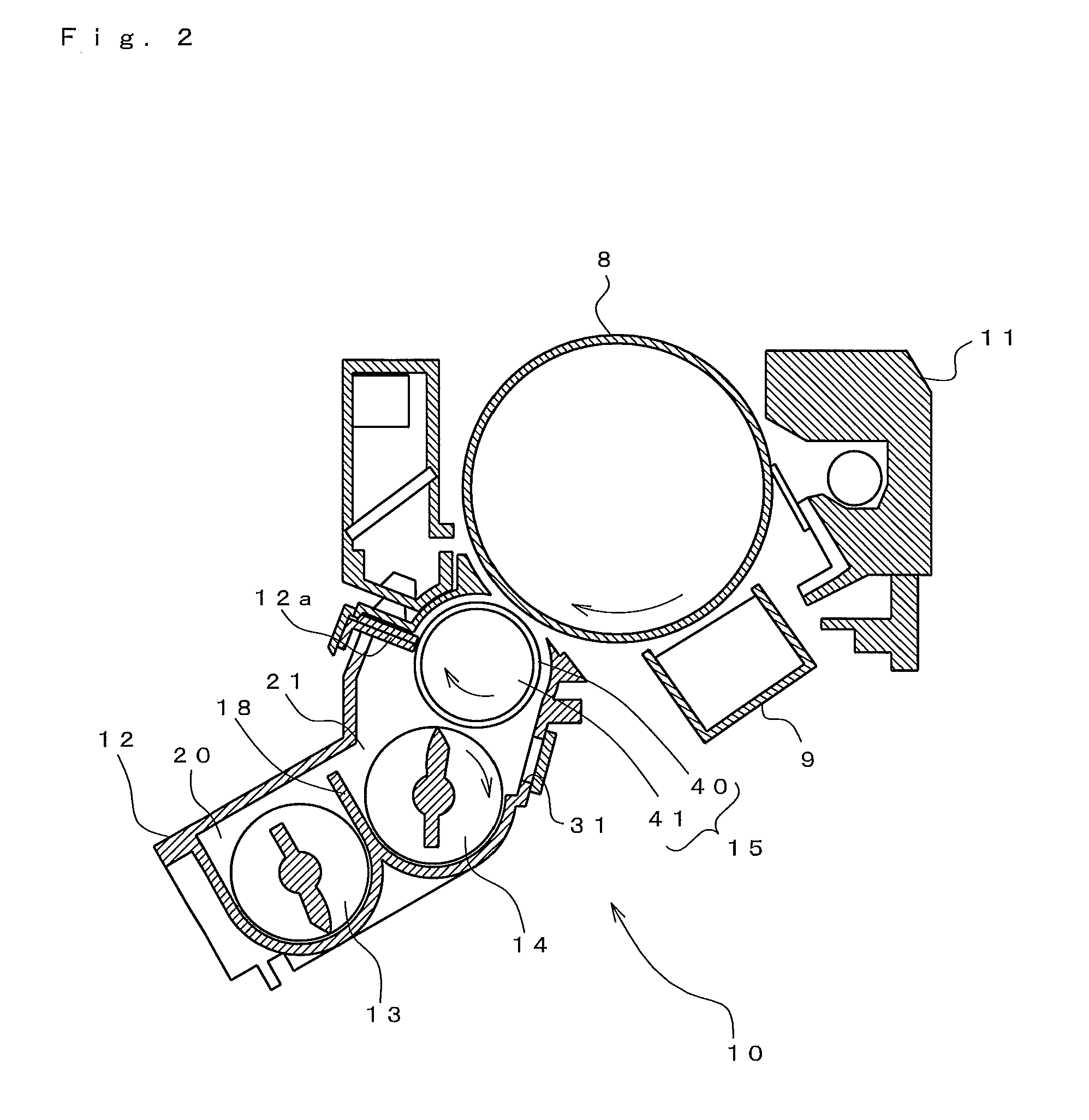

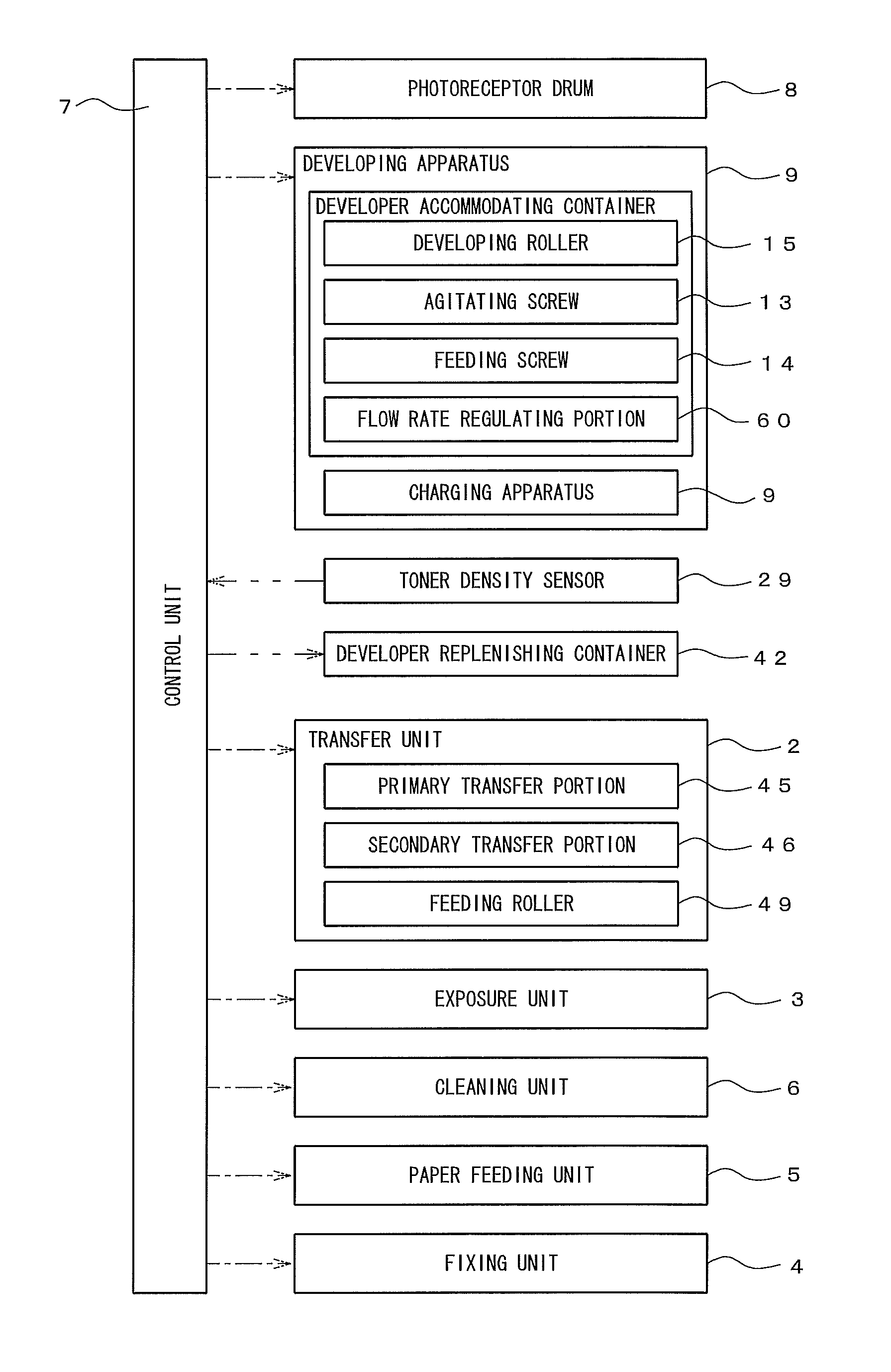

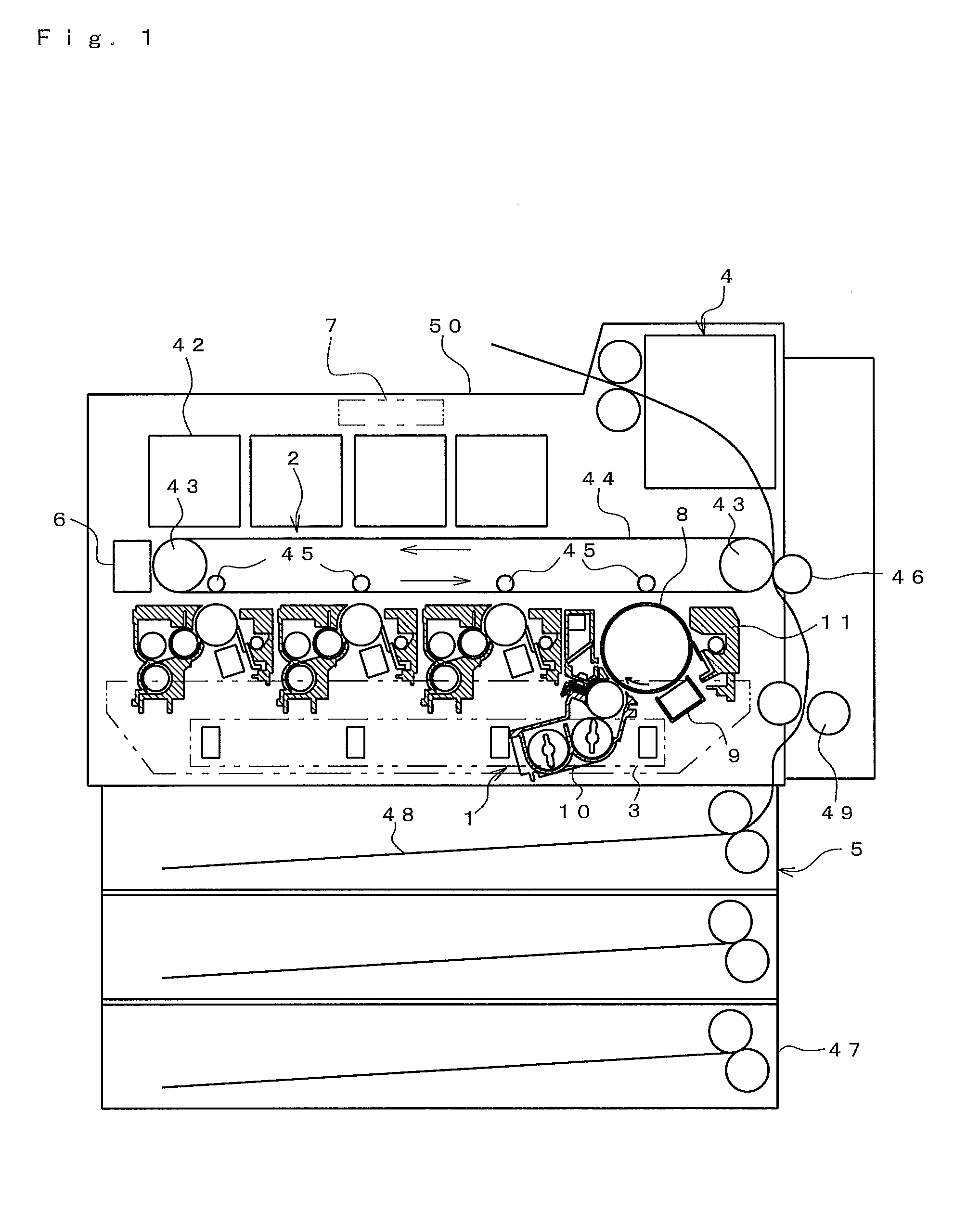

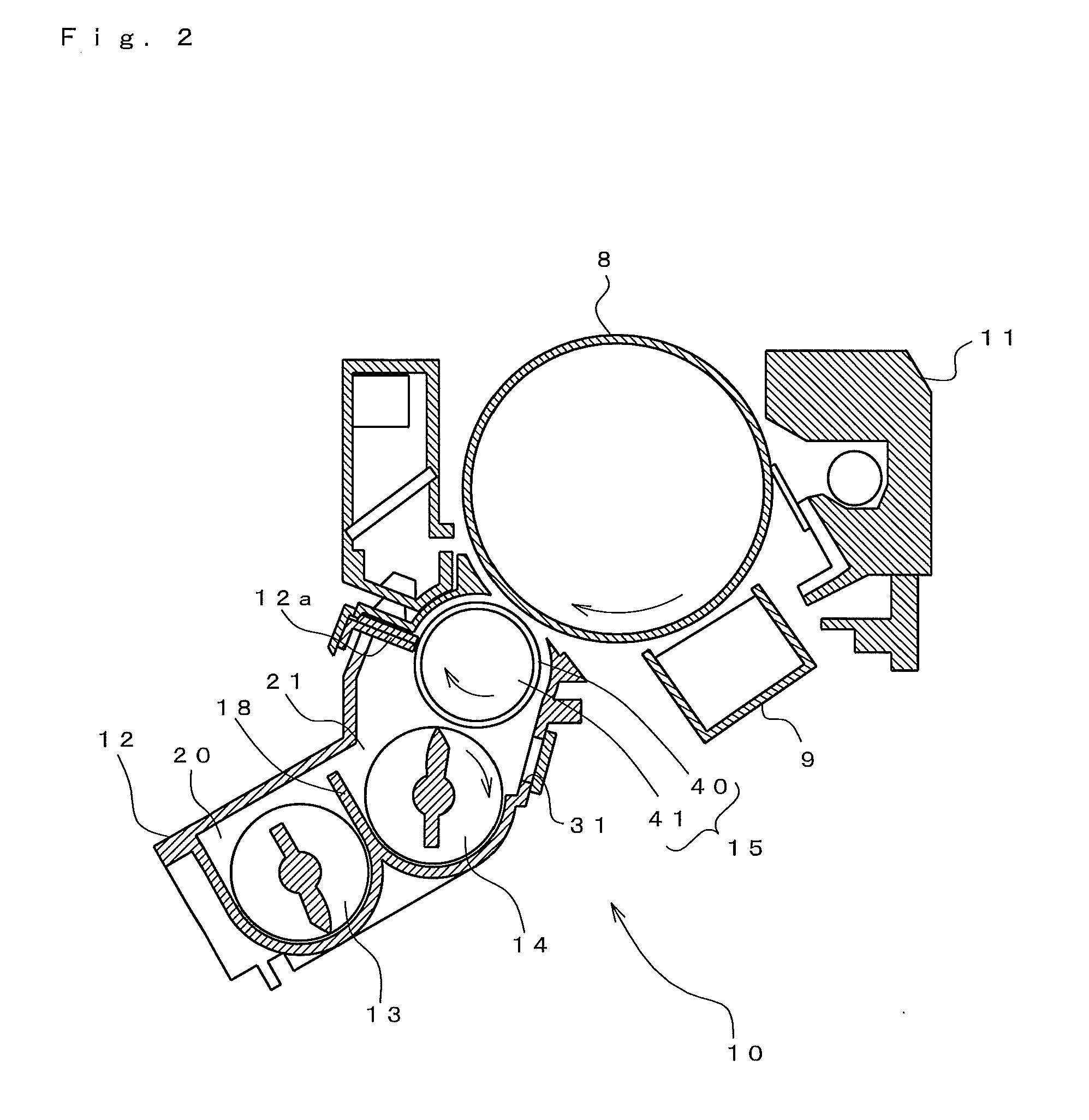

Developing apparatus and image forming apparatus

ActiveUS8295741B2Stable positionFast weighingElectrographic process apparatusEngineeringMechanical engineering

A developer accommodating container is structured such as to be provided with a first accommodating portion in which the first feeding member is arranged, a second accommodating portion in which the second feeding member is arranged, a first communication portion communicating the first accommodating portion and the second accommodating portion in one end side, a second communication portion communicating the first accommodating portion and the second accommodating portion at the other end side, a developer replenishing portion arranged in the other end side rather than the second communication portion, in the other end side of the first accommodating portion, a developer discharge portion arranged in the other end side rather than the second communication portion, in the other end side of the second accommodating portion, and a flow rate regulating portion arranged between the second communication portion and the developer discharge portion, and regulating an amount of the passing developer.

Owner:KONICA MINOLTA BUSINESS TECH INC

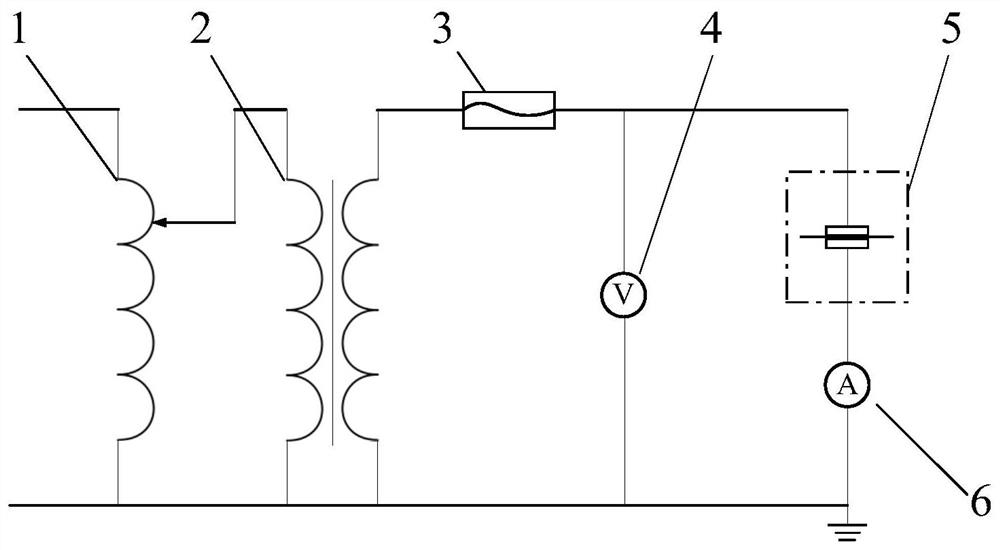

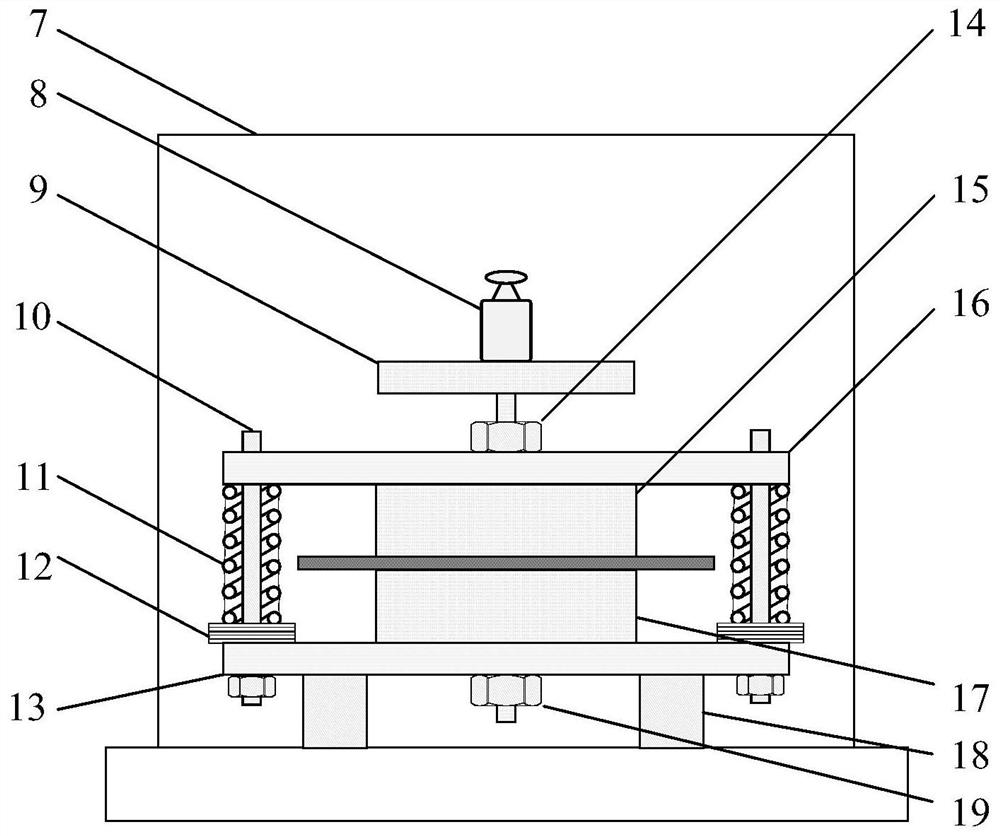

Current and surface pressure adjustable cable buffer layer ablation fault simulation device and method

ActiveCN111929544AGuaranteed Surface Pressure ParametersPrecise adjustment of current amplitudeTesting dielectric strengthWeather/light/corrosion resistanceVoltage loopUtility frequency

The invention discloses a current and surface pressure adjustable cable buffer layer ablation fault simulation device and method. The device comprises a power frequency voltage loop unit used for providing voltage applied to a buffer layer and a buffer layer ablation experiment unit connected to the power frequency voltage loop unit. The buffer layer ablation experiment unit comprises a sealed cavity, a fixing and clamping assembly arranged in the sealed cavity and used for fixing and clamping a buffer layer, an electrode assembly used for applying current to the buffer layer, a pressure adjusting piece used for applying surface pressure to the buffer layer and a self-weight adjusting assembly. By adjusting the amplitude of the externally applied voltage and the mass of the voltage regulating part, the ablation working condition simulation of the buffer layer under different currents and surface pressures is realized, the ablation characteristics of the buffer layer under the influenceof different current amplitudes and surface pressures are further researched, and a reliable experimental platform can be provided for the fault simulation analysis of the buffer layer of the high-voltage cable.

Owner:SICHUAN UNIV

Optical fiber weighing system

An optical fiber weighing system features connecting slightly bended optical weighing transducer to light emitter and receiver through optical fiber ,emitting constant light signal by light emitter , converting weight light signal to be electric signal by light receiver , connecting said emitter and receiver to light transceiver driving circuit separately and connecting this driving circuit to high speed analog converter being connected with data processing system where digital signal is processed and compensated .

Owner:烟台艾森信息技术股份有限公司

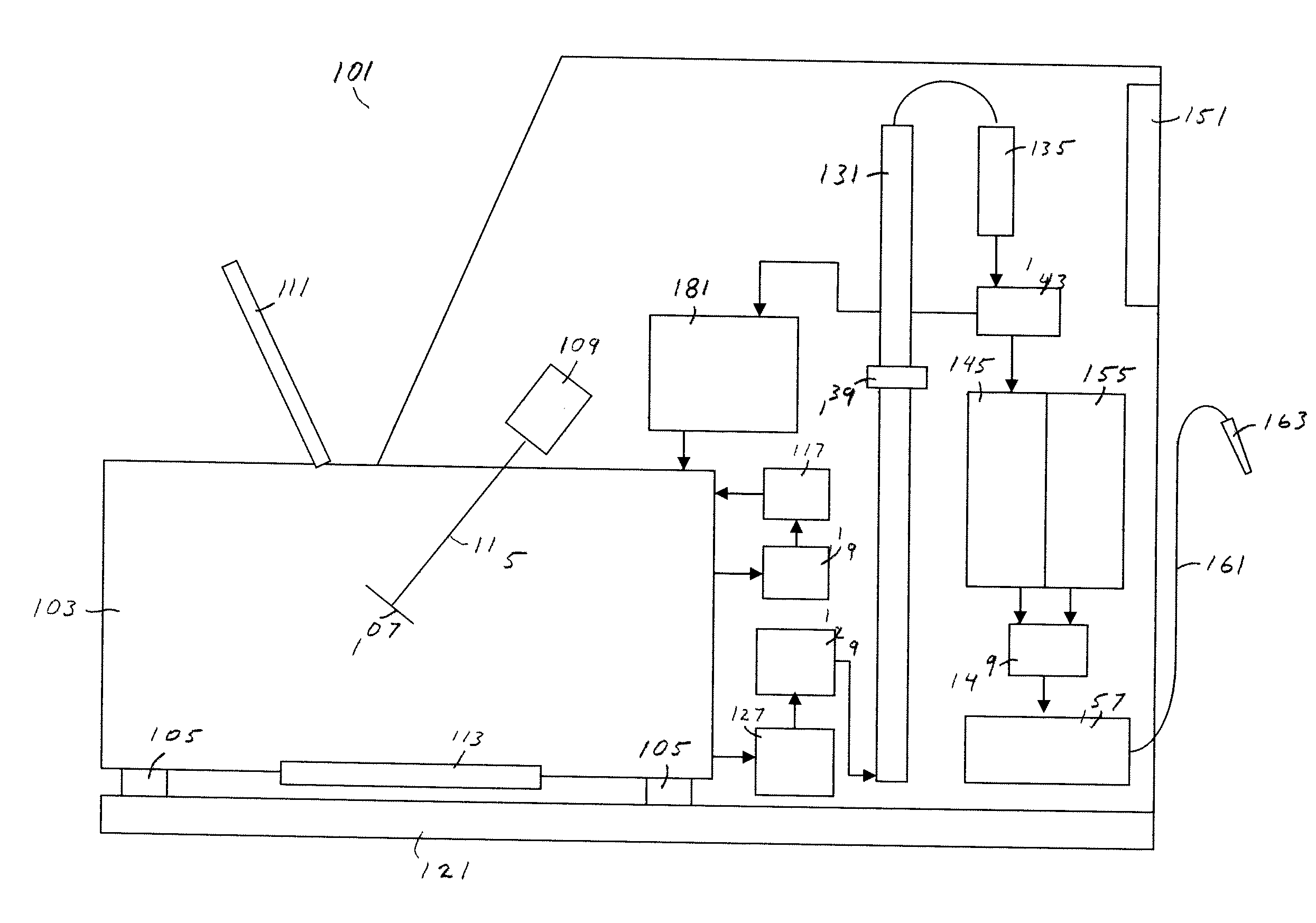

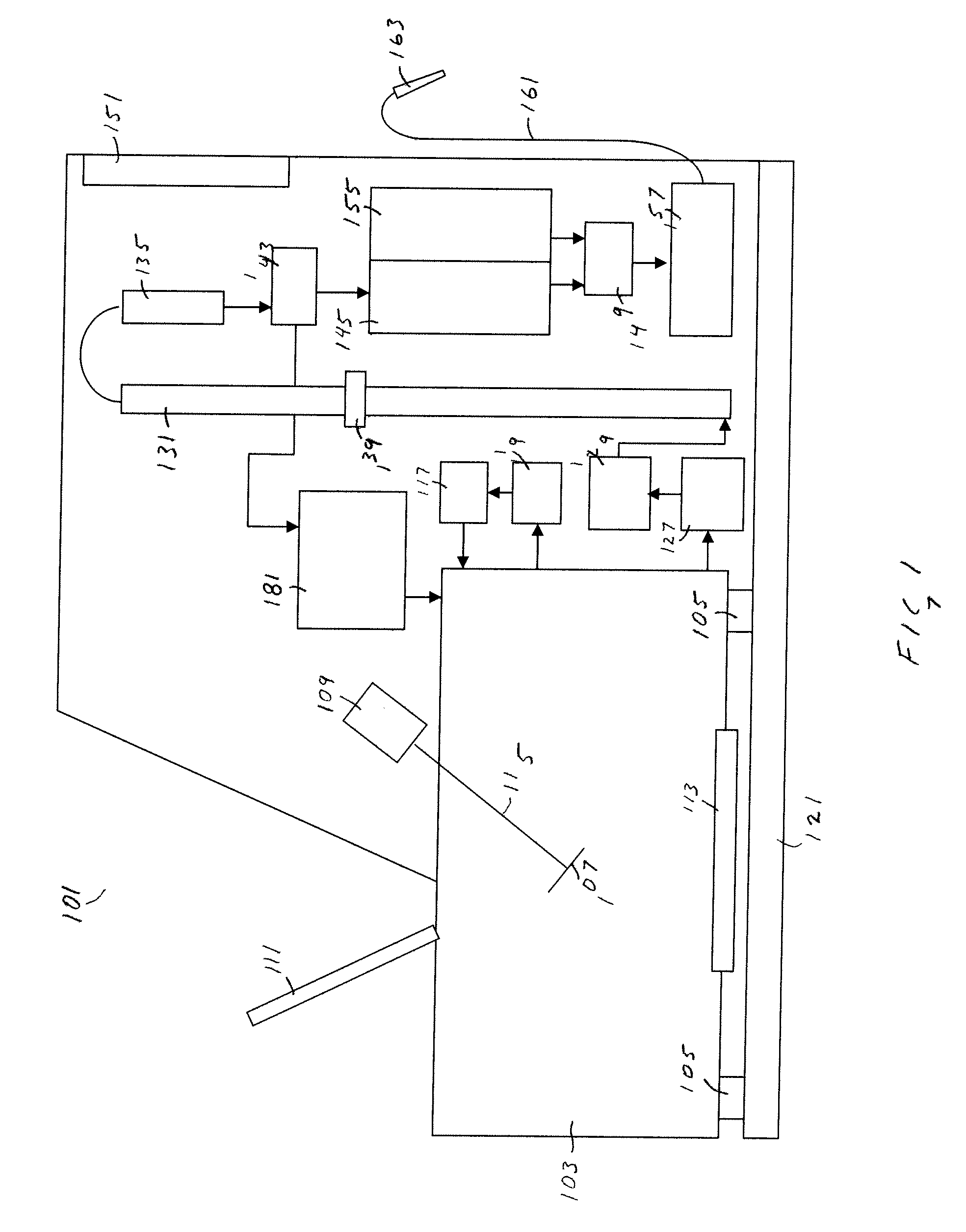

Micro refinery system for ethanol production

InactiveUS20090269834A1High purityPrevent movementBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemDistillation

The micro refinery first detects the weight of the sugar added to the fermentation tank and then calculates the water needed for fermentation. The feed stock is then inserted into the fermentation tank and the system adds the corresponding volume of water. The control system monitors the weight of the batch and maintains the temperature within a fermentation temperature range so the batch is converted into ethanol. In another mode of operation, discarded alcoholic beverages can be placed in the fermentation tank and processed by the micro refinery to extract the ethanol. The fermented liquid is heated and the ethanol vapors travel through a distillation tube to a membrane separation unit that separates water from the ethanol. The distillation tube has an alignment system that orients the distillation tube vertically automatically. The ethanol from the membrane separation unit is then stored in a storage container prior to use in a vehicle. The micro refinery can blend the ethanol with gasoline to produce any desire ratio of fuel.

Owner:E FUEL CORP

Developing apparatus and image forming apparatus

ActiveUS20100239322A1Stable positionFast weighingElectrographic process apparatusEngineeringMechanical engineering

A developer accommodating container is structured such as to be provided with a first accommodating portion in which the first feeding member is arranged, a second accommodating portion in which the second feeding member is arranged, a first communication portion communicating the first accommodating portion and the second accommodating portion in one end side, a second communication portion communicating the first accommodating portion and the second accommodating portion at the other end side, a developer replenishing portion arranged in the other end side rather than the second communication portion, in the other end side of the first accommodating portion, a developer discharge portion arranged in the other end side rather than the second communication portion, in the other end side of the second accommodating portion, and a flow rate regulating portion arranged between the second communication portion and the developer discharge portion, and regulating an amount of the passing developer.

Owner:KONICA MINOLTA BUSINESS TECH INC

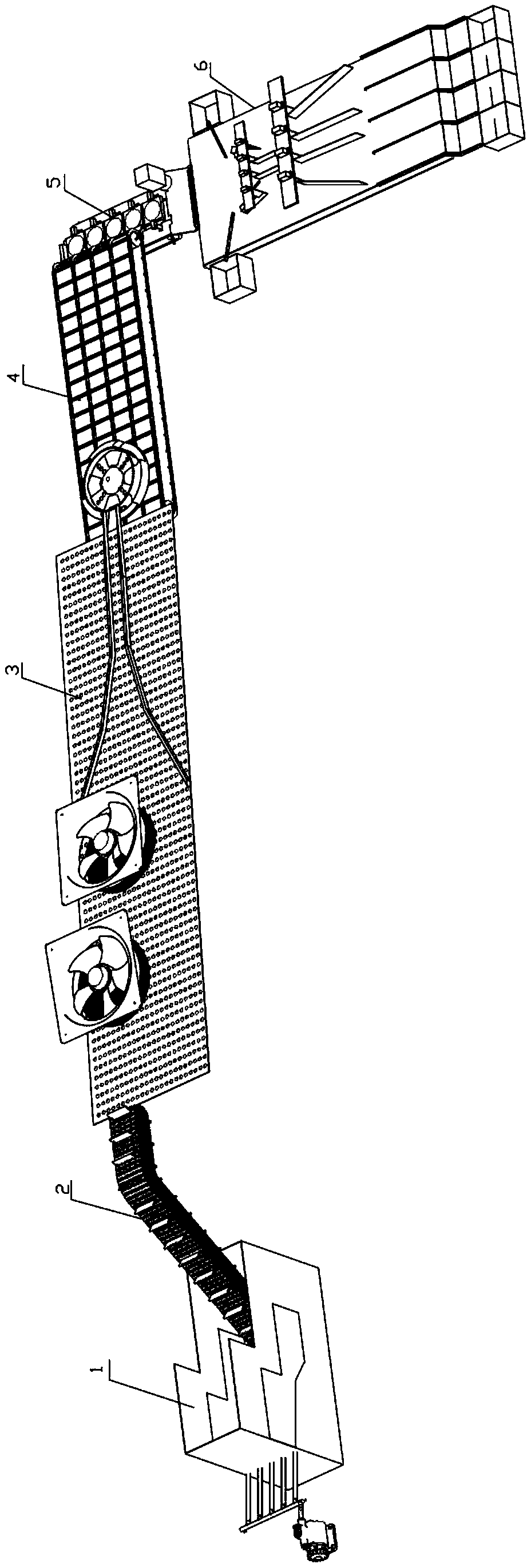

Green plum sorting production line and sorting method

ActiveCN110584164AHigh economic valueHigh sorting productivityClimate change adaptationSortingProduction lineEngineering

The invention discloses a green plum sorting production line and a sorting method. The green plum sorting production line comprises a cleaning module, a feeding module, a blow-drying module, a discharging module, a weighing module and a sorting module, wherein the cleaning module comprises a water tank; an oblique bevel is arranged in the water tank; the feeding module comprises a feeding conveyorbelt; the feeding conveyor belt is arranged in a sloped manner; a plurality of feeding baffle plates are uniformly arranged on the feeding conveyor belt; the blow-drying module comprises a sieve plate; the lower end of the sieve plate extends to the discharging module; the discharging module comprises a rotary discharging device and a discharging conveyor belt; and the weighing module comprises aplurality of weighing machines and a weighing conveyor belt. Through the adoption of the green plum sorting production line which integrates cleaning, feeding, blow-drying, discharging, weighing andsorting of green plums provided by the invention, the green plums processed by the production line can be sorted according to quality and weight, so that deep processing can be further performed on the green plums of different quality and different weight to increase the economic value of the green plums; and the sorting production efficiency is high, and the labor cost is low.

Owner:NANJING FORESTRY UNIV

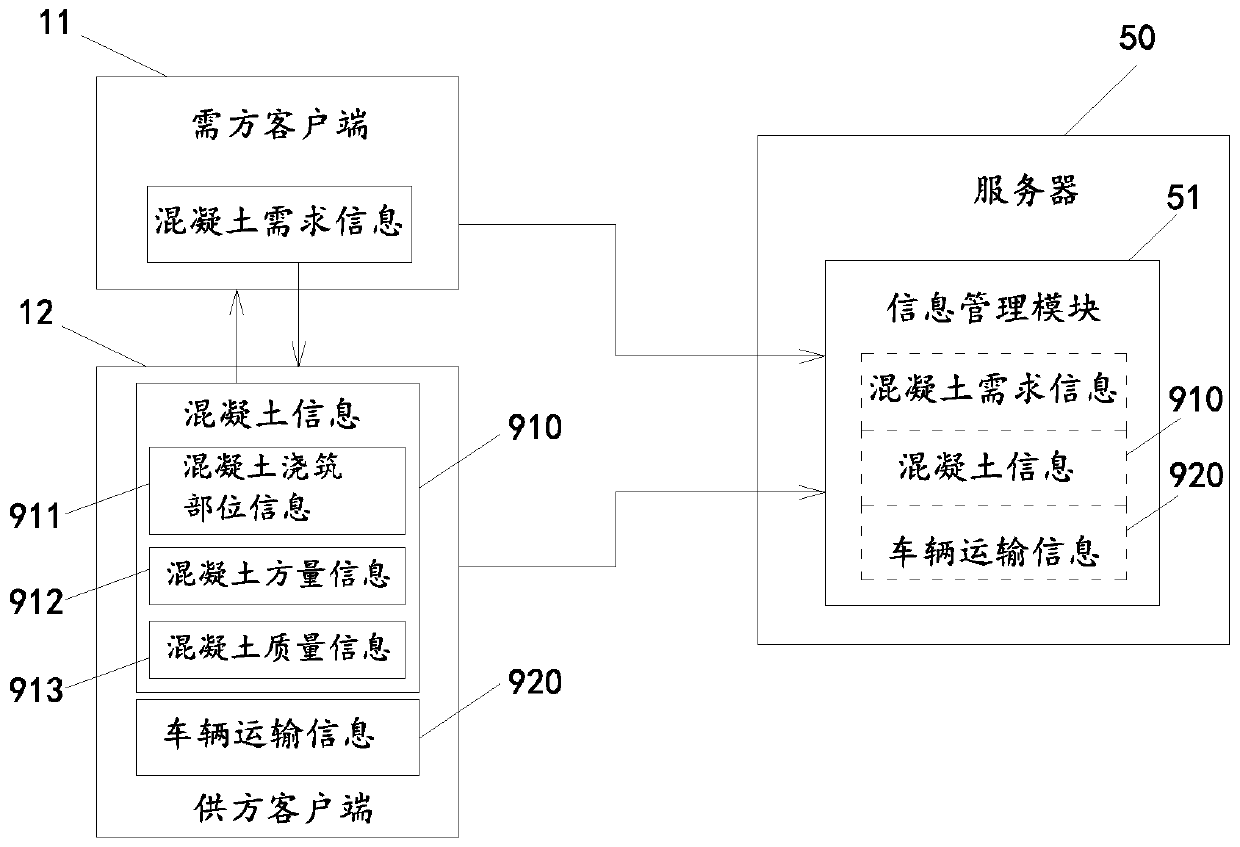

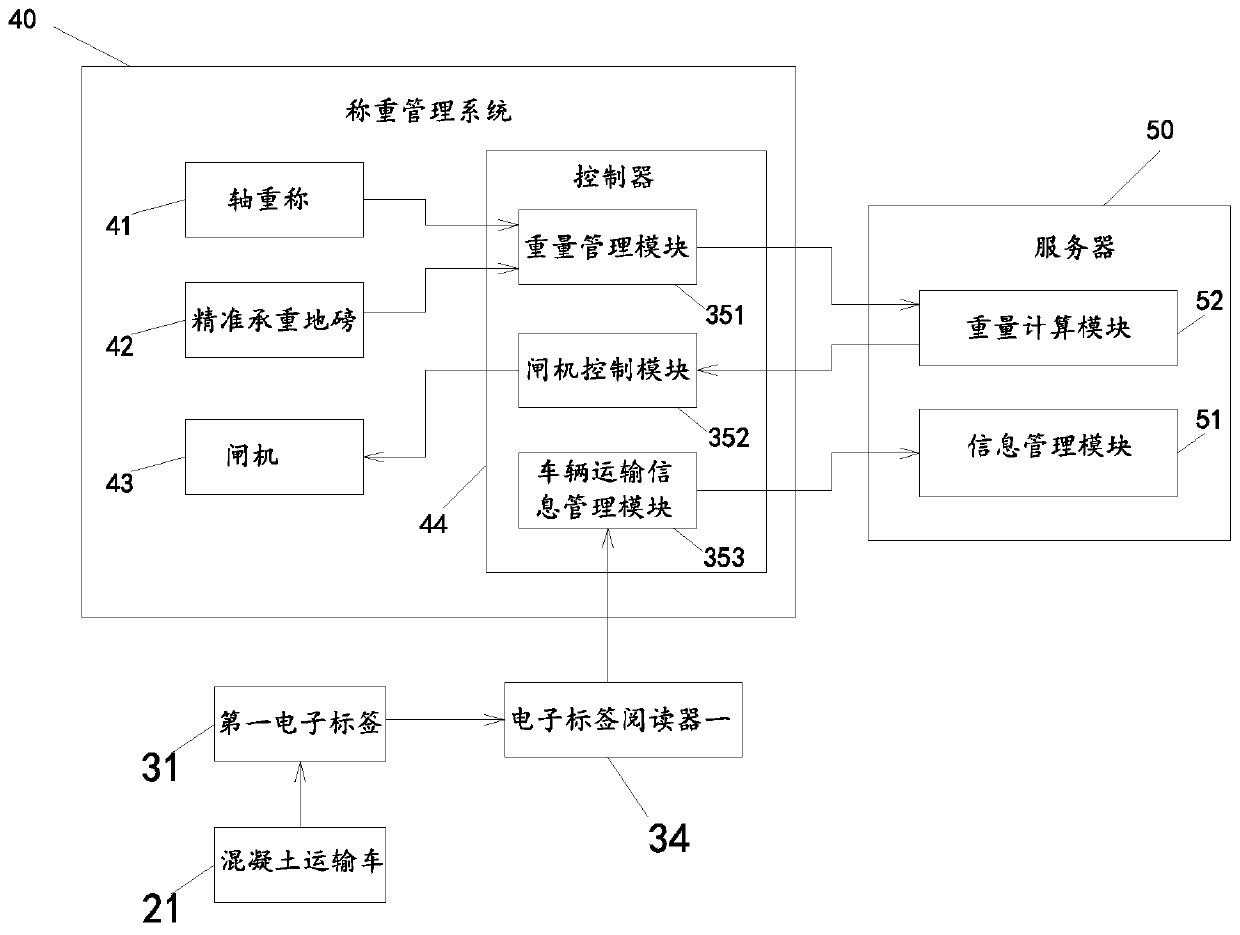

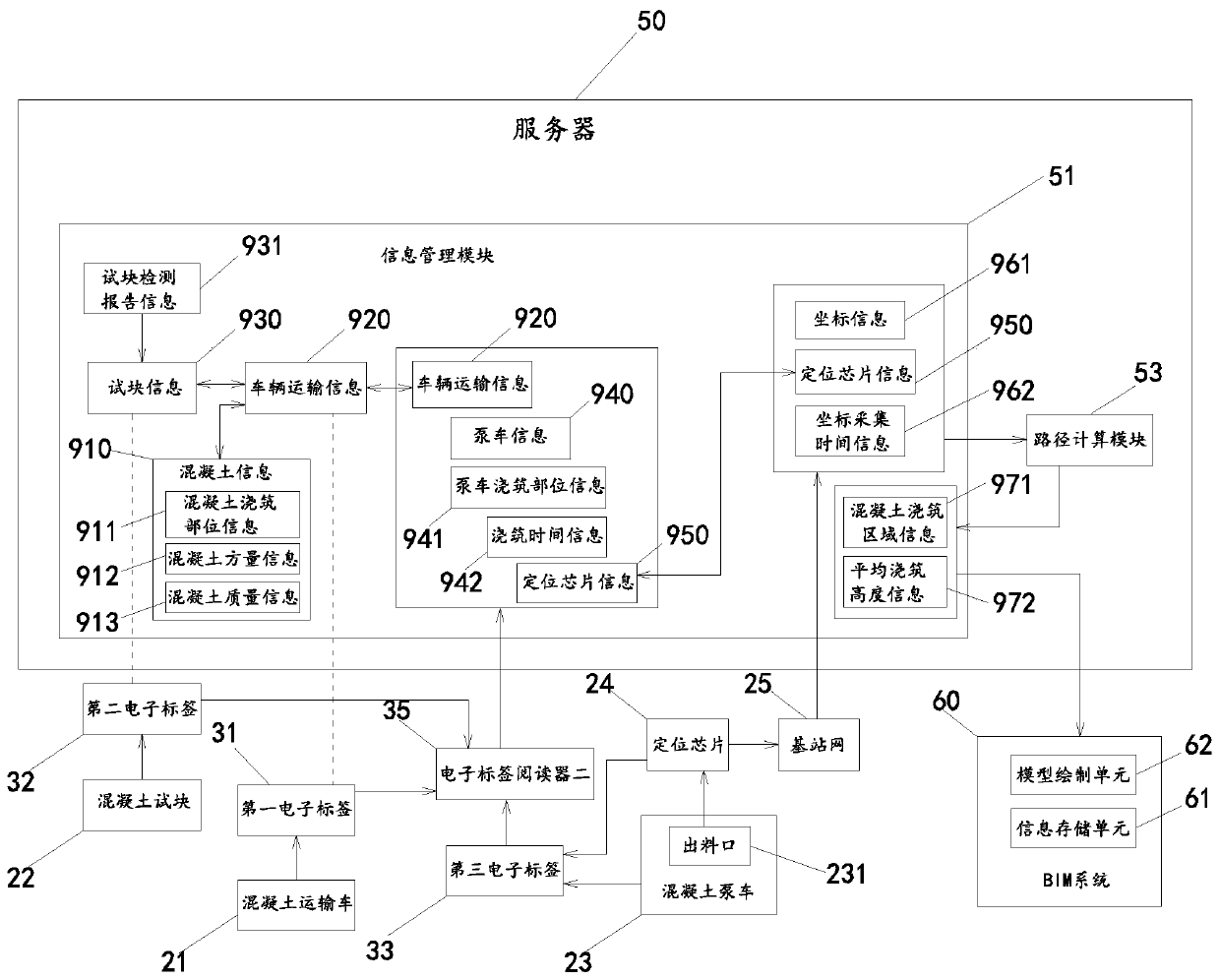

An intelligent concrete management and control method and system

PendingCN109784436AEasy constructionFast weighingCo-operative working arrangementsResourcesInformatizationElectronic tagging

The invention relates to an intelligent concrete management and control method and system, and belongs to the technical field of construction engineering material management. The system comprises a demander client, a supplier client, a server, a first electronic tag, a second electronic tag, a third electronic tag, a first electronic tag reader, a second electronic tag reader, a weighing management system and a positioning device. According to the method and system, automatic operation of the whole material weighing process is achieved through an informatization means, association between a BIM sub-model and test block detection report information, concrete information and concrete pouring area information is achieved in the BIM system, and the project progress and related information aredynamically reflected; Whether the concrete pouring part information is matched with the pump truck pouring part information or not is judged, and concrete with wrong performance can be prevented frombeing poured into building components; And path guidance on the concrete transport vehicle can be realized, so that the concrete transport vehicle travels to the corresponding concrete pump truck.

Owner:SHANGHAI CONSTRUCTION GROUP +4

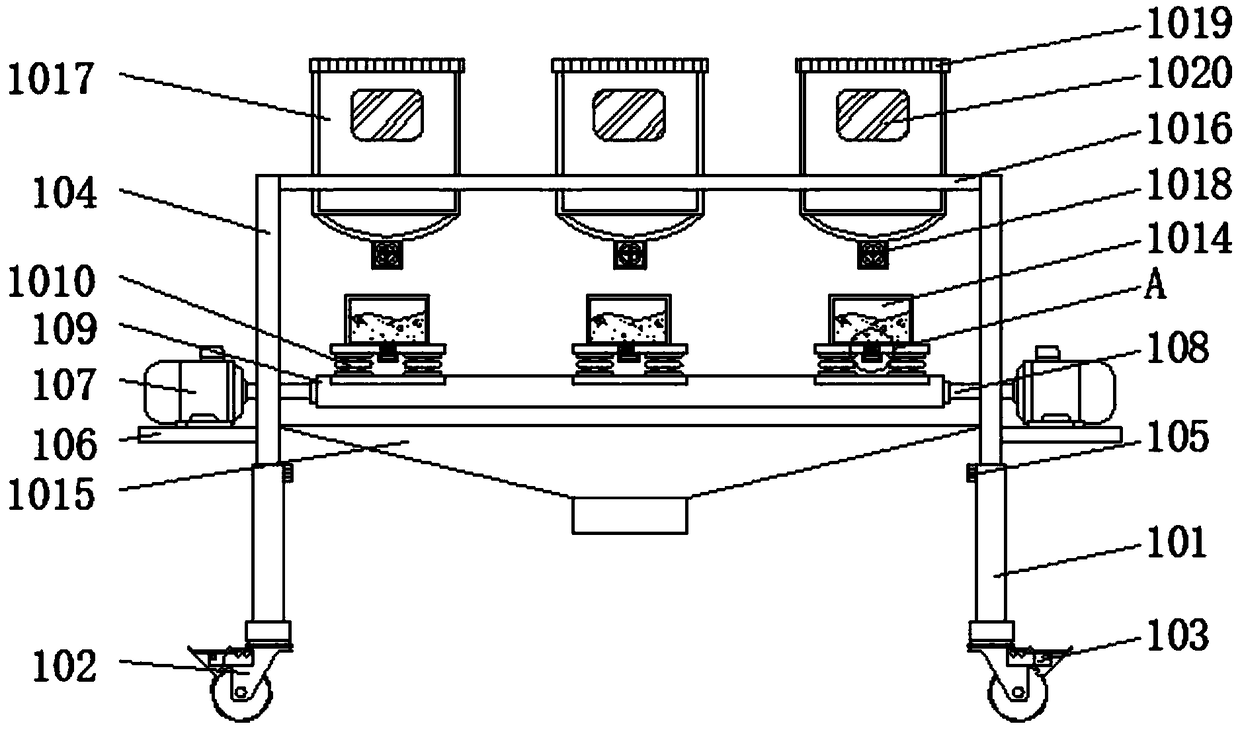

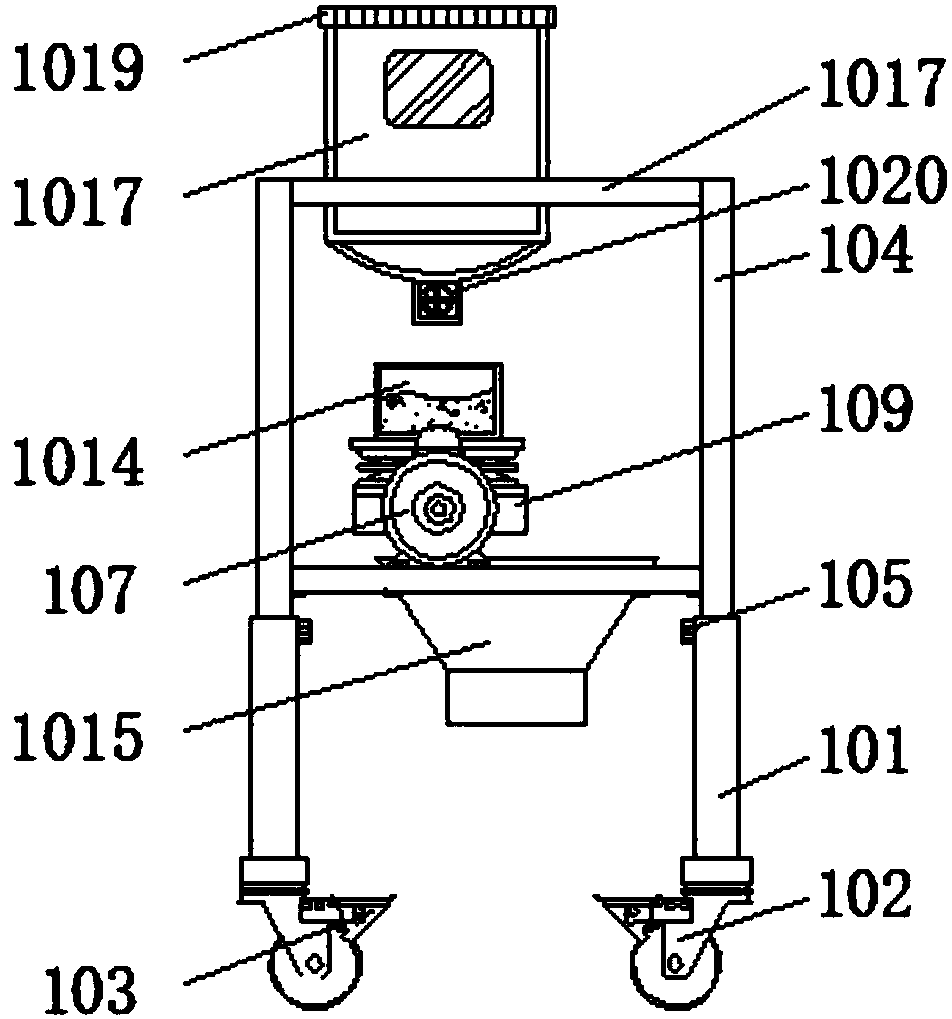

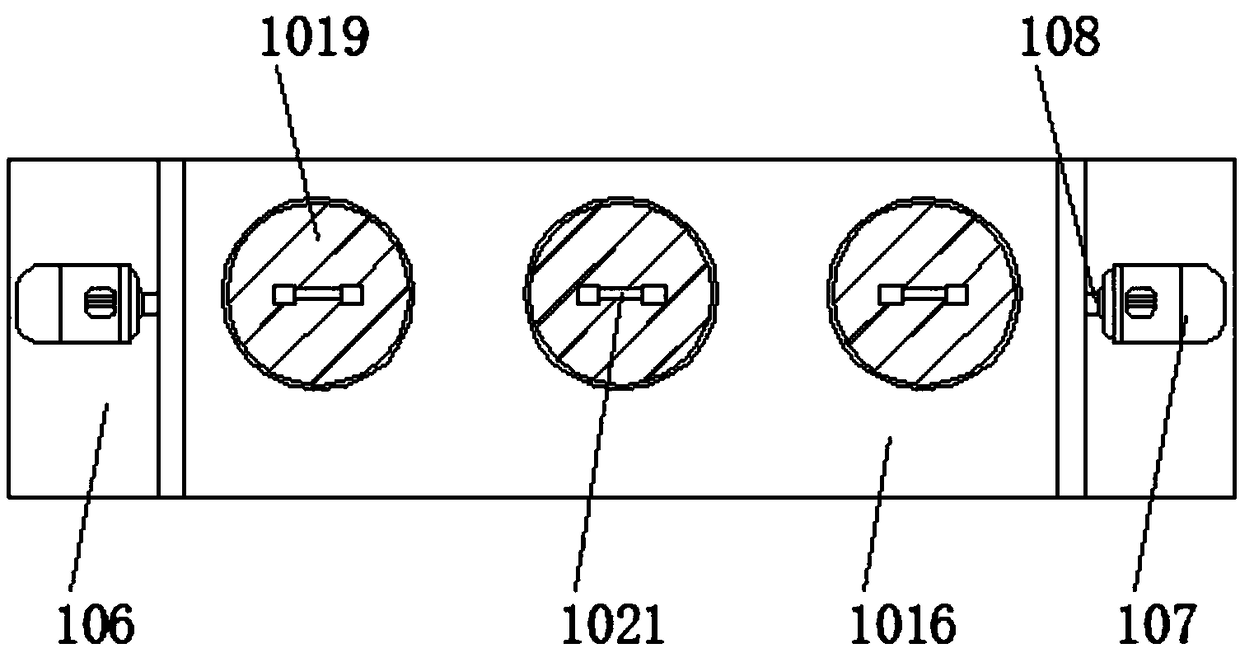

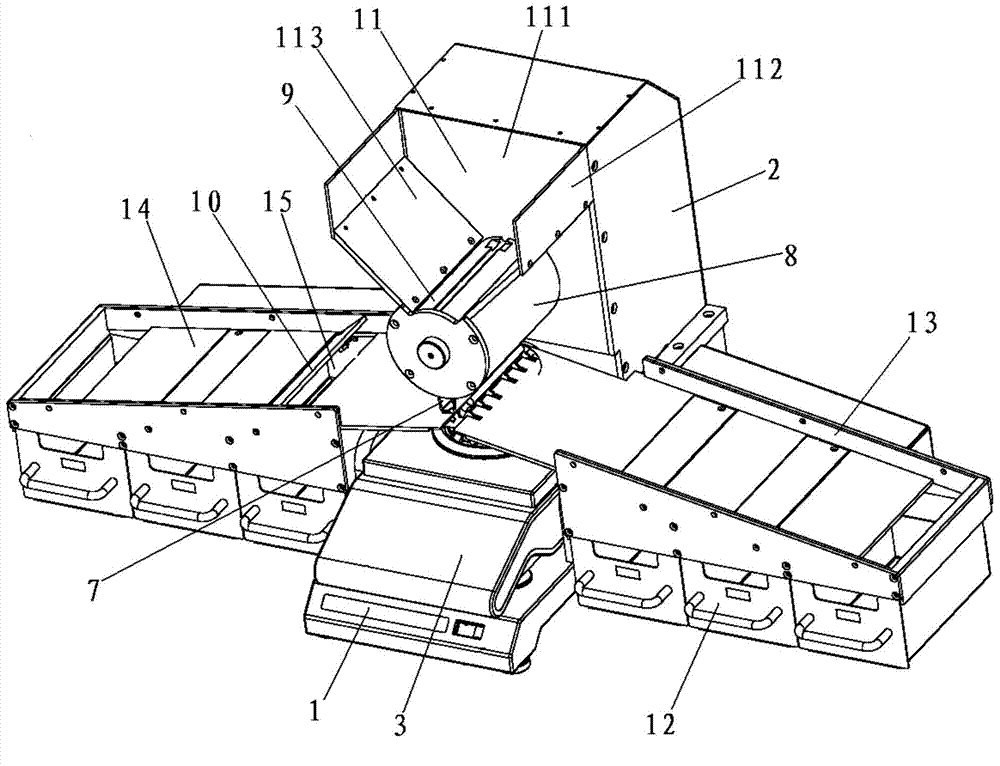

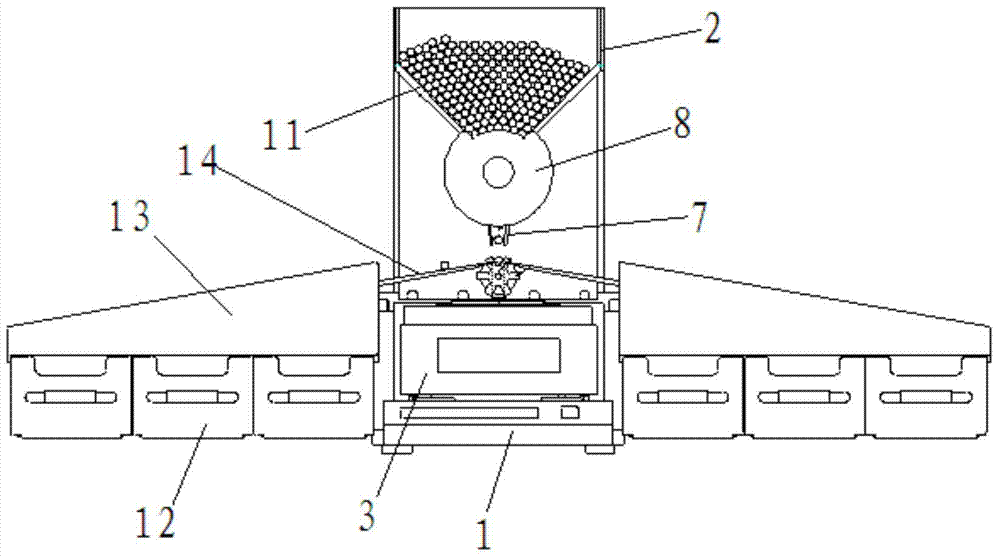

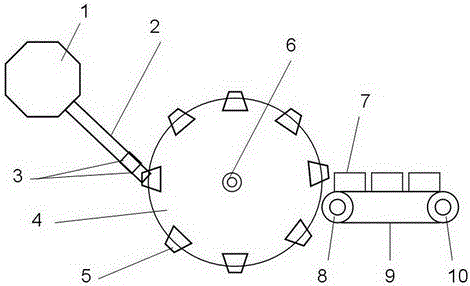

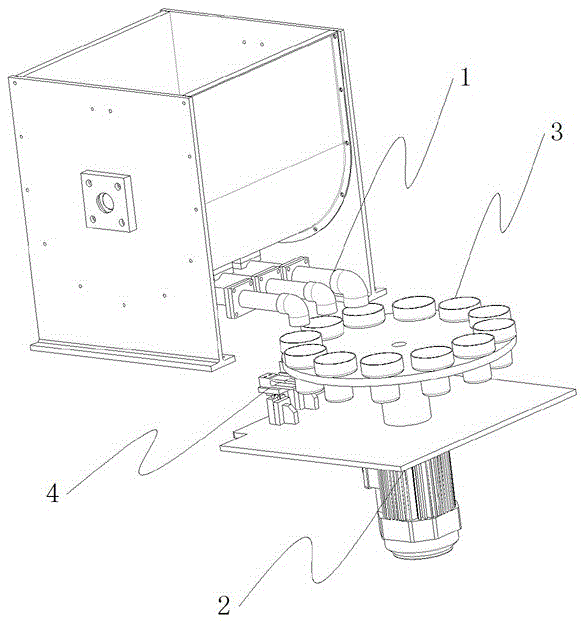

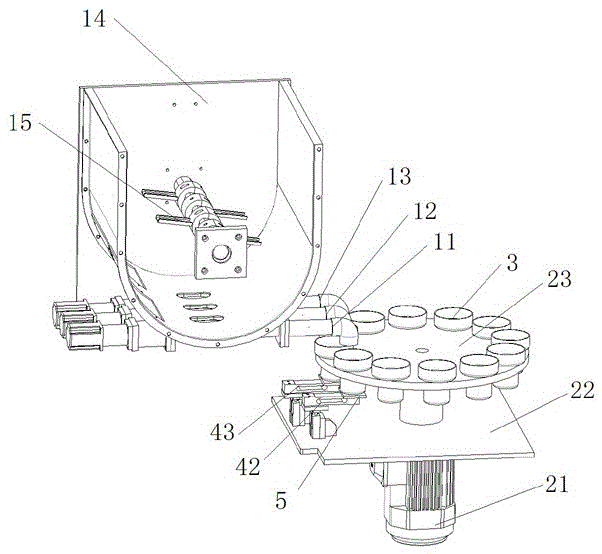

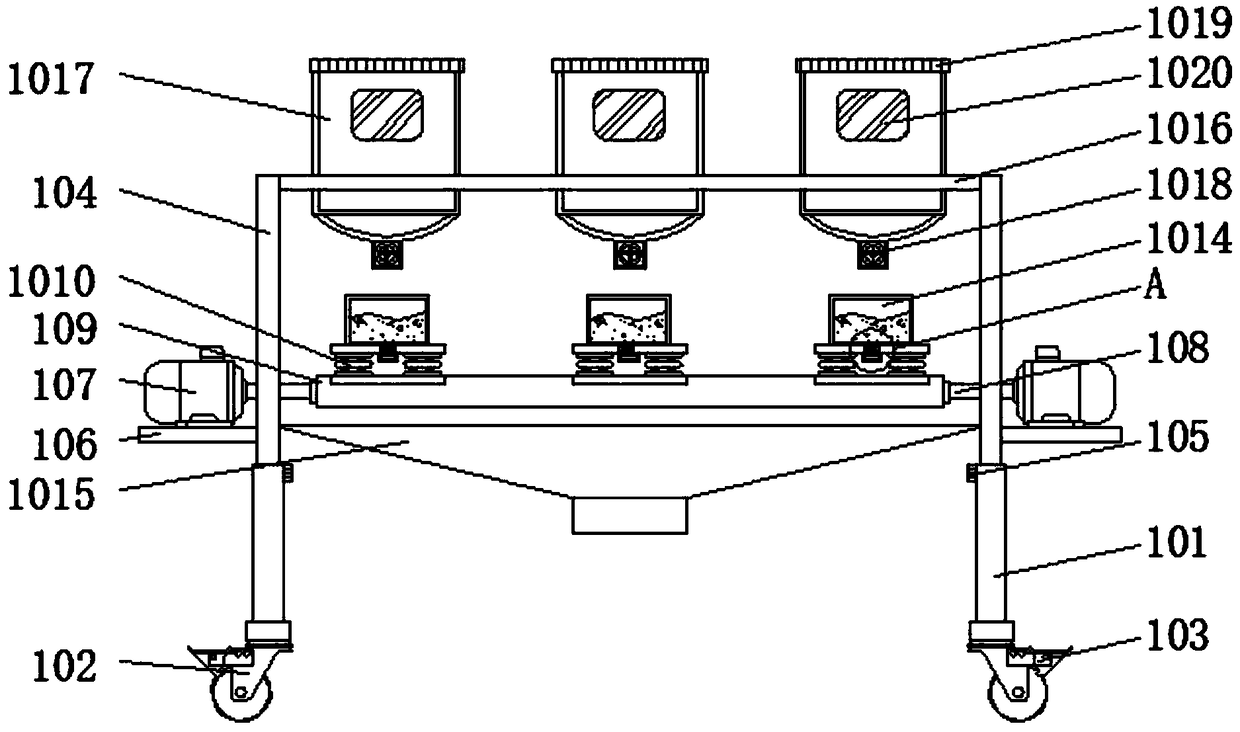

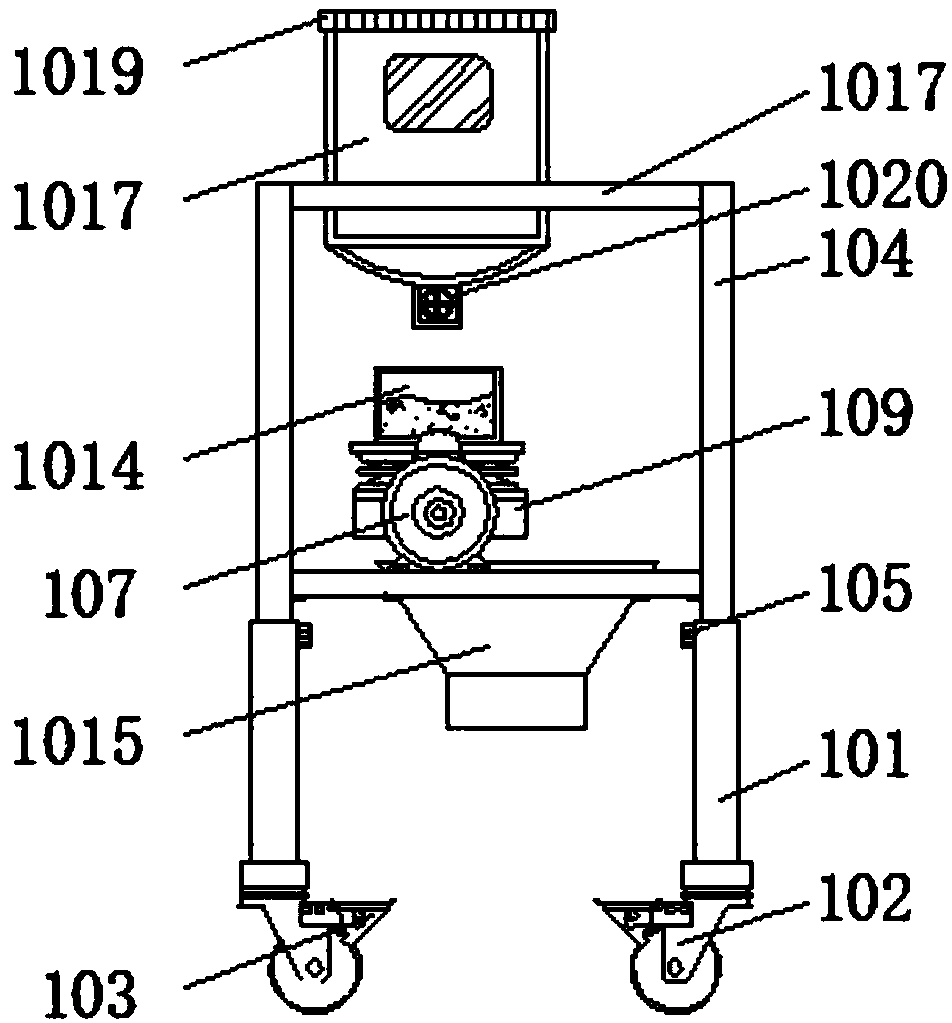

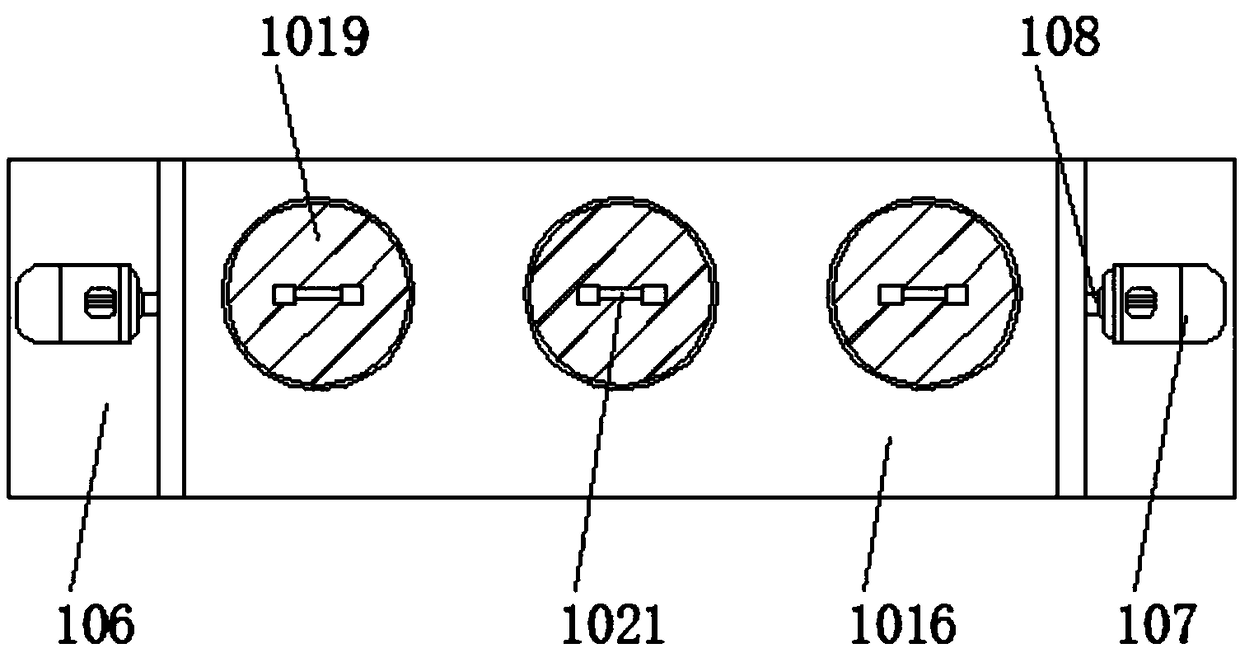

Multi-station weighing machine and method

ActiveCN105466533AShorten weighing timeFast weighingSpecial purpose weighing apparatusEngineeringMechanical engineering

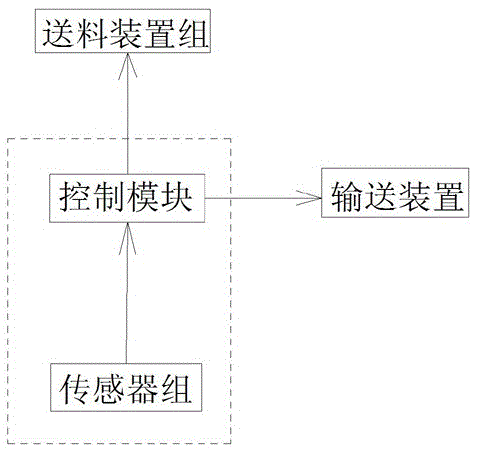

The invention discloses a multi-station weighing machine and method. The multi-station weighing machine is provided with a feeding device group, a conveying device, a material weighing container group and a control system. The feeding device group is provided with at least two feeding devices, and each feeding device is provided with a material inlet and a material outlet. The conveying device is provided with a plurality of conveying stations which are successively arranged in the arranging direction of the material outlet. The material weighing container group is composed of a plurality of material weighing containers, and each material weighing container is correspondingly installed on one conveying station. The control system is provided with a control module and a sensor group electrically connected with the control module, and the control module is electrically connected with the feeding device group and the conveying device. The multi-station weighing machine has the advantages that the weighing speed is high, the weighing precision is high, material overflow is prevented, the size is small, the cost is low, the operation is easy, the structure is simple, the maintenance is simple, etc.

Owner:ZHUHAI HUALI FRICTION MATERIAL

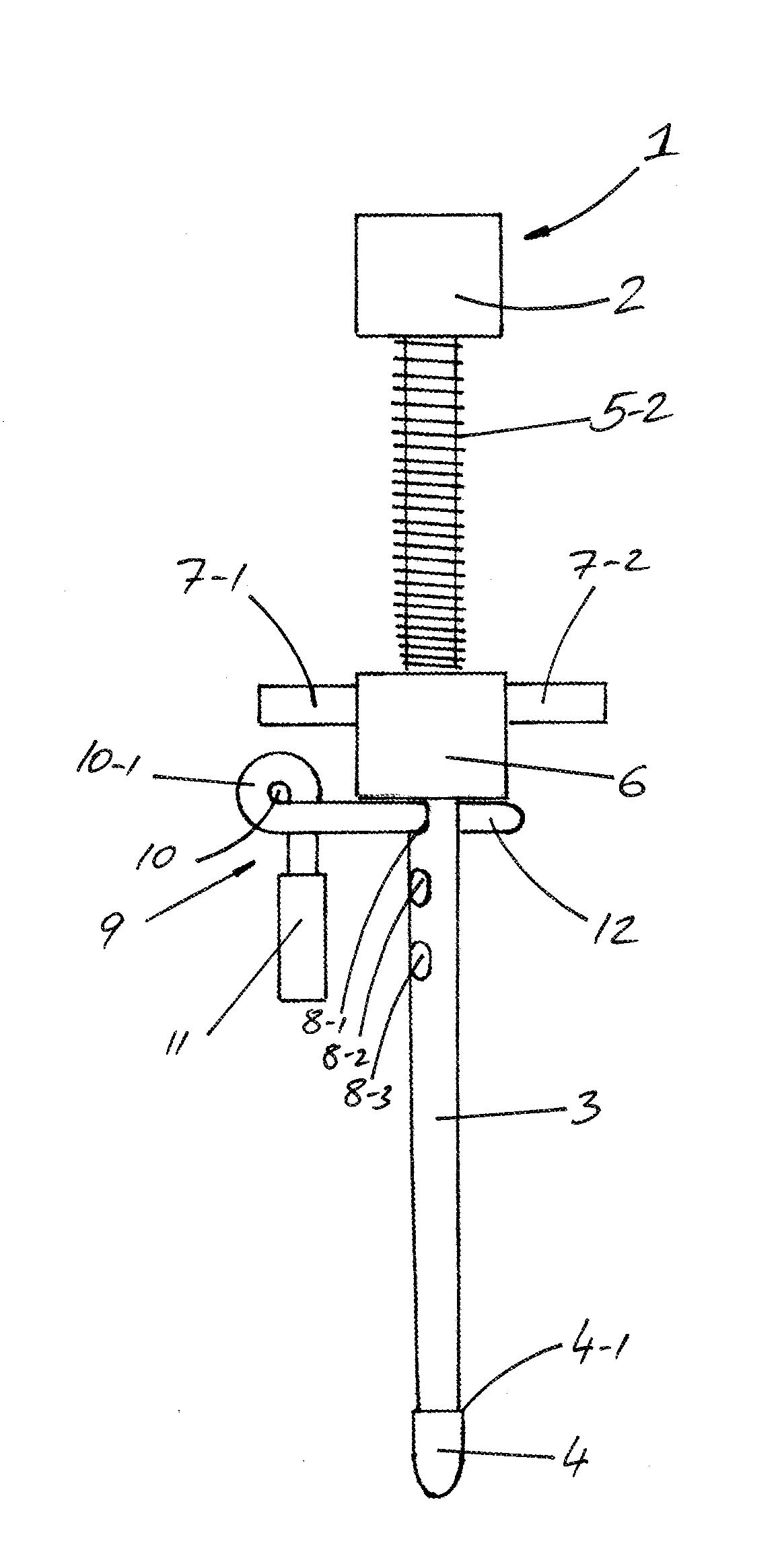

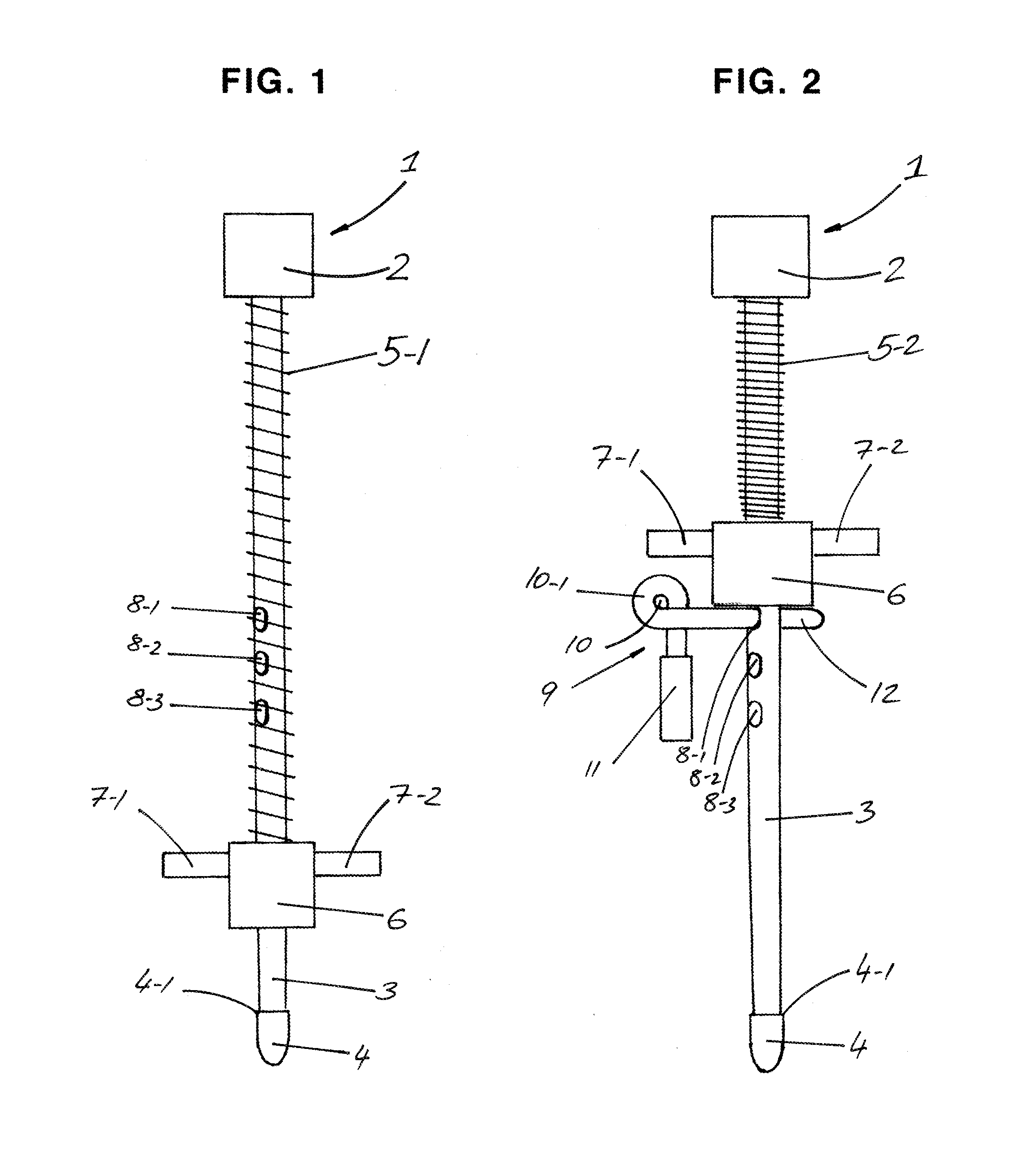

Spring loaded weight stack selector pin

InactiveUS20140274591A1Fast weighingUltimate level of performanceMuscle exercising devicesMechanical engineeringUltimate tensile strength

A portable spring loaded selector pin device comprising of an automatic release mechanism for use in performing intense weight lifting exercises involving reduced weight lifting sequences on weight lifting machines having weight stacks comprising of a plurality of weight plates. One or more spring loaded selector pin devices may be deployed, allowing the selection of multiple weight reductions to be preset. The spring loaded selector pin device utilizes the friction created by the weight plates to remain engaged while the weight is lifted, and automatically releases immediately after the weight is set down, making the next preset weight ready to be lifted without any interruption in the exercise.

Owner:MILTNER HEINZ RICHARD +1

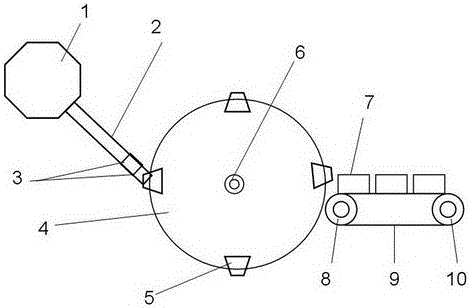

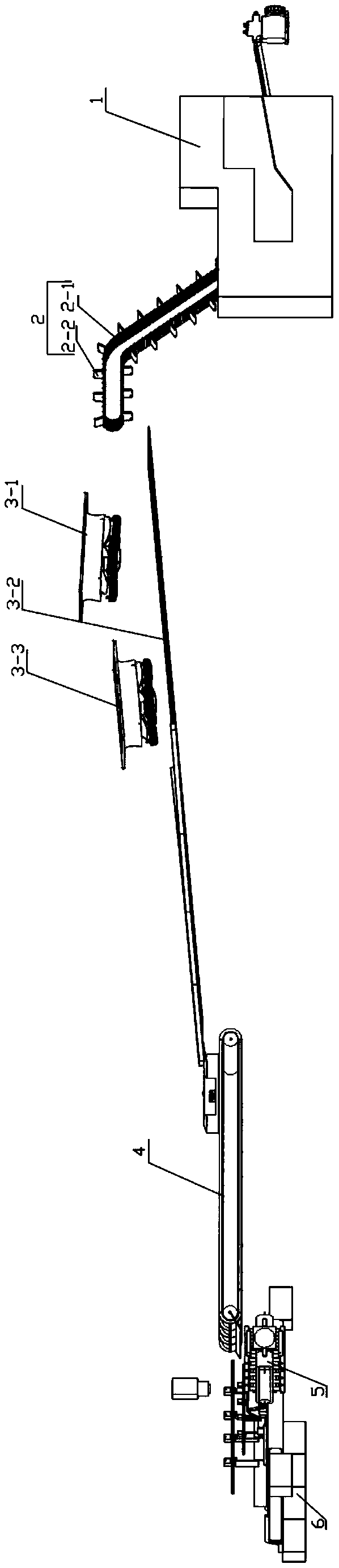

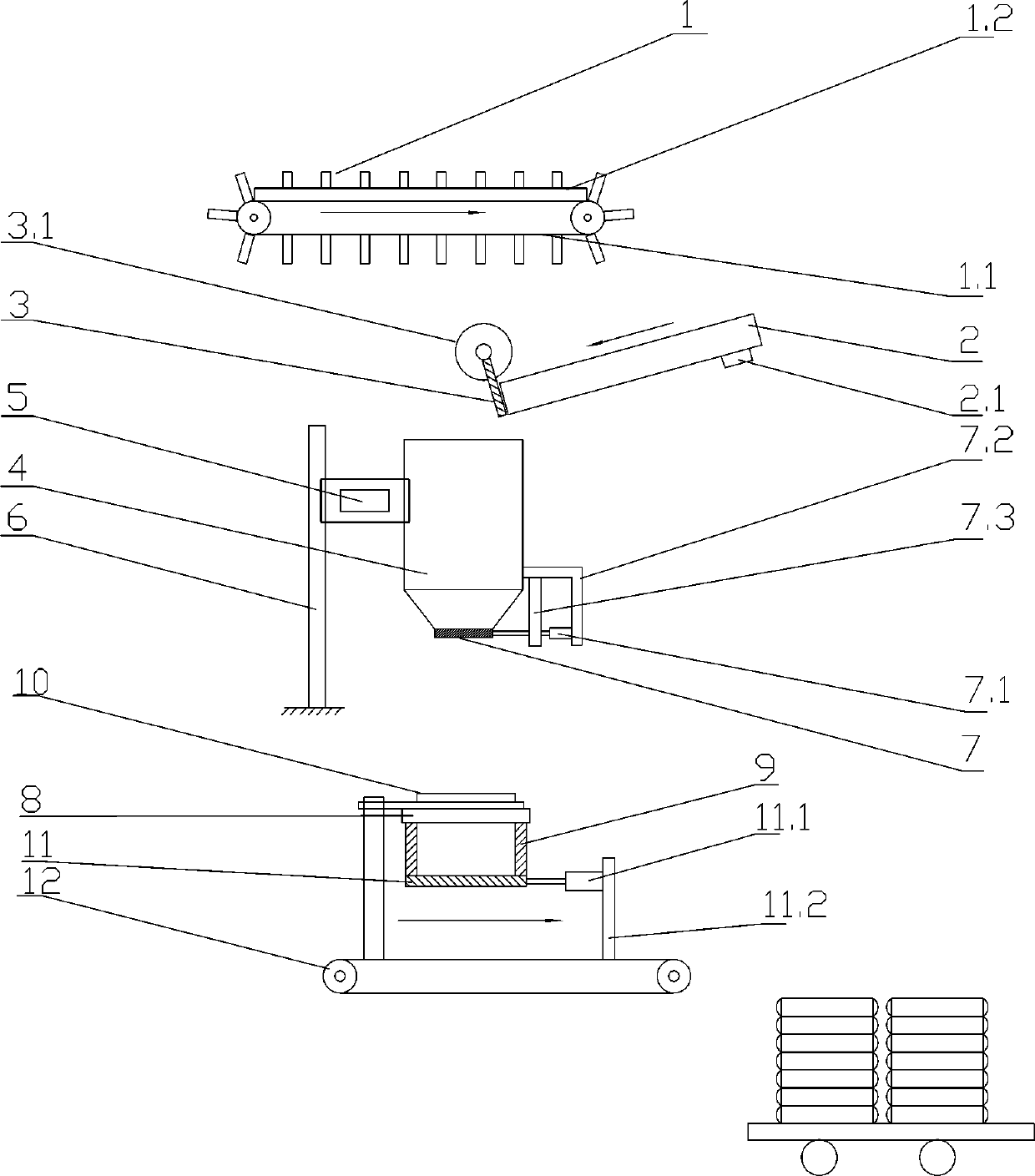

Quick weighing and packaging system for citrus sinensis

InactiveCN110481876AFast weighingQuick operabilityWrapper twisting/gatheringPackaging fruits/vegetablesGraduated cylinderEngineering

The invention discloses a quick weighing and packaging system for citrus sinensis. The quick weighing and packaging system comprises a scraper type conveyor, wherein an arc conveying groove is formedunder the conveying tail end of the scraper type conveyor in an oblique manner; a rotatable baffle plate is arranged at the tail end of the arc conveying groove; a weighing tube is arranged under therotatable baffle plate and is connected with a support rod through a weighing sensor; a first telescopic baffle plate is arranged at a bottom outlet of the weighing tube; a bag sealing machine is arranged under the first telescopic baffle plate; a tank body is arranged under a a sealed mouth of the bag sealing machine; a packaging bag is arranged in the tank body; a second telescopic baffle plateis arranged at the bottom of the tank body; and a conveyor belt device is arranged under the second telescopic baffle plate. According to the quick weighing and packaging system for the citrus sinensis disclosed by the invention, the citrus sinensis can be quickly weighed and packaged, so hat the labor intensity of workers is reduced, and the working efficiency is improved.

Owner:ZIGUI COUNTY QUGU FOOD

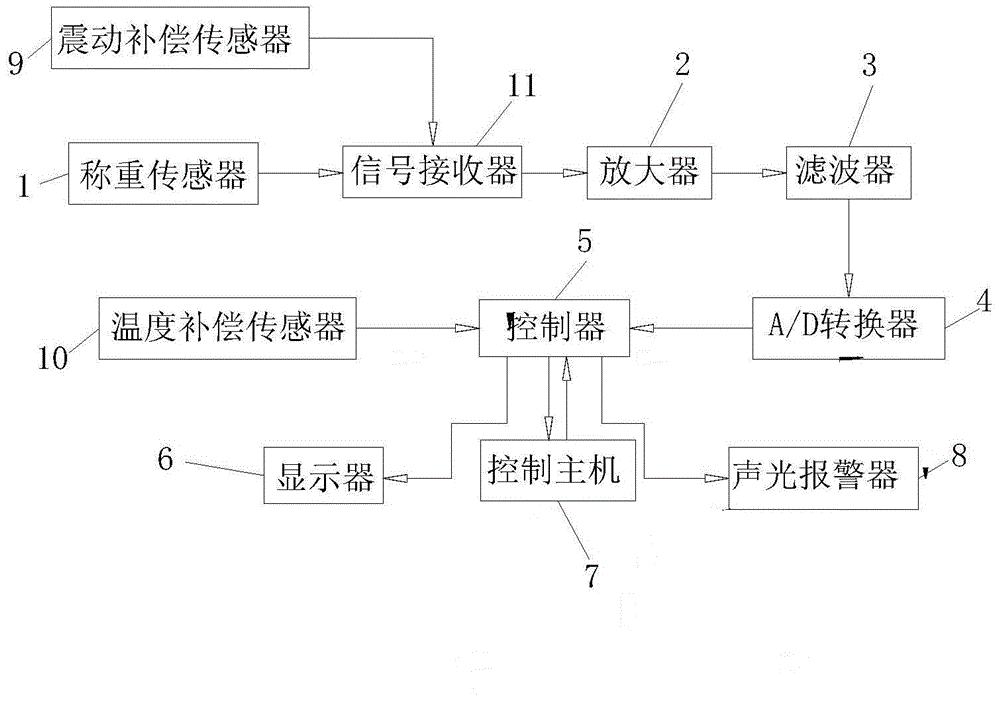

High-precision anti-vibration electronic balance

InactiveCN104359534AImprove weighing accuracyImprove dynamic stabilityWeighing apparatus using elastically-deformable membersEngineeringSignal amplifier

The invention discloses a high-precision anti-vibration electronic balance. The high-precision anti-vibration electronic balance comprises a weighing sensor, a signal amplifier, a signal filter, an A / D (analog / digital) converter, a controller, a display screen, a control mainframe, an audible and visual alarm, a vibration compensation sensor, a temperature compensation sensor and a signal receiver. An output end of the temperature compensation sensor is connected with an input end of the controller, the vibration compensation sensor and the weighing sensor are subjected to actions of mechanical vibration signals simultaneously, and output ends of the vibration compensation sensor and the weighing sensor are simultaneously connected with an input end of the signal receiver. An output end of the signal receiver is connected with an input end of the signal amplifier, an output end of the signal amplifier is connected with an input end of the signal filter, an output end of the signal filter is connected with an input end of the A / D converter, and an output end of the A / D converter is connected with the input end of the controller. The high-precision anti-vibration electronic balance has the advantages that weighting precision is improved while weighting speed is increased, and dynamic stability in operation of weighing systems in severe environment is improved.

Owner:合肥市再德高分子材料有限公司

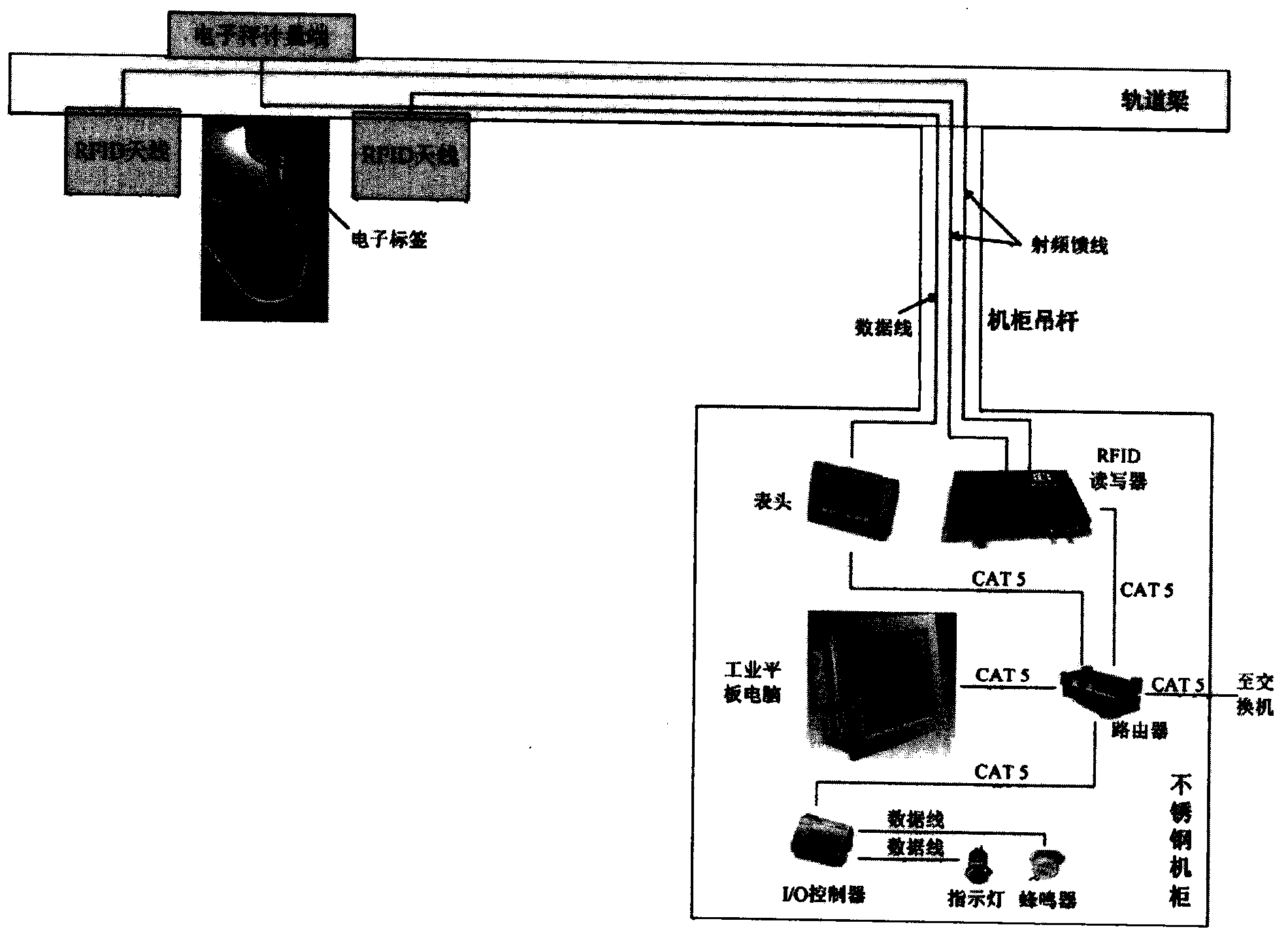

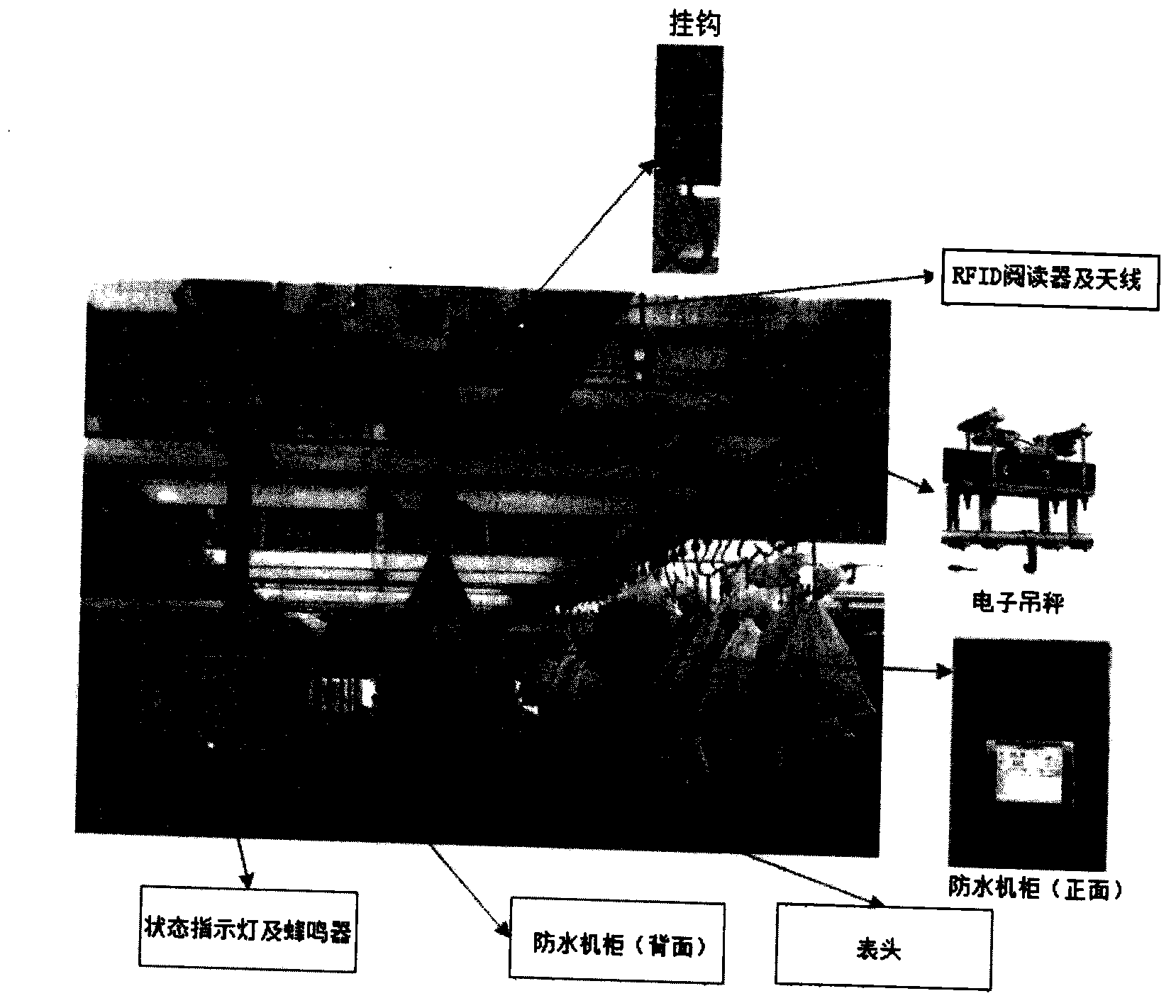

RFID-based rapid automated weighing system

ActiveCN103487124AAutomate managementFast weighingWeighing indication devicesSpecial purpose weighing apparatusReader writerEngineering

The invention discloses an RFID-based rapid automated weighing system. A data acquisition module comprises an electronic scale and a piece of RFID equipment, which are respectively used for acquiring weight information and hook tag information. A mechanical module comprises a guide rail and a sling, an electronic scale sensor is installed on the guide rail, RFID equipment antennas are respectively installed at the two sides of the guide rail, and a hook is movably arranged on the guide rail. The weight on the guide rail is transferred to the electronic scale sensor, and an RFID reader-writer identifies an electronic tag on the hook through the antennas. An information processing module converts the acquired hook tag information into a hook number, associates the hook number with the acquired weight information and outputs a complete weighting record. An information output module provides a friendly man-machine interactive interface, and gives a warning for abnormal conditions or suggests other information through a warning maker. The RFID-based rapid automated weighing system has the advantages of automated weighing management, high weighing speed, accurate weighing value, high system compatibility, strong versatility and easy installation and can be used for weighing in many fields.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

Concrete preparation system and preparation method thereof

InactiveCN108556131AWell mixedExpand the scope of workDischarging arrangementCeramic shaping plantsRaw materialCivil engineering

The invention relates to the technical field of concrete preparation, in particular to a concrete preparation system. The concrete preparation system comprises a raw material weighing device, a raw material mixing device, a pouring mold-entering device, a curing device, a demoulding device and a mold cleaning device. The concrete preparation system performs concrete preparation through the reasonable arrangement of a plurality of above processes and the division of labor and cooperation, realizes the automatic process of concrete preparation, saves manpower, improves work efficiency and is easy to use.

Owner:湖南道同消防工程有限公司

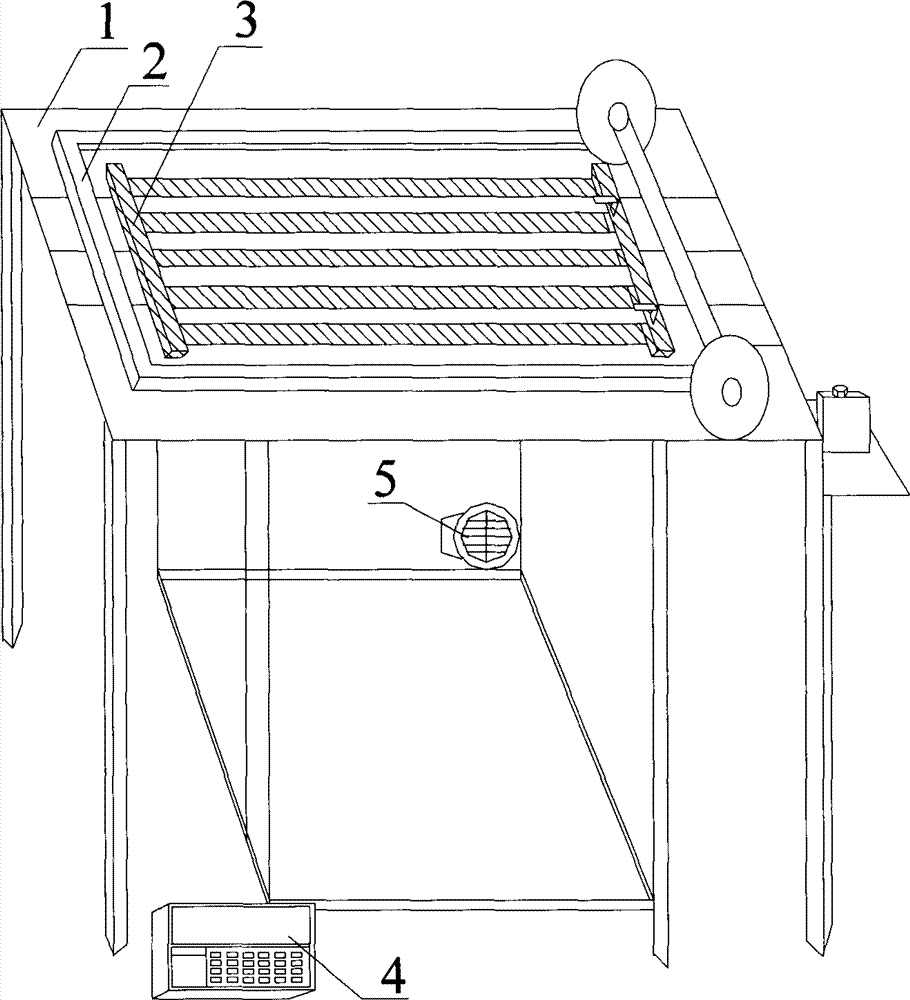

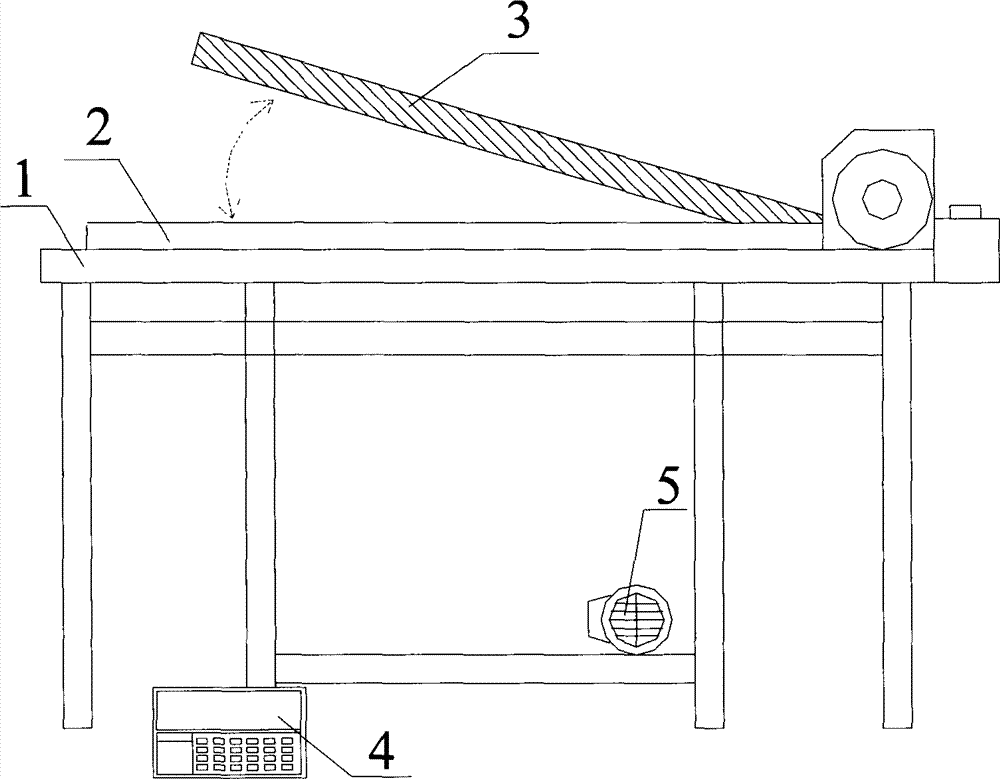

Automatic plate turnover machine with weighing function

InactiveCN103043254AIngenious designEasy to manufacturePackaging automatic controlControl systemElectric machinery

The invention discloses an automatic plate turnover machine with weighing function which comprises a rack, a control system, a weighing frame, a turnover board, a drive motor and a weighing device. The weighing frame and the flip board are arranged above the rack, the drive motor and the weighing device are arranged below the rack; the flip board is arranged below the weighing frame and one end of the flip board is connected with the rack through a rotating shaft, the flip board is capable of penetrating through the weighing frame and rotating 180 degrees around the shaft; the weighing frame is connected with the weighing device, and both the weighing device and the drive motor are connected with the control system. By the automatic weighing flap machine, products can be turned over after automatic weighing and fall in the packing box which is placed on one side of the machine, so that workers can clear up products conveniently, the labor is reduced, and work efficiency is increased.

Owner:CHANGSHU RONGXIN NONWOVEN PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com